Numerical Simulation on Influence Factors of Coal Explosion

GUO Xiuxia,ZAN Wentao,SHAO Jianli

(State Key Laboratory of Explosion Science and Technology,Beijing Institute of Technology,Beijing 100081,China)

Abstract:The mathematical physical model and reaction model of coal dust explosion are established,and the two-phase flow model equations of coal dust explosion are solved by using CE/SE(time-space conservation element and solution element)method.More‐over,the influence factors of coal dust explosion are analyzed by numerical simulation,focusing on the initial particle size,environ‐mental pressure and temperature.Based on the evolution of pressure and temperature distribution field and wave system diagram,the propagation law of explosion is analyzed.According to pressure waveform,the variation trend of explosion threshold with coal dust particle size,pressure and temperature is given.In addition,considering the change of coal dust concentration in space,we set the distribution of coal dust in accordance with a certain concentration gradient.The simulations show the propagation and attenua‐tion laws of pressure and temperature to space after local combustion and explosion.The simulation method and preliminary law in this work can provide reference for related engineering analysis.

Key words:coal dust;two-phase flow;multi-phase detanation;numerical simulation

0 Introduction

With the rapid development of the global econ‐omy,the demand for coal energy in countries around the world is growing rapidly.The frequent occurrence of explosion accidents in coal mining and coal chemical industry production not only caused huge loss of life and property safety,but al‐so seriously affected social stability.

Therefore,coal dust explosion has always been a hot issue in the field of science and technology,and a large number of related mechanisms and laws researches[1-3]have been carried out so far.

Wang[4]used fluent software to simulate the ex‐plosion process of mixed coal dust with different particle sizes in the roadway,and obtained the law of the influence of different particle size ratios on the explosion pressure.Tan et al.[5]comparatively studied the influence of coal dust particle size on the explosion characteristics and found that the ex‐plosion hazard level of nano-scale coal dust is stron‐ger.Ma et al.[6]found that low-temperature oxida‐tion can increase the explosion overpressure of the coal dust-methane coupling system,but at the same time it will reduce the flame propagation speed.

Pu et al.[7]studied the combustion explosion and propagation characteristics of bituminous coal in closed containers and open combustion tubes of different sizes and shapes.It is found that the ex‐plosive characteristics and strength of coal dust in the air are basically not affected by the particle size of coal dust.Fedorov et al.[8-10]established a physi‐cal and mathematical model of coal dust explosion based on the theory of two-phase flow,and obtained the influencing factors of coal dust explosion.Zhang et al.[11]theoretically analyzed the propaga‐tion of methane and coal dust explosions,and found that obstacles in the flow field can effectively pro‐mote the mixing process between the components and enhance the explosion intensity.Wei[12]used the vortex dissipation conceptual model to analyze the process of gas and coal dust mixed explosion,and found that the maximum explosion overpressure val‐ue decreases obviously with the increase of coal dust particle size,and increases first and then de‐creases as the concentration of coal dust increases.

As for the coal dust problem,Eckhoff[13]point‐ed out in his summary study that the internal factors of dust(concentration,particle size distribution,ag‐glomeration dispersion)and external environmental factors(turbulence intensity)will affect dust explo‐sion during the explosion process.Wang et al.[14]used a 20 L spherical explosive device to test the lower explosion limit(LEL)of coal dust explosion,and analyzed the influence of coal dust particle size and ignition probability on the LEL.Zhao et al.[15]used thermal explosion theory to analyze dust explo‐sion and found that there is a certain linear relation‐ship between dust particle size and LEL.For actual working conditions,coal dust explosion accidents usually occur in large confined spaces and open spaces.The coal dust explosion parameters mea‐sured by the 20 L ball device are not suitable for coal dust explosion in large confined spaces,so nu‐merical simulation methods can be used to study the process of coal dust explosion in large confined spaces.

In this work,the mathematical and physical model and reaction model of coal dust explosion are established,and the CE/SE(Time-space Conserva‐tion Element and Solution Element)method is used to solve the two-phase flow model equations of coal dust explosion.The influence of coal dust particle size,coal dust concentration,and ambient tempera‐ture on the silver explosion threshold of coal dust is investigated,and the kinetic properties of the explo‐sion under a certain density gradient are investigated.

1 Computational details

The simulation process in this work adopts a two-phase flow model.The explosion process of coal dust/air mixture is very complicated,involving homogeneous chemical reaction,two-phase chemi‐cal reaction,force action between two phases,heat conduction and radiation heat transfer.In order to simplify the problem,the following basic assump‐tions are given to simulate the two-phase mixed ex‐plosion problem[16]:(1)Both gas phase and solid phase substances are regarded as continuous media,and the solid phase and the gas phase permeate each other and occupy a total space;(2)The inter‐nal diffusion effect and viscosity between the gas phase and the solid phase are ignored;(3)The solid phase is distributed in the gas phase in the form of spherical particles.The crushing,deformation and interaction of the solid phase particles are not con‐sidered,and the volume change of the particles after being compressed is ignored;(4)It is considered that the internal temperature of the particles is even‐ly distributed and constant;(5)The energy released by the chemical reaction is completely absorbed by the gas.Based on the above assumptions,according to the volume average method[16],the control equa‐tions of gas and solid phase fluid dynamics can be given respectively.

In Equations(1)and(2),ρgis the density of the gas.Egis the total energy per mass of the gas.ug,vgand wgare the velocities of the gas in x,y and z directions,respectively.ρsis the concentration of solid particles.Esis the total energy per unit mass of solid particles.us,vsand wsare the velocities of solid particles in x,y and z directions,respectively.ctis the mass change rate of coal dust particles per unit volume caused by combustion.The source terms ft,x,ft,y,and ft,zrepresent the pressure of the gas on the particle in the x,y,and z directions.Npis the number of particles per unit volume.Ctis the reaction rate of coal dust[17].

φsis the percentage of the volume of the solid parti‐cles.

The CE/SE method provides a new way to solve the hyperbolic conservation equation.The CE/SE method treats time and space as one entity.In the SE,variables are continuous.The conservation equation is integrated over the CE.Details are illus‐trated in Ref.[18-19].For the Euler equation part,the CE/SE method is used to solve the flow field.The fourth-order Runge-Kutta method is used for the source term part.The CE/SE method can cap‐ture shock waves without other methods,and it has higher precision and resolution,and the solution is simpler.Our numerical program is verified by the ex‐periments.For example,a two-dimensional pipeline model was used to simulate the combustion and ex‐plosion process of coal dust/air mixture in a horizon‐tal pipeline.When the flame propagates to 14.2 m,the simulated and experimental flame velocity is 467.4 m/s and 450.5 m/s,respectively.When the flame propagates to 14.7 m,the simulated and ex‐perimental flame velocity is 433.1 m/s and 407 m/s,respectively.In addition,the explosion characteris‐tic parameters of coal dust in actual conditions are quite different from those in small space,but few re‐lated studies have been performed in large space.In this paper,the simulation model of explosion threshold was 3 m×3 m,and the model with concen‐tration gradient was 3 m×5 m.The mesh size was 5 mm,the CFL number was set as 0.2,and the time step was self-adaptive.

2 Numerical results and discussion

2.1 Simulation analysis of coal dust explosion

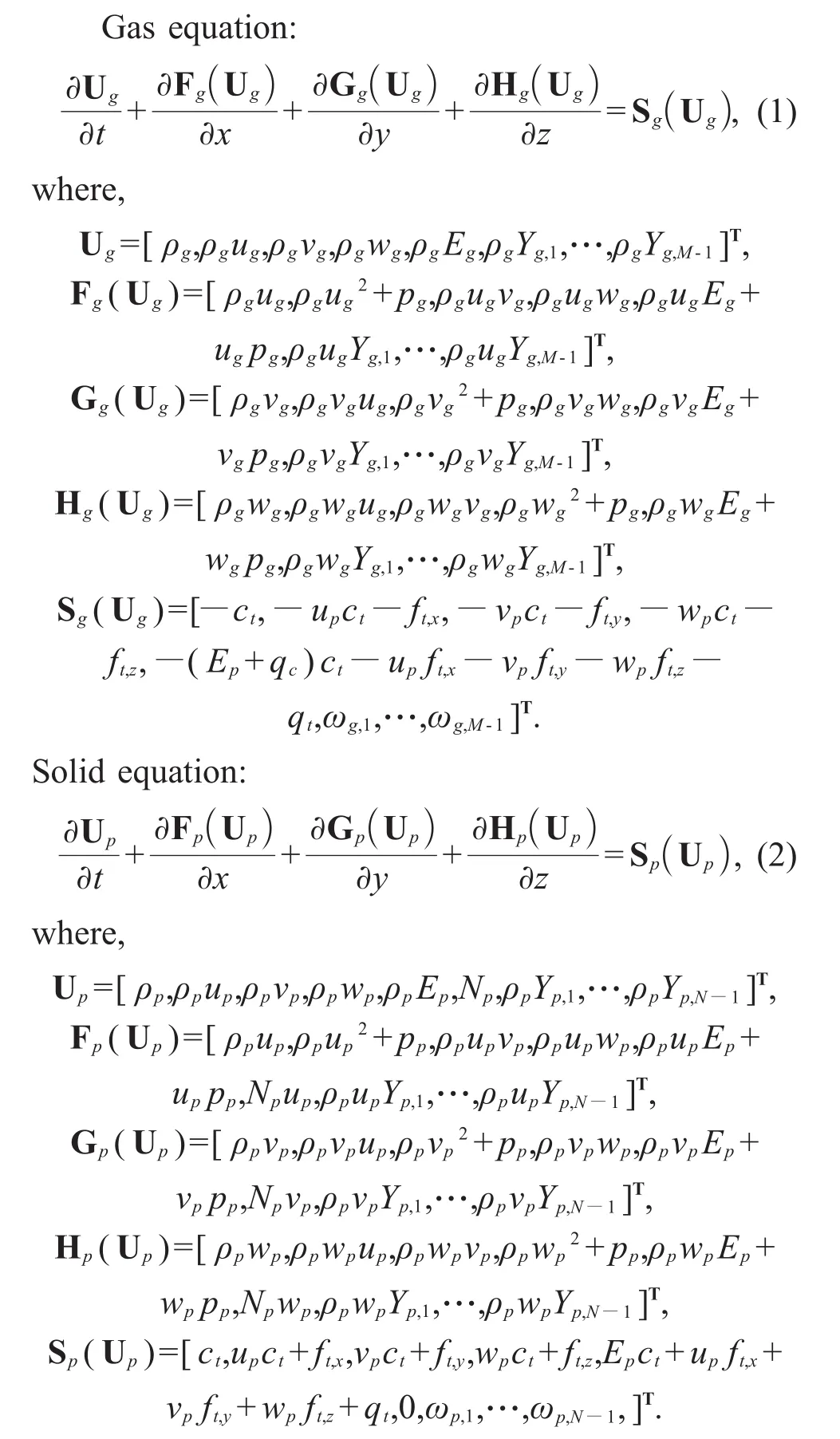

The initiation and propagation of coal dust are given by our simulation results.Taking representation status of the specific coal size(2 μm)and density(250 g/m3),we draw the time evolution process of pressure,temperature,gas density,gas and coal dust volume fraction under certain initiation setting conditions(ρg=2.2 kg/m3,ug=1 000 m/s,vg=1 000 m/s,Tg=3 000 K).Here is the initial impact velocity of the gas,ugis the longitudinal velocity,vgis the transverse velocity.Because of the different setting of initiation area,it can realize different waveforms.From Fig.1(a),it can be seen that with the increase of time,the initial pressure propagates outward,especially the right side forms a relatively stable pressure peak.Accordingly,a high temperature propagation region(b)is formed on the right.The gas density distribution(c)shows that the high density zone is formed at the front of the explosion wave,while the central region forms the release wave propagation with the unloading of high pressure.The change of gas(d)and coal(e)volume fraction further indicates that the high temperature area is exactly the area where the coal dust is fully reacted,and there is a concentrated zone of coal density due to the propagation of explosion wave.

Fig.1 Time evolution image of explosion process.(a)Pressure;(b)temperature;(c)gas density;(d)gas volume fraction;(e)coal dust volume fraction

Taking the case of 2 μm coal dust as an exam‐ple,we calculate the evolution process at different concentrations(200 g/m3,300 g/m3and 500 g/m3)of coal dust.Through the analysis of pressure and temperature wave system,we can clearly see the process of coal dust from no explosion to stable ex‐plosion wave propagation.The simulation results are shown in Fig.2.For the case of 200 g/m3,with the increase of time,the initial high pressure propagates to both sides,but accompanied by obvi‐ous attenuation.At the same time,the temperature only exists in the central region,and decreases rap‐idly with the propagation of compression wave,es‐pecially at 0.2 ms.For the case of 300 g/m3,we can see a relatively stable overpressure peak on the right side.Besides the central region,there is also a significant temperature rise near the overpressure front.In other words,a typical detonation wave propagation state is formed,where the concentration threshold of coal dust explosion is already reached.For the case of 500 g/m3,the peak value of over‐pressure propagates to both sides.Then,a continu‐ous compression region is formed after the detona‐tion wave,and the temperature and pressure in this region maintain a certain value without rapid attenu‐ation.The temperature of the central region is al‐ways significantly higher than that of the areas on both sides,which is caused by the setting of igni‐tion conditions.Due to the short explosion time,the temperature of the high-temperature region has not been diffused and transmitted to the surrounding area,resulting in the high temperature of the central region,which will drop to about 1 400 K over time.

Fig.2 Wave system diagram((a)pressure,(b)temperature)at the coal dust densities of 200 g/m3300 g/m3and 500 g/m3,and the evolution curves of pressure and temperature in the central region.Here,the radius of coal dust particle is 2 μm,the environmental pressure and temperature are respectively 1 bar and 298 K

2.2 Influence factors on coal dust explosion

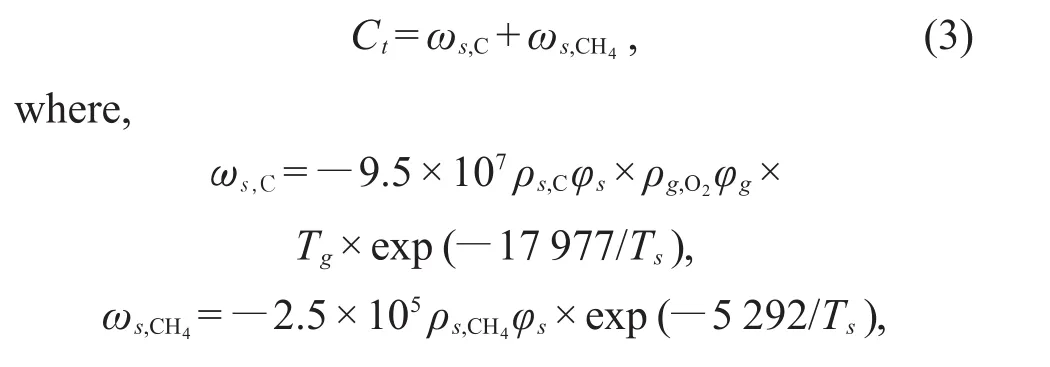

We carry out a series of simulation analysis for different particle sizes and concentrations of coal dust,and the simulation results are shown in Fig.3.Here,three particle sizes of coal dust are listed:(a)2 μ m,(b)5 μ m and(c)10 μ m.For each particle size of coal dust,the explosion processes under dif‐ferent densities are simulated.The ambient pressure and temperature are respectively 1 bar and 298 K.For the case of particle radius of 2 μm,when the coal density is no more than 225 g/m3,the initial high pressure propagates to the right for a certain distance and then begins to decay rapidly,indicating that there is no sustainable detonation process.When the density reaches 250 g/m3,a stable over‐pressure peak is formed on the right side,and the detonation wave has been formed.When the con‐centration of coal dust reaches 400 g/m3,the over‐pressure plateau forms,which indicates that the sta‐ble detonation wave propagates to both sides.For the particle radius of 5 μm,when the density reach‐es 400 g/m3,the detonation wave is formed on the right side,when the density reaches 500 g/m3,the detonation wave is formed on both sides,and the explosion threshold is higher than that of small par‐ticles.The change trend is further illustrated by the particle radius of 10 μm,where the explosion con‐centration threshold is 950 g/m3.

Fig.3 Pressure waveform of typical coal dust particle size at different concentrations.(a)2 μm;(b)5 μm;(c)10 μm

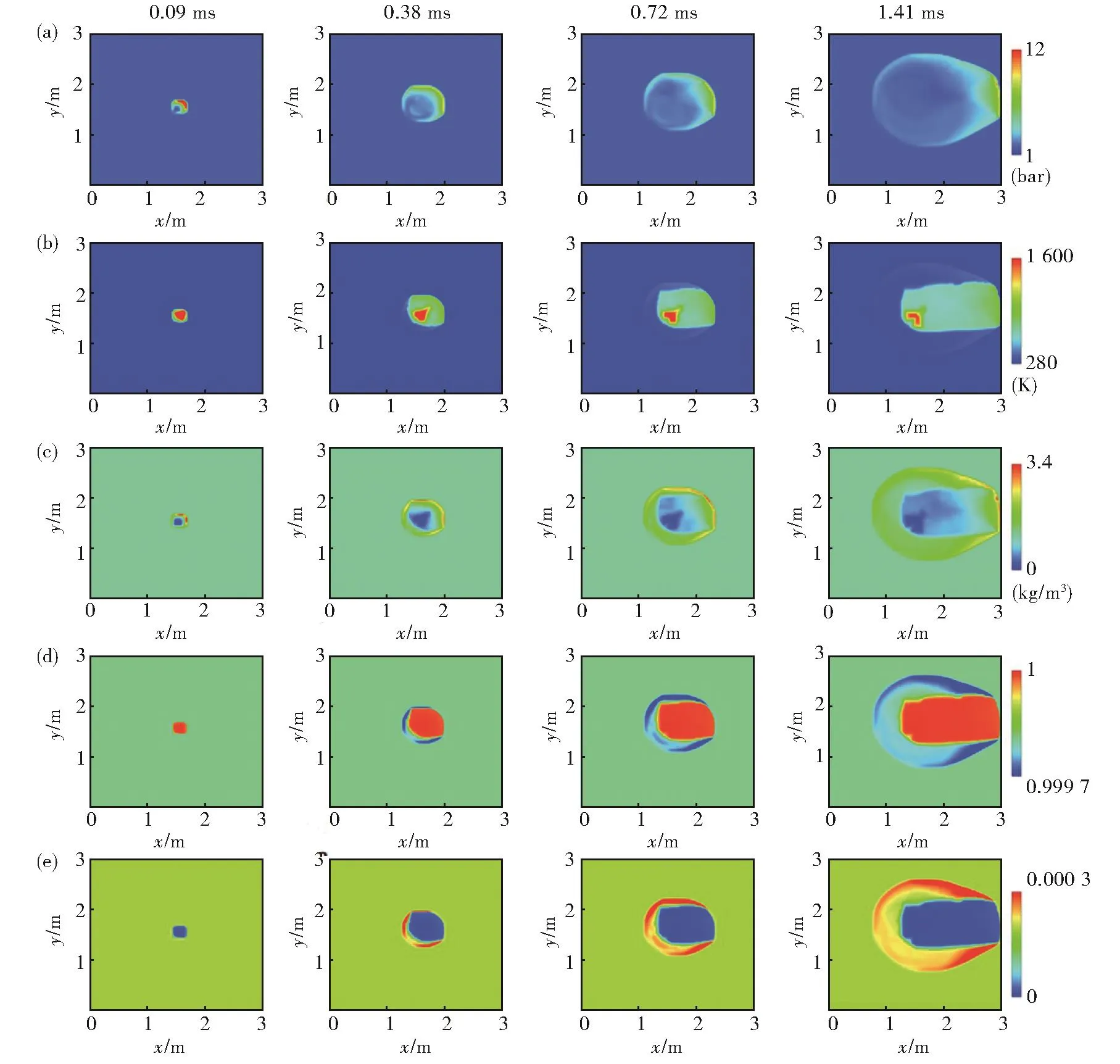

In addition to the particle size,the influence of ambient pressure and temperature on explosion threshold was further investigated.The simulation results are shown in Fig.4.The pressure changes from 1 bar to 5 bar,and the temperature changes from 298 K to 500 K.Here,the particle size of coal dust is selected as 1μm.The simulation results show that,the threshold density of detonation wave formation is 250 g/m3at 1 bar,700 g/m3at 3 bar,and 1 325 g/m3at 5 bar.As a whole,the explosion density threshold increases with the initial pressure.According to our knowledge,the critical density of explosion can reach the minimum at a certain pres‐sure state,which is slightly lower than the normal density.

Fig.4 Pressure waveform of typical initial gas pressure at different concentrations.(a)1 bar;(b)3 bar;(c)5 bar

In Fig.5,we present the influence of tempera‐ture on concentration threshold of coal dust explo‐sion.The simulation results show that,at the tem‐perature of 350 K,the curve with coal dust concen‐tration over 175 g/m3begins to form a sustained det‐onation wave,which is lower than the concentration threshold at 298 K.When the temperature rises to 400 K,the concentration threshold of coal dust for sustained detonation wave is reduced to 175 g/m3,and when the temperature is 500 K,the concentra‐tion threshold of coal dust is reduced to 125 g/m3.In general,with the increase of temperature,the ex‐plosion threshold of coal dust decreases obviously.

Fig.5 Pressure waveform of typical initial gas temperature at different concentrations.(a)350 K;(b)400 K;(c)500 K

According to the above simulation analysis,we can preliminarily give the relationship between the explosion threshold of coal dust and the influencing factors of particle size,ambient temperature and pressure,and the results are shown in Fig.6.We can see that with the increase of coal particle radius from 1 μ m to 10 μ m,the explosion concentration threshold can be increased from about 250 g/m3to 950 g/m3,which is about three times significantly increased.This is because the specific surface area of coal dust with smaller particle sizes will be larg‐er,making the reaction easier.At the same time,the mechanism of the reaction will change.When the particle size is large,diffusion combustion is the main combustion,and when the particle size is small,kinetic combustion is the main combustion.For the same particle size,the concentration thresh‐old of coal dust increases with the increase of pres‐sure,which is consistent with our expectation,be‐cause the pressure at which the explosion is most likely to occur is slightly lower than 1 atmospheric pressure.When the temperature increases from 298 K to 500 K,the explosion concentration threshold de‐creases linearly.This result is consistent with the existing experimental results[20]. These changing rules and data can provide reference for practical ap‐plication.Of course,more detailed analysis needs to be further carried out.

Fig.6 Concentration threshold of coal dust with different particle sizes,and the influence of initial pressure and temperature

2.3 Coal dust explosion process under density gradient distribution

In practice,there is often a certain concentra‐tion distribution in the process of coal dust leakage.Here,a typical concentration gradient distribution is assumed,that is,the concentration of coal dust radi‐ates from the center to the surrounding.It is mainly aimed at the short time leakage of coal dust in the limited space,such as the processing workshop of coal chemical enterprises.There may be a concen‐tration gradient in space.The model is shown in Fig.7.We investigate the process of explosion from the position of maximum concentration.Our calculation results show that the spherical detonation wave is formed gradually after initiation,and there is a certain pressure and temperature(0.94 ms)be‐hind the detonation wave.However,due to the geo‐metric effect,the peak value of detonation wave gradually decays in space(1.29 ms),and there is a temperature hot spot in the central reaction region.In addition,when the detonation wave reflected from different boundaries,a relatively high overpres‐sure peak is formed,we can see the overpressure re‐gion(2.73 ms)formed by the interaction of detona‐tion waves.At the same time,it can be observed that the right-hand detonation wave propagates in the gas without coal dust.In this process,the pres‐sure gradually decreases,but the temperature sud‐denly decreases in the gas region.

Fig.7 The pressure and temperature cloud diagrams of the flow field at different times

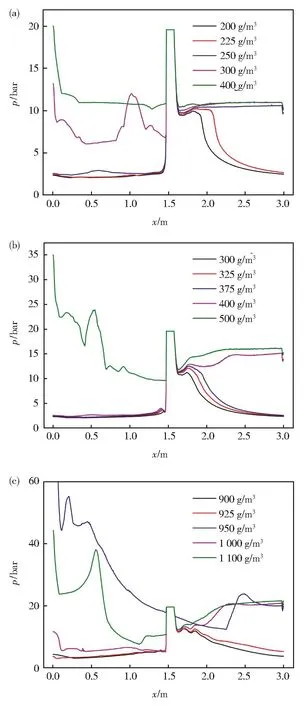

Fig.8 further shows the pressure and tempera‐ture waveforms of the above process in the x direc‐tion.The time interval in the figure is 0.4 ms.It can be seen that the peak value of overpressure propagating to both sides was formed in the early stage,but the peak value experiences rapid attenua‐tion in space,and the attenuation trend gradually weakens with the increase of radius.The tempera‐ture waveform shows that the coal dust area pres‐ents a gentle distribution above 500 K(except for the high temperature in some areas),and the temper‐ature of single coal decreases significantly in the pure gas area,which is mainly caused by the tem‐perature rise effect of shock wave.

Fig.8 The pressure(a)and temperature(b)profiles at different times

3 Summary

Through numerical simulation analysis,the ef‐fects of initial particle size,ambient pressure and ambient temperature on pulverized coal explosion threshold and propagation are revealed in this work.It is found that with the increase of particle size,the lower limit of pulverized coal explosion density continues to increase,and shows an expo‐nential growth trend.At the same time,the explo‐sion threshold increases with the increase of pres‐sure and decreases with the increase of tempera‐ture.In addition,the gradual attenuation law of pul‐verized coal after explosion from high density posi‐tion under a certain density gradient distribution is also calculated.In general,the simulation method established is suitable for general explosion mecha‐nism research and safety risk assessment of pulver‐ized coal and gas mixture,which has potential appli‐cation value in coal chemical technology,coal min‐ing and other fields.In the follow-up research,it is important to further develop the dynamic descrip‐tion of particle reaction process and conduct indepth coupling analysis of mechanical,thermal and chemical complex behavior of pulverized coal gas.