High-end equipment development task decomposition and scheme selection method

XU Xiangqian, YANG Kewei, DOU Yajie, ZHOU Zhexuan, CHEN Ziyi, and TAN Yuejin

College of Systems Engineering, National University of Defense Technology, Changsha 410073, China

Abstract: Decomposition of tasks and selection of optimal schemes are key procedures in high-end equipment development processes. However, such procedures are highly innovative,technology intensive, interdisciplinary, and multi-party engineering projects, making the decomposition and scheme selection more difficult and complicated than that in the development of ordinary equipment. In this study, we consider three factors,namely, functional structure, task granularity, and task feasibility in task decomposition of high-end equipment development.Based on the principles of systems engineering, a method of task decomposition is proposed. As for decomposition scheme selection, a method based on the superiority and inferiority ranking (SIR) method mixed information and multiple attribute decision making is proposed by considering attributes of scheme feasibility, uncertainty risk and task integration complexity. To verify the proposed method, development of a military electric vehicle is used as an example to demonstrate the calculation process.

Keywords: high-end equipment, task decomposition, decomposition scheme selection.

1. Introduction

High-end equipment refers to technical equipment with advanced technology involving multiple knowledge fields, huge capital investment in construction, and long service life, such as new digital control machine tools,space vehicles, satellites, new energy vehicles, intelligent robots, and large machinery [1-3]. Compared with ordinary equipment, the development of high-end equipment is a highly innovative, technology intensive, interdisciplinary and multi-party engineering project. The development processes are more complicated, in which every step is closely related [4-6]. Scientific theories and methods are needed for the acquisition of required materials,product design, manufacturing, and system validation.Due to the high value and investment in the development of high-end equipment, it is necessary to carry out scientific management in the early stages of argumentation and design. Task decomposition and selection of the optimal schemes are the key processes. The tasks involved in the development of high-end equipment usually comprise subtasks of different dimensions and levels. There are various logical correlations and associations between these subtasks. The development plans of high-end equipment can be truly implemented only when all tasks are fully decomposed, and optimal schemes are selected from numerous task decomposition schemes. Thus, the efficiency and feasibility of the development process can be improved to a great extent.

The difficulty in the decomposition of tasks in highend equipment development and program selection lies in the following three points.

(i) The lack of evaluation indicators

Since there are no standardized evaluation criteria or indicators suitable for task decomposition and program selection, it is often difficult to compare the advantages and disadvantages of various decomposition schemes.

(ii) Complex mapping correlations

There are many logical correlations and associations between different tasks during development, which make task decomposition in high-end equipment development more challenging.

(iii) Uncertain information

The development of high-end equipment contains a lot of uncertain information, such as risks involved in the projects and stakeholder preferences, which makes it difficult to make certain evaluations of the programs.

The above difficulties have led to huge challenges in tasks decomposition and scheme selection in high-end equipment development, which need to be dealt with reasonable scientific methods.

Substantial research has been carried out on task decomposition, especially in the field of industrial engineering,which has important guiding significance for equipment manufacturing. A typical method is to use the design structure matrix (DSM) to represent the correlation between tasks [7-9]. The various information interactions between tasks and the degree of association can be expressed by the value of the DSM. Recently, Yang et al. [10] used the DSM for the cluster analysis between the tasks of product development projects, and matched the corresponding development tasks to the appropriate research and development (R&D) team. In addition, Liu et al. [11] proposed a DSM task decomposition and reorganization method with adjustable task granularity. However, the DSM has weak quantitative analysis capabilities in the processing of uncertain information, and it is weak in dealing with the complex task decomposition in the development of high-end equipment. Shriyam et al. [12] proposed a dynamic grid algorithm to decompose survey missions in order to efficiently perform ground survey missions for unmanned surface vehicles (USV). Zhu et al. [13] proposed a task scheduling model for multi-satellite imaging based on immune algorithms that reasonably decompose the imaging tasks of satellites. The combination of algorithms and decomposition models improve task decomposition in numerical calculations to a certain extent with certain theoretical values.

Task decomposition has also been studied in temporal and spatial dimensions. Albus [14] defined a hierarchical reference model architecture for real-time intelligent control. The task is decomposed into sub-commands by a command method, and sent to the subordinate task decomposition module that solves the task decomposition problem in the temporal and spatial dimensions. Pang et al.[15] proposed a method for decomposing detection tasks using an information technology called system on chip(SoC). Subtasks are generated and accurately timed and evaluated based on different attributes of the task and different decomposition strategies. Pang’s study expands the dimensions of the research domain of task decomposition problems, making the application capabilities of the task decomposition model more powerful. Some new theoretical methods of task decomposition have also been proposed. Lin et al. [16] proposed a task decomposition method for task flow under information focus, sorting the priority of subtasks, and using information focus to analyze the correlations between tasks. Bao et al. [17] studied customized production, defined the concepts of task granularity, task coupling degree, task balance degree,and their respective calculation formulae in R&D tasks,and proposed a task decomposition model for collaborative development. Stone et al. [18] coordinated the information exchange between tasks by setting a unified structure for the tasks, and establishing communication rules between tasks. Most of the above mentioned task decomposition models or methods focus on the attributes from the perspective of the corresponding tasks. However, the reference value of function for task decomposition is generally ignored.

As for the choice of decomposition schemes, methods have been proposed on the basis of task decomposition.Liu et al. [19] proposed a capability-based collaborative decomposition design method for heavy military vehicles.The core technology measures the capability requirements,project relevance, and project coupling as metrics, and calculates the appropriate granularity and weak coupling to evaluate the decomposition scheme. Wang et al. [20]decomposed aviation enterprise dynamic alliance tasks into multi-objective planning analyses, and constructed evaluation indices to screen the task decomposition scheme. Liang et al. [21] modeled task decomposition in cloud manufacturing for current techniques, and realized optimal matching between tasks and resources. These methods generally use evaluation indicators to select decomposition scheme, but they generally do not consider the influence of the uncertainty factors on the evaluation models, which is one of the important factors to be considered in the development of high-end equipment.

Thus, although there is a certain research foundation for task decomposition and scheme selection, there are few methods or theories of task decomposition and scheme selection with high-end equipment development as the primary objective. Task decomposition in high-end equipment development with hierarchical structure is more complex, and requires more refined decomposition methods. In addition, the information in high-end equipment development is wider, and the uncertainty is greater in the selection of decomposition schemes. Therefore, it is of high theoretical and practical value to realize efficient task decomposition and scheme selection methods for high-end equipment development.

The main objective of this study is to realize efficient task decomposition and scheme selection for high-end equipment development. We analyze the attributes of high-end equipment development tasks (task characteristics, types, and decomposition principles), and define concepts such as task granularity, task feasibility, and task integration complexity. Firstly, the tasks in high-end equipment development are decomposed according to the functional structure, and the preliminary set of decomposed tasks is obtained. Then, the task decomposition set is decomposed extensively according to the task granularity and task feasibility, and the threshold of task granularity is set to obtain several feasible schemes. Finally, an optimal task decomposition scheme is selected based on the superiority and inferiority ranking (SIR) mixed information and multiple attribute decision making method, according to the feasibility, uncertainty risk and task integration complexity of the task decomposition scheme.

The remainder of this paper is structured as follows:the problem analysis and description are contained in Section 2. The task decomposition method for high-end equipment is presented in Section 3. The task decomposition scheme selection method for high-end equipment is contained in Section 4. An example for task decomposition and scheme selection in military electric vehicle development is demonstrated in Section 5. The conclusions of this study are presented in Section 6.

2. Problem description and analysis

High-end equipment development task refers to the collection of processes and activities for R&D, in order to meet user requirements. Specifically, it can be expressed as various requirements and constraints that need to be realized in the R&D process to reach a predetermined level, including time requirements, functional requirements, and performance requirements. High-end equipment is different from general equipment, because the scales involved are larger, and the correlations among tasks are complicated. Therefore, it is necessary to start with the characteristics and relevance of high-end equipment development tasks to develop a reasonable task decomposition and scheme selection method for high-end equipment.

2.1 High-end equipment development task characteristics and relevance

Combined with existing complex product manufacturing,the characteristics of high-end equipment development tasks can be summarized as follows. (i) Information exchange is frequent: In the era of big data, high-end equipment has frequent data interactions during the manufacturing process, which include user demand acquisition,demand confirmation, and information exchange between R&D teams and suppliers during the development process. (ii) The task correlation is complex: Due to the complex structure of high-end equipment, the tasks in highend equipment development usually have multi-level,multi-dimensional, and multi-functional characteristics,and the correlation among tasks is very complicated.(iii) The manufacturing network is collaborative: Highend equipment are technology-intensive products that require multi-disciplinary integration, multi-party collaboration, and cross-domain manufacturing to form a highend equipment manufacturing network. (iv) The manufacturing environment is dynamic: With rapid development of smart manufacturing, the Internet and big data,manufacturing models have been upgraded and demands have changed, which has led to dynamic manufacturing environments for high-end equipment.

In the development of high-end equipment, tasks are collections of subtasks that include several logical, temporal, and spatial correlations. It has been suggested that the correlation between subtasks can be mainly divided into the following two categories:

(i) Task related-correlation

From the perspective of related-correlations, tasks can be divided into three categories: uncorrelation, single correlation, and strong correlation.

i) Uncorrelation: It means that there is no correlation and no information interaction between high-end equipment development tasks. Different tasks are completed independently.

ii) Single correlation: It means that there is a correlation between task A and task B and it is a unilateral dependency, which means that either task A depends on task B, or task B depends on task A in the process of highend equipment development.

iii) Strong correlation: It means that there is a strong correlation and strong information interaction between high-end equipment development tasks. This kind of correlation is inseparable, which is one of the most important factors in high-end equipment development processes.

(ii) Task logical-correlation

From the perspective of logical-correlation, tasks can be divided into three categories: series connection, parallel connection, and cross.

i) Series connection: It means that there is a logical correlation between the pre-order tasks and the subsequent tasks. The subsequent task can be performed only after the pre-order task is completed. If the pre-order task is not completed, the subsequent task will not be executed.

ii) Parallel connection: It means that tasks are executed in parallel. It is important to note that there is parallelism in task execution times, but no information interaction between tasks.

iii) Cross: It means that there is a partial cross correlation between tasks. When cross correlation occurs, both parallelism in task execution times and information interaction exist in high-end equipment development processes.

2.2 Principles of task decomposition and scheme selection for high-end equipment development

After analyzing the R&D processes of high-end equipment, it is found that the processes are complex systems engineering methods, consisting of subsystems with different associations. Therefore, formulating the principles of high-end equipment development task decomposition and scheme selection principles from the perspective of systems engineering can effectively deal with the problems that need to be solved urgently.

(i) Development task decomposition principles

In order to execute the decomposition of the development tasks of high-end equipment, the complete task can be analyzed from the perspective of functional structures and cohesive relevance. Hence, the decomposition principles of high-end equipment development tasks are enacted as follows.

i) Value functionality: The design and development of any high-end equipment is inseparable from the desired functions. Therefore, it is important to consider the functions of high-end equipment, and perform decomposition based on functional analyses.

ii) Measurable decomposition unit: The task decomposition cannot be infinitely fine or rough. Therefore, it is particularly important to find a method to measure the fineness of the task decomposition units.

iii) Satisfiable sub-tasks: In order to avoid situations where the sub-tasks cannot be executed and to ensure that the sub-tasks can be completed after the decomposition, it must be assumed that a corresponding supplier can perform the sub-tasks.

(ii) Decomposition scheme selection principles

Identically, the decomposition scheme selection principles of high-end equipment development tasks are enacted as follows.

i) Satisfiable schemes: A decomposition scheme is a collection of decomposition sub-tasks, so it must be considered that a corresponding supplier can perform the subtasks that are included in the scheme.

ii) Risks in the dynamic environment: The development of high-end equipment is time consuming, so it is necessary to consider the risks in a dynamic environment as one of the important factors in the selection of solutions.

iii) Sub-task integration complexity: The decomposition and scheme selection of high-end equipment development tasks is a systems engineering problem, which not only considers the top-down decomposition process, but also considers the bottom-up integration process.

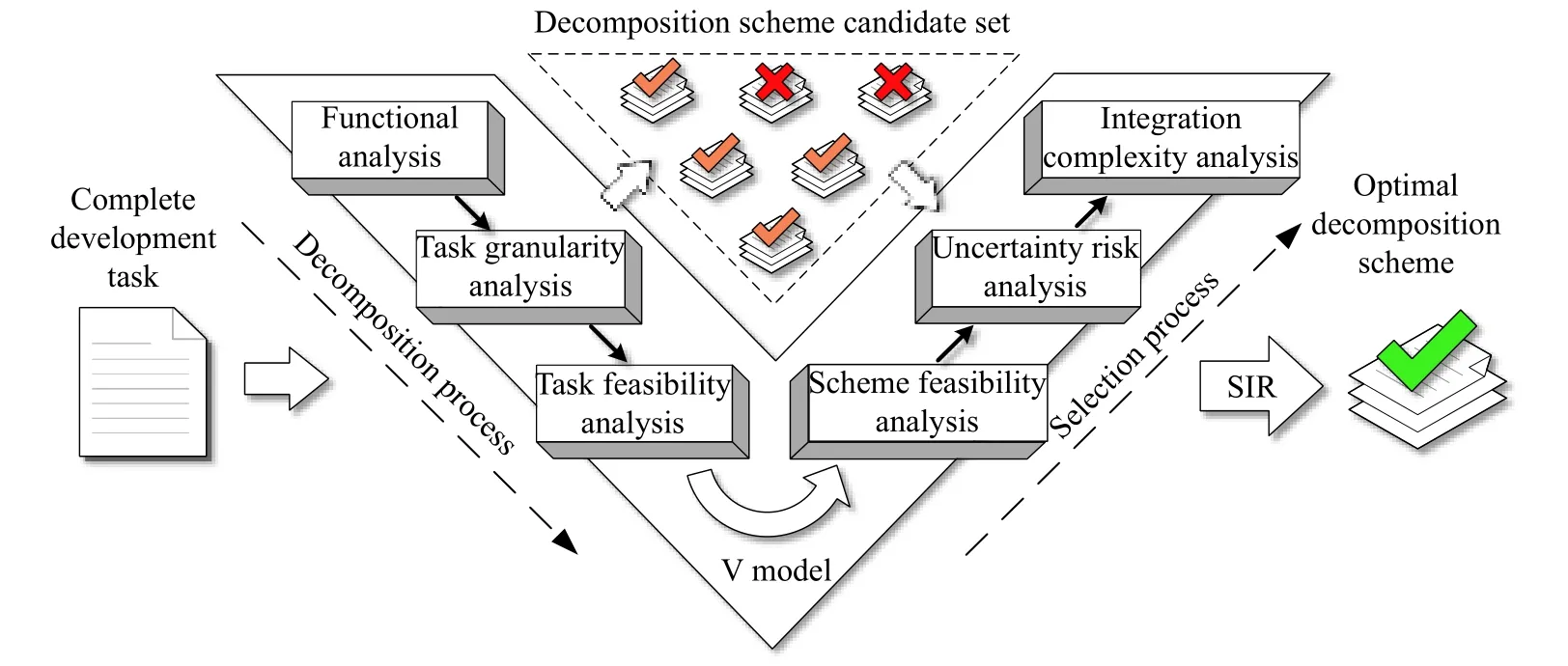

According to the principles of task decomposition and scheme selection for high-end equipment development,we consider two aspects of task decomposition and scheme selection. The technology roadmap is shown in Fig. 1.

Fig. 1 High-end equipment development task decomposition and scheme selection method (V model)

As shown in Fig. 1, the complete development task of high-end equipment is the input of the entire technical route, and the optimal decomposition scheme is the output of the technical route. The technical route is based on the V model of systems engineering. The left side of the V model is the task decomposition process that includes three steps: functional analysis, task granularity analysis,and task feasibility analysis. The right side of the V model is the scheme selection process that includes three steps:scheme feasibility analysis, uncertainty risk analysis, and integration complexity analysis. Firstly, the complete development task of high-end equipment is input into the V model. Then, after preliminary decomposition, some noncompliant decomposition schemes can be excluded to obtain a candidate scheme of decomposition schemes. After selecting the scheme based on SIR, the optimal decomposition scheme can be obtained.

3. High-end equipment development task decomposition methods

According to the characteristics of high-end equipment development tasks and the principle of decomposition,we propose three methods of development task decomposition: a development task decomposition method based on functional structure, a development task decomposition method based on the development task granularity, and a development task decomposition method based on the development task feasibility.

3.1 Development task decomposition method based on functional structure

High-end equipment usually meet the needs of users through corresponding functions. These modules contain different functions corresponding to the product development task structure. In the early stage of product design,the coupling relationship of each functional module in the development task structure can be understood more accurately through functional analysis, so that the overall task can be initially decomposed according to the relationship between the functions.

Therefore, the development tasks can be preliminarily decomposed into N subtasks with low functional correlation and high cohesion, by analyzing the functions of high-end equipment.

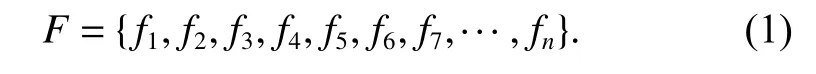

Let a finite field F be the high-end equipment function set, which contains n sub-functions:

Assume that the function set F′is obtained through the functional coupling relationship analysis method:

Assume that the finite field T is the task set, which can be decomposed into

After the functional analysis, the development task is initially decomposed into m subtasks, which are t1(f1,f2),t2(f3), t3(f4), t4(f5,f6,f7),···, tm(fn).

This method can quickly decompose high-end equipment development tasks, and is in agreement with the logical thinking of designers and manufacturers. It can also effectively refine a complex manufacturing task, and turn it into a module that can continue to operate in the next step.However, in practice, the preliminary decomposition of the subtasks does not necessarily match the supplier.Furthermore, whether the supplier is satisfied with a subtask at a particular time needs to be tested in the next step. Therefore, in view of the above analysis, after the preliminary decomposition of the high-end equipment using the functional analysis method, the attributes of the mission task granularity and feasibility will be considered to accurately decompose high-end equipment development tasks.

3.2 Development task decomposition method based on task granularity

In order to make sub-tasks more compatible with suppliers, we further establish a task decomposition method based on task granularity for high-end equipment development. Task granularity is a commonly used metric in task decomposition. Task granularity calculation can analyze the relevance and the task size of high-end equipment development tasks. Generally, task granularity calculation includes calculation of the task correlation coefficient and the task reuse coefficient.

Task granularity, which mainly reflects the level of task aggregation, is one of the important attributes to describe tasks. At a macro level, the granularity of tasks can be used to reflect the hierarchical relationship between tasks. The higher the task level, the greater the task granularity; the lower the task level, the smaller the task granularity. At the micro level, each task is a point in the set.The smaller the number of tasks, the larger the task granularity; the larger the number of tasks, the smaller the task granularity. The granularity of the task can directly affect the time, technical resources, cost, etc., required to achieve the task.

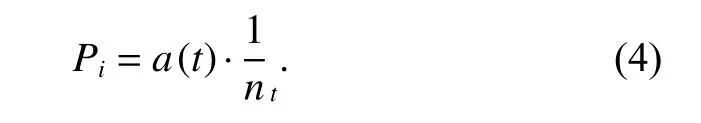

Definition 1Task granularity

If Piis the task granularity, ntis the number of tasks,and a (t) is the task granularity coefficient, the task granularity Pican be expressed as

The task granularity coefficient a (t) is generally considered to be related to the cohesion between tasks. The higher the cohesion of the system, the stronger the maintainability of the system, and thus, the stronger the reusability of the subsystem. Here, the decomposition of highend equipment development tasks draws on this idea for task granularity analysis.

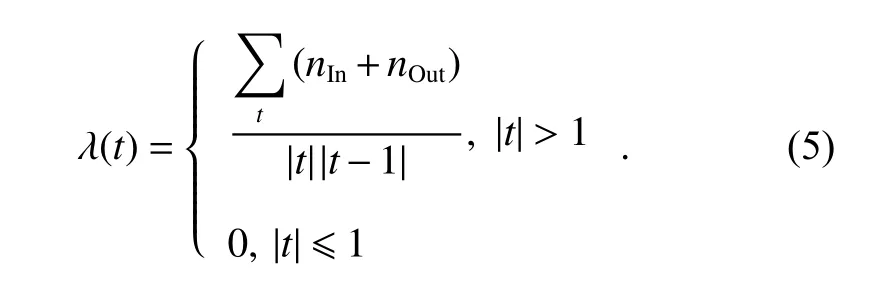

Definition 2Task correlation coefficient

The correlation coefficient of a task is a quantified level describing the degree of correlation between tasks.|t|is the number of basic task decomposition structure.nIn, nOutare the number of times that one input/output activity appears in other basic task decomposition structures. Thus, the task correlation coefficient λ(t) can be expressed as

For example, the more frequently the input and output activities of one constrained control element occur in other constrained control elements, the more the information interaction, and thus, the larger the task correlation coefficient.

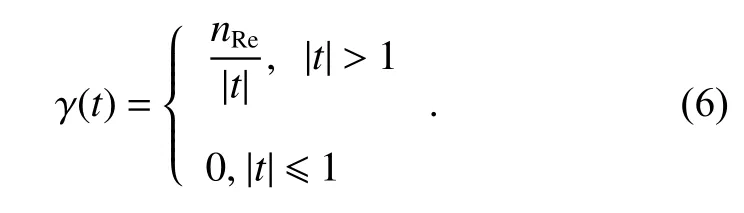

Definition 3Task reused coefficient

The task reused coefficient refers to the degree to which the input/output activity in the task decomposition structure is reused. It is equal to the ratio of reused activities to all activities in the task decomposition structure.nReis the number of times that one input/output activity is reused in other basic task decomposition structures. Thus,the task reused coefficient γ(t) can be expressed as

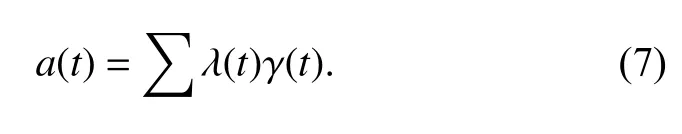

The task granularity coefficient a(t) is determined by the relationship between tasks, which mainly refers to the correlation and reuse between tasks. Then, the task granularity a (t) can be expressed as

Therefore, the concept of task granularity can be used to decompose development tasks layer by layer, which considers the logic and relevance of tasks fully. Specifically, a certain task granularity threshold is set, and task decomposition is performed within the range of the value until the appropriate sub-task is reached. When the task continues to decompose less than the threshold, it indicates that the sub-task has a strong cohesion at this time,and is not suitable for further decomposition.

3.3 Development task decomposition method based on task feasibility

During the development of high-end equipment, the subtask set obtained by preliminary decomposition does not have a high degree of satisfaction for existing suppliers.That is, existing suppliers cannot provide high functional satisfaction for the sub-task set at this time. Therefore, it is necessary to analyze the feasibility of the sub-tasks obtained from the preliminary decomposition. In addition,the supplier’s satisfaction with the task should be calculated, multiple decomposition schemes should be compared, and the scheme with a higher degree of coupling between the supplier and the task should be selected.

Definition 4Task feasibility

Task feasibility refers to the degree to which the task can be performed by the supplier within the scope of the project bidding. Specifically, it is the existence of suppliers who can implement the sub-task within the scope of the project bidding, and the richness of the supplier candidate set that can realize the sub-task. The value range of the supplier candidate set is [0,1). The task feasibility can be expressed as

where x , s are integers greater than or equal to 0. x is the number of suppliers that can satisfy the sub-tasks, and s is the preset threshold for the number of suppliers required. Ai(x) is an increasing function on x∈[0, s], and its value is [0,1]. When x= 0, Ai(x)= 0; when x >s , Ai(x)= 1.

It can be found from the task feasibility function that when there is no supplier that can implement the subtask, the task feasibility is zero. When there are suppliers that can satisfy the sub-task, the greater the number of such suppliers, the richer the candidate set, and the greater the value of the task’s feasibility.

Through the analysis of task feasibility, we can judge whether the sub-task set of preliminary decomposition is reasonable, and whether the decomposition strategy should be chaged for the next task decomposition. This analysis method can reduce the cost of interaction when the supplier cannot achieve the task.

3.4 Refined decomposition process of high-end equipment development tasks

Through the first step decomposition of the functional analysis of high-end equipment development tasks, we can get the preliminary decomposed task set. However, in most cases, the preliminary decomposed task sets cannot be directly assigned to different R&D teams, because the information interaction between the task sets at this time will be relatively large. In order to make the sub-tasks more explicit, the sub-task set needs to be further decomposed. Therefore, the degree of information interaction between sub-tasks needs to be fully considered, and the association relationship between sub-tasks needs to be calculated. We quantify the attributes of the sub-tasks in this study, and accurately decompose the task with criteria such as task granularity and task feasibility.

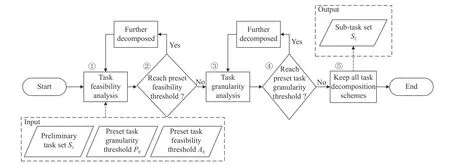

The refined decomposition flowchart of high-end equipment development tasks is shown as Fig. 2.

As shown in Fig. 2, the refined decomposition process of high-end equipment development tasks is described below.

InputThe preliminary decomposition task set S1obtained from the functional analysis, the preset task granularity threshold P0, and the preset task feasibility threshold A0.

OutputSub-task set S2.

Step 1Perform task feasibility analysis on the subtask set obtained by functional decomposition.

Fig. 2 Refined decomposition flowchart

Step 2Determine whether the task feasibility reaches the preset feasibility threshold. If it does not, it means that the supplier can implement the sub-task; if it does,the sub-task set will be further decomposed, and return to Step 1.

Step 3After the task feasibility of the sub-task set has met the preset feasibility threshold condition, the task granularity analysis is performed.

Step 4Determine whether the sub-task set reaches the preset task granularity threshold. If it does not, it means that the task decomposition scheme at that time is retained; if it does, the sub-task set will be further decomposed, and return to Step 3.

Step 5Keep all task decomposition schemes within the preset task granularity threshold.

This is the complete process of refined decomposition of high-end equipment development tasks. This process provides inputs (candidate solutions) for selection methods of high-end equipment development task decomposition schemes.

4. High-end equipment development task decomposition scheme selection method based on SIR mixed information and multiple attribute decision making

In the process of high-end equipment task decomposition,several feasible solutions can be obtained by decomposing according to the preset threshold of the task decomposition model. Choosing an optimal scheme from these schemes is one of the keys to the decomposition and transformation mechanism of high-end equipment development tasks. In other words, it is necessary to comprehensively measure and rank the task decomposition schemes from multiple dimensions and attributes.

However, a limited number of studies have investigated the evaluation of high-end equipment development and decomposition schemes. This section focuses on three issues: setting the evaluation attributes of the highend equipment development task decomposition scheme,calculating the attributes, and constructing a high-end equipment task decomposition scheme optimization strategy.

4.1 Determination of task decomposition scheme attributes

From the analysis and decomposition high-end equipment development tasks, it is concluded that a higher feasibility PAiof the task decomposition scheme is preferable,because the higher the feasibility of the task decomposition scheme, the more suppliers can meet the task, and the more recipients can be selected during the implementation of the solution.

However, considering that the uncertain factors in the task allocation process induce risks, experts in this field need to evaluate the uncertain risks of the task decomposition schemes. The lower risk value of the plan is preferable. Due to time consuming, high cost, and complex in development high-end equipment composition, etc., it is necessary to evaluate the uncertainty risk URiin the process of task decomposition scheme implementation.

At the same time, the task integration is an iterative process. The more complex and more sub-task-level relationships, the more iterations are required, and the cost(including various resources such as time, manpower, and cost) will increase. Therefore, when selecting the decomposition scheme of high-end equipment, the task integration complexity fi(li,nti) must be considered. Lower task integration complexity is desired in high-end equipment development.

The task decomposition scheme is selected considering the attributes of the three decomposition schemes described above. The importance of these three attributes to the decomposition scheme is also different. It is necessary to consider the task decomposition scheme feasibility, uncertainty risk, and importance of task integration complexity for multi-attribute decision making.

In addition, the information values of the attributes such as the task decomposition scheme feasibility, the complexity of task integration, and the risk of uncertainty during the execution of the solution may be of different types. Therefore, this is a multi-attribute high-level preparation task decomposition scheme decision problem with mixed information. This section will optimize the feasible task decomposition scheme of high-end equipment. Considering the three attributes of the high-end equipment decomposition scheme (the task decomposition scheme feasibility, the uncertainty risk during execution,and the task integration complexity), the SIR method is used to optimize the decomposition scheme.

4.2 Calculation of task decomposition scheme attributes

The calculation method of the task decomposition scheme feasibility, the uncertainty risk during execution, and the task integration complexity are explained below.

(i) Task decomposition scheme feasibility

Definition 5Task decomposition scheme feasibility

The feasibility of a task decomposition scheme refers to the sum of the feasibility of all subtasks in the task decomposition scheme. The task decomposition scheme feasibility P Aican be expressed as

(ii) Uncertainty risk

The uncertainty risk of the task decomposition scheme will be evaluated using hesitant fuzzy numbers. In realworld decision-making processes, people usually use hesitant fuzzy information to express preference assessments.Xia and Xu [22] defined hesitant fuzzy set (HFS), which includes several different degrees of membership and nonmembership.

Definition 6HFS

The HFS can be described as

where hH(x) is a value belonging to [0, 1], that is, this value belongs to the element X in the set H. Xia and Xu[22] defined hH(x) as the hesitant fuzzy number.

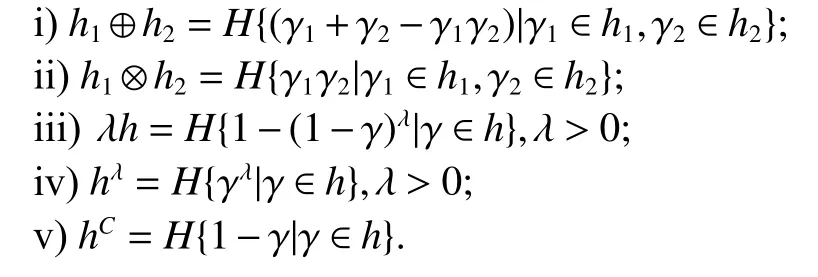

According to the definition of hesitant fuzzy numbers,the following algorithm can be obtained. Suppose there are two hesitant fuzzy numbers h1and h2, then:

Assumption 1Element expansion

In order to calculate the distance between two hesitant fuzzy numbers and compare them, element expansion is performed for fuzzy numbers with fewer elements. If the decision maker’s preference is a risk type preference, the largest element of the hesitant fuzzy number is repeatedly added until the number of elements of the two hesitant fuzzy numbers is equal. If the decision maker’s preference is the risk aversion type, the smallest element in the hesitant fuzzy number is repeatedly added until the number of elements in the two hesitant fuzzy numbers is equal. If the decision maker’s preference is the risk-neutral type, the largest and smallest elements of the hesitant fuzzy number are added simultaneously until the number of elements of the two hesitant fuzzy numbers is equal.

In the process of hesitant fuzzy multi-attribute decisionmaking, the ranking of hesitant fuzzy numbers is a very important step. Xia and Xu [22] defined a hesitant fuzzy scoring function. Farhadinia [23] proposed an improved hesitant fuzzy score function. Zhang and Xu [24] proposed a new hesitant fuzzy scoring function, which simplified the hesitant fuzzy ranking to one step. However,the score function proposed by Zhang and Xu [24] has parameters that need to be analyzed. Therefore, we analyze the geometric hesitant fuzzy scoring function, which is considered in combination with the geometric mean,and is described as follows.

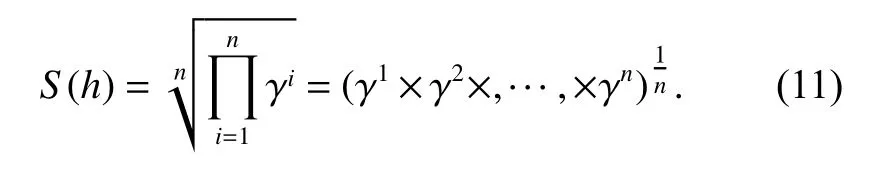

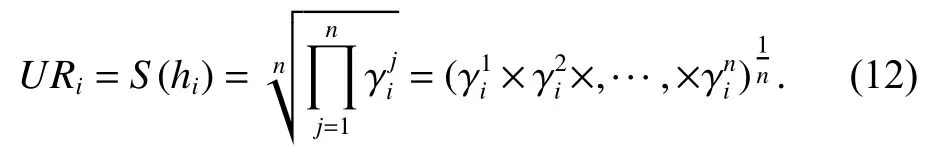

Definition 7Hesitant fuzzy score function

There exists a hesitant fuzzy number h ={γ1,γ2,···,γn},and a new hesitant fuzzy score function S (h) is defined as follows:

According to this scoring function we can get the following properties.

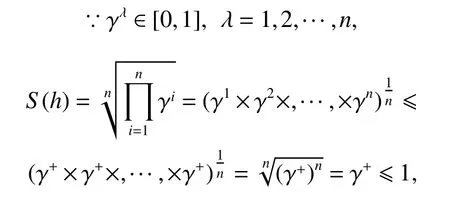

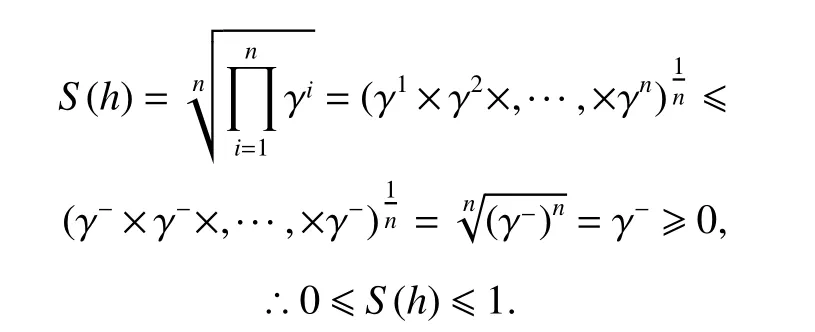

Property 1Range limit

For any hesitant fuzzy number h={γ1,γ2,···,γn}, its new score function value S (h)∈[0,1].

Proof

Let γ+=max{γλ|λ=1,2,···,n} andγ−=min{γλ|λ=1,2,···,n}.

and

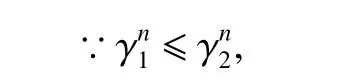

Property 2Consistency

There are two hesitant fuzzy numbersandThe elements inside them are arranged in an increasing manner, and their number of elements is equal. Ifthen S(h1)≤S(h2).

Proof

then

For the new hesitant fuzzy score function, a new ranking method can be obtained.

Definition 8Hesitant fuzzy ranking method

For two hesitant fuzzy numbersa new ranking methodisdefined asfollows.

i) If S(h1)>S(h2), then h1is better than h2, written as h1≻h2;

ii) If S(h1)=S(h2), then h1is equivalent to h2, written as h1∼h2;

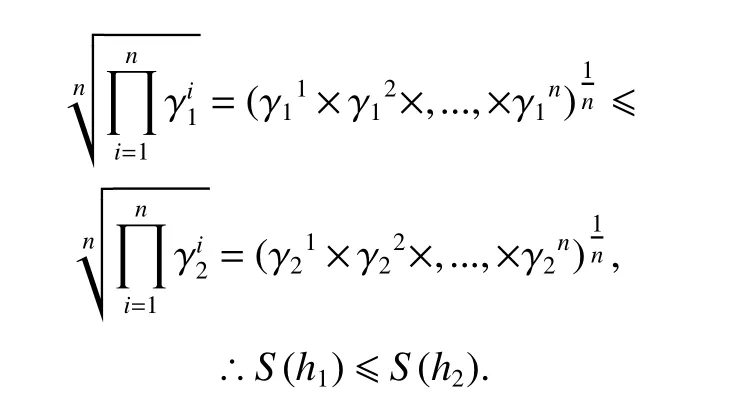

iii) If S (h1)<S(h2), then h1is worse than h2, written as h1≺h2.hesitant fuzzy numbers: h1={0.3,0.5}, h2={0.4}, and h3={0.2,0.4,0.6}.

The example in [24] is used to illustrate the usability of this newly proposed scoring function. There are three

According to the newly proposed scoring function, the following results can be obtained:

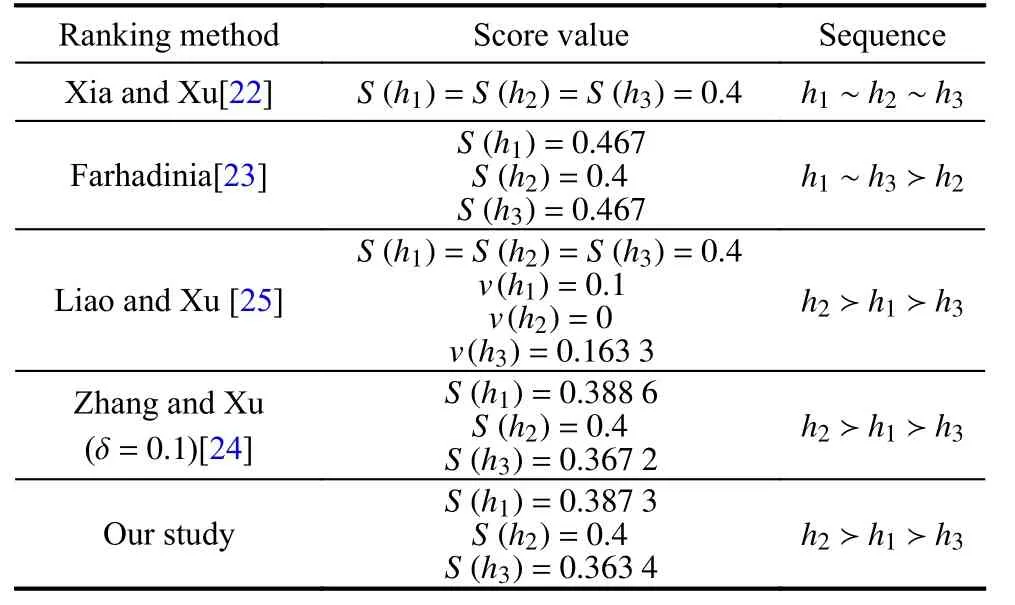

Table 1 shows the calculation results of other ranking methods.

From Table 1, it can be seen that the methods of Xia and Xu [22] cannot distinguish the three hesitant fuzzy numbers, and Farhadinia’s method [23] cannot distinguish between h1and h2. The ranking results of the hesitant fuzzy score function proposed in this study is consistent with that of Liao and Xu [25] and Zhang and Xu [24].However, Liao and Xu’s method [25] is complicated to calculate, and Zhang and Xu’s model [24] needs to analyze the parameter δ. Thus, the method of fuzzy score function ranking of geometric hesitation proposed in this study has both practicability and operability.

Table 1 Calculation results of different ranking methods

The uncertainty risk U Rican be expressed as

(iii) Task integration complexity

Definition 9Task integration complexity

The task integration complexity is a measure of the level and quantity of complexity of sub-tasks in the process of task integration. The task integration complexity will affect the cost of sub-task integration, including time,technology, cost, and personnel. Therefore, when selecting a high-end equipment task decomposition scheme, the lower task integration complexity is preferred.

According to Definition 9, let the positive integer l be the number of levels of sub-tasks and the positive integer ntbe the number of sub-tasks, then the task integration complexity can be expressed as z(l,nt). The following properties exist:

i) As the number of sub-task levels l increases, the integration complexity of the task z(l,nt) also increases.

ii) As the number of sub-tasks ntincreases, the integration complexity of the task z(l,nt) also increases.

iii) There exists positive integers l and nt, making the task integration complexity z(l,nt) range (0, 1).

iv) The quantities satisfy the relationshipthat is, the vertical complexity increase rate of the task integration complexity z(l,nt) is greater than the horizontal complexity increase rate at the task level.

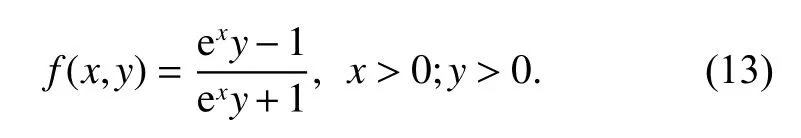

In view of the above, a function having the above four properties is introduced:

The task integration complexity fi(li,nti) can be expressed as

4.3 Task decomposition scheme selection method based on SIR

In recent years, multi-attribute decision-making has been studied extensively, and ranking schemes based on multiple attributes have been found to be important. At present, there are many methods for ordering solutions, such as technique for order preference by similarity to an ideal solution (TOPSIS). The SIR method is a multi-attribute decision ranking method proposed by Xu [26]. This is a higher-level method, and is widely used in the ranking of schemes. The advantage of this method is that schemes can be sorted under weaker conditions. The algorithm of this method constructs the superiority and inferiority of the scheme, and obtains the partial and complete ranking of the scheme according to the superiority and inferiority of the final scheme.

The basic principle of SIR is as follows:

Let a scheme set be X={x1,x2,···,xn}, the attribute set be C ={c1,c2,···,cn} , andrepresents the attribute value of scheme xiunder attribute ck. The calculation process can be divided into the following steps.

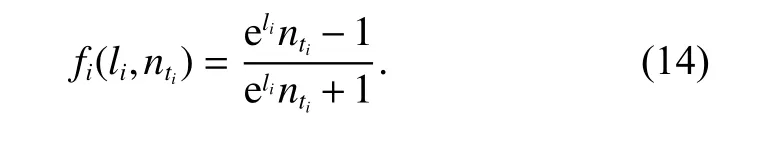

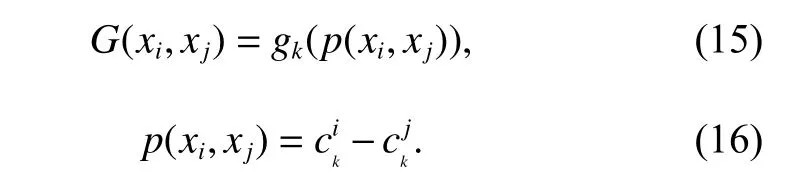

(i) Calculate the advantages and disadvantages between the schemes.

The advantages and disadvantages between the different schemes can be expressed as

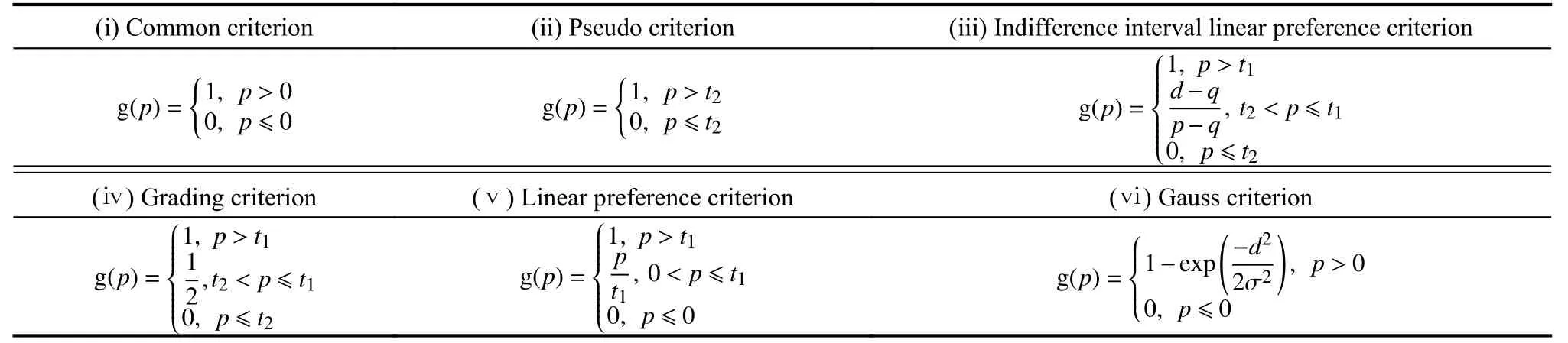

Normally, the value of gk(p(xi,xj)) is [0, 1]. This function has six forms (shown in Table 2), which represent different preference structures of decision makers.

Table 2 Six different preference structures of decision makers

Different decision makers have different decision preferences. Decision makers can choose different calculation forms according to their own knowledge structure,environment, and interests, to obtain different calculation results and assist decision-making. Let t1be the decision preference parameter of the decision maker, and t2be the neutral value of the decision. Among them, the Gauss criterion is used more in practical decision-making [27].

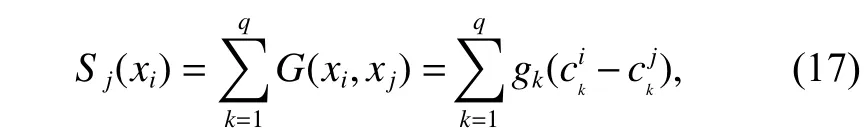

(ii) Construct the advantage matrix and disadvantage matrix of scheme attributes.

Let S(xi) be the advantage index of scheme xifor attribute cj, and I(xi) be the disadvantage index of scheme xifor attribute cj. The advantage matrixS=[Sj(xi)]q×rand the disadvantage matrix I=[Ij(xi)]q×rcan be obtained through the advantage index and the disadvantage index:

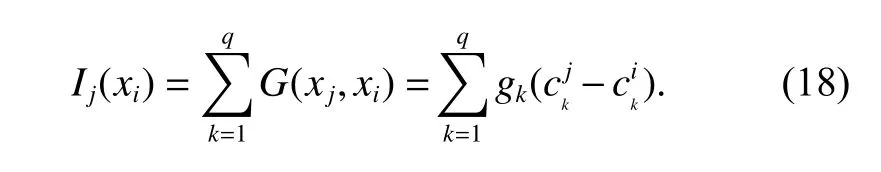

(iii) Construct the advantage flow and disadvantage flow of the scheme.

According to the above formulae, the advantage flow and the disadvantage flow of the scheme can be expressed as

where φ is the decision information integration function[28] that can be integrated with TOPSIS or the simple weighting method.

Let the deviation be

Therefore, the larger the advantaged flow υj(xi)>and the smaller the disadvantage flow υj(xi)<, the larger the value d(xi), and the better the scheme.

According to the above steps, the optimal task decomposition scheme can be selected based on the multi-attribute decision-making with the SIR mixed information for the high-end equipment task decomposition scheme.

5. Example

Military electric vehicles are completely powered by onboard power supplies, and use electric motors to generate power to drive the wheels. Generally, military electric vehicles use high-efficiency batteries as the power source. The main components include the electric drive control system, chassis, bodywork, and electrical system.Among them, the electric drive control system, which mainly includes electric drive, vehicle power, and auxiliary modules, is different from that in traditional (nonelectric) cars.

We decompose the development task of military electric vehicles, and select the optimal decomposition scheme from different decomposition schemes obtained by the method proposed in this study.

5.1 Decomposition of military electric vehicle development tasks

We obtain the conceptual design of the military electric vehicle and the overall design task of the product from the Internet. According to the analysis of the functions of military electric vehicles, a task decomposition method based on the functions is used as the first step.

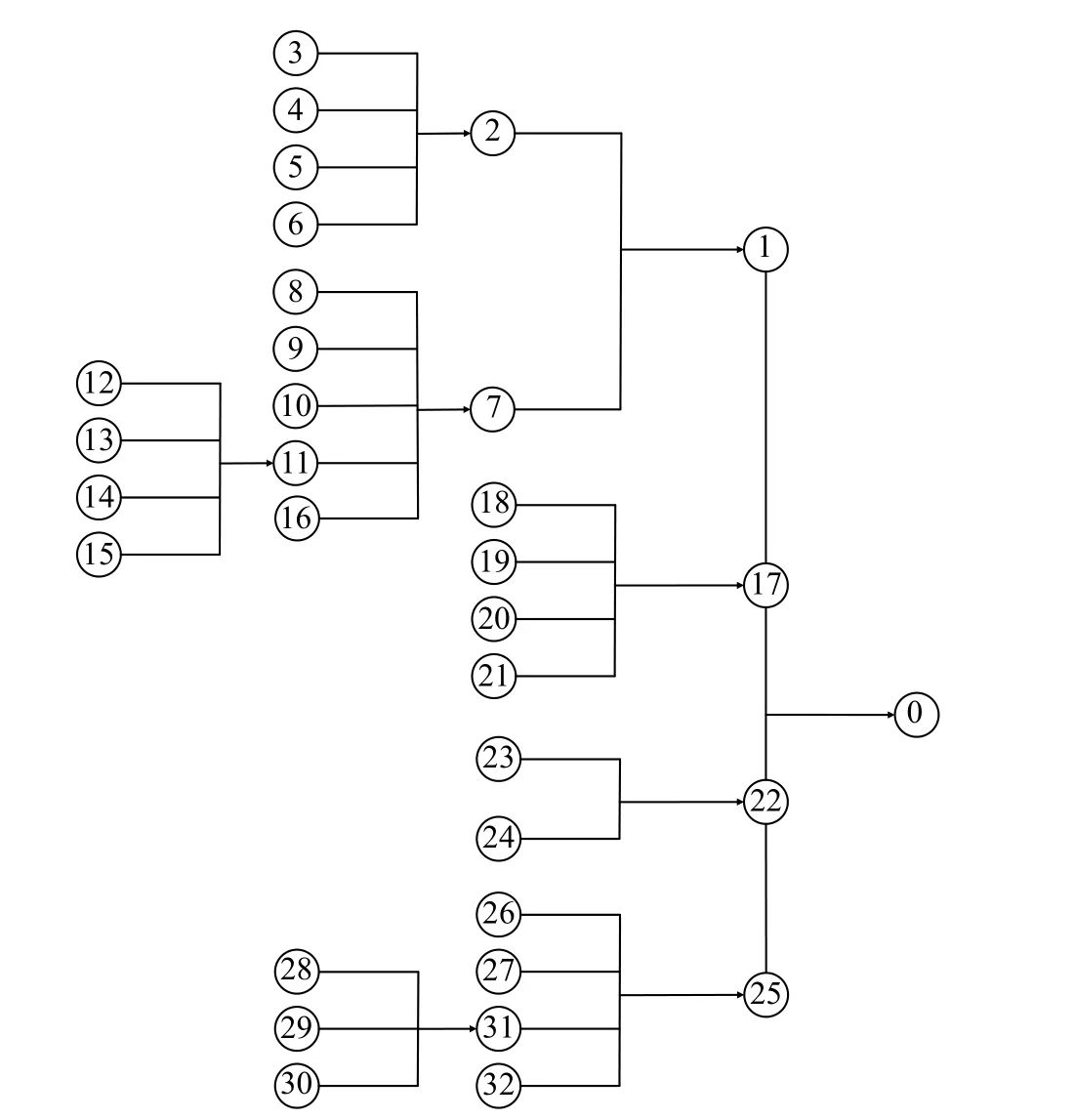

By analyzing the structure of military electric vehicles,its functional modules can be divided into four major parts: electric drive systems, vehicle controllers, bodywork, and auxiliary systems. Based on the actual research and development design of the military electric vehicle project, the logical relationship between the processes of R&D activities is shown in Fig. 3, where activity 0 represents the completed vehicle.

Fig. 3 Logical relationship between R&D activities

The expanded tree diagram includes 32 development and design activities. The specific design activity units are shown in Table 3.

Table 3 Specific design activity units chart

First, the task decomposition method proposed in this study is used for preliminary decomposition of the entire development task. According to the functional analysis of the military electric vehicle, four sub-tasks are obtained after preliminary decomposition: electric drive system design A, including project development activities 1 to 16; vehicle controller design B, including project design activities 17 to 21; body design C, including project design activities 22 to 24; auxiliary system design D, including project design activities 25 to 32.

The preliminary decomposition of the development task, called Scheme 0, is shown in Fig. 4.

Fig. 4 Preliminary decomposition of the development task

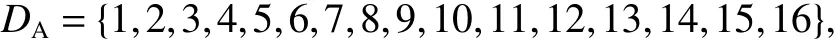

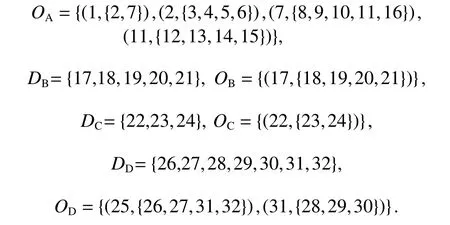

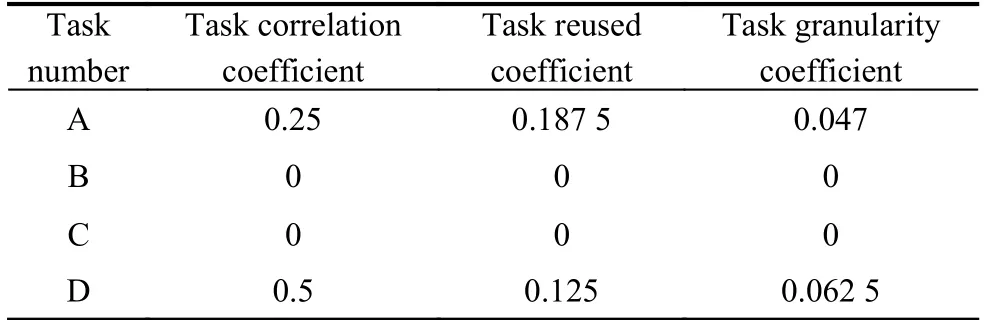

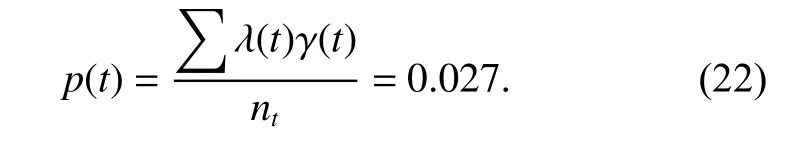

We calculate the task granularity of the original scheme.The control unit, input, and output activity unit of each sub-task are represented as follows:

According to (5)-(7), the task correlation coefficient,task reused coefficient, and task granularity coefficient of the preliminary decomposition scheme are calculated as shown in Table 4.

Table 4 Task correlation coefficient, task reused coefficient, and task granularity coefficient of the preliminary decomposition scheme

According to (4), the task granularity of this scheme is calculated as

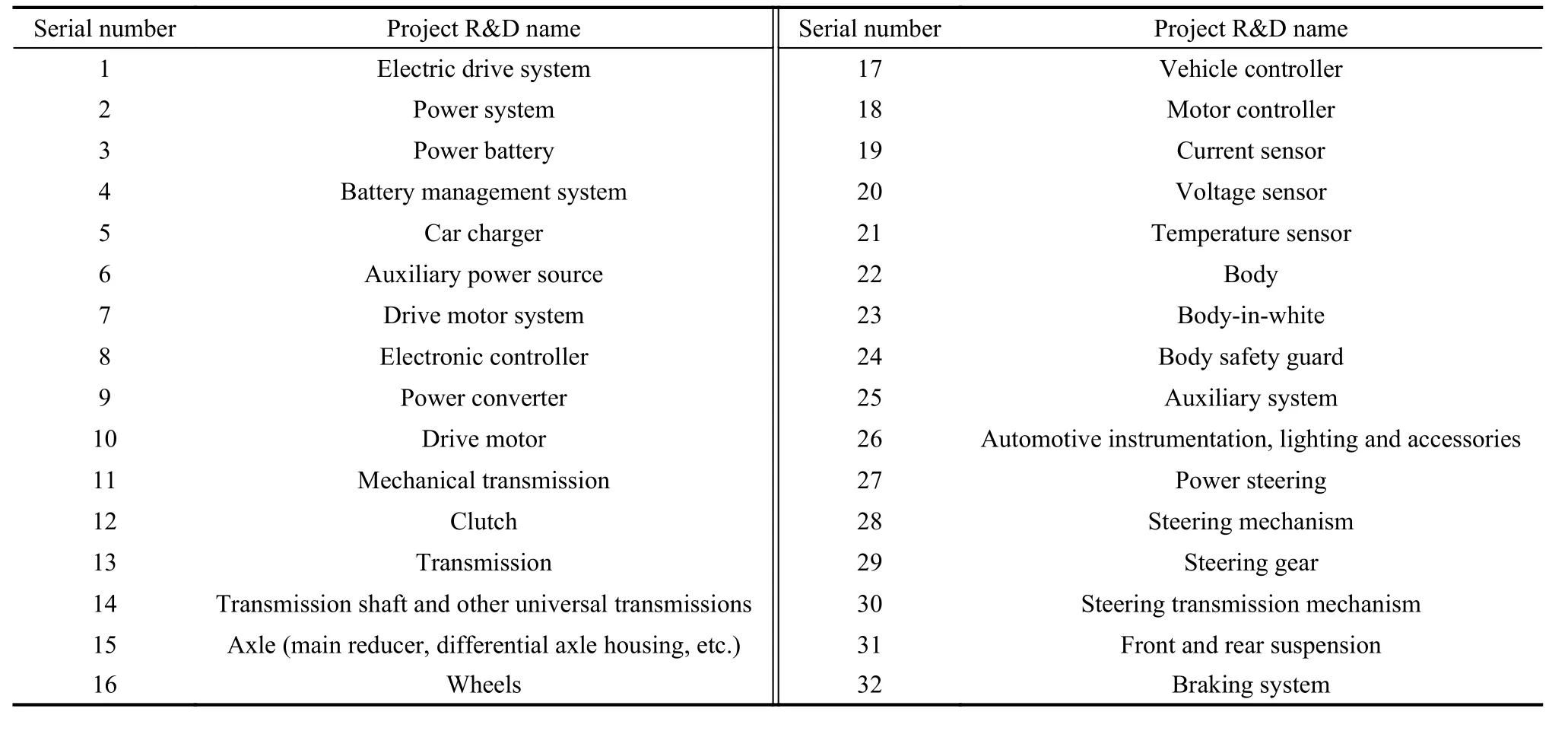

In general, the preset threshold for setting the granularity of equipment development tasks is 0.02 [17].However, the task granularity of this preliminary task decomposition scheme is greater than 0.02. Sub-tasks with larger task granularity coefficients need to be finely decomposed further to obtain the following four task decomposition schemes, as shown in Table 5.

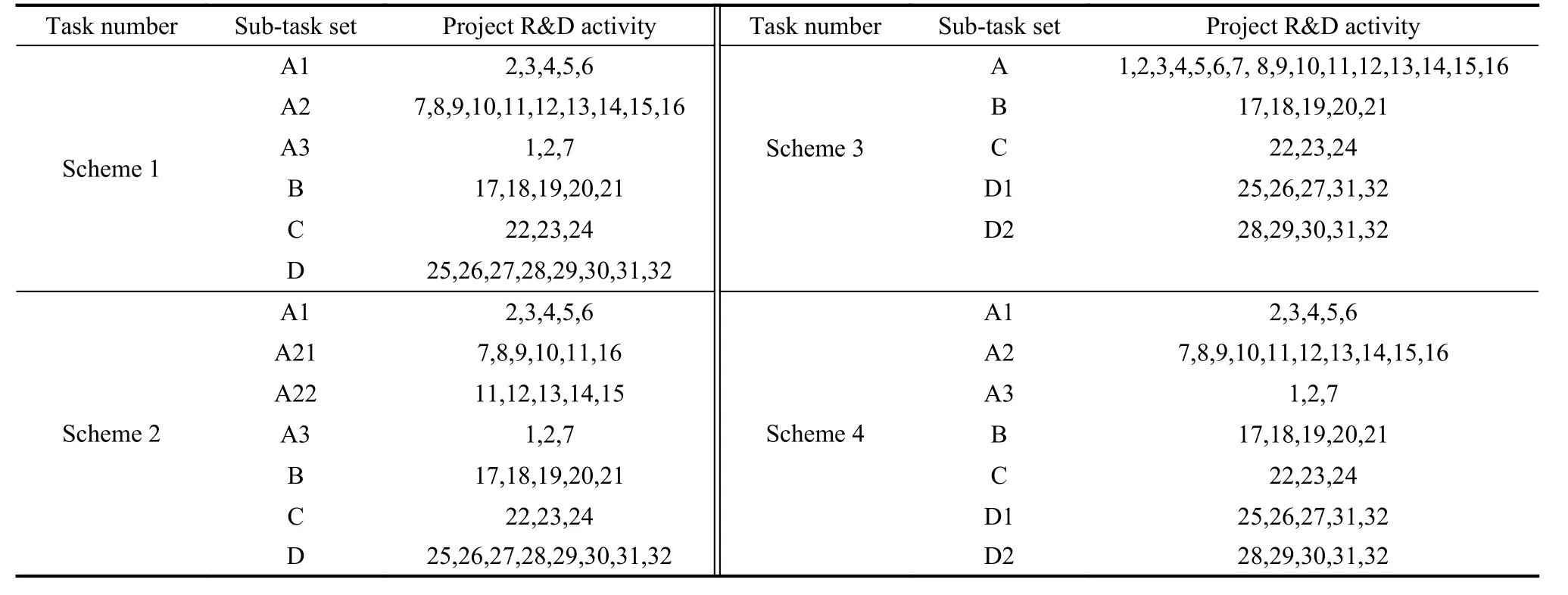

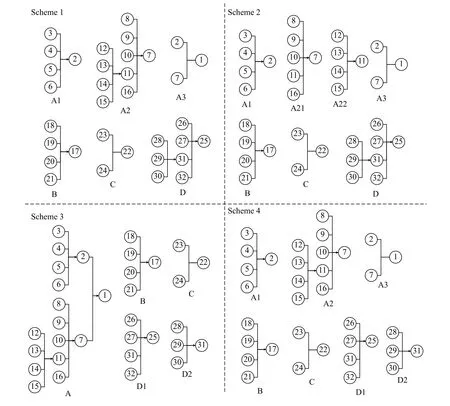

Table 5 Four task decomposition schemes chart

The corresponding decomposition scheme figures are shown in Fig. 5.

Fig. 5 Four task decomposition schemes

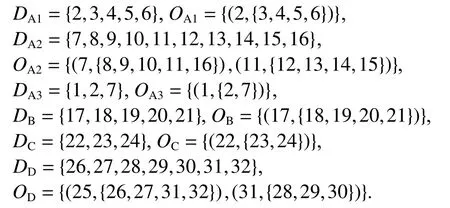

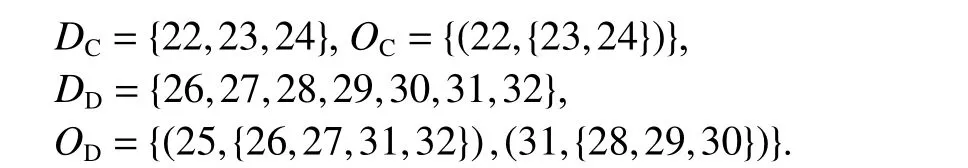

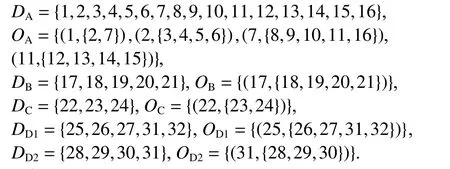

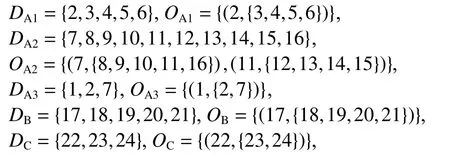

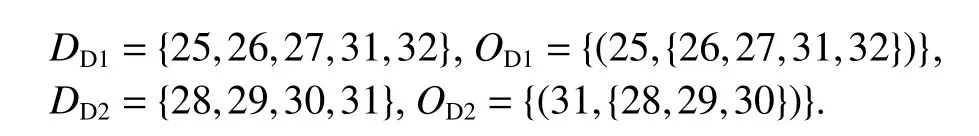

The control unit, input, and output activity unit of each sub-task in four different schemes are represented as follows.

Scheme 1:

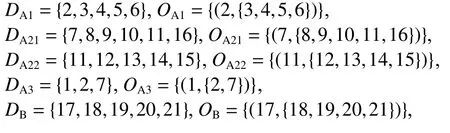

Scheme 2:

Scheme 3:

Scheme 4:

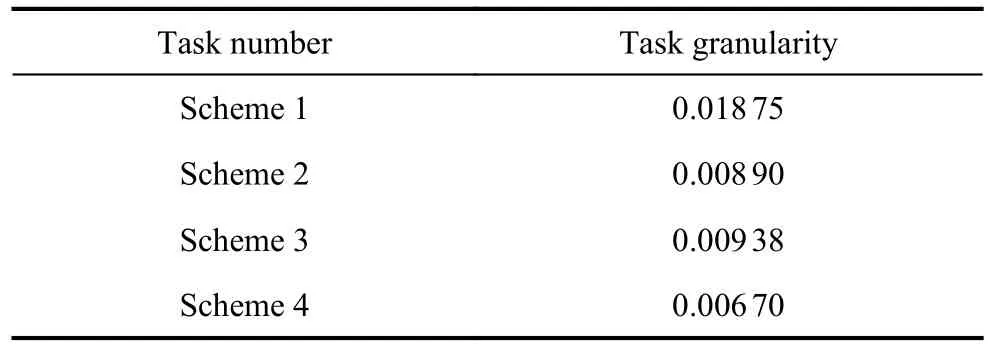

According to (4)-(7), the task granularity of four different decomposition schemes are calculated, as shown in Table 6.

Table 6 Task granularity of four different decomposition schemes

It can be seen from Table 6 that the task granularity of the four schemes are all below the preset threshold of 0.02. Therefore, these four schemes can be used as feasible solutions to task decomposition schemes. The next step is to further screen these four schemes, and finally choose the best decomposition scheme.

5.2 Scheme selection of military electric vehicle development tasks

Four decomposition schemes can be obtained according to the above decomposition. The selection of the decomposition scheme should be conducted with the feasibility of the task decomposition scheme, the uncertainty risk of the execution process of the task decomposition scheme,and the complexity of task integration. The task feasibility is mainly related to the number of suppliers that can perform sub-tasks. The uncertain risk of the task is based on the experience of experts in the field, and the value of the risk is judged using hesitant fuzzy numbers. Task integration complexity considers integrating all the subtasks.

(i) Calculate the task feasibility of the decomposition scheme

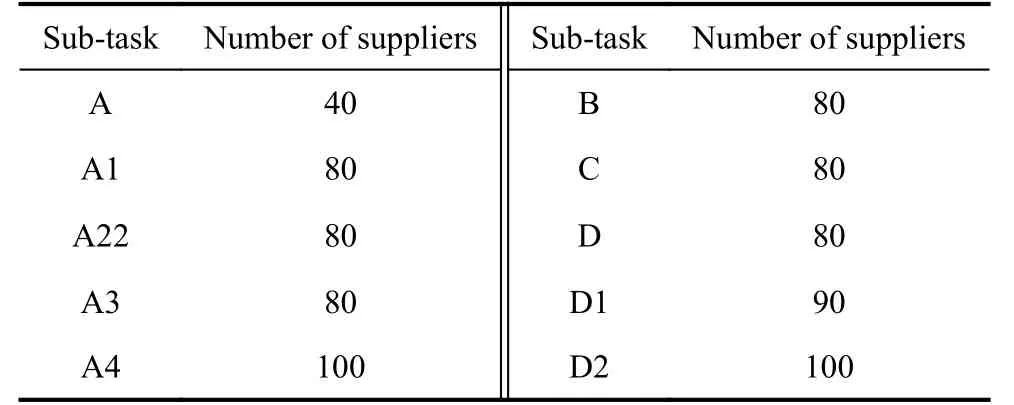

The supplier simulation data for all sub-tasks are shown in Table 7.

Table 7 Supplier simulation data for all sub-tasks

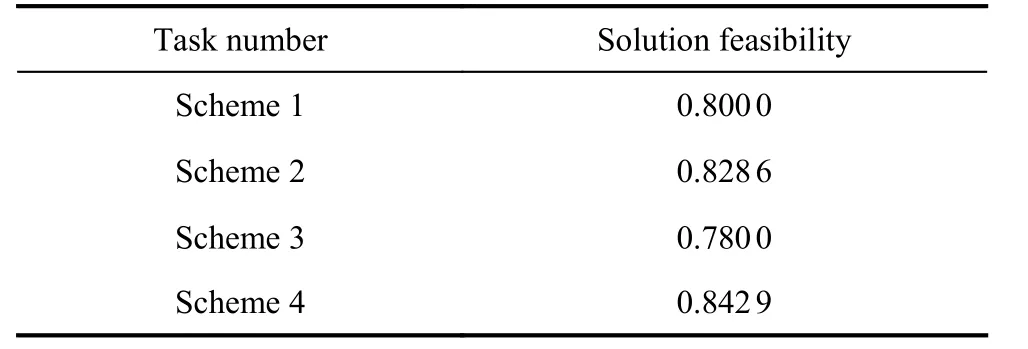

According to (9), the task feasibility of the four schemes are shown in Table 8.

Table 8 Task feasibility of four different decomposition schemes

(ii) Calculate the uncertainty risk of task decomposition schemes

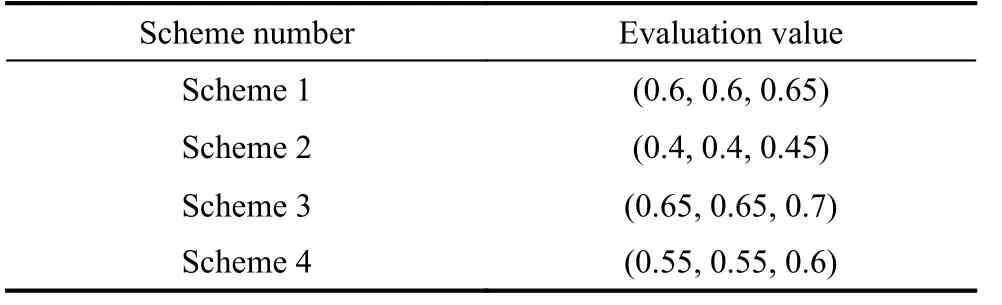

The uncertainty risks of the decomposition schemes are evaluated by experts in the field using hesitant fuzzy numbers, and the data are shown in Table 9.

Table 9 Uncertainty risks evaluation value of four different decomposition schemes

The hesitant fuzzy numbers of the task decomposition scheme are supplemented by Assumption 1. It is assumed that the decision maker is risk-conservative, so that the evaluation value is small. The results are shown in Table 10.

Table 10 Supplemented uncertainty risks evaluation value of four different decomposition schemes

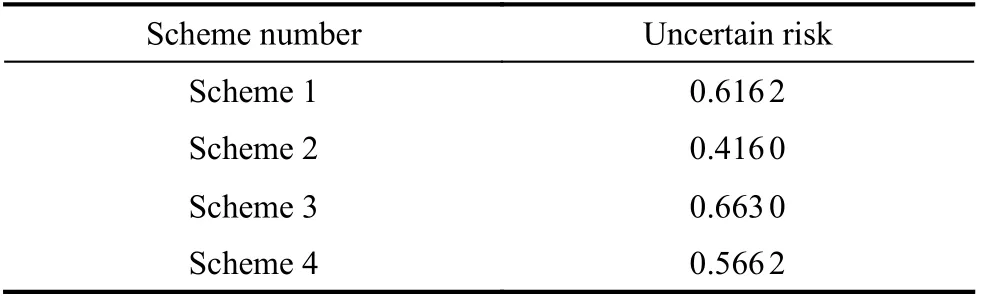

The hesitant fuzzy values of the uncertain risk of each decomposition scheme is calculated by using (11), as shown in Table 11.

Table 11 Hesitant fuzzy value of the uncertain risk of four different decomposition schemes

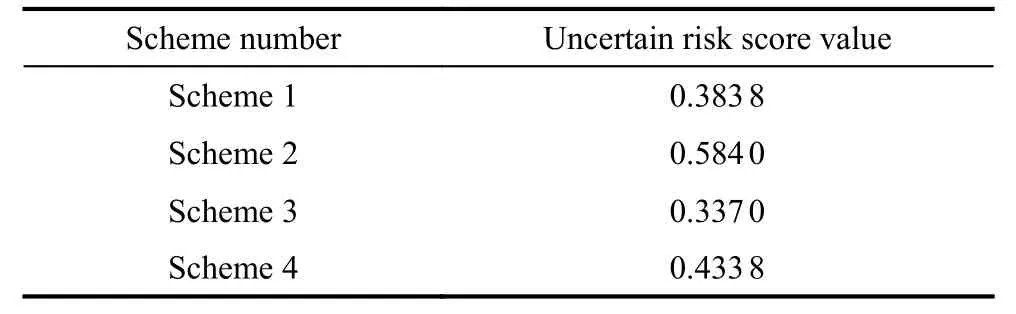

Since the risk value should be as low as possible, it is more appropriate to convert it to a positive value. Thus, 1 is used to subtract the uncertainty risk value. The results are shown in Table 12.

Table 12 Hesitant fuzzy score values of the uncertain risk of four different decomposition schemes

(iii) Calculate the integration complexity of the scheme

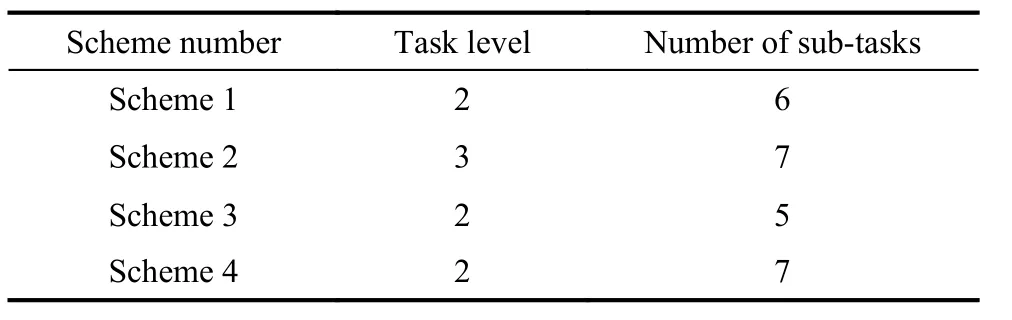

We first analyze the hierarchical relationship of each task decomposition scheme and the number of sub-tasks,as shown in Table 13.

Table 13 Hierarchical relationship of four different decomposition schemes

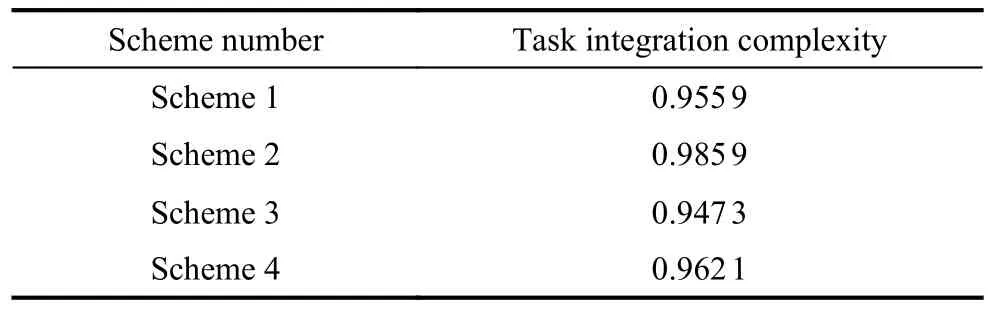

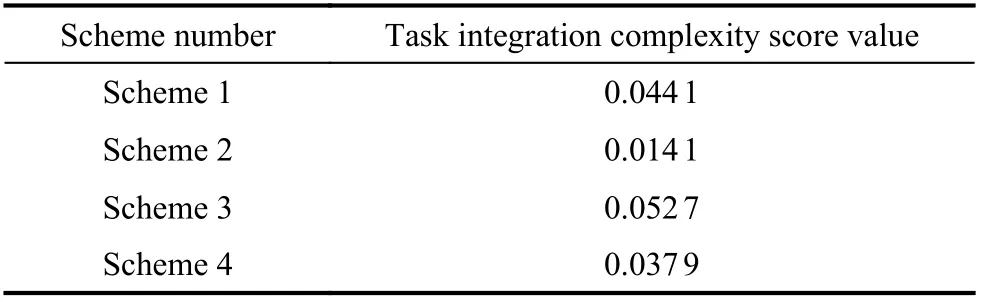

Then, the integration complexity of each task is calculated according to (14). The results are shown in Table 14.

Table 14 Task integration complexity of four different decomposition schemes

Since the task integration complexity value should be as low as possible, it is more appropriate to convert it to a positive value. Thus value 1 is used to subtract the task integration complexity value. The results are shown in Table 15.

Table 15 Task integration complexity score value of four different decomposition schemes

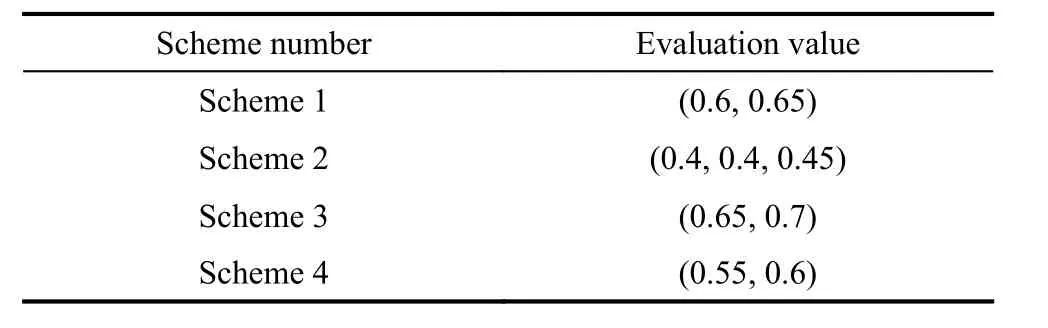

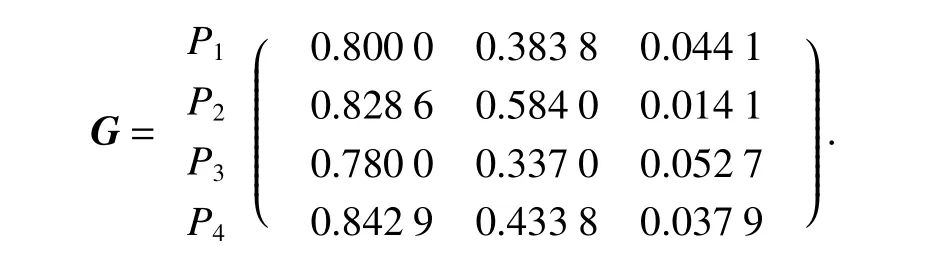

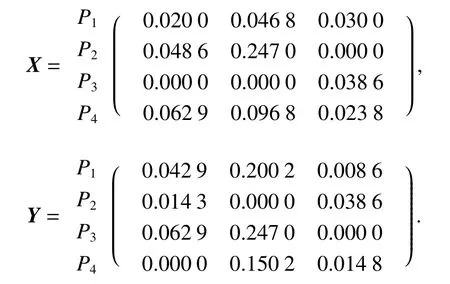

(iv) Construct a multi-attribute decision model for decomposition schemes

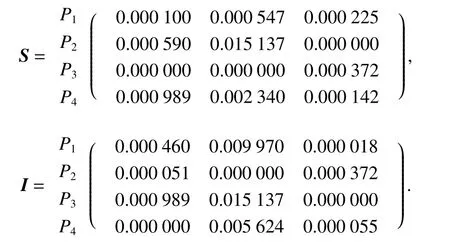

According to the task execution process, combined with the above steps, a multi-attribute decision is made on the development task decomposition scheme under mixed information. Let Pirepresent the scheme i. Then,the attribute values are as follows:

(v) Calculate the matrix of advantages and disadvantages between schemes

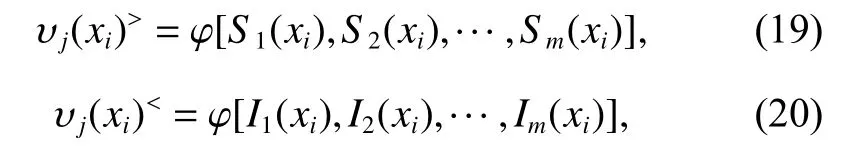

According to (15) and (16), the advantages and disadvantages between the schemes are calculated as

The decision preference is calculated by using the Gaussian distribution criterion, and a standard difference information matrix of the advantages and disadvantages of the scheme attributes is constructed. According to (17)and (18), a matrix of advantages and disadvantages between scheme attributes is obtained (parameter = 2).The decision Gauss criterion is used to process X and Y into standard difference information matrices. The results are as follows:

(vi) Construct the advantage flow and disadvantage flow of the scheme

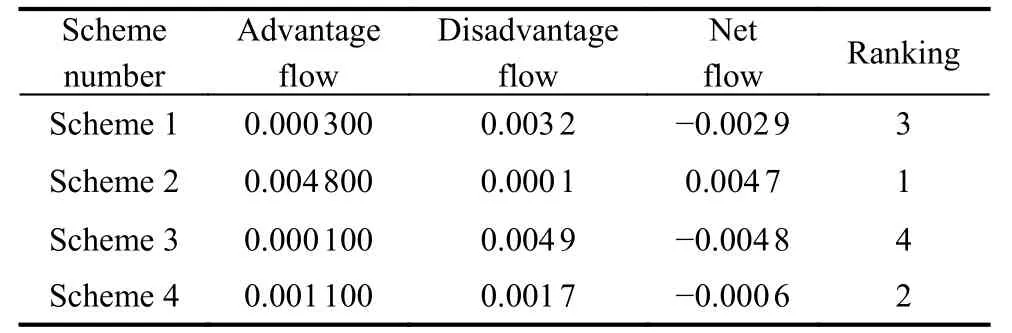

According to (19) and (20), the weight vector of the attributes is ω0=(0.4,0.3,0.3), and the calculated deviation is D(xi)=υj(xi)>−υj(xi)<between the advantage flow and the disadvantage flow between the schemes.The ranking of the high-end equipment task decomposition schemes are obtained, as shown in Table 16.

Table 16 Ranking results of the high-end equipment task decomposition schemes

By using the SIR method for the decomposition schemes, the task decomposition schemes are ranked in consideration of the feasibilities, the risks of the execution,and the complexity of task integration. The sorting result is as follows:

Scheme 2 > Scheme 4 > Scheme 1 > Scheme 3.

5.3 Comparative analysis of algorithms

The above results demonstrate the algorithm of task decomposition and scheme selection for military electric vehicles, and we obtain four task decomposition schemes that meet the granularity requirements, along with their rankings. Next, the efficiency and accuracy of the proposed algorithm are analyzed and compared.

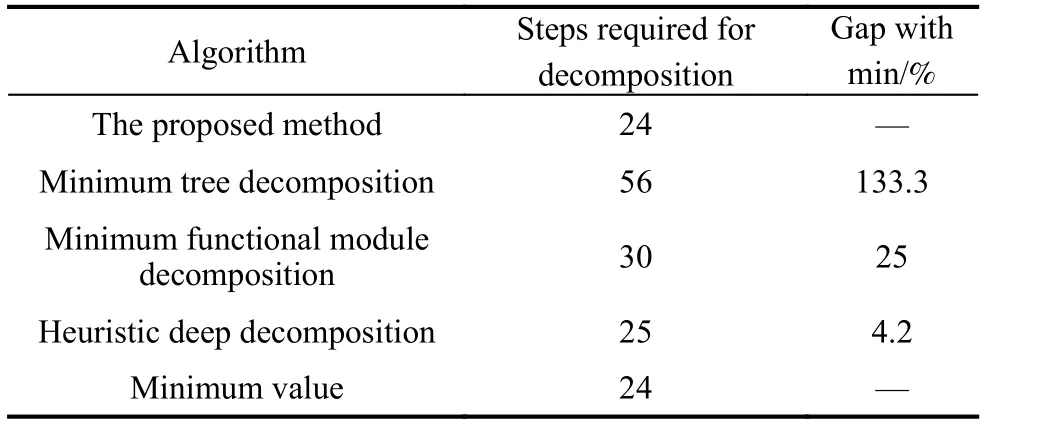

(i) Algorithm efficiency

The task decomposition method proposed in this study is firstly decomposed based on the functional structure of the product, and then, it is accurately decomposed by task feasibility analysis and task granularity analysis. Finally,a set of task decomposition schemes satisfying the preset conditions is obtained. This method can not only control the decomposition conditions, but also greatly improve the decomposition efficiency, as shown in Table 17. The following example compares the efficiency of different algorithms for the example of military electric vehicles(the task granularity is preset to 0.02).

Table 17 Algorithm efficiency comparison

It can be seen from Table 17 that the task decomposition method proposed in this study has a higher efficiency,compared with the commonly used decomposition algorithms.

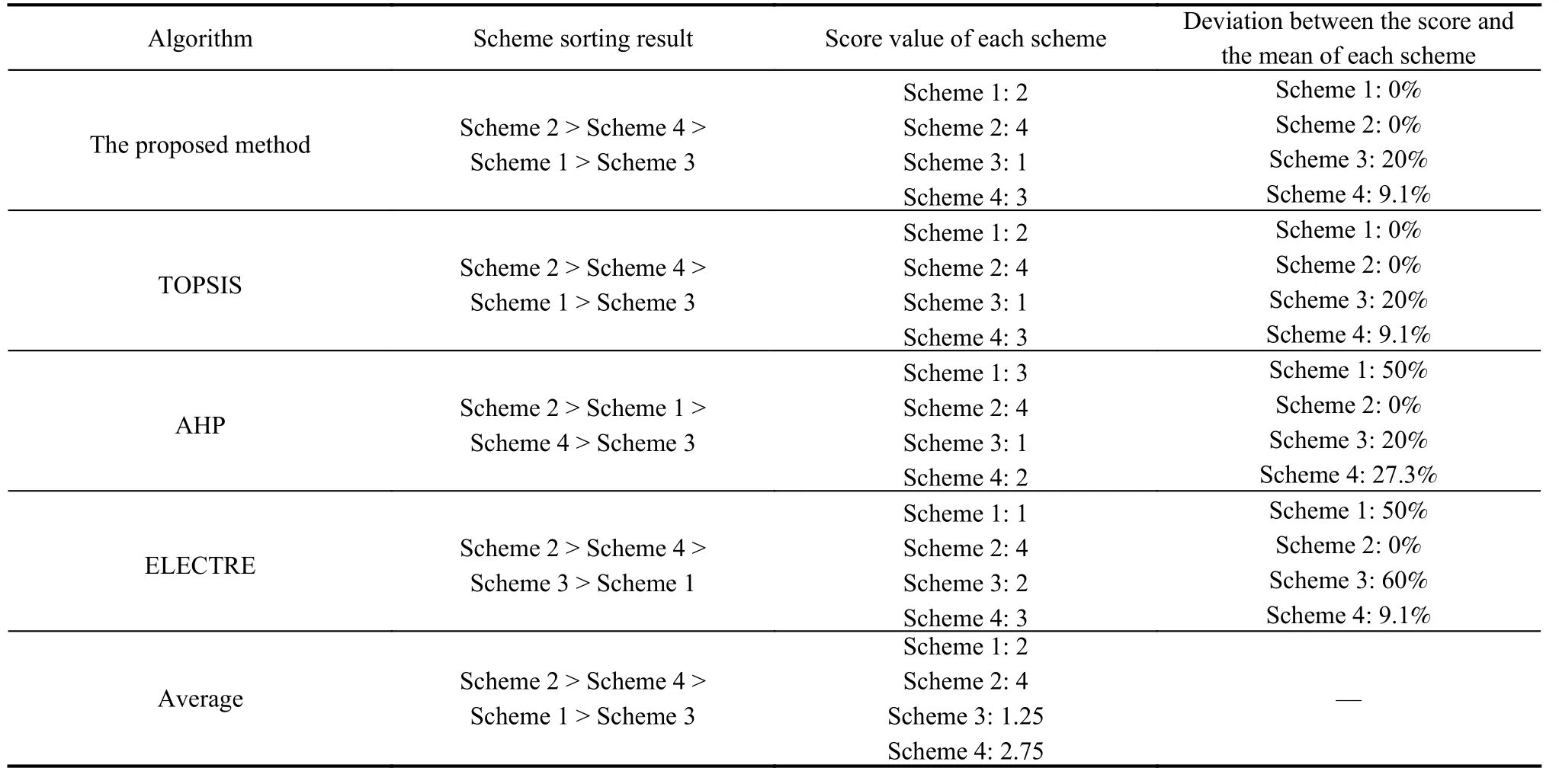

(ii) Algorithm accuracy

The scheme selection method based on SIR mixed information proposed in this study integrates three parameters: the task decomposition scheme feasibility, uncertainty risk, and task integration complexity, which can make a more comprehensive comparison of the decomposition schemes. To verify the accuracy of this method, we will use different sorting methods to sort the multiple decomposition scheme of military electric vehicles, and compare the sorting results under different sorting methods (under the same parameter conditions), as shown in Table 18.

Table 18 Algorithm accuracy comparison

It can be seen from Table 18 that the proposed sorting method has a better sorting accuracy.

6. Conclusions

This study proposes a new solution to the problem of task decomposition and program selection for high-end equipment development, based on the ideas of systems engineering. The decomposition method based on the functional structure, task feasibility and task granularity is more suitable for the actual needs of high-end equipment R&D tasks, and has a higher computing efficiency. The scheme selection method based on SIR mixed information and multi-attribute decision-making considers the scheme feasibility, uncertainty risk and complexity of task integration,and has good practical significance and algorithm accuracy. The proposed solution is a new attempt in the field of high-end equipment development task management.

Journal of Systems Engineering and Electronics2021年1期

Journal of Systems Engineering and Electronics2021年1期

- Journal of Systems Engineering and Electronics的其它文章

- Unsplit-field higher-order nearly PML for arbitrary media in EM simulation

- A deep learning-based binocular perception system

- STAP method based on atomic norm minimization with array amplitude-phase error calibration

- Higher order implicit CNDG-PML algorithm for left-handed materials

- Fast and accurate covariance matrix reconstruction for adaptive beamforming using Gauss-Legendre quadrature

- Multiple interferences suppression with space-polarization null-decoupling for polarimetric array