Design of liquid filling machine positioning system based on RBFneural network activedisturbance rejection controller

Yan-ming CHENG,Cheng LIU*,Jing WU,Yang CUI,Jing NIU

(1 College of Electrical and Information Engineering,Beihua University,Jilin 132013,China)

(2 Jilin Chemical Fiber Group Co.,Ltd.,Jilin 132013,China)

Abstract:In the filling production of chemical products,most of the filling products are poisonous and harmful products.Therefore,the precise,steady and quick positioning control for the filling nozzle reaching the sprue on the barrel is particularly important.The positioning control of the filling nozzle from a certain position to the sprue on the randomly placed barrel of the filling line is realized by two sets of lead screw systems.In this paper,aiming at the nonlinearity between servomotor and structure of lead screw,and the influence of the coupling between the X axis and Y axis in the plane on the control efficiency,a decoupling controlmethod,namely active disturbance rejection controller based on fuzzy RBF neural network,is proposed,which achieves the high efficiency operation of from a certain position to the sprue on the randomly placed barrel in the plane.The practical application of themethod in a chemical plant verifies that themethod has the high efficiency and high precision positioning control under the bad environment.

Key words:Filling production,Positioning control,RBF neural network,High efficiency,High precision

1 Introduction

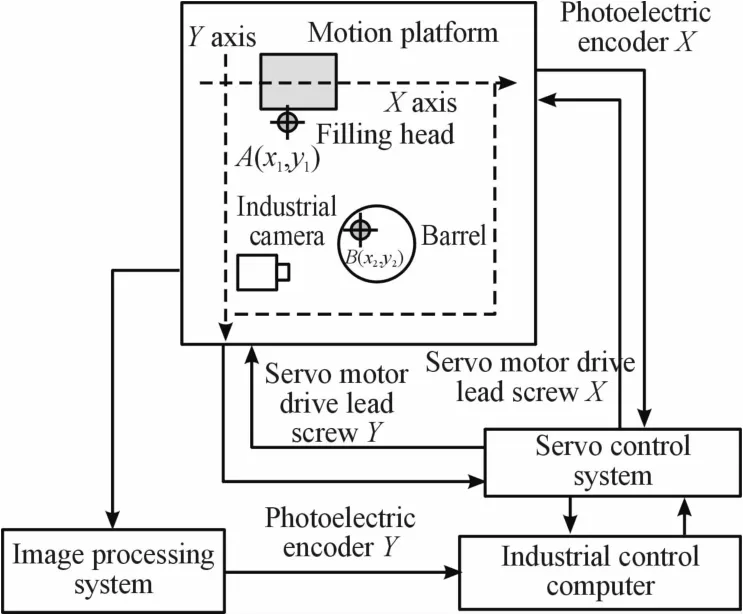

In chemical production,finished product filling is an important part.The fillingmachine is to pack the liquid products into the required barreled products according to the process requirements.Most of the chemical products are toxic and harmful products,whilemost of the filling containers are standard 200 L oil barrelswith a diameter of 600 mm and a diameter of 6 mm at the injection port.The filling nozzle is installed on the two-dimensional platform with two sets of servo driven lead screws.The diameter of the filling nozzle is approximately 5 mm.The diameter of the filling nozzle is relatively close to the diameter of the bunghole,so it is necessary to avoid the scraping or bumping between the filling nozzle and the bunghole and damaging the filling nozzle.Due to the inaccuracy of the injection port identification of the oil barrel,the fillingmachine notonly affects the efficiency of normal production,but also causes certain waste,and endangers the life and health ofworkers.Therefore,the positioning of the filling nozzle in the two-dimensional platform is very important.The automatic liquid filling machinemainly consists of vision part,servo control positioning part,pneumatic filling part and transmis-sion part[1-3].In this paper,in the two-dimensional plane as shown in Fig.1,it is assumed that the filling nozzle in the coordinate of the positionA(x1,y1)which is in the coordinate of position of the last bunghole.After the industrial camera detects the coordinate of the positionB(x2,y2)corresponding to the coordinates of the current bunghole,the filling nozzle can be controlled to quickly reach the positionB(x2,y2)from the positionA(x1,y1).The filling nozzle is fixed on the two-dimensional platform,which is composed of two servo motors and lead screw systems.Due to the bad environment and the increase of current labor cost,the filling nozzlemustmeethigher filling efficiency and positioning requirements.Some previous research[4-8]related to ADRC(Active Disturbance Rejection Control)and ADRC based on RBF have not been applied to the filling production control.Based on the above analysis,this paper proposes a decoupling control method,namely active disturbance rejection controller based on fuzzy RBF neural network,which aims at solving the nonlinear between servomotor and structure of lead screw,and the influence of the coupling between theXaxis andYaxis in the plane on the control efficiency.The method can achieve the high efficiency operation of from a certain position to the sprue on the randomly placed barrel in the plane.

Fig.1 Layout of fiIIing m achine

2 M odel of screw d rive system controlled by servo system

Screw feed drive system includes servo control and ball screw feed system,which controls the servomotor to drive the screw feed system to realize the platform running in two-dimensional plane.

2.1 State spacemodeling of ball screw feed system

The general equation of structural dynamics of screw feed system can be written as Formula(1).

Where,xiis the displacement vector,is velocity vector,¨xiis acceleration vector,Miismassmatrix,Ciis dampingmatrix,Kiis stiffnessmatrix andτis servo input of the system.

Add friction force and disturbance to Formula(1),and Formula(2)can be obtained.

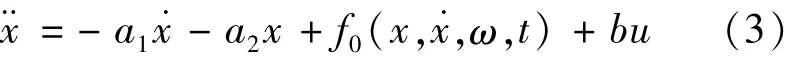

The dynamic Formula(2)of ball screw feed system can be converted into

Where,uis the system input,xis the system output,is the known modeling dynamics of the object,f0(x,˙x,ω,t)is the sum of the unknown modeling dynamics and external disturbances of the object,bis the uncertain control gain,andb0is the approximate value of the uncertain control gainb.Let(b-b0)uwhich is called it“total disturbance”.

2.2 Two dimensional platform modeling of ball screw

The mechanical structure of the two-dimensional ball screw feeding system is complex,and the two screws are coupled with each other,and the control structure is shown in Fig.2,X1(s)andX2(s)respectively is the input of the two-dimensional platform of ball screw,andY1(s)andY2(s)respectively is the output the two-dimensional platform of ball screw.When any inputXi(s)changes,the outputYi(s)changes.Therefore,in order to achieve high efficiency control in two-dimensional platform space,it is necessary to input two given inputs at the same time and decouple each other.

Fig.2 Structure of two dimensiona IbaIIscrew feed system

It can be seen from Fig.2,X1(s)andX2(s)are the two inputs of the system and,Y1(s)andY2(s)are the output of the system.When any inputXi(s)changes,the outputYi(s)changes.The two-dimensional ball screw feed system is composed of two inputs and two outputs,which are coupled with each other,and can be constructed as shown in Formula(4):

According to Formula(3)and(4),the system equation of two-dimensional platform can be obtained as follows:

2.3 Design of auto disturbance rejection control system

According to the principle of ADRC(Active Disturbance Rejection Control),ADRC can not only solve the coupling problem in the two-dimensional ball screw feed system,butalso solve the uncertainty problem in the model.By using the comprehensive disturbance observation ability of the extended state observer and selecting the appropriate feedback control law,the system can be decoupled and disturbance restrained.Therefore,the strong coupling problem can be solved by using ADRC in the feed system of two-dimensional ball screw.According to Formula(5),ADRC block diagram of two-dimensional ball screw feeding system is depicted in Fig.3.

Fig.3 ADRC b Iock diag ram of tw o d im ensiona I ba II screw feed system

3 Decoup ling control m ethod of ADRC based on RBF neural netw ork

The design structure of the controller is shown in Fig.4.The RBF neural network is used to identify the model of the controlled object and obtain the Jacobian information of the object.u(k)andy(k)are input and output of the object,respectively.The input structure of neural network is(3,h,1),that is,3 inputs,h hidden neurons,1 output.The inputs of neural network areu(k),y(k-1)andy(k-2),and the output isy(k).After training,the Jacobian information of the object is obtained.

Fig.4 Structure of ADRC contro IIer based on RBF

4 Sim u lation experim ent

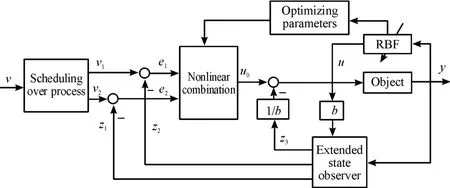

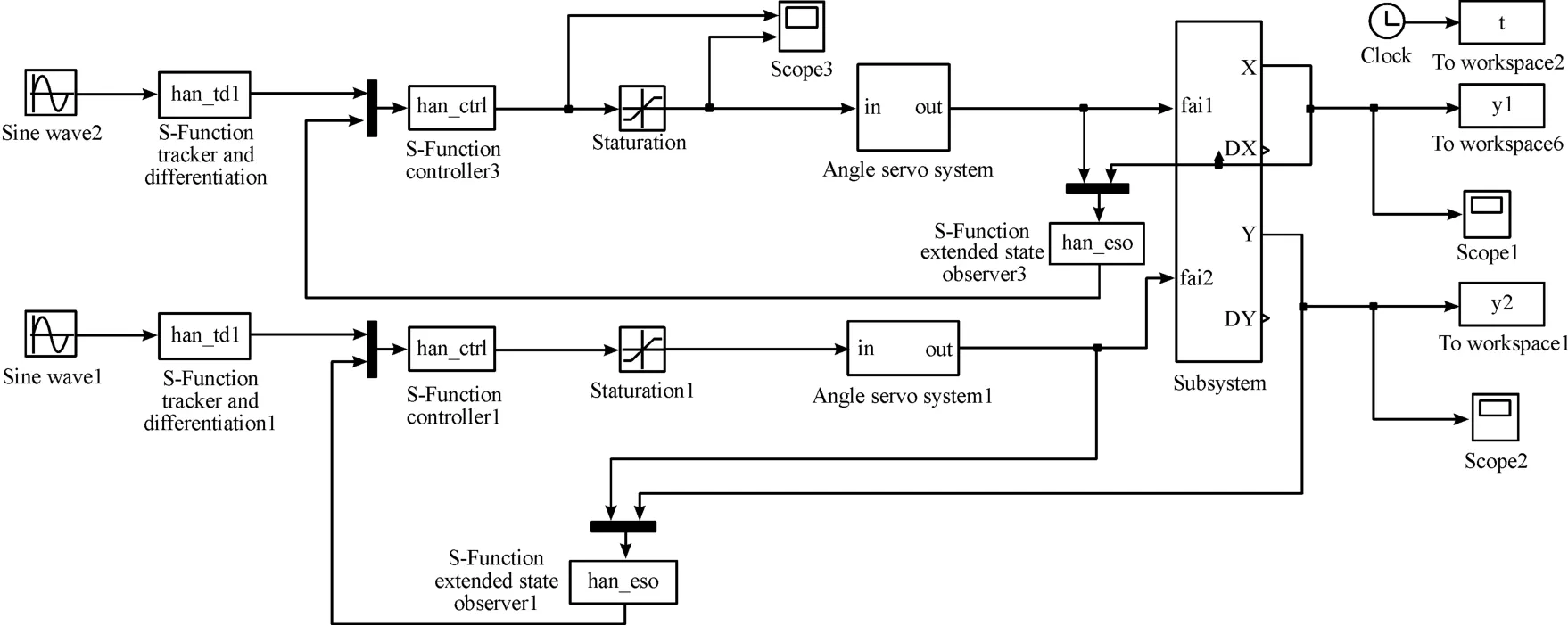

The simulation experiment is conducted in the MATLAB environment.The two-dimensional ball screw feed system model is established,and each part of themodel of the ADRC is encapsulated with s function,which is implemented in Simulink.The nominal parameters in the experimentare summarized in Table 1.

Tab Ie 1 Sim u Iation param eters of two-dimensiona I baIIscrew feed system

The simulation experiment model is shown in Fig.5.

Fig.5 Simu Iation m odeIof two-dim ensiona Iba IIscrew feed system

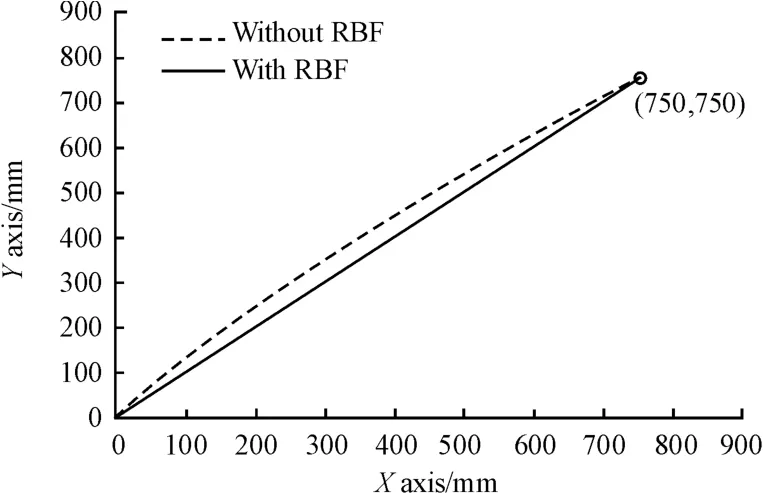

In order to verify the proposed method,set the initial the coordinate of the position of filling nozzle is(0,0),the coordinate of the position of destination is(750 mm,750 mm)corresponding to the coordinates of the bunghole.Parameters of Controller are set up as:β02=65,β03=80,β1=10,β2=100,r=10,h=0.01,h1=0.1,b=-7.The simulation research is carried out by using the ADRC based on RBFneural network.The obtained control curve is shown in Fig.6.

Fig.6 Trajectory of the fiIIing nozzIe of two-dim ensiona Iba IIscrew feed system con tro Iunder cond ition of w ithout any disturbances

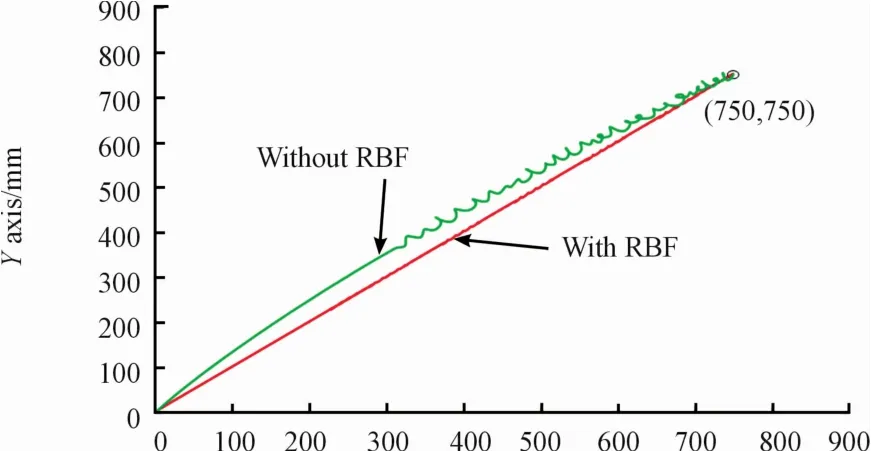

Fig.6 indicates that trajectory of the filling nozzle in the case of ball screw feed system control does not use RBF neural network,which is longer than trajectory of the filling nozzle in the case of ball screw feed system control with RBF neural network.When the disturbances is introduced,the disturbances signal is shown in Fig.7.

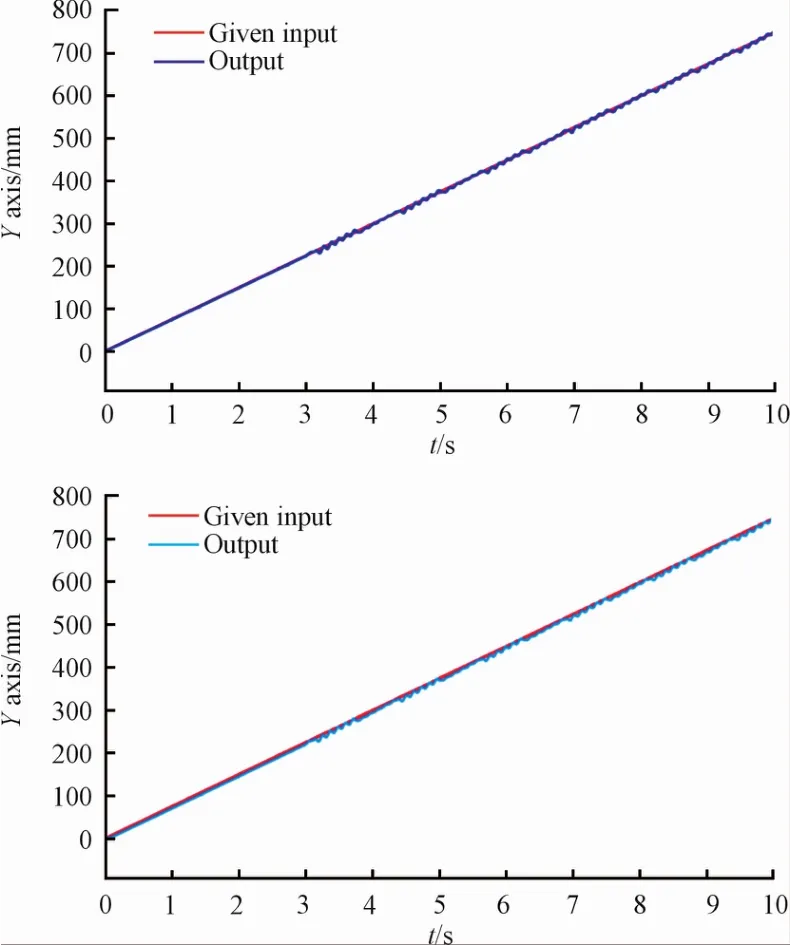

Fig.7 shows that the disturbances is introducewhen the running time is at the third second.Consequently,in the case of ball screw feed system control using ADRC based on RBF neural network.The given input control and its corresponding output inXaxis,the given input control and its corresponding output inYaxis are obtained in Fig.8.

Fig.7 The introduced disturbances

Fig.8 The given input contro Iand its corresponding output

Fig.9 Trajectory of the fiIIing nozzIe of two-dim ensiona Iba IIscrew feed system contro I in the p resence of d istu rbances

5 Conclusion

The device using the ADRC based on RBF neural network has been used in a chemical plant.Due to the use of the two-dimensional ball screw feeding system,the control system controls the precision of the filling nozzle within 0.1mm.If the system parameters are properly adjusted,the collision between the filling nozzle and the bunghole can be avoided.In the case of filling the same number of 50 barrels,it takes 1 hour before the transformation,and only 45 minutes after the transformation.Consequently,efficiency can be increased by 25%,which verifies that by adopting the decoupling controlmethod of RBF neural network auto disturbance rejection controller,the positioning operation time of the filling machine is significantly improved,and the production efficiency of the enterprise is greatly improved.

- 机床与液压的其它文章

- Study on Face detection method based on lightweight convolutional neural network

- Application of genetic optim ization lvq neural network in equipment fault diagnosis system

- Research on sliding mode control of manipulator based on RBF neural network optim ized by bionic swarm intelligence

- Research on bearing fault diagnosis technology based on deep convolution neural network

- Research on the application of improved machine learning collaborative recommendation algorithm in intelligent control

- Kinematics and dynam ic performance analysis of a 3-R2H2S parallel robot