Effects of heat treatment on the corrosion behavior and mechanical properties of biodegradable Mg alloys

Meysm Mohmmdi Zernkeshi,Rez Alizdeh,*,Ehsn Gershi,Mohmmd Asdollhi,Terence G.Lngdon

aDepartment of Materials Science and Engineering,Sharif University of Technology,Tehran,Iran

b Materials Research Group,Department of Mechanical Engineering,University of Southampton,Southampton SO17 1BJ,United Kingdom

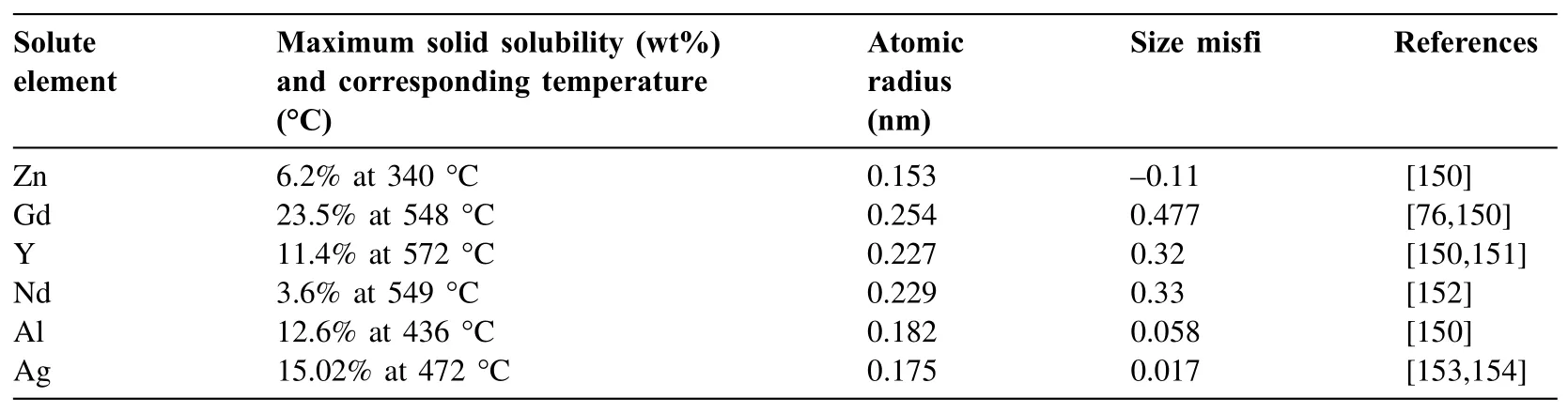

Abstract Biodegradable magnesium(Mg)alloys exhibit great potential for use as temporary structures in tissue engineering applications.Such degradable implants require no secondary surgery for their removal.In addition,their comparable mechanical properties with the human bone,together with excellent biocompatibility,make them a suitable candidate for fracture treatments.Nevertheless,some challenges remain.Fast degradation of the Mg-based alloys in physiological environments leads to a loss of the mechanical support that is needed for complete tissue healing and also to the accumulation of hydrogen gas bubbles at the interface of the implant and tissue.Among different methods used to improve the performance of the biodegradable Mg alloys to address these challenges,it appears that heat treatment is the most effective way to modify the microstructure and thus the corrosion behavior and mechanical properties without changing the composition or shape of the alloys.A desirable combination of corrosion and mechanical properties can be obtained through a precise control of the heat treatment parameters.In this report,the effects of different heat treatments(T4 and T6)on the microstructure,corrosion behavior,and mechanical properties of some of the most important heat-treatable biodegradable Mg alloys(Mg-Zn,Mg-Gd,Mg-Y,Mg-Nd,Mg-Al and Mg-Ag)are examined as well as new perspectives to enhance their clinical implementation.

Keywords:Biodegradable implants;Corrosion rate;Heat treatment;Mechanical properties;Mg alloys.

1.Introduction

Regenerative medicine needs a further development of novel biomaterials to help the process of recovery of the damaged tissues,where this has become of special importance and interest in recent years as a consequence of the aging and overall longevity of the world’s population.The biodegradable implants have attracted too much attention in recent years due to their outstanding performance in the process of tissue regeneration.Such implants can act as a temporary structure which helps the damaged tissue to carry the loads,and after the execution of their clinical function they will degrade gradually within the biological media to be replaced by the native tissue.As a consequence,the issues concerning the use of permanent implants,such as the chronic inflammation,physical irritation,endothelial dysfunctions and the need for secondary surgery for the implant removal,are effectively avoided[1–8].

Mg-based alloys as biodegradable implants exhibit a significant potential for use as temporary structures for tissue engineering purposes.In this regard,the Mg alloys are considered as an exceptional candidate for fracture treatments due to their comparable density(1.74-2.0 g/cm3)and tensile strength(100-200 MPa)to those of the human bone.The stress shielding effect and associated problems,such as implant loosening,skeleton thickening and serious impediments to the healing process,would be mitigated by the similar elastic modulus(41-45 GPa)of the Mg alloys to that of natural bone(10-30 GPa)[9].Magnesium,as the fourth most abundant cation in the human body,is essential to human metabolism and its daily recommended intake for an adult is of the order of 240-420 mg/day,where the excess Mg cations can be excreted in the urine without any toxicity[10–12].The Mg alloys would be degraded in biological environments due to the presence of Cl-[13,14].The associated mechanical properties,together with the biocompatibility characteristics of the Mg alloys,like osteogenesis inductivity[15],antibacterial[16]and anti-tumor effects[17]and anti-inflammatory properties[18],make them a distinctive choice in biomedical applications such that extensive research has been conducted in this area.A summary of the numbers of published articles containing“biodegradable Mg”or“biodegradable magnesium”expressions in the title is presented in Fig.1a,implying a very significant growth after 2005.

The success in the regeneration of damaged bone tissue is strongly related to attaining a balance between the corrosion rate of the implant and the bone healing rate,the presence of an adequate mechanical support during the healing time,a through degradation of the implant after complete bone healing and the absence of any signs of a systematic response(e.g.,chronic inflammation and allergy)due to the created byproducts.Despite the outstanding properties of the biodegradable Mg-based implants and their extensive development in clinical applications in recent years,several challenges remain unaddressed that inhibit their extensive use in biomedical applications[19].For example,it is generally believed that the corrosion rate of the biodegradable Mg alloys is too high for implant applications since fast corroding implants cannot provide sufficient mechanical support for the tissue.The localized corrosion processes,such as pitting and stress corrosion cracking,lead to a reduction in the mechanical strength of the implant in the early stages of implantation.Furthermore,rapid corrosion of the Mg in the physiological environment leads to the generation of large quantities of hydrogen gas bubbles between the implant and the bone interface and this may hinder the healing process[3,20].

Many different ways and methods have been suggested for improving the properties of biodegradable Mg alloys through the use of procedures such as coatings[21,22]and alloying[23,24].However,it appears that the use of heat treatment is the most valuable tool for manipulating the mechanical properties and corrosion behavior of the biodegradable Mg alloys.The reason is because a heat treatment does not alter the chemical composition or the shape of the alloys but instead,it simply modifies the microstructure.The well-established solid solution treatment(T4)and the solid solution with subsequent aging treatment(T6)are two common heat treatments that have been widely conducted on biodegradable Mg alloys[14].Changes in the morphology and volume fraction of the secondary phases,the introduction of a protective corrosion film and the effect on grain size during the heat treatment may all affect the corrosion performance of the Mg alloys.Moreover,solid solution strengthening,precipitation strengthening and grain growth are three important factors determining the overall mechanical properties of the heat-treated Mg alloys.

Depending on the chemical composition of the alloy and the heat treatment that was used,significantly different combinations of mechanical and corrosion properties may be obtained.Fig.1b demonstrates a noticeable progress in applying the heat treatment process to biodegradable Mg alloys where the number of published articles in this area from 2007 to 2020 is presented.A summary of the properties and challenges of biodegradable Mg alloys is given in Fig.2.Accordingly,this review aims to provide a comprehensive summary of the different effects of the T4 and T6 heat treatments on the corrosion performance and mechanical properties of the biodegradable Mg alloys.A detailed understanding of the effects of heat treatment on each alloying system will help to control the properties of the biodegradable Mg alloys in order to achieve the desired properties for biomedical applications without the need to change the composition or shape of the alloys.

2.Clinical applications

Mg alloys have been used for biomedical applications since the 1800s.Initially,Mg wires were devised by Edward C.Huse as ligatures to hinder bleeding[25].Moreover,in 1900,Erwin Payr proposed that Mg implants can be employed for the fabrication of fixator pins,plates and nails[26].However,since the early 2000s,the modern era of the research on Mg alloys for biomedical applications has been initiated.Currently,Mg alloys are used in two main categories of biomedical applications:vascular stents[27],and orthopedic applications[28].In this regard,the Mg stenting procedure was employed for 63 patients who had plaque in their arteries,and the results obtained indicated that such stents can be used safely[29].There is also a great potential for Mg alloys,as surgical implant materials,to be used for bone repair[30].Mg alloys have been utilized in different types of fixation devices for orthopedic surgery,including as fasteners,screws,and plates.These extensive biomedical practices of Mg-based alloys are due to their excellent biocompatibility,such as their minimal effect on blood composition change,which does not lead to damage of excretory organs like the liver or the kidneys[31].

To make biodegradable Mg alloys suitable for these applications,there is a need to adjust some properties,where the most important one is the degradation rate.The acceptable corrosion rate for biomedical implants depends on many factors and there is not a specific rate for all applications[32].As Mg alloys produce hydrogen in the body,the acceptable corrosion rate can be determined by the evolved hydrogen.For example,according to[33],when the hydrogen evolution rate is 0.01 mL/cm2/day it can be tolerated by the human body and there will not be a serious threat.Also,it has been reported that the corrosion rate should be less than 0.5 mm/y in simulated body fluid(SBF)solution at 37°C,which reflects a functionality time of 3-6 months[34].It is worth mentioning that the pH,alloying element release and osmolality(caused by a high concentration of Mg2+ions)of the medium are all affected by the degradation rate of Mg-based alloys,where a high degradation rate would result in an increment of pH,excess amount of alloying element and osmolality,leading to the cytotoxicity of human osteoblasts[35,36].Therefore,tailoring the corrosion rate of biodegradable Mg alloys is of great significance.

Fig.1.The numbers of publications per year and the cumulative number of publications for(a)biodegradable Mg alloys and(b)the heat treatment of biodegradable Mg alloys.

Fig.2.Properties and challenges associated with biodegradable Mg alloys and the potential role for addressing these challenges through the use of heat treatment.

Mechanical integrity of an orthopedic implant is of great importance to provide structural support during the bone reconstruction process.It has been reported[14,37]that biodegradable implants should have tensile strength and ductility higher than 200 MPa and 10%,respectively.Fortunately,Mg-based alloys usually can be designed to reach these properties[38].However,loss of the load-bearing ability of Mg implants as the result of fast degradation is still challenging.Most of the biodegradable Mg-based alloys would be thoroughly degraded within 6-12 weeks,while the designed implant should maintain its support for 24-36 weeks,which is the bone regeneration duration[39,40].As will be reviewed and discussed in the following sections,heat treatment,as an effective implement,can control and further improve the corrosion and mechanical properties of the Mg alloys to the limits required for use as biodegradable implants.

3.The general effects of heat treatment

Although a heat treatment affects different Mg alloys in distinct ways,some effects of T4 and T6 treatments on microstructure and hence the characteristics of biodegradable Mg-based alloys are common and will be discussed here.

3.1.The general effects of a T4 heat treatment

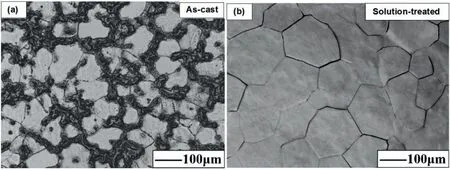

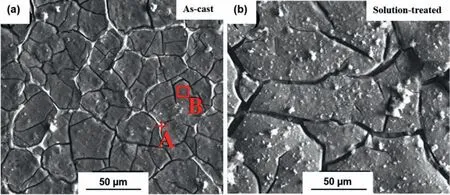

The solid solution heat treatment T4 removes the dendritic structure and the associated segregations in addition to reducing the density of dislocations,twins and other defects with the overall driving force of decreasing the internal energy of the as-cast alloy.The effect of a solid solution heat treatment will become more significant by increasing the concentration of the alloying elements[41,42].After the T4 heat treatment,the alloying elements are more homogeneously distributed and some or all of the precipitates are dissolved in the matrix as the result of the increased solubility of the alloying elements with temperature.Fig.3 depicts a single-phase microstructure and complete dissolution of intermetallic compounds of the Mg-2.49 at% Gd alloy into the matrix by the solution treatment at 535 °C for 9 h[43].

The rearrangement of the alloying elements and secondary phases during the solution treatment can be very beneficial for the corrosion resistance since finely and uniformly distributed secondary phases may effectively improve the corrosion resistance of the Mg alloys.In fact,the distribution and size of the secondary phase particles remarkably affect the corrosion performance of the biodegradable Mg alloys[44].Thus,large particles deteriorate the corrosion resistance of the Mg alloys with respect to the micro-galvanic corrosion and this is an effect that will be discussed in detail in this review.

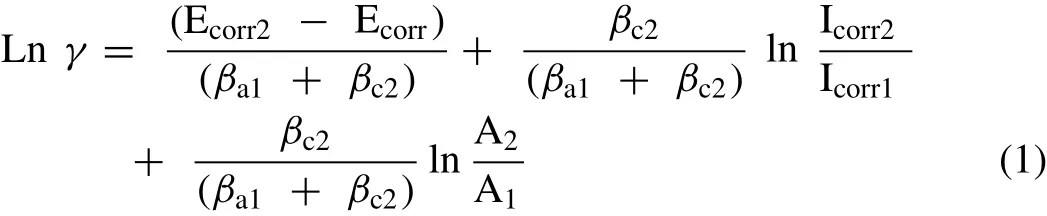

The following eq.(1)demonstrates the relation between the corrosion rate and the cathodic area:

whereγis the galvanic corrosion effect,Ecorr2and Ecorr1are the cathodic corrosion potential and the anodic corrosion potential,respectively,Icorr2and Icorr1are the cathodic corrosion current density and the anodic corrosion current density,respectively,βa1andβc2are the anodic slope and the cathodic slope,respectively,and A2and A1are the cathode area and the anode area,respectively[45].

Fig.3.Optical microstructure of the Mg–2.49 at% Gd alloy in(a)the as-cast and(b)the solution-treated conditions.Reproduced from[43].

In addition to the effect of the morphology of the particles on the galvanic corrosion in Mg-based alloys,the grain size distribution is also an important factor.A non-uniform grain size distribution is highly destructive due to the formation of galvanic corrosion between the fine and coarse grains.During the T4 heat treatment,due to the coalescence of the small grains,the smaller grains are gradually removed and the grain size becomes more uniform and larger[46,47].As the time/temperature of the solid solution heat treatment increases,grain growth becomes more severe while the rate of growth will be a function of both the temperature and time of the heat treatment as well as the type of alloy.On the other hand,the corrosion rate is usually improved by reducing the grain size of magnesium alloys.Accordingly,the corrosion behavior of Mg alloys after a T4 heat treatment will be affected by these two parameters.

The solution heat treatment affects the strength of the Mg alloys from two important aspects.First,the solution treatment establishes a supersaturated solid solution where the atomic size difference between the Mg atoms and the solute atoms generates a lattice distortion in theα-Mg matrix and this leads to solid solution hardening.Second,due to the high annealing temperatures,the casting precipitates dissolve in theα-Mg matrix and this produces some softening[48].This means in effect that the mechanical properties of the solution-treated biodegradable Mg alloys originate from attaining a balance between these two factors.Grain growth and the loss of some strengthening from the grain boundaries should also be added to these factors.In this respect,it is generally considered that after a solid solution treatment the yield strength(YS)of magnesium alloys is slightly reduced compared with the as-cast condition due to the occurrence of grain growth and also the dissolution of some of the precipitates[49].

3.2.The general effects of a T6 heat treatment

During aging,the secondary phases precipitate again from the supersaturated solid solution formed during the T4 treatment,and as the aging time increases so the size of the precipitates and the distance between them also increases due to the enhanced diffusion[48].In this process,the morphology of the precipitates changes continuously with time.This is accompanied by grain growth while the growth kinetics are smaller compared to the solution treatment due to the lower temperatures typically used in aging.The temperature and time of the aging heat treatment also significantly affect the morphology of the precipitates and thus the final properties of the alloy:this effect will be discussed in detail in this review.

Regarding the influence of the T6 treatment on the corrosion resistance of Mg alloys,it is believed that the precipitates may play different roles with respect to their homogeneity,morphology,distribution and the type of alloy.Thus,they may act both as micro-cathodes which cause an acceleration in the corrosion rate of the alloy and also as barriers against corrosion propagation[50].

There are many factors that may affect the efficiency and also the amount of precipitate strengthening.For example,these factors include the precipitate size,precipitate shape,precipitate volume fraction and distribution,the nature of the interface with the surrounding matrix,the elastic modulus,the strength of the precipitates and the precipitate crystal structure[50,51].Usually,these parameters change during aging and this will appear in the aging curve where the strength or hardness is plotted against time.

Fig.4.Comparison of the experimental results with model predictions for the evolved Mg17Al12 phase in T6 treatment of AZ91 alloy at 200 °C:(a)volume fraction,and(b)particle size are plotted against time of T6 heat treatment.Reproduced from[54].

The proper selection of time and temperature of heat treatment is a critical factor to obtain the best results.It is wellestablished that phase diagrams,which are based on equilibrium phases,are the most practical tools to define the temperature of heat treatment for each alloy.Since the conditions may deviate from equilibrium due to kinetic considerations,different experimental techniques such as thermal analysis,X-ray diffraction(XRD),electrical conductivity,scanning electron microscopy(SEM)and transmission electron microscopy(TEM)can also be employed to determine the appropriate time and temperature of the heat treatment.All of these techniques rely on measuring changes in physical,chemical and structural properties of a material when a phase transformation occurs[52].For instance,electrical resistivity and hardness tests have been utilized to assess the optimum solid solution time for a biodegradable Mg-Y-Ag alloy[53].It was realized that electrical resistivity and hardness significantly decreased and increased,respectively,after 3 h of T4 treatment at 500 °C(determined according to phase diagram)and no remarkable changes were noticed after that,indicating that most of the precipitates were dissolved by 3 h of solution treatment at 500 °C,which was chosen as the heat treatment time and temperature.

In addition to experimental techniques,models and simulations are also being developed and performed respectively to further predict the appropriate time and temperature of heat treatment.Interestingly,a novel microstructure model has been devised to predict the microstructure evolution of some Mg-based systems such as Mg-Zn and Mg-Al alloys during T6 treatment[54,55].This model is mainly based on thermodynamic calculations for the physical phenomena of nucleation,growth and coarsening,which can give valuable information for deciding the time and temperature of the heat treatment.Fig.4 shows a reasonable fit between experimental data and model predictions,where volume fraction and size of Mg17Al12phase in an Mg-9Al-1Zn alloy aged at 200°C(obtained by TEM measurement)are plotted against time of heat treatment[56],implying the potential of this model for developing for other Mg alloys.However,some important parameters such as the morphology of precipitates are not included in these nascent models,which necessitate future investigations for higher predictive accuracy.

4.The effects of heat treatment on Mg-Zn alloys

4.1.The corrosion behavior

4.1.1.The corrosion behavior of Mg-Zn alloys in the as-cast condition

Zinc is a common alloying element in biodegradable Mg alloys that is omnipresent in all of the human body tissues as a vital nutritional element[57].In practice,the addition of Zn improves the corrosion performance of biodegradable Mg alloys by enhancing the nobility.In addition,it appears that Zn increases the stability of the corrosion film by reducing impurities and also boosts the charge transfer resistance of the Mg alloys and thereby improves the corrosion resistance[58,59].

The general microstructure of the as-cast Mg-Zn alloys includes Mg-Zn secondary phases embedded in an Mg-Zn solid solution matrix together with some zinc-rich segregation areas.The secondary phases can be found both at the grain boundaries and within the grains[51].The corrosion behavior of the Mg-Zn alloys is mainly determined by three factors:the purity,the zinc concentration and the morphology and composition of the secondary phases in the microstructure.

The role of the Zn content in enhancing the corrosion resistance of as-cast Mg-Zn alloys is more evident in Fig.5.In this diagram,the surfaces of the binary Mg-xZn alloys(x=1.25,2.50,and 4.00 wt%)are shown after immersion in a Kokubo solution for 144 h.In this respect,it was concluded that the addition of 4 wt% Zn can significantly improve the corrosion resistance of Mg-Zn alloys for biomedical applications by forming a protective film.It was also noted that the number of cracks appearing on the surface of alloys decreases through the addition of Zn.A uniform corrosion product is formed on the surface of the Mg-4Zn alloy where it is much thicker than in other alloys with less Zn content.The volume fraction of the secondary phases and the thickness of the Zn

Fig.5.The morphology of the corroded surfaces of the Mg-1.25Zn(a),Mg-2.5Zn(b)and Mg-4Zn(c)alloys after immersion for 144 h in a Kokubo solution.Reproduced from[60].

oxide layer will assess the corrosion resistance of the Mg-Zn alloys.However,due to the presence of different phases and also the dendritic character of the microstructure of the ascast Mg-Zn alloys,these alloys in the as-cast condition are very vulnerable to galvanic corrosion and usually have insufficient surface layer protection and passivation[60].The use of heat treatment effects is an effective way to modify the microstructure of the Mg-Zn alloys and this will be reviewed and discussed in the following sections.

4.1.2.The corrosion behavior of Mg-Zn alloys after a T4 heat treatment

Irrespective of the location of the secondary phases,whether at the grain boundaries or within the grains,they can act as micro-cathodes and thus increase the corrosion rate.From this point of view,a solid solution heat treatment will be the most suitable option for improving the corrosion resistance of as-cast Mg-Zn alloys as it can significantly reduce the volume fraction of the secondary phases[45,61].In some cases,an incomplete dissolution of the secondary phases has been reported due to the excellent thermal stability of the secondary phases at the temperature used for the solution treatment.For example,there are reports of an incomplete dissolution of the Mg70Zn25Sr5particles in the Mg-4.0Zn-0.5Sr alloy[62]and the Mg12Zn13particles in the Mg-1.5Zn alloy[42]).Nevertheless,by precisely controlling and adjusting the heat treatment parameters it is also possible to dissolve these phases.

In a comparative study[63],the corrosion resistance of an Mg-2Zn-1Mn(ZM21)alloy was studied and compared in the solution-treated,the extruded and the T5 heat-treated states.The results showed that the alloy in the solution-treated condition had the lowest amount of secondary phases,impurities,dislocations and other defects.In addition,the solution-treated alloy exhibited the best film protection according to the higher breakdown potential(Eb)value from the polarization curves(Fig.6).Therefore,an alloy solution-treated at 510 °C for 4 h showed the best corrosion resistance.

An investigation was conducted on the effect of temperature and time of the solid solution heat treatment on the corrosion behavior of an Mg-3Zn-0.3Ca alloy 44.The results demonstrated that the optimum properties may be achieved by

Fig.6.Comparative polarization curves of the Mg-2Zn-1Mn alloy in the T4,the extruded and the T5 states.Reproduced from[63].

properly controlling the time and temperature of the solution treatment.In this respect,the as-cast alloy had the smallest grain size but the largest fraction of the secondary phases and the alloy experiencing the solution treatment at the highest temperature for the maximum time had the lowest fraction of secondary phases but the largest grain size.Both of these samples possessed an inappropriate corrosion rate and optimum properties were achieved for a sample with a balanced secondary phase volume fraction and grain size.Fig.7a shows the results of a hydrogen evolution test during a 240 h immersion in SBF solution in which the T4-treated alloy at 420°C for 24 h exhibited the best corrosion resistance.As shown schematically in Fig.7b,the results obtained show how the corrosion rate decreases with a reduction in the secondary phase content and an increase in the grain size.According to Fig.7c,a solution-treated alloy after 420 °C for 24 h,with a balanced secondary phase content and grain size,demonstrated a lower density and depth of the corrosion pits where this is in accordance with the sample showing the best corrosion resistance.Therefore,the conditions of time and temperature associated with the solid solution heat treatment play a significant role in determining the corrosion behavior of the Mg-Zn alloys[64].

Fig.7.(a)The effect of heat treatment on the corrosion rate(evaluated as the evolved hydrogen gas during immersion in SBF)of an as-cast Mg-3Zn-0.3Ca alloy.(b)Schematic plot showing the variations of the corrosion rate with the volume fraction of the secondary phases(dashed red curve)and grain size(dashed blue curve).The black solid curve refers to the overall effect of the solution treatment on the corrosion rate.(c)The corroded surfaces of the Mg-3Zn-0.3Ca alloy in the as-cast and heat-treated conditions(indicated in the top-right corner)after immersion in SBF for 240 h.All micrographs were obtained by SEM after removal of the corrosion products.Reproduced from[44].

It has been reported[49]that by increasing the time and temperature of the solution treatment some passivation is achieved and a protective film is formed on the alloy so that uniform corrosion occurs instead of pitting[25].For example,passivation occurred in the T4-treated Mg-2Zn-0.5Nd-0.5Zr alloy after increasing the solution temperature up to 500 °C.The homogenous composition of the alloy after the solution heat treatment caused the formation of a uniform protective film.In this study,while many secondary phases exist in the untreated alloy(Fig.8 a),following the solution treatment the volume fraction of the secondary phases decreased considerably(Fig.8 b).With immersion in Hank’s solution,the alloy corroded homogenously(Fig.8 c)and a uniform protective corrosion layer formed on the alloy surface,which could inhibit the corrosion propagation(Fig.8 e,d)[49].

It has been reported[42]that,after the solid solution heat treatment,a more protective film forms on the surface of the alloys with higher Zn content,and this covers the surface of the alloy and acts as a barrier against the penetration of chloride ions[19].For example,the film formed on an Mg-9Zn alloy was reported to be more protective than a film formed on an Mg-1.5Zn alloy in the solid solution state.Adding other alloying elements such as Yb and Nd to the Mg-Zn alloys up to 1% and 0.6%,respectively,further strengthened the surface film and thus improved the corrosion resistance in the solid solution condition[65].The corrosion resistance improvement during the solution treatment was mainly attributed to the stabilization of the Mg matrix by the addition of Yb.However,increasing the Yb content to 2 wt% resulted in some undissolved eutectic phases and relatively more severe corrosion compared with the alloy containing only 1 wt% Yb in the solution-treated state,where this is probably due to the microgalvanic corrosion between the undissolved secondary phases and theα-Mg matrix[66].Therefore,the type and amount of the alloying elements,and the conditions of the solid solution heat treatment in terms of time and temperature,are very effective parameters in controlling the corrosion behavior of the Mg-Zn alloys and this should be considered in any attempt to achieve the optimum desired properties.

Fig.8.Schematic representation of the corrosion process in the T4-treated Mg-2Zn-0.5Nd-0.5Zr alloy.While there were many secondary phases present in the untreated alloy(a),the volume fraction of the secondary phases decreased considerably after the solution treatment(b),which resulted in homogenous corrosion(c).The uniform film formation process on the surface of the T4-treated alloy is shown in(d)and(e).Reproduced from[49].

4.1.3.The corrosion behavior of the Mg-Zn alloys after a T6 heat treatment

The standard potential of magnesium is about-2.37 V and for zinc it is-0.762 V versus a standard hydrogen electrode(SHE).An Mg-Zn alloy containing secondary phases is susceptible to galvanic corrosion due to the formation of a galvanic battery between the secondary phases containing zinc as the cathode and the magnesium matrix as the anode[51].An investigation compared the corrosion resistance of the Mg-5.2Zn-0.03Mn(ZK60)alloy in the as-cast and T6 conditions and it was reported that,while the amount of secondary phases were almost the same in both states,the T6-treated sample showed minor corrosion resistance due to the dispersed distribution of the precipitates along the grain boundaries[27].By contrast,the concentrated distribution of the precipitates in the as-cast condition resulted in a better corrosion resistance.In another study[67],the higher volume fraction of the secondary phases in the T6-treated alloy compared to the as-cast alloy increased the amount of microgalvanic couples which accelerated the galvanic corrosion.In this investigation,the presence of the Mg-Zn particles as a robust cathode triggered the micro-galvanic corrosion in the aged alloy.In addition,it was reported[68]that the aging process cannot produce a thick and protective film on the Mg-Zn-Ca-Mn alloys so pitting corrosion was activated to a great extent[36].

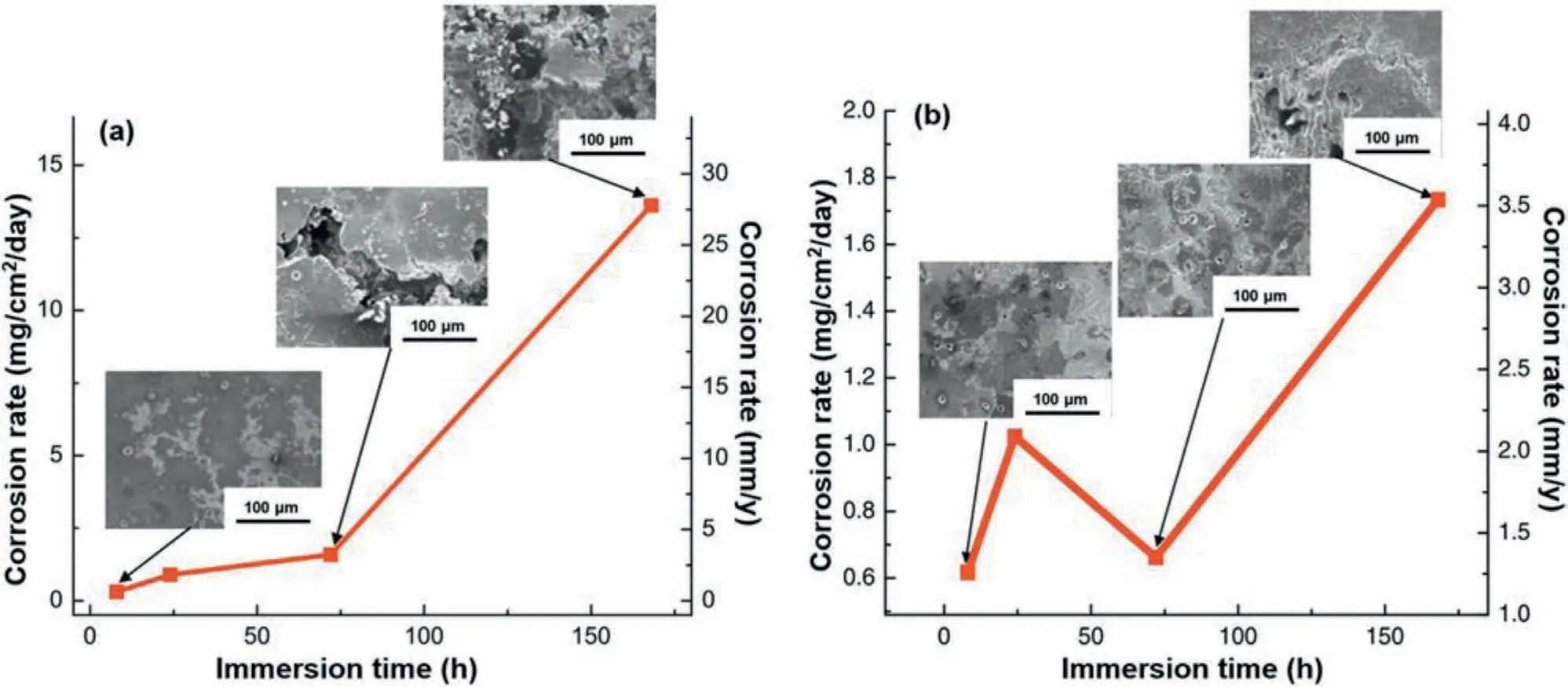

An Mg-5Zn alloy was aged for different times(4,6 and 10 h)at 230 °C in order to study the effects of the morphology,distribution,and volume fraction of the MgxZnysecondary phases on the corrosion behavior[50].By extending the aging time,more secondary phases were precipitated and their dimensions increased up to~2 μm after 10 h aging.Also,the distribution,morphology,and volume fraction of the secondary phases changed with time and after 10 h the MgxZnysecondary phase appeared as a continuous network.However,the results from this study indicated that this continuous distribution of the MgxZnysecondary phases were unable to act as a corrosion barrier hindering the corrosion propagation.Thus,by comparing different morphologies of the secondary phases in an aged Mg-5Zn alloy,it was concluded that irrespective of the distribution of the MgxZnysecondary phases whether discrete or continuous,in both cases these phases act as micro-cathodes and deteriorate the overall corrosion resistance of the alloy.Fig.9 shows severe corrosion pits in the T6-treated alloy located at the grain boundaries and within the grains at a high magnification.In this case,each corrosion pit is the result of a micro-galvanic corrosion caused by the presence of the MgxZnysecondary phases[50].

Fig.9.After immersing the aged Mg-5Zn alloy in a 0.1 M NaCl solution for 30 min,the corrosion pits appear both at the grain boundaries(a),and within the grains(b).Reproduced from[50].

Fig.10.TEM micrographs of the Mg-5.8Zn-0.5Zr-2Yb alloy after the T6 treatment(a,b),together with the corresponding TEM-EDS results of the corresponding precipitates(c).Reproduced from[66].

Contrary to the T6-treated Mg-5Zn alloy,some researchers[65,66]concluded recently that fine precipitates with homogeneous distributions are a barrier to corrosion whereas coarse precipitates with random distributions act as micro-cathodes and thereby intensify the galvanic corrosion.TEM was used to investigate the secondary phases formed during the aging heat treatment of Mg-5.8Zn-0.5Zr-xYb alloys(with Yb content varying from 0 to 2%)[66].The TEM micrographs of the Mg-5.8Zn-0.5Zr-2Yb alloy presented in Fig.10 demonstrate the presence of three types of secondary phases;dotshaped Mg-Zn-Yb particles(point 1),rod-shaped Mg-Zn particles(point 2)inside the grains and a small number of coarse blocky Mg-Zn-Yb phases(point 3)which were mostly located at the boundaries.These secondary phases with different sizes and distributions play different roles in the corrosion process for these alloys.The coarse blocky particles that were discontinuously located at the grain boundaries cause local corrosion due to the significant potential difference between the magnesium matrix and the relatively large intermetallic phase.In this study,the corroded surface did not experience severe pitting corrosion because these coarse particles were minimal.On the other hand,for the fine Mg-Zn-Yb and Mg-Zn particles distributed within the grains,an internal galvanic corrosion was observed to occur uniformly along the matrix,forming a passive film due to the very small sizes and the more uniform distribution.This passive film covered the entire surface and prevented further corrosion activity,thus creating an anticorrosion barrier to protect the underlying magnesium surface[66].

With increasing aging time,it was observed that the size of the precipitates increased and the distribution of the precipitates became more inhomogeneous,where this can significantly influence the corrosion behavior of the Mg alloys.This was studied for an Mg-5.8Zn-2.0Yb-0.5Zr alloy[65].Three kinds of samples were investigated,each aged for different times such that the under-aged sample(UA)was aged at 200 °C for 8 h,the peak-aged sample(PA)was aged at 200 °C for 16 h and the over-aged sample(OA)was aged at 200 °C for 24 h.It was concluded that the volume fraction and the distribution of the precipitates were noticeably different in these three samples(Fig.11).The open circuit potential(OCP),dynamic polarization and immersion tests in Fig.12 show that the PA sample exhibited a thermodynamically stable film and the best corrosion resistance,where the stable and compact film formed on the PA sample came directly from the uniform and fine nano-precipitates.The corrosion rates after the 240 h of immersion in an SBF solution at 37 °C showed that the corrosion rate of the OA sample was up to 26-fold higher than for the PA sample and multitudes of corrosion pits were observed on this sample(Fig.12c and d).

A peak aging condition(aging at 200 °C for 10 h,after solutionizing at 510 °C for 3 h)in the Mg-1.2Zn-0.5Ca alloy with fine and uniformly dispersed precipitates was reported to improve the corrosion resistance and also the uniformity of the corrosion compared to the as-cast alloy and other aging conditions[69].In this study,the as-cast alloy had the highest mass loss and degraded entirely after 28 days immersion in the modified SBF while the 10 h aged alloy possessed the lowest mass loss(Fig.13).Therefore,the time and temperature of the aging treatment strongly affect the corrosion behavior of the Mg-Zn alloys depending on the composition of the alloy.

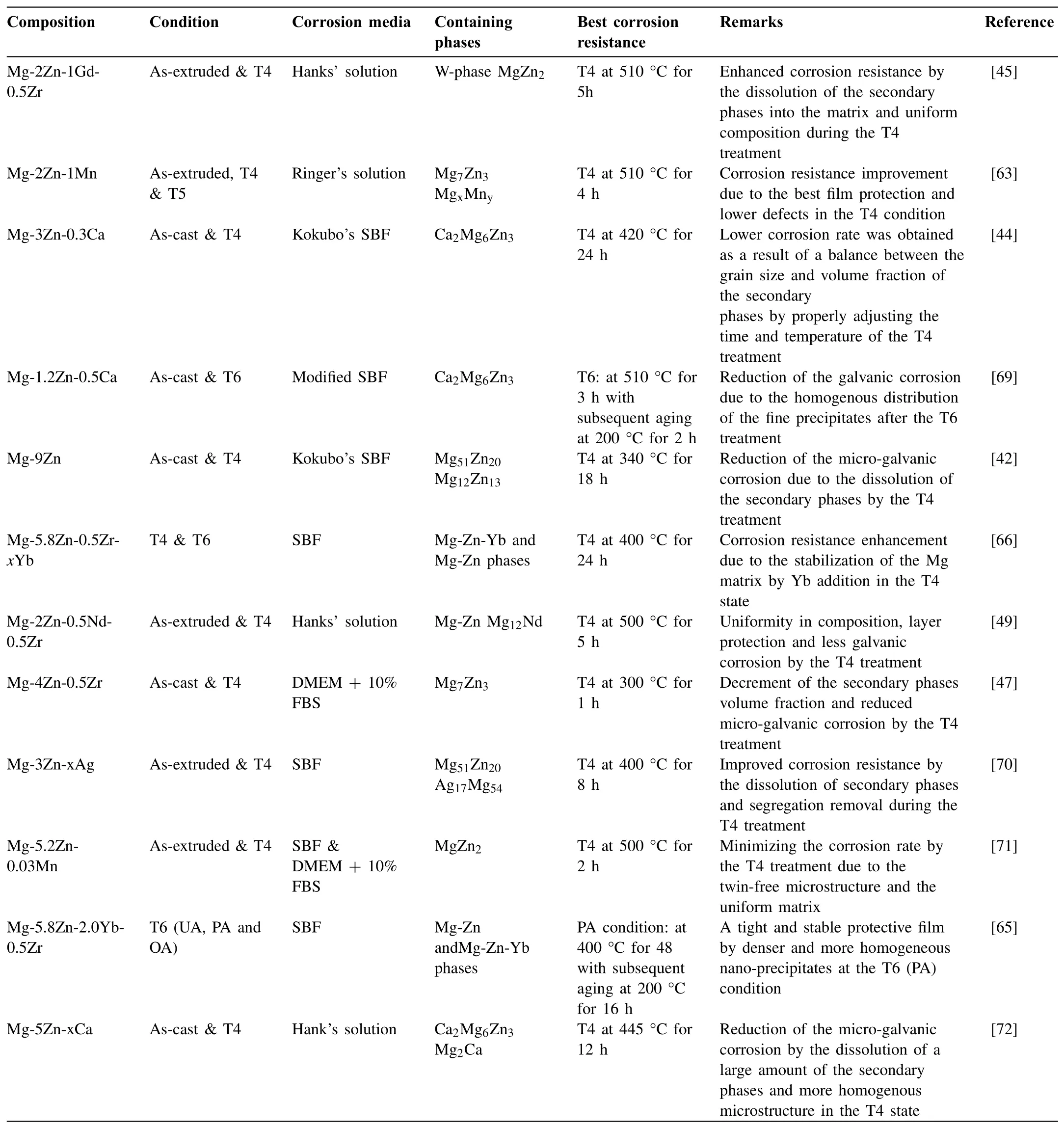

To provide an easier comparison,a summary of the effects of different heat treatments on the corrosion behavior of the biodegradable Mg-Zn alloys is presented in Table 1.In this tabulation,the chemical composition of the studied alloys is given in column 1,the processing condition is given in column 2,the corrosion media are presented in column 3,the Mg-Zn phases are presented in column 4,the condition to achieve the best corrosion resistance is given in column 5,some remarks are presented in column 6 and finally the corresponding references are given in the last column.

Table 1Effects of different heat treatments on the corrosion behavior of biodegradable Mg-Zn alloys in summary

4.2.Mechanical behavior

4.2.1.The mechanical behavior of the Mg-Zn alloys after a T4 heat treatment

As already noted,the strength properties of the as-cast alloys after the solution treatment depend mainly on the two opposing factors of solid solution strengthening and the softening induced by the dissolution of the secondary phases.The former depends on some factors such as the severity of lattice distortion due to the atomic size difference and the latter depends mainly on the thermal stability of the secondary phases at the annealing temperature.It was reported that the ultimate shear strength of an as-cast Mg-2Zn-1Gd-1Ca alloy decreased up to 6% after solution treatment due to the dissolution of precipitates[24].

It has been reported[39]that a solution treatment at 400°C for 2 h removed the deformation twins and defects and also homogenized the microstructure of the extruded ZK60 alloy.Such microstructural changes correspond to some softening which is reflected by the hardness reduction from 81.2 Hv in the extruded sample to 68.1 Hv in the solution-treated sample.More grain growth occurred by increasing the solution heat treatment temperature from 400°C to 500°C,where the grain size increased from 8.6 to 36 μm.This increase led to a further hardness reduction to 62.9 Hv.

In another study,the strength of an as-forged Mg-6.7Zn-1.3Y-0.6Zr alloy was compared with a T4-treated alloy[41]and it was found that the mechanical properties of the solution-treated alloy were influenced by two critical factors:(1)grain growth and the dissolution of the MgZn2precipitates and(2)the precipitation of nano-scale I-Mg3Zn6Y quasicrystals.While the first factor deteriorates the mechanical strength,the second factor has a strengthening effect.Overall,it was found that the mechanical properties of the alloy were degraded slightly by the solid solution heat treatment.There are also some reports of increasing the strength of the Mg-Zn alloys after the solution treatment.For example,it was reported that,by a solution heat treatment at 445 °C for 12 h,the ultimate tensile strength(UTS)of an as-cast Mg-Zn-Ca alloy was improved significantly as the result of an elimination of the casting defects,a homogenization of the microstructure and also solid solution hardening[40].

In addition to strength,the solution heat treatment can also affect the ductility of the Mg-Zn alloys.Thus,both a deterioration[63]and an improvement[49]of the ductility after the solution heat treatment were reported.It should be noted that two contrary factors control the ductility after the T4 treatment since severe grain growth decreases the ductility whereas the dissolution of the precipitates improves the ductility because of the easier dislocation movement.Accordingly,it may be concluded that a solution treatment at intermediate temperatures can improve the ductility while using very high temperatures may lead to some ductility reduction.This is confirmed in experiments where the elongation of an asextruded Mg-2Zn-0.5Nd-0.5Zr alloy increased when the solution treatment temperature was below 500 °C[25].However,when the solution temperature was higher,as at 550 °C,the grain coarsening phenomenon became more pronounced and this gave a decrease in the elongation.Fig.14 shows the fracture surface of this alloy after different conditions.According to these SEM images,a cleavage fracture was observed on the fracture surface of the sample heat-treated at 550 °C.

Fig.11.(a)The micro-hardness evolution during aging,(b-d)SEM micrographs of the UA,PA,and OA samples,(e)the TEM micrograph of the PA sample,and(f)the EDS results of the precipitates in the PA sample,all for an Mg-5.8Zn-2.0Yb-0.5Zr alloy.Reproduced from[65].

4.2.2.The mechanical behavior of the Mg-Zn alloys after a T6 heat treatment

Generally,it is reasonable to anticipate that the aging treatment will result in some strengthening due to the precipitate strengthening effect and it is also common to lose some ductility after the aging treatment.During aging,some precipitates become thermodynamically stable and thus the solute atoms tend to diffuse and make clusters which gradually evolve to precipitates by a progressive diffusional process.Considering the mechanical strength,this is accompanied by gaining some precipitate strengthening at the expense of losing some solute strengthening.It was reported that there was a considerable increase in the critical resolved shear stress(CRSS)for basal slip in an Mg-4Zn alloy aged to peak aging condition(aging for 100 h at 149 °C)by comparison with the solution-treated sample 73.This was mainly attributed to the interaction ofβ;1 precipitates with the basal dislocations.In this case,these rod-shaped precipitates were elongated along thec-axis of the matrix and thus could effectively inhibit the motion of dislocations on the basal planes(Fig.15).In another study,a considerable increase in creep resistance was reported in an aged Mg-4Zn alloy[43].All of these reports indicate that the Mg-Zn precipitates can effectively strengthen the aged Mg-Zn alloys both at room temperature and at elevated temperatures.

Fig.12.(a)The OCP curves,(b)the dynamic potential polarization curves,(c)the corrosion morphology(both optical microscopy and SEM)after 24 h immersion and(d)the corrosion rates after 240 h immersion.The corrosion solution was SBF at 37 °C,and the studied material was an Mg-5.8Zn-2.0Yb-0.5Zr alloy.Reproduced from[65].

Fig.13.Optical micrographs showing the initial and corroded surfaces of the Mg-1.2Zn-0.5Ca alloy in the as-cast(top row)and aged(bottom row)conditions.Samples were immersed in the SBF solution(with a pH range of 7.3-7.8)at 37 °C for 3,7,14,21 and 28 days.Reproduced from[69].

The amount of strengthening obtained by the aging treatment depends strongly on the Zn content.In this regard,it was reported that by increasing the Zn content of Mg-Zn alloys both the yield stress and the ultimate tensile strength increase,where this was mainly attributed to the grain refining effect of Zn together with the increased solid solution andprecipitation strengthening effects[29].Moreover,the aging behavior strongly depends on other alloying elements added to Mg-Zn alloys.For example,it was reported that with the addition of 2% Yb to an Mg-Zn-Zr alloy a much higher density of nano-scaled precipitates was formed and this considerably improved the mechanical strength of the alloy[34].By the addition of alloying elements,precipitates other than Mg-Zn phases can also contribute to the strengthening.The solid solution strengthening and precipitate strengthening by the MgZn2,Mg2Zn3,and Ca2Mg6Zn3intermetallic compounds caused a substantial strengthening effect in a biodegradable Mg-2Zn-0.5Ca-1.0Mn alloy artificially aged at 175 °C for 8 h[74].

Fig.14.SEM micrographs showing the fracture surfaces of the Mg-2Zn-0.5Nd-0.5Zr alloy in the as-extruded condition(a),and also after the T4-treatment at 450 °C(b),500 °C(c)and 550 °C(d).Reproduced from[49].

In addition to the as-cast alloys,the aging treatment was also performed on wrought alloys.Thus,a T6 heat treatment at 170 °C for 10 h was conducted on an as-extruded ZK60 alloy after a T4 treatment at 500 °C for 2 h.In this case,the high temperature of the solution treatment caused considerable grain growth and thus a coarse precipitation of MgZn secondary phases at the grain boundaries which led to a slight decrease in YS and UTS.Also,some ductility enhancement was achieved after the aging treatment due to the elimination of microstructural defects:for example,defects such as the work-hardening effects introduced during the extrusion process and the corresponding residual stresses and the thick and non-uniformly distributed secondary phases present in the microstructure of the extruded alloy[51].

Typically,the mechanical strength decreases after the peak aging condition which is attributed to a coarsening of the precipitates.Fig.10 shows two types of precipitates in an Mg-Zn-Yb-Zr alloy in the peak-aged alloy:(1)rod-shaped Mg-Zn precipitates of 50-100 nm in length and(2)dot-like Mg-Zn-Yb precipitates with diameters of 20-50 nm.These precipitates are responsible for the microhardness increment in the early stages of the aging heat treatment,while extending the time of the process causes coarsening of the precipitates and this produces a microhardness decrement.In another report[69],the mechanical strength of an Mg-1.2Zn-0.5Ca alloy was improved by the aging heat treatment and reached a maximum level at 3-5 hours of aging(peak-age duration).Further increase in the aging time led to a lower number density of the Ca2Mg6Zn3fine precipitates,and therefore the mechanical strength of the alloy was decreased.

Table 2 is presented for an easier understanding and provides a comparison of different effects of heat treatments on the mechanical properties of biodegradable Mg-Zn alloys.In this table,the chemical composition of the studied alloy,the processing condition,the time and temperature of the best heat treatment condition,the mechanical properties of the heat-treated alloys(yield strength,ultimate tensile strength and elongation),and some remarks are presented in columns 1-7,respectively,and finally the corresponding references are given in the last column.

Table 2Effects of different heat treatments on the mechanical properties of the biodegradable Mg-Zn alloys in summary

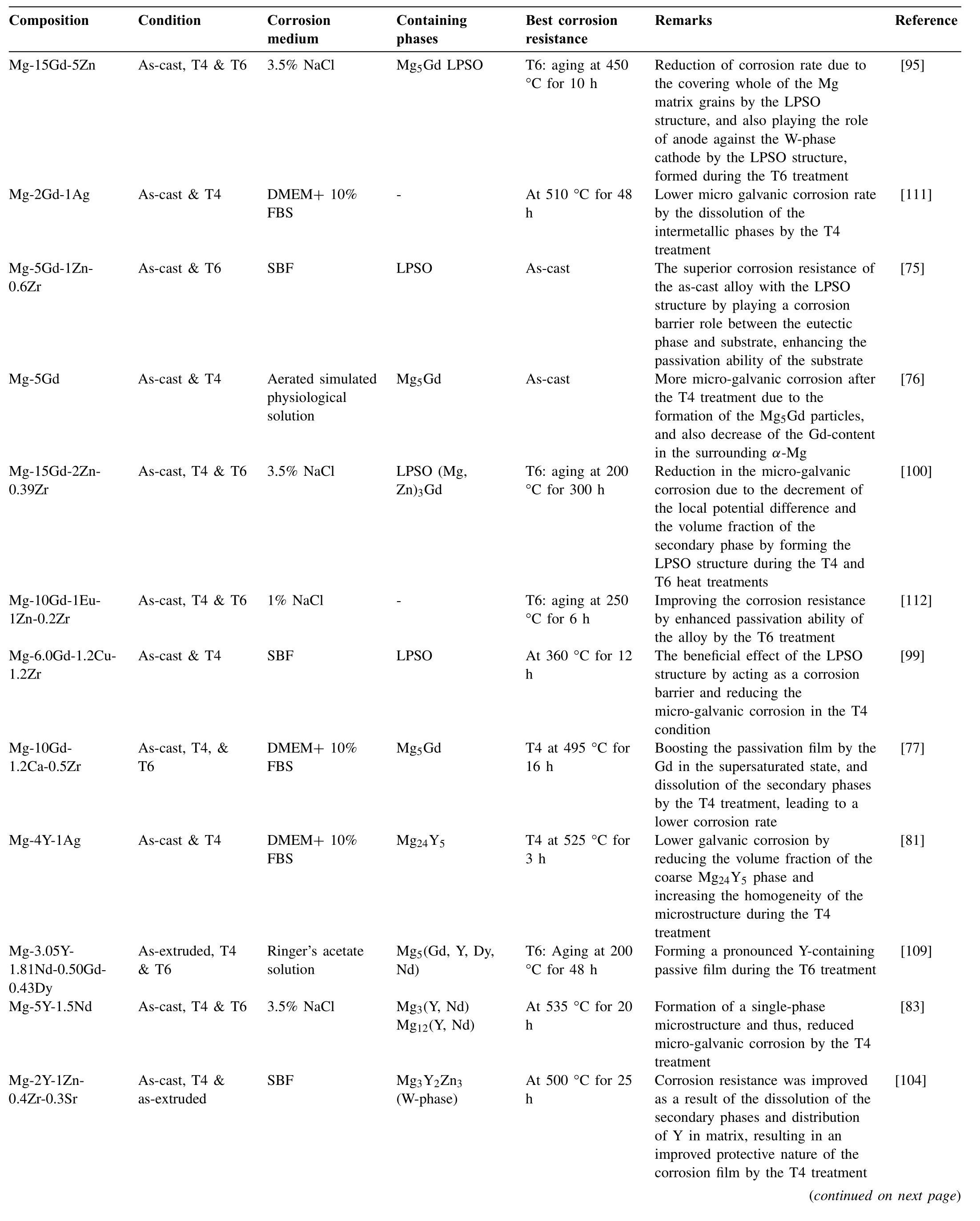

Table 3Effect of different heat treatments on the corrosion behavior of the biodegradable Mg-rare earth alloys in summary

Table 3(continued)

5.The effects of heat treatment on the Mg-rare earth alloys

Incorporation of biocompatible rare earth(RE)elements can substantially promote the bioperformance of biodegradable Mg alloys.In this section,the effects of heat treatment(T4 and T6)on the corrosion behavior and mechanical charac-teristics of some well-known and heat-treatable Mg-rare earth alloys such as Mg-Gd,Mg-Y and Mg-Nd alloys are comprehensively discussed and reviewed.

5.1.Corrosion behavior

5.1.1.The corrosion behavior of the Mg-rare earth alloys in the as-cast condition

Gadolinium(Gd)is one of the common RE elements that has been widely used in the biodegradable Mg alloys with the intention of improving the mechanical properties,corrosion behavior,and biocompatibility[75].The as-cast microstructure of the Mg-Gd alloys is mainly composed of primaryα-Mg,dendrites and secondary phases which form a network structure.Gd has a high solid solution solubility in theα-Mg matrix which approaches the maximum solid solubility of 23.5 wt% at 548 °C.Therefore,the majority of Gd is concentrated in theα-Mg solid solution and thus the volume fraction of secondary phases is not significant,leading to lower galvanic corrosion in the as-cast condition of the biodegradable Mg-Gd alloys compared to other Mg-based alloys with less solid solution solubilities[76].The additionof other alloying elements to Mg-Gd binary alloys significantly affects the properties of the as-cast Mg-Gd alloys by modifying the microstructure and mainly by increasing the volume fraction of the secondary phases.For example,it has been reported[77]that the high amount of the Mg5Gd and Mg2Ca secondary phases in the as-cast microstructure of the Mg-10Gd-1.2Ca-0.5Zr alloy,due to the addition of the alloying elements,accelerated the corrosion rate by promoting the galvanic corrosion.

The corrosion behavior of the magnesium alloys depends strongly on the protectiveness of the surface hydroxide-based corrosion products and,interestingly,it has been reported that Gd improves this protective film[78].According to a report[76],the Gd boosted the magnesium hydroxide layer and the Gd3+cations substituted the Mg2+cations in a brucite lattice.The Gd3+cations interacted with Cl-anions,which mitigated the penetration of Cl-anions in the hydroxide layer to the metallic substrate thereby producing a lower corrosion rate.

The Mg biodegradable alloys with long period stacking order(LPSO)structures have received significant attention in recent years due to their exceptional mechanical and corrosion properties.The LPSO phases are three-dimensional stacking and chemically ordered structures that have been reported in the Mg-M-RE systems(M:Al,Ni,Gd,Cu,and Zn,while RE:Y,Gd,Dy,Ho,Er,Tb and Tm).The LPSO phase has a considerable effect on the corrosion behavior of Mg-Gd biodegradable alloys and plays a dual role in tailoring the corrosion rate.They can either promote the filiform corrosion or act as a corrosion barrier[79].It has been reported[80]that the LPSO structure in the as-cast Mg-3Gd-1Zn-0.4Zr alloy acted as a corrosion barrier between the matrix and the eutectic phase by forming at the outer edge of the matrix-grains,leading to a lower level of the micro-galvanic corrosion.

Yttrium(Y)is another interesting RE element to be utilized in biodegradable Mg implants which can induce many desirable properties.The Mg-Y alloys exhibit unique corrosion properties due to the equality of the standard electrochemical potential of Y with Mg(-2.37 V relative to the standard hydrogen electrode).The element Y shows no or relatively low signs of toxicity in the human body so that it is a common alloying element in the biodegradable Mg alloys[81,82].The microstructure of the as-cast Mg-Y alloys mainly consists of theα-Mg dendrites and the eutectic phases.The concentration of the solutes in theα-Mg is reported to be inhomogeneous and this inhomogeneity becomes more pronounced with a higher concentration of the alloying elements[83].

The incorporation of Y in the oxide film and also the precipitation of the Y-containing intermetallic compounds are the main two contributors in determining the corrosion behavior of the Mg-Y alloys.While the Mg-Y intermetallic compounds(e.g.,Mg24Y5)may lead to micro-galvanic corrosion and thus accelerate the corrosion rate,Y can also become incorporated into the surface film and enhance the oxide film protection effect,thereby producing a corrosion resistance improvement[84,85].According to[86],significantly improved corrosion resistance of the Mg-5.3Y-2.1Nd-0.9Gd-0.3Zr(WE54)alloy was attributed to the stabilization of the surface oxide layer by the Y and a scavenger effect of an RE addition.The impact of Y on the stabilization of the corrosion film is a distinguishing characteristic of this element which plays a determinant role in controlling the corrosion properties of the biodegradable Mg-Y alloys.

In addition to Gd and Y,Neodymium(Nd)is considered as another promising RE element to improve the mechanical properties and corrosion resistance of the biodegradable Mg alloys[87].The biodegradable Mg-Nd-RE alloys with enhanced biocompatibility and antibacterial properties have been widely investigated[88–91].The presence of Nd produces no cell toxicity making it a convenient alloying element for the Mg alloys in biomedical applications[92].The maximum solid solubility of Nd in Mg is 3.6 at% at the eutectic temperature,but this is reduced sharply by decreasing temperature thereby indicating that the binary Mg-Nd alloy can be considered as a heat-treatable alloy.The dendritic structure,solute segregation,and inhomogeneous distribution of the secondary phases are the main microstructural characteristics of the as-cast Mg-Nd alloy[93].The secondary phases play a dual role in affecting the corrosion behavior of the as-cast Mg-Nd alloys.These phases can act as a corrosion barrier and hinder any further corrosion propagation,while they can also act as the micro-cathodes and thus accelerate the micro-galvanic corrosion[94].

5.1.2.The corrosion behavior of the Mg-rare earth alloys after a T4 heat treatment

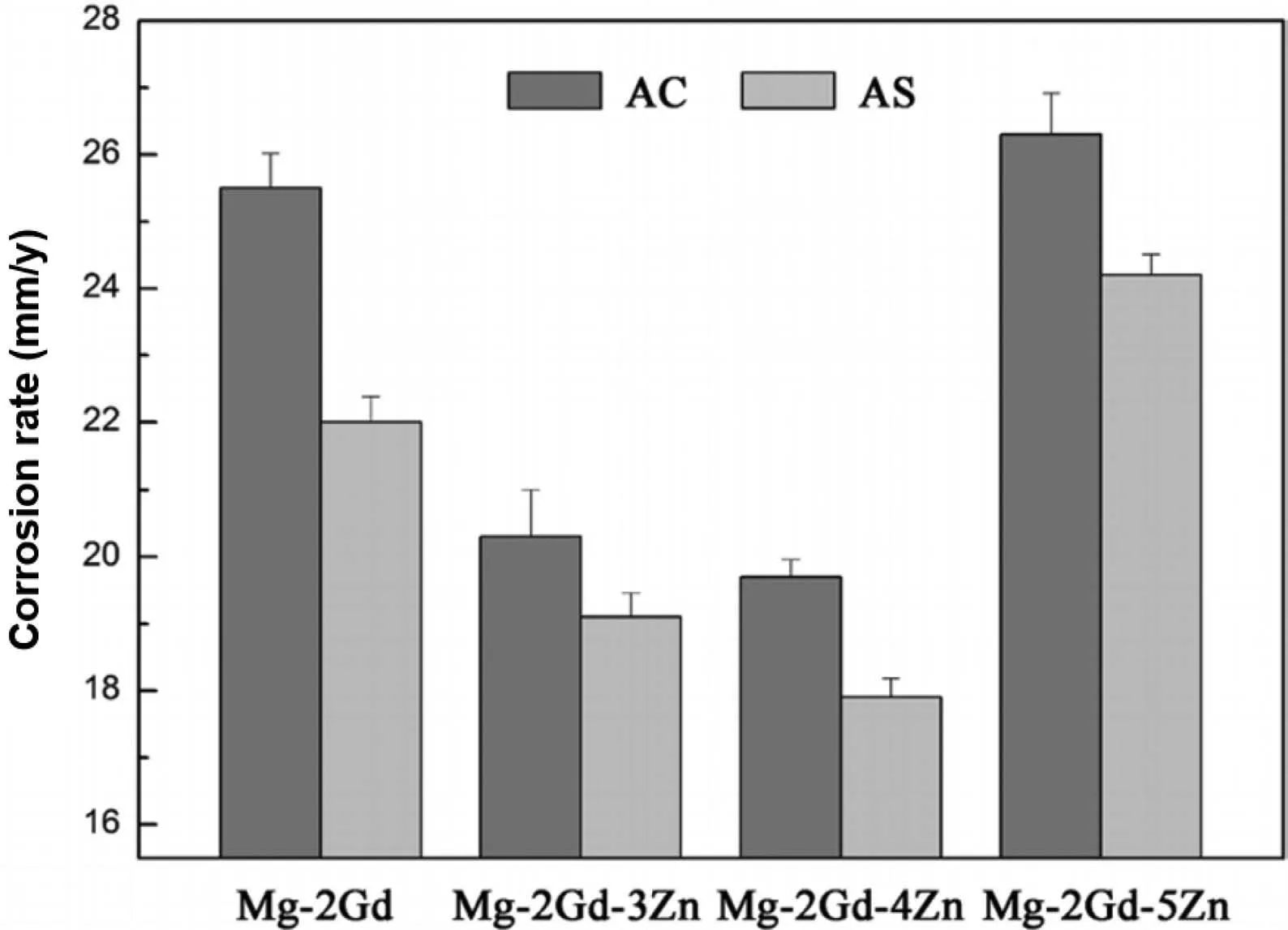

Substantial changes occur with the solid solution heat treatment in the microstructure of the Mg-RE biodegradable alloys.In the case of Mg-Gd alloys,the high solution treatment temperature leads to a decrease in the number of secondary phases and generates a supersaturated solid solution,resulting in the mitigation of the micro-galvanic corrosion and thus a lower corrosion rate.It was observed[95]that although the solution treatment of the Mg-15.24Gd-4.75Zn alloy at 540 °C for 4 h did not result in complete dissolution of the W-phase into the matrix,it limited the number of secondary phases and this resulted in a lower level of the micro-galvanic corrosion.On the other hand,as discussed earlier,grain growth is another notable phenomenon during the solution treatment.It has been reported[96]that the solution heat treatment of the Mg-10Gd at 525 °C for 24 h increased the grain size of the extruded alloy from 24 μm to 140 μm.As mentioned previously,the grain size and volume fraction of the secondary phases are two important factors that determine the overall corrosion rate of the biodegradable Mg alloys,and the best corrosion performance can be obtained with a balanced grain size and secondary phase volume fraction.In this regard,it was concluded[97]that the addition of Zn to the as-cast Mg-2Gd alloy decreased the grain size of the alloy and increased the volume fraction of the secondary phase.Subsequent solution treatment at 420 °C for 24 h balanced the secondary phase content and the grain size.In this study,the solutiontreated Mg-2Gd-4Zn alloy exhibited the lowest corrosion rate(Fig.16).

The formation of the protective film plays a vital role in the corrosion behavior of the biodegradable Mg-Gd alloys.The solid solution heat treatment generates a more homogenous microstructure with a more uniform distribution of the alloying elements existing in a supersaturated form,where this can help to form a better passivation layer that acts as a protective film.It has been reported[98]that the solution treatment of the Mg-7Gd-3Y-0.4Zn(GW73K)alloy at 520 °C for 8 h created a compact yellowish corrosion film.This tight corrosion film covered the surface and caused no localized corrosion on the surface of the alloy.Fig.17 presents the results of the weight loss test after immersion in 5 wt% NaCl.According to these results,the T4 treatment remarkably decreased the corrosion rate by forming a tight corrosion film.

It is generally believed that the LPSO structure formation depends on the Gd content.The Gd atoms diffuse from the secondary phases and the LPSO structure to theα-Mg matrix throughout the solid solution heat treatment of the Mg-Gd alloys.Thus,the volume fraction of the LPSO structure varies during the heat treatment.A solid solution heat treatment was conducted on the as-cast Mg-6Gd-1.2Cu-1.2Zr alloy at four different temperatures(360,390,420,and 450 °C)for 12 h and,due to the composition and thermodynamic requirements of the LPSO structure formation,the volume fraction of the LPSO structure was the highest in the solution-treated alloy at 360 °C(T4-360)(Fig.18b)99.However,the LPSO structure disappeared at 450 °C due to the lack of Gd(Fig.18e).According to mass loss and hydrogen evolution tests,the T4-360 alloy exhibited the best corrosion resistance,which was proof of the favorable effect of the LPSO on the corrosion properties.The LPSO structure acted as a barrier between the secondary phases and theα-Mg matrix,impeding the microgalvanic corrosion.On the other hand,the T4-450 alloy suffered from severe galvanic corrosion due to lack of the LPSO structure,the large grain size and the dominant galvanic corrosion effect by the secondary phase,thereby exhibiting the weakest corrosion resistance.

Fig.16.The corrosion rate of the Mg-2Gd-xZn alloys in the as-cast(AC)and as-solution-treated(AS)conditions,after 9 days immersion in the SBF at 37.0±0.5 °C.Reproduced from[97].

Fig.17.The corrosion rates of the as-cast,T4-treated,and T6-treated GW73K alloy in the 5 wt% NaCl solution at 25±2 °C for duration of 72 h.Reproduced from[98].

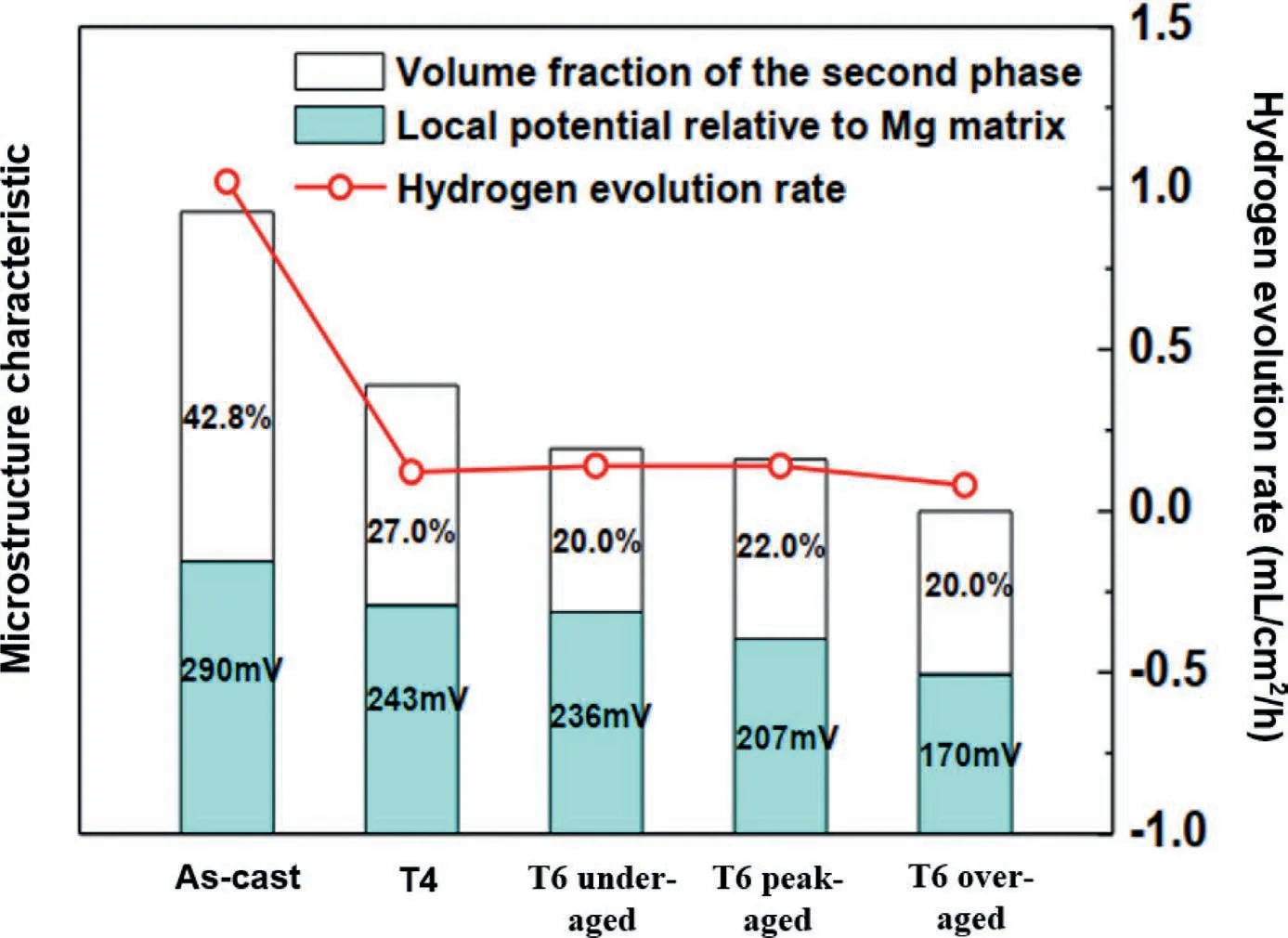

The volume fraction of the secondary phase and its local potential in relation to the Mg matrix determine the overall severity of the micro-galvanic effect.It has been observed[100]that a new X phase with a 14H-type LPSO structure transformed during the solution treatment of the Mg-15Gd-2Zn-0.39Zr alloy at 500 °C for 35 h.In this study,the as-cast alloy possessed the highest volume fraction of the secondary phases and a local potential difference of 290 mV,resulting in a high hydrogen evolution rate.The solution treatment caused a decrement in the volume fraction of the secondary phase from 42.8% to 27.0% and the generation of a new LPSO phase with a local potential difference of 243 mV.Therefore,the micro-galvanic corrosion was considerably mitigated by comparison with the as-cast alloy(Fig.19).On the other hand,the solution treatment of the Mg-3Gd-1Zn-0.4Zr(GZ31K)alloy at 535°C for 12 h caused the dissolution of both the eutectic phase and the stacking faults(SFs)and precipitation of abundant needle-like particles[80].The SFs at the outer edge of the matrix grains played the same role as the LPSO structure and protected the grains against the corrosion propagation.Hence,the solid solution heat treatment in this study reduced the corrosion resistance.Fig.20 depicts the corrosion process schematic diagram of the GZ31K alloy in the as-cast,T4,and as-extruded conditions in which the T4-treated alloy,with no stacking fault structures,in the later stages of the corrosion was severely damaged.

Fig.18.The morphology of the LPSO structure in the Mg-6.0Gd-1.2Cu-1.2Zr alloy,in the as-cast(a),and also solution-treated states(b-e),where the solution temperature was 360 °C(b),390 °C(c),420 °C(d),and 450 °C(e).Reproduced from[99].

In another study[76],the formation of new Mg5Gd particles during the solution treatment of an Mg-5Gd alloy at 500 °C for 30 h reduced the corrosion resistance of the alloy.It was observed that with the formation of the new Mg5Gd particles,theα-Mg matrix was depleted from Gd,and the amount of Cu was increased to 0.4% in the new particles,which increased the nobility of the new phases,all of which resulted in a reduced corrosion resistance.

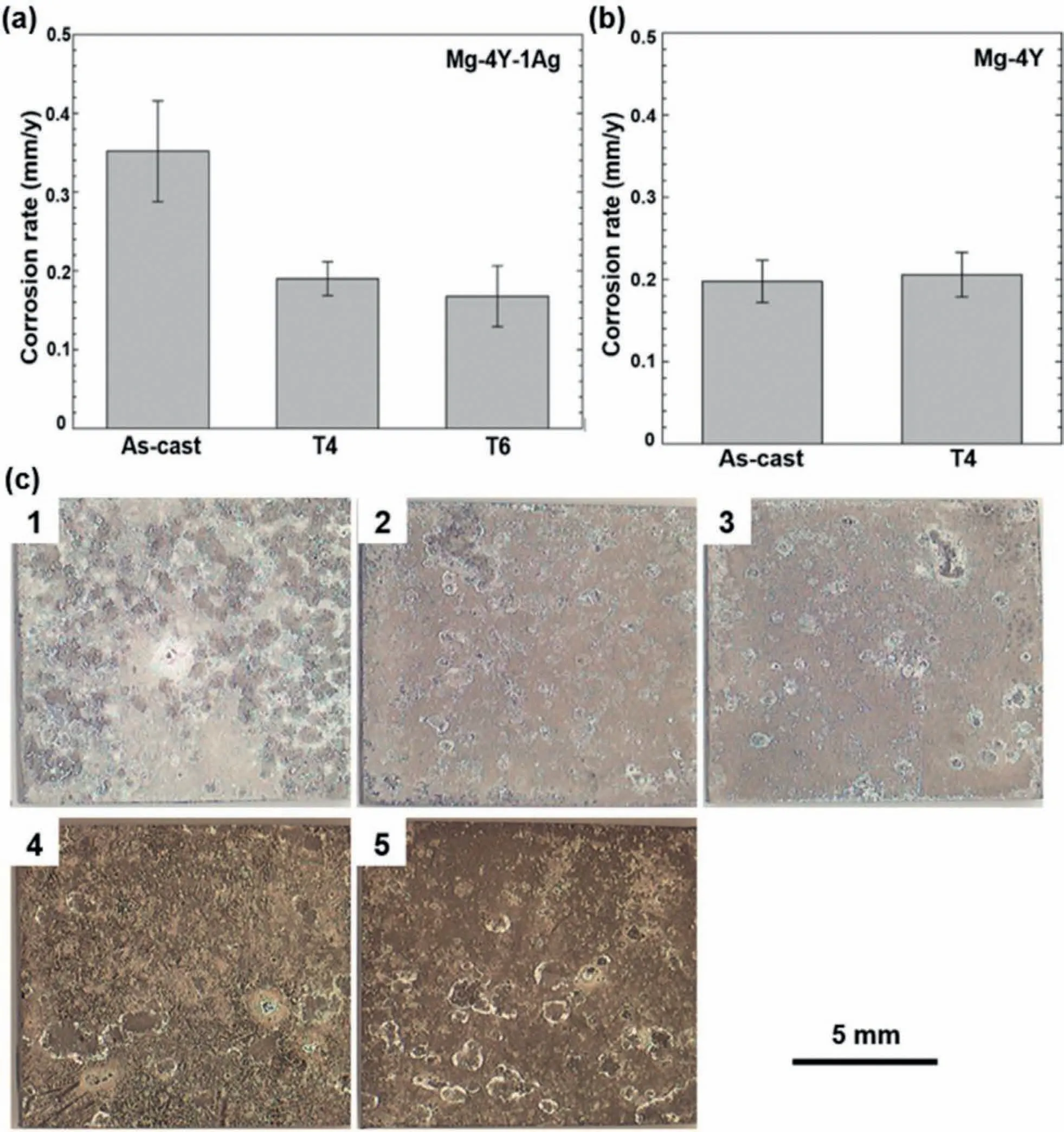

The implementation of T4 treatment on Mg-Y alloys has shown great promise.The solid solution heat treatment of the as-cast Mg-Y alloys reduces the residual casting stresses,decomposes and decreases the eutectic phases,increases the uniformity of the elemental distribution through the matrix and generates a supersaturated solid solution with the Y element[101].All of these changes favor the corrosion resistance and effectively can decrease the corrosion rate[102].Dissolution of the secondary phases during the solution treatment is one of the most important microstructural changes.According to 81,the solution treatment of the as-cast Mg-4Y-1Ag alloy at 525 °C for 3 h eliminated the coarse Mg24Y5particles and reduced the corrosion rate by almost one-half compared with the primary as-cast alloy.At the same time,the solution treatment was practically ineffective in the case of the Mg-4Y alloy due to its better microstructural homogeneity in the as-cast condition(Fig.21).Therefore,the extent of microstructural changes,and thus the extent of change in the corrosion properties by the solution treatment,is strongly related to the concentration of the alloying elements in the as-cast conditions.Fig.21c shows the macrostructures of the Mg-4Y and Mg-4Y-1Ag alloys in both the as-cast and T4-treated conditions,after immersion in Dulbecco’s modified eagle medium(DMEM)with 10% Fetal Bovine Serum(FBS)for 168 h.The results indicate more severe corrosion pits on the as-cast Mg-4Y-1Ag alloy compared to the T4-treated alloy due to the improved homogeneity in the solution-treated conditions.

Fig.19.The effects of two important microstructure characteristics(the volume fraction of the secondary phases and also local potential relative to the Mg matrix)on the hydrogen evolution rate of an Mg-15Gd-2Zn-0.39Zr alloy,in the as-cast,T4,T6-under aged,T6-peak aged and T6-over aged conditions.Reproduced from[100].

Fig.21.The corrosion rate of the as-cast and heat-treated alloys,immersed in DMEM+10% FBS for 7 days:(a)Mg-4Y-1Ag alloy,and(b)Mg-4Y alloy.The macrostructures of the as-cast and heat-treated alloys after the corrosion test are presented in(c),where:(1)as-cast Mg-4Y-1Ag,(2)T4-treated Mg-4Y-1Ag,(3)T6-treated Mg-4Y-1Ag,(4)as-cast Mg-4Y,and(5)T4-treated Mg-4Y.Reproduced from[81].

As discussed earlier,the element Y can be incorporated in the corrosion products as Y2O3(and partly as Y(OH)3)and thus enhance the protecting effect of the corrosion film.In addition,the dissolution of Y into theα-Mg matrix can improve the protective nature of the corrosion film and the film containing the Y element becomes more uniform[103].Fig.22 shows the corrosion morphologies of the as-cast and T4-treated Mg-2Y-1Zn-0.4Zn-0.3Sr alloy both prior to and after removal of the corrosion products from the samples immersed in the SBF[104].As can be observed,the corrosion layer of the T4-treated alloy is relatively uniform and presents lower micro-galvanic corrosion couples compared to the ascast alloy.

Fig.22.SEM micrographs of the corroded samples of the Mg-2Y-1Zn-0.4Zn-0.3Sr alloy,both prior to(left)and after(right)removal of the corrosion products.The samples were immersed in the SBF solution(37 °C)for 45 min.The results are for the as-cast(a,b)and T4(c,d)conditions.Reproduced from[104].

In another investigation[105],the influence of Y on the corrosion properties of the heat-treated Mg-Y alloys was studied.The corrosion rate was first decreased and then increased with increasing Y content(3-7 wt%)and the Mg-2Y alloy showed significantly different corrosion properties among the studied alloys.The single-phase solid solution and a lower number of Y-containing intermetallic compounds caused the Mg-2Y alloy to exhibit an extraordinary protective surface film(Fig.23).By contrast,alloys with more Y concentrations suffered from severe filiform corrosion induced by a large amount of Y-containing intermetallic compounds.In conclusion,the presence of Y in the solid solution form improves the corrosion resistance by forming a protective surface film,while the Y-containing intermetallic compounds deteriorate the corrosion resistance by accelerating the micro-galvanic corrosion.

Remarkable modifications of corrosion features of Mg implants have been reported after the execution of T4 treatment on Nd incorporated Mg alloys.By solution treatment of the Mg-Nd alloys,the micro-segregation of the alloying elements and volume fraction of the secondary phases decrease and this seems to improve the corrosion resistance compared to the as-cast condition.However,some grain growth also occurs[76,106].The as-cast Mg-Nd alloys possess a higher volume fraction of the secondary phases due to the lower solid solubility of the Nd in Mg at low temperatures compared to elements like Gd and Zn.Thus,the galvanic corrosion strongly affects the biodegradation behavior of the Mg-Nd alloys.For this reason,heat treatment is considered as a valuable tool for the modification of the microstructure to control the corrosion behavior,as well as mechanical properties of the biodegradable Mg-Nd alloys.In this regard,it has been reported[76]that the solid solution heat treating of the Mg-4Nd alloy at 520 °C for 20 h improved the corrosion resistance by partial dissolution of the eutectic Mg12Nd phase in the Mg matrix,and this led to a lower galvanic corrosion rate.

Fig.23.SEM micrographs,showing the corroded surfaces of the Mg-xY(x=2,3,4 and 7)alloys after immersion in the 0.1 M NaCl solution for 72 h.(a)Mg-2Y,(b)Mg-3Y,(c)Mg-4Y,and(d)Mg-7Y.Reproduced from[105].

Fig.24.The corrosion morphologies of the Mg-2.5Nd-0.3Zn-0.1Sr-0.4Zr alloy after immersion in SBF for 120 h:(a)the as-cast condition,and(b)the T4-treated condition.Reproduced from[93].

An investigation was conducted to determine the effect of 12 h solution treatments at different temperatures(500,520,540,and 560 °C)on the corrosion properties of the asextruded biodegradable Mg-2.25Nd-0.11Zn-0.43Zr(NZ20K)alloy[88].It was observed that grain growth and the decrease of the volume fraction of the precipitates significantly influenced the corrosion properties.The best corrosion resistance was achieved after the solution treatment at 540 °C due to a balance between the positive effect of the dissolution of the secondary phases and the negative impact of the grain growth.In this study,the solution-treated alloy at 560 °C suffered from irregular grain growth which was responsible for the 62% observed increase in the corrosion rate compared to the alloy solution-treated at 540 °C.In another investigation[107],a solution treatment of the Mg-2.7Nd-0.2Zn-0.4Zr alloy at 475 °C for 1 h,considered for a cardiovascular stent application,improved the corrosion resistance.A compromise between the grain size and volume fraction of the secondary phase was obtained at 475°C leading to a minimum corrosion rate.

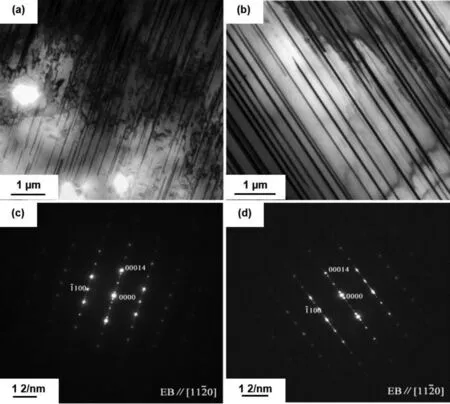

Fig.25.TEM micrographs of the LPSO phase in the Mg-15.24Gd-4.75Zn alloy in different conditions:(a)T6-treated,and(b)T6F-treated.The corresponding SAED patterns of(a)and(b)are represented in(c)and(d),respectively.Reproduced from[95].

It has been reported[108]that a solution treatment of the Mg-1.59Nd-2.91-Zn-0.05Zr-0.35Mn(NZKM)alloy at 480°C for 10 h changed the continuous distribution of theβ-(MgNd)4Zn7phase(β-compounds)in the as-cast condition to discontinuous necklace-type distribution.Theβ-compounds acted as a cathode and accelerated the micro-galvanic corrosion in both the as-cast and T4-treated conditions.However,with the propagation of corrosion,theβ-compounds in the solution-treated alloy piled off from theα-Mg matrix due to the lack of a stable attachment,resulting in a lower volume fraction of the cathodic phase and thus remarkably increased the corrosion resistance.

Contrary to the studies already described,it has also been reported[93]that a solution treatment decreased the corrosion resistance of the as-cast biodegradable Mg-2.5Nd-0.3Zn-0.1Sr-0.4Zr alloy.The deterioration of the corrosion resistance was mainly attributed to grain growth and the presence of a discontinuous intermetallic phase.The eutectic phase in the as-cast alloy was distributed relatively continuously,which wrapped the Mg matrix and acted as a corrosion barrier that could hinder the corrosion propagation.The solution treatment changed the continuous form of the eutectic phase into a discontinuous scattered form with a lower volume fraction,and thus the barrier effect was effectively diminished.Fig.24 shows the corrosion morphology of the as-cast and T4-treated alloy after immersion in SBF for 120 h.The width of the micro-cracks on the corroded surface demonstrates the extent of the corrosion.The width of the micro-cracks was thicker in the T4-treated alloy than the as-cast alloy which shows that the solution-treated alloy possessed lower corrosion resistance.

5.1.3.The corrosion behavior of the Mg-rare earth alloys after a T6 heat treatment

Fig.26.The hydrogen evolution curves(a)and the corresponding calculated corrosion rates(b)of the Mg-15.24Gd-4.75Zn alloy in the as-cast,T4,T6 and T6F conditions.The corrosion process is schematically presented in(c),where the occurrence of the localized corrosion(1-3)and uniform corrosion(4-6)can be observed for the T4-and T6-treated samples,respectively.Reproduced from[95].

Aging is another important heat treatment process which has significant impacts on the corrosion behavior of Mg-RE alloys.It is important to note that the size,distribution,morphology,and volume fraction of the precipitates after the T6 heat treatment dictate the corrosion behavior of the Mg-RE alloys.For instance,with the modification of microstructure and re-precipitation of new precipitates during the aging heat treatment,the micro-galvanic corrosion will be a decisive factor in determining the corrosion behavior of the Mg-Gd alloys.As discussed before and according to Eq.1,the cathode to anode surface area ratio is an essential item in assessing the corrosion rate.It has been reported[98]that the size of the precipitates in the T6-treated Mg-7Gd-3Y-0.4Zr(GW73K)alloy was in the range of nanometers,while large particles in the range of micrometer were observed in the as-cast alloy.As a result,the galvanic corrosion was more severe in the ascast alloy,and numerous corrosion pits having great depths were observed on these samples.

Another factor that affects the corrosion behavior of the aged Mg-Gd alloys is the LPSO structure.There is a report of a study on the effects of two different aging heat treatments on the microstructure and corrosion behavior of an ascast Mg-15.24Gd-4.75Zn alloy 95.The first type of the heat treatment was solution treating at 540 °C for 4 h with subsequent aging at 450 °C for 10 h(T6)and the other type was s solution treatment at 540 °C for 4 h but this time the sample was furnace cooled(T6F).The LPSO structure,which was absent in the as-cast alloy,was formed within the aging process by the atomic diffusion.Fig.25 shows the bright-field TEM images of the LPSO structure in the T6 and T6F samples.The LPSO structure in the T6 and T6F samples were discontinuous/dense and long/thick,respectively.The results of the hydrogen evolution tests revealed that the T6-treated alloy with dense distribution of the LPSO structure had the best corrosion resistance(Fig.26a)and its corrosion rate reached the lowest 4.98 mm/y value(Fig.26b).In this study,the LPSO structure in the T6-treated alloy occupied the whole of theα-Mg grains and reduced the exposed surface area to corrosion media,where this decreased the overall corrosion rate.The lamellar LPSO structure acted as an anode against the W-phase cathode during the micro-galvanic corrosion and obstructed the penetration of the corrosive ions.Fig.26c depicts a schematic of the corrosion process of the T4-treated and T6-treated alloys and the influential role of the LPSO structure in enhancing the corrosion resistance.

Fig.27.The hydrogen evolution curves(a),and the corrosion rates calculated from the weight loss tests in SBF at 37 °C for 120 h(b),for the GZ51K alloy in the as-cast and T6 conditions.The corrosion process is schematically presented in(c),where the occurrence of the uniform(1-3)and localized corrosion(4-6)can be observed with increasing the immersion time for the as-cast(with the LPSO structure)and T6(without the LPSO structure)samples,respectively.Reproduced from[75].

Contrary to the previous work,while the as-cast Mg-5Gd-1Zn-0.6Zr(GZ51)alloy contained the LPSO structure,aging at 120 °C for 12 h(after T4 treatment at 535 °C for 12 h)did not result in further LPSO formation and instead,the LPSO structure disappeared after this heat treatment[75].In this study,after aging the eutectic phase and LPSO structure faded and new needle-like precipitates were formed.The immersion tests in SBF for 120 h disclosed numerous pits on the surface of the T6-treated alloy(without the LPSO structure)while the as-cast alloy(with the LPSO structure)exhibited a smooth and uniform surface.In this investigation,significantly improved corrosion resistance of the alloys with the LPSO structure was attributed to two main factors:(1)an enhanced passivation ability of the substrate material in forming a compact film on the surface by means of the LPSO structure and(2)the barrier role of the LPSO structure between the substrate and the eutectic phase.Fig.27a and Fig.27b show the results of the hydrogen evolution test and weight loss test after immersion in SBF.Fig.27c demonstrates a schematic diagram of the corrosion processes of the as-cast and T6-treated GZ51K alloy with and without the LPSO structure in which the loss of the LPSO structure in the aged alloy caused severe corrosion damage.

The re-precipitation of the secondary phases during the aging treatment affects the corrosion properties of the Mg-Y alloys in many different ways.The precipitate would act as a cathode and accelerate the micro-galvanic corrosion.Also,the phases can contribute to forming a more pronounced passive layer which inhibits any further corrosion propagation and decreases the overall corrosion rate.It has been reported[83]that the solution treatment of the as-cast Mg-5Y-1.5Nd alloys at 535 °C for 20 h with subsequent aging at 225 °C for different times(6,14,and 24 h)deteriorated the corrosion resistance by increasing the micro-galvanic couples.While the T6-24 h(overaged)alloy exhibited the highest amount of the bulky secondary phases and the highest corrosion rate,the T6-14h(peak-aged)alloy showed a more uniform distribution of the precipitates which formed a corrosion barrier and improved the corrosion resistance(Fig.28).

Fig.28.The results of the weight loss test for the Mg-5Y-1.5Nd alloy in the as-cast,T4,T6(6 h),T6(14 h)and T6(24 h)conditions.The samples were immersed in the 3.5% NaCl solution for 24 hours.Reproduced from[83].

Fig.29.SEM images of the extruded biodegradable Mg-5Nd alloy after different conditions:(a)T4 treatment,(b)T6 treatment at 200 °C,and(c)T6 treatment at 245 °C.TEM bright-field micrograph of the sample aged at 200 °C is shown in(d).Reproduced from[110].

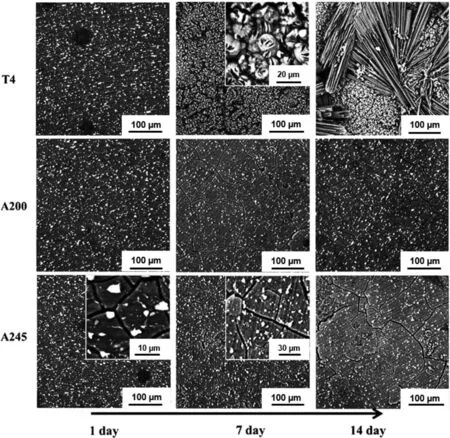

Fig.30.SEM micrographs showing the morphology of the corrosion surfaces of the biodegradable Mg-5Nd alloy after immersion for 1,7,and 14 days in DMEM+Glutamax solution.T4 refers to the sample solution treated at 530 °C for 24 h,A200 refers to the sample aged at 200 °C,and finally,A245 refers to the sample aged at 245 °C.Reproduced from[110].

According to[109],the aging treatment of the Mg-2.78Y-1.43Nd-0.43Gd-0.41Dy(WE32)and Mg-3.05Y-1.81Nd-0.50Gd-0.43Dy(WE33)alloys at 200 °C for 45 h remarkably decreased the corrosion rate.This improved corrosion behavior of the aged alloys was mainly attributed to the formation of a very noticeable passive layer,as a result of a sufficient amount of micro-galvanic couples between theα-Mg and precipitates at short distances.The results indicate that the T6-treated alloys corroded the least among the other mentioned conditions.In conclusion,the corrosion resistance of the Mg-Y alloys would be determined by the accelerated micro-galvanic corrosion by the precipitates or barrier effect of the Y-containing passive film and this can be significantly modified with heat treatment.

The Mg-Nd system is another biodegradable Mg-RE alloy,and it is demonstrated that aging treatment can remarkably influence its properties.Due to the low solid solubility of Nd in Mg(3.6 wt% at 549 °C),there are few investigations on the corrosion behavior of aged biodegradable Mg-Nd alloys.The distribution,volume fraction,and morphology of the precipitates significantly affect the corrosion behavior.It has been reported[110]that after the solution treatment of the Mg-5Nd alloy(at 530 °C for 24 h),some intermetallic compounds(Mg41Nd5)remained and failed to dissolve with these compounds distributed mainly at the grain bound-aries.With subsequent aging at 200 °C,new fine precipitates(Mg12Nd)were formed both at the grain boundaries and inside the grains,shown in Figs.33c and d.With increasing the aging temperature to 245 °C,fine Mg41Nd5precipitates formed,while the number of the Mg12Nd particles was reduced.Accordingly,the large Mg41Nd5particles(at the grain boundaries),fine Mg41Nd5precipitates,and possibly some Mg12Nd precipitates were present in the microstructure of the Mg-5Nd alloy aged at 245 °C.The microstructure of the Mg-5Nd alloy after different heat treatment conditions mentioned above is shown in Fig.29(a-d).The effects of such microstructural differences would be reflected in the corrosion resistance of the alloys,as shown in Fig.30.In this figure,the corrosion surfaces of the Mg-5Nd alloy in the T4,T6-200 °C(A200),and T6-245 °C(A245)conditions are shown after immersion in the DMEM+Glutamax+10% FBS solution for three different numbers of days(1,7,and 14).The SEM images indicated that the thickness of the corrosion layer was the thickest for the T4-treated alloy.This is in accordance with the corrosion results,which showed that the lowest corrosion resistance among the studied heat treatments was achieved for the sample heat-treated by the T4 treatment where the microstructure contained no nano-sized particles.By contrast,the corrosion layer of the T6-treated alloy with nano-sized Mg12Nd precipitations was much thinner,thereby implying exceptional corrosion resistance.Fine nano-scale precipitates formed during the aging treatment and no corrosion products were observed around them at the initial stage of corrosion indicating that no corrosion occurred inside the grains.However,they played an essential role in the propagation of the corrosion.Thus,fine nano-scale precipitates enhanced the corrosion resistance due to their dense and homogenous distribution that resisted the corrosion propagation.

Fig.31.Microstructure of the Mg-11Gd-1Zn alloy,showing the morphology of the precipitates and the LPSO structures:(a)SEM image of the as-cast specimen,(b)SEM image of the annealed specimen,(c,d)TEM image and the corresponding SAED pattern of the as-cast alloy,and(e,f)TEM image and the corresponding SAED pattern of the as-annealed alloy.Reproduced from[117].

Table 3 summarizes the effects of different heat treatments on the corrosion behavior of the biodegradable Mg-RE alloys.In this table,the chemical composition of the studied alloy,the processing condition,the corrosion media,Mg-Nd phases,the condition to achieve the best corrosion resistance,and some remarks are presented in columns 1-6,respectively,and finally the corresponding references are given in the last column.

5.2.Mechanical behavior

5.2.1.The mechanical behavior of the Mg-rare earth alloys after a T4 heat treatment

A T4 treatment can remarkably modify the mechanical behavior of biodegradable Mg-RE alloys.According to the phase diagram of the Mg-Gd alloying system,by proper heat treatment and subsequent quenching,a single-phase solid solution can be formed[43].In this state,solid solution strengthening is the main strengthening mechanism in Mg-Gd alloys due to the notable atomic size difference between the Gd and Mg atoms(12.5%)which generates a strong lattice distortion[115].