Effect of natural and synthetic fibers reinforcement on California bearing ratio and tensile strength of clay

Mhdi Ghsemi Nezhd,Alirez Trs,*,Nim Ltifi

a Department of Civil Engineering,Faculty of Engineering,Golestan University,Gorgan,Iran

b Terracon Consultants,Inc.,5217 Linbar Dr #309,Nashville,TN,37211,USA

Keywords:Natural fibers Synthetic fibers Indirect tensile strength (ITS)California bearing ratio (CBR)Reinforced soil

ABSTRACT Use of environmentally friendly approaches with the purpose of strengthening soil layers along with finding correlations between the mechanical characteristics of fiber-reinforced soils such as indirect tensile strength (ITS) and California bearing ratio (CBR) and as well as the evaluation of shear strength parameters obtained from the triaxial test would be very effective at geotechnical construction sites.This research was aimed at investigating the influence of natural fibers as sustainable ones including basalt(BS)and bagasse(BG)as well as synthetic polyester(PET)fibers on the strength behavior of clayey soil.To this end,the effects of various fiber contents (0.5%,1% and 2%) and lengths (2.5 mm,5 mm and 7.5 mm)were experimentally evaluated.By conducting ITS and CBR tests,it was found that increasing fiber content and length had a significant influence on CBR and ITS values.Moreover,2%of 7.5 mm-long fibers led to the largest values of CBR and ITS.The CBR values of soil reinforced with PET,BS,and BG fibers were determined as 19.17%,15.43% and 13.16%,respectively.The ITS values of specimens reinforced with PET,BS,and BG fibers were reported as 48.57 kPa,60.7 kPa and 47.48 kPa,respectively.The results of the triaxial compression test revealed that with the addition of BS fibers,the internal friction angle increased by about 100%,and with the addition of PET fibers,the cohesion increased by about 70%.Moreover,scanning electron microscope (SEM) analysis was employed to confirm the findings.The relationship between CBR and ITS values,obtained via statistical analysis and used for the optimum design of road pavement layers,demonstrated that these parameters had high correlation coefficients.The outcomes of multiple linear regression and sensitivity analysis also confirmed that the fiber content had a greater effect on CBR and ITS values than fiber length.

1.Introduction

California bearing ratio (CBR),considered the most important parameter,is essential to evaluate the subgrade soil strength and improve the engineering properties of pavement layers materials used in road construction.In earthen structures,thickness of layers is determined based on the CBR value.Moreover,the tensile strength is an effective parameter to determine the suitable construction materials used in pavement layers (Kumar et al.,2011;Mishra and Gupta,2018;Tan and Huat,2019).Moving loads and traffic lead to the development of tensile stress in pavement layers.When the developed tensile stresses exceed the tensile strength of the layers,cracking of the pavement layers begins and excessive deformation occurs.As a result,these parameters are effective to design pavement layers at construction sites (Ardah et al.,2017;Sayida et al.,2019;Singh et al.,2019).Poor engineering and geotechnical properties of weak soils make them unsuitable for construction purposes.Different methods such as chemical stabilization and fiber reinforcement are used to improve the mechanical properties of such weak soils.Among various methods,fiber reinforcement has drawn considerable attention from researchers for construction purposes.In this context,use of fiber-reinforced soils in projects such as building retaining walls,railway embankments construction,earthen structures and pavement layers significantly increases their strength(Kapogianni et al.,2016;Saleh et al.,2019;Tran et al.,2019).

Fig.1.Grain size distribution of the soil studied.

Table 1Geotechnical characteristics of soil used.

Table 2Engineering properties of PET fibers used.

In recent years,use of natural fibers as sustainable materials for soil improvement purposes has increased which could be attributed to factors such as abundance of resources and being environmentally friendly(Danso et al.,2015;Jo et al.,2016;Ghosh et al.,2017;Yadav and Tiwari,2017a,b).In this regard,bagasse(BG)is a waste material produced following the extraction of juice(Gowthaman et al.,2018).Researches have come up with innovative applications to use BG fibers as construction materials.In Iran,about 2 tons of BG is produced for each hectare of land which ends up being burnt.Moreover,as basalt(BS)fibers are beneficial to the environment and enjoy unique mechanical and chemicalproperties,they are attractive for many purposes.Therefore,these fibers,as reinforcement elements,have attracted more attention compared to other fibers (Fiore et al.,2015;Jamshid,2017;Singh et al.,2019;Wang et al.,2020).Besides,synthetic fibers have high tensile strength and good corrosion resistance (Harnnecker et al.,2012;Orasutthikul et al.,2017).Polyester (PET) as one type of such fibers has many suitable properties including low moisture absorption capacity and high abrasion resistance (Bunsell,2018).

Table 3Engineering properties of BG fibers used.

Table 4Engineering properties of BS fibers used.

According to previous studies,the indirect tensile strength(ITS)of soil specimens increased by adding waste cornsilk fibers to finegrained soil(Tran et al.,2018),while adding discrete fibers to sandy soil failed to have a significant effect on its final shear strength.However,its brittle behavior improved and the tensile and shear strengths increased (Yetimoglu and Salbas,2003;Li et al.,2014;Ghadakpour et al.,2020).Moreover,the CBR test results revealed that increase in clayey soil strength was related to the increased fiber content (Yadav and Tiwari,2017a,b).

Geotechnical properties of clayey soil due to the addition of glass synthetic fibers as subgrade reinforcement were investigated by Sujatha et al.(2020).The results indicated that the type of fibers and the fiber content are two parameters affecting the properties of reinforced soil.Also,the CBR has increased by at least 48%with the addition of glass fiber.Patel and Singh(2019)found that the CBR of soil mixed with glass fiber increased to 2.48 times that of unreinforced soil,and also the CBR increased with fiber content up to 0.75%.Meena et al.(2019) found that natural fibers also have a positive effect on the strength of clayey soils.The results showed that soil compressive strength has increased to about three times and the CBR has increased by about 44%.It is also shown that clayey soil reinforced with wheat straw fibers can be used under rural roads.

Fig.2.Fibers used in the study:(a) PET fiber;(b) BG fiber;and (c) BS fiber.

Fig.3.CBR test machine.

Recycled tire polymer and glass fibers in different lengths and fibers content were used to determine the effect on the strength of clay(Valipour et al.,2021).The results indicated that the addition of fibers increased the ductility.The changes in soil cohesion were significant.The highest shear strength was obtained at the fiber contents of 1%(glass fibers)and 0.5%(recycled tire polymer fibers).

Thus,use of alternative and environmentally friendly approaches as well as incorporating sustainable materials into problematic soils is highly important for geotechnical construction purposes.Moreover,it is required to determine the design parameters such as the CBR and ITS values of fiber-reinforced clay used in the area of civil engineering projects such as road and pavement construction.

One of the most important factors affecting the performance of fiber-reinforced pavements is their durability and long-term performance.The results of Shekhawat et al.(2018)demonstrated the positive performance of fiber-reinforced soils in durability tests.In that study,the durability tests were not considered.According to the standards of these two tests,the specimens must be placed at 100% humidity to obtain accurate test results.While the clay specimens,tested in Shekhawat et al.(2018),were prepared at optimum moisture and maximum dry density.There is another important parameter in determining the durability of road pavement called freezing depth.This parameter is related to the freezing index over one-year period.To determine the freezing index,the average temperature of different months over one year must be calculated.

According to the literature,few studies have been conducted to determine the effect of natural fibers on CBR and ITS values of clayey soil.This study is primarily aimed at investigating the effect of BG and BS fibers as sustainable materials on the mechanical characteristics of subgrade soil used for construction purposes.Furthermore,the performance of synthetic fibers such as PET is compared with that of natural fibers to evaluate the effect of fiber type on the mechanical behavior of soil.To this end,the CBR and ITS values of the investigated soil reinforced with various fiber contents and lengths are measured.In this research,the relationship between ITS and CBR values is also presented to meet the requirements of pavement design codes.The multiple nonlinear regression analysis is established to predict the ITS and CBR values of the unreinforced and reinforced soils with and without fiber inclusion using two basic parameters,i.e.fiber content and fiber length.Besides,the sensitivity analysis is also applied to determining the effective degree of fiber content and fiber length on the ITS and CBR values.Scanning electron microscope (SEM) analysis has also been carried out to confirm the findings.

2.Experimental program

2.1.Materials

2.1.1.Soil

The soil used was provided from Gonbad city,Golestan province,Iran.The grain size distribution of the soil is shown in Fig.1.According to the unified soil classification system (USCS),the soil is classified as silty-clay (CL-ML).The engineering properties of the soil are summarized in Table 1.

2.1.2.PET fibers

The PET fibers used were provided from the Sorin polymer Caspian Co.,Kordkuy industrial estate,Golestan province,Iran.The engineering characteristics of these fibers are given in Table 2.Fig.2a shows the PET fibers used.

2.1.3.BG fibers

BG fibers used were obtained from the Haft Tapeh Co.,Iran.The engineering characteristics of these fibers are presented in Table 3.Fig.2b shows the BG fibers used.

2.1.4.BS fibers

BS fibers used were provided from Rioniz Vira Pars Co.,Iran.The engineering characteristics of these fibers are given in Table 4.Fig.2c shows the BS fibers used.

The engineering characteristics of the fibers are very important because they are effective in their tensile and compressive behavior.Fibers absorb moisture if placed in a humid environment.The amount of moisture absorbed by the fibers not only depends on fiber type but also is a function of environmental moisture.Fiber moisture absorption is considered an important parameter which causes changes in soil physical properties.Moreover,the tensile strength of fibers is the stability of fibers against tensile force.The strength of fibers depends on their material and thickness under various environmental conditions such as heat,cold,sunlight and some chemicals as well as humidity.

2.2.Testing program

In this investigation,CBR and ITS tests were conducted on unreinforced and reinforced soil specimens.The influences of various contents of PET,BG and BS fibers(wf=0.5%,1%and 2%),as well as different fiber lengths (lf=2.5 mm,5 mm and 7.5 mm),were studied.

2.2.1.CBR test

The CBR test machine has a metallic grid plate and a tripod for holding the gage on the mold.The hydraulic jack of the CBR test machine exerts a uniform pressure of 44.5 kN to the soil specimen at a loading rate of 1.27 mm/min.The diameter and cross-section of the piston are 49.63 mm and 1935 mm2,respectively.The force magnitude of piston penetration into the soil specimen is measured using the load cell (Fig.3).

Fig.4.Specimen preparation process and ITS test:(a) Cylindrical mold;(b) Materials used;(c) Clay specimen;(d) ITS test;and (e) Failure of clay specimen.

Table 5Experimental program summary.

2.2.2.ITS test

The magnitude of ITS is estimated using the uniaxial compressive strength(UCS)test machine.The loading rate of the machine is 1.27 mm/min.The ITS of soil specimens is measured based on the following equation (Sayida et al.,2019;Tran et al.,2019):

Fig.5.Effect of fiber length on the CBR values of the specimens studied (wf=0.5%).

where P,l,and d are the applied force(N),length(cm)and diameter(cm) of the specimens,respectively.

2.3.Specimen preparation

CBR test is the most common method to determine the relative strength of soils for pavement design purposes and measures the bearing capacity of road layers.In the current research,a series of CBR tests was performed on unreinforced soil as well as soil specimens reinforced with BG,BS and PET fibers in soaked conditions(ASTM D1883-99,1999).The fibers are randomly mixed with soil.Based on the standard Proctor test,the optimum moisture content(OMC) and maximum dry unit weight (MDD) values were determined as 12% and 17 kN/m3,respectively (ASTM D698-12,2012).The soil was oven-dried for 24 h.The unreinforced specimen was prepared based on MDD and OMC values.The metallic cylindrical mold of the CBR test has an internal diameter of 152.4 mm and a height of 177.8 mm.The unreinforced and reinforced specimens were compacted in three layers via 56 blows.The compaction was conducted in CBR test cylindrical mold using a 24.4-N rammer dropping from a height of 305 mm.Then,the 4.54-kg steel plate is placed on the compacted specimen surface.The compacted soil specimens in cylindrical molds were kept in a water tank for 96 h to be saturated.The final swelling was determined by the swell measurement gage.To estimate CBR,the stress values were determined using the stress-penetration curve provided for 2.5 mm and 5 mm-deep penetrations.Dividing the load measured from the test by the standard load,the CBR value was calculated.

Fig.6.Load-penetration curves for different fiber lengths:(a) PET fiber;(b) BS fiber;and (c) BG fiber.

In this investigation,a series of tensile strength tests was also carried out based on NBR 7222 (1983).Generality,easy operation,time-saving,cost-effectiveness,inexpensive equipment,reliable results,and repeatability are among the main advantages of this test.The cylindrical mold used has a diameter of 50 mm and a height of 100 mm(Fig.4a).The materials used are shown in Fig.4b.First,the soil was oven-dried for 24 h.Then,the fibers were mixed with soil at OMC and MDD values.Using a cylindrical mold,the soil specimens were compacted in three equal layers with 25 blows for each.To achieve a homogeneous mixture,all materials were mixedcarefully.The UCS test machine was employed to determine ITS values.The test continued until the specimen failed(Fig.4d and e).The laboratory details of this study are summarized in Table 5.

Table 6Results obtained from statistical software analysis.

Table 7t-distribution (Montgomery et al.,2012).

Table 8Results of ANOVA.

Table 9Fisher distribution (Montgomery et al.,2012).

3.Results and discussion

In this section,the results of CBR,ITS and triaxial tests on unreinforced soil as well as the specimens reinforced with various fiber contents and lengths are provided.

3.1.CBR tests

3.1.1.Effect of fiber length

According to the results,a direct relationship was found between the CBR value and both fiber content and length.Moreover,the CBR value could be considered a function of fiber content and length.Fig.5 shows the influence of fiber length on the CBR values of the reinforced specimens.The CBR value corresponding to the plain sand was 5.7%;while the CBR values of soil specimens reinforced with 0.5% of 2.5 mm-long BG,BS,and PET fibers were determined as 7.39%,8.7% and 9.26%,respectively.According to Fig.5,as fiber length increased,the CBR values for all types of fibers increased.For a constant fiber length of 2.5 mm,the CBR values of soil specimens reinforced with BG,BS and PET fibers increased to 1.3,1.53 and 1.62 times the CBR value of unreinforced one,respectively.While increasing fiber length did not have a significant effect on the CBR values of soil specimens reinforced with 0.5%of BS fibers.Furthermore,2.5 mm-and 5 mm-long BG fibers had the least impact on the CBR values.However,7.5 mm-long BG fibers had a greater effect on the CBR value than the corresponding BS fiber length.Past studies have shown that increasing fiber length has increased the CBR (e.g.Moghal et al.,2018).

Fig.6 shows the load-penetration curves of the unreinforced and reinforced soil specimens.In Fig.6a,a direct relationship was found between PET fiber length and the CBR values of reinforced specimens.Moreover,the CBR values of those specimens reinforced with 1% of 2.5 mm-,5 mm-and 7.5 mm-long PET fibers were determined as 1.4%,1.29% and 1.46%,respectively.The highest increase was observed in that specimen reinforced with 2% of 7.5 mm-long PET fibers.In Fig.6b,BS fibers had an increasing effect on the CBR values of reinforced soil.However,for specimens reinforced with 1% of such fibers,fiber length had little effect.Furthermore,for those specimens reinforced with 2% of BS fibers,the CBR values for 2.5 mm-,5 mm-and 7.5 mm-long fibers were determined as 13.97%,14.73%and 15.43%,respectively.In Fig.6c,as fiber length increased from 2.5 mm to 7.5 mm,the CBR values had an increasing trend.For specimens reinforced with 1%of 2.5 mm-,5 mm-and 7.5 mm-long fibers,the CBR values were determined as 9.58%,10.33%,and 11.16%,respectively.Moreover,for specimens reinforced with 2%of such fibers,the CBR values were reported as 12.4%,12.65% and 13.16%,respectively.

Fig.7.Effect of fiber content on CBR value:(a) lf=2.5 mm;(b) lf=5 mm;and (c)lf=7.5 mm.

Table 10CBR and ITS values for various fiber contents and lengths.

Fig.8.Load-penetration curves of CBR tests:(a) wf=1% and lf=2.5 mm;and (b)wf=1% and lf=5 mm.

Fig.9.Effect of fiber length on ITS value:(a) BS fiber;(b) BG fiber;and (c) PET fiber.

Analysis of variance (ANOVA) is used to evaluate the positive effectiveness of fiber length on the CBR values of soil specimens.According to the results of CBR experiments,it is found that increasing fiber length led to the higher CBR values of the reinforced soil specimens.This trend is obvious for those specimens reinforced with PET and BG fibers.However,the positive effect of fiber length on the CBR values of the BS fiber-reinforced specimens is evaluated using ANOVA.

Fig.10.Effect of fiber type on ITS value:(a) wf=0.5%;(b) wf=1%;(c) wf=2%;(d) lf=2.5 mm;(e) lf=5 mm;and (f) lf=7.5 mm.

Using statistical software and regression model,the ANOVA is performed as follows:

where b0and b1are the regression coefficients,y is the CBR,x is the fiber length,and e is the error.

In order to have significant difference among the values,two statistical hypotheses related to the coefficient b1have been examined.The first assumption is that the value of b1is zero which must be rejected to make the difference among the significant values.The second assumption is that the value of b1should not be equal to zero.Therefore,the relationship between the values would not be linear and the difference between the values would not be significant either.The second assumption is considered a necessary condition to have a significant difference among the values.In this context,the P-value is considered an important parameter.In order to have significant difference among the values,the P-value must be less than 0.05.The results of this investigation conducted using statistical software are listed in Table 6.

Based on Table 6,the values of b0and b1as well as the standard deviations of each coefficient are obtained.The parameter t-value is used to test these two hypotheses.This parameter must be greater than similar values to make the hypotheses meaningful.Pr(>|t|)indicates the probability value corresponding to each coefficient.According to the results shown in Table 6,the following conclusions can be made:

Fig.11.Effect of fiber content on ITS value:(a)PET fiber;(b)BS fiber;and(c)BG fiber.

(1) The t-value was obtained from Table 6.For the difference between the values to be significant,t-value must be greater than the similar values(t)presented in Table 7.In Table 7,the values of confidence level α and degree of freedom v are 0.05 and 26,respectively.Therefore,the t-value is equal to 2.056.Thus,it is significant.

(2) The values of Pr(>|t|),calculated for b0and b1,are 1.78×10-7and 0.04,respectively,which are appropriate values.

(3) The P-value,as the most important parameter to determine the significance of the difference among values,is 0.03999.This value is less than 0.05 and the difference between the values is significant.

The results of ANOVA are listed in Table 8.The Fisher distribution (F) obtained from this table must be greater than(Fv1·v2·α=F1·n-2·α)determined in Table 9.It is worth mentioning that the degree of freedom for the numerator v1is equal to 1,because regression is one variable.On the other hand,the degree of freedom for the denominator v2is n-2 (n is the number of variables which is equal to 28) and α is 0.05.

By examining Table 9,the value of F1·n-2·α is determined as 4.23 which is less than the value of F observed in Table 8.These results indicate that the difference between the desired values(i.e.the CBR values and the fiber length) is statistically significant.

3.1.2.Effect of fiber content

Fig.7 shows the effect of fiber content on the CBR values of reinforced specimens.As can be seen,higher fiber content led to greater CBR values.These results are consistent with the findings of the previous investigation (Kumar and Singh,2008).According to Fig.7,adding 0.5%of fibers to the soil did not considerably affect the CBR value.Among specimens reinforced with PET fibers,1%of such fiber led to the highest CBR.Moreover,using 2% of such fibers caused a considerable increase in CBR.Among specimens reinforced with 0.5%and 2%of 5 mm-long fibers,BS fibers had a greater effect on the CBR compared to BG fibers.This is inconsistent with CBR values of 2.5 mm-long fibers,indicating 2.5 mm-and 5 mmlong BS fibers had less effect than BG fibers did.Moreover,the highest CBR was observed in that specimen reinforced with 2% of PET fibers,and the CBR value was increased from 5.7% to 19.17%.

The positive effect of reinforcement on CBR values can be measured using the reinforcement ratio (η).This parameter is defined as the proportion of the CBR value of the reinforced specimens to the unreinforced one.This ratio highlights the influence of reinforcement on increasing the CBR value.Table 10 provides the results of CBR and ITS tests for various fiber contents and lengths.Using fibers at various contents and lengths led to a reinforcement ratio greater than 1,indicating the positive effects of such fibers as soil reinforcements.As can be seen,adding 2%of 7.5 mm-long PET fibers caused the highest reinforcement ratio.Standard deviation values are added to Fig.7 and Table 10.

3.1.3.Effect of fiber type

Fig.8 shows the load-penetration curves of specimens reinforced with 2.5 mm-and 5 mm-long fibers.According to Table 8,use of PET fibers as reinforcement led to higher values of CBR compared to using BS and BG.Similar studies also revealed that the effect of synthetic fibers on the CBR value was greater than that of natural fibers (Das and Singh,2019).By comparing the CBR values of reinforced specimens,it is evident that adding 1%of 7.5 mm-long fibers resulted in a relatively low increase in CBR value.Moreover,it can be concluded that 2% of 7.5 mm-long fibers is the optimum reinforcement conditions for PET fiber-reinforced specimens.While 1% of 7.5 mm-long fibers can be considered the optimum conditions for both BS and BG fiber-reinforced soils (Table 10).

3.2.ITS tests

3.2.1.Effect of fiber length

Fig.12.Triaxial shear test(UU):(a)Triaxial test machine;(b)Loading on soil specimen;(c)Specimen deformation during loading;and(d)Deformation of soil specimen after test.

The relationship between ITS value and fiber length is shown in Fig.9.Adding 2% of 7.5 mm-long BS fibers led to a significant increase in ITS value.By comparing 2.5 mm-and 5 mm-long fibers at 0.5% and 1% fiber contents,a slight difference was found in the increased values of ITS.While the highest ITS value was observed at specimen reinforced with 7.5 mm-long fibers,indicating the effectiveness of the fiber on ITS.A similar trend was also observed in BG fiber-reinforced soils.The ITS value of the unreinforced soil was determined as 23.69 kPa.The lowest value of ITS was observed at specimen reinforced with 0.5%of 2.5 mm-long fibers(28.68 kPa),while the highest one was observed at specimen reinforced with 2%of 7.5 mm-long fibers (47.48 kPa).The PET fiber length had also direct relationship with ITS value.For all types of fibers studied in this study,the optimum fiber length was determined as 7.5 mm.Divya et al.(2014) showed that the peak tensile strength of fiberreinforced specimens was higher than unreinforced specimens,and with increasing fiber length,the amount of peak tensile strength increased.

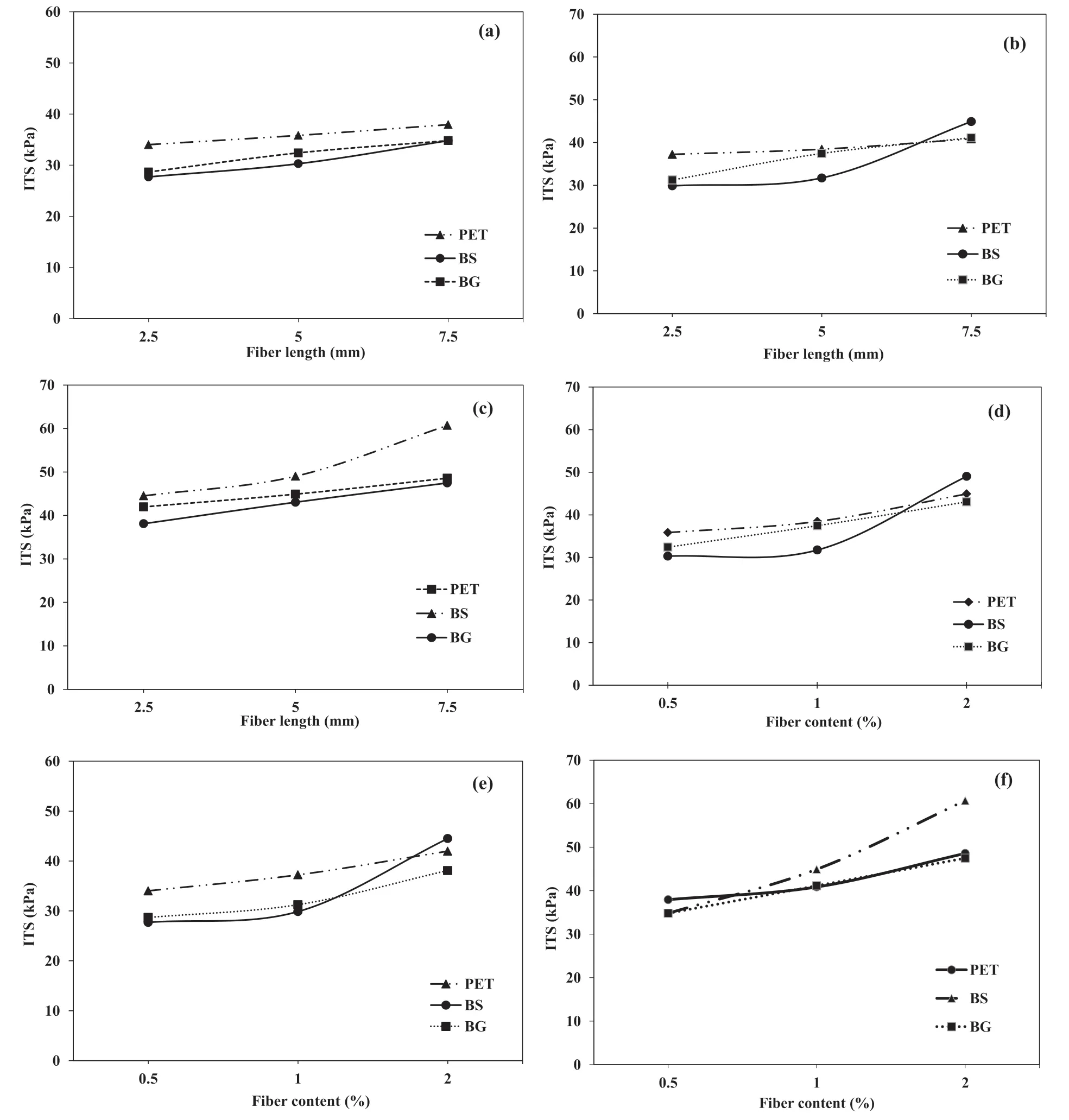

3.2.2.Effect of fiber type

The tensile behavior of soil plays a pivotal role in engineering projects.Dense soils,utilized in geotechnical structures,are always subjected to cracking caused by tensile failure.Therefore,increasing the tensile strength of soil by discrete fibers is considered a novel method.Fig.10 shows the ITS values of fiber-reinforced soil specimens.As can be seen,1%and 2%of 7.5 mm-long BS fibers had the best performance.Moreover,at similar fiber content,2%of BS fibers led to the highest ITS value compared to the other two types of fibers.While 0.5%of PET fibers resulted in the highest ITS values for all lengths compared to the other two types of fibers.PET and BG fibers demonstrated similar trends at 0.5% and 1% fiber contents.Nonetheless,PET fibers led to higher ITS values than BG fibers did.Among specimens reinforced with 0.5% and 1%of these two types of fibers,the ITS values had relatively increased.However,those specimens reinforced with 0.5% of PET fibers indicated appropriate tensile strength compared to other types of fibers.Among specimens reinforced with BS fibers,2% of 7.5 mm-long fibers led to the highest ITS value (60.70 kPa).According to Fig.10a-c,the ITS values gradually increased as fiber content increased from 0.5% to 2%.Fig.10d-f shows the ITS values of specimens reinforced with PET,BS and BG fibers at constant fiber lengths.For specimens reinforced with various fiber lengths(2.5 mm,5 mm and 7.5 mm),the PET and BG fibers indicated a similar trend,i.e.fiber content had a direct relationship with ITS values.While the increased ITS values caused by 0.5%and 1%of 2.5 mm-and 5 mm-long BS fibers are not significant,using 2%of such fibers led to a considerable increase in ITS.Using 2%of BS fibers at various fiber lengths(2.5 mm,5 mm and 7.5 mm)led to higher ITS values than PET and BG fibers did,while 0.5% and 1% of BS fibers had a lower impact compared to PET and BG fibers.Generally speaking,higher fiber contents and lengths led to increased ITS values for specimens reinforced with BS,BG and PET fibers.Natural fibers have a greater effect on improving the tensile properties of clayey soil than synthetic fibers.Also,longer fibers are more effective in improving post-cracking behavior than shorter fibers.Better cohesion of natural fibers than synthetic fibers is probably due to the increased roughness of the fibers (Chebbi et al.,2020).

Fig.13.Variation of shear strength parameters of soil with respect to the fiber type at fiber content of 1% and fiber length of 5 mm:(a) Internal friction angle;and (b)Cohesion.

3.2.3.Effect of fiber content

Fig.11 shows the effect of BS,BG and PET fiber contents on the ITS values.According to Fig.11a,PET fibers resulted in higher ITS values.In other words,the ITS value increased as fiber content increased.Therefore,the optimum PET fiber content is considered 2%.As can be seen in Fig.11b,the ITS value increased slightly as 2.5 mm-and 5 mm-long BS fiber content increased.Nonetheless,the ITS value increased significantly as 7.5 mm-long BS fiber content increased.The tensile strength of soil specimens has increased with increasing BS fiber content(Xiao et al.,2019).

One can see from Figs.11c,2%of BG fibers led to the highest ITS value.This improvement in the tensile strength of reinforced specimens caused by fibers can be attributed to the mechanical interaction between fiber surface and the soil matrix.Moreover,the tensile strength has a direct relationship with fiber content.

Fig.14.Stress-strain curves of unreinforced soil and soil reinforced with fiber at fiber content of 1%and fiber length of 5 mm under different confining pressures:(a)50 kPa;(b) 100 kPa;and (c) 200 kPa.

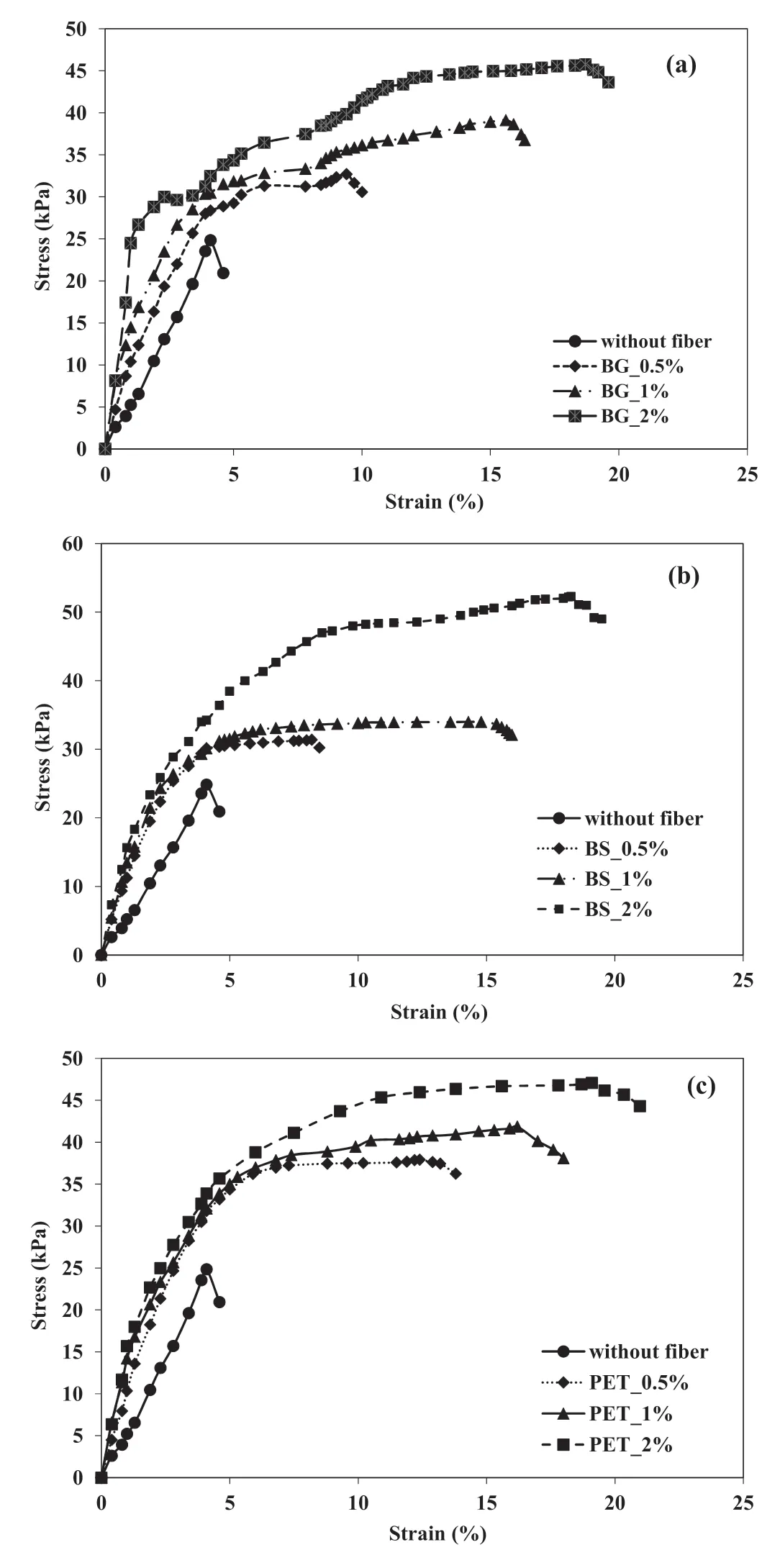

3.3.Triaxial compression tests

The test results indicate that there is no significant difference among the CBR values of specimens reinforced with various fibers contents (0.5%,1% and 2%).Therefore,the most optimum value of CBR was obtained at specimen reinforced with 1% of 5 mm-long fibers.In this research,unconsolidated-undrained (UU) triaxial tests were performed on specimens reinforced with 1% of 5 mmlong BS,BG and PET fibers.Fig.12a shows a triaxial compression test machine.The diameter and height of the test specimen are 38 mm and 76 mm,respectively.The specimens were sheared at a rate of 1.27 mm/min (Fig.12b).After applying the load,the soil specimen is broken and the deformation of the specimen can be seen in Fig.12c and d.

Fig.15.SEM images of (a) Plain soil;(b) BG fiber;(c) BS fiber;and (d) PET fiber.

Fig.16.Macrostructural failure of soil specimens under ITS test:(a) Bridging effect;(b) Crack;(c) Close view of bridging effect.

The shear strength parameters of soil including cohesion(c)and internal friction angle (φ) were determined using UU triaxial tests and Mohr-Coulomb fracture criterion.Variation of shear strength parameters of soil versus the fiber type is shown in Fig.13.The values of c and φ of the unreinforced soil are 60 kPa and 15°,respectively.Similar studies have shown that the addition of the fibers increased the values of shear strength parameters of soil.By adding the fibers to the soil,the value of c increases significantly.Use of PET fibers increases the value of c by about 40%compared to the unreinforced soil.This improvement can be attributed to the interaction between the fibers and soil particles which causes the particles to bind together and increases the value of c of the reinforced soil.According to Fig.13,the value of internal friction angle also increases and the highest value belongs to the soil reinforced with BS fibers.

Fig.14 shows the stress-strain curves of soil specimens reinforced with 1% of 5 mm-long BS,BG and PET fibers.At confining pressure of 200 kPa,the stress-strain curve is slightly amplified due to the difference between the stress-strain curves.According to Fig.14a and b,the deviatoric stress corresponding to PET and BS fiber-reinforced soil specimens is continuously increased,indicating the high ability of the reinforced soil specimens to deform.These results also show that the addition of fibers can improve soil strength.Among the fibers,PET fibers show higher strength.According to Fig.14c,there is little difference in the initial slope between the PET and BS fiber-reinforced soil specimens,meaning that these fibers have similar performance at confining pressure of 200 kPa in terms of resistance to deformation.

3.4.SEM analysis

Fig.17.Stress-strain curves of ITS test at fiber length of 5 mm:(a) BG fiber;(b) BS fiber;and (c) PET fiber.

Fig.15 shows the results of SEM analysis.Fig.15a demonstrates the clayey soil without fibers.Plain soil has pore spaces that are easily visible (Ahmad et al.,2010).Fig.15b shows the soil matrix and BG fibers.As can be seen,the surface of BG fibers is rough,which will increase the friction between the fibers and soil.This increased friction results in higher strength of the reinforced soil.These observations are consistent with the results of the ITS and CBR tests.The rough surface of fibers is a good geometric feature which enhances adhesion to the soil.In Fig.15c,the interaction between the soil particles and fibers is clearly visible.Moreover,small cavities with the dense matrix are also observed in the reinforced specimen,indicating the increased strength of the clayey soil specimen.As explained,the BS fibers are randomly mixed with soil.Thus,the soil particles are well surrounded by BS fibers which in turn create a stable and interconnected structure via combined cementing,filling the pores and bridging processes.Fig.15d shows the interaction among clay particles and PET fibers,demonstrating appropriate bonds within the reinforced soil.

Fig.18.Stress-strain curves of ITS test at fiber content of 1%:(a)BG fiber;(b)BS fiber;and (c) PET fiber.

3.5.Macrostructural failure of soil specimens

Fig.19.Stress-strain curves of ITS test at fiber content of 1%and fiber length of 5 mm.

SEM analysis has been used to investigate the effect of fibers on the microstructural properties of soil specimens and the bonding method between the fibers and soil particles.Photographs are provided to observe the microstructure of the unreinforced as well as reinforced soil specimens.Fig.15 shows the shape and location of the fibers within the stabilized soil specimens.It is obvious that the fibers are tightly wrapped by surrounding clay particles.Due to the interactions among the fibers and soil particles,they jointly bear the external load.When the stabilized soil is subjected to external loads,the surface force among the clay particles and fibers,bearing the external loads,gradually increases.As a result,the strength of the stabilized soil is clearly increased by addition of fibers which has been confirmed macroscopically.At higher magnification,Fig.16 clearly shows this effect among fibers and soil particles.Macrostructural failure is also the most common way to observe the state of failure of soil specimens.The type of failure observed in the unreinforced and reinforced specimens caused by ITS tests is almost the same.After the tensile degradation,several fine cracks are created on the surface of the fiber-reinforced specimen.However,large cracks are created in the unreinforced soil specimen.While the tensile stress,caused by fibers,prevents the expansion of tensile cracks which in turn prevents the premature failure and improves the strength and ductility of the fiber-reinforced specimens.In this research,the failure of the specimens begins from the center of the specimen.In similar studies,the reinforced specimens endured more tensile stress.Moreover,residual stress appeared after failure of those specimens which was caused by the presence of fibers.These fibers act as bridges and resist against the tensile load (Liu et al.,2020).The macrostructural behavior of clay specimens under ITS tests is observed in Fig.16.

Fig.20.Correlation between ITS and CBR values for all types of fibers.

Fig.21.Correlation between ITS and CBR values for individual BG,BS and PET fibers.

3.6.Modulus of elasticity of soil specimens

In this section,the moduli of elasticity of unreinforced and reinforced specimens,determined by the stress-strain curves of the ITS tests,have been evaluated.The compressive strength and modulus of elasticity are among the parameters which show the behavior of soil against stress.As the compressive strength increases,the bearing capacity of the soil increases.Furthermore,the modulus of elasticity indicates the potential degree of soil to deform.The modulus of elasticity is the value of strain against a certain amount of stress.The higher value of this parameter leads to less deformation of soil against stress.In this study,ITS tests were performed and stress-strain curves were obtained.The modulus of elasticity of the unreinforced and fiber-reinforced specimens was determined using these curves.

Fig.22.Correlation between ITS and CBR values:(a) Natural fiber;and (b) Synthetic fiber.

Fig.23.Estimated versus experimental CBR data.

Fig.17 shows the stress-strain curves of the fiber-reinforced specimens,obtained by the ITS tests,at a fixed fiber length of 5 mm and various fiber contents of 0.5%,1%and 2%.As fiber content increases,the tensile strength of specimens also increases as a result of bridging.This process prevents cracking through elongation which strongly depends on the tensile strength and modulus of elasticity of the soil specimen.

Fig.18 shows the stress-strain curves of the fiber-reinforced specimens,obtained by the ITS tests,at a fixed fiber content of 1%and various fiber lengths of 2.5 mm,5 mm and 7.5 mm.As the modulus of soil elasticity increases,the ductility of soil specimens improves.The results show that the modulus of elasticity increases with increasing amount of fibers.

Fig.19 shows the stress-strain curves of specimens reinforced with 1% of 5 mm-long fibers for various fiber types.This study shows that the moduli of elasticity of the unreinforced soil and those specimens reinforced with BS,PET and BG fibers are 6.06 kPa,11.3 kPa,10.88 kPa and 10.21 kPa,respectively.

Fig.24.Estimated versus experimental ITS data.

3.7.Correlation between CBR and ITS

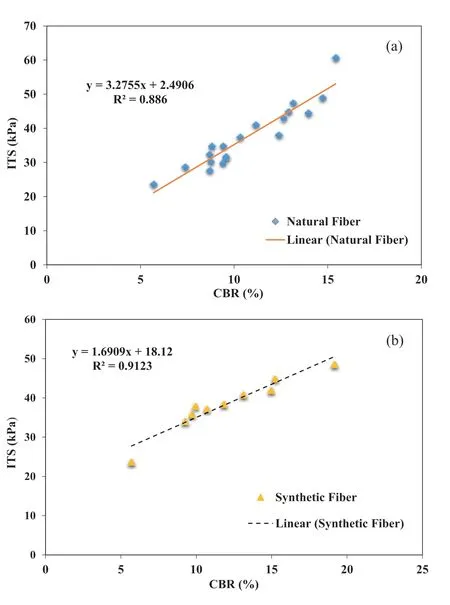

In the past studies,the relationships of ITS and CBR versus UCS have been presented.It can be concluded that relationships between ITS and CBR must be determined for building materials.The relationship between CBR in soaked conditions and UCS at 0 d,7 d,14 d and 28 d of curing was analyzed and presented through a nonlinear regression model.Furthermore,a linear relationship between UCS and ITS at different soil moisture contents with a high correlation coefficient was proposed (Ahmad et al.,2010).Therefore,a relationship between CBR and the tensile strength can be suggested.To this end,the results of ITS and CBR tests for various fiber contents and lengths are given in Fig.20.The relationship between these parameters was linear and the correlation coefficient(R2)was determined as 0.7381.The ITS and CBR values for natural and synthetic fibers are shown in Fig.21.In this investigation,the R2values were 0.866 and 0.9123,respectively.A significant linear relationship was also observed between CBR and ITS values for clay specimens.As can be observed in Fig.21,the R2values for BS,BG,and PET fibers were determined as 0.9013,0.9032 and 0.9123,respectively.By comparing Figs.20 and 21,it can be concluded that the type of fiber used as reinforcement is an effective factor to identify a linear relationship between CBR and ITS values.Moreover,the results of CBR and ITS tests conducted on specimens reinforced with BS,BG and PET fibers at various contents(0.5%,1%and 2%)and lengths(2.5 mm,5 mm and 7.5 mm)indicated the presence of a significant relationship between the results of the two tests.In Eqs.(3)-(5),three relationships with a high correlation coefficient were hypothesized between CBR and ITS values for BS,BG,and PET fiber-reinforced soils,ensuring that the data were not scattered and a linear relationship could be established.According to Fig.22,it can be concluded that the ITS value of fiberreinforced soil increases as CBR value increases.

It should be noted that no relationship was reported between CBR and ITS in previous studies.However,there is a relationship between CBR and the resilient modulus.On the other hand,in the present study,the relationship between CBR and the tensile strength was presented.By increasing tensile strength,the CBR value and resilient modulus increase.According to the AASHTO method,increasing the resilient modulus leads to a decrease in the pavement structural number (SN) as well as the thickness of road layers.Therefore,the design would become economical.

3.8.Multiple regression analysis

Multiple regression analysis was adopted to estimate the association between different variables affecting the CBR and ITS values.The multiple regression models are assumed as(Singh et al.,2019):

Table 11Sensitivity analysis of input parameters.

where C0and I0are the CBR and ITS values of plain soil,respectively;and X1to X10are the multiple regression coefficients.To evaluate the relationship between the variables affecting the CBR and ITS values based on Eqs.(6)and(7),the results of CBR and ITS tests conducted on the unreinforced and reinforced specimens were taken into account.Therefore,Eqs.(8)and(9)were obtained.The R2values were determined as 0.9182 and 0.9168,respectively.As can be seen in Figs.23 and 24,a good correlation was observed between the experimental and estimated CBR values based on Eq.(8).Moreover,a similar correlation was also found between the experimental and estimated ITS values based on Eq.(9).

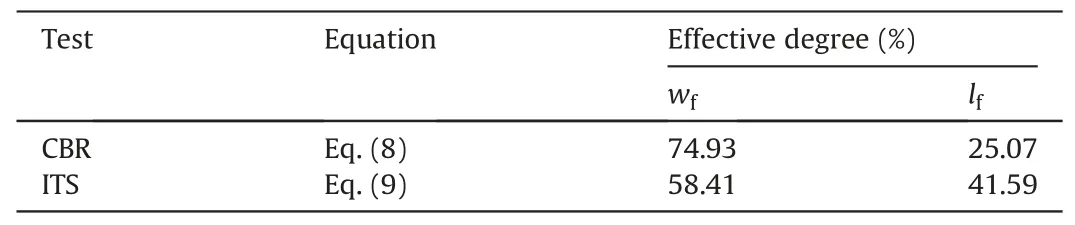

3.9.Sensitivity analysis

After obtaining the regression models for CBR and ITS values,the sensitivity analysis was performed.According to Eqs.(8) and(9),effective degrees of input variables including fiber length and content on CBR and ITS values are calculated by

where Niand Siare the mean values of the other variables and the effective degree of the input variables,respectively;are the maximum and minimum outputs for the desired variable,respectively,when considering the mean values of the other variables(Ni);and n and i are the number of input variables and the domain of input variables,respectively (Tran et al.,2019).The effective degrees of fiber content and fiber length on CBR are 74.93%and 25.07%,respectively,while those on ITS are 58.41%and 41.59%,respectively.The degree of sensitivity of the input variables is listed in Table 11.Among the studied variables,fiber content had the highest effect on CBR and ITS values.The multiple regression models suggested that fiber content had a more considerable effect on compressive and tensile strengths of soil than fiber length did.

4.Conclusions

The results of this research indicate that addition of BS and BG as sustainable materials as well as PET fibers has significant effect on the CBR and ITS values of CL-ML soil used for road construction purposes.The following conclusions can be made:

(1) Using 0.5%of PET fibers as reinforcement leads to the highest CBR value,while 2.5 mm-and 5 mm-long BG fibers have the lowest effect on the CBR values of reinforced soil.Moreover,7.5 mm-long BG fibers are more effective on the CBR value than BS with similar length.

(2) Using 2% of 7.5 mm-long fibers increases the ITS value considerably.Furthermore,among specimens reinforced with BG fibers,the highest ITS value is observed at specimen reinforced with 2%of 7.5 mm-long fibers(47.48 kPa).Adding 2% of 7.5 mm-long PET and BS fibers leads to the highest values of CBR and ITS,respectively.

(3) According to the SEM analysis,plain soil has less strength than fiber-reinforced soil which could be attributed to the pores.The interaction of soil and fibers along with the presence of a dense matrix increases the strength of fiberreinforced clay specimens.

(4) By comparing the results of ITS and CBR tests,a significant relationship with a high correlation coefficient is found for natural and synthetic fibers.The effects of fiber content and length on CBR are reported as 74.93% and 25.07%,respectively,while those on ITS are 58.41%and 41.59%,respectively.According to the results of sensitivity analysis,fiber content has the highest effect on CBR and ITS values.

(5) Use of fibers improves strength parameters of weak clayey soil such as CBR and ITS.It also controls the development of tensile cracks.According to the results,CBR and ITS are two influential parameters in pavement layer construction.Therefore,considering the relationship between them would be beneficial for the optimum design of road layers.

(6) The internal friction angle of soil increases by about 100%due to the addition of BS fibers,and also addition of PET fibers increases the soil cohesion by 70%.

(7) Macrostructural failure is one of the most intuitive ways for observing specimen failure.In reinforced specimens,the fibers prevent the expansion of tensile cracks due to the bridging effect,thus increasing soil strength.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors would like to appreciate Golestan University for supporting this research.

Journal of Rock Mechanics and Geotechnical Engineering2021年3期

Journal of Rock Mechanics and Geotechnical Engineering2021年3期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Uncertainties of thermal boundaries and soil properties on permafrost table of frozen ground in Qinghai-Tibet Plateau

- Bearing capacity of surface circular footings on granular material under low gravity fields

- Engineering and microstructure properties of contaminated marine sediments solidified by high content of incinerated sewage sludge ash

- Effects of oil contamination and bioremediation on geotechnical properties of highly plastic clayey soil

- Modification of nanoparticles for the strength enhancing of cementstabilized dredged sludge

- Rock-like behavior of biocemented sand treated under non-sterile environment and various treatment conditions