Effects of flow parameters on thermal performance of an inner-liner anti-icing system with jets impingement heat transfer

Zhiqiang GUO, Mei ZHENG, Qian YANG, Xiaofeng GUO, Wei DONG

School of Mechanical Engineering, Shanghai Jiaotong University, Shanghai 200240, China

KEYWORDS Hot air anti-icing system;Icing;Icing wind tunnel;Jets impingement heat transfer;Thermal performance

Abstract The multiple jets impingement heat transfer is widely applied in the wing anti-icing system.It is challenging to apply the similarity criterion to carry out the anti-icing experiments due to the complex flow and heat transfer behavior.In the present study,the full-scale slat model is used to carry out anti-icing experimental researches in a 2 m×3 m icing wind tunnel of China Aerodynamics Research and Development Center. The effects of icing parameters Liquid Water Content(LWC)and Median Volume Diameter(MVD)and hot air parameters(mass flow rate and temperature) on the thermal performance of an inner-liner anti-icing system with jets impingement heat transfer are studied.The effects of the experimental parameters are analyzed in detail by combining impingement and evaporation heat transfer mechanisms. The impingement hot air mass flow rate dramatically affects the heat transfer performance of the impingement stagnation region within the range of the experimental parameters.The temperature of impingement hot air and that of wing skin are approximately linear correlated. The experimental results show the effects of LWC and MVD on water film formation and runback ice accretion. The formation of water film is analyzed by an analytical method based on the wing skin temperature difference of dry and wet air conditions.

1. Introduction

Ice accretion on the wing leading edge may change the lift-drag characteristics and affect safe flight of aircraft.The hot air and electro-thermal anti-icing system are used to solve the problem. And the hot air anti-icing method with jets impingement heat transfer is applied widely.

The heat source of hot air anti-icing system is bled from high-pressure compressor of the jet engine, so the mass flow rate must be as low as possible.Therefore,the design and optimization of hot air anti-icing system are essential. However,the design of hot air systems is a complicated problem due to the large number of parameters that affect system performance and efficiency. Therefore, it is necessary to study the heat transfer characteristics of the hot air anti-icing system.

The hot air anti-icing system adopts jet impingement heat transfer with excellent heat transfer performance. And there are many influence parameters which are mainly divided into structural parameters and flow parameters. The research on the influence of structural parameters includes the size, shape,arrangement of impinging jets, curvature, roughness, etc.Many researches have been done on the shapes of the impinging jets.Besides round,square, and rectangle, there are also some special shapes. Nevertheless, round impinging jets are easy to process and usually used in practice. The flow parameters studied include Re,Ma,flow rate, temperature,pressure,and so on.However,in practice,the mass flow rate and temperature are mostly used to control the jets impingement heat transfer. Therefore, the present investigations of impingement hot air focus on the influence of flow rate and temperature.

Besides, to conveniently obtain the heat and mass transfer characteristics in the hot air anti-icing system, many studies ignore the external boundary conditions.Planquart et al.performed steady-state heat transfer measurement in a hot air anti-icing system without considering the flight environment.The mapping of the convective heat transfer coefficient resulting from impingement of multiple jets was determined by the heated foil technique combined with infrared thermography.Through the similar experimental methods, Imbriale et al.carried out an experimental investigation to get heat transfer performance of a row of jets impinging an internal surface of NACA0012 airfoil leading edge. The investigation showed the presence of Go¨rtler vortices, which form in the wall jet downstream of the jet impingement, lead to the stream-wise streaks of local Nu maxima. Philippe and Michele measured the temperature of the impinging target surface by infrared thermography, which does not affect the flow in anti-icing chamber.According to Bu’s experimental investigations,the temperature distribution on the internal surface of airfoil leading was measured by the calibrated type T thermocouples.The influence of structural parameters on heat transfer in the anti-icing chamber is revealed. Chang et al.investigated the multiple jets impingement from round holes to NACA0015 airfoil concave surface and measured wall temperature with K thermocouples. According to the researches, the curvature of the impinging surface can be one of the significant factors for the fluid flow of multiple jets impingement, and it is not appropriate to improve the heat transfer efficiency by enlarging the diameters of the jet holes in the hot air system of aircraft. The above research works concentrated on the influences of geometric structure and flow parameters, which plays an essential role in engineering designs. The empirical formulas of jets impingement heat transfer, which can directly guide engineering application, can be summarized through experimental researches. The empirical formula summarized by Goldstein et al.in the experimental study of jet impingement heat transfer was applied to the optimum design of hot air anti-icing chamber structure.Because the optimization time required for numerical calculations was too long, the jet impingement heat transfer coefficient obtained by empirical formula was taken as boundary conditions in the optimization algorithm. In addition to heat transfer characteristics, some researchers also studied the mass transfer characteristics of jet impingement. The smoke wire visualization was used to investigate the jet flow structure of a round jet impingement on concave surfaces by Cornaro et al.Furthermore, an experimental study of an axisymmetric turbulent jet impinging on a semi-cylindrical concave surface was carried out using Particle Image Velocimetry (PIV) by Hashiehbaf et al.

However, in order to explore the real heat transfer characteristics of the hot air anti-icing system,the experimental study coupling external heat transfer is necessary. At present, there are a few experimental data about internal and external coupling researches due to the need for large-scale ice wing tunnel.The classical icing wind tunnels with the capability of simulating natural icing cloud were operated by NASA,Boeing,NRC,Cox,CIRA,Papadakiset al. carried out an experimental investigation in NASA Glenn Icing Research Tunnel to document temperature distribution and leading edge ice shapes for a full-scale wing. The experimental data were used to validate thermal and icing analysis computer codes by Wong et al.

In the present work, the effects of flow parameters on the hot air anti-icing system are studied based on 2 m×3 m icing wind tunnel of China Aerodynamics Research and Development Center (CARDC). The research parameters include hot air flow rate, hot air temperature, and Liquid Water Content(LWC),Median Volume Diameter (MVD)of freestream flow.The heat transfer characteristics of the anti-icing system’s internal and external flow fields are revealed by analyzing the steady-state temperature data of the wing surface under different influence parameters. And the present work developed a method based on the wing skin temperature difference of dry and wet conditions to estimate the evaporation of water droplets and infer the formation of water film.This method solves the problem that the water film on the anti-icing surface is tough to observe and measure in large-scale icing wind tunnel experiments.

2. Experimental setup

2.1. CARDC icing wind tunnel

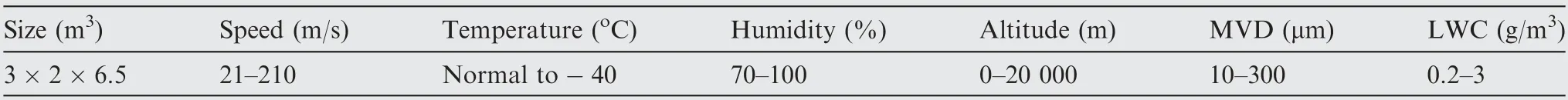

The icing wind tunnel of CARDC includes refrigeration system, spray system, altitude simulation system, humidification system, engine intake simulation system, anti-icing system,and deicing system, which can implement the control of temperature, mist, pressure, humidity, and hot air supply. The wing,as shown in Fig.1,is installed in the 2 m×3 m test section. The primary performance parameters of the wind tunnel are shown in Table 1.The layout of the spray shown in Fig.2 consists of 1000 water–air mixed atomizing nozzles (Spray 98818),which can generate icing mist with specific droplet size and liquid water content by adjusting the water supply and air supply pressure of the nozzle. For the icing wind tunnel with high H of 2 m and width W of 3 m, the mist field calibration of the main test section has been completed. The mist field’s uniformity can cover more than 60% of the cross-sectional area of the test section, and the uncertainty levels of MVD and LWC are better than ±10% and ±20% relatively.

A high-precision hot air supply system device is adopted to provide hot air to the experimental device, and the air supply system includes air sources, pressure reducing devices, filters,multi-stage electric heater, and test sections. The multi-stage electric heater is adopted for precise temperature control,which can realize temperature control of the high-pressure and high-temperature air before entering the test model step by step. The air enters the test section, and the mass flow rate is measured and is discharged through the flow meter and the muffler after passing through the wind tunnel test section. As shown in Fig. 3, the hot air enters the piccolo tube from the bottom of the experimental wing and is discharged from the top of the wing. The flow of hot air in the anti-icing chamber is obtained by the flow difference value between hot air inlet and outlet. The error of the hot air mass flow rate for the experiment is±2%.Besides,cameras are installed in the wind tunnel test section to record possible icing phenomena on the wing surface.

2.2. Wing geometry

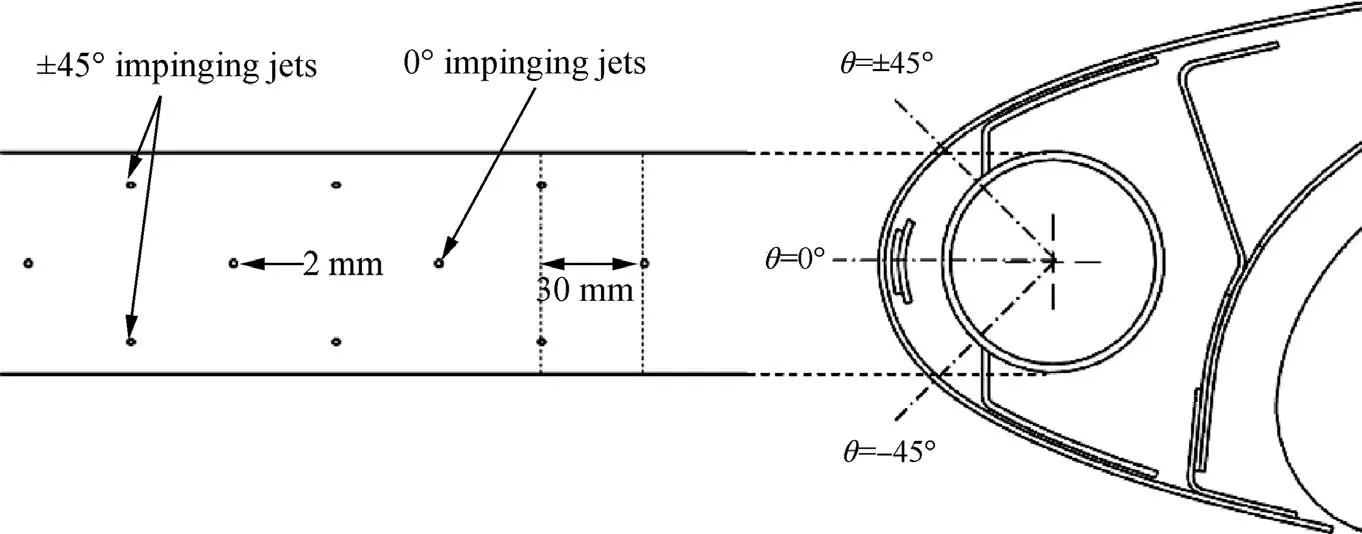

As shown in Fig. 4, the wing model, which consists of a slat and a wing box, has an airfoil section with a span of 1 m and a chord of 1.2 m.The slat shown in Fig.5 is equipped with a novel inner-liner type hot air anti-icing system consisting of a piccolo tube and two inner-liner skins (Inner-liner skin No. 1 and Inner-liner skin No. 2). The piccolo tube has outer diameter of 60 mm and a diamond hole-pattern,as shown in Fig.6.The diameter of each piccolo hole is 2 mm, and the spacing between adjacent two-hole sections is 30 mm. The single hole in the diamond pattern is placed halfway between sections containing two holes.The two holes are placed at+45°and-45°and the single hole at 0° with respect to an axis through the center of the piccolo and parallel to the airfoil chord line. 47 impinging jets are installed on the piccolo tube. The heated region extends to 16.9%chord(203 mm)on the upper surface and 7.5% chord (90 mm) on the lower surface.

Fig. 1 Wing model installed in 2 m×3 m test section.

Fig. 2 Layout of spray.

Figs.7 and 8 show the front view and side view of the innerliner skins. At the section of the 0° impinging jet, in order not to affect the jet impingement, a rectangular hole of 18 mm×18 mm (the width of the front inner skin is 25 mm)is set for the 0° impinging jet on the Inner-liner skin No. 1.The protrusion of 26 mm×19 mm was added to enhance the heat transfer intensity of ±45° jets impingement at the wing leading edge. The protrusion thickness is 2 mm, as shown in Fig. 8. Because of the existence of the protrusion, there are two-channel heights for Inner-liner skin No. 1: 2 mm and 4 mm. The 4 mm channel at the edge of the inner skin is designed to lead the impingement flow from ±45° jet to enter the 2 mm inner skin channel. The narrowed flow channel can compress and destroy the boundary layer to enhance heat transfer. The special structure of Inner-liner skin No. 1 has been verified by numerical simulations, which is a design method to improve the performance of hot air anti-icing system. The Inner-liner skin No. 2 is a classical U-shaped inner skin with a channel height of 1 mm and a horizontal width of 50 mm.

The flow characteristics in the slat are shown in Fig.9.The slat is divided into three chambers (front chamber, middle chamber,and rear chamber).The hot air ejected from the three rows of jet holes carries out sufficient heat transfer in the front chamber.Then it enters the middle chamber through the channel of Inner-liner skin No. 2. Moreover, the hot air exhaust holes are set in the rear chamber, so the hot air flowing on the lower surface needs to enter the rear chamber through the middle chamber.

2.3. Wing skin temperature acquisition

The thermocouple is installed on the inner surface of the external skin and buried in a small pit with a depth of 0.5 mm and a diameter of 1 mm and arranged along the chord direction.Three thermocouples fixed troughs with a depth of 0.5 mm,and a width of 2 mm are arranged on the inner surface of the outer skin. All the thermocouple wires are divided into three groups and buried into wire troughs to minimize the influence on the flow heat transfer of the anti-icing chamber.The thermocouple buried in the pit is shown in Fig.10.A thermal grease with thermal conductivity of 1.2 W/(m·K) isinjected into the pit,and a layer of foil paper is attached to fix the thermocouple.The thermocouple is T-type with a diameter of 0.2 mm and ±0.5 ℃uncertainty. The Agilent temperature acquisition system collects data every two seconds. As shown in Fig. 11, the thermocouples are arranged on the central line of the jet holes at ±45° and 0° relatively. The distributions of thermocouples on the two sections are shown in Fig. 12. The position of the measuring point of the section is expressed by the airfoil streamwise coordinate S, which is positive for the upper surface and negative for the lower surface. The number of thermocouples on the±45°section and 0°section is twelve and thirteen, respectively.

Table 1 Main performance parameter of icing wind tunnel.

Fig. 3 Hot air supply system.

Fig. 4 Geometry of wing model.

2.4. Test conditions and procedure

As shown in Table 2, test parameters include flight condition(airspeed (V) and angle of attack α), icing condition(MVD, LWC, and freestream static air temperature) and hot air condition (hot air mass flow rate (M)and total temperature(T)).The hot air mass flow rate is 85–45 g/s,which is the total flow rate in the piccolo tube. So the mass flow rate of each impinging jet is 1.81–0.96/s.

Each experimental case is separated into two parts: dry air condition experiments and wet air condition experiments.During the dry condition experiment, the wind tunnel experiment parameters, i.e., freestream velocity and freestream temperature, are adjusted until they become stable. When adjusting the wind tunnel parameters, the anti-icing hot air flow rate and temperature are adjusted. Then, 10–20 min after the wind tunnel experiment parameters and hot air parameters become stable (or after the inner surface temperature of the anti-icing chamber has stabilized), the inner surface temperature of the hot air anti-icing chamber in dry condition is recorded. The wet condition experiment is carried out when the inner surface temperature of the anti-icing chamber in dry condition has stabilized.The spraying system is started,and the spraying time is recorded. The configurations of the runback water and runback ice are observed through a sight glass. The spraying is ended 10–15 min later (or after the inner surface temperature of the anti-icing chamber is stabilized).

Fig. 5 Hot air anti-icing cavity of slat wing.

Fig. 6 Piccolo tube.

Fig. 7 Front view of inner-liner skins.

Fig. 8 Side view of inner-liner skins.

Fig. 9 Flow characteristics in slat wing cavity.

Fig. 10 Thermocouple installation.

Fig. 11 Thermocouple arrangement sections.

3. Characteristics of heat transfer on wing surface

Under the dry condition, there are no supercooled water droplets.So the temperature of the anti-icing surface is affected by the impingement heat transfer of the jets, the external convection heat transfer, and the heat conductions.The heat flow on the anti-icing surface is shown in Fig. 13.

Based on the energy conservation,the relationship between the convective heat transfer(qand q)and the thermal conductivity (q) is obtained:

The convective heat transfer is calculated by the convective heat transfer coefficient(hand h)and the temperature difference between air temperature (impinging air temperature Tand freestream air temperature T) and the wing skin temperature(Tand T).The Formula(1)transformed into:

And the Bi number is minimal(Bi ≈10),thus the temperature is considered the same on both of the wing skin siders(Tand T) and approximately considered as the temperature measurement value Tof thermocouples. Therefore,the following formula can be obtained:

which reflects that the ratio of the internal and external convective heat transfer coefficient is composed of two parts,one is the ratio of temperature difference, and the other is the ratio of heat transfer of conduction and external convection.

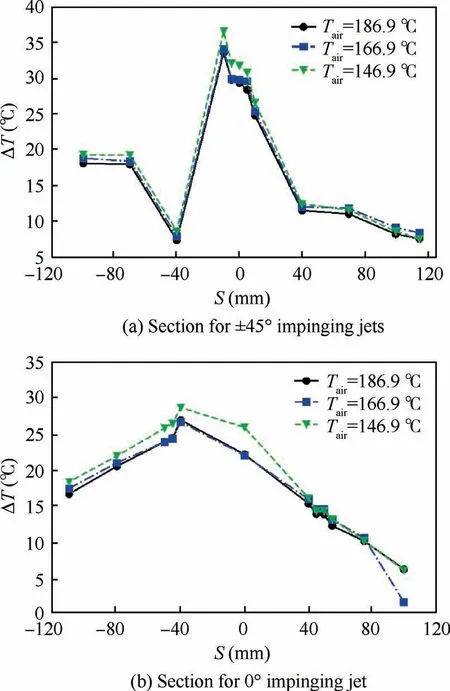

After the icing wing tunnel starts to spray, the supercooled droplets impinge on the wing skin.The impinging characteristics of water droplets are expressed by the local collection efficiency β, which can be calculated by the Eulerian approach.Moreover, the impinging range of water droplets is mainly affected by the freestream velocity, so the range involved in this research is unchanged.As shown in Fig.14,the impinging range is -60 mm As shown in Fig. 15, the supercooled droplets may evaporate directly or form water film on the wing skin surface.Once the water film flows out of the heated area of hot air,there will be ice accretion on the wing surface.Heat transfer on the wing surface with water film is shown in Fig. 16. Compared with the dry condition experiments,the wet condition experiments include the kinetic energy of water droplet impingement q, the energy of water film and the energy of water droplet evaporation q. When the impinging droplets on the wing skin are evaporated completely,there is no energy transfer of the water film. At this time, the measured temperature of thermocouples is T, and the following formula is obtained: The Tcan be expressed as the relationship between the Tand the temperature difference ΔT. The Formula (4) is converted into: Fig. 12 Thermocouple distributions. Table 2 Test conditions. Fig. 13 Heat transfer under dry air condition experiments. and combines with the Formula (2): which qualitatively reflects the relationship of temperature difference,evaporation,conduction,and heat transfer coefficient. Fig. 14 Local collection efficiency distribution on the wing. Fig. 15 Formations of water film and ice under wet condition experiments. Fig. 16 Heat transfer under wet condition experiments. Fig. 17 shows the dry condition temperature distributions of the wing skin at selected sections under different hot air mass flow rate corresponding test Cases 1–4 in Table 2. The heat transfer intensity on the stagnation zone of jet impingement is exceptionally high, so the temperature is higher at the position facing impinging jets. And the lower surface temperature is slightly higher than that of the upper surface due to the asymmetric convective heat transfer on the upper and lower surface. As the angle of attack of the wing increases, the stagnation point position moves down along the surface, and the flow velocity of the upper surface increases, which results in higher external heat transfer coefficient.Moreover,the temperature of the wing skin decreases significantly with the reduction of hot air mass flow rate. Fig.17 Temperature distributions of dry conditions for different hot air mass flow rate. The hot air mass flow rate changes the impinging velocity of hot air and affects the internal surface heat transfer.However,the external surface heat transfer is unchanged.So the ratio of the external surface heat transfer coefficient and the internal surface heat transfer coefficient can be used to qualitatively analyze the influence of the hot air mass flow rate. However,it is difficult to obtain accurate thermal conductivity in the experiments, but the temperature distribution shown in Fig. 17 indicates that the temperature trend does not change significantly with the change of hot air mass flow rate (the curves are nearly parallel), so it is inferred that the thermal conductivity does not change much with the change of hot air mass flow rate. Therefore, the change characteristics of the heat transfer coefficient can be qualitatively reflected by the ratio of temperature difference in Formula (3). According to Fig. 18, the change of temperature difference ratio at the impinging stagnation point is the most severe;the hot air flow rate has a more significant influence on heat transfer characteristics of the impingement stagnation region,while the influence on the other region is relatively lower. Under the wet conditions,as shown in Fig.19,the trend of temperature variation is similar to that of the dry conditions.The drop scope of temperature on the anti-icing surface is between 5 ℃and 45 ℃compared to the dry conditions. The temperature difference between dry and wet conditions is shown in Fig.20.The temperature decrease amplitude of the wing leading edge is significantly higher than that of other positions, because the droplet impingement is concentrated on the wing leading edge. And the temperature decrease on the upper surface of the studied wing is slightly smaller than that on the lower surface, which is due to the 2.5°flight angle of attack and the higher water droplets impingement of lower surface. According to Formula (7), the temperature difference between the dry and wet conditions is mainly affected by the convective heat transfer coefficient, impingement kinetic energy, evaporation energy, and thermal conduction difference. The stagnation points of ±45° jets at the edge of the impinging range of droplets are less affected by the droplets.Nevertheless, the internal heat transfer coefficients are significant, so the temperature differences at those locations are smaller.However,the droplets’impingement of the 0°jet stagnation point is massive. Although the internal heat transfer is not low,the temperature difference at this location is still large. Fig. 18 Ratio of external and the internal surface heat transfer coefficient for different hot air mass flow rate. Fig.19 Temperature distributions of wet conditions for different hot air mass flow rate. Fig. 20 Temperature difference between dry and wet conditions for different hot air mass flow rate. Moreover, with the decrease of the hot air flow rate, the temperature difference curves of the cases are close to each other. For example, the temperature difference between dry and wet conditions of 1.17 g/s case and 0.96 g/s case is very close. The decrease of hot air flow inevitably leads to a reduction of the internal convective heat transfer coefficient,and the denominator of Formula (7) will decline. And when the water droplets on the wing skin completely evaporate, the evaporation heat and impingement heat are constant. Besides, as shown in Fig. 19, the temperature distribution curves of wet conditions are similar to the dry conditions, so the change of thermal conduction is relatively small. It is considered that the numerator of Formula (7) remains basically unchanged when the impinging droplets are completely evaporated.Therefore, the temperature difference between dry and wet conditions should increase with the decrease of the internal surface heat transfer coefficient or hot air flow rate. While the internal heat transfer is not enough to directly evaporate the impinging water droplets on the wing skin,the evaporation decreases with a reduction of wall temperature. So when the evaporation decreases, the numerator and denominator of Formula(7)decrease at the same time,resulting in the temperature difference curve between different cases that tend to be consistent.Therefore,within the range of the droplet impingement (-60 mm With 187.9°C as the datum mark in the study of hot air temperature, the effects of three different hot air temperatures on the anti-icing performance are researched, corresponding to the test cases 5–7 in Table 2. The freestream temperature of these three working conditions is-20°C,and the skin temperature is lower than the working conditions 1–4 where the freestream temperature is-9°C.As shown in Fig.21,the decrease range of wing skin temperature is between 10 ℃and 20 ℃.Take Case 5 and Case 6 as an example. The results show that the hot air temperature decreases by 10.7%(taking 0 ℃as the reference temperature), and the average temperature of the wing skin decreases by 11.3 ℃(taking all the temperature measurement points). However, the jet flow rate dropped by 17.8%, and the average temperature dropped by 4.3°C for Case 1 and Case 2. Through comparison, the effect of hot air temperature is more significant than that of the hot air flow rate.Therefore,in the engineering design of impingement heat transfer, it is more effective to enhance the heat exchange between the wall and the hot air by raising the temperature of the hot air.However,in practical application,it is challenging to raise the temperature relative to the increase of mass flow rate. Therefore, adequate temperature isolation measure is essential. Based on the wing skin temperature of the case for 186.9 ℃hot air, as shown in Fig. 22, the bar chart of temperature reduction is obtained. With the same decrease of hot air temperature, the reduction of wing skin temperature is close. The effect of the hot air temperature on the wall temperature at each measurement point position seems to be more balanced than the effect of the hot air mass flow rate. This is since that the change of hot air temperature has a relatively slight effect on the internal surface heat transfer coefficient. When the external heating load is constant, the wing skin temperature is linearly related to the hot air temperature. The temperature distribution curves of the wet conditions and the temperature difference curves are shown in Figs. 23 and 24.According to Formula(7),when the change of internal and external surface heat transfer coefficient is small, and the impinging droplets evaporate completely,the decrease of wing skin temperature should be very close for each case.However,as hot air temperature drops to 146.9 ℃, the temperature difference curve changes obviously,which is higher than the other two cases. This phenomenon may be due to the incomplete evaporation which is caused by the temperature drop of the wing skin. The ±45° impinging jets section’s internal heat transfer is higher than that of the 0° impinging jet section, so the temperature difference changes only on the wing’s leading edge with higher water impingement. However, the lower surface’s internal heat transfer for the 0° impinging jet section is much smaller than that of the ±45° impinging jets section,so the evaporation of the impinging droplets is incomplete with the decrease of the hot air temperature.Moreover,the unevaporated water flowing into other positions and increasing external heating load. Fig.21 Temperature distributions of dry conditions for different hot air total temperature. Fig. 22 Temperature drop for different hot air total temperature. Fig.23 Temperature distributions of wet conditions for different hot air total temperature. Fig. 24 Temperature difference between dry and wet conditions for different hot air total temperature. Fig.25 Temperature distributions of dry conditions for different LWC. The experiments of four kinds of LWC are carried out for test Cases 8–11 in Table 2.The dry air condition experiments without supercooled water droplets are required before various LWC experiments are performed. The wing skin temperature should be constant when freestream temperature, airspeed,and internal heat transfer are entirely unchanged. As shown in Fig. 25, the temperature distributions of the four cases under dry conditions are nearly the same. Therefore, it is sufficient to study wet condition experiments based on the temperature data. The wing skin temperature distributions after spraying are shown in Fig. 26. The wing skin temperature for LWC of 0.5 g/mcase is significantly higher than other cases, and temperature distributions of the other cases are relatively close.According to the heat transfer characteristics described above,the temperature difference between dry and wet conditions should be linearly related to LWC when the impinging droplets are evaporated completely. However, as shown in Fig. 27, the data obtained in the experiments do not conform to the theory.Especially the temperature difference curve at S<-40 mm is nearly the same at LWC of 1.0 g/m, 1.5 g/m, and 2.0 g/m.This phenomenon illustrates that the impinging droplets are not completely evaporated for the reasons explained below. Fig.26 Temperature distributions of wet conditions for different LWC. Fig. 27 Temperature difference between dry and wet conditions for LWC. Fig. 28 Ice accretion on wing for different LWC. Fig. 29 Water droplet and vapor layer. Fig.30 Temperature distributions of dry conditions for different MVD. Actually,the runback ice is observed in the experiments.As shown in Fig.28,runback ice is formed on the lower surface at LWC of 1.0 g/m, 1.5 g/m, and 2.0 g/m. And the icing range of the 2.0 g/s LWC case is more extensive than that of the 1.0 g/s LWC case and 1.5 g/s LWC case. This phenomenon further indicates that the water film formed and flowed out of the anti-icing limit.The upper surface’s heated region is larger than that of the lower surface,so the runback water on the upper surface can evaporate entirely in the region and the upper surface temperature still decreases with the increase of LWC due to the skin heat conduction. However, due to the smaller heated region of the lower surface, the runback water flows out of the heated region, which reduces the evaporation heat transfer of the lower surface. The 0° section is the single jet impinging heat transfer.Lack of internal heat transfer with the increase of LWC may lead to incomplete evaporation.However, the ±45 ° section is different from the 0° section.The surface temperature and internal heat transfer of the section are higher. Moreover, the maximum temperature difference between the supercooled droplet and the wing skin is about 170 ℃. The traditional anti-icing analysis mostly thinks that it is impossible to have incomplete evaporation in this case.Through in-depth analysis,it is found that excessive wall temperature may hinder the evaporative heat transfer of water droplets, which is called the Leighton frost phenomenon. Fig.31 Temperature distributions of wet conditions for different MVD. As shown in Fig. 29, when the wall temperature is very high, the impinging droplets boil and evaporate directly, and the heat transfer between the droplets and the skin may enter into a transitional boiling state. The vapor layer is generated by boiling, resulting in supercooled droplets unable to effectively heat exchange with the wing skin and may directly bounce off or blow away. In addition, the increase of LWC leads to more supercooled water droplets impact on the wing skin, and the thickness of the vapor layer increases, further reducing the heat exchange between the water droplets and the wing surface. And the droplets failed to evaporate may rebound and re-impact on wing surface under the aerodynamic effect of airflow.Therefore,the ice accretion,shown in Fig.28,is observed. However, this experimental phenomenon has not been reported in published anti-icing experiments,and it is difficult to determine whether it is caused by the Leighton frost phenomenon.However,this experimental phenomenon should be investigated in future research. The experiments of three kinds of MVD are carried out for test Cases 12–14 in Table 2.As shown in Figs.30 and 31,the temperature distributions of the three cases under the dry condition are very close, and the temperature difference between the three cases under wet condition increased slightly. The related research found that the impinging area and amount of water droplets are enlarged with the increase of MVD.Overall,the increase of MVD leads to a rise in the temperature difference in dry and wet conditions, but the effect is slight. However, the effect of MVD is not limited to changes in temperature,as shown in Fig.32,the ice accretion on the lower surface is photographed during the experiments. The LWC of this group of experiments is 1.5 g/m, so there is a small amount of ice accretion for MVD of 20 μm. In addition, it is evident that the ice on the wing for MVD of 40 μm is much more than other cases. As the research object of this experiment is the slot wing hot air anti-icing system, the heating range of the lower surface is far smaller than that of the upper surface. So larger diameter water droplets are easy to hit outside the heating area and freeze. Fig. 32 Ice accretion on wing for different MVD. A full-scale hot air anti-icing system with a novel inner-liner structure is investigated in a 2 m×3 m icing wind tunnel of CARDC. The present work is emphasized on investigating the effect of icing parameters (LWC and MVD) and hot air parameters(mass flow rate and temperature)on the heat transfer of the anti-icing system.And an analytical method is developed based on the wing skin temperature difference of dry and wet conditions to analyze the evaporation of water droplets and the formation of water film. Compared with the scaling experiments, the full-scale experiments more intuitively reflect the anti-icing performance and contribute to a better understanding of anti-icing system. The effects of hot air mass flow rate and temperature are studied to guide for anti-icing engineering design. The change of mass flow rate has an influence on the heat transfer characteristics near the impingement stagnation region. Thus a proper impinging angle not only enhances the heat transfer performance, but also increases the response speed of the anti-icing system. Furthermore, the hot air temperature has a more significant effect on the wing skin temperature. In addition, a special phenomenon is obtained based on the analysis of water film formation. Under the conditions of big LWC,although the wing skin temperature is very high, the impingement water droplets still evaporate incompletely. Declaration of Competing Interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgements This study was co-supported by the National Numerical Wind Tunnel Project (No. NNW2018-ZT2B04) and the ‘‘973” Program of China (No. 2015CB755800).

4. Results and discussion

4.1.Effects of hot air mass flow rate on heat transfer of the antiicing system

4.2.Effects of hot air total temperature on heat transfer of antiicing system

4.3. Effects of LWC on heat transfer of anti-icing system

4.4. Effects of MVD on heat transfer of anti-icing system

5. Conclusions

CHINESE JOURNAL OF AERONAUTICS2021年9期

CHINESE JOURNAL OF AERONAUTICS2021年9期