Chromatograph Skeleton Components of Feng-flavor Baijiu during Different Production Stages

Lili LIU, Hui YANG, Zongke YAN, Yaohua QI, Xiong JING, Pengfei SU

1.School of Food and Biology Engineering, Shaanxi University of Science & Technology, Xi’an 710021, China; 2.Shaanxi Xifeng Wine Co., Ltd., Baoji 721000, China

Abstract Production of Feng-flavor baijiu includes six stages(first fermented stage, second fermented stage, third fermented stage, normal fermented stage and quitting fermented stage, ending of fermented stage).Each stage of the base liquor has its own style.The main chromatogram structure components were analyzed by gas chromatography(GC), to explore the characteristics of base baijiu during different production stages, which can provide a reference for classification storage and body design of baijiu.

Key words Feng-flavor baijiu, Production stages, Chromatograph skeleton components

1 Introduction

Baijiu is a type of Chinese traditional distilled liquor and regarded as one of the most famous distilled liquors in the world, together with brandy, gin, rum, vodka, and whiskey[1].Baijiu can be divided into 12 categories, Feng-flavor baijiu is one of them and characterized by higher alcohol and lower ester, and sweet entrance and elegant aftertaste[1-2].Feng-flavor baijiu is represented by Xifeng-jiu, we took Xifeng-jiu as an example to describe the production process of baijiu since it involves several important steps in relation to baijiu production.Xifeng-jiu is primarily produced in Shaanxi China using sorghum as the raw material in combination with medium-temperature Daqu(maximum temperature reaching 58-60 ℃)to carry out alcoholic fermentation[1].In total, there are five major characteristic:(i)crude traditional fermentation in mud pit,(ii)30 d is the fermentation time,(iii)six production stages,(iv)low-distillation,(v)Jiuhai storing.

The production cycle of Xifeng-jiu is one year, from the beginning of September, to the end of June of the next year, the whole making process includes six stages: Lijiao, Pojiao, Dingjiao, Yuanjiao, Chajiao and Tiaojiao[4].Lijiao, the first round of fermentation, When the temperature of the fermented materials(sorghum, husk with Daqu)reduces to between 18 ℃ and 20 ℃, the mixture is loaded into an mud pit.In particular, the volume of mixture is only three-fifths of the volume of the mud pit.Fermented after 30 d into the Pojiao which is the second round of fermentation, fermented grains are distilled into wine after adding sorghum and rice husk, good distilling operation could successfully transfer 80% flavoring materials of fermented grains in liquor.When the temperature of the distilled fermented grains reduces to around 35 ℃, mixing with Daqu to form the fermented materials.The volume of mixture is only four-fifths of the volume of the mud pit.Fermented after 30 d into the Dingjiao which is the third round of fermentation, the process operation is the same as Pojiao, while the fermented materials will fill the mud pit.Yuanjiao, the normal and higher alcohol yield(40%)production stage.After the Dingjiao fermented by a fermentation cycle, take four-fifths of the fermented grains which mixed with new grain are distilled, that aired and added Daqu to form the new fermented materials.The one-fifths fermented materials distilled to form spent grains.In the ordinary way, the Yuanjiao production will continue for five months.Chajiao, the penultimate production round of the year, the process operation is the same as Yuanjiao, but the difference is that sorghum is not added.Tiaojiao, final round of fermentation, the all fermented materials distilled to form spent grains.There are no sorghum and Daqu in this stage of the production process.Each wine-making stage is a gradual process with slightly different techniques, and the production mainly rely on the experience of technical personnel continue to set up, adjust process parameters to ensure product quality.

The flavor compounds determined the style and quality of baijiu[1-3].Because of the different production technology, the Feng-flavor raw wine has its own characteristics in each stage[5].In this paper, working with Feng-flavor raw baijiu produced in different stages, the main chromatographic skeleton components were detected by gas chromatography(GC)to discuss the characteristics of the original wine.It is intended to provide a reference for storage and body design of original wine.

2 Materials and methods

2.1 MaterialsRaw baijiu samples at each production stage of Lijiao, Pojiao, Dingjiao, Yuanjiao, Chajiao and Tiaojiao were studied, 30 samples each stage.

N-butyl acetate(internal standard), ethyl acetate, ethyl butyrate, sec-butanol, n-propanol, isobutanol, n-butanol, isoamyl alcohol, ethyl hexanoate, and ethyl lactate standards were purchased from Sigma-Aldrich Chemical Co.(St.Louis, MO).Water purified through an Arium Comfort I purification system(Sartorius, Germany)was used for all solution preparations and dilutions.

2.2 MethodsVolatile compounds were examined by Gas Chromatograph(8890, Agilent Technology Co., Ltd.)according to method of analysis for baijiu(GB/T 10345-2007).Chromatographic separations were done on an CP-WAX 57 CB fused-silica capillary column(50 m×0.25 mm ID, 0.20 m film thickness).The carrier gas, nitrogen, was circulated at 1 mL/min, the combustion gas, hydrogen, was circulated at 30 mL/min.The sample size is 0.5 μL, the injection was conducted in a split ratio mode(19∶1)at 200 ℃.The oven temperature program was as follows: 46.5 ℃ for 6 min, 3.15 ℃/min ramp to 140 ℃, 5 ℃/min ramp to 150 ℃ and holding for 12 min, 3.5 ℃/min ramp to 190 ℃ and holding for 12 min.

Origin 2019 software was used to calculate the data and Minitab 18 software was used to analyzed the relevant data of principal component.

3 Results and discussion

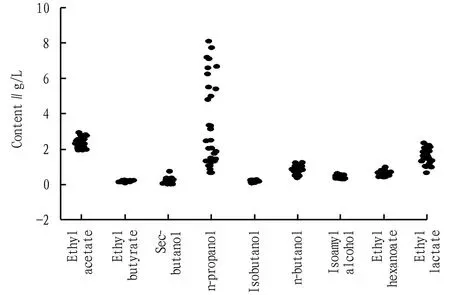

3.1 Analysis of skeleton components of Xifeng-jiu in Pojiao

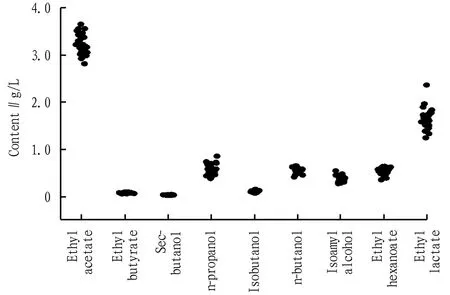

The main volatile compounds include ethyl acetate, ethyl butyrate, sec-butanol, n-propanol, isobutanol, n-butanol, isoamyl alcohol, ethyl hexanoate, and ethyl lactate in Xifengjiu.Fig.1 shows the substance contents of 30 Pojiao wine samples, the content ranges of ethyl acetate is 1.97-2.96 g/L, ethyl butyrate is 0.10-0.27 g/L, sec-butanol is 0.04-0.77 g/L, n-propanol is 0.69-8.12 g/L, isobutanol is 0.10-0.30 g/L, n-butanol is 0.40-1.27 g/L, isoamyl alcohol is 0.33-0.65 g/L, ethyl hexanoate is 0.45-1.01 g/L, ethyl lactate is 0.69-2.37 g/L.

Fig.1 Skeleton components of base liquor in Pojiao

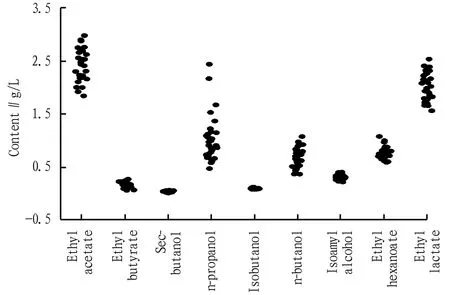

3.2 Analysis of skeleton components of base Xifeng-jiu in DingjiaoFig.2 shows the skeleton components content of the base baijiu in Dingjiao, the content ranges of ethyl acetate is 1.84-2.98 g/L, ethyl butyrate is 0.07-0.28 g/L, sec-butanol is 0.02-0.07 g/L, n-propanol is 0.50-2.44 g/L, isobutanol is 0.09-0.13 g/L, n-butanol is 0.38-1.08 g/L, isoamyl alcohol is 0.23-0.41 g/L, ethyl hexanoate is 0.59-1.08 g/L, ethyl lactate is 1.56-2.53 g/L.

Fig.2 Chromatograph skeleton components of base liquor in Dingjiao

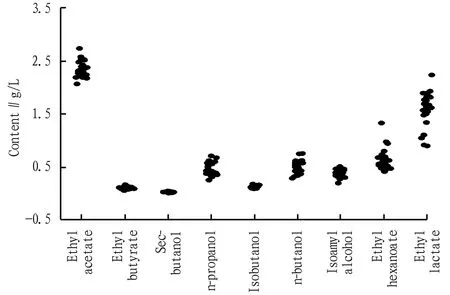

3.3 Analysis of skeleton components of Xifeng-jiu in YuanjiaoFig.3 shows the skeleton components of Yuanjiao baijiu, the content ranges of ethyl acetate is 2.07-2.73 g/L, ethyl butyrate is 0.06-0.17 g/L, sec-butanol is 0.09-0.49 mg/L, n-propanol is 0.25-0.71 g/L, isobutanol is 0.90-1.81 mg/L, n-butanol is 0.29-0.76 g/L, isoamyl alcohol is 0.20-0.51 g/L, ethyl hexanoate is 0.42-1.33 g/L, ethyl lactate is 0.90-2.23 g/L.

Fig.3 Skeleton components of base liquor in Yuanjiao

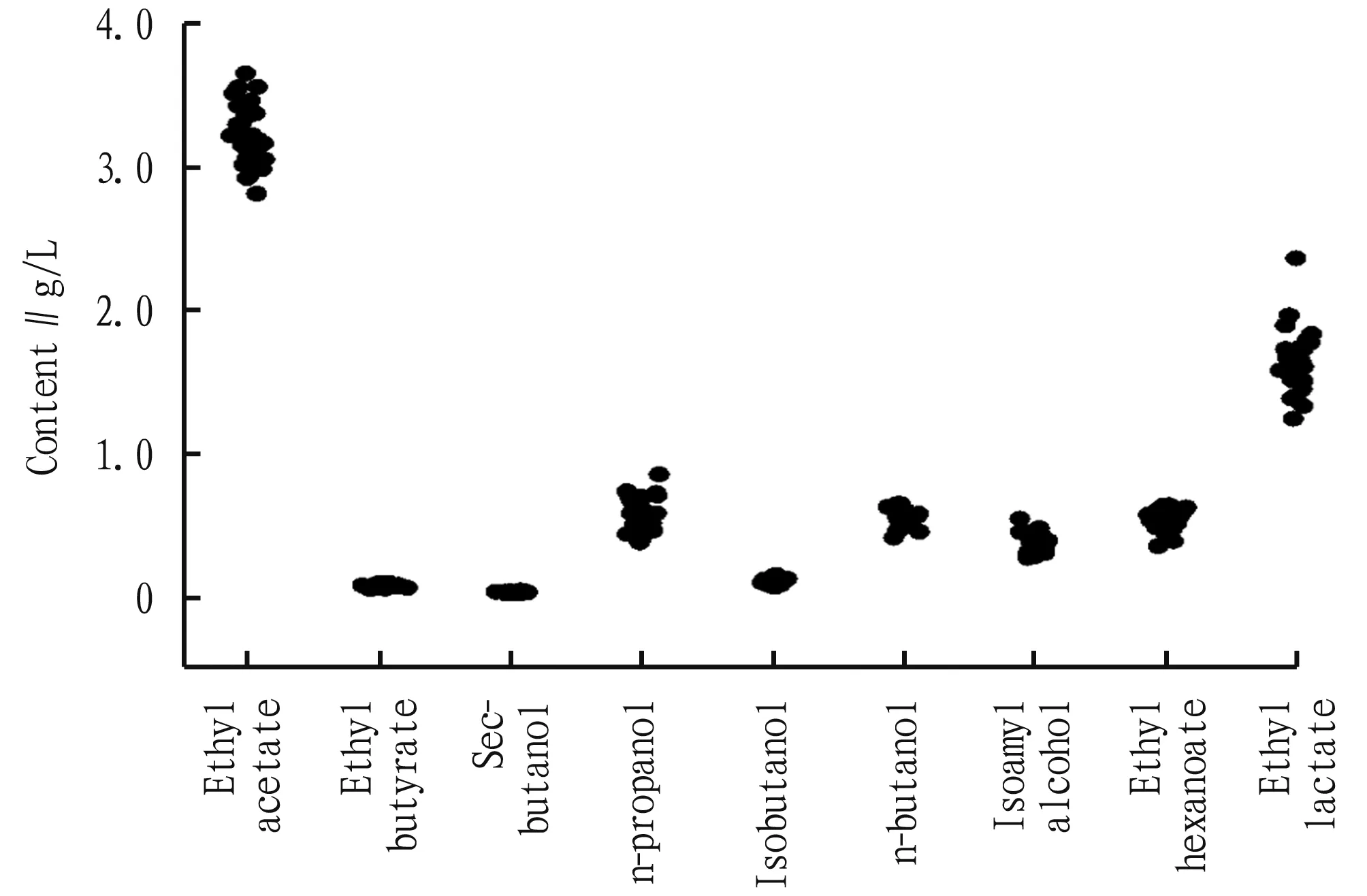

3.4 Analysis of skeleton components of Xifengjiu in Chajiao

Fig.4 shows the skeleton components of the Chajiao baijiu, the content ranges of ethyl acetate is 2.82-3.66 g/L, ethyl butyrate is 0.06-0.11 g/L, sec-butanol is 0.03.3-0.06 g/L, n-propanol is 0.39-0.86 g/L, isobutanol is 0.08-0.16 g/L, n-butanol is 0.42-0.66 g/L, isoamyl alcohol is 0.28-0.55 g/L, ethyl hexanoate is 0.36-0.65 g/L, ethyl lactate is 1.25-2.37 g/L.

Fig.4 Chromatograph skeleton components of base liquor in Chajiao

3.5 Analysis of skeleton components of Xifengjiu in Tiaojiao

Fig.5 shows the skeleton components of the Tiaojiao baijiu, the content ranges: of ethyl acetate is 1.05-3.81 g/L, ethyl butyrate is 0.06-0.16 g/L, sec-butanol is 0.08-0.21 g/L, n-propanol is 0.71-2.50 g/L, isobutanol is 0.087.9-0.13 g/L, n-butanol is 0.74-1.25 g/L, isoamyl alcohol is 0.24-0.45 g/L, ethyl hexanoate is 0.30-0.64 g/L, ethyl lactate is 0.67-1.34 g/L.

Fig.5 Chromatograph skeleton components of base liquor in Tiaojiao

It is known that the ester content of the chromatograph skeleton components of baes liquor is mainly based on three esters(ethyl acetate, ethyl hexanoate and ethyl lactate), and the higher alcohol contents is mainly n-propanol and n-butanol.Among them, the content of ethyl acetate and n-propanol is relatively high.In addition, the high alcohol content of the base liquor in the Yuanjiao and Chajiao is lower.Other stages of the base liquor the high alcohol content is higher.

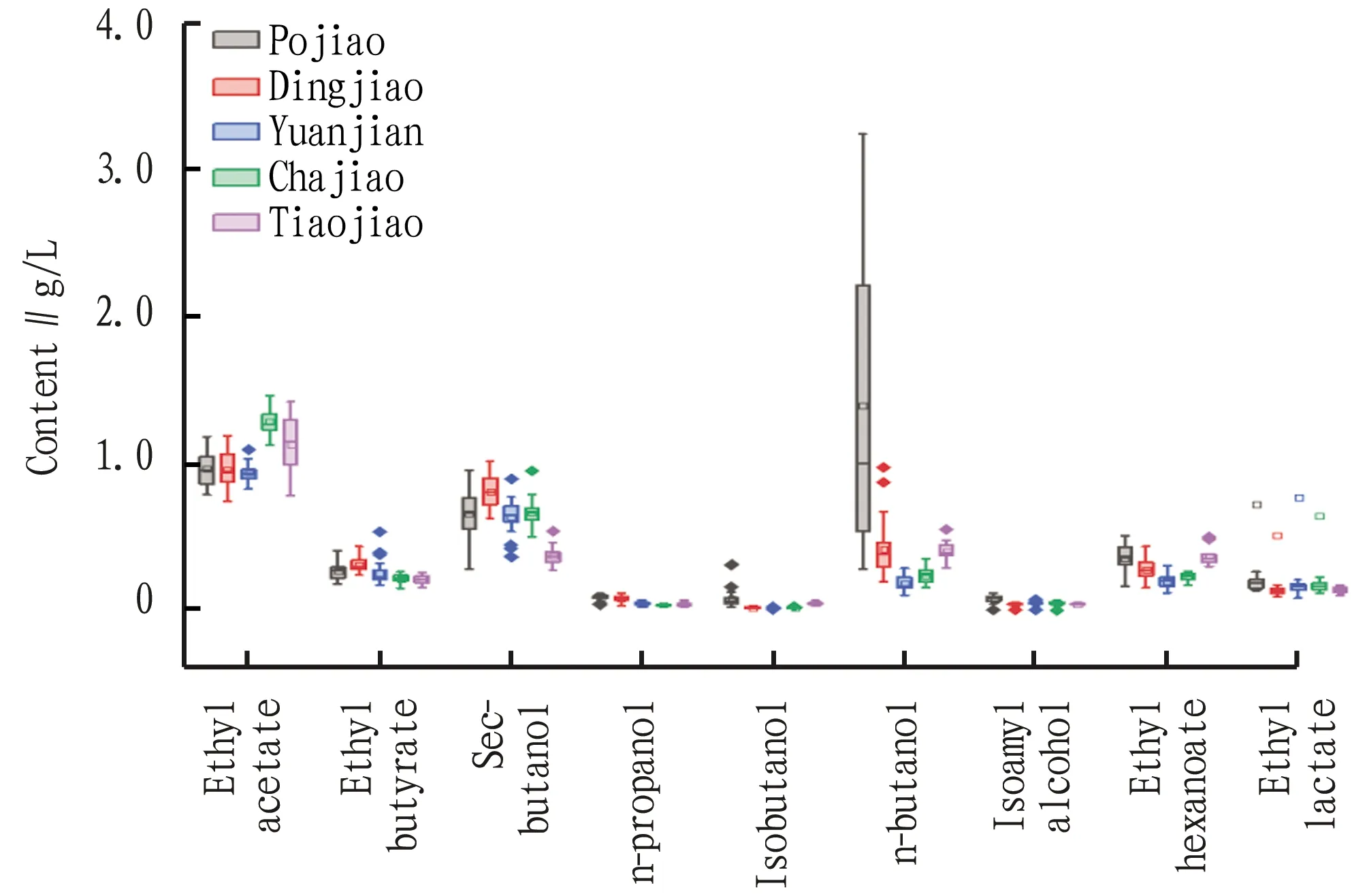

3.6 PCA analysis of Baijiu in every stageFengxiang baijiu has different quality produced from different stages, as can be seen from Fig.6, the trace composition difference is larger, with the extension of the wine time, ethyl acetate in cellar, cellar period content increase, ethyl acetate, ethyl lactate in round cellar, cellar, cellar, cellar content, propanol content is the largest, and the range is wide, this may be related to the higher fermented grains starch and Daqu concentration.The contents of secondary butanol and isobutanol were larger in Pojiao and decreased in other stages.The contents of butanol were lower in round Yuanjiao and Chajiao, and the difference in contents of isoamyl alcohol during all stages of between two varieties was not significant.

Fig.6 Box plot of substance content in different stages raw wine

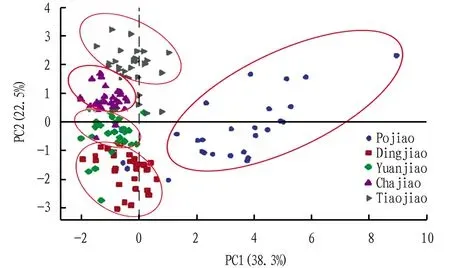

Fig.7 is the analysis diagram of principal component of baijiu at each stage, which can be known from principal component analysis, the base baijiu of Pojiao is mainly distributed in one and four quadrants, the Dingjiao baijiu is mainly distributed in three and four quadrants, the Yuanjiao baijiu is mainly distributed in two and three quadrants, the Chajiao baijiu is mainly distributed in two quadrants, the Tiaojiao baijiu is mainly distributed in one and two quadrants.It can be seen that the baijiu produced at different stages is difference.

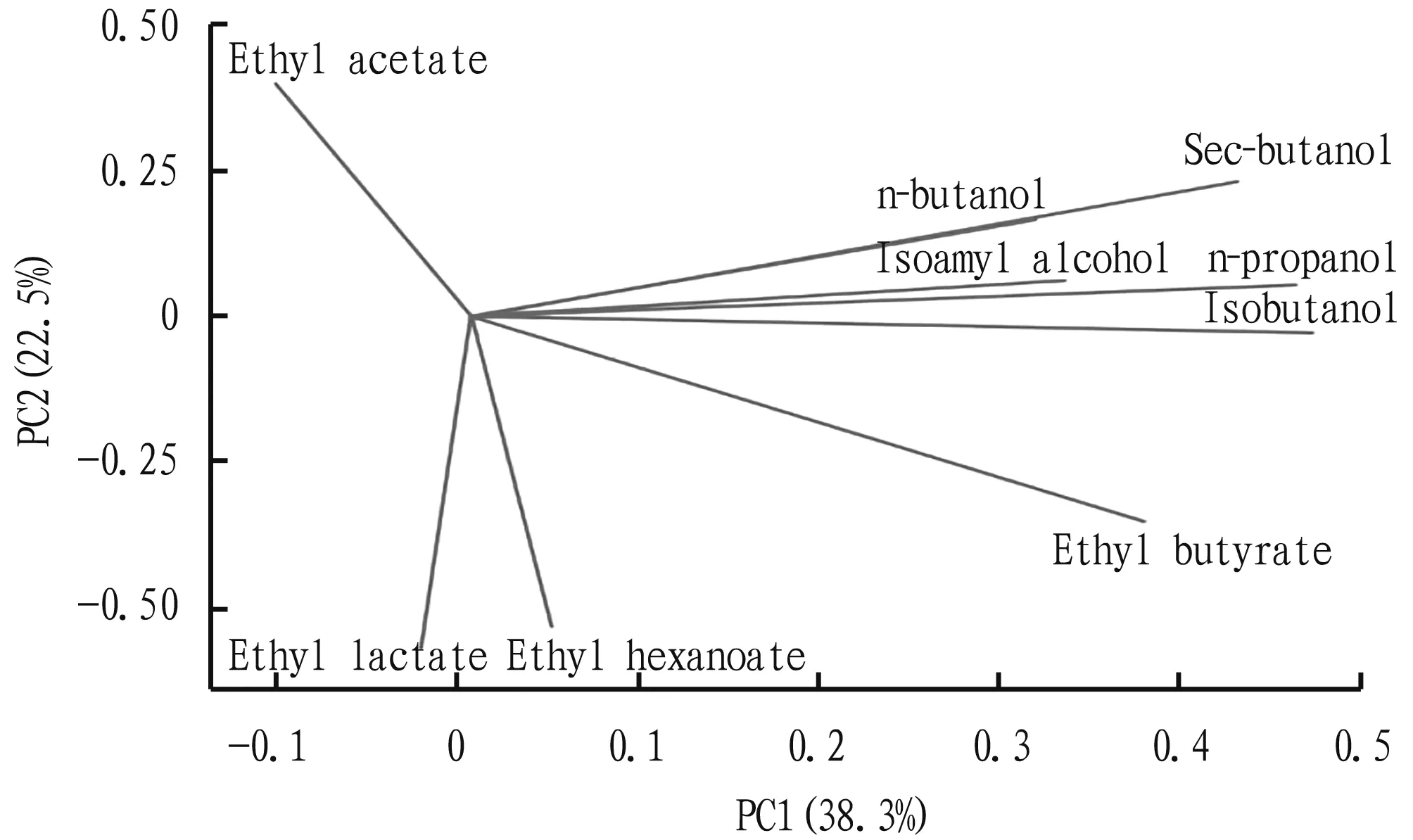

Fig.8 is loading diagram of components in every stage.Combined with Fig.7-8, the characteristic components of the Pojiao are n-propanol, isobutanol and ethyl hexanoate, which have a relatively large impact on the quality of the Pojiao wine.The characteristic components of Dingjiao are ethyl lactat and ethyl hexanoate, which have relatively large effects on the quality of the Dingjiao wine.The characteristics of Yuanjiao are ethyl acetate and ethyl lactate, the Chajiao are ethyl acetate, Tiaojiao are ethyl acetate, n-propanol and isobutanol, these indicators have relatively large impact on the quality of different original wine.

Fig.7 Analysis of the principal component of base liquor in every stage

Fig.8 Loading diagram of chromatograph skeleton components

According to the above analysis, the main aroma of the original wine in the Yuanjiao and Chajiao is mainly ethyl acetate, which can be used as the basic wine in Xifengjiu blending, while the higher alcohol or ethyl hexate in other stages have a great impact on its quality and can be used as flavoring wine.Xifengjiu was formed through the liquor body design, which is characterized by the main flavor of lower ester and higher alcohol.

4 Conclusions

In this paper, we study the main chromatographic skeleton compositions of Fengxiang raw wine at each production stage, showing that Fengxiang raw wine has a compound aroma with ethyl acetate as the main low-grade ester and n-propane alcohol as the main higher alcohol.Principal component analysis(PCA)showed that obvious differences of the characteristic components of the original wine in each stage.At the same time, the original wine in the Yuanjiao and the Chajiao can be used as the basic wine during blending, while the original wine in other stages can be used as the flavoring wine.It is expected to provide a reference for classification storage and body design of raw wine.

Asian Agricultural Research2022年4期

Asian Agricultural Research2022年4期

- Asian Agricultural Research的其它文章

- A Sustainable Production Model for Potato at Low Latitude Plateau in Winter in Yunnan Province

- Occurrence and Damage and Pathogene of Potato Early Blight in Winter in Yunnan Province, China

- Analysis and Strategy Research on the Mathematics Learning Situation of the Postgraduate Candidates

- Application of ETA in the Management of Mental Health Education for College Students

- Research on the Types of Cigarette Products Preferred by Consumers

- Current Situation of E-commerce Entering Rural Areas in Datong County of Qinghai Province