Norwegian oil and gas storage in rock caverns - Technology based on experience from hydropower development

Bjørn Nilsen

Department of Geoscience and Petroleum, Norwegian University of Science and Technology (NTNU), Trondheim, Norway

Keywords:Underground storage Oil Gas Liquefied petroleum gas (LPG)Hydropower Air cushion chamber

ABSTRACT Underground storage in rock caverns is widely used in Norway for many different petroleum products,such as crude oil, fuel, propane and butane.Basically, the caverns for such storages are unlined, i.e.containment is ensured without using any steel lining or membrane.The main basis for the storage technology originates from the extensive hydropower development in Norway.As part of this activity,about 4500 km of tunnels and shafts have been excavated, and around 200 large powerhouse caverns have been constructed.The hydropower tunnels are mainly unlined,with hydrostatic water pressure on unlined rock of up to 1000 m.Some of the projects also include air cushion chambers with volumes of up to 1×105 m3 and air pressure up to 7.7 MPa.Many lessons which are valuable also for underground oil and gas storage have been learnt from these projects.For a storage project to become successful, systematic, well planned design and ground investigation procedures are crucial.The main steps of the design procedure are first to define the optimum location of the project, and then to optimize orientation, shape/geometry and dimensions of caverns and tunnels.As part of the procedure, ground investigations have to be carried out at several steps integrated with the progress of design.The investigation and design procedures, and the great significance of these for the project to become successful will be discussed.Case examples of oil and gas storage in unlined rock caverns are given, illustrating the relevancy of experience from high-pressure hydropower projects for planning and design of unlined caverns for oil and gas storage.

1.Introduction

Norway has long traditions for utilizing the underground space for a variety of important purposes such as communication (road,railway and metro tunnels), hydropower development, water supply, storage of various products, sport utility caverns, sewage treatment and much more.

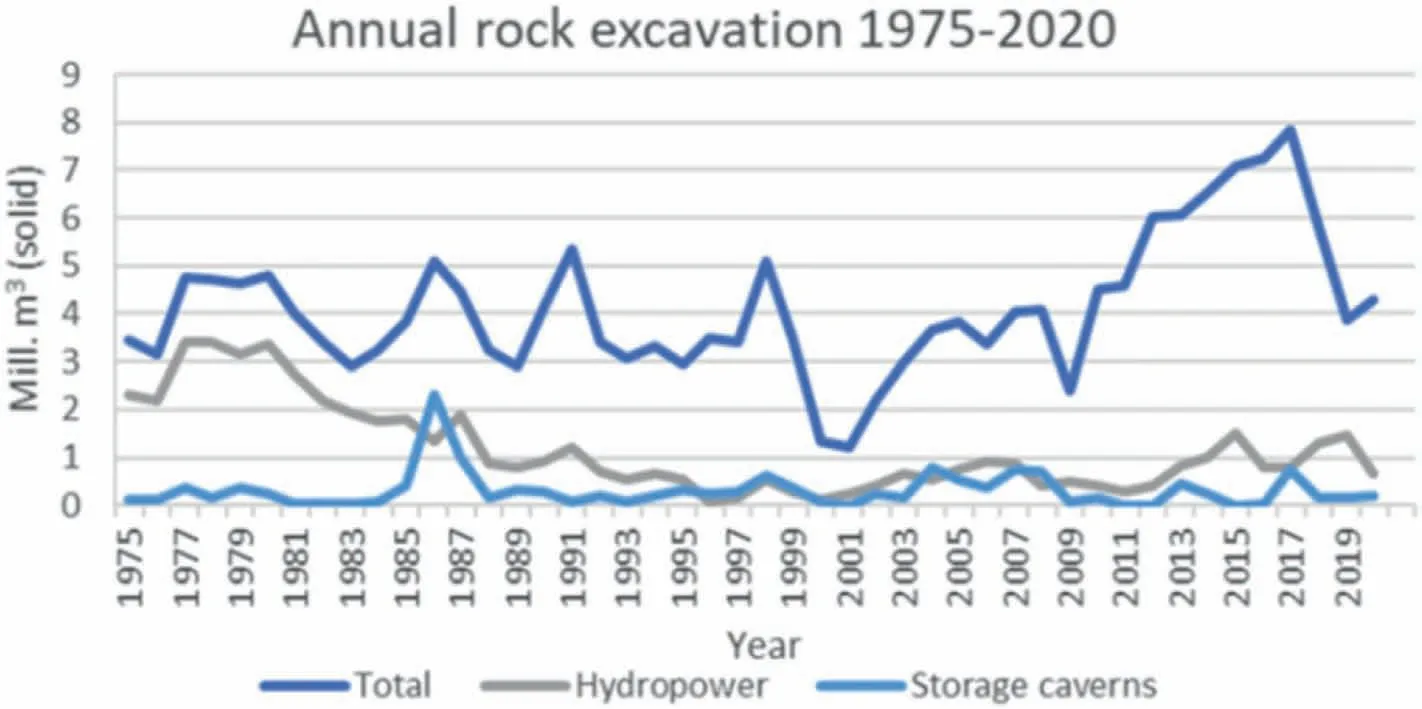

The high activity regarding underground projects is reflected by statistics published by the Norwegian Tunneling Society(NFF,2020),as shown in Fig.1.As can be seen, the tunnel production has been going up and down during the years covered by the statistics,reflecting variations in market demands, but the average annual excavation volume has been as high as around 4×106m3.In recent years, the production has been the highest in road and railway tunneling, although there has also been a considerable production related to hydropower tunneling,which used to be the main activity until the mid-1980s.Excavation related to storage caverns (predominantly for petroleum products)has been at average just above 3×105m3,with a maximum of 2.3×106m3in 1986.

A hydropower project, including tunnels, shafts, large caverns,intake structures, etc., is far more complex than a road or railway tunnel (and most other underground projects).Rock excavation related to underground hydropower development in Norway includes around 4500 km of tunnels and shafts, around 200 powerhouse caverns, unlined tunnels and shafts with up to 1000 m hydrostatic water pressure and 10 air cushion chambers with air pressure of up to 7.7 MPa and volume up to 1.1 ×105m3.

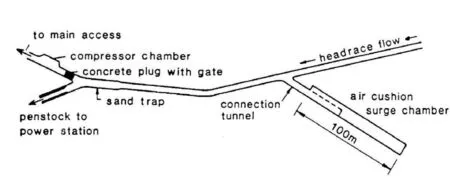

Most of the Norwegian hydropower projects have a surge shaft from the headrace tunnel, which mitigates the hydraulic pressure(“water-hammer effect”)in case of sudden stop of power production,but as mentioned above,some have air cushions for this purpose.The latter is of most interest in this connection.Typical layout of a Norwegian hydropower project with air cushion chamber is illustrated in Fig.2.

Fig.1.Underground excavation for civil purposes (mining for minerals not included) in Norway during 1975-2020 (based on NFF, 2020).

The experience from hydropower projects has played a key role in the technology development for many other types of underground projects in Norway,such as underground storage of oil and gas.The air cushion chambers are actually large gas(i.e.air)storage caverns with considerable pressure, representing a very valuable base of experience for planning and operation of gas storage facilities.The large caverns related to hydropower projects represent a valuable base of experience regarding excavation and support of caverns for oil and gas storage.Finally, the technology related to design and sealing of concrete plugs,particularly the plug between the dry access tunnel and the water filled headrace tunnel, as illustrated in Fig.3,is highly relevant for plugs related to oil and gas storage caverns.

The two fundamental requirements for design of the concrete plug are static capacity which can withstand the water pressure,and satisfactory sealing effect to prevent leakage.The length of the plug is normally 10-40 m,depending upon the static head and the geological conditions(in most cases around 4%of the head).In most cases,extensive grouting is required for sealing of the surrounding rock,as well as the spaces between concrete and rock,and between steel pipe and concrete.

2.Experience from air cushion chambers

The air cushion concept has been used at 10 Norwegian hydropower projects.Several air cushion chambers have also been built in China,South Korea and Japan(Hu et al.,2007).Contrary to the Norwegian unlined air cushion chambers, to the author’s knowledge, most of these (if not all) are, however, lined.The Norwegian air cushions were all built before 1990.This is due to the fact that most of the recent projects represent refurbishment/upgrading of existing plants.Moreover, for newer projects, the topographic conditions have not been in favor of air cushion instead of surge shaft.

Key data of the 10 Norwegian air cushion chambers are shown in Table 1.As can be seen,8 of the projects are built in gneissic rocks,while 2 are built in meta-sediments (phyllite and meta-siltstone).Most of the chambers have rock cover of hundreds of meters, and only two have rock cover less than 200 m.The volumes of the air cushion chambers vary greatly,from 1950 m3for the smallest(Tafjord)to 1.1×106m3for the largest(Kvilldal).The highest operating pressure of an air cushion has been 7.7 MPa(Tafjord).

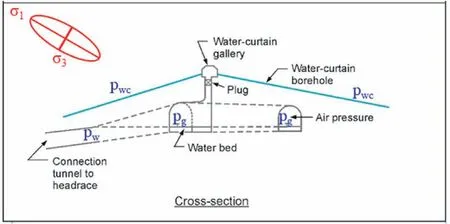

To illustrate the design concept of Norwegian air cushion chambers,plan viewand cross-section of Torpa air cushion chamber are shown in Fig.4.As can be seen from Table 1,Torpa represents an approximate average regarding volume,air pressure and rock cover,and is also the newest of the Norwegian air cushion chambers.In addition,it is one of air cushions equipped with water curtain,which is a common concept also for underground oil and gas storage.

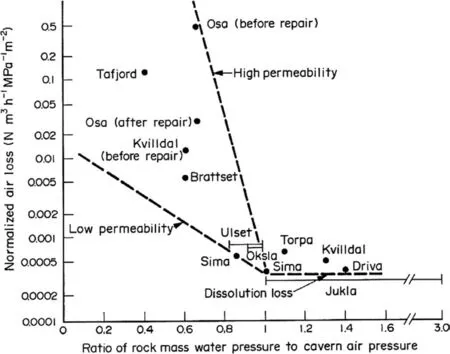

The operational experience of the Norwegian air cushion chambers is summarized in Table 1, and the air loss is illustrated more in detail in Fig.5.As can be seen, the majority of the air cushions have functioned very well, with no or neglectable air leakage for design and measures as originally planned(i.e.without extensive grouting or water curtain system).In one case(Kvilldal),establishment of water curtain was, however, required after short time of operation,and in another case(Osa),remedial grouting was required to reduce leakage to an acceptable level.After the remedial measures, these two air cushions have also functioned well.

For the great majority of the Norwegian air cushions, the longterm air leakage has been very low, corresponding approximately to what is dissolved in water.This indicates very little/neglectableleakage through the rock mass.For further details of the Norwegian air cushion chambers,reference is made to Nilsen and Olsen(1989),Kjørholt (1991) and Broch and Nilsen (1992).

Fig.2.Principle sketch of hydropower project with air cushion chamber (from Palmstrøm, 2008).HWL denotes the highest water level of the reservoir.

Fig.3.Typical layout of hydropower project (Brattset) with air cushion chamber and access to the headrace tunnel through concrete plug with gate (from Goodall et al.,1989).

Table 1Key data for the Norwegian air cushion chambers (based mainly on data from Kjørholt(1991) and Broch and Nilsen (1992)).

3.Basic criteria for containment

To prevent leakage of high-pressure liquid or gas from unlined tunnels or caverns, there are certain requirements that need to be fulfilled.Basically, these may be divided into two main categories:geological and rock stress requirements.

The basic geological requirement is that a location for the facility has to be found with as favorable rock mass conditions as possible,i.e.a site with low permeability and favorable stability conditions.Particularly, conditions such as highly porous rocks, karstic rock,heavily fractured rock and faults/weakness zones should be avoided.

The basic rock stress requirements are as follows:

(1) For liquid containment,the pressure of the liquid(pw)should be less than the minor principal stress(σ3)in the surrounding rock mass(i.e.low enough to prevent deformation):

(2) For gas containment,the gas pressure(pg),multiplied with a factor of safety F (often set to 1.5) should be lower than the water pressure in the surrounding rock mass (pwc), and σ3has to be higher than pwc:

which means

The rock stress requirements are illustrated in Fig.6, which represents the situation at the lower part of the headrace tunnel of a hydropower project with air cushion.In this case, it is crucial to prevent water leakage from the headrace tunnel as well as gas(air)leakage from the air cushion chamber.This is achieved by preventing hydraulic jacking and assuring water flow towards the air cushion chamber.

Fig.4.Design of the air cushion chamber at Torpa hydropower plant (based on Kjørholt,1991).

Fig.5.Air loss during operation versus pressure-ratio for the Norwegian air cushion chambers (from Goodall et al.,1989).

In the following sections, main focus will be on underground storage facilities for oil and gas.As will be seen,the basic principles and the experience discussed above are very relevant also for such facilities.

4.Engineering geological planning and design

Planning of underground structures is very challenging due to the complexity of the “construction material” (the rock mass), the limited information about the construction material and the complex project design(with a network of tunnels,shafts and caverns).Therefore, thorough pre-construction investigation is crucial and follow-up/further investigation during construction is also required.

The best approach for planning and design is a stepwise procedure as illustrated in Fig.7,where pre-construction investigations are carried out in several stages and design amendment/modification,if required according to investigation results,is accepted.

Rock stress measurement, which is of great importance in connection with design of storage facilities for pressurized liquid and gas in underground excavations,is preferably done at an early stage of planning, and supplemented with monitoring (most commonly hydraulic jacking or fracturing) at an early stage of excavation.

The main decisions to be taken based on investigation results are related to optimization of location, orientation and geometry/layout.For oil and gas storage caverns,planning and design of pregrouting, water curtains and concrete plugs are of particular importance.

In European Union (EU) countries, the rules and guidelines for geotechnical design described in Eurocode 7(EC 7)(CEN EN,1997-1:2008, 2008) have to be complied with.EC 7 is focusing more on soil than rock (more on soft rock than hard rock), and special guidelines regarding use of EC 7 for rock engineering design were therefore published by NBG (2011).EC 7 has a geotechnical categories classification as shown in Table 2.

The geotechnical category defines requirements regarding quality and efforts on all aspects of the design base (maps,geotechnical data,etc.)and all steps of investigations,planning and control.For higher geotechnical category,more investigation,more thorough planning and more control are required.

Several design principles may be used according to EC 7,including design based on calculation, design based on “prescriptive measures”, load/model testing and the observational method(CEN EN,1997-1:2008,2008;NBG,2011).For design of challenging projects such as underground oil and gas storage caverns, the observational method, with calculation based on “half empirical”(Q-method)as well as numerical methods,is most commonly used in Norway today.

5.Case examples of oil and gas storage

Unlined caverns for underground fuel storage have been built in Norway since the early 1970s.Before 1945, storage facilities were based on steel tanks at the surface, and during 1945-1950 mainly on underground steel tanks.The main reasons for switching to underground storage were safety and environmental concerns,limited space at surface, cost effectiveness, and more freedom regarding design and future expansion.

Norwegian caverns for crude oil and refined oil products have typical dimensions of 17-20 m in width, 25-35 m in height and 200-500 m in length.The largest facilities of this type are located on the west coast of Norway: Mongstad with a total volume ofabout 1.3 × 106m3and Sture with a total volume of about 1 ×106m3.The basic technology for excavation, rock support and containment assurance of the large storage caverns is inherited from experience related to many large underground hydropower plants.The same is the case for technology related to concrete plugs, which are important elements of storage caverns.

Fig.6.Sketch illustrating confinement requirements for the air cushion chamber and adjacent water tunnel in Fig.4.σ1 is the major and σ3 the minor principal stress in the surrounding rock mass.

Fig.7.Stepwise investigation and design of underground structures as recommended by the International Association of Engineering Geology (from IAEG Commission on Site Investigations,1981).

Fig.8 shows Sture in western Norway as case example of a modern crude oil storage facility with air curtain.This facility has a water curtain similar to the one for the air cushion chamber shown in Figs.4 and 6,which prevents oil and gas seepage along fractures in the surrounding Precambrian gneiss.In the Sture case,the water curtain is however drilled from the surface,which is quite common for low-pressure crude oil facilities.

Note: CC/RC is consequence class/reliability class.a The classification is evaluated individually.

As discussed above, the basic principle for containment of underground oil and gas storage is that the groundwater pressure has to be higher than the pressure represented by the storage product.For Norwegian facilities, it is required by the Directorate for Civil Protection and Planning (DSB) that an extra safety margin corresponding to minimum 20 m water pressure is included (Haug,2007).For crude oil caverns, this may be achieved without water curtain.Therefore, some older facilities do not have water curtain,and still have operated successfully for several decades.Most of newer facilities have been built with water curtain as extra precaution.For the Sture facility(Fig.8),54 mm diameter holes of up to more than 50 m length, oriented to intersect the main joint sets,were drilled for the water curtain (Midtlien, 2007).For underground storage of pressurized gas,water curtain is mandatory,with holes for the curtain normally drilled from a gallery as shown in the example in Fig.9.

Fig.8.Cross-section of underground crude oil caverns with a total volume approximately 1 ×106 m3 at Sture, western Norway (from Midtlien, 2007).

Fig.9.Rafnes storage cavern for propane:(a)Layout and contour lines for bedrock surface;and(b)Water curtain shown in plane and profile(based on Johansen and Madsen,1989).Unit in m.

Due to the complexity and great variety of geological conditions,design of water curtains is no exact science.The optimum design depends much on the local geological conditions and pressure ratios,and it is therefore difficult to describe any “typical design”.One factor often causing particular difficulty for design planning is that the permeability of discontinuities in the rock mass is often governed by flow channels.This makes calculation and numerical analysis very difficult and uncertain.In practice, most decisions regarding design were made based on experience and testing/trials during excavation.Most commonly,a distance of around 15-25 m between the water curtain and the roof of the storage cavern has been used.Spacing between drillholes is adjusted according to rock mass conditions,with final decision taken based on testing/trials in boreholes.For most Norwegian oil and gas storage facilities, the borehole spacing is within the range of 5-10 m.

For concrete plugs,like the ones indicated in Figs.4 and 9,there are two main concerns regarding design: (1) sufficient frictional resistance to prevent displacement,and(2)leakage prevention.To ensure frictional resistance, the tunnel profile is preferably excavated with a shape which provides a “wedge effect”for the concrete plug,as illustrated in Fig.10.To prevent leakage,grouting is done at several stages,starting with rock grouting before casting of the plug(Fig.10a), followed by cement grouting of the space between concrete and rock (Fig.10b).Finally, when permanent temperature inthe plug is reached after casting, chemical contact grouting of all contact zones,i.e.between rock and concrete,concrete joints,steelconcrete contacts,around pipes,etc.,is done from tubes which are installed before pouring concrete.Further details of the grouting procedure have been described by Aasen et al.(2007).

Fig.10.Example of grouting principle for concrete plug at Norwegian LPG storage plant(from Aasen et al.,2007).A-G refer to separate plugs which were made at this facility.All numbers at the top are in mm.

In order to reduce the volume, propane and butane (liquefied petroleum gas,LPG)are always stored as liquid.As for Rafnes,this is achieved at temperature corresponding to that of the surrounding rock(around 6°C)and a pressure of 0.5-0.65 MPa.The bedrock at Rafnes is Precambrian granite,and the roof of the storage cavern is located 90 m below sea level.This gives extra safety against gas leakage.At other facilities, LPG is stored at atmospheric pressure and -42°C.For storage at low temperature,the sealing of concrete plugs is often a major challenge.

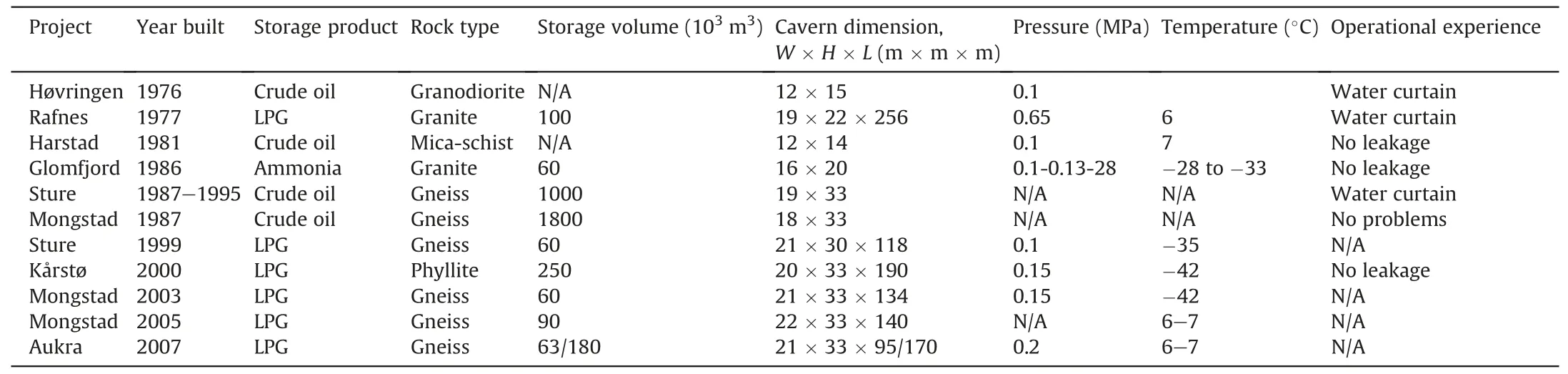

Key data for selected Norwegian underground oil and gas storage caverns are given in Table 3.As revealed in Table 3, storage is being done for many petroleum products at various geological conditions/rock types, and at a wide range of pressures and temperatures.No major operational problems have been reported from any of these caverns.

Inspired by the success of the Norwegian high-pressure air cushion chambers, the feasibility of storing high-pressure natural gas in unlined caverns has also been investigated.The study was connected to a proposed gas powerplant in Central Norway, for which the feasibility of storing 1×106m3natural gas at pressure of up to 10 MPa was evaluated (Thidemann, 1989).Although it was concluded that such storage was feasible,no such project has been built, and research on underground storage of natural gas is now more focusing on liquefied natural gas (LNG)and lined caverns.

6.Conclusions

Underground storage of oil and gas has several obvious advantages compared with storage at surface.As described in this paper,long-term operation of a large number of storage facilities for a variety of different products in Norway, at different temperatures and pressures, as well as the operation of many high-pressure air cushion chambers, has proven the robustness of such storage.

As discussed in this paper, a systematic, stepwise investigation and design procedure is crucial for achieving maximum reliability of oil and gas storage caverns.The following steps are considered the most important ones regarding containment assurance and operational safety:

(1) Stepwise, thorough pre-excavation geological investigations for ensuring optimum location and best possible geometry/layout of the storage facility.

(2) Rock stress monitoring before and during construction to ensure sufficient confinement of the rock mass surrounding the storage facility and eliminate the jacking risk.

(3) Thorough planning and design of measures for containment assurance, such as pre-grouting and water curtain.

(4) Quality control and assurance in accordance with established guidelines and recommendations, such as EC 7, and incompliance with international and national guidelines regarding operational safety.

Table 3Key data for selected Norwegian storage caverns for petroleum products, based mainly on Johansen et al.(1989), Grøv (2007)and Midtlien (2007).

Due to their complexity and potentially large consequences of error in design or construction, storage caverns for oil and gas are classified as Category 3 projects, implicating strict requirements regarding site investigation, planning/design, construction and control at all respective stages.

As discussed in this paper,experience from hydropower projects is highly relevant and may be very valuable for planning and design of oil and gas storage caverns.In particular, this applies to design and operation of water curtains for high-pressure storage, but experiences regarding excavation methodology and design of highpressure concrete plugs are also highly relevant.

Declaration of competing interest

The author declares that he has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Journal of Rock Mechanics and Geotechnical Engineering2021年2期

Journal of Rock Mechanics and Geotechnical Engineering2021年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Physics-informed deep learning for one-dimensional consolidation

- On the measurements of individual particle properties via compression and crushing

- Particle breakage of sand subjected to friction and collision in drum tests

- Permeability and setting time of bio-mediated soil under various medium concentrations

- Novel experimental techniques to assess the time-dependent deformations of geosynthetics under soil confinement

- Case study of a driven pile foundation in diatomaceous soil.II: Pile installation, dynamic analysis, and pore pressure generation