Parametric study of high-frequency characteristics of plasma synthetic jet actuator

Guozheng SONG (宋国正), Haohua ZONG (宗豪华), Hua LIANG (梁华),Zhi SU (苏志), Like XIE (谢理科) and Xing ZHENG (郑猩)

1Science and Technology on Plasma Dynamics Laboratory, Air Force Engineering University, Xi’an 710038, People’s Republic of China

2 School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, People’s Republic of China

Abstract A major issue of plasma synthetic jet actuator (PSJA) is the severe performance deterioration at high working frequency.In this study, experiments and numerical simulation are combined together to investigate the influence of thermal conductivity, throat length (Lth) and discharge duration (Td) on the high-frequency characteristics of PSJA.Results show that the variation of the actuator thermal conductivity and discharge duration will not alter the saturation frequency of the actuator, whereas decreasing the throat length results in an increase of the saturation frequency.For a short-duration capacitive discharge of 1.7 μs, a clear shock wave is issued from the orifice, followed by a weak jet.As a comparison, when the discharge duration is increased up to 202.6 μs, a strong jet column is formed and no obvious shock wave can be visualized.Based on numerical simulation results, it becomes clear that the long-duration pulse-DC discharge is able to heat the cavity gas to a much higher temperature (3141 K) than capacitive discharge, greatly improving the conversion efficiency of the arc discharge energy to the internal energy of the cavity gas.In addition, high-speed Schlieren imaging is deployed to study the performance degradation mechanism of PSJA at high working frequency.Monitor of the exit jet grayscale indicates that as long as the saturation frequency is exceeded, the actuator becomes unstable due to insufficient refresh time.The higher the discharge frequency, the more frequently the phenomenon of ‘misfires’ will occur, which explains well the decaying jet total pressure at above saturation frequency.

Keywords: thermal conductivity, throat length, discharge duration, plasma synthetic jet,saturation frequency

1.Introduction

Plasma flow control(PFC)is a novel and promising active flow control technology, having the advantages of simple structure,fast response, wide working bandwidth, no mechanical moving parts, etc [1–3].Surface dielectric barrier discharge actuator(SDBDA) [4–6], arc discharge plasma actuator (ADPA) [7],plasma synthetic jet actuator (PSJA) [8, 9] are the three main actuation methods of PFC.Among them, plasma synthetic jet can generate high-energy jets with speeds up to hundreds of meters per second,and shock waves with approximate speed of sound.At present, plasma synthetic jet has demonstrated sufficient control capabilities in lift augmentation [10, 11], jet noise control [12], and shock wave/boundary layer interaction[13, 14].To realize better flow control effect at high-Reynolds number flow, it is necessary to conduct meticulous research on frequency characteristics of plasma synthetic jet actuator.

Since Grossmanet al[15] proposed the first plasma synthetic jet actuator in 2003, PSJA has received growing attention from the active flow control community.According to previous researches, frequency characteristics of plasma synthetic jet are mainly affected by the geometric parameters of the actuator,which consist of the electrode distance,orifice diameter, throat length, and cavity volume.Cybyket al[16]used numerical simulations to study the performance characteristics (single-pulse) of PSJA with different orifice size,cavity volume, and energy deposition.They found that the average orifice exit velocity increases with the growth of energy deposition and orifice diameter, decreasing with increasing cavity volume.Popkinet al[17]focused on novel actuator designs that could potentially improve the reliability,efficiency and lifetime of individual actuators.Based on their result, larger electrode distances lead to higher peak cavity pressure efficiency up to 75%,and by increasing the electrode diameter, both electrode endurance and discharge reliability can be enhanced.

Previous researches mainly focused on the influence of geometrical parameters and atmospheric parameters on the performance of PSJA, and the impact of actuator material’s thermal conductivity and discharge duration on frequency characteristics of PSJA remains unknown.What’s more, the performance degradation mechanism of PSJA at high frequency needs to be revealed for purpose of actuator optimization.This study fills these knowledge gaps.Three actuators made of different materials and three lids with different thickness are manufactured to study the influence of throat length and thermal conductivity on PSJA.The total pressure of PSJA is measured by a pressure transducer, and the working process of PSJA is studied in detail with a highspeed Schlieren system.Furthermore, numerical simulations are carried out to assist the analysis.The experimental setup and computational setup are introduced in section 2.Results and analyses are presented in section 3.

2.Experimental setup

2.1.Actuator and power supply

As shown in figure 1(a),the plasma synthetic jet actuator is twoelectrode,consisting of ceramic lid,ceramic cavity,and tungsten needles.The lids and cavities of the actuators are made of three different ceramic materials,which are ZrO2(3 W/(m·K)),Al2O3(32 W/(m·K)), AlN (150 W/(m·K)).The cavity volume of the actuator is approximate226 mm ,3 the in-close electrode distance is 2.5 mm, the orifice is in the center of the ceramic lid,with a diameter of 1 mm,the range of throat length is 3 mm, 6 mm, and 9 mm.

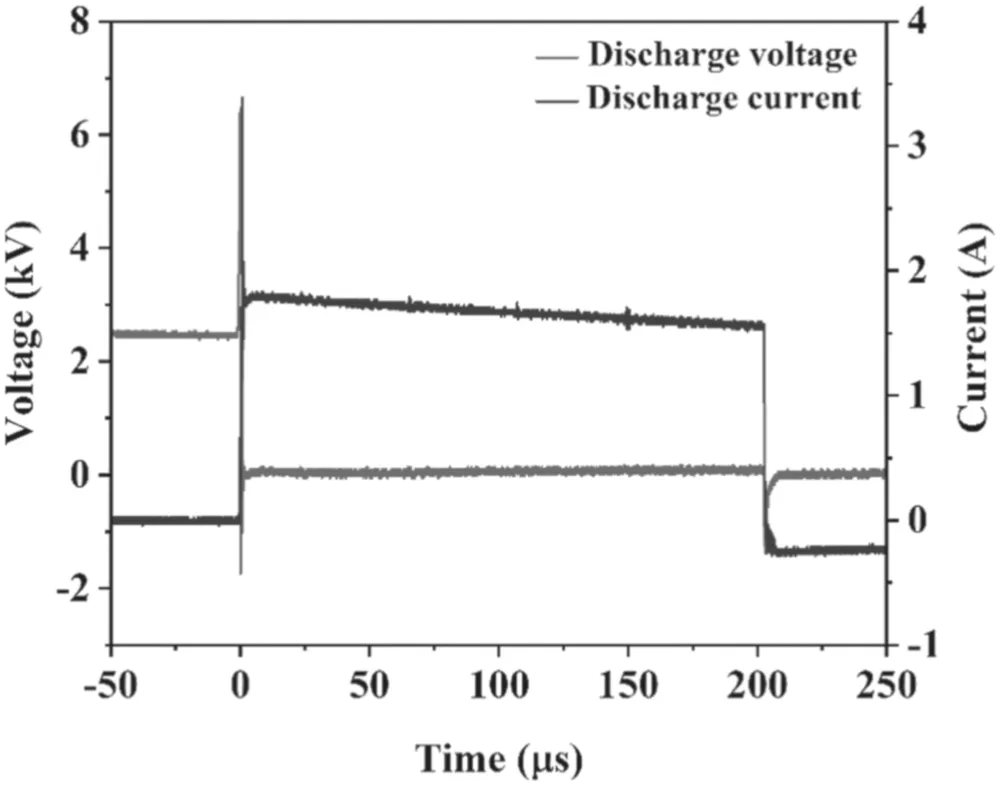

A sequential discharge (capacitive discharge) power supply is adopted to feed the plasma synthetic jet actuator,as shown in figure 2(a).A DC power supply (output voltage:U0=2 kV;power:8 kW),a resistor(R1,resistance:1.5 kΩ;power: 400 W), and an energy-storing capacitor (C1, capacitance:C1=0.1 μF)constitute the charging circuit.A highvoltage power supply (output voltage: 0–10 kV; width: 2 μs;output frequency: 1–4000 Hz) is used for breaking the electrode gap and controlling the discharge frequency.Immediately after breakdown, the energy stored in C1 is rapidly released into the discharge channel in the form of arc heating.Two high voltage diodes (D1 and D2) isolate the capacitivedischarge circuit and the trigger-discharge circuit from each other to ensure protection from back-current overloading.

The DC power supply generates a relatively large current with high discharge frequency, producing a DC arc in the actuator and imposing threat of burning the actuator.In order to avoid DC arc and ensure higher working frequency, we connect a high voltage transistor switch in series into the charging circuit, using a DG535 to control the high voltage transistor switch and the high-voltage pulsed power supply with TTL signal 1 and signal 2 respectively.The timing diagram of signal 1 and signal 2 is displayed in figure 2(c).The low-level time of signal 1(15 μs)completely contains the high-level time of signal 2(10 μs)in single discharge period,meaning that the high voltage transistor switch is off and DC power supply cannot generate current into the discharge circuit during the whole process of arc discharge.With this circuit, the safe working frequency range of the plasma synthesis jet actuator is totally consistent with the output frequency of the high-voltage pulsed power supply without DC arc.In order to study the effect of discharge duration,we developed another sequential discharge (pulse-DC discharge)power supply, removing the energy-storing capacitor and connecting an inductor (L1, inductance:L1=40 mH) in series to the actuator discharge circuit.Because the inductor has the function of maintaining the current constant, after breakdown,the DC source forms a stable DC arc between the electrodes of the actuator, and the discharge duration can be controlled by the high voltage transistor switch.The timing diagram of signal 1 and signal 2 in this power supply is displayed in figure 2(d).

2.2.Discharge characteristic measurement

The electrical parameters acquisition system consists of a high voltage probe(Tektronix P6015A),a current probe(P6021A),and an oscilloscope (DPO4104B).The high voltage probe and current probe are set in P1 and P2 respectively to measure the discharge voltage and current of actuator, as shown in figure 2(a).The voltage and current waveforms pertaining to the ZrO2actuator obtained at a DC output voltage of 1.6 kV,a pulse voltage of 8 kV, and a repetition rate of 1000 Hz are shown in figure 3.Before breakdown, the voltage on the actuator increases with the output voltage of high-voltage pulsed power supply.When the voltage on the actuator reaches 7.7 kV, the air between the electrodes is ignited, and the voltage quickly drops.Meanwhile, the current goes up rapidly and reaches a maximum of 189 A at 0.8 μs.After breakdown, both the charging voltage and discharge voltage have obvious oscillations, resulting from impedance mismatch, which are second order transient responses to a fast voltage variation.The pulse width of the current is 1.7 μs,and the single pulse energy is integrated to be 32.8 mJ for figure 3,much less than the energy stored in capacitor C1 (136.4 mJ).

The voltage and current waveforms of theAl2O3actuator with DC power supply outputting 1 kV and high-voltage power supply pulsed at 8 kV, and 1400 Hz are shown in figure 4.The average discharge current is 1.7 A, the pulse width of the current is 202.6 μs,and the single pulse energy is 20.4 mJ.In order to keep the single pulse energy on the actuator consistent, the capacitor charging voltage is set to 1.2 kV during the study of the influence of the discharge duration,and the single pulse energy is 19.8 mJ in capacitive discharge under 1400 Hz.

2.3.Time-averaged total pressure measurement and Schlieren system

Total pressure of plasma synthetic jet indicates the mechanical energy incorporated in the jet, and thus can reflect its authority to control external flow.A digital pressure transducer (DPT 6000, range: −5 to 5 kPa, accuracy: 0.02% F.S)together with a thin total pressure probe was used to measure the total pressure at a distance of 1 mm from the exit orifice,as shown in figure 5.The pressure probe is connected to the pressure transducer with a 0.5 m long PVC tube.Coping with EMI generated by the arc discharge, the measures we have adopted include using two uninterruptible power supplies to drive PSJA and pressure transducer respectively; the highvoltage wire in the discharge circuit is reduced to the shortest;all signal wires and the high-voltage power supply are completely wrapped by shielding net;the high-voltage output wire and ground wire of the high-voltage power supply are twisted together to form a shielded twisted pair.After taking these measures, the influence of EMI on the pressure measurement is well eliminated.In each test,the sampling frequency of the pressure transducer is set as 100 Hz,and the sampling time is 2 s.Three sets of data are collected at each discharge frequency.From the variation of time-averaged total pressure with discharge frequency, the saturation frequency of the actuator can be directly picked up.

Looking for a job in a foreign country is not easy, but I will never give up. After going through the past year, I become more confident in overcoming difficulties. The road is chosen by me, I have to keep going and never hesitate in front of cross of life. Having a goal of making an ideal career, I strongly believe that all of my efforts will bring me great success.

A high-speed Schlieren system with Z-type light path is used for studying the performance of the actuator as shown in figure 6.A high-power xenon lamp is used as a continuous point light source.The vertical knife edge is chosen to change the amount of light entering the camera to improve the contrast of the captured image.The frame rate of CCD camera(Phantom v2512) is set as 100,000 fps, the exposure time is set as 2 μs,and the resolution 128×256 pixels.One pixel in the Schlieren image represents a physical distance of 0.22 mm.According to the Schlieren images, the working process of PSJA can be directly visualized.

2.4.Numerical model and computational grids

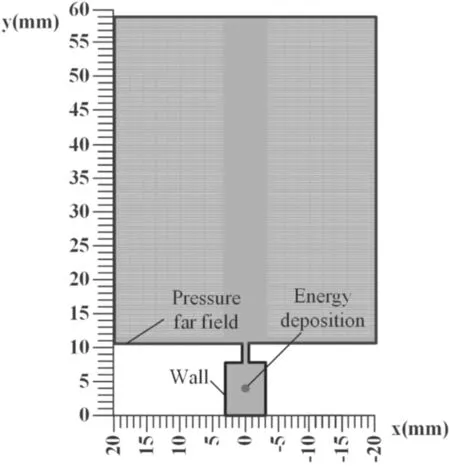

In order to understand the physical evolution process of PSJ in depth, the commercial software FLUENT was used to conduct a transient simulation of the energy deposition and jet ejection process in two-dimensional domain.The turbulence model is SSTk-ω model, and the calculation time step increases gradually from 10 ns at discharge energy deposition to 50 μs at jet expulsion.Based on a preliminary grid independence check, the number of grids is chosen as 210,000,above which further refinement would not bring any accuracy improvement.An adiabatic non-slip wall boundary condition and pressure-far-field boundary condition are set at the outer boundary, as shown in figure 7.The red part of the grids represents the energy deposition area,which is a circle with a diameter of 1 mm in the center of the cavity.In order to simulate the energy deposition process of the actuator, the power densityShof the energy deposition aera is added to the heat source term of the energy equation,and the definition ofShis shown in equation (1), whereηdenotes the energy conversion rate from electrical energy to heat (40%);Q0represents the single pulse energy(20 mJ);τpis the discharge duration;Vhis the total volume of heating region.

3.Results and analyses

3.1.The effect of thermal conductivity

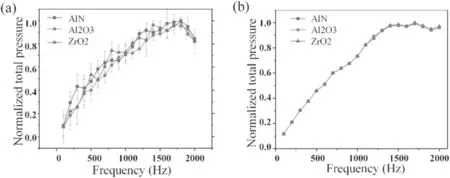

With the capacitive discharge power supply displayed in section 2, the variations of time-averaged total pressure with discharge frequency under different thermal conductivities are shown in figure 8.In order to better compare the variations,data presented are normalized by dividing the largest value of all these three curves.

From figure 8(a), the time-averaged total pressure first increases and then decreases.The saturation frequency of PSJA is the discharge frequency corresponding to the total pressure peak.The saturation frequencies of AlN,Al2O3,and ZrO2actuators are 1800 Hz, 1700 Hz and 1800 Hz, respectively.In addition, the peak time-averaged total pressures of Al2O3and ZrO2actuators are 95.0% and 99.8% of that of AlN actuator.Theoretically, the greater the thermal conductivity of the actuator material, the greater the power of the actuator to dissipate heat to the outside atmosphere,while the electrical power of the actuators is basically the same, so the time-averaged total pressure of the actuator should decrease as the thermal conductivity increases.In our experiment, the time-averaged total pressure ofAlN actuator is larger than that ofAl2O3actuator.The reason may be due to the different positions of the total pressure probe relative to the orifice during the measurements.

To compensate for the limitations of the experiment, we used the analytic model established by Zonget al[24] to study the influences of thermal conductivity and throat length on the frequency characteristics of the plasma synthetic jet actuator.Key thermal parameters set in the analytic model are shown in table 1.The single pulse energy is set as 33 mJ,the discharge duration is 2 μs, and the ratio of input energy to internal energy of the cavity air is set as 40% according to Popkinet al[25].Through analytic calculation,the variations of time-averaged total pressure with discharge frequency under different thermal conductivities are shown in figure 8(b).The saturation frequencies and total pressure of actuators with different thermal conductivities are basically the same.The effect of improving the thermal conductivity of the actuator material is similar to slightly reducing the input energy of the actuator,and the frequency characteristic of the actuator will not be changed.The peak time-averaged total pressures of ALN actuator and Al2O3actuator are 99.1%and 99.2% of that of ZrO2actuator.Higher thermal conductivity results in smaller time-averaged total pressure, but the difference is negligible.

3.2.The effect of throat length

With the capacitive discharge power supply,the variations of time-averaged total pressure with discharge frequency under different throat length are shown in figure 9(a).For a throat length of 3 mm, 6 mm and 9 mm, the value of the saturation frequency is determined to be 1700 Hz, 1200 Hz and 1100 Hz, respectively.The peak time-averaged total pressure of 6 mm actuator and 9 mm actuator is 81.2% and 59.5% of that of 3 mm actuator.

Through the analytic model established by Zonget al[24], the variations of time-averaged total pressure with discharge frequency under different throat lengths are shown in figure 9(b).The saturation frequencies of 3 mm, 6 mm and 9 mm actuators are 1700 Hz, 1100 Hz and 900 Hz, respectively.The peak time-averaged total pressure of 6 mm actuator and9 mm actuator is 84.3% and 77.7% of3 mm actuator.

Compared with experimental result, the calculated timeaveraged total pressure is larger,and the saturation frequency decreases more quickly with the throat length.The reason for the deviation between the analytic results and the experimental results is that the influence of gas viscosity in the throat length is ignored in the analytic model.The lowvelocity fluid in the throat will hinder the ejection of the highpressure gas in the cavity.Ignoring the effect of gas viscosity in the throat length will increase the jet velocity,make the jet velocity attenuate slower, and the actuator will enter the refresh stage later.The jet duration and time-averaged total pressure are correspondingly increased, making the actuator more sensitive to the change of discharge frequency and improving the speed of the saturation frequency changing with throat length.

Table 1.Key thermal parameters set in the solver.

3.3.The effect of discharge duration

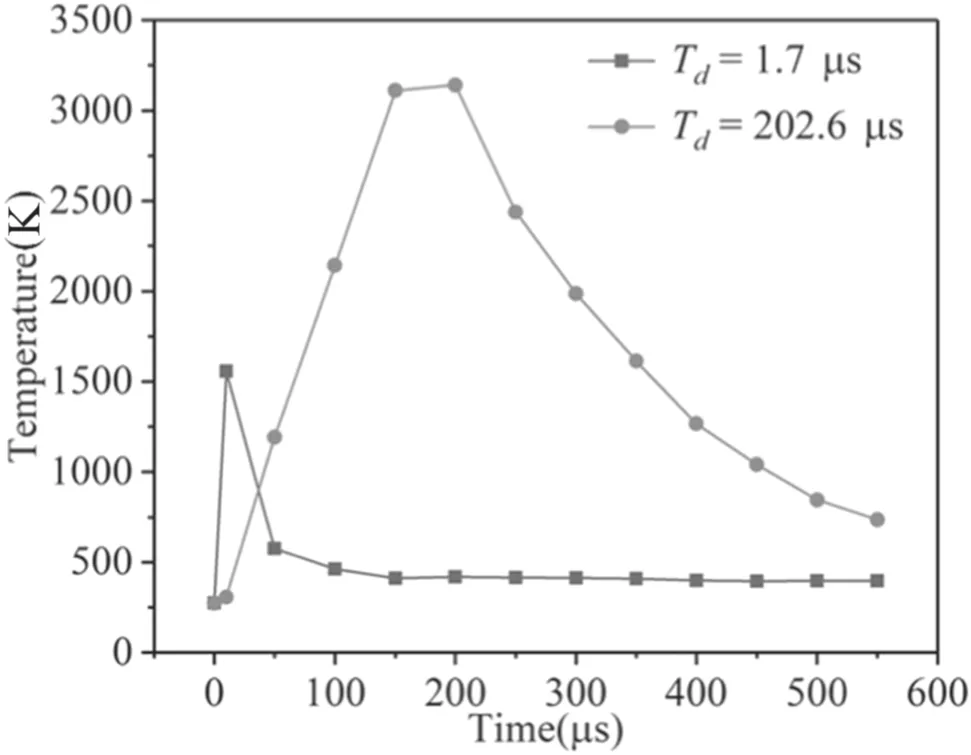

The pulse width of the current is 1.7 μs in capacitive discharge,and 202.6 μs in pulse-DC discharge.Variation of the time-average total pressure of with different discharge durations at different discharge frequencies is shown in figure 10.Although the time-averaged total pressure increases with the increase of the discharge duration, the saturation frequency remains approximately unchanged, both of which are 1800 Hz.The peak total pressure corresponding to capacitive discharge is only 26.8% of that in long-duration pulse-DC discharge.These observations can be explained as follows.PSJA is similar to a spring-mass-damper system, and its saturation frequency is dominant by the Helmholtz natural oscillation frequency (fh), which is related to both atmospheric parameters and geometrical parameters as[26, 27].Therefore, increasing the discharge duration does not change the saturation frequency of the actuator.The large total pressure of pulse-DC discharge at high frequency may be attributed to the increasing energy conversion efficiency of the actuator, and the corresponding mechanisms deserve further investigation.

The working process of the actuator recorded by high-speed Schlieren system under different discharge duration is shown in figure 11.From the Schlieren images,it can be seen that the jet produced by pulse-DC discharge is stronger than that by capacitive discharge.In capacitive discharge, the actuator can produce obvious shock waves.As a comparison, no shock waves are observed in pulse-DC discharge.These Schlieren images are consistent with the pressure measurements.Under capacitive discharge,the gas in the cavity is heated rapidly and the spatial distribution of pressure and temperature is largely nonuniform,producing obvious shock wave and weak jet.However, as for pulse-DC discharge, the pressure and temperature of the gas increase more slowly and distribute more evenly, inducing stronger jet with negligible shock waves.

Numerical simulations are further performed to understand the impact of discharge duration on inter-cavity heating.Figure 12 compares the average temperature in the cavity under different discharge duration, and the temperature distribution at different moments is shown in figure 13.At capacitive discharge,the gas in the cavity is rapidly heated to produce shock waves.The shock waves propagate back and forth in the cavity to dissipate heat and continuously take away a large amount of heat through the orifice to the outside,causing the temperature in the cavity to drop quickly.So obvious shock waves and a weak jet are formed one by one at the orifice.Compared to capacitive discharge, there is no obvious shock wave formed at pulse-DC discharge, and the gas in the cavity is gradually heated to a pretty high temperature (3141 K), greatly improving the efficiency of converting the heat generated by the arc into the internal energy of the gas in the cavity.Therefore, stronger jet is generated with large discharge duration.

Figure 1.The configuration of plasma synthetic jet actuator.(a) Schematic diagram, (b) physical map.

Figure 2.The power supply system and trigger signal.(a)Capacitive discharge, (b) pulse-DC discharge, (c) signal timing diagram in (a),(d) signal timing diagram in (b).

Figure 3.Representative voltage and current waveforms obtained in capacitive discharge.

Figure 4.Representative voltage and current waveforms obtained in pulse-DC discharge.

Figure 5.The total pressure measurement system.

Figure 6.The high-speed Schlieren system.

Figure 7.Computational mesh.

Figure 8.The variations of time-averaged total pressure with different thermal conductivities.(a) Experimental result, (b) analytic result.

Figure 9.The variations of time-averaged total pressure with different throat lengths.(a) Experimental result, (b) analytic result.

Figure 10.The variations of time-averaged total pressure with different discharge durations.

Figure 11.The working process of the actuator at 1800 Hz under different discharge durations.(a)Capacitive discharge,(b)pulse-DC discharge.

Figure 12.The average temperature in the cavity under different discharge durations.

Figure 13.The temperature distributions in the cavity at different moments.

Figure 14.The Schlieren images processing.(a) Monitoring area, (b) fd=1800 Hz, (c) fd=2200 Hz, (d) fd=2600 Hz.

Figure 15.Variations of the mean grayscale in one period at increasing frequencies.(a) Capacitive discharge, (b) pulse-DC discharge.

Figure 16.The misfire ratio at different working frequencies.

3.4.The mechanism of the performance degradation at high frequencies

To study the mechanism of the performance degradation at high frequencies,the mean grayscale of a 3 mm×3 mm area near the orifice in the Schlieren image is monitored, and the monitoring area is shown in figure 14(a).When the 3 mm actuator works at different discharge frequencies with pulse-DC discharge, the mean grayscale varies with time as shown in figures 14(b)–(d).Before reaching the saturation frequency,the mean grayscale curves have obvious periodicity, and the peak-to-peak values of the mean grayscale curves increase as the frequency increases.After the saturation frequency is exceeded, the periodicity of the mean grayscale curves decreases,and the peak-to-peak value decreases rapidly as the frequency increases.Under pulse-DC discharge and the discharge frequency of 2200 Hz,the mean grayscale curve has a significant decrease in amplitude after 0.58 s from the start of discharge, while it has a significant decrease in amplitude after 0.13 s after the beginning of discharge at a discharge frequency of 2600 Hz.In addition, when the discharge frequency is 2600 Hz, due to insufficient discharge stability,the gas between the electrodes is not ionized during some discharge cycle, which results in enough refresh time for PSJA,causing obvious fluctuations in the mean grayscale curve.These results show that when the actuator is working at high frequencies, due to the reduction of the refresh time, the higher the working frequency,the sooner the jet generated by the actuator will be weakened, and the performance of the actuator degrades rapidly.

The instantaneous grayscale variation in figure 14 is averaged over multiple cycles, resulting in a phase-averaged variation of the jet grayscale in one period, as shown in figure 15.The phase-averaged result shows the process of PSJA’s working performance changing with the discharge frequency, which is in good agreement with the pressure measurements.As the discharge frequency exceeds the saturation frequency, the peak values of mean grayscale curves decrease rapidly, and PSJA exhibits obvious degradation in its authority.

Previous analyses of the Schlieren images indicate that as long as the peak-to-peak value of grayscale variation in one cycle is less than 1.5, no obvious jet can be observed at the orifice.As such, we use this threshold grayscale variation(1.5) to evaluate whether the pulsed jet is fired normally in one cycle or abnormally as‘misfire’.Further,the misfire ratio at different working frequencies is calculated, as shown in figure 16.When the working frequency does not exceed the saturation frequency, the ratio of ‘misfires’ cycle to the total cycle is 0,and the jets appear periodically at the orifice of the actuator.As the working frequency reaches 2200 Hz,the ratio increases to 51.5%under capacitive discharge,and remains 0 under pulse-DC discharge.When the working frequency is improved to 2600 Hz, the ratio further increases to 67.4%under capacitive discharge, and 65.3% under pulse-DC discharge.So the performance of PSJA degrades rapidly as discharge frequency exceeds the saturation frequency,and the phenomenon of ‘misfires’ becomes more frequent.

4.Conclusion

In the present paper, experimental investigation and numerical simulation were conducted to study the effects of the thermal conductivity,throat length and discharge duration on PSJA.Furthermore, the mechanism of the performance degradation of PSJA at high working frequencies is analyzed in detail.

It is found that the saturation frequency of PSJA is not affected by the thermal conductivity and discharge duration,but decreases with the increase of the throat length.This verifies that the saturation frequency of PSJA is determined by its own Helmholtz natural oscillation frequency(fh),which is related to both atmospheric parameters and geometrical parameters.With different thermal conductivities, the total pressure near the orifice remains basically unchanged.While the discharge duration is larger (202.6 μs), the total pressure increases significantly,and its peak reaches 3.7 times that under the discharge duration of 1.7 μs.The larger the discharge time, the longer the arc heating the air in the cavity, the more uniform the gas temperature and pressure distribution in the cavity, and no shock wave will be generated.But the temperature in the cavity will gradually rise to a higher level, and a stronger jet will be produced.In addition, as the working frequency exceeds the saturation frequency, due to the reduction of the refresh time,the higher the working frequency, the sooner the jet generated by the actuator will be weakened, the more frequent the phenomenon of ‘misfires’, and the performance of the actuator degrades rapidly.

In future study, the effect of the discharge duration on PSJA should be more in-depth researched.As the discharge duration further increases,it is likely that the reduction of the refresh time will reduce the saturation frequency and the intensity of the jet.In addition, the saturation frequency is determined by the geometrical parameters of PSJA.The configuration of the actuator deserves to be further optimized to improve its performance.

Acknowledgments

This research work is supported by National Natural Science Foundation of China (No.12002384), the National Key Laboratory Foundation of China (No.614220210200112), and the Foundation Strengthening Project (No.2019-JCJQ-JJ-077).

ORCID iDs

Plasma Science and Technology2021年12期

Plasma Science and Technology2021年12期

- Plasma Science and Technology的其它文章

- A study on nuclear analysis of the divertor region of the CFETR

- Evaluation of gases’ molecular abundance ratio by fiber-optic laser-induced breakdown spectroscopy with a metal-assisted method

- Thermophysical properties of pure gases and mixtures at temperatures of 300–30 000K and atmospheric pressure:thermodynamic properties and solution of equilibrium compositions

- Plasma treatment for enhancement of the sorption capacity of carbon fabric

- Energy properties and spatial plume profile of ionic liquid ion sources based on an array of porous metal strips

- Analysis of optical emission spectroscopy data during silicon etching in SF6/O2/Ar plasma