Integrated TEM/transmission-EBSD for recrystallization analysis in nickel-based disc superalloy

Fei Sun

WPI-Advanced Institute for Materials Research (WPI-AIMR),Tohoku University,Sendai,980-8577,Japan

Keywords:Superalloy TEM Transmission-EBSD Recrystallization

ABSTRACT Turbine discs in gas-turbine engines always experience high-temperature and high-stress environment.Extensive investigations have been performed towards achieving high performance.Deformation behaviors and degradation factors above normal service temperature are important to be comprehensively understood for further development and optimization of turbine disc superalloys.In this study,the low cycle fatigue behaviors were investigated under total strain amplitude control in U720Li disc superalloys.The results revealed that with the increasing strain,the number of dislocation increased and dislocation configuration transferred from pile-up at the matrix/γ′ precipitates interfaces to penetrating into γ′ precipitates.The great extent of recrystallization was found above the normal service temperature through transmission-EBSD combined with TEM analysis.The low cycle fatigue property above the normal service temperature was weakened to a large extent after recrystallization of small-angle grains formed by the dislocation substructures and movements.Large extent of local recrystallization could also provide much more sites for the crack initiation and propagation.

1.Introduction

High performance superalloys have been developed and optimized continuously to meet the demand for the various component applications in harsh environments.For the engine turbine disc,the experienced environment make it possess excellent properties in fraction toughness,creep and fatigue resistance,etc.,which was also in view of the high speed of rotation and associated centrifugal stresses and high operating temperatures [1].Given the thermal cycling and stress state imposed on a turbine disc,low cycle fatigue (LCF) from ground-air-ground engine cycles is of critical importance for ensuring structural integrity of engine components.Therefore,LCF property is an important consideration in design of the components in turbine discs[2-6].The most advanced and commercial wrought Ni-based U720Li superalloy has and continues to be of great interest for turbine disc applications and exhibit superior elevated temperature tensile strength and LCF properties,excellent hot corrosion resistance and particularly the excellent workability [7,8].U720Li alloy developed for disc application and its maximum service temperature is around 680°C [9,10].Through the LCF test under total strain-controlled mode above 680°C,deformation behaviors and related microstructure evolution are quite important to be well understood the degradation factors and damage mechanisms above the normal service temperature,which could give great insights into development of turbine disc superalloys.However,literatures available in open domain to develop an understanding of these properties in U720Li alloy is rather limited.

Transmission electron backscatter diffraction (t-EBSD),a scanning electron microscopy (SEM)-based electron diffraction characterization technique,could provide a significant improvement in spatial resolution over conventional EBSD and images and detailed quantitative orientation data comparable with that obtained by transmission electron microscopy (TEM) for crystallographic analysis of materials [11].In this study,t-EBSD measurement was performed using the same TEM sample to analyze the recrystallization behaviors at different strain levels during LCF tests.T-EBSD technology could also obtain high resolution images in local regions at micro/nano-scale levels.More detailed microstructure evolution in such micro/nano-sized local regions could also be analyzed using TEM,which mainly in terms of dislocation substructures and interactions with γ′precipitates in U720Li alloy.This could be of benefit to understanding the effect of microstructure on properties and providing some fundamental suggestions for further development and optimization of turbine disc superalloys.

2.Materials and methods

Solid solution heat treatment was carried out at sub-solvus temperature 1100°C for 4 h followed by oil quenching.First-stage aging heat treatment was conducted at 650°C for 24 h followed by air cooling.The second-stage aging heat treatment was conducted at 760°C for 16 h followed by subsequent air cooling.The LCF tests were performed on the smooth cylindrical specimens (gauge diameter of 6.35 mm and gauge length of 19.0 mm)in a closed-loop servohydraulic testing machine with computer-controlled loading spectra programmed as specified by ASTM E606.The strain was monitored continuously using an extensometer.The uniaxial strain-controlled cyclic tests were carried out at 650°C and 725°C with a wide strain ranges (0.8%,1.0% and 1.2%) in air using triangular waveform at a frequency of 0.5 Hz in fully reversed(R=-1)condition.T-EBSD characterization can be performed on any sample that is acceptable for conventional TEM by incorporating a special holder for TEM samples.In this study,the sample observed by TEM(FEI Tecnai 20 TEM operating at 200 kV) and t-EBSD in SEM (JSM 7001 F)could be the same one,which is beneficial for obtaining more detailed and exactly information.Discs of 3 mm in diameter were punched out of the tested specimens and mechanically thinned down to about 40 μm in thickness.TEM samples were further prepared by a standard electropolishing technique using a twin-jet electro-polisher.

3.Results and discussion

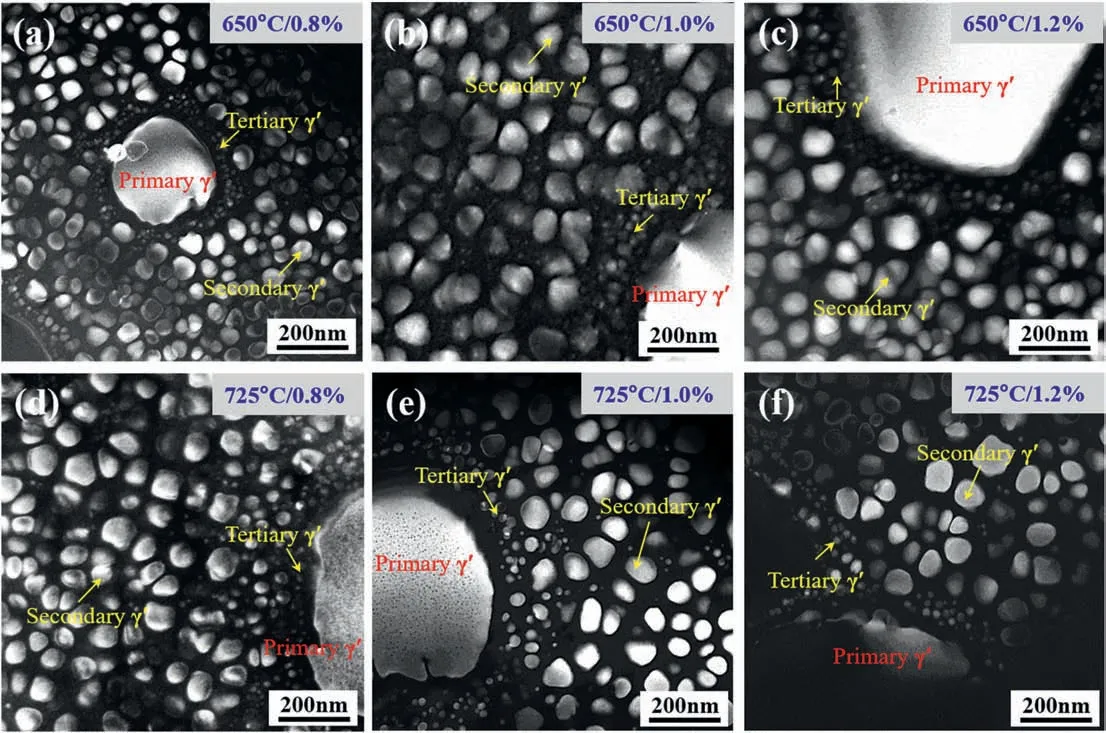

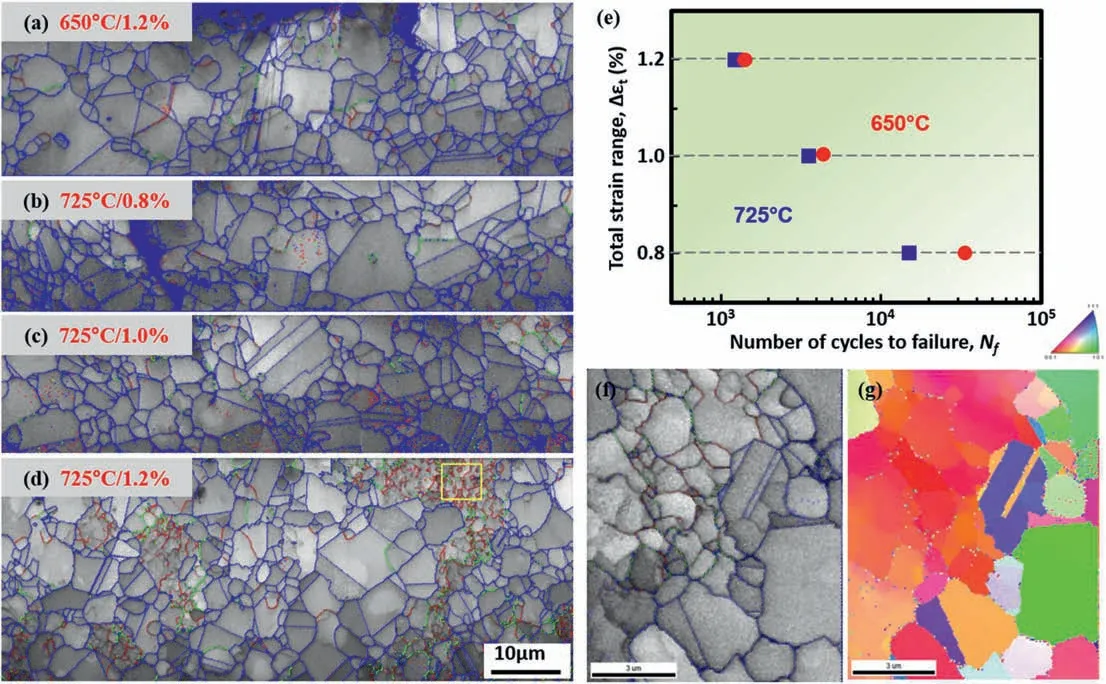

LCF tests were performed at 650°C and 725°C for comparison of the deformation behaviors and degradation factors above normal service temperature.After LCF tests,classical spherical γ′precipitates in terms of primary,secondary and tertiary γ′precipitates were observed by TEM dark field imaging method,as shown in Fig.1 (a)-(f),which were indicated respectively (650°C/0.8%,650°C/1.0%,650°C/1.2%,725°C/0.8%,725°C/1.0%,725°C/1.2%).Secondary γ′precipitates distributed homogeneously and the finer-sized tertiary γ′precipitates have a strong tendency to form around primary γ′precipitates.T-EBSD measurement were performed to obtain the microstructure evolution of the samples after LCF tests at 650°C/1.2%,725°C/0.8%,725°C/1.0%,725°C/1.2%,and the t-EBSD images were shown in Fig.2 (a)-(d),respectively.Among those images,the blue,green and red lines indicate grain boundary misorientation angles larger than 15°,5°-15°,and 2°-5°,respectively.Generally,the fraction of small angle grain boundaries increases at higher temperature and higher strain.The corresponded LCF properties of U720Li was shown in Fig.2 (e),which indicates that the LCF property decreased with the increasing temperatures and total strains.At higher strain 1.2%,the LCF property decreased obviously with increasing temperature.T-EBSD technology could be helpful to obtain images with higher resolution to give more detailed information.As shown in Fig.2 (d),the local region in the sample of 725°C/1.2%,as marked by a yellow square,contained large number of small angle grain boundaries.And the corresponded high magnification and high-resolution images are shown in Fig.2(f).Some quite small grains still exhibited very small disorientations through the inverse pole figure,as shown in Fig.2 (g).These small grains maybe formed with small misorientation inside one large grain.It was possible that the dynamic recrystallization occurred under this condition.According to the microstructure evolution at the different temperatures and strains,some factors and interactions might exist to control the dynamic recrystallization and the properties change.

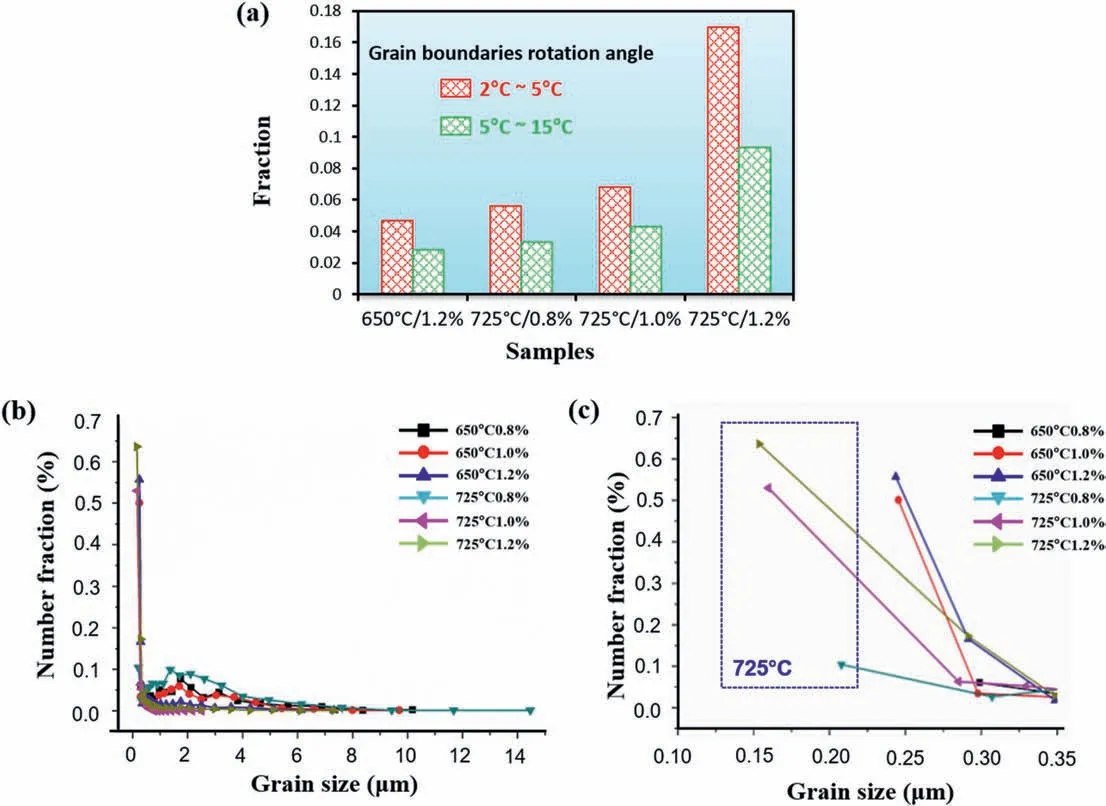

Further analyzing of t-EBSD data was conducted to obtain the grain boundary misorientation angles and grain sizes distribution behaviors,as shown in Fig.3(a)-(c),respectively.In Fig.3(a),the misorientation smaller than 5°is shown in red,and smaller than 15°is shown in green.It is clearly that the grain boundary rotation angle (<15°) fraction at 725°C was larger than that at 650°C.At 725°C,the grain boundary rotation angle (<15°) fraction increased with the increasing strains.According to the grain size and related number fractions,as shown in Fig.3(b),there definitely existed a large number of small grains or subgrains at nanoscale level(<0.5 nm)at 725°C,as shown clearly in Fig.3(c),marked by a blue dashed line rectangle,which is further enlarged from Fig.3 (b).Moreover,the number fraction of grain size also increased with increasing strain at 725°C.It could be proposed that a large number of low-angle grain boundaries or sub-grain boundaries(<15°)formed during LCF tests at 725°C.That is also prone to forming smaller grains or sub-grains inside some large-sized grains.

Fig.1.TEM dark field images of γ′ precipitates after LCF tests at (a) 650 °C/0.8%,(b) 650 °C/1.0%,(c) 650 °C/1.2%,(d) 725 °C/0.8%,(e) 725 °C/1.0%,(f)725 °C/1.2%.

Fig.2.Transmission-EBSD patterns at (a) 650 °C/1.2%,(b) 725 °C/0.8%,(c) 725 °C/1.0%,(d) 725 °C/1.2%.The red,green and blue lines indicate the grain boundary rotation angles at 2-5°,5-15° and 15-180°,respectively,(e)numbers of cycles to failure vs.total strain ranges,(f)high magnification transmission-EBSD pattern in (d),as marked by a yellow square,(g) inverse pole figure map.

Fig.3.Transmission-EBSD results of (a) grain boundary rotation angles and (b) grain size distribution as functions of number fractions.

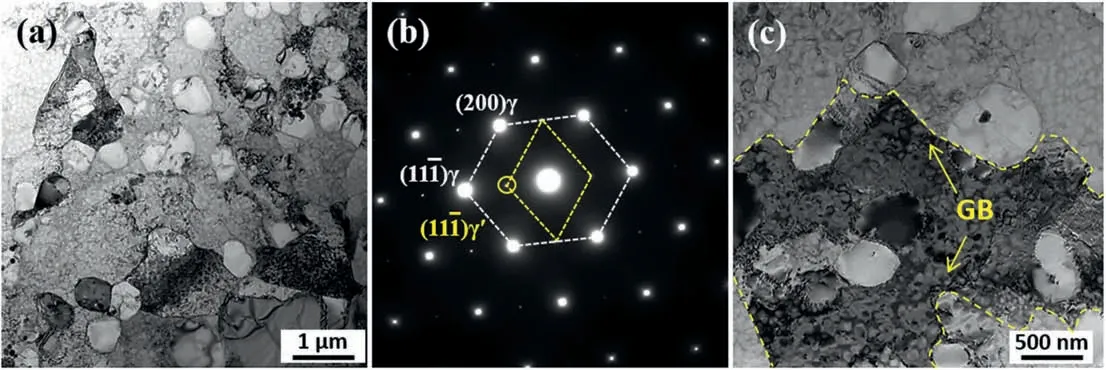

Due to T-EBSD characterization can be performed on TEM sample,local region observation could be conducted on the same sample.Microstructure of the local region,marked by a yellow square in Fig.2(d),was also observed by TEM,as shown in Fig.4(a).A large number of precipitates around a few hundred nanometers could be observed in Fig.4(a).The identification by the diffraction pattern in Fig.4 (b),showed the existence of definitely γ′precipitates.These large-sized γ′precipitates could be primary γ′precipitates,remaining in the grain or pinning at grain boundaries after the sub-solvus solution heat treatment.The distribution behaviors of primary γ′precipitates was further studied through high magnification TEM image,as shown in Fig.4 (c).Obviously,the primary γ′precipitates could not form during the fatigue process at 725°C.The primary γ′precipitates with large size were possible to be identified as separate sub-grains due to the incoherent γ/γ′interface.Besides,it may be possible that the large number of small grains formed during the LCF tests also resulted from the dynamic recrystallization,which could be induced by dislocation movements.

Fig.4.(a) Bright field TEM image of the local region in the sample at 725 °C/1.2%,as marked by a yellow square in Fig.1 (d),(b) diffraction pattern of γ′ precipitates in (a),(c) high magnification TEM image showing primary γ′ precipitates distribution behaviors.

Focusing on the recrystallization possibility,TEM observation was conducted to analyze in more details about it.Those microstructures containing primary γ′precipitates,dislocations and grain boundaries are shown in Fig.5 (a)-(f) for the LCF test conditions of 650°C/0.8%,650°C/1.0%,650°C/1.2%,725°C/0.8%,725°C/1.0%,725°C/1.2%,respectively.Through the LCF test at different strain level,the dislocations glide inside the grains interacted with γ′precipitates,especially primary γ′precipitates.As shown in Fig.5(a)-(c),the dislocations could concentrate into walls and acted as sub-grain boundaries.Those dislocation walls combined with primary γ′precipitate near grain boundary could form sub-grains,as shown clearly by the TEM imaging contrast in Fig.5 (c).In Fig.5(d)-(f),it can be observed that the dislocation densities increased with increasing strain at 725°C due to the deformation to a large extent.It is clear that the large sized primary γ′precipitate could prevent dislocation gliding in the grain interiors.And the dislocation may pin at the interfaces between primary γ′precipitate and matrix.According to the TEM observation,at larger strain,the dislocations could be found inside the primary γ′precipitates.It means that with the increasing total strain,the dislocations configuration transferred from pile-up at the matrix/primary γ′precipitates interfaces to penetrating into primary γ′precipitates.The reason is that the stress concentration at the matrix/primary γ′precipitates interfaces promoted the pinning dislocations to overcome the energy barrier and further glide into the primary γ′precipitates.In Fig.5 (d) and (f),the dislocations glided inside the grains and could pin at the matrix/primary γ′precipitates interfaces.Therefore,those dislocations had tendencies to form dislocation walls and combine few primary γ′precipitates to form sub-grain boundary inside some large-sized grains.

The results of t-EBSD analysis mentioned above also showed that a large number of quite small grains or sub-grains with very small grain boundary rotation angles formed at 725°C.Generally,those primary γ′precipitates,together with secondary and tertiary γ′precipitates kept the same lattice constant and chemical composition.However,the change of chemical composition and lattice constant of the γ phase leads to the variable of the γ-γ′lattice misfit [12].Consequently,one part of those primary γ′precipitates could act as small sub-grains separately.Otherwise,in large-sized grains,the gliding dislocations could be prevented by the primary γ′precipitates,and pinned at the matrix/primary γ′precipitates interfaces.Those dislocations could be acting as sub-grain boundaries through concentration into dislocation walls.Furthermore,those dislocations could also associate local few primary γ′precipitates to form sub-grains.In addition,some fine grain formation at high strains might result from a kind of strain-induced continuous reactors taking place during LCF deformation.That is essentially similar to continuous dynamic recrystallization.During the LCF deformation,recrystallization could occur and the extent also increased with the increasing strain.Therefore,the LCF property at 725°C could be weakened to a larger extent than that of 650°C.As a whole,after comparison of deformation behaviors and microstructure evolution at 650°C and 725°C (above normal service temperature),the main factor causing the degradation at 725°C could be recrystallization directly.While,the recrystallization with large extent at higher temperature and higher total strain might result from the dislocation configuration and movements which were induced by the strain during the LCF tests.Large extent of local recrystallization could also provide much more sites for the crack initiation and propagation.It maybe the significant reason to reduce the fatigue life dramatically.

4.Conclusions

This study focused on the dislocation sub-microstructures and interactions with γ′precipitates to analyze the recrystallization behavior in Ni-based disc superalloy U720Li alloy during LCF tests at 650°C and 725°C with strains of 0.8%,1.0% and 1.2%.T-EBSD and TEM technologies have been integrated to characterize the details in micro/nano scaled regions correspondingly and also with high resolution.The extent of recrystallization at 725°C is larger than that of 650°C and also increases with the increasing strains.Also,the dislocations configuration transfers from pile-up at the matrix/primary γ′precipitates interfaces to penetrating into primary γ′precipitates.The gliding dislocations tend to concentrate into walls to form sub-grain boundaries.Then,the sub-grains form through the combination of dislocation walls and local primary γ′precipitates.Low cycle fatigue property at 725°C can be weakened to a large extent after recrystallization.Large extent of local recrystallization can also provide much more site for the crack initiation and propagation.

Declaration of competing interest

The authors declared that they have no conflicts of interest to this work.

Progress in Natural Science:Materials International2021年1期

Progress in Natural Science:Materials International2021年1期

- Progress in Natural Science:Materials International的其它文章

- Dynamic response characteristic of 7N01/7A01/7050 aluminium multilayer plate at high strain rate

- Synergetic effect of multiple phases on hydrogen desorption kinetics and cycle durability in ball milled MgH2-PrF3-Al-Ni composite

- Growth mechanisms of Ag and Cu nanodendrites via Galvanic replacement reactions

- Highly mechanical and high-temperature properties of Cu-Cu joints using citrate-coated nanosized Ag paste in air

- Ab-initio investigation for the microscopic thermodynamics and kinetics of martensitic transformation

- Rapid directionally solidified microstructure characteristic and fracture behaviour of laser melting deposited Nb-Si-Ti alloy