Identification and characterization of a novel tetrapeptide from enzymatic hydrolysates of Baijiu byproduct

Qing Wu, Chngqing Zhong*, Guirong Zeng, Xu Zhng, Liping Xing, Chng Wn, Yougui Yu,*

a College of Food and Chemical Engineering, Shaoyang University, Shaoyang 422000, China

b Department of Cardiovascular Medicine, Hunan Provincial People's Hospital, Changsha 410005, China

c Hunan Experimental Animal Center, Hunan Drug Safety Evaluation and Research Center, Liuyang 410331, China

ABSTRACT

In order to prepare angiotensin I-converting enzyme (ACE) inhibitory peptides, distilled spent grains of Chinese strong-flavor Baijiu were hydrolyzed by alcalase followed by papain under optimized conditions.A superior ACE inhibitory peptide was separated and purified by ultrafiltration and high-performance liquid chromatography (HPLC), and its amino acid sequence was further identified as Gln-Gly-Val-Pro (QGVP)by electrospray mass spectrometry (ESI-MS). QGVP formed 6 hydrogen bonds with the active site of ACE,which is responsible for reducing α-helix structure content of ACE causing subsequent inactivation. M oreover,it showed no significant cytotoxicity toward human umbilical vein endothelial cells (HUVECs), a nd significantly i nduced phosphorylation of endothelial nitric oxide synthase (p-eNOS) and decreased endothelin 1 (END1) expression in angiotensin I (Ang I)-treated HUVECs, demonstrating the potential antihypertensive effect. The peptide QGVP hydrolyzed from distilled spent grain proteins of Chinese strong- flavor Baijiu was expected to be used as a food ingredient to prevent or co-treat hypertension with other chemical drugs.

Keywords:

Baijiu

Distilled spent grain

ACE inhibitory peptide

Inhibition mechanism

1. Introduction

As a traditional fermented beverage, the liquor-making raw materials loaded with starch matrix and protein, including crushed sorghum, corn, wheat, sticky rice and rice, are fermented in pit for 2 months by spontaneous solid-state fermentation, and the fermented grains are distilled to produce Baijiu (Chinese liquor) [1]. The starch matrix in liquor-making raw materials is degraded by microorganisms in Daqu and pit mud in to fermentative sugar for ethanol production [2],but there ar e plenty of cereal-derived proteins that are not unutilized by microorganisms, and remain in final distilled spent grains [3].Distilled spent grains, a major byproduct from the processing of Baijiu industry, presents with 167.8 g/kg dry weight of protein content and reaches an output of 30 million tons in China [4]. However, the distilled spent grains are utilized as low-cost fodder, or even thrown away. Rational exploiture and utilization of the protein-loaded distilled spent grains need to be performed.

Angiotensin I-converting enzyme (ACE, EC 3.4.15.1)undertakes a critical role in peripheral hypertension therapy. Not only can it hydrolyze angiotensin I (Ang I) to a strong vasopressor angiotensin II (Ang II), but also breaks the potent vasodilator bradykinin [5]. Therefore, the inhibition of ACE activity contributes to hypertension treatment. Food-based ACE inhibitory peptides are expected to be identified from soya milk [6], lysozyme [7] or collagen [8], and produced in microbial fermentation or enzymatic digestion (hydrolysis) [9-11]. We have previously discovered ACE inhibitory peptides from medicinal macrofungi and marine resources [12-14].I n recent, many bioactive peptide compounds were identified from traditional Baijiu, including Ala-Lys-Arg-Ala from sesame flavor-type Baijiu, Pro-His-Pro from strong-flavor Baijiu and lichenysin from Chinese liquor Jiannanchun, although they were present with very low concentration in Baijiu [15-18]. It is worthy to note that lichenysin can form hydrogen bonds with the phenolic hydroxyl group of 4-ethyl guaiacol, inhibiting the volatility of this phenolic substance and reducing the odor intensity of liquor [18].Further study presented that Ala-Lys-Arg-Ala formed hydrogen bonds with the hydroxyl hydrogen of para-cresol to improve the desirable flavor of liquor [19]. Hence, these non-volatile peptide substances play an important role in the aroma characteristic of Chinese Baijiu.Recently, 18 ACE inhibitory peptides have been identified in distilled spent grains by UPLC-Q-TOF-MS, and the concentration of these water-soluble peptides in distilled spent grain extract was 0.53–92.14 μg/g [20]. Given the distilled spent grain of Baijiu riches in proteins, we anticipate using distilled spent grains to prepare ACE inhibitory peptides by selective enzymatic hydrolysis. Moreover,the inhibition mechanism of the potent ACE inhibitory peptide from the enzymatic hydrolysate is further verified. The anti-hypertensive cell model is established by Ang I treated with human umbilical vein endothelial cells (HUVECs) for exploring the underlying molecular mechanism of it on hypertension therapy. Not only can the identified peptide improve the utilization rate of liquor-making raw proteins,but also it is expected to be added into liquor, leading to improving its flavor and health quality.

2. Materials and methods

2.1 Materials

Distilled spent grains of Chinese strong-flavor Baijiu were obtained from Hunan Xiangjiao Industry (Shaoyang, China).hippuryl-histidyl-leucine (HHL) and ACE were purchased from Sigma-Aldrich (St Louis, MO, USA). Roswell Park Memorial Institute (RPMI) 1640 medium and fetal bovine serum (FBS) were obtained from Gibco-BRL (Grand Island, NY, USA). HUVECs were from Boster Biological Technology Company (Wuhan, China). Ang I (S49999) was from Yuanye Biotechnology Company (Shanghai,China). Anti-endothelin 1 (END1) antibody (ab2786) were from Abcam (Cambridge, MA, USA). Anti-phosphorylated endothelial NO synthase (p-eNOS) Ser1177 antibody (ARG20524) was from Arigo Biolaboratories (Hsinchu City, Taiwan, China), and β-actin antibody(Cat# 12620) were from Cell Signaling Technology (Danvers, MA,USA). Acetonitrile, trifluoroacetic acid, acetic acid and isopropyl alcohol used were chromatographic grade, and other reagents were analytical grade.

2.2 ACE inhibitory activity assay

ACE inhibitory activity measurement was carried out according to our previous publication [12]. The mixture of 125 μL HHL solution (6.5 mmol/L in 50 mmol/L sodium borate buffer containing 0.3 mol/L NaCl, pH 8.3) and 50 μL peptide solution was performed. After incubation at 37 °C for 5 min, 50 μL of ACE solution (20 U/L)reacted with the mixture at 37 °C for 60 min. The reaction was terminated by the addition of 125 μL 1 mol/L HCl, and 750 μL of ethyl acetate was used to extract hippuric acid (HA) in the reaction mixture. Finally, 500 μL of the upper layer was evaporated at room temperature for 50 min in a vacuum concentration system (Thermo,USA). Then, 1.5 mL distilled water was used to dissolve the obtained HA, and the absorbance was measured at 228 nm using a UV spectrophotometer (Hitachi, Japan). The ACE inhibitory rate was calculated in accordance with the following formula:

where A1indicated the ACE activity without ACE inhibitor, A2was the residual ACE activity in the presence of ACE inhibitor, and A0represented the background value. Each determination was carried out in triplicate. IC50represented the peptide concentration required for inhibiting 50% of ACE activity.

2.3 Preparation of distilled spent grain hydrolysate

A two-step hydrolysis method was performed to prepare ACE inhibitory peptides from distilled spent grains of Chinese strong- flavor Baijiu. 50 g distilled spent grains powder was mixed with 4 times volume (m/V) of 20 mmol/L phosphate buffer with the desired pH value to remove the upper rice husk followed by homogenization for 20 min at 10 000 r/min. After pre-incubation at 45 °C for 5 min,alcalase was added to the desired enzyme dosage (m/m) for hydrolysis.The hydrolysate obtained in the first step was heated at 95 °C for 5 min to inactivate alcalase. It was cooled rapidly in ice bath followed by centrifugation at 4 000 r/min for 20 min. Sequentially, papain in the desired enzyme dosage (m/m) was added into the supernatant for the second-step hydrolysis at 55 °C for the desired time. Following by inactivation, thefinal hydrolysate was collected for determining ACE inhibitory activity.

The influence of these hydrolysis conditions for a single-factor test on the ACE inhibitory activity was analyzed. Then, the two-step hydrolysis conditions including alcalase dosage (0, 0.1%, 0.3%, 0.5%,1.0%, and 2.0%), thefirst-step hydrolysis time (0, 1, 2, 3, 4, and 5 h),hydrolysis pH (5.5, 6.0, 6.5, 7.0, and 7.5) and papain dosage (0,0.1%, 0.3%, 0.5%, 1.0%, and 2.0%) were optimized by response surface methodology (RSM). The response variable (Y) was the ACE inhibitory rate, and the independent variables were alcalase dosage (A),the first-step hydrolysis time (B), hydrolysis pH (C) and papain dosage (D). The Box-Behnken design and data analysis were carried out by Design-Expert software (7.1.3). Finally, the hydrolysate was prepared under optimum hydrolysis conditions to verify the predictive production of ACE inhibitory peptides, and lyophilized using a freeze-dryer (ThermoFisher, USA), and stored at -20 °C until use.

2.4 Isolation of ACE inhibitory peptides

Ten grams of the hydrolyzed distilled spent grains of Baijiu were homogenized using a PT-2100 homogenizer (Kinematica,Switzerland) at 8 000 r/min for 20 min in a fourfold volume of 20 mmol/L sodium phosphate buffer (pH 7.0). The slurry was centrifuged at 10 000 × g for 20 min. Then, the resulting supernatant was ultra-filtrated through 100 and 10 kDa molecular weight cut off (MWCO) membranes (Millipore, USA). Thefiltrates (molecular weight < 10 kDa, > 100 kDa and between 10 and 100 kDa) were collected, and their ACE inhibitory activities were measured. All operations were performed at 4 °C. Thefiltrate with the highest ACE inhibitory activity was lyophilized.

2.5 Purification of ACE inhibitory peptides

The lyophilized powder was dissolved in distilled water and then applied to preparative high-performance liquid chromatography (HPLC)system (Shimadzu, Japan) equipped with a TSK-gel G2500 PWXL column (7.8 mm × 300 mm, Toson, Japan) at 25 °C, which was eluted with 25% acetonitrile containing 0.1% trifluoroacetic acid at a flow rate of 0.3 mL/min. The eluent was monitored at 220 nm and tested for ACE inhibitory activity. The fraction with the highest ACE inhibitory activity was further purified by using reversed-phase HPLC system (RP-HPLC) on a Symmetry-C18column (4.6 mm ×250 mm, Waters, USA). The column was equilibrated with 100% of solvent A (0.1%, tri fluoroacetic acid in distilled water, V/V) for 5 min,and eluted by a linear gradient of solvent B (0.08%, trifluoroacetic acid in acetonitrile, V/V) from 0 to 90% over 20 min. The flow rate was performed at 1 mL/min. The peak with dominant ACE inhibitory activity was collected for structure identification.

2.6 Identification of the purified ACE inhibitory peptide

The amino acid sequence of the purified ACE inhibitory peptide was identified by electrospray mass spectrometry (ESI-MS)methods using a Thermo-Fisher LTQ Velos Pro mass spectrometer (ThermoFisher, USA) equipped with a HESI-II ESI probe (ThermoFisher, USA) according to our previous report [12].Sample loading, experiment settings and data collection were performed with the LTQTune software (ThermoFisher, USA). Data analysis was conducted by using the Xcalibur software (ThermoFisher, USA). In detail, lyophilized samples were dissolved in 50% methanol solution with the addition of 1% acetic acid. Experimental conditions were set as: of fline injection mode with the syringe pump set at flow rates within 2.5–15.0 μL/min; 60 and 300 °C as source heater and capillary temperature, respectively; 5–10 arb for sheath gas flow rate with aux/sweep gas off; positive detection mode with the spray voltage set at 3.5 kV. Collision induced dissociation (CID) were carried out under these conditions, including collision energy within the scope of 28%–35%, an activation Q at 0.25, and an activation time of 10 ms.The peptide configurations were elucidated by tracking the b-type fragmentation pathway and crosschecked with all major productions. The identified peptides with the same sequence were synthesized by Cellmano Biotechnology Company (Hefei, China) with a purity > 95%.

2.7 Molecular docking between the ACE inhibitory peptide and ACE

Molecular docking was performed to predict the inhibition mechanism of the ACE inhibitory peptide against ACE. The structure of the superior peptide was drawn and exported into a PDB file by Chem3D software (19.0), and the crystal structure of human ACE (PDB: 1O8A) was downloaded from the Protein Data Bank (PDB).The flexible docking of the superior peptide bound with the ACE-binding site was analyzed by AutoDock software and Discovery Studio software (2.5) to present an interaction mechanism. Detailed procedures were as follows: three modules including AutoDockTools,AutoGrid and AutoDock in AutoDock software are used for molecular docking between receptor and ligand interaction (ACEIP and ACE).The docking result was displayed as a PDBQTfile. Then, the result was imported into Discovery Studio software to generate 2D diagrams of ACEIP and ACE.

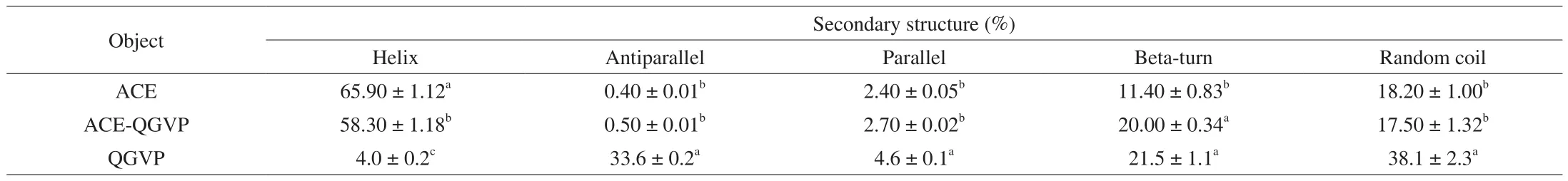

2.8 Circular dichroism analysis

ACE with high purity (> 85%) purified from fresh pig lungs was given as a present from the National and Local Joint Engineering Research Center for Deep Processing Technology for Aquatic Products (Xiamen, China). It was concentrated by ultrafiltration membrane of 100 kDa to obtain a concentration of 1 mg/mL for circular dichroism (CD) analysis. According to our previously reported method with slight modification [13], 200 μL QGVP (dissolved in 10 mmol/mL Tris-HCl buffer with the final concentration of 1 mg/mL, pH 8.3) was mixed with 200 μL of the purified ACE (1 mg/mL). Subsequently, the mixture was incubated at 37 °C for 1 h. Finally, the secondary structure of the QGVP-ACE complex was analyzed using a Chirascan CD spectrometer (Applied Photophysics, Surrey, UK), and the scanning wavelength range was set at 180–380 nm. The ACE solution in absence of QGVP was used as a control. The report of the scan results was imported to CDNN software for calculating the secondary structure content.

2.9 Cell culture

HUVECs were cultured at 37 °C and 5% CO2, and the medium was replenished three times a week. The used medium was RPMI 1640, which was supplemented with 10% FBS, 100 U/mL penicillin and 100 U/mL streptomycin. Finally, HUVECs were sub-cultured using 0.25% trypsin timely.

2.10 Cytotoxicity assay

The cytotoxicity of the ACE inhibitory peptide toward HUVECs in this study was performed by MTS assay as described previously [21].In brief, HUVECs (1.0 × 105cells/mL) were cultured and grown in 96-well culture plates, treated with the differentfinal concentrations (0,25, 50, 100, 200 and 400 μg/mL) of the ACE inhibitory peptide for 2 h, respectively, followed by exposure to Ang I (1 μg/mL). After co-culture at 37 °C in 5% CO2for 12 h, the medium was removed,and added with 100 μL of fresh RPMI 1640 medium and 20 μL MTS.The plate was incubated for another 2 h at 37 °C, and the absorbance was determined at 490 nm for calculating the percentage of cell viability. In addition, the morphological change of HUVECs was expressed as a remarkable toxicological index.

2.11 Total RNA extraction and real-time quantitative polymerase chain reaction (RT-qPCR)

HUVECs were cultured in 6-wells plates at a density of 1 × 105cells/mL for 16 h. Cells were treated with QGVP (0, 50, 100 and 200 μg/mL) for 2 h followed by adding Ang I (1 μg/mL) to incubate for 12 h. The experimental details were described in our previous study [12,21]. Total RNA from cells was extracted by using Transzol-Up reagent kit (Transgen, Beijing, China), and the resulting RNA (2 μg) was used as a template for reverse-transcribing tofirst-strand cDNA synthesis by using High-Capacity cDNA Reverse Transcription Kit (Applied Biosystems, Foster City, CA, USA) in a total volume of 20 μL. RT-qPCR was performed to analyze the relative mRNA expression levels of p-eNOS and END1. The amplification conditions: 94 °C, initial denaturation for 3 min; 94 °C, denaturation for 30 s; 56 °C, annealing for 40 s; 72 °C, extension for 1 min, 40 cycles. Relative expression levels of the target genes were calculated based on the 2-ΔΔCt(RQ) method. The PCR primers were used as following: END1 reverse: 5’-CAGAAACTCCACCCCTGTGT-3’,forward: 5’-TCCTCTGCTGGTTCCTGACT-3’; eNOS reverse: 5’-GGTGGCCCTCGTGGACTTGC-3’, forward:5’-AGGAGGCCTTCCGAGGCTGG-3’; β-actin reverse:5’-G C C A G A G G C G T A C A G G G A T A-3’, f o r w a r d:5’-CGAGGCCCCCCTGAAC-3’.

2.12 Extraction of total proteins

HUVECs were cultured in 10 cm dish at a density of 1 × 105cells/mL for 48 h. After incubation, HUVECs were treated with different concentrations of QGVP (0, 50, 100 and 200 μg/mL) for 2 h,and induced with Ang I at a concentration of 1 μg/mL for 18 h.Before the extraction of proteins, HUVECs were washed twice with ice-cold PBS and finally harvested. Total protein from the cells was extracted with radio immunoprecipitaion assay (RIPA) buffer (2 mmol/L PMSF, 2 mmol/L EDTA and 2 mmol/L orthovanadate, 1% Triton X-100, 0.5% SDS, 0.1% deoxycholate, 0.1% protease inhibitor and 0.1% phosphatase inhibitor). Based on the manufacturer’s instruction,the cell lysates were centrifuged at 12 000 × g at 4 °C for 20 min,respectively. The supernatants were collected for total protein concentration determination using BCA Protein Assay Kit (Beyotime,Shanghai, China), and for intracellular Ang II concentration determination by RP-HPLC.

2.13 Western blot analysis

The prepared protein extracts (50 μg) were separated by 12% sodium dodecyl sulfonate (SDS)-polyacrylamide gels, and transferred to polyvinylidene difluoride membranes. After blocking with 5% bovine serum albumin for 1 h at room temperature, the blots were incubated with primary antibodies, including anti-p-eNOS (1:5 000),anti-END1 (1:5 000) and anti-β-actin (1:5 000) at 4 °C overnight,respectively. Subsequently, the membranes were washed with TBST three times, and each time for 5 min and then incubated with goat horseradish peroxidase (HRP)-conjugated anti-rabbit or anti-mouse secondary antibody (1:10 000) for 1 h. Finally, the immunoreactive proteins were detected using the ECL Plus™ Western blot detection system (Pierce, Rockford, IL, USA) and were imaged in ChemiDoc™XRS+gel imaging system (Bio-Rad, Hercules, CA, USA). Consistent with our previous publication [21], the relative expression quantity of the target protein compared to the control protein was determined by calculating the integral light density value of each band using the imaging system.

2.14 Statistical analysis

The ACE inhibitory rate curve under different peptide concentrations wasfitted by Logistic function using Origin (software version 8.0). The empirical equations for the curve, established by regressive analysis, were used to calculate the IC50values of ACEIPs in the hydrolysate of Baijiu distilled spent grains. Statistical analysis was performed using the Statistical Package for Social Science (SPSS, software version 20.0). One-way analysis results of variance (ANOVA) and student’s t-test were used for determining the statistically significant differences between the values of various experimental and control groups. P < 0.05 was taken as the level of statistical significance, and P < 0.01 was considered statistically significant. Multiple compassion of ACE inhibitory activities of the collected fractions from the processing of ultrafiltration and purification was performed based on Duncan’s multiple range tests.

3. Results and discussion

3.1 Optimization of hydrolysis parameters of distilled spent grains

Nowadays, peptides from food proteins exhibit various levels of ACE inhibitory activity [22]. Alcalase was used to hydrolyze skipjack roe protein to produce ACE inhibitory peptides with an IC50value of 2.5 mg/mL [23]. The hydrolysate derived from duck skin byproducts showed an IC50value of 1.7 mg/mL [24]. The cuttlefish muscle hydrolysate prepared with various digestive proteases exerted moderate ACE inhibitory activities, ranging 1.19–2.31 mg/mL,and 3 peptides Met-Ala-Trp, Val-Ile-Ile-Phe and Val-Tyr-Ala-Pro from the hydrolysate presented the IC50values of 16.32, 8.7 and 6.1 μmol/L, respectively [25]. Little information regarding the ACE inhibitory peptide of the hydrolysate of Baijiu distilled spent grains is available. Based on Fig. S1, the crude extract of distilled spent grains of Chinese strong-flavor Baijiu revealed ACE inhibitory activity with an IC50value of 1 564.85 μg/mL, and the ACE inhibitory rates at different peptide concentrations presented an “S”-fitted logistic function. The result suggested that the potential utilization of this by-product could be used as an ideal source for the preparation of ACE inhibitory peptides.

In accordance with the result of the single-factor design, the hydrolysis parameters including alcalase dosage, the first-step hydrolysis time, hydrolysis pH and papain dosage were important factors for the preparation of the ACE inhibitory peptides from distilled spent grains (data not shown). The hydrolysis conditions were optimized by RSM to reach the maximized ACE inhibitory activity. ACE inhibitory activities of the hydrolysates under different conditions were shown in Table S1, and the results were further analyzed to establish the quadratic regression model. The independent variables were calculated, and the equation to predict ACE inhibitory activity (IC50) of the hydrolysate of distilled spent grains (HDG) was expressed as followed:

The ANOVA for fitted quadratic polynomial regression model were summarized in Table S2. Except for hydrolysis pH (C) and papain dosage (D) without significant effects on ACE inhibitory activity of HDG (P> 0.05), the alcalase dosage (A) and the first-step hydrolysis time (B) presented extremely significant effects on it (P< 0.01). The result of lack of fit analysis (P= 0.200 4)indicated that the value of ACE inhibitory activity was little affected by unmentioned factors. In addition, the coefficient of multiple determinations (R2) for the above-mentioned equation was 0.971 7(data not shown), suggesting that the corresponding model and equation were suitable to predict the response to ACE inhibition.

As shown in Fig. S2, 3D response surface plots were used to show the relationship between different variables and the ACE inhibitory activity (IC50). The increase of ACE inhibitory activity was attributed to alterations of alcalase dosage, hydrolysis pH and alcalase dosage.There was obvious interaction between alcalase dosage and hydrolysis pH (Fig. S2B) and between alcalase dosage and papain dosage were found (Fig. S2C). But no evident interaction between alcalase dosage and the first-step hydrolysis time (Fig. 1A) and between hydrolysis pH and papain dosage (Fig. S2D). Furthermore, the optimized hydrolysis conditions were obtained as followed: In the first-step hydrolysis for 3.6 h at pH 6.7, the temperature was at 45 °C, alcalase dosage was 0.46% (m/m). In the second-step hydrolysis for 4 h at pH 6.0, the temperature was at 55 °C, and papain dosage was 1.2%.Under these conditions, HDG presented ACE inhibitory activity with an IC50value of 909.4 μg/mL. It further confirmed that the regression model was adequate to re flect the expected optimization required to produce high ACE inhibitory peptides.

3.2 Isolation of ACE inhibitory peptide from HDG

For further study, the extract wasfiltered through 100 and 10 kDa cut-off membranes. As shown in Fig. 1A, the low molecular weight fraction (passed through the 10 kDafilter membranes, F3) revealed supreme ACE inhibitory activity, exhibiting an IC50value of(911.3 ± 21.0) μg/mL, while the yield of F3 was 4.2% (fraction/dried HDG,m/m). This may be in agreement with the result that peptide with lower molecular weight can preferentially bind with the active sites of ACE [26]. The fraction F3 was thus worthy of further analysis.

3.3 Purification of ACE inhibitory peptide from HDG

The fraction F3 was separated by a gel column of TSK-gel G2500 PWXL, which is used to separate peptides below 8 kDa. 10 fractions (F3-a to F3-j) with obvious peak were collected, and their significant analysis of ACE inhibitory activities were performed(Fig. 1B and Table 1). The fraction F3-h resealed the strongest ACE inhibitory activity with IC50of (314.5 ± 33.4) μg/mL, while F3-a showed the weakest ACE inhibitory activity with IC50of (1 800.1 ± 30.2) μg/mL.Given the superior yield of the fraction F3-h (0.8%, fraction/dried HDG,m/m), it was selected for further purification. As shown in Fig. 1C,using Symmetry-C18column, mixed components in fraction F3-h were separated into eleven peaks designated as F3-h-a to F3-h-k. The peak F3-h-i with the yield of 0.05% (peak/dried HDG,m/m) presented an IC50value of (58.4 ± 13.1) μg/mL (Fig. 1C inset), suggesting prominent ACE inhibitory activity.

Table 1Significant analysis of ACE inhibitory activity of the fractions isolated from distilled spent grains of Chinese strong- flavor liquor.

Table 2Conformation analysis of QGVP binding to ACE by CDNN software.

Fig. 1 Isolation and purification of ACE inhibitory peptides from the hydrolysate of distilled spent grains. (A) The ACE inhibitory activity of the three fractions wasfiltered through 100 and 10 kDa cutoff membranes. F1, the fraction unfiltered through the 100 kDafilter membrane; F2, the fraction passed through the 100 kDa membrane but unfiltered through 10 kDa; F3, the fraction passed through the 10 kDa membrane. (B) HPLC trace on TSK-gel G2500 PWXL column(7.8 mm × 300 mm) of the fraction F3 (lower panel) and the ACE inhibitory activity of fractions (upper panel). The eluent is 25% acetonitrile containing 0.1% tri fluoroacetic acid at a flow rate of 0.3 mL/min. (C) Purification chromatogram of fraction F3-h. Inset: ACE inhibitory activity of fractions.

3.4 Structural characterization of ACE inhibitory peptide from HDG

As showed in Fig. 2, the purified active fraction F3-h-i was identified by ESI-MS/MS. It was noticed that the amino acid sequence of the purified peptide is Gln-Gly-Val-Pro (QGVP) corresponding to the molecular weights of 399 Da. It has been reported that ACE inhibitory peptides typically contain 2–12 amino acids with molecular weight below 800 Da [27]. Crystallography study also supported that large peptides are restricted from entering into the active site of the catalytic domain [28]. Moreover, the existence of hydrophobic amino acid residues at each of the three C-terminal positions is an added advantage for ACE inhibitory peptides [29]. In particular, Val and Pro frequently appear in C-terminal of ACE inhibitory peptides, such as Arg-Val-Pro-Ser-Leu from egg white protein with an IC50value of 20 μmol/L [30], Ala-Phe-Val-Gly-Tyr-Val-Leu-Pro from cuttlefish muscle protein (IC50: 14.41 μmol/L) [31], Gly-Ala-Met-Val-Val-His from silkworm pupae protein (IC50: 19.39 μmol/L) [32], and Thr-Leu-Val-Gly-Arg from hazelnut (IC50: 249.3 μmol/L) [33]. Val-Val-Gly-Gly-Thr-Gly-Pro-Val-Asp-Glu-Trp-Gly-Ile-Gly-Ala-Arg from R-phycoerythrin of red algae presented an IC50value of 66.2 μg/mL in our previous research [13]. Obviously, the diverse sequences and IC50values suggest low selectivity.

3.5 Inhibition mechanism of QGVP against ACE

Molecular docking 3D and 2D structures were shown in Fig. 3A,hydrogen bond and Van der Waal interaction between QGVP and ACE are the major two interactions, which contributed to the ACE inhibitory activity. QGVP was bound with amino acid residues in the bottom of ACE involved in Tyr360, Asp358, Ala356, Ser355, Asn66 and Asn70 (close to the S1’ pocket), and thereby formed six hydrogen bonds, suggesting the advantage of the hydrogen bond position in the S1’ pocket on ACE inhibition.

Fig. 2 Identification of the purified ACE inhibitory peptide from F3-h-i by electrospray ionization mass spectrometry (ESI-MS). The peptide configurations were elucidated mainly by tracking the b-type fragmentation pathway [400(b4)→285(b3)→186(b2)→129(b1), Q1-G2-V3-P4], while non-dominant fragmentation pathway y-type was used to verify the correctness of the sequence obtained by b-type.

Fig. 3 Inhibition mechanism of Gln-Gly-Val-Pro (QGVP) against ACE. (A) Molecular docking between ACE and QGVP. (B) Conformation structure of ACE changed by QGVP. (C) Conformation structure of ACE and QGVP.

The α-helical structure formation of proteins correlates with hydrogen bonds with the backbone or side chains on themselves [34,35]. Furthermore, the helix transition must be an entropically unfavorable process, and arises from a loss in configurational entropy of hydrogen bonds, with different residues possessing different∆S[35]. It is postulated that blocking their own hydrogen bonding of the residues in the backbone or the side chain, replaced by exogenous peptide amide residues, leads to the helix transition.

Based on our present CD analysis, the secondary structure of ACE was mainly composed ofα-helix, exhibiting two negative bands at 208 and 222 nm and a positive band at 190 nm [36]. But they were changed in presence of QGVP, supporting conformational change of ACE caused by QGVP (Fig. 3B). The scan report of CD was imported to CDNN software for calculating the secondary structure content (Table 2). QGVP revealed with potent ACE inhibitory activity(IC50: 58.4 μg/mL), and the content ofα-helix in the ACE-QGVP complex ((58.30 ± 1.18)%) was visibly lower than ACE ((65.90 ± 1.12)%),but it was opposite with the content ofβ-turn. Hence, we hypothesized that QGVP formed 6 potent hydrogen bonds with the S1’ active pocket of ACE, leading to the changed secondary structure of ACE such asα-helix andβ-turn, leading to subsequent ACE inactivation.

3.6 The effects of QGVP on p-eNOS and END1 expression

ACE is usually located in the vascular endothelial cell membrane [37].The endothelium plays an important role in the regulation of vascular tone and blood pressure, by regulating the release of relaxing factors such as NO and the vasoconstrictor factor such as END1 after stimulation with vasoactive substance [38]. Ang I is cleaved by ACE generating Ang II, which induces final hypertension, fibrosis and inflammation in cardiovascular diseases by binding to G-protein coupled receptor named angiotensin receptor type 1 (ANGR1) [39].It was classically considered that the major mechanism of action of ACEIPs is the inhibition of Ang I hydrolysis into Ang II by ACE.Hence, the HUVECs model of Ang I-induced hypertension was established in this study. As shown in Fig. 4, no visible cell viability decrease was noticed, when QGVP was incubated with HUVECs for 24 h at concentrations ranging from 25 μg/mL to 400 μg/mL.

It was reported that the phosphorylation of eNOS was responsible for inducing NO production, resulting in improved endothelial function and lowering blood pressurein vivo[40]. In cultured endothelial cells, as a marked vasoconstrictor factor, END1 was significantly induced after stimulation with Ang II, which is the degradation product of Ang I hydrolyzed by ACE [41]. We have provided evidence supporting the role of the ACE inhibitory peptide in up-regulated eNOS phosphorylation and down-regulated END1 expression in Ang I-induced HUVECs [12]. It was noted that the intracellular level of Ang II in HUVECs decreased gradually in the peptide concentration of QGVP. Compared with the Ang I-induced group, after protection with QGVP at 200 μg/mL, a sharp drop of intracellular concentration of Ang II in HUVECs was observed(Fig. 5A and S3). Compared with Ang I group, QGVP treatment remarkably increased the mRNA expression level ofeNOSin a dose-dependent manner (Fig. 5B), but it reduced the expression ofEND1(Fig. 5C). Protein expression analysis further confirmed that QGVP treatment stimulated the phosphorylation of eNOS (Fig. 5D),whereas it inhibited the protein expression level of END1 (Fig. 5E).Particularly, the protein expression of p-eNOS induced by Ang I in the 200 μg/mL QGVP treatment was up-regulated nearly 5.2-folds.The anti-hypertension of QGVP in Ang I-induced HUVECs was probably due to a reduction of Ang II level, which was associated with the ACE inhibitory activity of QGVP. The results supported the report that blocking of ACE-Ang II-ANGR1 axis can be used as an ideal method for hypertension therapy [39]. Future studies on the cellular mechanism of ACEIPs inhibiting hypertension should be conducted to confirm thisfinding.

Fig. 4 Cytotoxicity of QGVP in Ang I-induced HUVEC. (A) The morphologic change of Ang I-induced HUVEC after treatment with QGVP. (B) Effects in cell viability. OD: optical density. #P > 0.05.

Fig. 5 Regulation on the expression of the target genes in Ang I-induced human umbilical vein endothelial cell (HUVEC) of QGVP. (A) Production of Ang II in HUVEC. (B) Relative expression of eNOS mRNA. (C) Relative expression of END1 mRNA. (D) Relative protein expression of p-eNOS. (E) Relative protein expression of END1. (F) Representative image of Western blotting from three independent experiments. Comparing with Ang I group, *P < 0.05; **P < 0.01; #P > 0.05.

4. Conclusion

Bioactive peptides with potent ACE inhibitory activity were prepared by selective enzymatic hydrolysis of the distilled spent grain proteins from Chinese strong-flavor Baijiu. Ultrafiltration and consecutive purification such as gel filtration and HPLC were performed for acquiring the potential ACE inhibitory peptide. The purified peptide was further identified as QGVP. Additionally,it revealed potent ACE inhibitory activity with an IC50value of 58.4 μg/mL, associated with the formed six hydrogen bonds with the S1’ pocket position of ACE to change its secondary structure. Moreover, it exhibited excellent biosafety and potential anti-hypertension toward HUVECs. Particularly, it exerted up-regulation on p-eNOS, and suppressed the END1 expression in Ang I-treated HUVECs. Therefore, the identified novel peptide QGVP from HDG by-produced from Baijiu would be a promising candidate as potential nutraceuticals.

Declaration of competing interest

The authors have declared that no con flict of interest exists.

Acknowledgment

This study was sponsored by the Outstanding Youth Project of Hunan Education Department (19B505), Changsha City Science and Technology Plan Project (kq2004113), the 2020 Natural Science Foundation of Hunan Province of China (2020JJ8061), the 2020 Science and Technology Innovation Project of Hunan Province of China (2020SK50921) and the Undergraduate Inquiry Learning and Innovative Experimental Project of Hunan Education Department(2019[100]-1886).

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in the online version, at http://doi.org/10.1016/j.fshw.2022.06.023.

- 食品科学与人类健康(英文)的其它文章

- Production of antihypertensive and antidiabetic peptide fractions from quinoa (Chenopodium quinoa Willd.) by electrodialysis with ultrafiltration membranes

- Effects of phosvitin phosphopeptide-Ca complex prepared by efficient enzymatic hydrolysis on calcium absorption and bone deposition of mice

- Structural requirements and interaction mechanisms of ACE inhibitory peptides: molecular simulation and thermodynamics studies on LAPYK and its modified peptides

- Anti-diabetic and anti-hyperlipidemic effects of sea cucumber(Cucumaria frondosa) gonad hydrolysates in type II diabetic rats

- Antibacterial and antibiofilm activity of peptide PvGBP2 against pathogenic bacteria that contaminate Auricularia auricular culture bags

- Lunasin peptide promotes lysosome-mitochondrial mediated apoptosis and mitotic termination in MDA-MB-231 cells