Optimization of Making Process for Whole Fish Frying Using a Universal Oven

Yuhan WANG, Can OUYANG

College of Cuisine, Sichuan Tourism University, Chengdu 610100, China

Abstract [Objectives]To study the effects of different temperature, time and humidity on the sensory quality of fish meat, and to determine the optimal process parameters for whole fish frying of Sichuan-style dry-roasted fish using a universal oven.[Methods]The effects of different heating temperature, time and humidity on the sensory quality of whole fish frying were analyzed by single factor experiment and orthogonal experiment.[Results]In the whole fish frying process of the universal oven, the optimal parameters in the first stage steaming mode was as follows: 215 ℃ for temperature, 15% for humidity, and 10 min for time; the optimal parameters in the second baking mode was as follows: 250 ℃ for temperature, 70% for humidity, and 5 min for time.[Conclusions]Different from the traditional whole fish frying of Sichuan-style dry roasted fish, universal oven is greatly optimized in convenience, safety and environmental protection.Besides, the use of oil is reduced, and the cost is well controlled, thus it is conducive to mass production in the later period.

Key words Universal oven, Process optimization, Whole fish frying, Orthogonal experiment, Sensory evaluation

1 Introduction

In Chinese cuisine, fish is a commonly used cooking material.However, the process of fish frying takes a lot of time and effort, and there are heavy oil fumes, manual operation is difficult to realize mass production[1].The universal oven is a new type of automatic cooking and heating equipment.Using universal oven, it is convenient to standardize and standardize the production process, realize the large-scale and standardized production of dishes, and also ensure that they are still delicious.

In this experiment, we mainly studied the whole fish frying and shaping in the process of steaming and baking of Sichuan-style dry-roasted fish in a universal oven, and studied the effects of different temperature, time and humidity on the sensory quality of fish meat, to determine the optimal process parameters for whole fish frying of Sichuan-style dry-roasted fish using a universal oven.

2 Materials and methods

2.1 Materials and instrumentsGrass carp, universal oven, baking tray, electronic balance, scallion, ginger, Laohenghe Cooking Wine, China Salt Refined Salt.

Equipment: universal oven(model: LM100BE; power: 10.8 kw; manufacturer: Germany Rational AG); baking tray(model: 6035.1017TriLax; manufacturer: Germany Rational AG); electronic balance(model: BS210S; manufacturer: Sartorius Scientific Instruments(Beijing)Co., Ltd.).

2.2 Methods

2.2.1Sample production.After killing 600 g of grass carp, removed the internal organs and black membranes, and washed them.In the early stage of the preliminary experiment, cut the carp into pieces, and in the later stage, directly use the whole fish, cut three lines separately on both sides of the carp for the experiment.

Washed the scallion and ginger, cut the scallion into segments and smashed the scallion segments and ginger, took the scallion and ginger juice for later use.Calculated the amount of salt, cooking wine, ginger, and scallion at the ratio of salt: 0.8%, cooking wine: 2.5%, ginger: 0.85%, scallion: 2.5%; put the initially processed grass carp in this for 12 min[1-2].Brushed oil evenly on the tray, put the processed grass carp on the tray, and put it in the universal oven.First selected the steaming mode, adjusted the time, temperature, and humidity, and then closed the oven door to set the steaming shaping.When the time was up, took the carp out for the first sensory evaluation, turned it over, and changed to the baking mode.After adjusting the time, temperature and humidity, closed the oven door for coloring.Finally, took the carp out and conducted the second sensory evaluation when the temperature dropped to 30-40 ℃.

2.2.2Sensory evaluation method of the whole fish.We randomly selected 20 staff members who have received sensory evaluation training to set up a sensory evaluation team.In accordance with the principles of food sensory evaluation, the team assigned weights to the sensory quality of Sichuan-style dry-roasted fish under different shapes and coloring conditions[3-5].The sensory evaluation indicators of Sichuan-style dry-roasted fish mainly include color, shape, smell, and mouthfeel, which are also the focus of consumers when tasting.During the experiment, each member scored each indicator individually, and then calculated the average of the overall scores as a comprehensive score(Table 1).

Table 1 Sensory evaluation criteria of Sichuan-style dry-roasted fish

2.2.3Single factor experiment in the steaming mode.After the preliminary experiment, we found that the time range of the universal oven in the steaming mode was 3-11 min, the humidity range was 0%-80%, and the temperature range was 190-230 ℃[6].With reference to Table 1, we optimized the time, temperature and humidity during the experiment to obtain the change trend of the sensory scores of each factor with the independent variables.

(i)Determination of time.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the temperature was 260 ℃, the humidity was 60%, and the time was 1, 3, 5, 7 and 9 min, respectively.After steaming and shaping of the whole fish that has undergone preliminary processed in Section2.2.1, took it out.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate time range according to the scoring results.

(ii)Determination of humidity.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the temperature was 220 ℃, the time was 6 min, and the humidity was 0%, 20%, 40%, 60% and 80%.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate humidity range according to the scoring results.

(iii)Determination of temperature.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the humidity was 60%, the time was 6 min, and the temperature was 190, 200, 210, 220 and 230 ℃.After steaming and shaping of the whole fish that has undergone preliminary processed in Section2.2.1, took it out.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate temperature range according to the scoring results.

2.2.4Single factor experiment in the baking mode.After the preliminary experiment, we found that the humidity range of the universal oven in the baking mode was 20%-100%, the time range was 1-9 min, and the temperature range was 230-270 ℃[7].With reference to Table 1, we optimized the time, temperature and humidity during the experiment to obtain the change trend of the sensory scores of each factor with the independent variables.

(i)Determination of time.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the temperature was 260 ℃, the humidity was 60%, and the time was 1, 3, 5, 7 and 9 min, respectively.After steaming and shaping of the whole fish that has undergone preliminary processed in Section2.2.1, took it out.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate time range according to the scoring results.

(ii)Determination of humidity.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the temperature was 260 ℃, the time was 3 min, and the humidity was 0%, 20%, 40%, 60% and 80%.After baking of the whole fish that has undergone preliminary processed in Section2.2.1, took it out.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate time range according to the scoring results.

(iii)Determination of temperature.According to the whole fish frying process of traditional Sichuan-style dry-roasted fish, we determined the value of each factor: the humidity was 60%, the time was 3.5 min, and the temperature was 230, 240, 250, 260 and 270 ℃.After baking of the whole fish that has undergone preliminary processed in Section2.2.1, took it out.According to the sensory evaluation criteria of Sichuan-style dry-roasted fish in Table 1, the team scored the finished fish, and we finally determined the appropriate temperature range according to the scoring results.

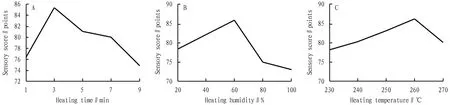

2.2.5Orthogonal experiment.On the basis of the single factor experiment, we carried out two orthogonal experiments to optimize the influencing factors of the whole fish frying in the universal oven in two modes(steaming mode and baking mode).We selected temperature, time and humidity as the experimental factors, and regarded the interaction as a blank column, as an unknown factor or interaction column[8].Then, we designed two L9(34)orthogonal experiments, a total of 18 groups of samples(Table 2).When conducting the orthogonal experiment on the steaming mode, we used single-factor optimal combination of the baking mode, andviceversa, as indicated in Table 2.

Table 2 Orthogonal experiment factor levels for steaming and baking modes

2.2.6Data processing.Taking the sensory condition as the indicator, we optimized the different processing factors of Sichuan-style dry-roasted fish in the universal oven by the method of orthogonal experiment.With the aid of Excel 2019, using the range calculation analysis method, we obtained the optimal sensory quality condition for whole fish frying of Sichuan-style dry-roasted fish using a universal oven.

3 Results and analysis

3.1 Single factor experiment results in the steaming mode

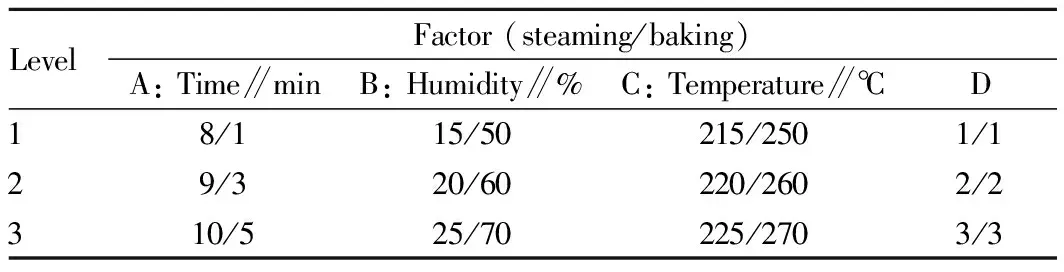

3.1.1Effects of time on sensory factors.In the steaming mode, when the humidity was 20% and the temperature was 220 ℃, we analyzed the effects of time on the sensory quality.From Fig.1A, it can be seen that the optimal level was reached at 9 min; between 8 and 10 min, the sensory quality of the whole fish was relatively stable and had a small change.Thus, we selected 8, 9 and 10 min as the steaming time.

Note: A, B and C are separately effects of heating time, humidity and temperature on sensory score.

3.1.2Effects of humidity on sensory factors.In the steaming mode, the temperature was 220 ℃, and the time was 6 min, we analyzed the effects of humidity on the sensory quality.From Fig.1B, it can be seen that the optimal time was 20%; between 15% and 25%, the sensory quality of the whole fish was relatively stable and had a small change.Therefore, we selected the 15%, 20% and 25% as the optimal humidity points.

3.1.3Effects of temperature on sensory factors.In the steaming mode, the humidity was 60%, and the time was 6 min, we analyzed the effects of temperature on the sensory quality.From Fig.1C, it can be seen that the optimal temperature was 220 ℃, between 215 and 225 ℃, the sensory quality of the whole fish was relatively stable and had a small change.Therefore, we selected 215, 220 and 225 ℃ as the optimal temperature points.

3.2 Single factor experiment results in the baking mode

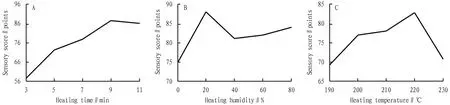

3.2.1Effects of time on sensory factors.In the baking mode, when the humidity was 60% and the temperature was 260 ℃, we analyzed the effects of time on the sensory quality.From Fig.2A, it can be seen that the optimal level was reached at 3 min; between 1 and 3 min, the sensory quality of the whole fish was relatively stable and had a small change.Thus, we selected 1, 2 and 3 min as the steaming time.

3.2.2Effects of humidity on sensory factors.In the baking mode, the temperature was 260 ℃, and the time was 3.5 min, we analyzed the effects of humidity on the sensory quality.From Fig.2B, it can be seen that the optimal time was 60%; between 50% and 60%, the sensory quality of the whole fish was relatively stable and had a small change.Therefore, we selected the 50%, 60% and 70% as the optimal humidity points.

3.2.3Effects of temperature on sensory factors.In the baking mode, the humidity was 60%, and the time was 3.5 min, we analyzed the effects of temperature on the sensory quality.From Fig.2C, it can be seen that the optimal temperature was 260 ℃, between 250 ℃ and 270 ℃, the sensory quality of the whole fish was relatively stable and had a small change.Therefore, we selected 250, 260 and 270 ℃ as the optimal temperature points.

Note: A, B and C are separately effects of heating time, humidity and temperature on sensory score.

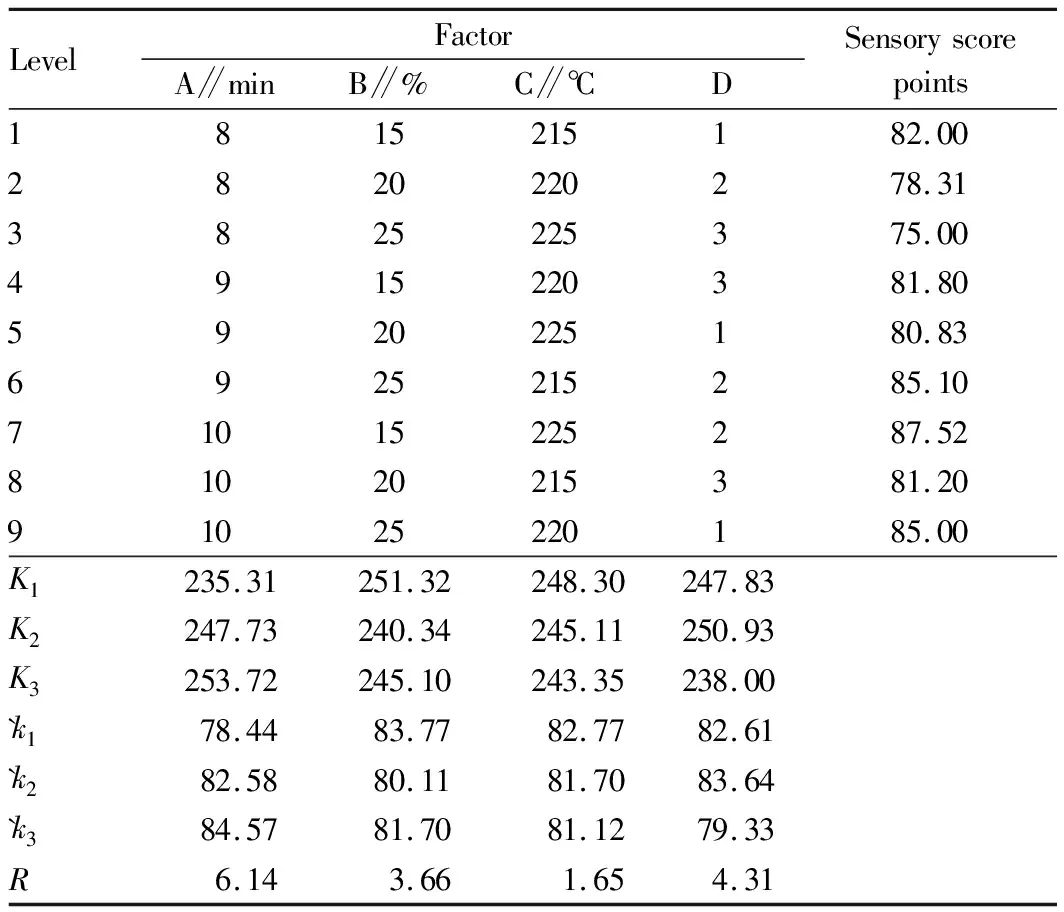

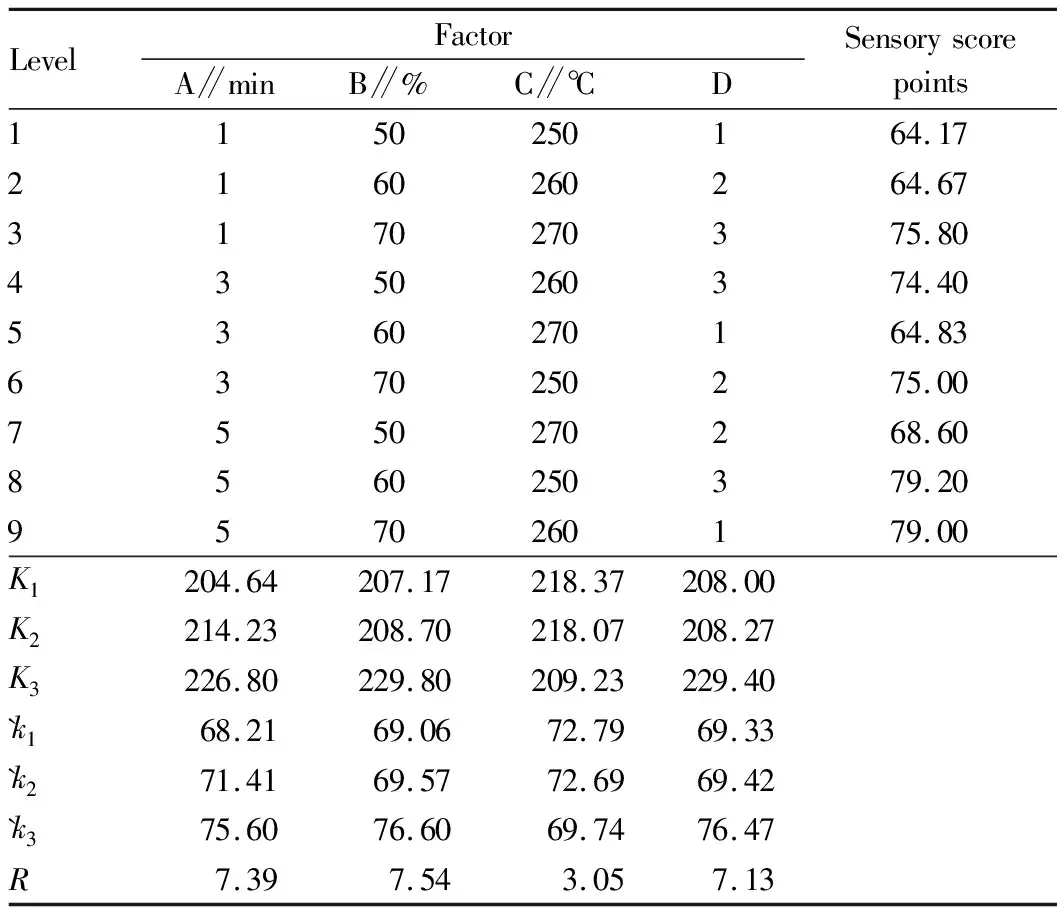

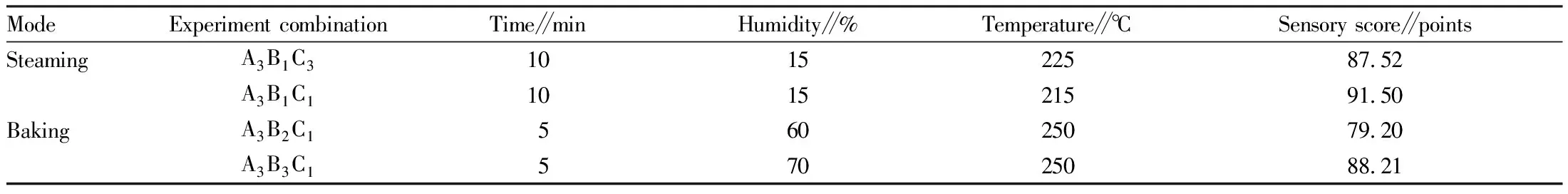

3.3 Results and analysis of orthogonal experimentAccording to the factor analysis of the orthogonal experiment in Table 2, we obtained the following results of the orthogonal experiment(Table 3-4).According to the analysis of the range value(R)in Table 3, the main factor affecting the sensory quality of dry-roasted whole fish in the steaming mode is time, followed by interaction, and then is humidity and temperature.According to the analysis of the range value(R)in Table 4, the main factor affecting the sensory quality of dry-roasted whole fish in the baking mode is the heating humidity, followed by interaction, and then is time and temperature[9].Combined with Table 3 and Table 4, without considering the interaction, the optimal combination in the steaming mode is A3B1C1and the optimal combination in the baking mode is A3B3C1.

Table 3 Orthogonal experiment results in the steaming mode

3.4 Verification experimentAfter the optimal combination was calculated by the range analysis method, we compared with the optimal combination in the orthogonal table.Taking these two combinations as the tested formulas, we conducted verification experiments[9-10].In accordance with the sensory evaluation criteria of Sichuan-style dry-roasted fish(Table 1), the quality of the fish was evaluated in groups, as shown in Table 5.

From Table 5, we found that the sensory scores of dry roasted whole fish in the optimal combination obtained by the orthogonal experiment range analysis were higher than those in the optimal combinations[9-10].Therefore, the optimal formula combination for the whole fish frying of dry-roasted fish is A3B1C1for the steaming mode and A3B3C1for the baking mode.Specifically, using the universal oven, at the heating time of 10 min, humidity of 15%, and temperature of 215 ℃ in the steaming mode, and at the heating time of 5 min, humidity of 70%, and temperature of 250 ℃ in the baking mode, it is able to obtain the optimal sensory quality Sichuan-style dry-roasted whole fish.

Table 4 Orthogonal experiment results in the baking mode

Table 5 Orthogonal experiment verification of steaming and baking modes

4 Conclusions

In the process of studying the whole fish frying process using a universal oven, we found that the main factor was not the temperature factor in the traditional heating as the public thinks, but the time, interaction, and humidity.In this study, we determined the optimal process parameters for Sichuan-style dry-roasted whole fish frying using a universal oven: in the first stage steaming mode, the time is 10 min, the humidity is 15%, and the temperature is 215 ℃; in the second stage baking mode, the time is 5 min, the humidity is 70%, and the temperature is 250 ℃; using these parameters, the fish skin will not fall or bubble, and the color is golden and smell is attractive and the whole fish is delicious.

Compared with the traditional Sichuan-style dry-roasted whole fish frying, using a universal oven to shape and color the whole fish is greatly optimized in terms of convenience, safety and environmental protection.Besides, it reduces the oil and greatly controls the costs and facilitates the later mass production and promotion.In addition, the study on frying process optimization of whole fish is expected to lay a foundation for the standardization of Sichuan-style dried fish.Furthermore, the study on frying process optimization of whole fish can be extended to other industrial applications related to whole fish fried dishes, such as Yellow River Carp with Sweet and Sour Sauce, Stewed Carp with Hot Bean Sauce,etc.

Asian Agricultural Research2022年4期

Asian Agricultural Research2022年4期

- Asian Agricultural Research的其它文章

- A Sustainable Production Model for Potato at Low Latitude Plateau in Winter in Yunnan Province

- Occurrence and Damage and Pathogene of Potato Early Blight in Winter in Yunnan Province, China

- Chromatograph Skeleton Components of Feng-flavor Baijiu during Different Production Stages

- Analysis and Strategy Research on the Mathematics Learning Situation of the Postgraduate Candidates

- Application of ETA in the Management of Mental Health Education for College Students

- Research on the Types of Cigarette Products Preferred by Consumers