Study on the Deformation Behavior of Mg-Gd-Y-Zn-Mn Wrought Magnesium Alloys by Visco-plastic Self-consistent Modeling

WANG Yuye,ZHANG Junfa,WANG Shiwei,KANG Jing,MENG Jiajie,WANG Yanbo,XU Yuling,ZHOU Haitao

(1.Shanghai Spaceflight Precision Machinery Institute,Shanghai 201600,China;2.Beijing Institute of Space Long March Vehicle,Beijing 100076,China)

Abstract:The plastic deformation behavior of new Mg-Gd-Y-Zn-Mn magnesium alloys gains great necessity to clarify and understand the mechanism deeply.In the present work,the tensile mechanical property test and visco-plastic self-consistent(VPSC)model are used to investigate the activities of deformation modes of VW84M and VW94M magnesium alloys during the tensile deformation.The results show that the mechanical properties of the above extruded alloys are similar but VW94M has higher strength than VW84M after the same aging process.Compared with the extruded alloys,the as-aged alloys have significantly higher activation of pyramidal slip at the later stage of plastic deformation.In addition,the as-aged VW94M alloy with higher strength has the largest activity of pyramidal slip.In summary,the addition of Gd increases the critical resolved shear stress(CRSS)in each slip system of VW94M,while the increase in the strength and the decrease in the elongation of as-aged alloys are associated with the significant activation of pyramidal slip.

Key words:Mg-RE alloy;wrought magnesium alloy;visco-plastic self-consistent(VPSC)model;deformation behavior

0 Introduction

As the lowest density structural metal material,magnesium alloy has the properties of both high spe‑cific strength and high specific stiffness.Therefore,it is quite advantageous in lightweight structural de‑sign,and has been widely used in transportation,aerospace,and other related products.In addition,the wrought magnesium alloy with higher comprehen‑sive mechanical properties has gradually become a re‑search hot spot in lightweight structural materials in recent years.

Mg-RE based wrought magnesium alloys exhibit relatively high mechanical properties under suitable de‑formation and heat treatment process.Especially,the comprehensive mechanical properties of high-strength Mg-Gd-Y-Zn-Mn magnesium alloys are close to 2000 series aluminum alloys through extrusion and the subsequent ageing process.LIU et al.produced the Mg-8.3Gd-4.2Y-1.4Zn-1.1Mn(wt.%)alloy by hot extrusion,and exhibited the ultimate tensile strength(UTS)of 388 MPa and the elongation(EL)of 16.4%.Furthermore,after aging,the alloy had the UTS of 538 MPa and the EL of 13.1%.WANG et al.inves‑tigated the effects of heat treatment and microstruc‑ture on the mechanical properties of Mg-9.2Gd-3.3Y-1.2Zn-0.9Mn(%)alloy.They showed that the maxi‑mum UTS of the extruded alloy after homogenization and solution treatment could reach 439 MPa with the yield strength(YS)of 360 MPa and the EL of 8.5%.

It is useful to expand an in-depth study on the deformation mechanism of wrought magnesium alloys with rare earth(RE)elements for understand‑ing the strengthen mechanism,which will provide some innovative ideas and methods for further alloy design and process optimization.The crystal plastici‑ty simulation is a useful method to analyze the defor‑mation behavior of polycrystalline materials.In re‑cent years,some researchers have started to use the visco-plastic self-consistent(VPSC)model to study the high-performance Mg-Gd-Y system alloys.CHI et al.investigated the deformation behavior of Mg-8.5Gd-2.5Y-0.3Zr(wt.% )and Mg-8.5Gd-2.5Y-0.5Zn-0.3Zr(wt.%)alloys by using in-situ synchro‑tron radiation and elastic visco-plastic self-consistent model(EVPSC).It was concluded that the deforma‑tion modes of these as-aged alloys during tensile de‑formation were dominated by prismatic〈a〉slip,and basal〈a〉slip,mainly owing to the precipitation of the β′ phase which increased the critical resolved shear stress(CRSS)of the prismatic〈a〉slip,and basal〈a〉slip and the strain hardening rate in the elas‑tic-plastic transition zone.

At present,the analysis of the Mg-Gd-Y-Zn-Mn system alloys is still focused on the macroscopic char‑acterization of the strengthen mechanism,and it is be‑lieved that the excellent strength and toughness are mainly because of the recrystallization refinement and precipitation strengthening of the long period stacking ordered(LPSO)phase formed after deformation.

However,the deformation behavior and mecha‑nism under the microscopic view has not been fully uncovered,and still remains to be further clarified.

In this paper,high-strength wrought Mg-RE based alloys are prepared by the conventional hot ex‑trusion method,and the VPSC is used to investigate the deformation behavior of VW84M and VW94M magnesium alloys during the tensile deformation.

1 Experiments and modeling procedures

1.1 Materials and mechanical property test

In the present study,the Mg-8.5Gd-4.3Y-1.6Zn-0.8Mn(wt.%)(VW84M)and Mg-9.0Gd-3.96Y-1.6Zn-0.8Mn(wt.%)(VW94M)as-extruded bars are produced by semi-continuous casting followed by hot extrusion.The homogenizing treatment is performed at 530 °C for 10 h,and then the homogenized samples are machined to 80 mm in the diameter and 300 mm in the height.All samples are preheated at 450°C for 5 h,and are extruded at an extrusion ratio of 25∶1.Finally,the as-extruded bars are aged at 190°C for 30 h.

The microstructures of the as-extruded specimens are observed by means of optical microscopy.The tensile properties are tested on the CMT-5305 material testing machine at ambient temperature.The textures of VW84M and VW94M are tested by the X-ray diffraction(XRD)detector of Panalytical Epyrean.The obtained texture data are used to generate complete pole figures by using the MTEX software toolbox.

1.2 VPSC modeling

The VPSC is one of the polycrystal plastic simu‑lation methods based on the physical shear mecha‑nisms of slip and twinning,and accounts for the grain interaction effects.Thus,it can be used to describe the transition of various deformation mechanisms in magnesium alloys under loading conditions.The code package of VPSC developed by AGNEW et al.is used to simulate and reflect the deformation behaviors of VW84M and VW94M alloys under ten‑sile deformation in this paper.In the VPSC method,the hardening behavior of each slip system or twin‑ning is described by the Voce law.Accordingly,the evolution of the threshold stress value(),which can be treated as the critical resolved shear stress(CRSS)in the deformation mode,is given by

where=ΣΔis the accumulated shear strain,and,,,and(+)are the initial CRSS,the ini‑tial hardening rate,the asymptotic hardening rate,and the back-extrapolated CRSS,respectively.

Furthermore,the possibility of“self”and“latent”hardening can be inferred by the coupling coefficient h,and the increase in the threshold stress of a systemowing to the new dislocations associat‑ed with theactivity is calculated as follows:

where hrepresents the self-hardening coefficient when=,and infers to the latent-hardening condi‑tion when≠.

2 Results

2.1 Experimental results

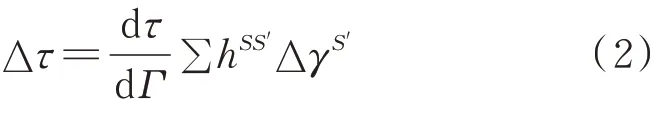

The optical microstructures of the as-extruded VW84M and VW94M alloys are shown in Fig.1.Both alloys contain the bulk and lamellar second phases in these microstructures,which is consistent with the report on similar alloy systems in the litera‑ture.It has been suggested that the structure of such second phases is mainly long period stacking or‑dered(LPSO).VW84M contains more blocky second phase.

Fig.1 Microstructures of as-extruded samples observed on transverse sections(ends vertical to the extruded direction)and longitudinal sections(ends parallel to the extruded direction)

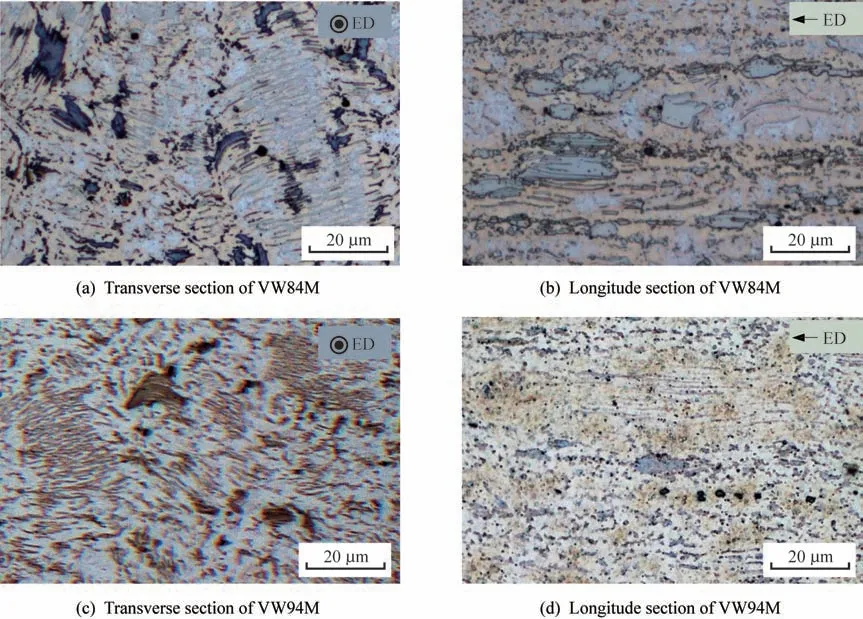

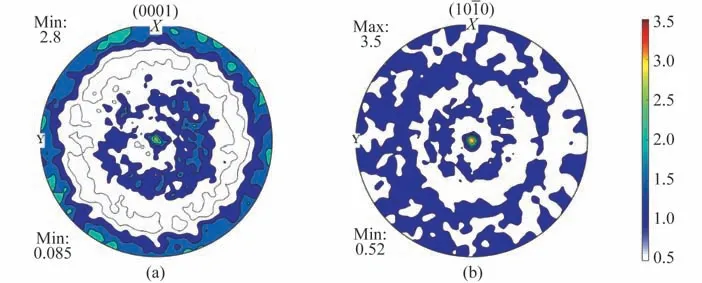

The pole figures of the as-extruded VW84M and VW94M alloys are shown in Fig.2 and Fig.3,respectively.The texture strength of VW84M and VW94M alloys is relatively weak with the maximum intensity of the texture remained at only 3.5 multiples of a random distribution(MRD).The prismatic component texture of VW94M is slightly higher than the prismatic component texture of VW84M.

Fig.2 The texture of as-extruded VW84M measured by XRD

Fig.3 The texture of as-extruded VW94M measured by XRD

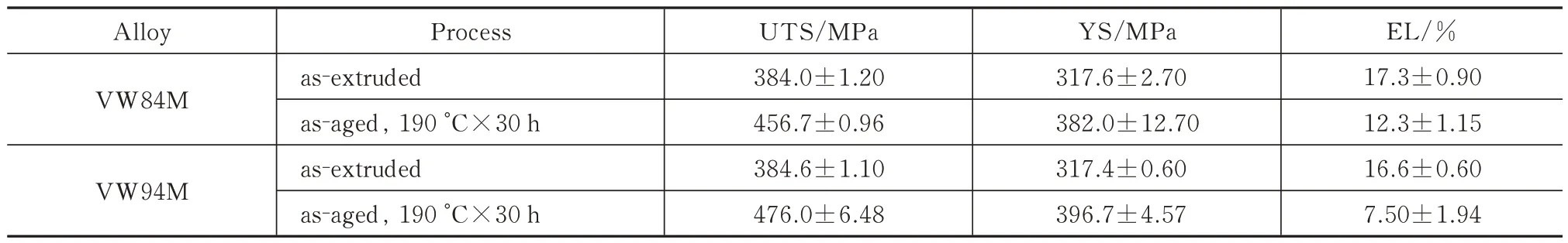

The tensile mechanical properties of the as-ex‑truded and as-aged alloys are summarized in Tab.1.It can be seen that the mechanical properties of VW84M and VW94M are close after the extrusion process,and the elongation of VW84M is slightly higher than that of VW94M.After the same aging treatment,the UTS and YS of VW94M are 19.3 MPa and 14.7 MPa higher than those of VW84M,but the elongation of VW94M is signifi‑cantly lower than that of VW84M.

Tab.1 Mechanical properties of VW84M and VW94M

2.2 Simulation results

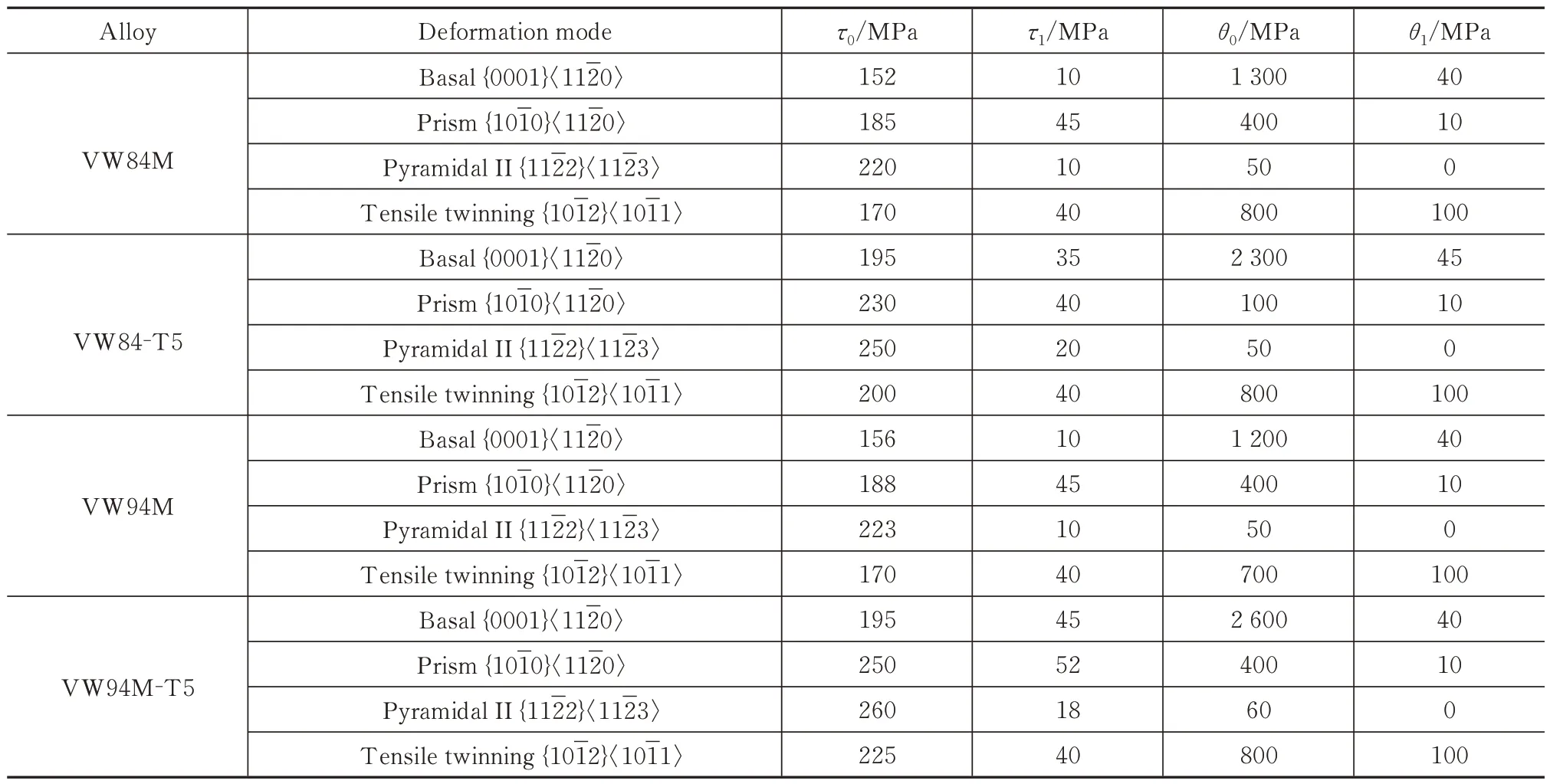

The initial grain orientations(about 10 000 ori‑entations)from VW84M and VW94M are intro‑duced into the VPSC model,which are used to ob‑tain the material parameters(,,,and)via fit‑ting the tensile true strain-stress curves of the as-ex‑truded and as-aged alloys.The material parameters of each deformation mode used in the VPSC simulation can be seen in Tab.2.The simulated engineering strain-stress relationship for the as-extruded and asaged alloys is shown in Fig.4.It can be seen that the VPSC method reproduces the tensile curves success‑fully,indicating that the parameters used for the sim‑ulations are reliable.It is generally considered thatcan be regarded as the CRSS in the VPSC modeling for activating the slip system.The fitting results of VW84M and VW94M are also consistent with the CRSS in most magnesium alloys,i.e.,CRSS<CRSS<CRSS<CRSS.Meanwhile,the CRSS in the as-aged alloy of each slip system and tensile twinning is significantly higher than that in the as-extruded alloy.A note of clarification is that the VPSC is currently used to simulate the plastic de‑formation of the alloy material,and it is hard to rely solely on this method to predict the elongation.Thus,the range of strains that can be simulated de‑pends on the tensile curve from the plastic deforma‑tion phase to fracture.Therefore,if the elongation of the material is low,the range of strains that can be simulated will be short.However,it is possible to ex‑trapolate from the simulation to infer the activation of the deformation modes if the material is to have a higher elongation.

Tab.2 Parameters for VPSC modeling of VW84 and VW94M

Fig.4 Tested and simulated tensile stress-strain curves,the open dot and solid line represented the simulated and experimental data

3 Discussion

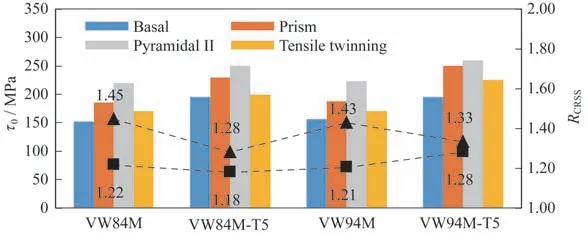

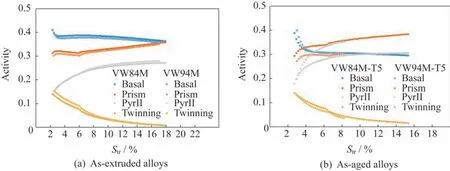

The CRSS values obtained by the VPSC method and the CRSS ratios between the non-basal and basal slips of VW84M and VW94M are shown in Fig.5.The relative activities of different deformation modes during tensile deformation are shown in Fig.6.

Fig.5 CRSS values and ratios of VW84M and VW94M in different deformation modes,the solid triangle and solid square represented CRSSpryll/basal and CRSSprism/basal

Fig.6 Relative activities of different deformation modes

The higher activation of the non-basal slip is re‑corded for both VW84M and VW94M under the ten‑sile condition.Compared with VW84M,the VW94M alloy with more concentration of Gd slightly elevates the CRSS values of the basal slip,prismatic slip,pyramidal slip,and tensile twinning after extru‑sion.Noticeably,as-aged alloys have CRSS values significantly higher than the as-extruded alloys.It is one of the reasons for the increase in the strength of both VW84M and VW94M after aging process.It is related to the promotion and strengthening effects of RE elements on the non-basal slip activation,the CRSS values of both basal and non-basal slip sys‑tems of magnesium alloys are enhanced owing to the addition of RE elements,which leads to a significant increase in the alloy strength.Moreover,the strengthening increase in the RE elements on the basal slip is higher than that on the non-basal slip,which narrows the ratio of the non-basal slip CRSS to the basal slip CRSS and makes the proportion of the non-basal slip activation increase.

It is generally believed that the β′ phase is the main aging strengthening precipitation of Mg-Gd-Y system alloy and precipitates in the prismatic planes of the magnesium matrix.As revealed by MALDAR et al.and ROBSON et al.,the precipitate phase formed in the prismatic plane not only strengthened the basal〈a〉slip significantly,but also had a strong strengthening effect on the prismatic〈a〉slip,which is also consistent with the results from the VPSC simulation in this study.It is assured that the strengthening and activation of the prismatic slip con‑tribute more to the strength and toughness enhance‑ment of VW84M and VW94M.

From Fig.6,it can also demonstrate that the ac‑tivity of the basal〈a〉slip is the highest,followed by the prismatic〈a〉slip in the as-extruded VW84M and VW94M alloys.Furthermore,the contributions of the basal slip and prismatic slip to the plastic deforma‑tion in VW94M are slightly lower than those in VW84M,while the pyramidal II〈c+a〉slip has a higher effect.In the middle and late stages of plastic deformation,the activation ratio of the basal slip de‑creases,while the activation ratio of the prismatic slip increases.Accumulate the stress,and intensify the dislocation entanglement.Then,the activation of the non-basal slip,especially the prismatic slip,coor‑dinates a part of dislocations moved to the prismatic plane.At the same time,the prismatic plane can withstand more intense deformation due to the signifi‑cant strengthening of the prismatic slip in the Mg-Gd-Y alloy.Moreover,the increase in the strength be‑fore fracture is mainly because of the increase in the participation of the prismatic slip in this stage.

Unlike the as-extruded alloys,the situation changes for the as-aged alloys,where the basal slip no longer plays a dominant role in both the as-aged VW84M and VW94M alloys in the middle and late stages of plastic deformation.For VW84M,the high‑est percentage of activity is the prismatic slip,while for VW94M,the activation of the pyramidal II slip increases significantly to become the highest slip sys‑tem activated.It assumes that the properties of high strength but low elongation of VW94M are related to this phenomenon.From Fig.5,it can be seen that CRSSand CRSSrepresent the ratio of CRSS values between the basal slip and the non-bas‑al slip,mainly including the prismatic slip and pyra‑midal II slip.The decrease in this ratio can laterally reflect the increase in the activation trend of the nonbasal slip relative to the basal slip.It can be seen that CRSSdecreases for both as-aged alloys.It is different from the as-aged VW84M alloy,and the CRSSvalue increases for the as-aged VW94M compared with the extruded VW94M,which ulti‑mately results in a higher tendency of activated pyra‑midal II slip for this alloy.The aforementioned phenomenon can be attributed to the assumption that the dislocations are blocked in the basal and prismatic planes and glided into the pyramidal plane via cross-slip as the deformation process continues in the as-aged VW94M alloy.The increase in the activation in the pyramidal slip makes the cohesive capability of the pyramidal plane become the main source of con‑tinued strength enhancement,but the limited coordi‑nation of the strain by the pyramidal slip leads to a de‑crease in the elongation in the end.

4 Conclusions

The VPSC method is used to investigate the de‑formation behavior of VW84M and VW94M alloys,and the main conclusions are as follows.

1)The mechanical properties and textures of the as-extruded VW84M and VW94M are close,and both have a weak fiber texture.

2)During the tensile plastic deformation,the non-basal slips are activated significantly in the as-ex‑truded and as-aged VW84M and VW94M alloys,and the CRSS of each deformation mode is higher in VW94M with a higher Gd concentration.

3)In the middle and late stages of plastic defor‑mation,the proportion of basal slip activation de‑creases and the activity of prismatic slip increases in the as-extruded VW84M and VW94M alloys,and the sustained strength enhancement in the late stages is mainly owing to the contribution of prismatic slip strengthening.

4)In the middle and late stages of plastic defor‑mation,the contributions of prismatic slip and pyra‑midal II slip in the as-aged VW84M and VW94M al‑loys are significantly higher.In summary,the great‑er strength increase after aging of VW94M alloy mainly originates from the higher activation of pyra‑midal II slip,which furth leads to the reduction in the elongation.

- 上海航天的其它文章

- Development and Application of Ti-based Alloy Casting Technologies in the Field of Aerospace

- Applications of Magnesium Alloys in Aerospace and Aviation

- Repair Welding of Casting Magnesium Alloys:A Review

- Research on Residual Stress Measurement of Magnesium Alloy Cabin Castings

- Microstructure and Hot Deformation Behavior of Mg-9Al-3Si-0.375Sr-0.78Y Alloy

- Effect of Semi-solid Isothermal Heat Treatment on Microstructure of VW63Z Alloy