电加热服的研究现状与进展

林磊 王宏付 柯莹

摘要: 为揭示电加热服的材料、加工工艺与热防护性能之间的关系,解析电加热服设计过程中的关键问题,文章首先对金属、镀金和非金属两个类别的电加热材料进行分别阐述并分析其各自的优缺点;接着介绍了电加热服的三种加工工艺,分别为直接利用电热丝制作、放置电加热片制作和涂覆电热薄膜或涂层制作。其中,直接利用电热丝制作电加热服加热均匀、直接高效,但工艺复杂;放置电加热片制作电加热服方便简洁,但容易造成加热不均;涂覆电加热薄膜或涂层的方式成本低、使用灵活,但服装透湿透气性和耐用性不佳。最后从电安全、电热、热舒适性三方面对电加热服的综合性能进行评价,总结得出未来电加热服将会在加热区域的设计、加工工艺优化、性能评价方式改进和功能升级四方面开展更加深入的研究。

关键词: 电加热服;电加热材料;加工工艺;热防护性能;性能评价;热舒适性

中图分类号: TS941.71

文献标志码: A

文章编号: 1001 7003(2022)03 0068 08

引用页码: 031110

DOI: 10.3969/j.issn.1001-7003.2022.03.010 (篇序)

低温环境下,人们通常穿着多层服装以防止热量散失,但服装过于厚重会限制着装者的身体运动,在一些特定场合并不实用。随着纺织技术的不断发展创新,智能加热服装得以广泛应用,它将传统保暖服的被动隔热变为主动加热。目前智能加热服主要有:电加热服、化学加热服、相变加热服、流体加热服和太阳能加热服 [1] 。电加热服以电为能源,将电能通过置入于服装中的电加热元件从而转化为热能,可以在低温环境中积极主动地提供热量,提高穿戴者的舒适性 [2] 。相比其他智能加热服,电加热服发热时间长、温度可调节、并且能较好地贴合人体。随着电发热系统技术的逐渐成熟,电加热服已成为最常见的智能加热服装之一 [3] 。本文从电加热服的材料、加工工艺、性能评价三方面介绍电加热服的发展现状,分析未来电加热服的发展趋势,并提出电加热服的性能评价流程,为后续相关研究提供一定参考。

1 电加热材料的分类

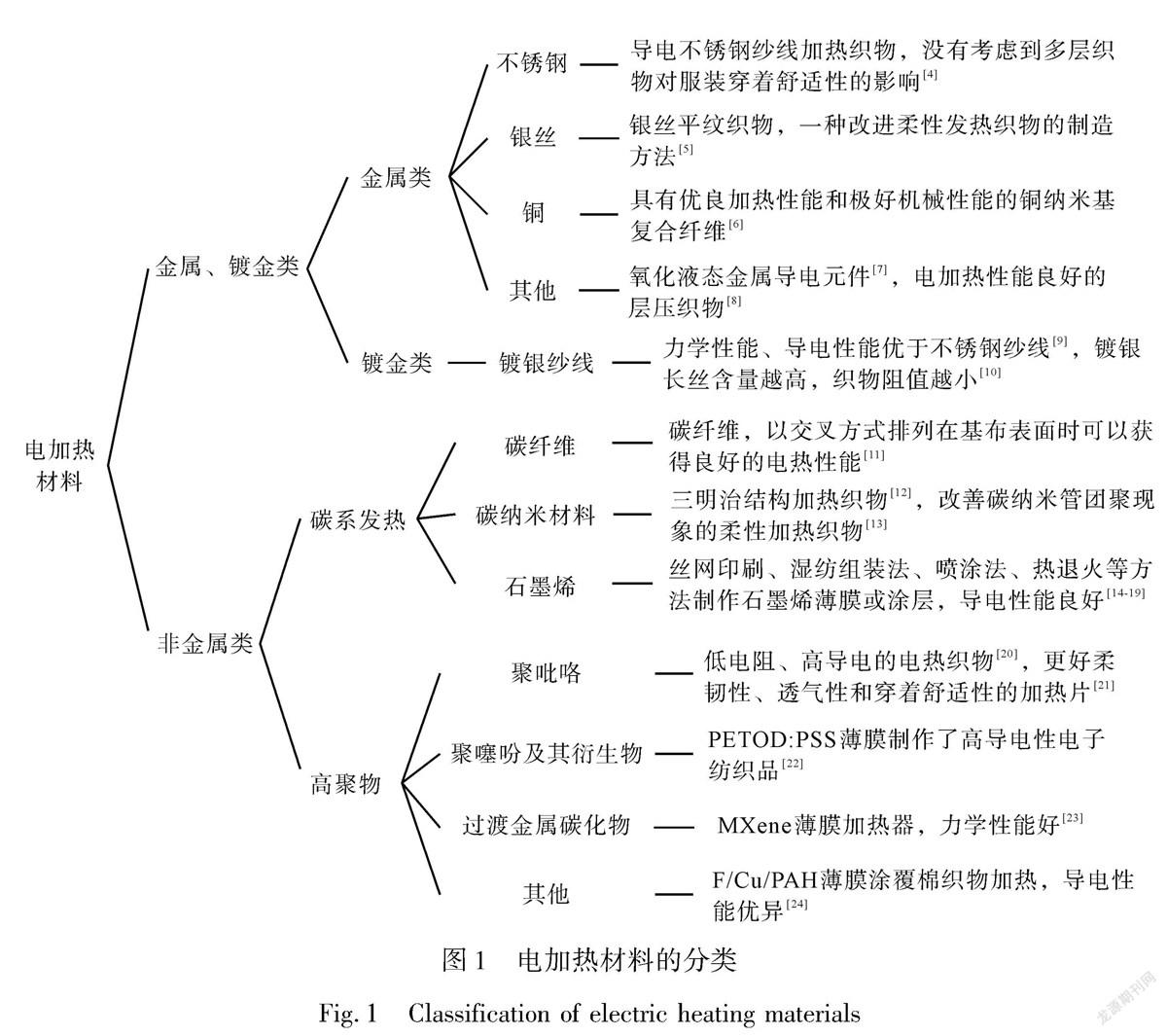

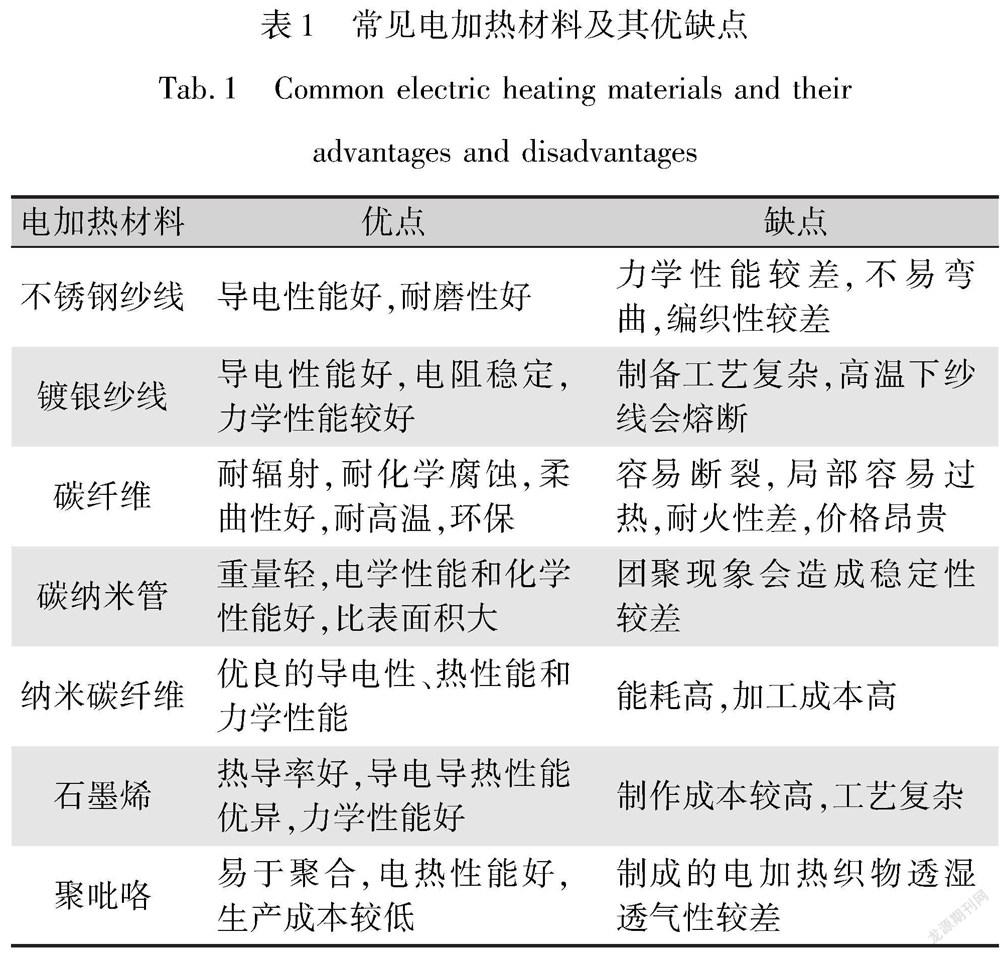

电加热材料主要分为金属、镀金和非金属类加热材

料,如图1所示。金属类加热材料主要有铁、铜、银、不锈钢和铝等金属或合金类材料,通常将金属丝制成导电纱线或包覆纱线,然后将其织入织物或者其他材料中制成电加热元件。镀金属类电加热材料通过电镀、化学镀和真空镀等方法将纯金属镀在普通纤维或者纱线上制成,其中镀金纱线的含量影响电加热材料的性能。镀银纱线导电性能优异,阻值稳定,延展性好,是目前金属镀金类加热材料中最常用的一种。

非金属类电加热材料来源广泛,主要有碳系发热材料、导电高聚物等。相对于金属类加热材料,非金属类电加热材料模量低,延展性好,便于织造,制成服装更贴合人体。碳系发热材料主要有碳纤维、碳纳米材料和石墨烯发热材料等,目前使用在电加热材料中的导电高聚物较多的有聚吡咯(PPy)、聚噻吩及其衍生物和过渡金属碳化物(MXene)。

虽然电加热材料的研究取得了相当大的进展,但在实际应用中仍然存在一些具有挑战性的问题。如表1所示为一些常用电加热材料性能优劣的总结。石墨烯、碳纳米材料和金属纳米线等电加热材料的能耗减少、加工过程优化和经济化生产是未来需要重点发展的,金属类加热材料的柔性化、轻薄化,非金属加热材料的耐洗性能、耐磨性能也是需要进一步解决的问题。

2 电加热服的加工工艺

电加热服的加工工艺主要有三种:直接通过电热丝制作、放置电加热片制作、通过电热薄膜或者涂层制作。

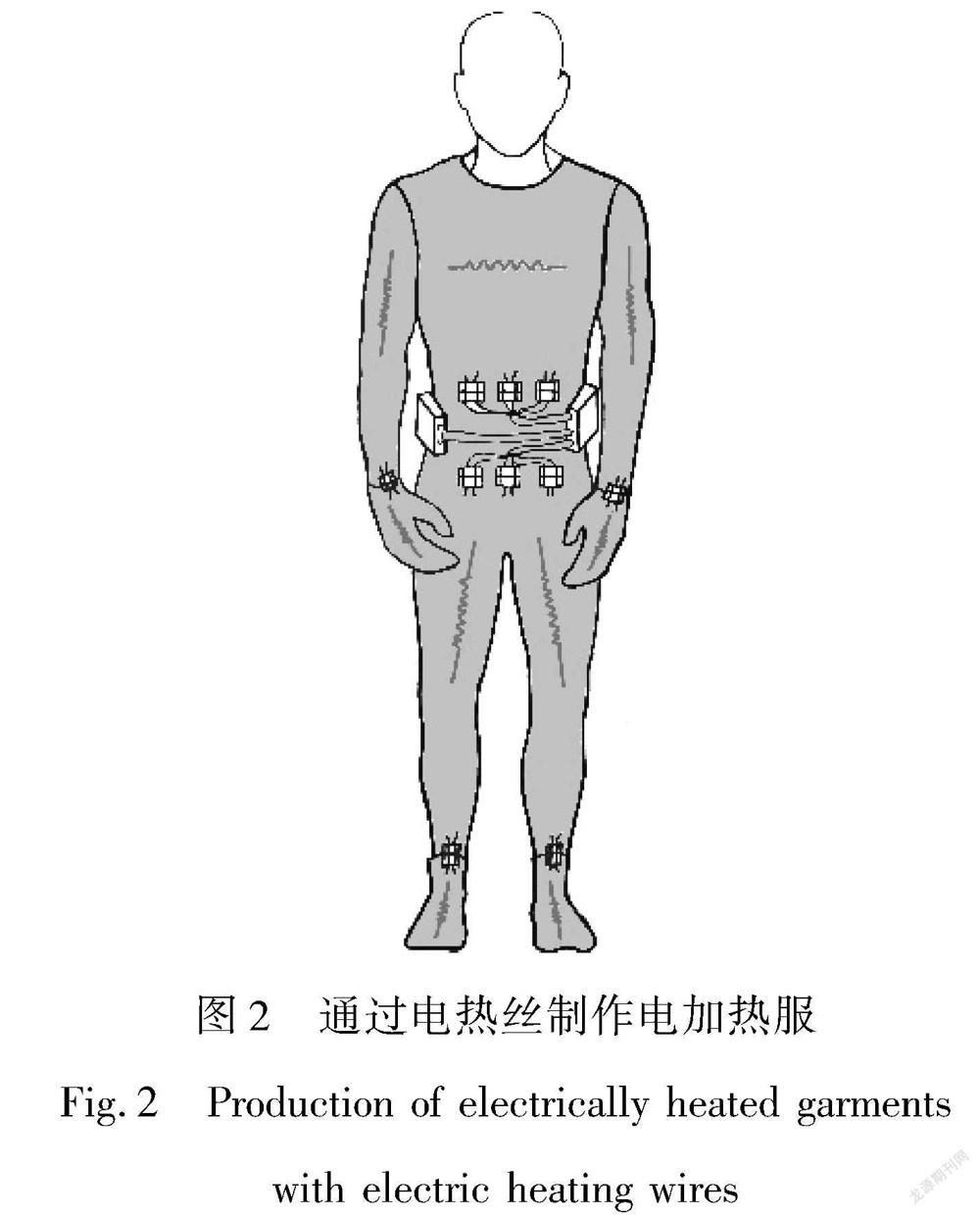

2.1 通过电热丝制作

将電热丝直接缝制到服装中,或者先缝制到织物上制作电加热元件,再将其置入电加热服装是较早的制作电加热服的方式,如图2所示。这种加工工艺的优点在于发热效率高,加热位置覆盖广。

Leveratt [25] 将柔性电加热线缝制到织物上,制成电加热服装,包括上衣、裤子、手套和袜子,通过电子控制器控制每根电热丝的电流,多个电路器控制供应的功率,自动且独立调节服装加热功率。Doganay等 [26] 用银纳米线制备了电加热手套,当施加3.5 V电压加热时,手套的温度分布相当均匀,且温度上升到70 ℃只需要100 s。Cheng等 [6] 利用铜纳米线基复合纤维织成保暖织物,并将其与单片机集成到服装中,设计了一个可穿戴的智能个人取暖系统,实现了取暖织物与智能手机的交互,为行动不便的人提供了一种有效取暖的解决方案。另外,将其固定在护膝和婴儿模型胸部位置,经红外热像显示,加热织物对相应部位进行了有效的加热,通过手机APP可以实现温度监测和加热温度控制,应用前景较好。

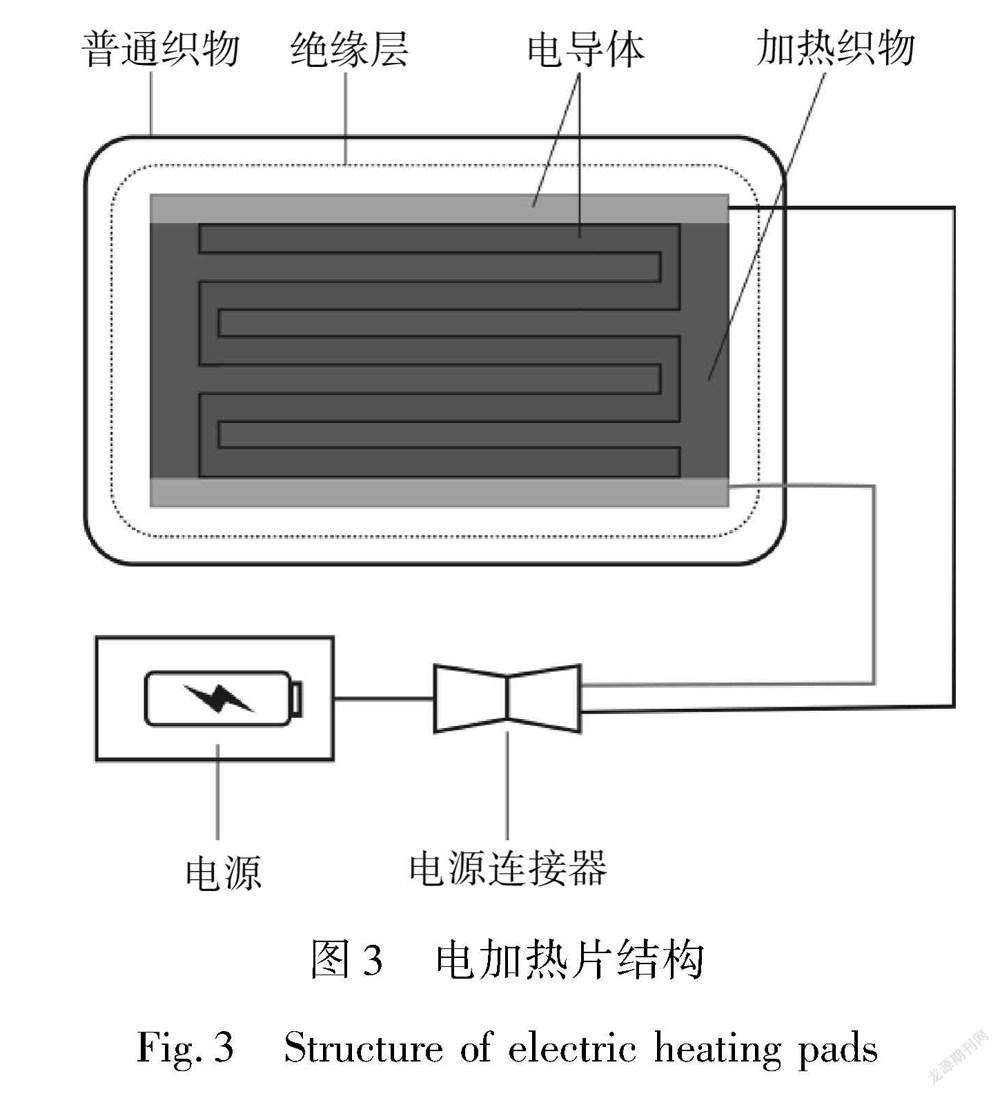

2.2 放置电加热片制作

电加热片也是常见的电加热元件,是目前最常用的制作电加热服的手段,其结构如图3所示。通常利用口袋放置电加热片,或者直接将电加热片缝制到服装中。根据所需要的加热部位不同,可以在不同位置放置加热片,根据用户要求,可以制作不同形状、大小的加热片。研究指出 [27] ,人体保暖不足的部位主要在前胸、肩部、腹部、前臂和小腿,因此加热片的放置应主要集中在这些区域。

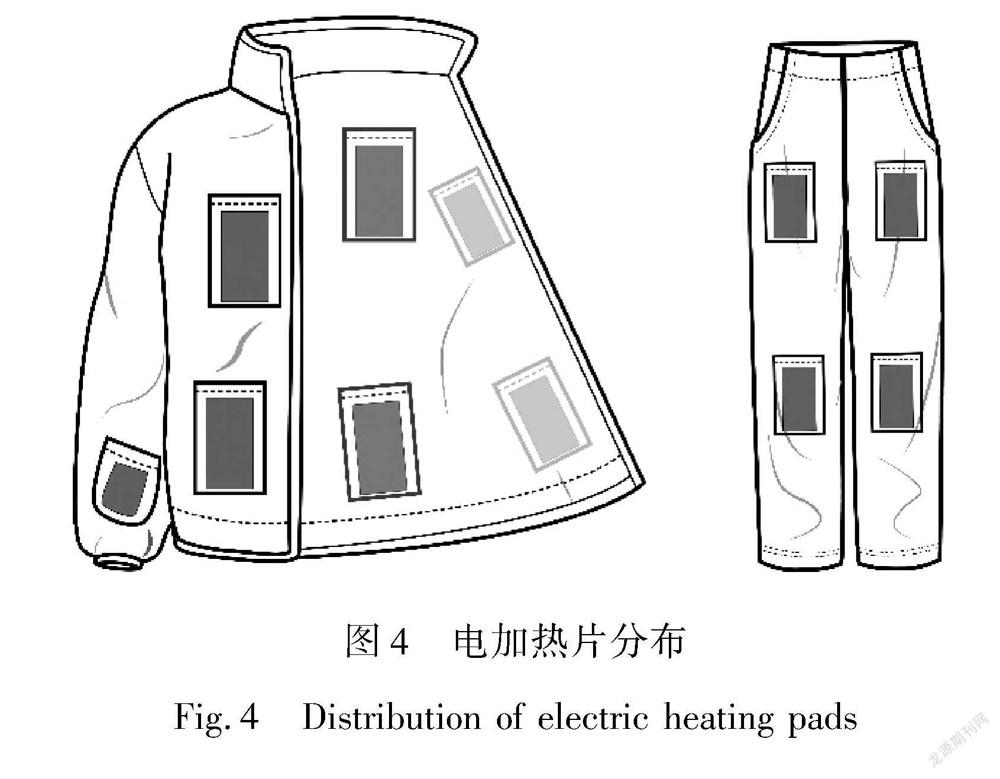

唐世君等 [28] 研制了一种由背心、电池和加热载体组成的电加热服装,背心前身两个口袋用来放置电池,发热载体布置在后背、前腹部,智能遥控电池有四档电压脉冲输出,电热服发热时间大于3 h,服装表面温度高于50 ℃。WU等 [29] 将基于热舒适控制模型设计得到电加热片应用于服装中,通过低温实验证明了电加热片对于人体热舒适调节的舒适性。Udayraj等 [30] 设计出由加热夹克和裤子组成的电加热服,放置12个加热片,两个在腹部,三个在上背部,三个位于下背部,另外在臀部和骨盆处各有两个,通过独立的两个电池提供电压,加热时间分别可达6 h和14.8 h。李佳怡等 [31] 研制了具有智能温控装置的新型防寒服,具有多层结构,上衣加热片位于防寒服内胆腹部和后腰,裤子加热片放置在两侧膝盖。图4是对常见电加热服中加热片分布情况进行的展示。

在低温环境,手指灵活性能会受到很大影响,温度过低也会导致冻疮、麻痹,因此手部保暖也很重要。马妮妮等 [32] 研制了一款轻便、可持续保暖的温控电热防护手套,包括手套本体、加热元件和智能调温装置,加热片形状为五指型,放置在手套背部隔热层和内里之间,通过真人实验发现电热手套能提供较好的保暖性能,提高手指舒适性。

2.3 涂覆电热薄膜或涂层制作

将电热薄膜或涂层涂覆在织物表面,也能得到电热性能良好的电加热服,制作方便,使用灵活,也常用于电加热服的制作中。Zhang等 [33] 在织物表面涂覆导电聚合物亚乙基二氧噻吩(PEDOT)涂层, 制备出一款柔软、质轻、透气的电热手套,施加电压几秒后,佩戴者就能感受到热量从织物传递到手指。有学者将MXene分别涂覆在棉手套、纤维素纤维表面制作了电热手套和电热护颈垫,热性能优良,温度分布均匀 [23-24] 。许冰等 [35] 基于石墨烯电加热膜研究出一款自动控温运动服,这种加热膜可以在10 V电压下连续工作500 h,5 000次稳定发热。

通过电热丝直接制作电加热服的方法直接有效,但是制作工艺复杂,简化制作工艺是一大挑战,如何将其合理地嵌入服装而不影响服装舒适性是未来研究重点。外置电加热片虽然可以根据人体部位所需进行加热,但是电加热服的加热均匀度得不到保障。除此之外,电加热片的厚度会影响舒适性,轻薄化电加热片是未来电加热服研究的热点。电加热片与服装的结合方式需要更加完善,以保证电加热服的舒适性。在织物表面涂覆电热薄膜或涂层虽然方便经济,但是薄膜和涂层的耐洗性能到目前为止都没有很好的保障,在长时间使用过后性能下降,且通过这种方式制作的电加热服,其透湿透气性能较差。

3 电加热服的性能评价

3.1 电安全性能

电加热服的电安全问题是人们一直关心的问题,到目前为止还没有关于电加热服电安全性能的一套完整评价体系。郑兆和等 [36] 将电加热服装的电安全性能分为移动电源安全性、电器安全性、电磁兼容性、电发热安全性、特殊存放安全性的要求。张妍 [37] 研究指出电加热服一般贴身穿着,所以存在一定安全隐患,应确保输出电压低于12 V,输出电流在2 A以下,同时设置短路保护装置,确保着装者人身安全。除此之外,电加热服应该注意的电安全问题还有:电路封装得严谨,防止出现短路或者意外接触液体后出现安全问题;电路设计的合理性,防止发热温度过高而对人体造成损伤;电加热服的防老化性能要好,保证在存放过程中不会造成导线脱胶、裸露等情况。

3.2 电热性能

电加热服的电热性能主要包括电热元件的热稳定性、加热均匀度、加热功率密度和升温速度等 [38] 。

热稳定性是指在稳定状态下工作温度的电阻稳定性和加热功率稳定性,是评价电热服电热性能的重要指标。其变化越小,说明电加热服的热稳定性越好。Ou等 [7] 通过红外热像系统测试由液态金属氧化薄膜制成的加热服装的热性能,其热像图显示在外力作用下,加热元件的电阻变化率小。

加热均匀度是指在稳定工作状态下加热织物表面温度的一致性,通常利用红外热像仪来进行测评。通过服装表面温度分布计算温度分布系数,其值越小说明温度分布越均匀。卢俊宇等 [39] 对用镀银纱线制作的加热织物进行了电热性能测试,通电后织物温度先上升后稳定,当镀银纱线与涤纶纱线横列排列方式为1 ︰ 2时,织物表面温度分布较为均匀。

加热功率密度是指单位面积内电加热服的加熱功率,常用数字万用表测量功率,除以电加热服的面积即得到加热功率密度,其值越大越好。Bhat等 [21] 测试了浸渍聚吡咯而制成的电加热织物,当施加稳定电压时,其产生的热量可达 1 000 W/m 2 ,使用9 V便捷式电源就能产生足够的热来维持体温。

升温速度是指电热服达到预设温度的快慢,升温速度越 高,电加热服就能更快地对环境做出反应。随着电加热材料

的不断发展,电加热服的升温速度已经有了很大提升,在几十秒内就能达到预设温度。Zhang等 [33] 测量了PEDOT涂层棉织物的电阻和加热性能,由其制作的加热手套只需一节3 V电池,就能在10~20 s后实现暖手效果。

3.3 热舒适性能

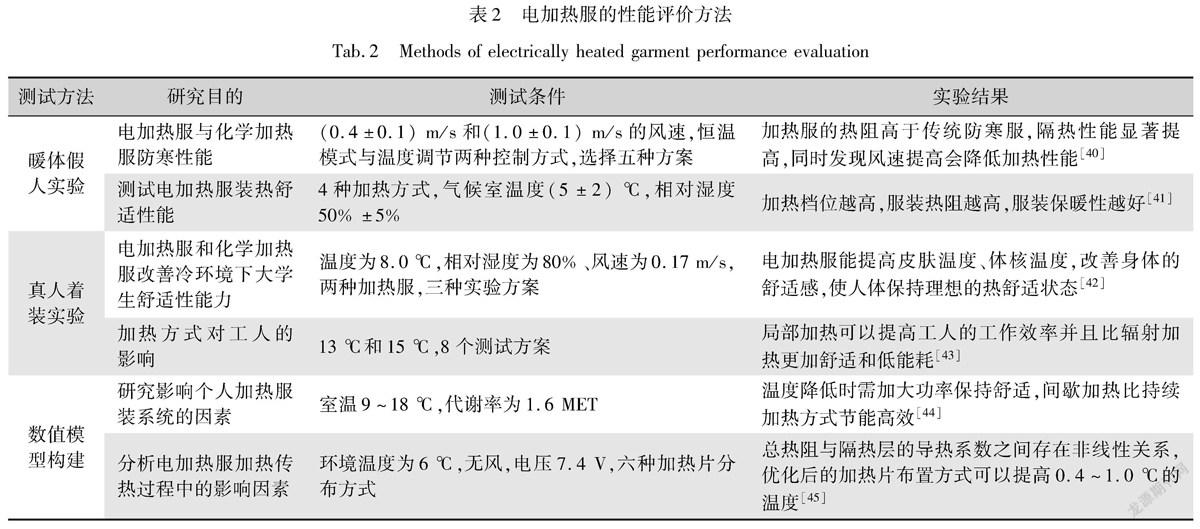

电加热服的热舒适性能通常与电热性能放在一起进行,一般通过暖体假人实验、真人着装实验和数值模型构建进行测评。暖体假人实验就是利用人体模型模拟人体与环境的热交换过程,在过程中测量电加热服装的温度变化、温度分布、加热功率等。真人着装实验即通过真人穿着电加热服装,在特定环境下对所穿着服装的主观评价,同时记录人体生理反应。数值模型构建就是通过人体、服装和环境之间的热传导、对流、辐射等建立理论模型,为电加热服的优化设计提供理论依据,方便调节参数。电加热服性能评价的流程如图5所示,表2为电加热服性能评价的方法比较及实验结果。

分析表2可知,暖体假人实验可以客观表征服装的热阻、热流量等物理指标,但不能体现人体真实热感觉。真人着装实验客观地评价穿着服装时的热感觉,可结果受实验对象影响,且实验成本高。 数值模型构建可以模拟人体与外界的热交换,但是受模拟环境的影响,有些条件模拟时会比较困难,往往会忽略一些外界因素的影响,模拟结果与实际情况存在一定误差。

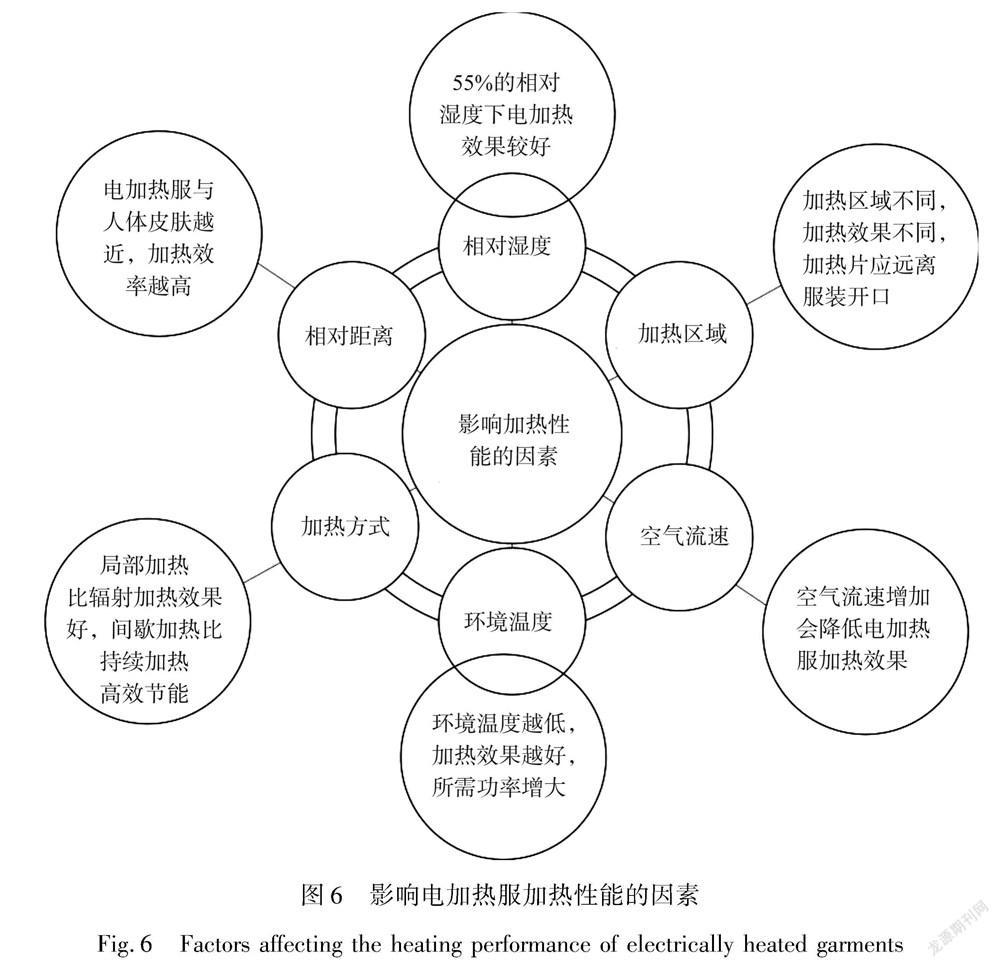

从以上研究来看,在不同条件下电加热服的热舒适性能有

所区别,对影响电加热服热舒适性能的研究可以为其设计提供更多依据。图6是影响电加热服加热性能的因素分析 [46-51] ,在设计过程中应充分考虑这些条件。目前较多研究重点集中在环境对于电加热服性能的影响,而关于电加热片形状对电热性能和热舒适性能的影响鲜有涉及。电热服的电热性能和热舒适性能已有比较完善的评价体系,但是对于电加热服的安全性能研究较少,完整的评价方案和标准有待进一步探索。

4 结 语

电加热材料包括金属与镀金类电加热材料和非金属类电加热材料,通常将其制成电加热元件集成到服装中制成电加热服。本文对制作电加热服的方式进行了分类,总结了三种方式的优缺点,并提出改进建议。对电加热服性能评价的指标做了详细阐述,介绍了性能评价的方法,综合现阶段存在的一些问题,提出了未来电加热服研究的展望。

1) 加热区域的设计。不同的加热片放置位置对电加热服的加热效率有不同的影响,未来可以研究不同加热区域组合对电加热服热舒适性能的影响,提高加热效率的同时节约能量。

2) 加工工艺的优化。将电热元件置入服装当中会造成服装舒适性降低,服装一体化成型技术的发展为电加热元件的置入提供一种解决方案。在同一件电加热服装的不同加热区域可以结合不同的加热方式,弯曲形变较多的部位可以使用电热膜,躯干部位用加热片,足部利用加热丝等。

3) 电加热服的功能升级。目前电加热服的研究多在提高人整体温度角度,但是人体各个部位对热的敏感程度不同,未来的研究应该合理量化电加热服各局部的热量,根据各部位的热需求进行设计,结合传感器技术,实现电加热服装的分区域智能加热,提高保暖性能。同时在电安全问题上,无线充电技术的发展为电加热服的电源问题提供了新的解决方案,既可以减少导线的使用和线路封装的安全问题,也能提高电加热服的轻便性。

4) 性能评价方式改进。目前对于电加热服的性能测試主要在人工气候仓中进行,并且温度设置多为稳态温度,实际使用中环境温度是实时变化的,所以需要对动态温度变化下电加热服的性能进行评价,得出的结果更加客观。

参考文献:

[1] XU P, WANG F, ZHAO M. Electrically Heated Clothing (EHC) for Protection Against Cold Stress[M]//Protective Clothing. Cambridge: Woodhead Publishing, 2014: 281-295.

[2]WANG F, GAO C, KUKLANE K, et al. A review of technology of personal heating garments[J]. International Journal of Occupational Safety and Ergonomics, 2010, 16(3): 387-404.

[3] 赵邵徽, 宋英莉. 电发热服的设计要素[J]. 轻纺工业与技术, 2018, 47(5): 58-60.

ZHAO Shaohui, SONG Yingli. Design elements of electric heating clothing[J]. Light and Textile Industry and Technology, 2018, 47(5): 58-60.

[4]KAYACAN O, BULGUN E Y. Heating behaviors of metallic textile structures[J]. International Journal of Clothing Science and Technology, 2009, 21(2/3): 127-136.

[5]LIU H, ZHANG Y, CHEN L, et al. Development and characterization of flexible heating fabric based on conductive filaments[J]. Measurement, 2012, 45(7): 1855-1865.

[6]CHENG Y, ZHANG H, WANG R, et al. Highly stretchable and conductive copper nanowire based fibers with hierarchical structure for wearable heaters[J]. ACS Applied Materials & Interfaces, 2016, 8(48): 32925-32933.

[7] OU M L, QIU W K, HUANG K Y, et al. Ultrastretchable liquid metal electrical conductors built-in cloth fiber networks for wearable electronics[J]. ACS Applied Materials & Interfaces, 2019, 12(6): 7673-7678.

[8]GUO Z, SUN C, WANG J, et al. High-performance laminated fabric with enhanced photothermal conversion and joule heating effect for personal thermal management[J]. ACS Applied Materials & Interfaces, 2021, 13(7): 8851-8862.

[9] 吴磊, 李凯林, 李龙. 柔性传感针织物用不锈钢纱线与镀银纱线的性能[J]. 上海纺织科技, 2021, 49(3): 43-46.

WU Lei, LI Kailin, LI Long. The properties of stainless steel yarn and silver-plated yarn for knitted fabric-based sensors[J]. Shanghai Textile Science & Technology, 2021, 49(3): 43-46.

[10] 许静娴, 刘莉, 李俊. 镀银纱线电热针织物的开发及性能评价[J]. 纺织学报, 2016, 37(12): 24-28.

XU Jingxian, LIU Li, LI Jun. Development and performance evaluation of electrically-heated textile based on silver-coated yarn[J]. Journal of Textile Research, 2016, 37(12): 24-28.

[11] 张猛, 富秀荣. 碳纤维发热织物的电热性能研究[J]. 合成纤维, 2015, 44(11): 25-27.

ZHANG Meng, FU Xiurong. Study on electrothermal properties of carbon fiber heating fabric[J]. Synthetic Fiber in China, 2015, 44(11): 25-27.

[12] QIU K L, ELHASSAN A, TIAN T H, et al. Highly flexible, efficient, and sandwich-structured infrared radiation heating fabric[J]. ACS Applied Materials & Interfaces, 2020, 12(9): 11016-11025.

[13] ARBAB AA, MEMON A A, SUN K C, et al. Fabrication of conductive and printable nano carbon ink for wearable electronic and heating fabrics[J]. Journal of Colloid and Interface Science, 2019, 539: 95-106.

[14] 崔志英, 楊诗慧, 张妍, 等. 石墨烯电加热服装的服用性能研究[J]. 毛纺科技, 2018, 46(8): 1-5.

CUI Zhiying, YANG Shihui, ZHANG Yan, et al. Evaluation on performance of electrically heated graphene garment[J]. Wool Textile Journal, 2018, 46(8): 1-5.

[15] DING J, ZHAO H, WANG Q, et al. An ultrahigh thermal conductive graphene flexible paper[J]. Nanoscale, 2017, 9(43): 16871-16878.

[16]LIU Z, LI Z, XU Z, et al. Wet-spun continuous graphene films[J]. Chemistry of Materials, 2014, 26(23): 6786-6795.

[17] 陈志华, 张炜栋, 郝云娜, 等. 石墨烯复合棉织物的电热性能研究[J]. 棉纺织技术, 2019, 47(4): 10-13.

CHEN Zhihua, ZAHNG Weidong, HAO Yunna, et al. Study on electrothermal property of graphene composited cotton fabric[J]. Cotton Textile Technology, 2019, 47(4): 10-13.

[18] 黄坤, 曾宪光, 裴嵩峰, 等. 低压高效石墨烯复合涂料的电热性能研究[J]. 涂料工业, 2016, 46(4): 13-17.

HUANG Kun, ZENG Xianguang, PEI Songfeng, et al. Research on low voltage high electric heating performance of graphene composite coatings[J]. Paint & Coatings Industry, 2016, 46(4): 13-17.

[19]WANG R, XU Z, ZHUANG J H, et al. Highly stretchable graphene fibers with ultrafast electrothermal response for low-voltage wearable heaters[J]. Advanced Electronic Materials, 2017, 3(2): 1600425.

[20]LEE J Y, PARK D W, LIM J O. Polypyrrole-coated woven fabric as a flexible surface-heating element[J]. Macromolecular Research, 2003, 11(6): 481-487.

[21]BHAT N V, SESHADRI D T, NATE M M, et al. Development of conductive cotton fabrics for heating devices[J]. Journal of Applied Polymer Science, 2006, 102(5): 4690-4695.

[22]JIN I S, LEE J U, JUNG J W. A facile solution engineering of PEDOT: PSS-coated conductive textiles for wearable heater applications[J]. Polymers, 2021, 13(6): 945-954.

[23] PARK T H, YU S, KOO M, et al. Shape-adaptable 2D titanium carbide (MXene) heater[J]. ACS Nano, 2019, 13(6): 6835-6844.

[24]LI X, LI Y, GUAN T, et al. Durable, highly electrically conductive cotton fabrics with healable superamphiphobicity[J]. ACS Applied Materials & Interfaces, 2018, 10(14): 12042-12050.

[25]LEVERATT B C. Electrically heated garments: US patent, 5032705[P]. 1991-07-16.

[26] DOGANAY D, COSKUN S, GENLIK S P, et al. Silver nanowire decorated heatable textiles[J]. Nano Technology, 2016, 27(43): 435201.

[27] 吴黛唯, 李红彦, 戴艳阳, 等. 加热装置在防寒服中的位置及其热效用[J]. 纺织学报, 2020, 41(6): 118-124.

WU Daiwei, LI Hongyan, DAI Yanyang, et al. Thermal function effectiveness and location of heating device in cold protective clothing[J]. Journal of Textile Research, 2020, 41(6): 118-124.

[28] 唐世君, 郭诗珧. 电加热服装的研制[J]. 中国个体防护装备, 2013(6): 5-8.

TANG Shijun, GUO Shiyao. Development of electric heating clothing[J]. China Personal Protective Equipment, 2013(6): 5-8.

[29]WU J X, LIAO Y C. Self-regulated thermal comfort control for wearable heating device[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 121: 74-80.

[30]UDAYRAJ, LI Z, KE Y, et al. A study of thermal comfort enhancement using three energy-efficient personalized heating strategies at two low indoor temperatures[J]. Building and Environment, 2018, 143: 1-14.

[31] 李佳怡, 盧业虎, 叶鑫, 等. 智能发热户外防寒服装研制与性能评价[J]. 东华大学学报(自然科学版), 2018, 44(1): 80-86.

LI Jiayi, LU Yehu, YE Xin, et al. Performance evaluation of outdoor cold protective clothing with smart heating function[J], Journal of Donghua University (Natural Science), 2018, 44(1): 80-86.

[32] 马妮妮, 许凡菲, 卢业虎, 等. 温控电热防护手套研制与性能评价[J]. 现代纺织技术, 2018, 26(5): 26-33.

MA Nini, XU Fanfei, LU Yehu, et al. Development and performance evaluation of electrically heated protective gloves with thermoregulation function[J]. Advanced Textile Technology, 2018, 26(5): 26-33.

[33]ZHANG L, BAIMA M, ANDREW T L. Transforming commercial textiles and threads into sewable and weavable electric heaters[J]. ACS Applied Materials & Interfaces, 2017, 9(37): 32299-32307.

[34] ZHAO X, WANG L Y, TANG C Y, et al. Smart Ti 3C 2T x MXene fabric with fast humidity response and joule heating for healthcare and medical therapy applications[J]. ACS Nano, 2020, 14(7): 8793-8805.

[35] 许冰, 钟冬根, 龚龑, 等. 基于石墨烯加热膜片的自动控温运动服[J]. 粘接, 2020, 45(3): 23-27.

XU Bing, ZHONG Donggen, GONG Yan, et al. Automatic temperature control sportswear based on graphene heating diaphragm[J]. Adhesion, 2020, 45(3): 23-27.

[36] 郑兆和, 伍伟新. 电加热服装的电学安全性和发热功能性评价方法[J]. 山东纺织科技, 2017, 58(4): 22-25.

ZHENG Zhaohe. WU Weixin. Evaluation method of electrical safety and heating function of electrically heated clothing[J]. Shandong Textile Science & Technology, 2017, 58(4): 22-25.

[37] 张妍. 电加热服装的服用性能研究[D]. 上海: 东华大学, 2017.

ZHANG Yan. Evaluation on Performance of Electrically Heated Garments[D]. Shanghai: Donghua University, 2017.

[38] 唐灿, 刘荣平, 徐志强. 电加热服装服用性能研究进展[J]. 轻纺工业与技术, 2021, 50(2): 58-59.

TANG Can, LIU Rongping, XU Zhiqiang. Research progress on wearability of electric heating clothing[J]. Light and Textile Industry and Technology, 2021, 50(2): 58-59.

[39] 卢俊宇, 陈莉, 刘皓. 针织加热织物的设计及其电热性能测试[J]. 上海纺织科技, 2017, 45(3): 31-34.

LU Junyu, CHEN Li, LIU Hao. Design and electrothermal performance of knitted heating fabric[J]. Shanghai Textile Science & Technology, 2017, 45(3): 31-34.

[40]SONG W, LAI D, WANG F. Evaluating the cold protective performance (CPP) of an electrically heated garment (EHG) and a chemically heated garment (CHG) in cold environments[J]. Fibers and Polymers, 2015, 16(12): 2689-2697.

[41] 田苗, 張向辉, 沈翀翌. 电加热服装的研究进展及热舒适性能评价[J]. 上海纺织科技, 2018, 46(8): 20-24.

TIAN Miao, ZHANG Xianghui, SHEN Chongyi. Research progress of electrically heated garment and evaluation on its thermal comfort performance[J]. Shanghai Textile Science & Technology, 2018, 46(8): 20-24.

[42]SONG W, WANG F, ZHANG C, et al. On the improvement of thermal comfort of university students by using electrically and chemically heated clothing in a cold classroom environment[J]. Building and Environment, 2015, 94: 704-713.

[43]WANG H, XU M, BIAN C. Experimental comparison of local direct heating to improve thermal comfort of workers[J]. Building and Environment, 2020, 177: 106884.

[44]WANG F, KANG Z, ZHOU J. Model validation and parametric study on a personal heating clothing system (PHCS) to help occupants attain thermal comfort in unheated buildings[J]. Building and Environment, 2019, 162: 106308.

[45]HUANG Q, XING G, YANG F, et al. Modelling and experimental study on electrically heating garment to enhance personal thermal comfort[C]//IOP Conference Series: Earth and Environmental Science. Bristol: IOP Publishing Limited, 2021, 696(1): 012046.

[46]KIM H, LEE S. Effect of relative humidity condition on electrical heating textile coated with graphene-based on cotton fabric[J]. Fibers and Polymers, 2021, 22(1): 276-284.

[47] 崔志英, 王綠英, 杨诗慧. 加热区域设计对电加热服热舒适性的影响[J]. 棉纺织技术, 2021, 49(5): 33-36.

CUI Zhiying, WANG Lüying, YANG Shihui. Influence of heating zone design on electrically heated garments thermal comfort[J]. Cotton Textile Technology, 2021, 49(5): 33-36.

[48] 宋英莉, 郭宇微, 唐志娟, 等. 基于人体局部热需求差异的电发热服发热片放置位置研究[J]. 轻纺工业与技术, 2018, 47(10): 13-15.

SONG Yingli, GUO Yuwei, TANG Zhijuan, et al. Study on the placement position of electric heating clothing heating plate based on the difference in local heat demand of human body[J]. Light and Textile Industry and Technology, 2018, 47(10): 13-15.

[49]MA N, LU Y, XU F, et al. Development and performance assessment of electrically heated gloves with smart temperature control function[J]. International Journal of Occupational Safety and Ergonomics, 2020, 26(1): 46-54.

[50]PARK H, HWANG S, LEE J, et al. Impact of electrical heating on effective thermal insulation of a multi-layered winter clothing system for optimal heating efficiency[J]. International Journal of Clothing Science and Technology, 2016, 28(2): 254-264.

[51] 范敏, 张辉. 电热服加热功率与内外层服装热阻的关系探讨[J]. 北京服装学院学报(自然科学版), 2018, 38(2): 30-34.

FAN Min, ZHANG Hui. Discussion on the relationship between heating power of electric garment and thermal resistance of inner and outer garment[J]. Journal of Beijing Institute of Fashion Technology (Natural Science Edition), 2018, 38(2): 30-34.

Research status and progress of electrically heated garments

LIN Lei a, WANG Hongfu b, KE Ying b

(a.College of Textile Science and Engineering; b.School of Design, Jiangnan University, Wuxi 214122, China)

Abstract:

As one of the important components of intelligent heated clothing, the electrically heated garment uses electrical energy as the energy source and converts it into heat energy through the built-in electric heating elements in the clothing to actively supply heat for human body, boasting the advantages of long heating time, adjustable heating temperature and good fit to the human body. In recent years, the positive role of electrically heated garments in the field of cold-proof and thermal clothing has been proved by a lot of studies. The development of electric heating materials and the research of heating body parts have promoted the development of electrically heated garments, providing vital references for the design of electrically heated garments. To reveal the relationship between the materials, processing technology, and thermal protection performance of electrically heated garments, and to analyze the key issues in the process of electrically heated garment design, this paper summarizes the development of electric heating materials. At the same time, this paper introduces the production process of the electrically heated garments, proposes the method of electrically heated garment performance evaluation, and prospects the development of electrically heated garment based on the current research.

The materials used for electrically heated garments are mainly divided into two types: metallic and gold-plated materials and non-metallic materials. Metallic and gold-plated electric heating materials are not readily implanted into clothing despite their high heating efficiency. On the contrary, non-metallic electric heating materials are easy to manufacture electric heating elements so that they are used in electrically heated garments. Although non-metallic electric heating materials are convenient and simple, and cost little for production, they have the drawback of short lifespan, which needs to be improved. There are three main processes for the production of electrically heated garments respectively by using electric heating wires directly, placing electric heating pads, and applying electric heating films or coatings. Among them, the production of electrically heated garments by directly using electric heating wires is direct and efficient, but the process is complex. Placing electric heating pads is convenient and simple, but it would easily cause uneven heating. Despite the low cost and flexible use of coating electric heating film or coating, the clothing moisture permeability, air permeability, and durability are not ideal. As a result, there is still great potential for the research of production process of electrically heated garments.

The electrically heated garment performance evaluation is mainly carried out from three main aspects: electrical safety performance, electrical heat performance, and thermal comfort performance. An objective evaluation of the performance of electrically heated garment could be carried out by combining the three aspects. The current means of testing the performance of electrically heated garments mainly include thermal manikin experiments, real person attire experiments, and numerical model construction. The thermal resistance, heat flow, and other objective physical indicators of electrically heated garments can be characterized by thermal manikin experiments, but they cannot reflect the real thermal sensation of the human body. The performance of electrically heated garments can be evaluated by real person attire experiments based on the objective and subjective feelings of the human body. The results are highly reliable, but the experiment cost is high. The numerical model construction method can simulate the heat exchange between the human body, clothing, and the environment, simulate the application environment of the electrically heated garments by changing the parameters. Because the results from this method have some deviation from the actual operating environment, they finally need to be verified by real person attire experiments.

Graphene and carbon nanotube heating materials as the current hotspots of the research ofelectrical heating materials can be made into coatings or thin films coated on the surface of fabrics to make electric heating elements, which have high heating efficiency and good flexibility. However, the production cost of these materials is high, the process is complicated, and the aging resistance needs to be improved. The research on the electrically heated garment performance evaluation is mainly focused on the electric heating and thermal comfort performance, but there is little research on the electric safety performance. Therefore, a complete system is needed to evaluate the performance of electrically heated garments.

As the research on the electrically heated garments has proven that it has great potential in the field of cold-proof clothing, the development of electric heating materials has also provided the basis for the development of electrically heated garments. Although the research on electric heating materials, cold-proof clothing, and human thermal comfort has accumulated many valuable results for electrically heated garments, it is necessary to carry out more studies on the design of the heating areas of the electrically heated garments. Limited by the production process, the electrically heated garments have not yet been widely popularized, hence optimizing the processing is also a challenge. At the same time, how the performance of the electrically heated garments is evaluated needs to be improved to ensure that users can accurately select an appropriate suit. Technological development will facilitate the functional upgrading of electrically heated garments, and integrating wireless charging technology into the design of the electrically heated garments is an effective way to reduce the wiring arrangement. Artificial intelligence can realize separate local heating according to the thermal needs of each body part, thereby meeting meet people’s requirements for thermal comfort in different environments.

Key words:

electrically heated garments; electric heating materials; processing technology; thermal protection performance; performance evaluation; thermal comfort

3764501186570