Effect of Solid Loading on the Property of Al2O3 Ceramics in Stereolithographic Additive Manufacturing

LIU Guoqian, YAN Changhai, ZHANG Keqiang, JIN Hua, HE Rujie

Effect of Solid Loading on the Property of Al2O3Ceramics in Stereolithographic Additive Manufacturing

LIU Guoqian1, YAN Changhai1, ZHANG Keqiang2, JIN Hua3, HE Rujie2

(1. Science and Technology on Space Physics Laboratory, China Academy of Launch Vehicle Technology, Beijing 100076, China; 2. Institute of Advanced Structure Technology, Beijing Institute of Technology, Beijing 100081, China; 3. School of Aerospace Engineering, Xiamen University, Xiamen, 361005, China)

For ceramic stereolithographic (SL) additive manufacturing, the solid loading of ceramic photosensitive slurry plays an important role during the SL process. In this study, Al2O3ceramics were fabricated by SL additive manufacturing from photosensitive Al2O3slurries with various solid loadings, and the solid loading-property relationships of Al2O3ceramic were performed. The effects of solid loading on not only the rheological behavior and curing property of the photosensitive Al2O3slurry but also the microstructure and mechanical properties of the Al2O3ceramic were investigated. The results showed that both the viscosity and shear stress increased with the increase of the solid loading. High viscosity was greater than the critical value for self-leveling during the SL process. The curing properties of photosensitive Al2O3slurries were highly depended on the sold loading. Moreover, clear effects on the defect characteristics of Al2O3ceramics manufactured from various photosensitive slurries were observed. These manufactured defects are critical for the mechanical behavior of Al2O3ceramic. In addition, the relationship between rheological behavior and curing property of photosensitive Al2O3slurry. Meanwhile, the resulting microstructure and mechanical properties of the Al2O3ceramic were also illustrated. Inhomogeneous structure caused by high viscosity can lead to a sintered ceramic with poor strength. These findings provide fundamental understanding for SL additive manufacturing of ceramics.

Al2O3ceramics; solid loading; stereolithography; additive manufacturing

Additive Manufacturing (AM) is a rapid prototyping technique based on the sequential layer-by-layer deposition, which provides possibility for the manufacturing of complex three-dimensional ceramic geometries with anisotropic macrostructure and/or microstructure, aiming to tailor structural or functional properties[1-3]. At present, several potential AM techniques have been reported[4-7]. Thanks to the high-quality parts with smoother surface and higher dimension precision, stereolithographic (SL) based on the UV polymerization of the photosensitive resin has received more attention[1,7-9]. For instance, due to its excellent chemical and mechanical properties, as well as thermal property, alumina (Al2O3) ceramic parts with complex shapes and working under high temperature and mechanically demanding environments have been manufactured using SL process[10-11].

During the SL process, Al2O3ceramic green body was fabricated through layer-by-layer recoating of photosensitive slurry. To achieve a high efficient recoating, the slurry should have excellent fluidity and curing property. Usually, the viscosity of photosensitive Al2O3slurry needs to be less than 3 Pa·s[12], which requires a moderate solid loading of the slurry. Li,.[13]have studied the rheological property of photosensitive Al2O3slurry, and observed that the viscosity increased with the increasing of solid loading. Manufactured Al2O3ceramicshowed a high relative density of 95% from a slurry with a solid loading of 40% (in volume) and viscosity of 2.12 Pa∙s. Many researchers tried various methods to obtain Al2O3slurry with solid loading as high as possible, and viscosity as low as possible. Nie,.[14]added plasticizer to regulate the rheological behavior of photosensitive Al2O3slurry used for SL, because the slurry with a high solid loading always exhibited a high viscosity, causing defects and poor mechanical property of the final ceramic body. On the other hand, some researchers addressed the importance of the solid loading on the microstructure and mechanical property of the Al2O3ceramic manufactured by SL. Azarmi,.[15]also manufactured Al2O3ceramic from photosensitive slurry with a solid loading of 50% (in volume), and evaluated the microstructural features of the Al2O3samples after printing, debinding and sintering process. The SL additive manufactured Al2O3ceramic showed a porosity of approximately 8%, unfortunately, the mechanical property was not studied in depth. From previous studies, it is found that the solid loading plays a significant role in both the performance of photosensitive Al2O3slurry and the microstructure and mechanical property of SL additive manufactured Al2O3ceramic. In fact, the higher the solid loading is, the higher the viscosity is. A moderate solid loading is always required to manufacture parts with low defect, high densification and strength. Some works demonstrated that solid loading exhibited obvious effects on the microstructure and mechanical property of Al2O3ceramic, however, previous works were limited to conventional techniques[16-17].Thus only few works focused on the role of solid loading during SL additive manufacturing of Al2O3ceramics, as well as the relationship between the rheological behavior of photosensitive Al2O3slurry and the resulting microstructure and mechanical property of the Al2O3sintered ceramic.

This study was attempt to provide a deep insight into solid loading-property relationships of Al2O3ceramic manufactured using SL additive manufacturing. In this work, the influences of solid loading on the rheological behavior, curing property of the photosensitive Al2O3slurry, and the microstructure, mechanical property of the Al2O3ceramic were investigated and discussed. The relationship between the rheological behavior, curing property of photosensitive Al2O3slurry and the resulting microstructure and mechanical property of the Al2O3sintered ceramic were also illustrated.

1 Experimental

1.1 Starting materials

Two kinds of Al2O3powders with different particle sizes were selected and mixed as raw powders. The weight ratio of fine grain Al2O3(f-Al2O3,50=1.05 μm, Zhongzhou Alloy, China) and coarse grain Al2O3(c-Al2O3,50= 10.34 μm, Zhongzhou Alloy, China) was 15 : 85. 3% (in mass) TiO2(rutile, 60 nm, Aladdin, China) and 1% (in mass) MgO (50 nm, Aladdin, China) based on as-mixed Al2O3powders were added as sintering additives.

The as-mixed powders were dispersed in photosensitive resin and thinner, including TMPTA (Hengrong, China) and HDDA (Aladdin, China) with a volume ratio of 1 : 4. A small amount of TPO (1% (in mass) based on as-mixed photosensitive resin) was added as photoinitiator. In addition, to improve the fluidity of the photosensitive slurries, 2% (in mass) of KOS110 based on as-mixed Al2O3powders was added as dispersant.

1.2 Slurry preparation

Firstly, starting materials were weighted and ball- milled by a planetary mill (Qmonoclinic3SP2, China) for 24 h at 400 r/min. Then, dispersed and stable photosensitive Al2O3slurries with different solid loadings were obtained. In this study, the solid loading was set at 45%, 50%, 55%, 60% and 65% (in volume), respectively, named S45, S50, S55, S60, S65.

1.3 SL additive manufacturing

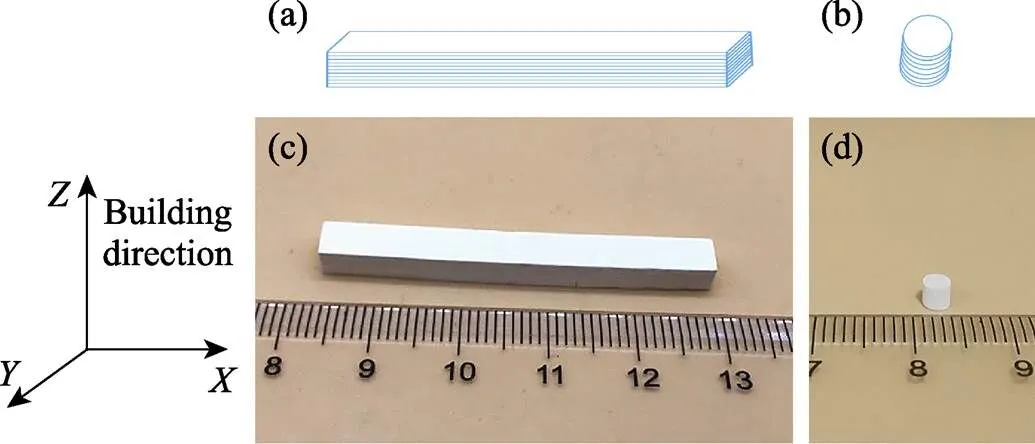

An additive manufacturing equipment (10Dim, China) based on SL was subsequently applied to fabricate Al2O3green bodies. Firstly, 3D model drawn by Solidworks software was sliced with a thickness of 50 μm. UV-light intensity and the exposure time were selected as 9000 μW·cm–2and 4 s, respectively. Various Al2O3green bodies, including rectangular bars (3.8 mm×5.0 mm× 46 mm), cylinders (25 mm×30 mm), were manufactured, respectively, as shown in Fig. 1. After manufacturing from the photosensitive slurries, Al2O3green bodies were washed with ethanol to remove uncured slurry. Finally, Al2O3ceramic green bodies were obtained.

1.4 Debinding and sintering process

Al2O3green bodies were carefully heated for debinding, a heating rate of 0.5 ℃·min–1was adopted at the temperature range of 250–550 ℃ with a dwell time of 2 h, and then pre-sintering was conducted at 1000 ℃ for 2 h in a conventional muffle furnace (Facerom, China) in air. After that, the pre-sintered samples were subsequently transformed to another air furnace (Facerom, China) and sintered at 1600 ℃ for 2 h. Debinding and sintering procedures have been reported in detail in our previous work[18]. For simplicity, the as-sintered Al2O3ceramics were denoted as A45, A50, A55, A60, and A65, respectively.

Fig. 1 (a, b) Schematic diagram of slicing model and (c, d) green bodies of rectangular bar and cylinder

1.5 Characterization

Rheological behavior of the Al2O3photosensitive slurries were tested using a rotational rheometer (Anton Parr., Austria) with a shear rate range of 0.01–200 s–1at 25 ℃. To evaluate the SL process, photosensitive Al2O3slurries were exposed at various time (1–68 s) and the cured layer thickness was measured by a digital micrometer (Anyi, China).

The size of both green bodies and sintered samples were measured using a digital micrometer, and then the linear shrinkage can be calculated. The relative density of the Al2O3ceramic was measured using Archimedes method. The flexural strength was tested using a three-point uniaxial bending test (Instron, USA). The loading span was 30 mm and the cross-head speed was 0.5 mm·min–1at room temperature. The standard, ISO- 14704[19], was used as reference.

如今的方便食品形式多样,营养丰富,满足了人们在快节奏生活中对美食的需求。那么,古代的同胞们有没有这种口福,享受到方便且好吃的食品呢?

The fracture topography of the mechanical tested samples was observed using a scanning electron microscope (SEM, Zeiss, Germany). The internal defect features within the Al2O3sintered ceramics were characterized by a X-Ray Computed-Tomography (X-CT, Zeiss, USA). An isotropic pixel size of 2.76 μm was obtained by binning two in each case.

2 Results

2.1 Rheological behavior of Al2O3 slurry

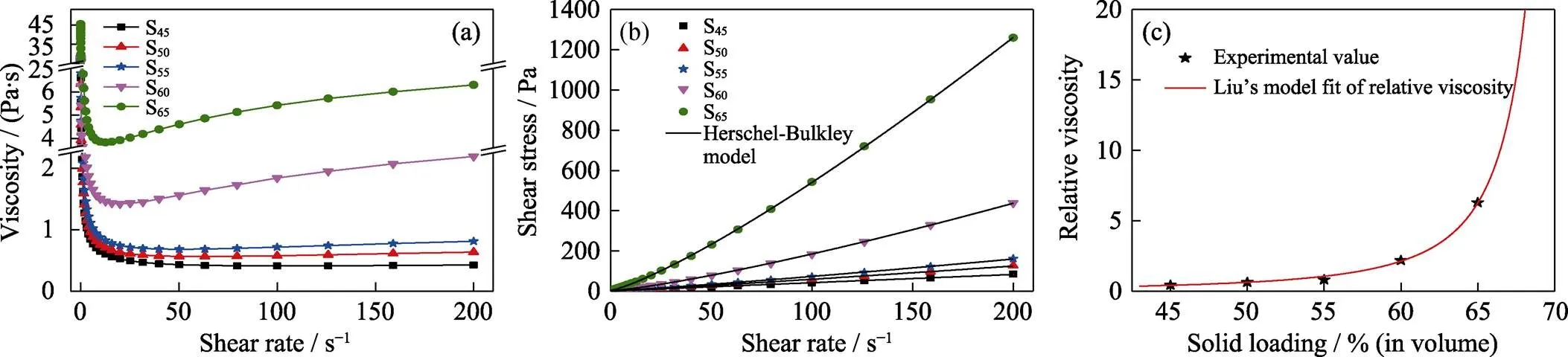

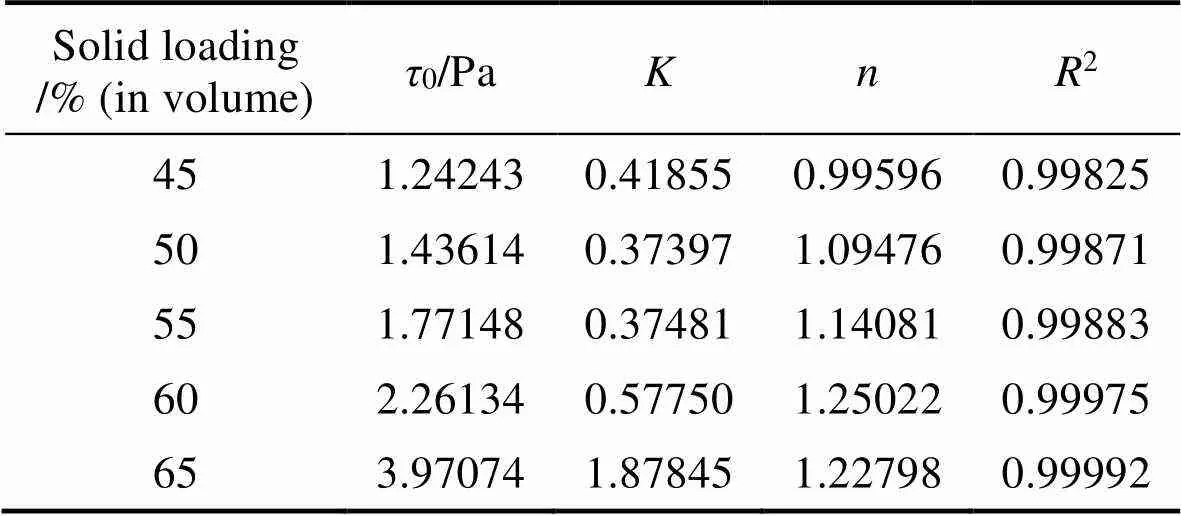

The effects of solid loading on the rheological behavior of these photosensitive Al2O3slurries were performed firstly, as shown in Fig. 2. The viscosityshear rate for these photosensitive Al2O3slurries was presented Fig. 2(a). The viscosity rises as the solid loading increasing. At the low solid loading of 45% and 50% (in volume), viscosity decreases with the increasing of shear rate and exhibits a typical shear thinning behavior. However, when the solid loading rises up to 55% (in volume), Al2O3slurry shows a remarkable shear plateau behavior when the shear rate is lower than 100 s–1, and then exhibits a slightly shear thickening behavior. However, when the solid loading is above 55% (in volume), Al2O3slurry presents evidently shear thickening behavior.

As presented in Fig. 2(b), the relationship between shear stress and shear rate can be expressed by Hersche- Bulkley model[20]:

whereand0refer to the shear stress and yield shear stress, respectively,refers to the consistency index,is the shear rate, andis the flow behavior index. It should be noted that the difference between non-Newtonian fluid and Newtonian fluid is characterized by the degree of difference betweenand 1. The experimental data is fitted by Herschel-Bulkley Model, as presented in Fig. 2(b). And the fitted Herschel-Bulkley Model parameters are given in Table 1. The experimental values are in good agreement with the Herschel-Bulkley Model results, which is consistent with theRresult (2>0.998). At the low solid loading of 45% and 50% (in volume), the flow behavior index,, is close to 1, indicating that the photosensitive Al2O3slurry prepared from a low solid loading exhibits a near Newtonian fluid behavior. However,value increases as the solid loading increasing, demonstrating that the slurry exhibits a shear thickening behavior. Moreover, the yield shear stress of the photosensitive Al2O3slurry increases from 1.24243 to 3.97074 Pa with the solid loading increasing from 45% to 65% (in volume), further revealing that the mutual attraction between Al2O3particles increases with the increasing of solid loading.

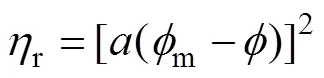

To study the relationship between the rheological behavior and solid loading of photosensitive Al2O3slurry in depth, the viscosities of photosensitive Al2O3slurries with various solid loadings were studied at the shear rate of 200 s–1, as shown in Fig. 2(c). When the solid loading is lower than 60% (in volume), the viscosity increases slowly which is lower than the critical viscosity value of self-leveling (3 Pa·s) required for the SL process[12]. The viscosity then rises sharply as the solid loading increasing due to the severe agglomeration of the Al2O3particles. At a higher solid loading, both Brownian motion and hydrodynamic interactions affect the rheological behavior[21]. Here, Liu’s model[22]can be introduced to describe the relation:

Fig. 2 (a) Apparent viscosity and (b) shear stress vs shear rate curves of photosensitive Al2O3 slurries with different solid loadings, and (c) relative viscosity dependence on solid loading at the shear rate of 200 s–1

Table 1 Herschel-Bulkley model parameters of Al2O3 slurries

whererrefers to the relative viscosity,andmrefer to the solid loading and maximum solid loading, respectively. The constantis determined experimentally. As given in Fig. 2(c), ther-plot is well fitted according to Eq. (2) (2=0.9972). Moreover, this model can predict the maximum particle packing density of a given powder, or maximum theoretical solid loading. In this regime, the constant is 0.057, andmis 0.72, respectively, indicating that the maximum theoretical solid loading of the photosensitive Al2O3slurry is around 72% (in volume) in this condition.

2.2 Curing property of Al2O3 slurry

Fig. 3 Curing thickness vs exposure time of Al2O3 slurries with different solid loadings

2.3 Mechanical property and microstructure of Al2O3 ceramics

Fig. 4 shows the flexural strength and relative density of the Al2O3sintered ceramics prepared from photosensitive slurries. It can be seen that the strength presents a strong dependence on the density of the sintered ceramic, which is consistent with the research of Ndinisa’s result[16]. Moreover, both the strength and density increase firstly, the highest relative density of (94.46±0.41)% and flexural strength of (279.54± 6.82) MPa are obtained from slurry with a solid loading of 50% (in volume), then the relative density and strength decrease with the increasing of solid loading. Interestingly, the strength obtained in this study is greater than some conventional methods. As mentioned above, the higher the solid loading is, the higher the viscosit is. It must be noted that high viscosity results in insufficient degassing and hinders the flow of photosensitive slurry, thereby air trapped and defects formed during the SL process. Hence, defects result in stress concentration in Al2O3sintered ceramic and have a negative effect on the density and strength.

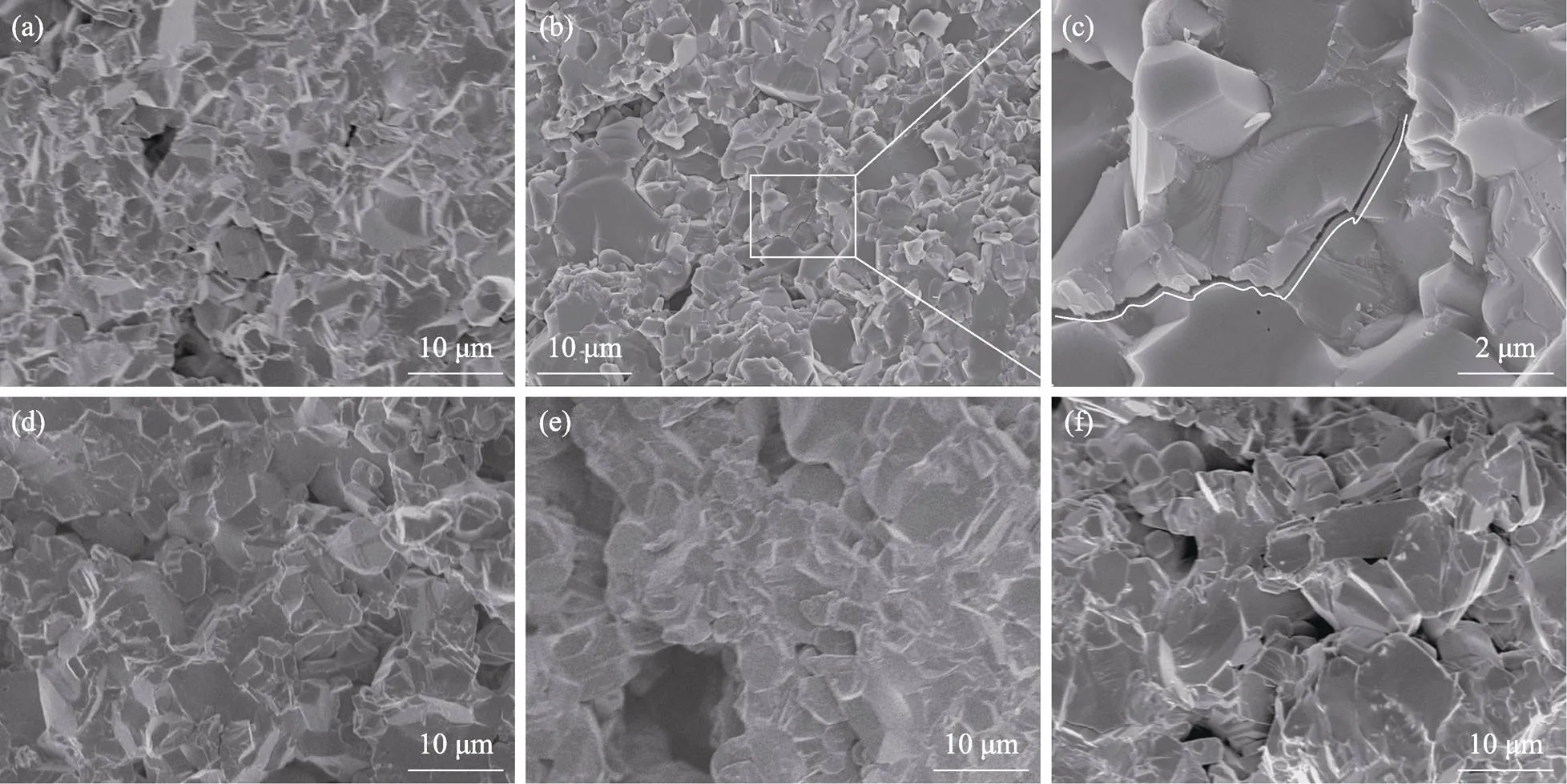

In addition, an inhomogeneous structure caused by high solid loading can also lead to sintered ceramic with poor strength. The fracture microstructure of sintered Al2O3ceramics are given in Fig. 5. After SL, the organics must be removed. Pores are observed in the sintered ceramics due to the volatilization of organics. The degree of densification is mainly related to the particles packing degree, and the solid loading of the initial slurry. Usually, the more the particles packing and the solid loading are, the higher the density is. At a low solid loading of 45% (in volume), correspondingly, the fraction of photosensitive resin is higher, distance between Al2O3particles is too far. Thus, some pores were formed in A45 ceramics and density is low (Fig. 5(a)). As the solid loading increasing, pores decreases and density increases (Fig. 5(b)). Moreover, intergranular fracture behavior is found in A50 ceramic (Fig. 5(c)), that is another reason why A50 ceramic has a highest strength. However, when the solid loading is higher than 50% (in volume), the significant increasing of viscosity leads to rise probability of pores and agglomeration during the inhomogeneous recoating process, thus forming pores and other defects in sintered ceramics after debinding and sintering process (Fig. 5(d–f)). The formed defects always cause cracks, thus reducing the strength of Al2O3ceramics.

Fig. 4 Flexural strength and relative density of sintered Al2O3 ceramics varied with solid loading

Fig. 5 Fracture microstructures of sintered Al2O3 ceramics

(a) A45; (b) A50; (c, d) A55; (e) A60; (f) A65

3 Discussion

To further investigate the relationship between the UV-light intensity, exposure time and curing thickness, the Jacobs equation derived from the Beer’s law[23]can be described:

where Cp refers to the absolute curing thickness (μm), Dp refers to depth of penetration (μm), Ei and Ec refer to the density of energy transmitted to the slurry (or input density of energy) and critical density of energy (mJ·cm–2), respectively. Curing thickness vs logarithm of input density of energy curves are shown in Fig. 6(a). The experimental values are in good agreement with the Beer-Lambert’s semi-logarithmic model result (R2>0.97). Thus, Dp and Ec of photosensitive Al2O3 slurries with various solid loadings can be calculated from Fig. 6(a), as plotted in Fig. 6(b). With the solid loading increasing from 45% to 65% (in volume), Dp sharply decreases to 60.14 μm. On the contrary, Ec increases to 11.27 mJ·cm–2. These results confirm the findings of Abouliatim[24], who found that apart from particle size, Dp was strong dependent on the solid loading of slurry and decreased with the increasing of solid loading. This can be attributed to the decreasing of the UV-light absorbed by photosensitive resin. On the other hand, high particle packing leads to the decrease of the interparticle spacing between particles, and the path of UV-light increases due to the light refraction of Al2O3 particles, which causes light loss. An equation introduced by Griffith and Halloran[25] is adopted to describe Dp and the interparticle spacing (s):

where50is the average particle size,refers to the wavelength of radiation,refers to the solid loading of slurry,pandrrefer to the refractive index of Al2O3particle and photosensitive resin, respectively. It can be seen from Fig. 6,correspondingly decreases to 2.43 μm with the increasing of solid loading from 45% to 65% (in volume). The shorter thebetween Al2O3particles in the slurry is, the greater the probability of mutual contact is, which hinders the movement of the slurry between layers and forms agglomerations.

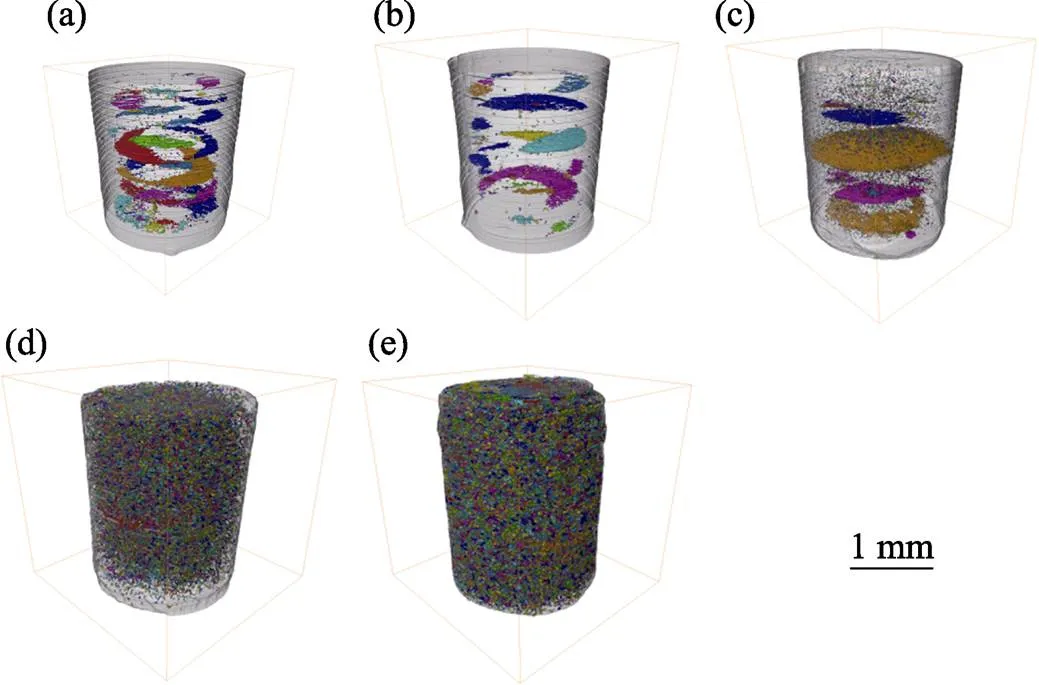

Although the microstructure of Al2O3sintered ceramics has been performed by SEM, and defects have been found, three-dimensional (3D) characterization of structures and defects within the sintered ceramics still needs inspection and discussion. X-CT is one of the most practical ways of non-invasive imaging technology, which can simultaneously carry out both the geometrical features and defects distribution of manufactured parts[26-27]. Fig. 7 presents the X-CT reconstructed images of Al2O3sintered ceramics prepared from various slurries. Colored layers in Fig. 7 show internal defects, such as delamination or cracks. And colored points present detected pores, according to their volume. Both delamination defects and pores are detected in all sintered Al2O3ceramics. One important finding is that the external area in contact with air shows low defect distribution, rather than internal area. Inevitable pores formed due to the volatilization of the organics as mentioned above within the green body during debinding and sintering process, so the defects near the internal area are difficult to eliminate than those in external areas. The defects decrease firstly and then increase with the increasing of solid loading, which is consistent with the result of relative density. Thus, these manufactured defects that are already critical for the mechanical behavior of sintered Al2O3ceramics. Moreover, at the high solid loading of 60% and 65% (in volume) (as shown in Fig. 7(d, e)), it can be obviously found that larger amounts of pores are formed in A60 and A65 sintered ceramics, mainly because the high viscosity leads to rising probability of pores and agglomeration during the inhomogeneous recoating process. These preliminary findings of defects should however be verified by a more extensive quantitative analysis. How to achieve the quantitative analysis of the defects was not the main focus of this paper, and would be investigated in our other study.

Fig. 7 X-CT reconstructed images of sintered Al2O3 ceramics (a) A45; (b) A50; (c) A55; (d) A60; (e) A65

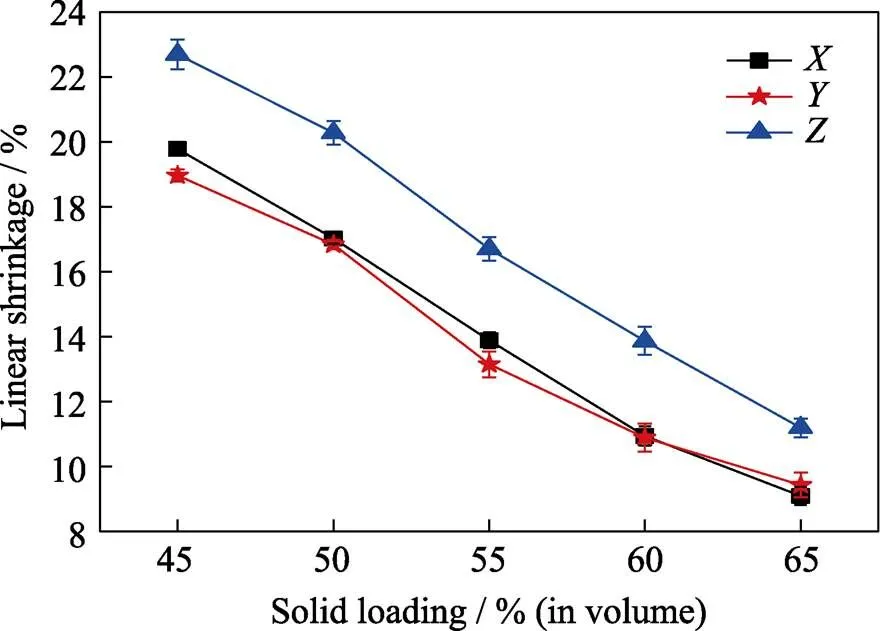

It should be noted that although the cylinder green bodies were prepared from photosensitive slurry with different solid loadings, the designed dimensions were same (as shown in Fig. 1(b)). From Fig. 7, it is clearly shown that cylinders present a different shrinkage behavior after debinding and sintering. These results were confirmed by the shrinkage findings, which were measured from the rectangular bars, as shown in Fig. 8. As expected, all different bars prepared from different slurries show significant shrinkage behavior. Out of expectation, different shrinkage values present not only in bars with various solid loadings, but also in different directions. Bars show a similar shrinkage inanddirections, however, a larger shrinkage indirection is presented because of green bars are manufactured by SL additive manufacturing based layer-by-layerrecoating of ceramic slurry along building direction, the interlayers binding in building direction (direction) is slightly weaker than the cured photosensitive slurry inanddirections. These objects can be eliminated after debinding and sintering process, thereby presenting a larger shrinkage[10-11,28]. This anisotropic shrinkage in different directions corresponds to the accurate prediction and control of the final ceramic product dimensions achieved with SL additive manufacturing.

Fig. 8 Linear shrinkage of the rectangular Al2O3 sintered ceramics in different directions

4 Conclusions

In this study, the effect of solid loading on rheological behavior and curing properties of photosensitive Al2O3slurry were investigated and discussed deeply. Results showed that both the viscosity and shear stress increased with the increasing of solid loading. The optimal exposure time was selected as 4 s. Then, both the highest relative density of (94.46±0.41)% and flexural strength of (279.54±6.82) MPa are obtained from the photosensitive slurry with a solid loading of 50% (in volume), respectively. A further increase in solid loading has a negative effectiveness on the densification of sintered Al2O3ceramics resulting from rise probability of pores and agglomeration during the inhomogeneous recoating process, which provides no improvement of mechanical of Al2O3ceramic. Both delamination and pores are detected in SL additive manufactured Al2O3ceramics. These manufactured defects that are already critical for the mechanical behavior of Al2O3sintered ceramic should be verified by a more extensive quantitative analysis in future study.

[1] LAKHDAR Y, TUCK C, BINNER J,Additive manufacturing of advanced ceramic materials., 2021, 116: 100736.

[2] LI X B, ZHONG H, ZHANG J X,Powder characteristics on the rheological performance of resin-based zirconia suspension for stereolithography., 2020, 35(2): 231–235.

[3] HE C, MA C, LI X L,Continuous fast 3D printing of SiOC ceramic components., 2021, 46: 102111.

[4] YANG L L, ZENG X J, DITTA A,. Preliminary 3D printing of large inclined-shaped alumina ceramic parts by direct ink writing., 2020, 9: 312–319.

[5] HU X A, ZHAO G L, LIU F C,. Microstructure and mechanical behavior of Inconel 625 alloy processed by selective laser melting at high temperature up to 1000 ℃., 2020, 39: 1181–1189.

[6] CHEN F, ZHU H, WU J M,Preparation and biological evaluation of ZrO2all-ceramic teeth by DLP technology., 2020, 46(8): 11268–11274.

[7] ZHANG K Q, XIE C, WANG G,High solid loading, low viscosity photosensitive Al2O3slurry for stereolithography based additive manufacturing., 2019, 45(1): 203–208.

[8] CHEN Z W, LI Z Y, LI J J,. 3D printing of ceramics: a review., 2019, 39(4): 661–687.

[9] HE R J, ZHOU, N P, ZHANG K Q,Progress and challenges towards additive manufacturing of SiC ceramic., 2021, 10(4): 637–674.

[10] SU B, DHARA S, WANG L. Green ceramic machining: a top- down approach for the rapid fabrication of complex-shaped ceramics., 2008, 28(11): 2109–2115.

[11] LI H, LIU Y S, LIU Y S,. Microstructure and mechanical properties of 3D printed ceramics with different vinyl acetate contents., 2021, 40: 3241–3250.

[12] DING G J, HE R J, ZHANG K Q,Dispersion and stability of SiC ceramic slurry for stereolithography., 2020, 46(4): 4720–4729.

[13] LI K H, ZHAO Z. The effect of the surfactants on the formulation of UV-curable SLA alumina suspension., 2017, 43(6): 4761–4767.

[14] NIE J B, LI M S, LIU W W,The role of plasticizer in optimizing the rheological behavior of ceramic pastes intended for stereolithography-based additive manufacturing., 2021, 41(1): 646–654.

[15] AZARMI F, ALI A. Microstructural evolution during fabrication of aluminalaser stereolithography technique., 2019, 45(1): 271–278.

[16] NDINISA S S, WHITEFIELD D J, SIGALAS I. Fabrication of complex shaped alumina parts by gelcasting on 3D printed moulds., 2020, 46(3): 3177–3182.

[17] WEI J J, LI J L, SONG X X,Effects of solid loading on the rheological behaviors and mechanical properties of injection- molded alumina ceramics., 2018, 768: 503–509.

[18] ZHANG K Q, HE R J, DING G J,Digital light processing of 3Y-TZP strengthened ZrO2ceramics., 2020, 774: 138768.

[19] ISO 14704-2000. Fine Ceramics-Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature.

[20] HERSCHEL W H, BULKLEY R. Konsistenzmessungen von gummi-benzollosungen., 1926, 39: 291–300.

[21] LEWIS J A. Colloidal processing of ceramics., 2000, 83: 2341–2359.

[22] LIU D M. Particle packing and rheological property of highly- concentrated ceramic suspensions:mdetermination and viscosity prediction., 2000, 35(21): 5503–5507.

[23] CHARITIER T, CHAPUT C, DOREAU F,. Stereolithography of structural complex ceramic parts., 2002, 37: 3141–3147.

[24] ABOULIATIM Y, CHARTIER T, ABELARD P,. Optical characterization of stereolithography alumina suspensions using the Kubelka-Munk model., 2009, 29(5): 919–924.

[25] GRIFFITH M L, HALLORAN J W. Freeform fabrication of ceramicsstereolithography., 1996, 79: 2601–2608.

[26] DIENER S, FRANCHIN G, ACHILLES N,. X-ray microtomography investigations on the residual pore structure in silicon nitride bars manufactured by Direct Ink Writing using different printing patterns., 2021, 5: 100042.

[27] ZHANG K Q, MENG Q Y, CAI N J,. Effects of solid loading on stereolithographic additive manufactured ZrO2ceramic: a quantitative defect study by X-ray computed tomography., 2021, 47(17): 24353–24359.

[28] ZHANG K Q, HE R J, DING G J,Effects of fine grains and sintering additives on stereolithography additive manufactured Al2O3ceramic., 2021, 47(1): 2303–2310.

立体光刻增材制造中固含量对Al2O3陶瓷性能的影响

刘国仟1, 闫长海1, 张可强2, 金华3, 何汝杰2

(1. 中国运载火箭技术研究院 空间物理重点实验室, 北京 100076; 2. 北京理工大学 先进结构技术研究院, 北京 100081; 3. 厦门大学 航空航天学院, 厦门 361005)

对于陶瓷立体光刻增材制造技术, 光敏树脂浆料的固含量发挥着重要的作用。本工作首先制备了不同固含量的Al2O3陶瓷浆料, 并采用立体光刻增材制造技术, 制备了Al2O3陶瓷, 并研究了Al2O3浆料的固含量与陶瓷性能的关联关系。其次, 探索了固含量对Al2O3浆料的流变行为、固化性能, 以及对Al2O3陶瓷的微观结构、力学性能的影响规律。结果表明, 随着固含量增加, 浆料的粘度和剪切应力均增大。在光固化增材制造过程中, 高固含量导致浆料的粘度高于其自流平的临界值, 且Al2O3浆料的固化性能与固含量高度相关。此外, 固含量明显影响光固化增材制造的Al2O3陶瓷的缺陷。这些制造缺陷对于Al2O3陶瓷的力学性能有重要影响。最后, 本工作总结了光敏Al2O3浆料的流变行为、固化性能与Al2O3陶瓷的微观结构和力学性能之间的关联关系。浆料的高粘度造成陶瓷的微观结构不均匀, 最终导致其力学强度较差。本研究结果可为陶瓷的光固化增材制造提供一定的参考。

Al2O3陶瓷; 固含量; 光固化; 增材制造

TQ174

A

2021-10-17;

2021-11-09;

2021-12-24

National Natural Science Foundation of China (51772028)

LIU Guoqian (1980–), male, senior engineer. E-mail: 15201631565@163.com

刘国仟(1980–), 男, 高级工程师. E-mail: 15201631565@163.com

HE Rujie, associate professor. E-mail: herujie@bit.edu.cn

何汝杰, 副教授. E-mail: herujie@bit.edu.cn

1000-324X(2022)03-0353-08

10.15541/jim20210636