Multilevel Tests and Measurement Evaluation Methods for the Application of Composite Materials in Spacecraft Structures

LIU Bo,WANG Jinming,HAN Han,TAO Jingya,LIU Tao,ZHANG Xiaodong,YI Guo,LIU Yihui

(1.Shanghai Spaceflight Precision Machinery Institute,Shanghai 201600,China;2.Shanghai Aerospace Engineering Research Institute,Shanghai 201108,China;3.Shanghai Academy of Spaceflight Technology,Shanghai 201109,China)

Abstract:With the implementation of new-generation launch vehicles,space stations,lunar and deep space exploration,etc.,the development of spacecraft structures will face new challenges.In order to reduce the spacecraft weight and increase the payload,composite material structures will be widely used.It is difficult to evaluate the strength and life of composite materials due to their complex mechanism and various phenomena in damage and failure.Meanwhile,the structures of composite materials used in spacecrafts will bear complex loads,including the coupling loads of tension,pressure,bending,shear,and torsion.Static loads,thermal loads,and vibration loads may occur at the same time,which asks for verification requirements to ensure the structure safety.Therefore,it is necessary to carry out a systematic multi-level experimental study.In this paper,the building block approach(BBA)is used to investigate the multilevel composite material structures for spacecrafts.The advanced measurement technology is adopted based on digital image correlation(DIC)and piezoelectric and optical fiber sensors to measure the composite material structure deformation.The virtual experiment technology is applied to provide sufficient and reliable data for the evaluation of the composite material structures of spacecrafts.

Key words:composite material structure;spacecraft;multilevel test;measurement evaluation

0 Introduction

Lightweight design is an eternal subject of aircraft structure design.For a material,higher specific strength and stiffness means greater loadbearing capacity for the same mass and thus larger cost-efficiency ratio per unit structural weight.The reduction in the weight of a missile structure can expand the effective combat radius and improve the maneuverability of the missile.The reduction in the weight of a vehicle structure can increase the payload of the vehicle and reduce the cost of a single launch.The reduction in the weight of the structure of a satellite or spacecraft in orbit means that the satellite or spacecraft can carry more fuel to improve its in-orbit operating life and carrying capacity.Therefore,the research on the structural lightweight materials in the aerospace field has become the focus of attention at home and abroad.

The composite products represented by carbon fiber laminated structure,honeycomb sandwich struc‑ture,and grid structure have been increasingly used in spacecrafts such as carrier rockets and satellites.The typical applications of carbon fiber resin matrix composite materials to foreign spacecrafts are shown in Tab.1.

Tab.1 Typical applications of carbon fiber resin matrix composite materials to foreign spacecrafts

It can be seen that a great quantities of compos‑ite materials are used in the engine,tail,and thermal protective structures of weapon equipment,and a lot of epoxy resin-toughened composite materials are al‑so used in the main and secondary bearing structures of satellites.Similarly,rockets such as Arion and Falcon are equipped with inter stages,fairings,and adaptors made of sandwich or grillage composite ma‑terials and composite storage tanks,with which the carrying capacity is greatly improved.Composite materials have also been widely used in the missile body,missile wing,air rudder,satellite bearing cylinder,solar panel base plate,carrier rocket sup‑port cabin,fairing,and interstage of domestic weapon models.

Compared with metal materials,composite ma‑terials exhibit more complex mechanisms and more phenomena in damage and failure.Therefore,it is difficult to evaluate the strength and fatigue life of composite materials.As the main load-bearing structure of spacecrafts,composite materials are bearing very complex loads,including static loads,temperature loads,vibration loads,etc.Thus,it is also difficult to obtain the damage initiation,damage expansion,and final failure mode of composite mate‑rials under various loads through experiments.

In this paper,based on the available experiences in spacecraft development,the multi-level tests and measurement evaluation methods for the applica‑tions of composite materials in spacecraft structures are studied.

First,the building block approach(BBA)of“material-component-typical combination structurefull scale structure”is introduced.Second,the ad‑vanced measurement technologies based on digital image correlation(DIC)and piezoelectric sensors are reviewed and discussed.Finally,the analysis and evaluation methods of the combination of physical and virtual tests are presented.

1 BBA

With a large dispersion coefficient,the structure performance of composite materials is very different from that of metal materials,even in the design con‑cept.The BBAis usually adopted to analyze com‑posite materials.The multi-level test process gradual‑ly increases the size parameters of a specimen,and the complexity of the specimen increases with the in‑crease in the size parameters.

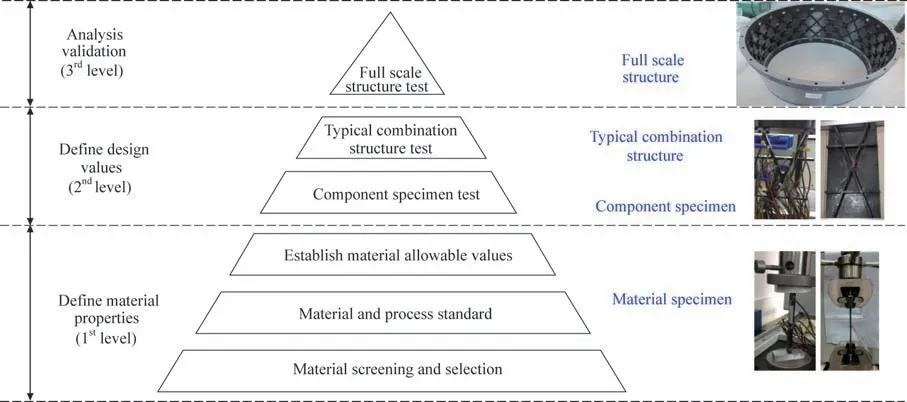

The test analysis and knowledge accumulation of each level are used as the basis for the analysis of the next level.Take the composite grille structure cabin as an example.The building block test is divid‑ed into four levels,i.e.,material specimen,compo‑nent specimen,typical combination structure,and full scale structure,as shown in Fig.1.

Fig.1 BBA for the composite grille structure

The material specimen analysis is the basis of the macroscopic mechanical analysis of composite ma‑terials.The material parameters are generally deter‑mined by a single plate test.The advanced composite monolayer contains the fiber phase and the matrix phase,which is equivalent to the orthotropic material in the macroscopic analysis.The most widely used test standard is the ASTM standard in the United States.Several typical tests are shown in Tab.2.Component specimens mainly include laminates,me‑chanical connectors,and adhesive connectors.Typi‑cal combination structure specimens include skin stiff‑ened panel,etc.The composite skin stiffened panel structure often occurs local buckling owing to the compression or shear.The analyses of damage and stability need to be considered.Full-scale structure level tests will be carried out to verify the overall strength,stiffness,and stability of the structure.

Tab.2 Standards for testing properties of composite materials

In the design of test schemes at all levels,the simulation method will be used to guide the test de‑sign,and the results will be used to modify the simu‑lation model.The tests and simulation results are used to improve the verification confidence.The dif‑ference between the real boundary conditions of the product and the feasible boundary conditions of the tests should be verified in the design of the test scheme.According to the material properties ob‑tained from the 1level tests and the mechanical properties of the 2level laminate,the comprehen‑sive elastic properties of the composite laminate are obtained,and the structural material properties of the finite element model are established.The possible sensitivities or key sources of differences(such as boundary conditions)are identified through a simula‑tion analysis,and the deviation between the tests and simulation is achieved to an acceptable consistency level through iterations.

In the development of space station engineering and cryogenic tank,the extreme temperature environ‑ment can cause the non-negligible internal stress be‑tween the components with the mismatched expan‑sion coefficients,and affect the mechanical properties and failure modes of the composite materials.The failure modes and related criteria are different from those of the mechanical properties at room tempera‑ture.The Hashin criterion and Mises criterion at room temperature are not applicable to the failure modes of the composites at very low temperatures.Therefore,temperature-force coupling tests are need‑ed.In order to meet the needs of long-term on-orbit stable operation of space station,structural perfor‑mance tests of composite materials affected by space temperature environment are carried out to obtain the performance degradation data of composite materials.In order to solve the delamination problem caused by the long-term in-orbit temperature alternation of com‑posite structures,the shear,tensile strength,and fracture toughness tests of composite layers after high temperature,low temperature,and high and low temperature cycles are carried out as the basis for the in-orbit life evaluation of composite materials.In or‑der to meet the development requirements of all-com‑posite cryogenic tank,experiments are carried out to obtain the mechanical properties of the composite structure in ultra-low temperature environment.The effects of lamination design on the longitudinal,trans‑verse,and shear mechanical properties of composite materials are studied,and the effects of adjacent lami‑nation are considered to verify the in-situ properties of the composite materials.At the same time,the damage mechanical parameters of carbon fiber composites are analyzed based on the nonlinear effect of mechanical testing of composite laminates.

Generally,the 1level tests are conducted for the screening,selection,and specification of a mate‑rial and the allowable value verification to determine the properties of the material.The 2level tests are carried out for the strength of components and com‑posite structures to determine the design value.The structural test pieces used in this level tests are also divided into standard type and non-standard type.The standard type test pieces are mainly used to de‑termine the allowable value of typical structure,while the non-standard test pieces are mainly verified according to the needs of specific models,e.g.,the assessment of the bearing limit of the structure.The material mechanical properties of the 2level are ob‑tained from the 1level tests,and the failure mode and bearing limit test results of the components and composite structure test pieces obtained from the 2level tests can provide a basis for the analysis and veri‑fication of the full-size component tests of the 3level.

2 Composite material test measurement technology

2.1 DIC optical full-field measurement method

The failure of composite structure is sudden,the initial failure locations are different among differ‑ent test pieces,and the test dispersion is high.There‑fore,in order to accurately evaluate the strength and fatigue life of composite structures,it is necessary to fully obtain the structural mechanical response data of the whole test process and the whole area of the test parts.However,the resistive strain gauge and dis‑placement gauge can only measure the response infor‑mation in the limited discrete area,and it is difficult to measure the response in the post-buckling stage of the structure during the tests.In addition,as a kind of heterogeneous medium material,the damage of composite materials is usually started at the discontin‑uous area such as the interface between fiber(micron level)and matrix.Moreover,the above strain mea‑surement method can only measure the macroscopic response of the composite structure,but cannot mon‑itor the deformation response of the microstructure.The DIC method is a non-contact optical measure‑ment method,which is developed on the basis of me‑chanical vision.The basic principle is to obtain the displacement vector of the measured object sur‑face by comparing and analyzing the speckle image deformation of the measured material surface and matching the position of the same shape scattered pat‑tern in the image,so as to obtain the strain data.

For material level and component level tests of composite materials,the DIC method is suitable for dynamic full-field strain measurement and strain mea‑surement in dynamic/static tensile tests,high tem‑perature tests,and dynamic fatigue tests,as shown in Fig.2.In addition,the DIC method can be used to measure the mechanical properties of composite materials in plane,and the thickness and the nonlin‑ear shear stress-strain relationship between layers is dominated by the resin matrix.The measure‑ment results of three-dimensional(3D)mechanical properties of composite materials provide basic mate‑rial parameters for the finite element model,which is the basis for predicting the service life of actual structures accurately.

Fig.2 Optical full-field measurement by the DIC method

For combination structure and component speci‑men tests of composite materials,the DIC method can improve the ability of 3D full-field measurement and monitoring of the whole process of tests,and fully obtain the data of the initial positions of the structural damage and damage propagation mode.As shown in Fig.3,in the shear tests of composite skin stiffened panels,the deviation between the strain measurement results of the DIC method and the strain gauge is less than 3% within the loading range of 400 kN.When the load increases,the cladding of the composite panel buckles and the debonding fail‑ure occurs between the strain gauge and the test piece.The DIC method can continue to measure the plane normal displacement and strain of the panel skin buckling,which provides a basis for the damage evolution modeling and mechanical property predic‑tion of structural products.

Fig.3 Strain results of the composite skin stiffened siding structure shear tests

2.2 Piezoelectric sensor measurement method

The piezoelectric sensor is used to measure and analyze the signal changes caused by the interaction between the guided wave signals of each channel and the structural damage,and the delay accumulation imaging algorithm is used to analyze the sensor path information,so that the damage location,shape,and other information of the structure in the form of imag‑es can be intuitively displayed.The delay-andsum method assumes that each point in the structure is a potential damage scattering point.The time of flight in the sensor array relative to each point is cal‑culated as the time delay.The damage scattering signals of each path are superimposed with the corre‑sponding time delay to characterize the damage ener‑gy of the point.

Based on the above process,all points of the structure are traversed,and the damage energy can be transformed into the gray value of the image to re‑alize the damage imaging.

Due to the anisotropy of composite materials,the group velocity of the guided wave varies with dif‑ferent paths.Therefore,it is necessary to optimize the group velocity difference of the guided wave of complex composite materials.In the imaging process,in order to match the velocity of the guided wave group with its propagation path,it is necessary to carry out the prediction quantity of the velocity of the guided wave group in the areas of skin,reinforce‑ment,and opening reinforcement and then map the velocity of the guided wave group to the correspond‑ing propagation path.Take the shear test of compos‑ite open-stiffened panel as an example.The whole structure fracture occurs when the load reached 280 kN.As shown in Fig.4,fracture occurs along the overall apex angle from the central hole apex angle,and the imaging results are consistent with the location,path,and shape of the real damage.

Fig.4 Damage results of the composite skin stiffened siding structure shear tests

2.3 Test measurement method for full size component level composite structures

The failure modes of composite structures are complex and diverse,which are extremely sensitive to factors such as manufacturing defects and environmental loads.As shown in Fig.5,comprehensive measurement methods such as resistance strain gauge,displacement gauge,DIC,and piezoelectric sensor network are used to ensure that the damage initiation,damage extension,and final failure mode could be obtained in the strength tests of the composite grid structure(full-size component level).The resistance strain gauge,displacement gauge,and DIC optical full-field measurement methods are used to obtain the deformation,strain,and stress responses of the composite grid structure for the analysis of the overall stiffness and strength of the structure.The DIC method can measure the 3D full-field strain of the composite skin in real time and the response of the structure buckling.At the same time,a broadband piezoelectric sensor network is deployed to monitor the damage of the composite structure,e.g.,fiber fracture,matrix cracking,and interface delamination.The weighted guided wave imaging method is used to characterize the damage propagation process,and the positioning accuracy of the damage location could be achieved within 20 mm.

Fig.5 Measurement method for the composite grille structure

3 Test data analysis and evaluation methods for composite materials

In the multi-level test process of composite ma‑terials with the BBA,a large amount of test data are generated owing to the various structural forms such as material screening,forensics,structural design as‑sessment,and acceptance.The material test da‑ta are used to evaluate the properties of the fiber and interfacial phase matrix,including the matrix crack‑ing,fiber debonding,and environmental effects.The experimental data of the structural elements are used to evaluate the effects of the design factors such as layering on the structural performance,including the proportion limit,strength limit,and elastic mod‑ulus.The composite structural test data are used to evaluate the structural discontinuities,including the open-hole tensile/compression,notched tensile/com‑pression,jointed shear/extrusion,and interlaminar response.The full-scale component test data are used to evaluate the overall structural behavior and failure modes.

However,owing to the multiple failure modes,coupled failure modes,and multi-scale characteristics of composite materials,it is still difficult to accurately evaluate the structural strength and life.Because of the high dispersion of composite materials,the predicted failure modes may differ from the actual ones.On the one hand,make full use of the test data to improve the accuracy and effectiveness of the analysis and evaluation.On the other hand,combine the virtual tests with the physical tests to improve the efficiency and effectiveness of verification.

As shown in Fig.6,based on the accumulated knowledge base,the structural strength,stiffness,buckling mode,buckling load,and failure load of composite materials are analytically calculated based on their structural geometry,materials,paving de‑sign,and load conditions.The assist engineering de‑sign quickly weighs and screens the composite struc‑ture scheme,and provides the basis for the subse‑quent physical tests and virtual tests.Then,the virtual experiments are carried out,and the numerical models for the composite structural re‑sponse and damage analysis are established based on the finite element analysis method,the strength of the composite material structure,the stiffness,the modal,the buckling load and buckling failure load calculation,the post-buckling path prediction,and the simulation of the damage evolution process for the assessment of physical experiment data compari‑son.The physical tests also adopt the multi-level test process of building blocks,and the test data are also used as the basis for modifying the virtual test model.Through the comparison and optimization of the physical and virtual tests,the accuracy and confi‑dence of the evaluation can be improved.Finally,the measurement data and calculation results togeth‑er support the perfection of the database,model li‑brary,and knowledge base,which provides a strong guarantee for the subsequent composite structural de‑sign and verification evaluation.

Fig.6 Analytical evaluation method with the physical and virtual tests

4 Conclusions

1)Based on the experiences of spacecraft devel‑opment,the BBA of“material-component-typical combination structure-full scale structure”for the composite material multi-level structures of space‑crafts is discussed.The material and component tests are used for the material screening and selection,ma‑terial process specification,and allowable value veri‑fication.The component and combination structure tests are used to examine the strength to determine the design value.The test results of the structural fail‑ure mode and bearing limit are taken as the basis for the test analysis and verification of the full-scale structure.The full-size component tests are used to determine the overall strength,stiffness,and bearing capacity of the structure.

2)The DIC method can realize the 3D full-field measurement and whole-process monitoring of the tests,and fully obtain data such as the initial posi‑tions of the structural damage and damage expansion mode.In the shear tests of composite skin stiffened panels,the deviation between the DIC method and the strain gauge is less than 3%,and the post-buck‑ling state of the structure can be measured.

3)The guided wave imaging method can accu‑rately reflect the number,location,and failure path of damage in the shear tests of composite open-rein‑forced panels by piezoelectric sensors.The damage location error is not more than 20 mm in the full-scale composite grid structure tests.

4)In the multi-level test process of composite material building blocks,the analysis and evaluation method combining the physical and virtual tests is adopted to improve the accuracy,efficiency,and credibility of the composite structural design and veri‑fication evaluation.

5)The BBA requires a long time and a high ex‑pense to complete the structure material and compo‑nent level tests.By testing,the variability of the ma‑terials and processes can be mastered and controlled,thus reducing the number of typical combination structure level and full scale structure tests and achieving the goal of reducing the risk and total cost of the whole verification process for the composite structure.In the aerospace field,advanced measure‑ment technologies are helpful to obtain more accurate and comprehensive test data.For instance,the DIC method can obtain the results of the whole test pro‑cess and the strain displacement in the whole field of the structure.The locations of the microstructure cracks and damage evolution path can be obtained by the piezoelectric testing method.These data are diffi‑cult to obtain by traditional testing methods,but are an important basis for the analyses of the ultimate bearing capacity and failure mode of composite mate‑rials.Based on this,higher precision simulation mod‑els can be established to predict structural failure more accurately,thus helping to reduce the number of physical tests and the cost.

- 上海航天的其它文章

- Development and Application of Ti-based Alloy Casting Technologies in the Field of Aerospace

- Applications of Magnesium Alloys in Aerospace and Aviation

- Repair Welding of Casting Magnesium Alloys:A Review

- Research on Residual Stress Measurement of Magnesium Alloy Cabin Castings

- Microstructure and Hot Deformation Behavior of Mg-9Al-3Si-0.375Sr-0.78Y Alloy

- Effect of Semi-solid Isothermal Heat Treatment on Microstructure of VW63Z Alloy