Experimental research on oil film thickness and its microwave scattering during emulsification*

Jie GUO , Chenqi XU , Genwang LIU , Xi ZHANG , Junmin MENG , Guangbo REN

1 Yantai Institute of Coastal Zone Research, Chinese Academy of Sciences (CAS), CAS Key Laboratory of Coastal Environmental Processes and Ecological Remediation, Yantai 264003, China

2 Shandong Key Laboratory of Coastal Environmental Processes, Yantai Institute of Coastal Zone Research, CAS, Yantai 264003,China

3 Center for Ocean Mega-Science, CAS, Qingdao 266071, China

4 University of Chinese Academy of Sciences, Beijing 100049, China

5 First Institute of Oceanography, Ministry of Natural Resources, Qingdao 266061, China

Abstract Synthetic Aperture Radar (SAR) plays a major role in identifying oil spills on the sea surface. However, obtaining information of oil spill thickness (volume) is still a challenge. Emulsification is an important process aff ecting the thickness and normalized radar cross section (NRCS) of oil film.Experiments of crude oil emulsification with C-band fully-polarized scatterometer were conducted combining airborne hyperspectral imaging spectrometer and 3D laser scanner observation data, to provide experimental parameters and method to support accurate remote sensing monitoring on marine oil spill.It is further proved that through quantitative homogeneous emulsified oil spill experiments, to a certain extent, the NRCS of oil film increased during the emulsification process of crude oil. The backscattering mechanism of crude oil emulsification was explored using a semi-empirical model (SEM); the change of oil film NRCS was modulated by its dielectric constant and surface roughness, in which the dielectric constant showed a dominant eff ect. The relationship between thickness and NRCS of oil film was studied under two experimental conditions. The diff erences of NRCS between oil film and adjacent seawater ( Δ σ 0) and the damping ratio (DR) were found to have a linear relationship with oil thickness, which were best in the vertical polarization mode (VV) at 45° incident angle during the quantitative crude oil homogeneous emulsification process. In the natural emulsification process of continuous oil spill in which oil film was mixed with both crude oil and emulsified oil, an empirical equation of oil film thickness is preliminarily established. The Δ σ 0,DR, and the empirical equation of oil film thickness were applied to the marine continuous oil spill incident on a 19-3 oil platform with spaceborne SAR image and successfully explained the distribution of the relative thickness of the oil film.

Keyword: crude oil emulsification; normalized radar cross section (NRCS); moisture content; oil film thickness; damping ratio

1 INTRODUCTION

Accidents of crude oil leakages often aff ect large areas of the marine ecological environment over long periods. Emulsification occurs when seawater is mixed with crude oil, and produces a water-in-oil(W/O) emulsion, resulting in an increase in the tension, viscosity, and volume of oil, so that a liquid product can be changed to a heavy and semi-solid material (Fingas and Fieldhouse, 2003; Guo et al.,2019). Emulsification significantly aff ects the cleanup response of oil spill. Oil film thickness (volume) can help determine the key areas of serious impact caused by oil spills, and is conducive to the implementation of oil spill fencing, recovery and clean-up work to minimize the damage (Leifer et al., 2012; Jones and Holt, 2018; Espeseth et al.,2020).

Synthetic aperture radar (SAR) plays a major role in the observation of oil spills and provides a unique opportunity for wide area surveillance, over day or night (Fingas and Brown, 2018). Single-polarization SAR use semi-automatic and automatic detection algorithms based on methods of multi-scale image classification, fuzzy logic, and neural network to accomplish oil film detection (Del Frate et al., 2000;Solberg et al., 2007; Garcia-Pineda et al., 2009; Liu et al., 2010; Song et al., 2017). With the development of full-polarization sensors, polarimetric SAR decomposition parameters, average alpha angle, and entropy are estimated to identify oil slick (Migliaccio et al., 2007; Nunziata et al., 2008; Zhang et al., 2011;Skrunes et al., 2014; Zheng et al., 2017). Minchew et al. (2012) proposed SAR has the potential to identify thicker and emulsified oil films. Garcia-Pineda et al.(2013) proposed a detection method that identifies the regions ofincreased radar backscattering within larger areas of oil-covered water to detect regions of thick and emulsified oil. Minchew (2012) showed a method to characterize emulsification by the volumetric fraction of oil using dual polarimetric imagery. The co-polarization ratio (CPR) is proposed as a useful quantity for estimating the volume percentage (Minchew, 2012; Angelliaume et al.,2018; Li et al., 2019), because it is a function of the incident angles and dielectric constant with the tilted-Bragg scattering model that is independent of sea surface roughness. Damping ratio (DR) is defined as the ratio of the radar-backscattered power from a clean and oil covered water surface. Relevant research has proposed that wave spectral damping increases with Bragg wavenumber, viscosity of the oil, and thickness of the oil layer (Wismann et al., 1998;Espeseth et al., 2017). Jones and Holt (2018) showed that the damping ratio attributed to the oil slicks and varied significantly; and Ivonin et al. (2016) attribute this mainly to the thickness variations, but they do not give detailed information about thickness variations.Sergievskaya et al. (2019) found that the wavedamping coeffi cient of emulsified crude oil film has a maximum at thicknesses of about 1-2 mm, and the maximum is approximately twice that of crude oil,based on a laboratory experiment using oil emulsion and crude oil with diff erent oil film thickness. Garcia-Pineda et al. (2020) generated an oil/emulsion thickness classification product based on RADARSAT-2 polarimetric imagery using entropy and the damping ratio derivations, but it is not possible to quantify or to discern in a qualitative way the level of thickness or the emulsification level.

In recent years, research on the characteristics and mechanism of the hyperspectral response of oil spills in visible, near-infrared, and short-wave infrared ranges (400-2 500 nm) has been greatly developed(Lu et al., 2013; Shi et al., 2018). Optical remotesensing estimation methods and models for oil film thickness are gradually advancing, which can distinguish thickness of oil film from micron to millimeter in scale (Wettle et al., 2009; Lu et al., 2011;Svejkovsky et al., 2016; Wen et al., 2018; Sun and Hu, 2019). However, marine oil spills mostly occur in bad weather conditions, which limits the use of optical data.

At present, there is still a “bottleneck” for SAR in quantitative inversion when studying oil film thickness. Once crude oil leaks at the marine environment, it emulsifies, thus, it is necessary to study the relationship between oil film thickness and normalized radar cross section (NRCS) under emulsification conditions. Guo et al. (2020) thought that moisture content was a good parameter to describe the emulsification process of crude oil within the stable emulsifying range, as it increased with the emulsification process; and they found that the NRCS of oil film increased with a certain degree of emulsification, although the influence of the oil emulsification process on NRCS had not been quantitatively described. Shu et al. (2020) analyzed the diff erence in backscattering between diff erent oil types emulsified oil film and calm water in detail.

In this paper, the scattering mechanism of crude oil emulsification is investigated based on a semiempirical model (SEM). The relationship between oil film thickness and NRCS was investigated under two experimental conditions: an artificially controlled quantitative crude oil emulsification process and a natural process of continuous oil spill, to advance the research of microwave remote sensing estimation of crude oil spill volume.

2 MATERIAL AND METHOD

2.1 Experimental setting

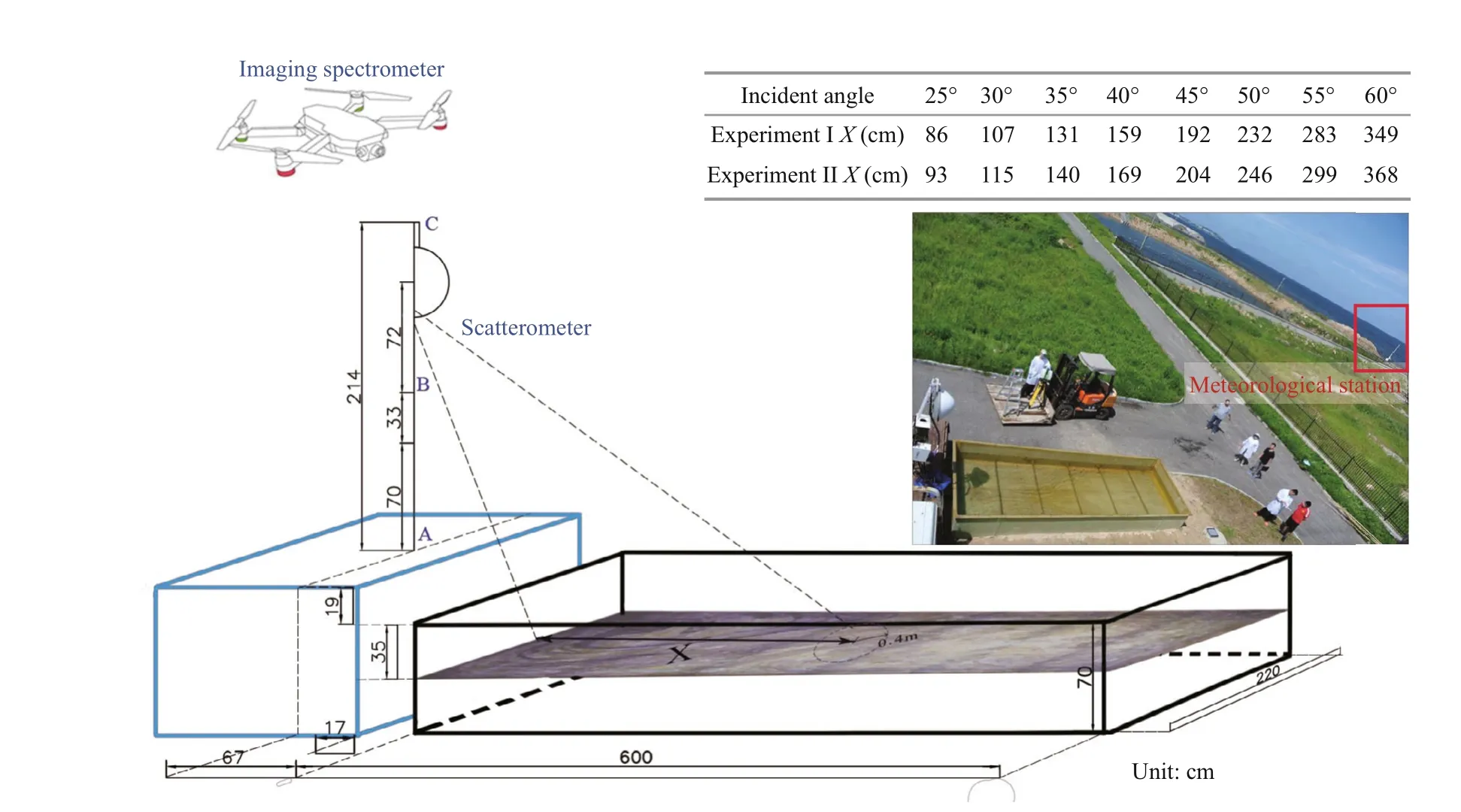

Fig.1 Experimental settings

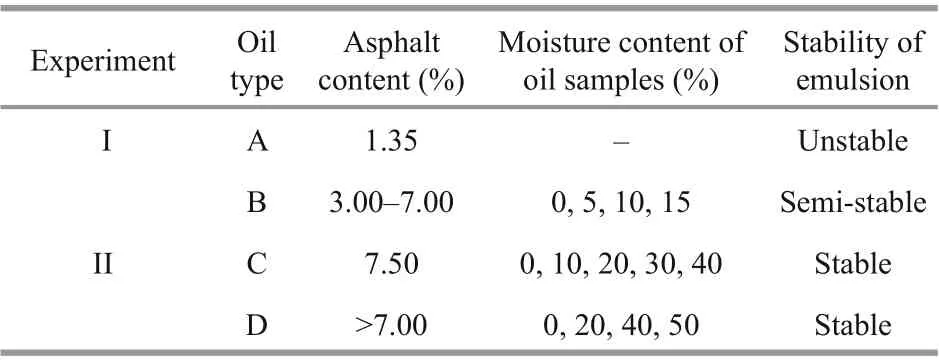

Table 1 Parameters of crude oil used in experiments

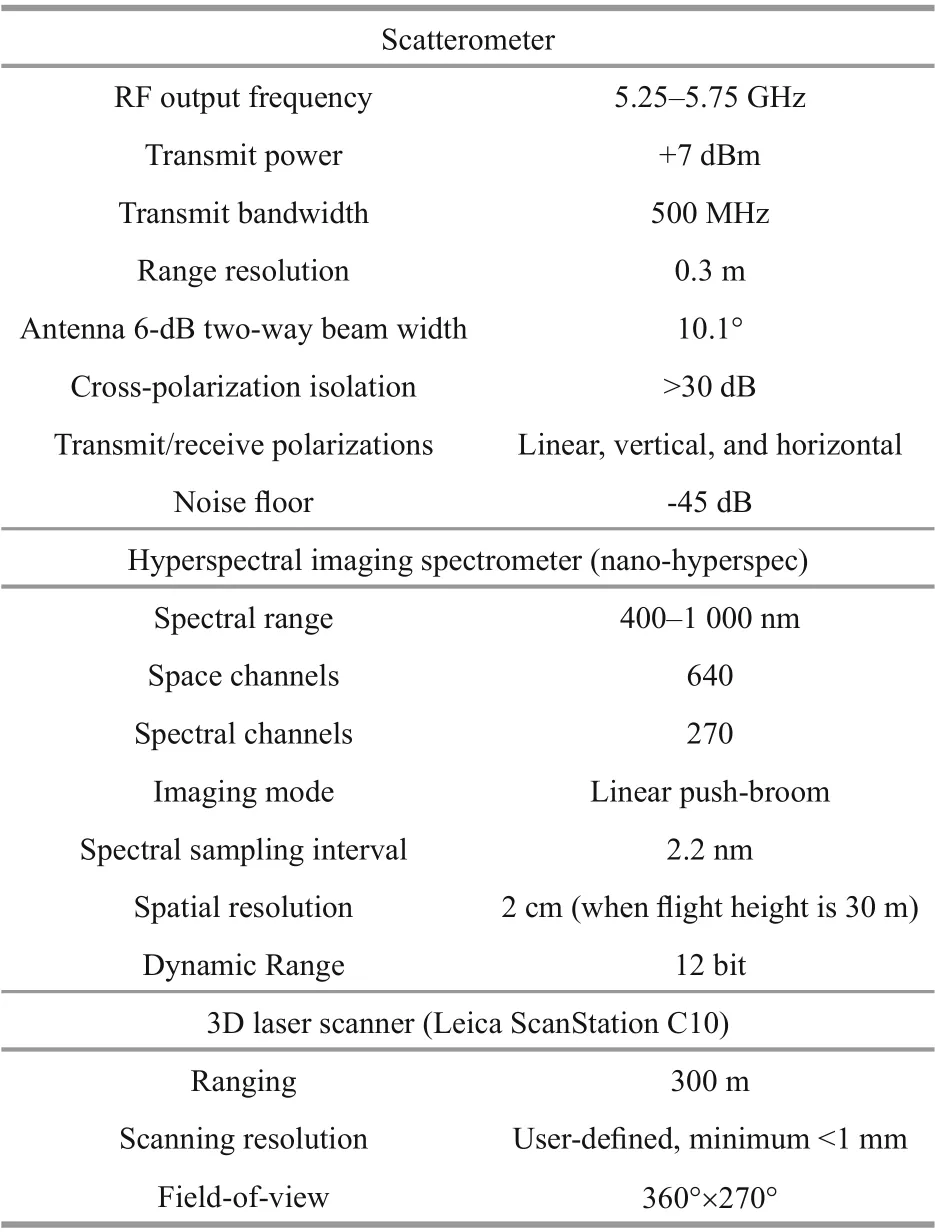

Stability of emulsions is related to the asphalt content of crude oil, and is defined as stable (asphalt content>7%), semi-stable (3%<asphalt content<7%),and unstable (asphalt content<3%) (Fingas et al.,1995, 1999). Crude oils with diff erent asphalt content were used (Table 1). Two kinds of oil, B and C, are extracted from oil platform wells, and A and D are dehydrated crude oil. Crude oil A was used in Experiment I to observe the natural emulsification process of simulated continuous oil spill. In Experiment II, crude oil B, C, and D were used to observe the controlled quantitative crude oil emulsification process, and oil samples of diff erent moisture contents were artificially formulated. All the samples of emulsified crude oil were made using 1-kg crude oil as per Guo et al. (2020). The moisture content interval of emulsified crude oil was set according to the maximum stable moisture content of diff erent oil types at 25 °C (A: 22%; B: 20%; C: 50%;D: 70%). The parameters of these crude oil and the oil samples are shown in Table 1.

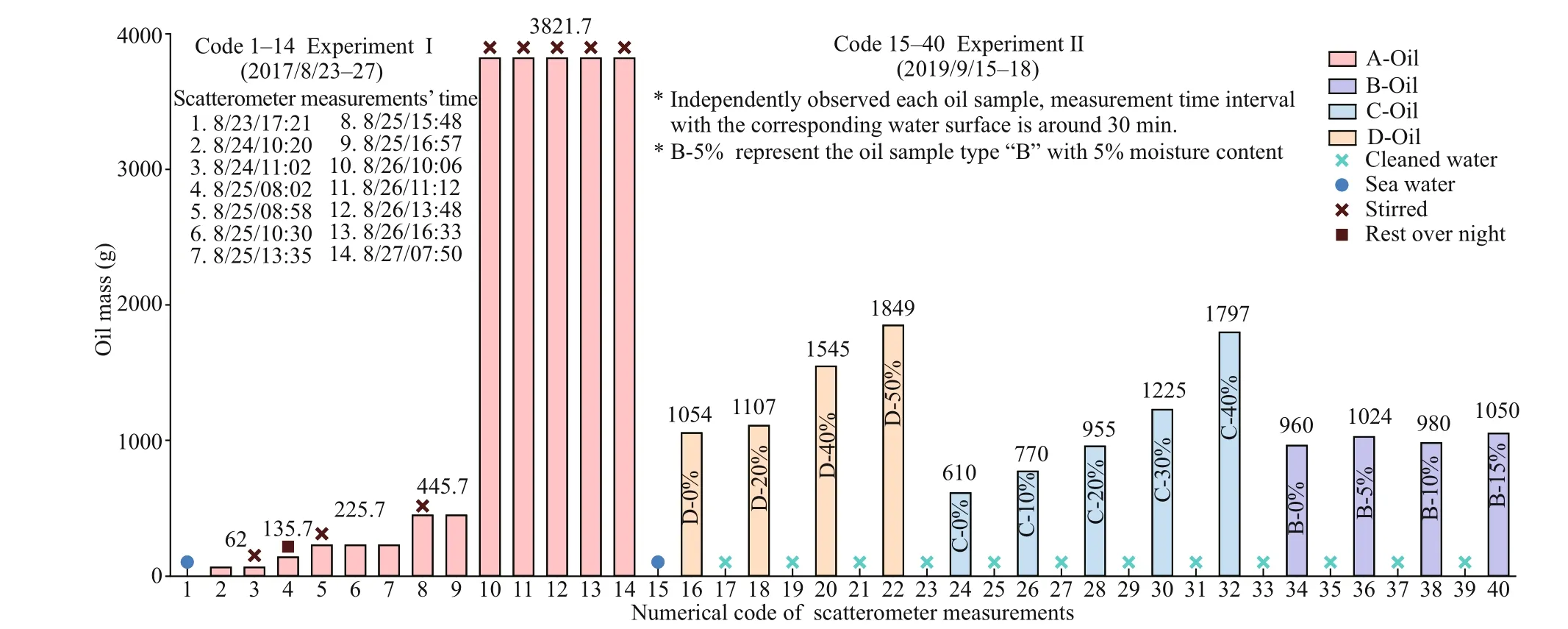

Two experiments were conducted in an outdoor fiberglass pool (6-m long, 2.2-m wide, and 0.7-m depth) (Fig.1). 4 700-kg filtered seawater in density of 1.02 g/mL was injected into the pool to a depth of 0.35 m. A fully-polarimetric C-band microwave scatterometer (polarization (VV, HH, VH/HV)) was mounted on a platform at the short side of the pool.Measurements were taken every 5° from the incident angle of 25° to 60°. The diameter of the scanned footprint was 0.8 m, and the distance (X) between the scanning center and the short side of pool are shown in Fig.1. Information of the measurement by scatterometer helped match the joint observation data and observe the oil film roughness of the corresponding position. In addition, Experiment I used a hyperspectral imaging spectrometer and a 3D laser scanner, to obtain hyperspectral images of oil films for thickness retrieval, and to measure the oil film roughness by vertical ranging on the oil film surface (Yue et al.,2017). Specific parameters of the instruments are shown in Table 2.

2.2 Experimental data acquisition

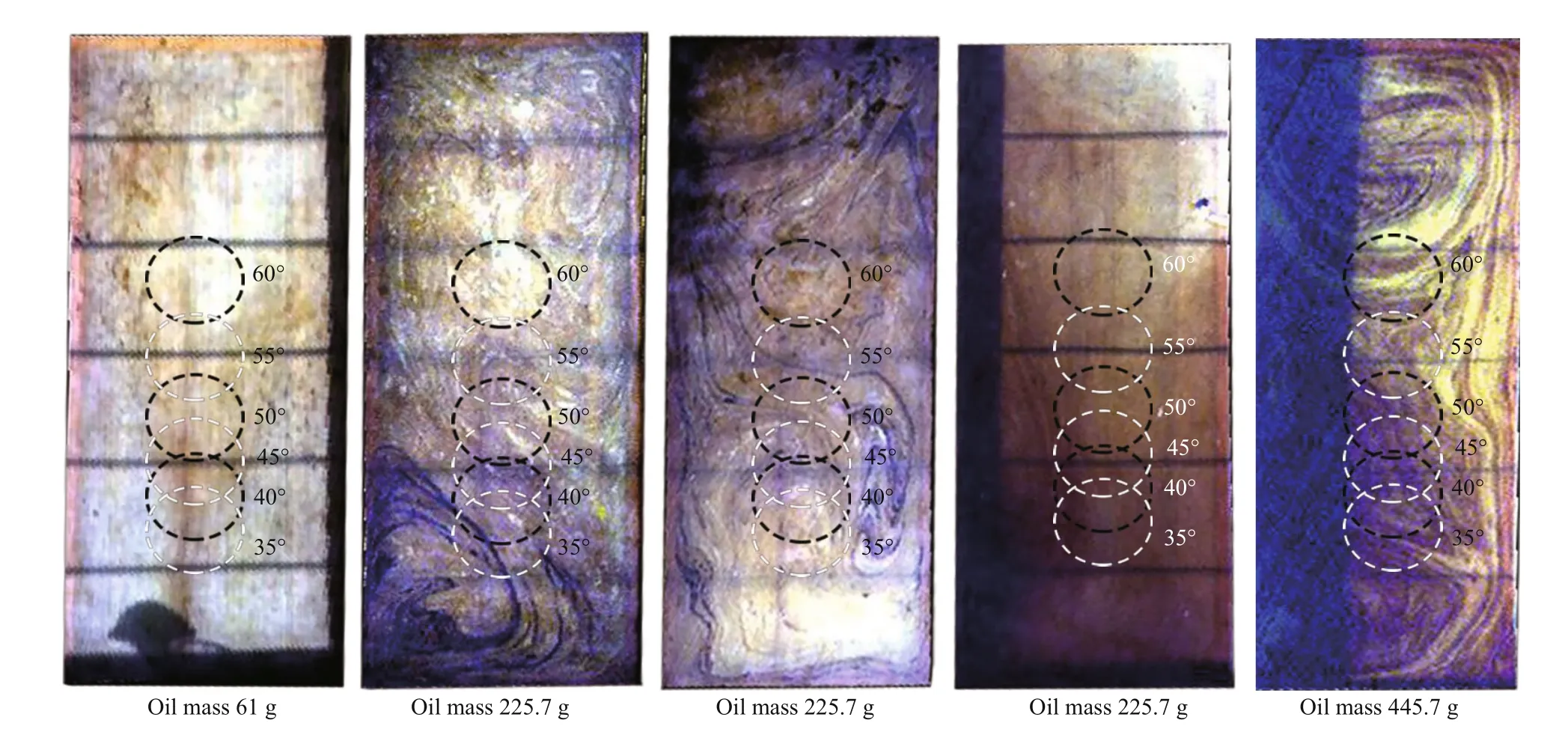

Fig.2 Experimental process and oil mass

Oil spill Experiments I and II were conducted at the Muping Coastal Environment Research Station of the Chinese Academy of Sciences which is located at Yantai. The specific experimental procedure and information of oil spillage included in two experiments are given in Fig.2. Experiment I was performed from August 23 to 27, 2017, and observed one type of oil A using scatterometer, hyperspectral imaging spectrometer, and 3D laser scanner. Crude oil was poured into the water pool in several increments, and oil film removal was not performed throughout the experiment, to simulate the process of continuous oil spill and its natural emulsification process. The oil film was scanned by scatterometer 10 min after diff usion, and was then manually stirred to ensure even distribution of the oil film and to accelerate the emulsification process. After that, another NRCS measurement of the oil film was performed. Once a measurement by scatterometer was accomplished, the imaging spectrometer started to work to obtain the hyperspectral data of oil film, then the 3D laser scanner. Synchronous sampling was carried out in the experiment process, and the moisture content of oil film was measured with a trace moisture meter(SCKF105). The observation by all the instruments was completed within half an hour.

Experiment II was performed from September 15 to 18, 2018, and observed oil samples (oil types: B, C,and D) with diff erent moisture content which were all made using 1-kg crude oil, to quantitatively observe homogeneous emulsified crude oil and research its microwave scattering characteristics. The scatterometer was the main instrument. Clean seawater was first scanned by the scatterometer, and then the NRCS of crude oil and emulsified oil samples.After each oil sample was observed, the NRCS of the water surface after oil removal was measured. Then the next oil sample was poured and the above process repeated for scattering observation. The measurement time interval between oil sample and its correspondingwater surface was around 30 min.

Table 2 C-band scatterometer and imaging spectrometer specifications

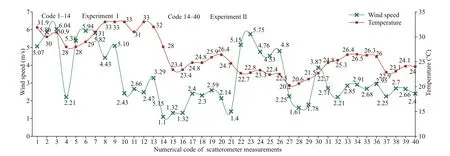

Wind speeds (30 min on average) were measured by a small meteorological station 200 m away from the water pool, and oil film temperatures were collected by thermometers (Fig.3). The surface wave height was measured by wave gauge before the oil film was poured, and was within 3 mm.

Fig.3 Wind speed and temperature

2.3 Matching of observation data scatterometer and hyperspectral imaging spectrometer

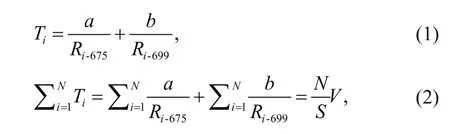

To study the relationship between oil film thickness and NRCS, thicknesses were retrieved by hyperspectral images in the footprint of the scatterometer. The oil film thickness retrieval model was proposed by Ren et al. (2019), and was based on the hyperspectral data from the same oil spill experiment. For a certain pixel (i), the model ofits thickness (T) was assumed as Eq.1, and the known total pixels number (N), area (S) of water surface and oil volume (V) in each image can establish the relationship with the oil film thickness as shown in Eq.2:

whereRi-675andRi-699are characteristic bands with 675 nm and 699 nm, andaandbare undetermined coeffi cients.

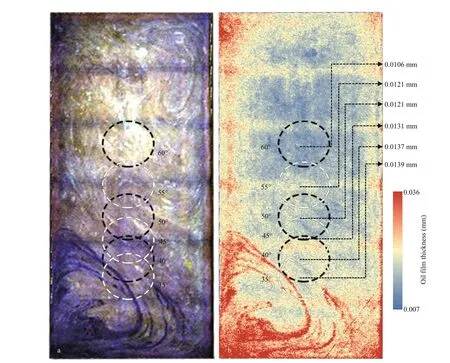

The retrieval model obtained by solving the undetermined coeffi cients could eff ectively retrieve the oil film thickness of any pixel in the images. The relative error (RE) of the estimated oil volume compared with the actual oil volume was 12% on average. As shown in Fig.4, based on the hyperspectral data of oil film (Fig.4a), oil film thickness images(Fig.4b) were calculated using the retrieval model.The pixels covered by the footprint of scatterometer in the thickness image were extracted. Then, the average oil film thickness in each scatterometer footprints at diff erent incident angles were calculated,which will be used to study the response relationship with NRCS.

3 RESULT

3.1 Analysis on NRCS of seawater and oil film

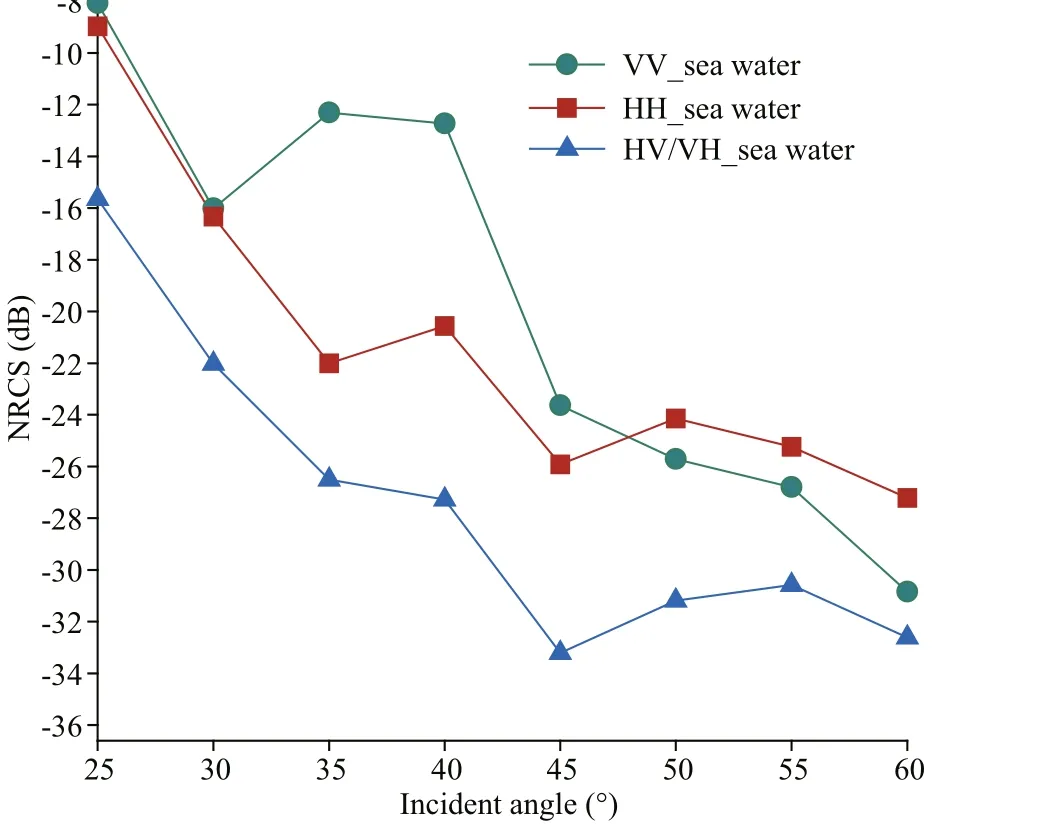

The NRCS change of seawater with the incident angle was tested. As shown in Fig.5, the overall trend of NRCS in VV (σ0VV), HH (σ0HH), and HV/VH(σ0HV/VH) polarization of water gradually decreases with the increase ofincident angles which is consistent with the scattering theory. Although the incidence Angle >50° (at VV) is abnormal due to the influence of the environment, it does not aff ect our subsequent analysis. Our analysis is based on the data measured at a 45° incident angle because the oil samples were poured on to the scanning area at this angle, and the position is at the center of the pool which was relatively less aff ected by the surrounding.

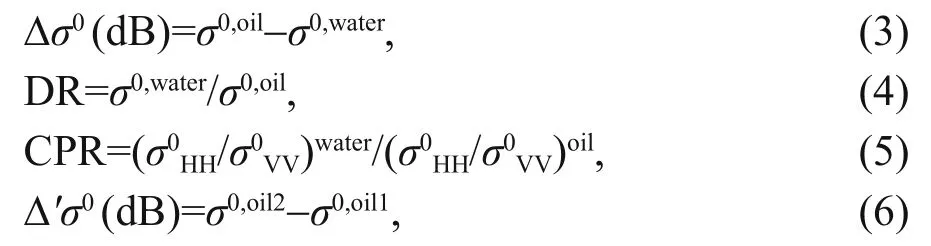

We found that the diff erence between the NRCS( Δσ0) of oil film and water could reflect how the emulsification degree might aff ect the NRCS (Guo et al., 2020). The damping ratio (DR) and the copolarization ratio (CPR) are characteristic parameters of scattering widely used in marine oil spill identification (Wismann et al., 1998; Minchew,2012; Espeseth et al., 2017; Angelliaume et al.,2018). We selected Δσ0, DR, and CPR to analyze these changes with the thickness of oil film in the process of emulsification in Experiment II and select the diff erence ( Δ′σ0) between adjacent observation results of oil film for analysis in Experiment I as follows:

whereσ0,oilandσ0,waterare the NRCS from oil slick and water, respectively.

Fig.4 Hyperspectral image of oil film (a) and inversion of oil film thickness image (b)

3.2 The eff ect of emulsification on NRCS of oil film

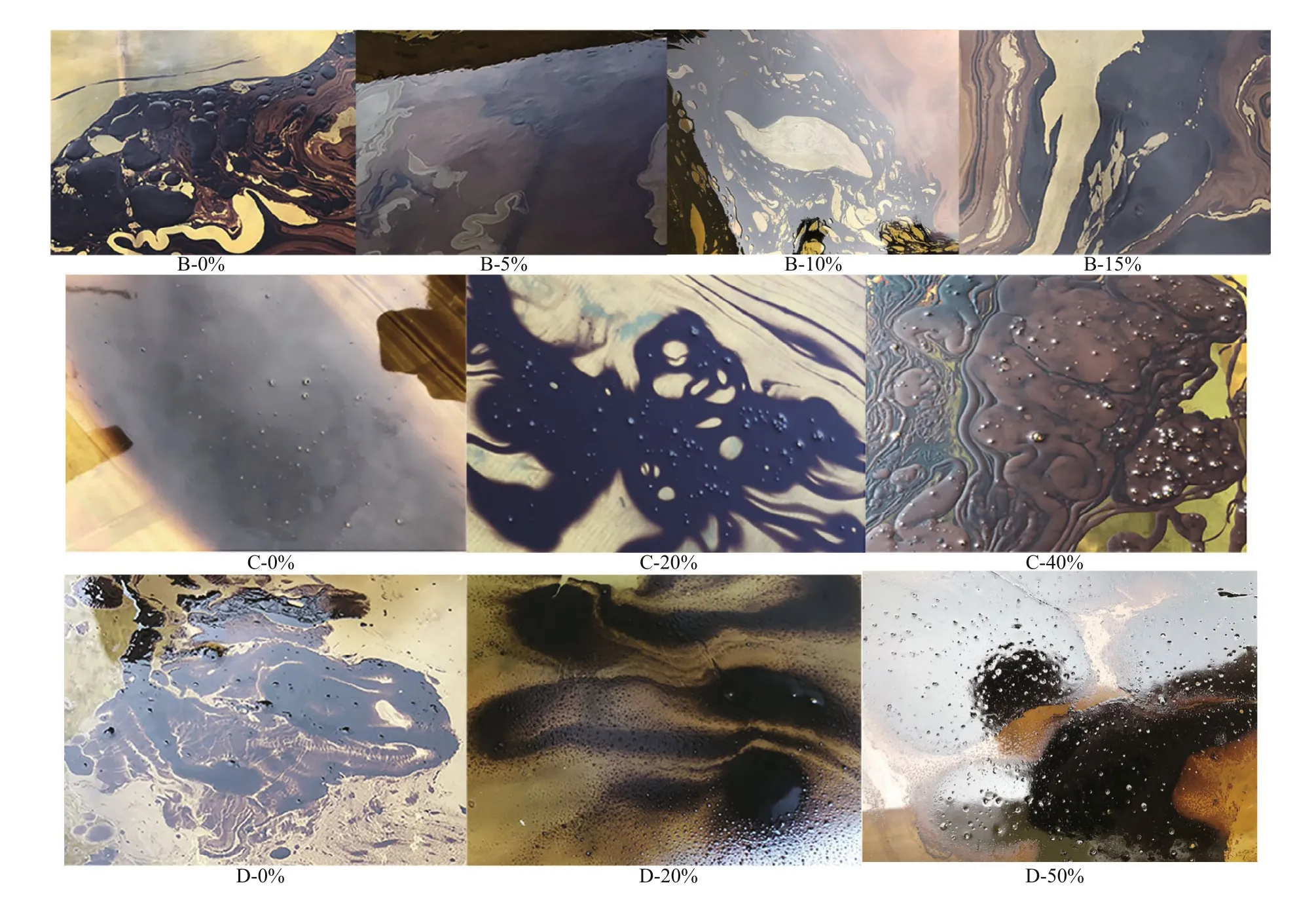

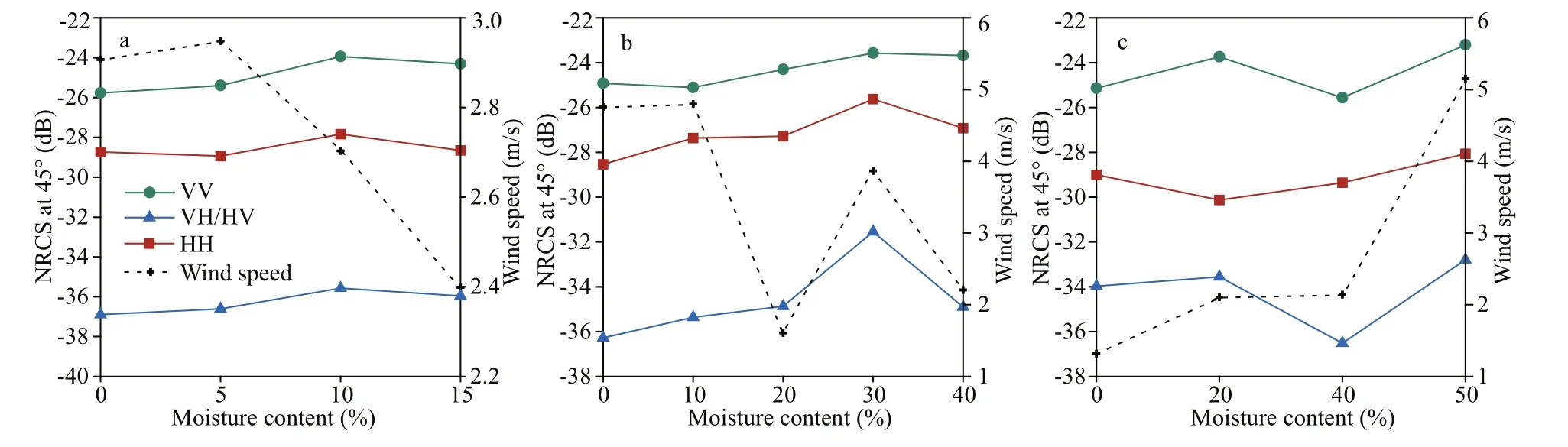

The NRCS of oil film can be aff ected by surface roughness and dielectric constant (Richards, 2009).Emulsification changes the oil film roughness,moisture content, and increases its thickness which will aff ect the NRCS of oil film. As the photos of oil film with diff erent moisture content show (Fig.6), the emulsified oil film with higher moisture content is closer to tan in color. The higher the degree of emulsification of the oil film, the denser the smaller droplets in the oil layer, resulting in a change of oil film surface roughness. Of the three types of oil (B, C,and D) in Experiment II, as shown in Fig.7, the overall trend of oil film NRCS in all polarization modes increased following an increase in the moisture content, and the eff ect of wind speed was not dominant.

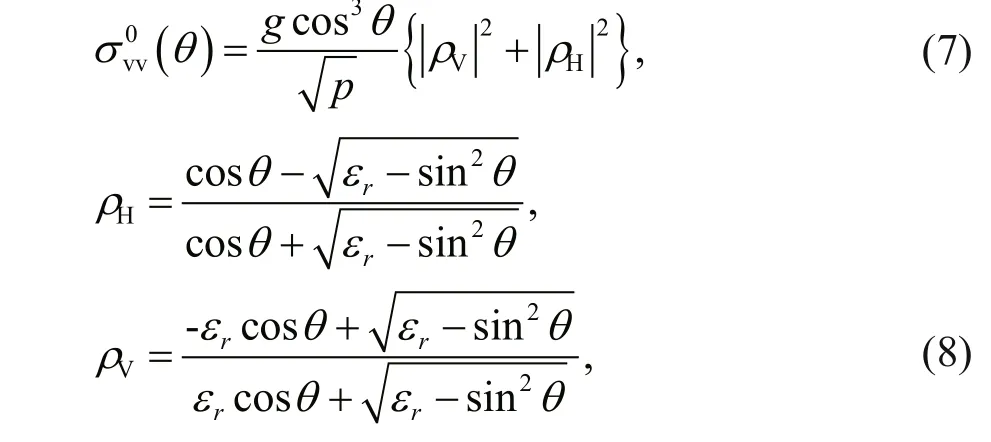

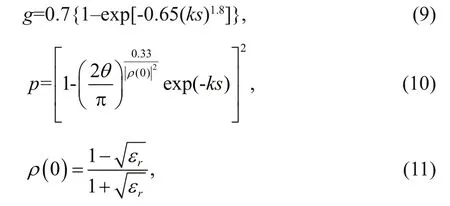

Because the experiments were conducted in a pool,the influence of wind and waves was too small to consider. The influence of wind does not play a dominant role in the 30-min emulsification process from the above analysis (Fig.7). To explore the scattering mechanism of the crude oil emulsification,the semi-empirical model (SEM) (Richards, 2009)was used to simulate the NRCS based on the measured roughness and moisture content of oil film. NRCS of VV polarization can be expressed as follows:

Fig.5 The NRCS of water with different incident angle

Fig.6 Photos of quantitative simulated crude oil emulsification process

Fig.7 The NRCS of 1-kg crude oil change with its moisture content

Fig.8 Simulation and measurement results of NRCS of oil film

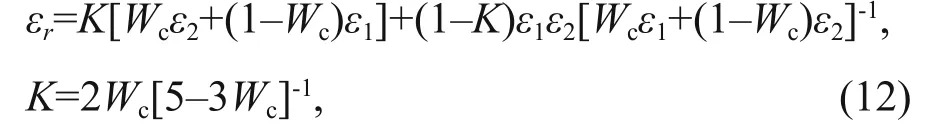

whereθis the incidence angle,kis the wave number of the radar,sis the root mean square (RMS) variation in the surface height,εris the relative dielectric constant, andρ(0) is the Fresnel reflection coeffi cient at vertical incidence.ρHandρVare polarization dependent reflection coeffi cients. The equivalent dielectric constant of emulsified crude oil can be calculated from the moisture content and the dielectric constant of crude oil and seawater (Han, 2019) as follows:

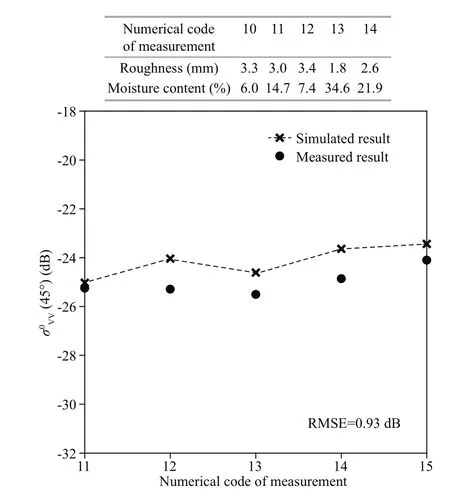

whereWcis the moisture content of oil,ε1andε2are the dielectric constants of crude oil and sea water,respectively, here we set them to 2.2 and 60. Equations 7-12 were used to simulate the NRCS of oil film based on the measured roughness and moisture content in Experiment I. Observation of moisture content was limited by oil film thickness, and we measured the moisture content when the oil mass reached 3 821.7 g which are ranged in the sequence 10-14, and the simulation results are shown in Fig.8.The simulated oil film NRCS is basically consistent with the measured results, the root mean square error(RMSE) is 0.93 dB, and it can be seen that oil film NRCS increases with the increase in the degree of emulsification.

Fig.9 Modulation eff ect of dielectric constant and oil film roughness on NRCS

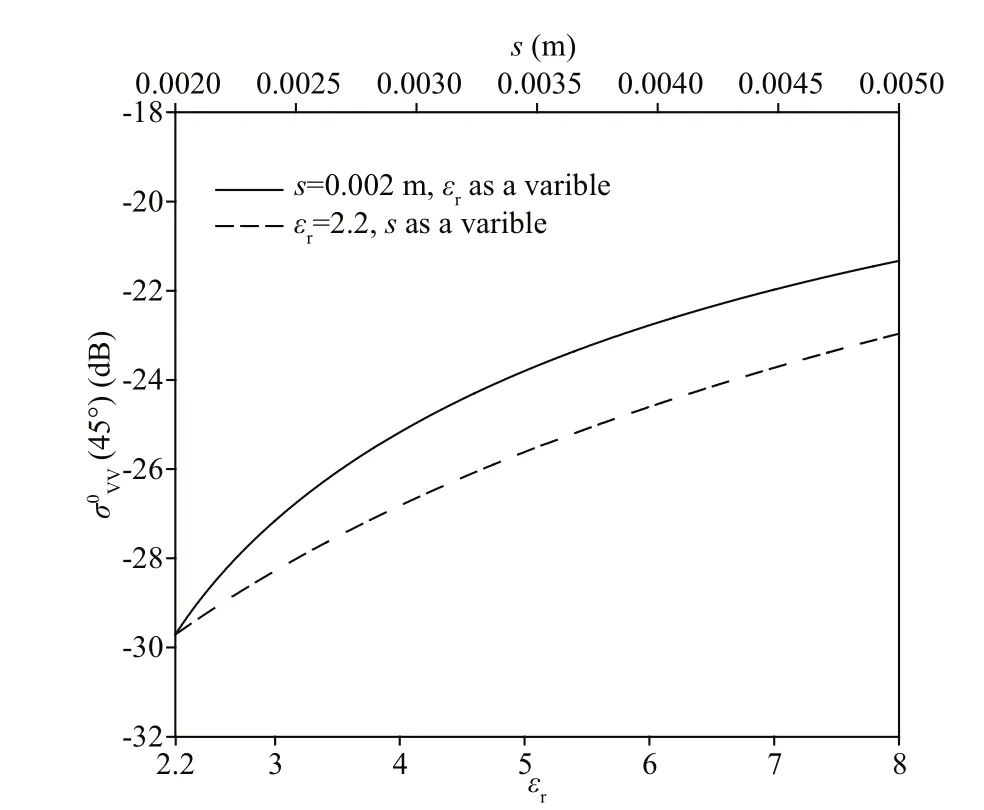

In order to explore the scattering mechanism of crude oil emulsification under experimental conditions, the eff ects of dielectric constant and roughness on oil film NRCS were studied. According to our pre-test, when the emulsified oil reaches the maximum steady moisture content, the dielectric constant changes up to 8, and the oil film roughness usually varies by several millimeters. NRCS with a fixed roughness of 0.002 m and a dielectric constant changing from 2.2 to 8 and NRCS with a fixed dielectric constant of 2.2 and a roughness changing from 0.002 m to 0.005 m were simulated. The simulation results are shown in Fig.9. The NRCS of emulsified crude oil increase with the increase of the dielectric constant and roughness, and it is more aff ected by changes in the dielectric constantg,indicating that the emulsification process plays a leading role in the influence of NRCS under experimental conditions. Therefore, the variation of NRCS of emulsified oil film is modulated by the dielectric constant of oil film and the surface roughness, and the influence of dielectric constant is dominant.

3.3 The relationship between emulsified oil film thickness and NRCS

Crude oil emulsifies when it leaks into the sea. It is necessary to research the relationship between oil film thickness and NRCS in emulsification conditions.

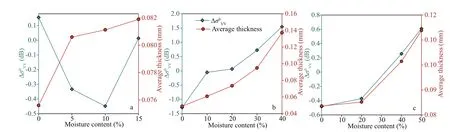

Relationship between oil film thickness and NRCS with Experiment II data measured under the conditions of the artificially controlled quantitative crude oil homogeneous emulsification process was first investigated. Both the average oil thickness (M/ρ·S,whereMis oil mass,ρis measured density, andSis the area of water pool) and Δσ0were found positively correlated with the moisture content (Fig.10), except for Δσ0of oil sample B-0%, which was abnormally high because ofits uneven distribution as shown in Fig.6. Therefore, a certain relationship exists between the thickness of oil film and its NRCS during emulsification and can be established by moisture content. The measurement of oil sample B-0% will be removed in the subsequent analysis.

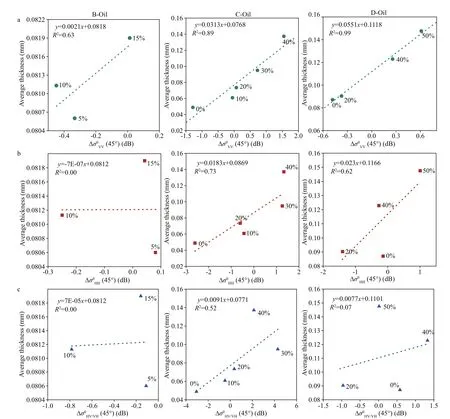

Fig.10 Variation trend of Δ σ 0 at 45° and oil film thickness with moisture content at VV

The Δσ0, DR, and CPR were used to build a relationship with average thickness of oil film. As shown in Fig.11, the Δσ0at VV has the strongest correlation with the thickness of oil film among the three polarization modes during the quantitative crude oil emulsification process, and the Δσ0at VV for oil types B, C, and D, all show a linear positive correlation, and the fitting determination coeffi cients(R2) are 0.63, 0.89, and 0.99, respectively (Fig.11a).The Δσ0at HH has no correlation with oil film thickness for oil type B and theR2of oil types C and D are 0.73 and 0.62, respectively (Fig.11b). For the HV/VH polarization, there is no significant correlation between Δσ0and oil film thickness, fittingR2are 0.00,0.52, 0.07, respectively (Fig.11c).

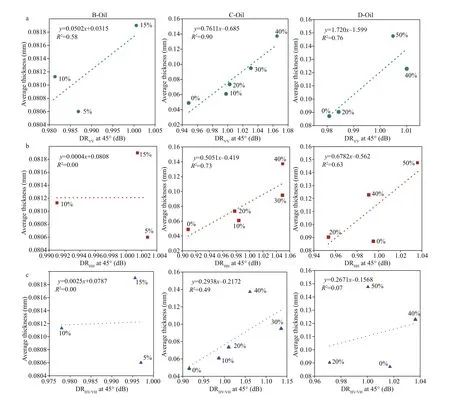

The fitting results of DR and oil film thickness during the quantitative crude oil emulsification process are shown in Fig.12. It can be seen that DR at VV for oil types B, C, D increases with an increase in the thickness of oil film (Fig.12a). TheR2are 0.58,0.90, and 0.76, respectively. TheR2of DR at HH for three oil types is 0.00, 0.73, and 0.63, respectively(Fig.12b). For the HV polarization, there is no significant correlation between the DR and oil film thickness, and theR2are 0.00, 0.49, and 0.07,respectively (Fig.12c).

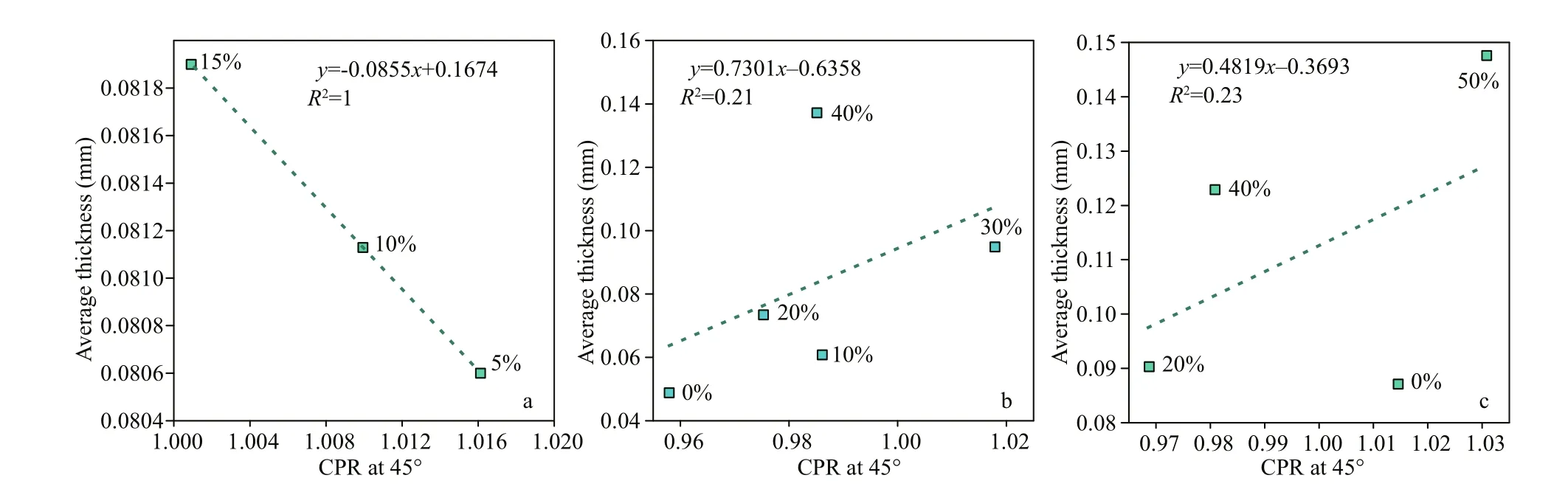

The correlation between the CPR and the thickness of oil film during quantitative crude oil emulsification process is shown in Fig.13. It can be seen that the CPR of oil types C and D increase to a certain extent with the oil film thickness. TheR2are only 0.21 and 0.23. There is a high linear negative correlation for type B oil. However, the observed thickness of type B is small in range, and this result is not representative.The experiment results showed that CPR is not sensitive to a change in oil film thickness in the emulsification of crude oil.

Therefore, the parameters Δσ0and DR can reflect the change of oil film thickness during the quantitative crude oil homogeneous emulsification process and the thickness of crude oil emulsion ranges between 0.04 and 0.15 mm. Also, Δσ0and DR show an increase with the degree of emulsification in the quantitative crude oil homogeneous emulsification process.

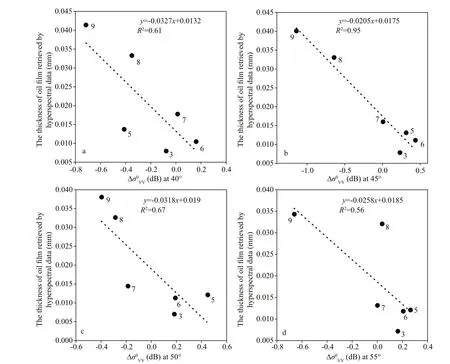

Experimental data obtained by both the hyperspectral imaging spectrometer and scatterometer in Experiment I were used to study the eff ect on NRCS of oil film thickness in a natural emulsification process. Since diff erent amounts of crude oil A were added throughout the whole experiment, it is equivalent to simulating the process of continuous oil spill, and the observed oil film was mixed with both crude oil and emulsified crude oil. Oil film thickness was retrieved based on the hyperspectral data and the match method with NRCS is introduced in Section 2.3. The hyperspectral images of diff erent volume of oil spill are shown in Fig.14. Oil film covers almost the entire water surface, from a sheen to a thicker oil film, where oil films in the circle footprints of scatterometer at incident angles 40°, 45°, 50°, and 55°showed a relatively uniform diff usion (visually consistent in appearance), thus the NRCS measured at the above incident angles and the average thickness of the oil film in these circle footprints have a good matching relationship. The fitting curves of VVpolarized Δ′σ0and the thicknesses of oil film are shown in Fig.15, which also shows a linear correlation.TheR2are 0.61, 0.95, 0.67, and 0.56 at the above incident angles, of which the incident angle at 45° is the best. The oil film thickness empirical equation fitted by oil film thickness retrieved by hyperspectral data at the range of 5-45 μm and 45° Δ′σ0is as follows,which reflects that under the mixed condition of crude oil and emulsified crude oil, the smaller the Δ′σ0, the greater the thickness of the oil film:

Fig.11 The relationship between thickness of oil film and Δ σ 0 during quantitative crude oil emulsification process at VV polarization (a), HH polarization (b), and HV/VH polarization (c)

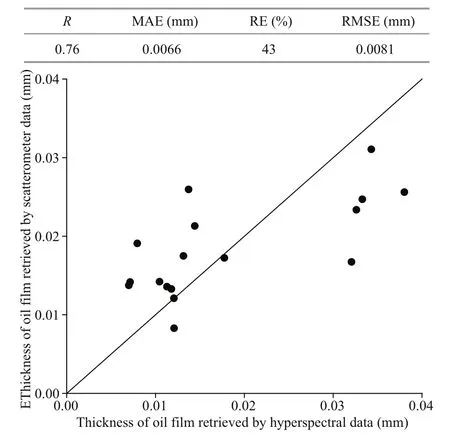

We used the Δ′σ0at other incident angles of 40°,50°, and 55° to retrieve the oil film thickness by Eq.13 and the results were compared with the corresponding hyperspectral retrieval results. The correlation coeffi cient (R) is 0.76, mean absolute error (MAE) is 0.006 6 mm, RE is 43% and RMSE is 0.008 1 mm as shown in Fig.16. It is considered that a certain error is caused by the certain incident angle eff ect since verified data were observed at diff erent incident angles of the scatterometer, and the experimental data was limited. The empirical equation can reflect that microwave scattering has a certain potential to estimate the thickness of oil film when mixed with emulsions and crude oil under the current experimental conditions.

4 DISCUSSION

Fig.12 The relationship between thickness of oil film and DR during the quantitative crude oil emulsification process at VV polarization (a), HH polarization (b), and HV/VH polarization (c)

Fig.13 The relationship between thickness of oil film and CPR during the quantitative crude oil emulsification process for oil type A (a), oil type B (b), and oil type B (c)

Fig.14 Hyperspectral images of oil film in natural emulsification process

Fig.15 Fitting results of Δ′ σ 0 and thickness of the oil film at incident angles of 40°(a), 45°(b), 50°(c), and 55° (d) in natural emulsification process

Fig.16 Results of oil film thickness retrieved by Eq.13

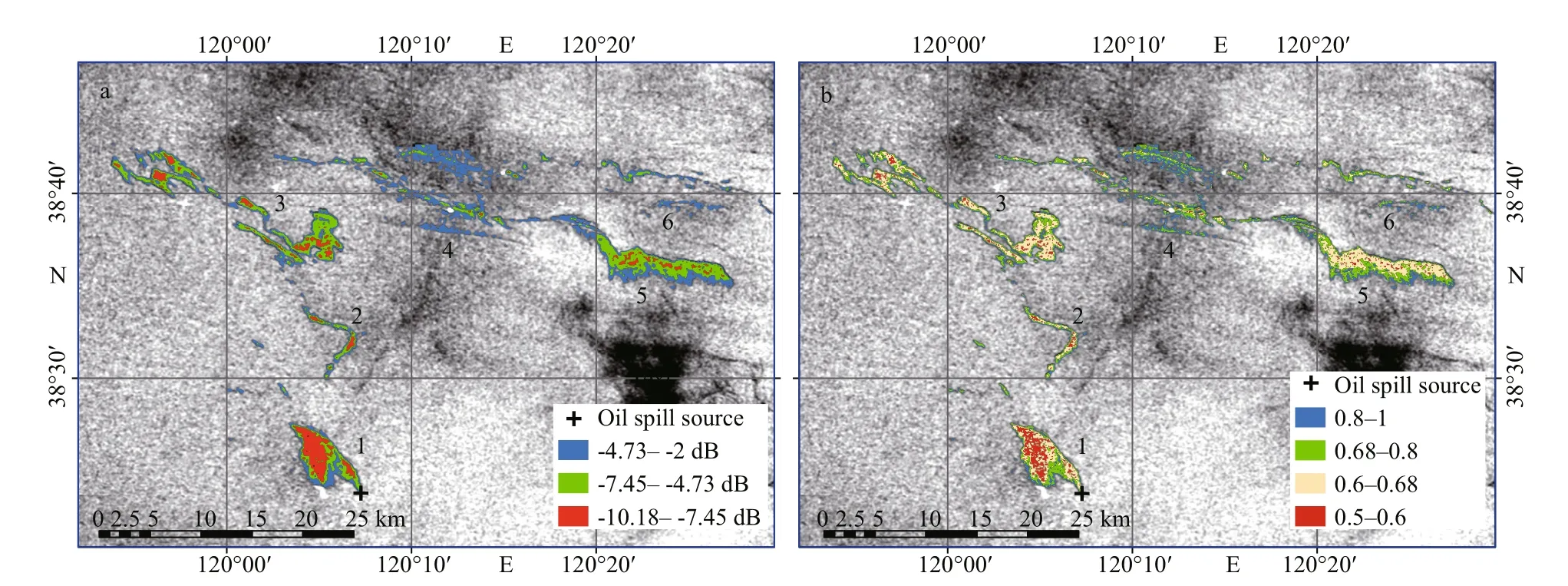

Fig.17 The images of the Δ σ 0 (a) and the DR (b) from Penglai 19-3 oil spill accident on Bohai Sea in China on June 11, 2011

Emulsification can enlarge the volume of crude oil,increase the surface tension and viscosity of oil spill,and thus increase the thickness of oil film. On the other hand, emulsification increases the dielectric constant and surface roughness of oil film, and increases NRCS to a certain extent. The relationship between oil film thickness and NRCS under diff erent conditions of crude oil emulsification was investigated.The Δσ0and DR were found to be sensitive to the variation of oil film thickness during the emulsification process of quantitative crude oil. An empirical equation is fitted under a natural emulsification process, which can provide reference for monitoring of continuous oil spill. To perform application experiments on the empirical Eq.13 of oil film thickness, Δσ0and DR were applied to SAR data(ASAR on June 11, 2011, C band, VV polarization) of Penglai 19-3 oil spill accident, which was a continuous spill of heavy crude oil (including asphalt). Empirical Eq.13 shows that the smaller the sensitive parameter value, the greater the oil film thickness. The Δσ0and DR values of No. 1 oil spot are relatively small compared with other oil spots as shown in Fig.17.Number 1 oil film is located near the source of the continuous oil spill. A large amount of oil spilled continuously collects here, and the oil film is relatively thick, while the Δσ0and DR values of Nos. 2-6 oil spots are relatively high. These oil spots were at a certain distance from the oil platform and were broken and dispersed by wind and waves, and the oil film is relatively thin. The application results show that Δσ0and DR can also reflect the change of oil film thickness under the mixed condition of crude oil and emulsified crude oil, and they are related to the distribution of the relative oil film thickness. The smaller the value of Δσ0and DR, the greater the oil film thickness, which is consistent with the empirical equation of oil film thickness constructed under continuous natural oil spill conditions. Crude oil emulsification often starts from the edge of the oil film, the Δσ0and DR values of the edge of each oil spot are higher than the center of the oil spot, which is consistent with the increase of Δσ0and DR with the degree of emulsification in the quantitative crude oil homogeneous emulsification process.

An empirical equation for estimating oil film thickness was preliminarily constructed under the condition of mixing crude oil and emulsified crude oil in an outdoor experiment, which showed the changing trend of oil film thickness with NRCS at a certain range. It preliminarily explains the relative distribution of oil film thickness in the SAR oil spill monitoring case. However, the amount of experimental data involved is limited, oil products are relatively simple,and the limit for estimating emulsified oil film thickness by full polarization scatterometer is unknown. More observational data from diff erent oil types should be obtained, and the empirical equation should be revised and optimized, to be applied to the quantitative remote sensing inversion of oil film thickness in oil spill accidents.

5 CONCLUSION

In this study, the eff ect of emulsification on NRCS and the relationship between the thickness of oil film and NRCS were studied. It is found that the formation of emulsion will change the microwave scattering characteristics of crude oil, increasing the NRCS of crude oil to a certain extent. A scattering theoretical model was used for exploring the backscattering mechanism of crude oil emulsification under existing experimental conditions. The simulation results show that the NRCS change of emulsified oil film is modulated by its dielectric constant and the surface roughness, where the influence of the dielectric constant is dominant. The Δσ0and DR are found to have a linear relationship with oil thickness during the artificial controlled quantitative crude oil homogeneous emulsification process, which were best at the VV polarization mode. An empirical equation of oil film thickness is initially established in the natural emulsification process of continuous oil spill when oil film was mixed with both crude oil and emulsified oil.The equation shows that the thickness of oil film increases with the decrease of Δ′σ0. The Δσ0, DR, and the empirical equation of oil film thickness were applied to the marine oil spill case by spaceborne SAR image data and successfully explained the distribution of the relative thickness of the oil film (heavy oil) in a continuous oil spill condition. It provided experimental parameters and method to support accurate marine oil spill remote sensing monitoring.

In a further study, it is necessary to observe a large number of experimental data under diff erent conditions and combination with scatterometer,hyperspectral imaging spectrometer and airborne SAR, to explore commonality to improve the oil film thickness inversion method. The experimental conditions should be further optimized under conditions closer to the natural sea state to better provide data references for spaceborne SAR to estimate the thickness of oil films.

6 DATA AVAILABILITY STATEMENT

All data generated and/or analyzed during this study are included in this article.

7 ACKNOWLEDGMENT

Thanks for the ASAR data provided by European Space Agency and the support from the Chinese Academy of Sciences Muping Integrated Experimental Station for the Coastal Environment.

Journal of Oceanology and Limnology2022年4期

Journal of Oceanology and Limnology2022年4期

- Journal of Oceanology and Limnology的其它文章

- Validation and error analysis of wave-modified ocean surface currents in the northwestern Pacific Ocean*

- The energy conversion rates from eddies and mean flow into internal lee waves in the global ocean*

- Observation of physical oceanography at the Y3 seamount(Yap Arc) in winter 2014*

- Decadal variation and trend of the upper layer salinity in the South China Sea from 1960 to 2010*

- Observations of turbulent mixing and vertical diff usive salt flux in the Changjiang Diluted Water*

- Oil-gas reservoir in the Mesozoic strata in the Chaoshan depression, northern South China Sea: a new insight from long off set seismic data*