Application of moderate nitrogen levels alleviates yield loss and grain quality deterioration caused by post-silking heat stress in fresh waxy maize

Jue Wang, Pengxiao Fu, Weiping Lu, Dalei Lu

Jiangsu Key Laboratory of Crop Genetics and Physiology/Jiangsu Key Laboratory of Crop Cultivation and Physiology, Agricultural College of Yangzhou University/Jiangsu Co-Innovation Center for Modern Production Technology of Grain Crops,Yangzhou 225009,Jiangsu,China

Keywords:Fresh waxy maize Grain quality Heat stress Nitrogen rate Starch granule size

A B S T R A C T High temperature (HT) during grain filling is one of the most important environmental factors limiting maize yield and grain quality. Nitrogen (N) fertilizer is essential for maintaining normal plant growth and defense against environmental stresses.The effects of three N rates and two temperature regimes on the grain yield and quality of fresh waxy maize were studied using the hybrids Suyunuo 5(SYN5)and Yunuo 7(YN7)as materials.N application rates were 1.5, 4.5, and 7.5 g plant−1, representing low, moderate, and high N levels(LN,MN,and HN,respectively).Mean day/night temperatures during the grain filling of spring- and summer-sown plants were 27.6/21.0 °C and 28.6/20.0 °C for ambient temperature(AT)and 35/21.0°C and 35/20.0°C for HT,respectively.On average,HT reduced kernel number, weight, yield, and moisture content by 29.8%, 17.9%, 38.7%, and 3.3%,respectively. Kernel number, weight, yield, moisture, and starch contents were highest under MN among the three N rates under both temperature regimes. HT reduced grain starch content at all N levels.HT increased grain protein content,which gradually increased with N rate.Mean starch granule size under MN was larger(10.9 μm)than that under LN and HN (both 10.4 μm) at AT. However, the mean size of starch granules was higher under LN(11.7 μm) and lower under MN (11.2 μm) at HT. Iodine binding capacity (IBC) was lowest under MN and highest under HN among the three N levels under both temperature regimes.In general,IBC at all N rates was increased by HT.Peak viscosity(PV)was gradually reduced with increasing N rate at AT. In comparison with LN, PV was increased by MN and decreased by HN at HT. Retrogradation percentage gradually increased with N rate at AT,but was lowest under MN among the three N rates at HT. LN + AT and MN + HT produced grain with high pasting viscosity and low retrogradation tendency. MN application could alleviate the negative effects of HT on the grain yield and quality of fresh waxy maize.

1. Introduction

Heat stress in plants is usually defined as stress resulting from high temperature(HT;usually 35°C)lasting for a period sufficient to cause irreversible damage to growth and development[1].The optimum temperature for maize grain development is between 27 °C and 32 °C [2]. Current climate change predictions indicate that HT during cereal growth will be more severe in future[3,4].

Nitrogen(N)is necessary for plant growth and development[1]. An adequate N supply promotes normal plant growth and defense against HT. N fertilization can minimize the adverse effects of HT on yield loss in maize [3–6], wheat [7,8], and rice[9–11]by maintaining high photosynthetic rates and increasing biomass accumulation and kernel-set percentages.

Effects of N fertilization on grain quality have been reported in cereal crops, including maize [12,13], wheat [14,15], barley[16,17], and rice [18,19]. Grain quality deteriorates under postsilking HT [20].The interaction of HT and N application affects grain quality of cereals. In wheat, grain protein content was increased by N fertilizer but was unaffected by high atmospheric CO2concentration and temperature [8].The protein content of wheat grain increased under post-anthesis HT with or without fertilizer [21]. However, protein yield (grain weight × protein content) decreased under HT [8,21]. In rice, HT damaged grain appearance and cooking quality by accelerating grain filling and amyloplast development, but this decrease in quality was alleviated by N application at heading stage [22]. Under HT, N application at heading stage delayed starch accumulation and reduced starch particle size, amylopectin chain-length, and relative crystallinity, thereby alleviating rice quality deterioration caused by elevated temperatures[23].

Pasting and thermal properties are important starch quality parameters of cereal crops [24,25]. In comparison with normal maize starch, waxy maize starch has a higher viscosity and a lower retrogradation tendency, traits of value in food and nonfood industries [24]. Fresh waxy maize has become a main vegetable crop in China[26].In our previous studies,N rate[27,28]and HT [29,30] affected the pasting and thermal properties of fresh waxy maize grain. Limited information is available about the interaction of N and temperature on the grain quality of fresh waxy maize, a special cereal crop that is harvested at the milk stage(approximately 21–26 days after pollination).

The objectives of the present study were to investigate the yield and grain quality of fresh waxy maize under a combination of three N rates and two post-silking temperatures.

2. Materials and methods

2.1. Experimental design

A pot trial was conducted at the experimental farm of Yangzhou University (Yangzhou, China) in 2015 using Suyunuo 5 (SYN5)and Yunuo 7(YN7)as materials.These two waxy maize hybrids are commonly used as control hybrids in national fresh waxy maize regional tests and widely planted throughout southern China. Plastic pots 38 cm in height and 43 cm in diameter(approximately 54,000 plants ha−1in field trials)were filled with 30 kg of sieved sandy loam soil.The soil moisture content was approximately 70%–80% during plant growth. The amounts of organic matter, total N, and available N, P, and K in the soil before transplantation were 10.1 g kg−1,0.95 g kg−1,82.3 mg kg−1,8.3 mg kg−1, and 62.2 mg kg−1. Seeds were sown on March 15(spring sowing)and July 1(summer sowing)and transplanted to pots at the one-leaf stage.Two seedlings were planted in each pot.One plant was retained at the six-leaf stage.

Plants were treated with 1.5 g N pot−1at transplantation,followed by 0,3.0,and 6.0 g N pot−1at the six-leaf stage,N rates defined respectively as low(LN),moderate(MN),and high(HN).LN, MN and HN were approximately equivalent to the 81, 243,and 405 kg ha−1rates applied to field trials [31]. P2O5and K2O were applied to all treatments upon transplantation at a rate of 1.5 g pot−1,equivalent to the 81 kg ha−1rate applied to field trials.

Plants were grown at ambient temperature (AT) until silking. After pollination, they were placed in a greenhouse at HT. The greenhouse temperature was set at 35.0 °C during the day (06:00–18:00). The door and windows of the greenhouse were left open at night (18:00–06:00) to ensure that the indoor temperature was identical to the outdoor temperature.Outdoor (day/night) temperatures of 27.6 °C/21.0 °C (springsown) and 28.6 °C/20.0 °C (summer-sown) were maintained from pollination to fresh stage (approximately 23 days after pollination)and adopted as the control treatment (AT;Fig.1).Each treatment comprised 50 pots.

2.2. Grain yield determination

Ears were harvested at the fresh stage(23 days after pollination),and kernel number per ear was recorded. The kernels were manually stripped from the cobs.Kernel fresh weight(mg)and yield(g plant−1)were recorded.Kernels were then deactivated at 105°C for 30 min and dried to constant weight at 60°C.Grain dry weight(mg)and moisture content(%)were recorded.The grain was then ground and passed through a 100-mesh filter(diameter (d) = 0.149 mm) for measurement of grain starch content,protein content,and pasting and thermal properties.

2.3. Starch and protein contents

Grain starch content was determined by the anthrone–sulfuric acid method [32]. Grain N content was determined by the Kjeldahl method[33].Protein content was calculated as N content× 6.25.

2.4. Starch granule size distribution

Starch in fresh kernels (100 g) was isolated at room temperature following Lu and Lu [34]. Starch granule size distributions were determined following Shi et al. [35].

2.5. Starch iodine staining

The maximum absorption wavelength(λmax)and iodine binding capacity(IBC)of starch were measured following Lu et al.[36].

2.6. Pasting properties

The pasting properties of flour (28 g total weight; 10%, w/w,dry basis)were evaluated by rapid visco analysis(RVA,Model 3D, Newport Scientific, Warriewood NSW, Australia) in accordance with a previously described method[34].

2.7. Thermal properties

The thermal characteristics of flour were determined by differential scanning calorimetry (DSC, Model 200 F3 Maia,NETZSCH,Bavaria,Germany)following a previously described method[34].

2.8. Statistical analysis

Values shown in all tables and figures are means of three independent ears. Means were compared by analysis of variance (ANOVA) with the least significant difference test at the 0.05 probability level using Data Processing System 7.05[37].

3.Results

3.1. Grain yield

In comparison with AT, HT reduced kernel number, fresh weight, yield, and moisture content, irrespective of hybrid,sowing date and N rate (Table 1). These reductions were by 29.8%, 17.9%, 38.7%, and 3.3%, respectively. Kernel number and yield were highest under MN among the three N rates under both temperature regimes for both sowing dates in both hybrids.In SYN5,the grain fresh weight of spring-sown plants was not affected by N rate; the values from summer-sown plants were similar for LN and MN under both temperature regimes,but were highest at AT and lowest at HT under HN.In YN7, grain fresh weight was highest under MN under both temperature regimes. In SYN5, the grain moisture content of summer-sown plants was unaffected by N rate under both temperature regimes,and the contents for spring-sown plants were similar for LN and MN and lowest under HN.In YN7,the grain moisture content at AT was similar for LN and MN and highest under HN. The content of spring-sown plants at HT gradually increased with N rate,while it was lowest at LN and similar between MN and HN for summer-sown plants.Compared with spring-sown plants, summer-sown plants showed higher grain moisture content and lower kernel number, weight, and yield. The two hybrids have similar kernel numbers, but YN7 has higher grain fresh weight,moisture content,and yield than SYN5.

Kernel number, weight, yield and moisture content were affected by single factors or interactions with season (S),temperature(T),and nitrogen(N),and the highest F-value for temperature indicated its strong effect on yield and related parameters (Table 1). On average, kernel number, weight,yield, and moisture content were highest under MN at both temperature regimes.

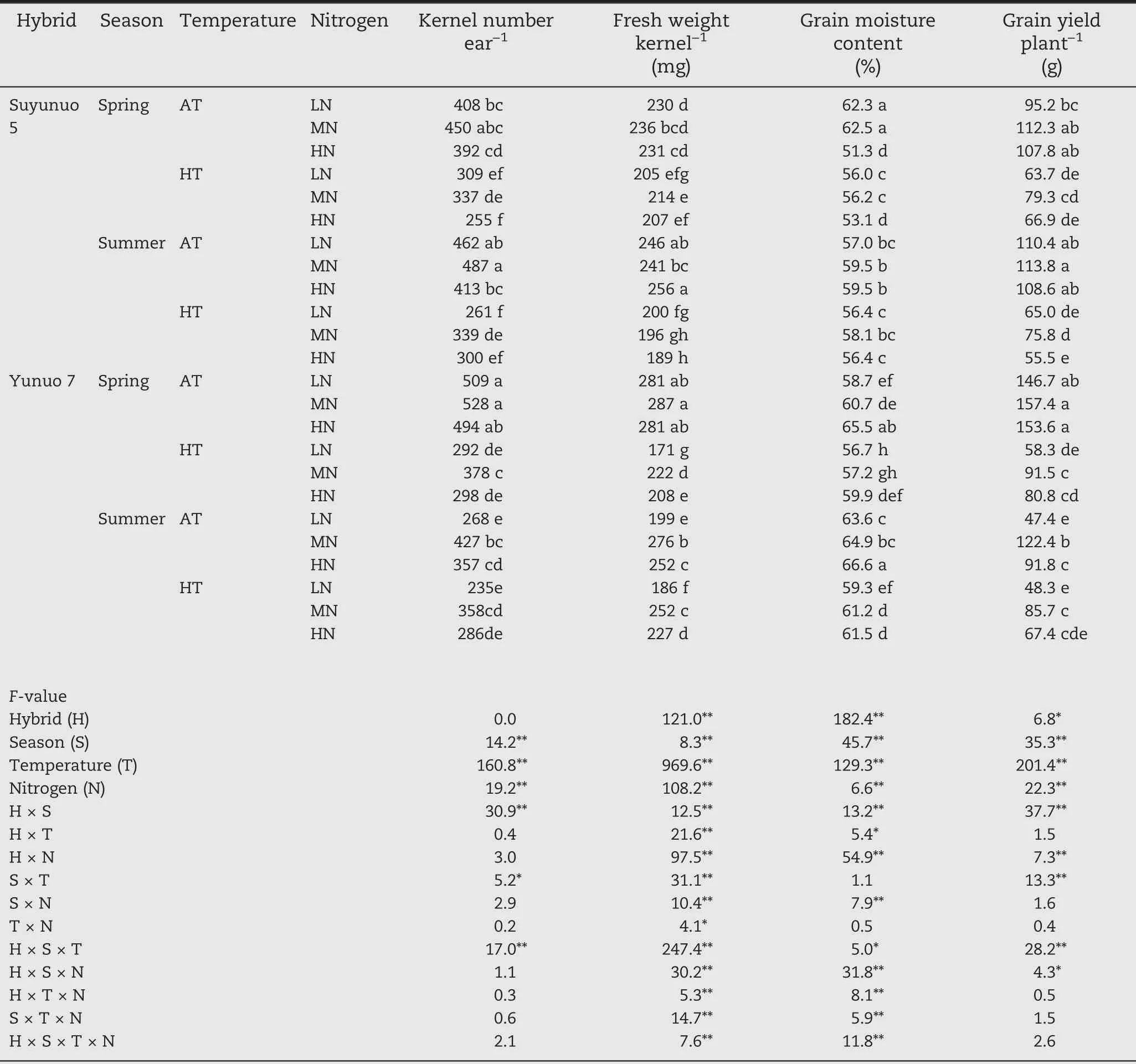

3.2. Grain starch and protein contents

Grain starch content was highest under MN among the three N rates,irrespective of hybrid and temperature regime(Fig.2,Table S1). HN and LN showed similar starch contents in all treatments except spring-sown SYN5 at HT,where the starch content under HN was lower than that under LN. In comparison with AT, starch contents at HT decreased by respectively 7.3%, 8.3%, and 9.7% under HN, MN, and LN(mean of two hybrids under two sowing dates). The high starch content under MN at HT indicated that MN alleviated the negative effects of HT.The grain protein contents of both hybrids gradually increased with N rate under both temperature regimes. Protein content was increased by HT at all N rates.Protein contents of both hybrids were highest at HT+HN among the treatments in both growth seasons.Summer-sown plants showed lower starch and higher protein contents than spring-sown plants.

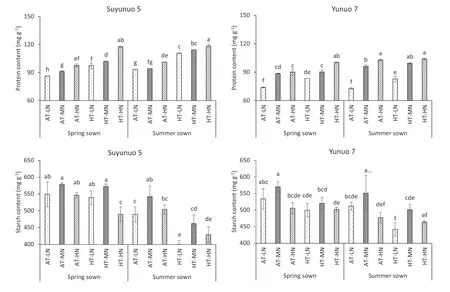

3.3. Starch granule size distribution

Grain starch granule size was significantly affected by N rate and temperature (Fig. 3, Table S2). At AT, the mean starch granule sizes of summer-sown grain of both hybrids initially increased and then decreased with increasing N rate. However,the starch granule size in SYN5 of the spring-sown grain showed a tendency similar to that of the summer-sown grain.By contrast,the value in YN7 gradually increased with N rate.In general, the mean starch granule sizes of both hybridsunder MN(10.9 μm)were greater than those under LN and HN(both 10.4 μm)at AT.At HT,the mean starch granule sizes of both hybrids under the summer-sown condition initially decreased and then increased with increasing N rate.Under the spring-sown condition, the starch granule size in YN7 grains showed a tendency similar to that of the summersown grain. The value in SYN5 gradually decreased with increasing N rates. At HT, the size of the starch granules under LN(11.7 μm)was greater than that under MN(11.2 μm)and HN (11.3 μm). HT significantly increased the mean starch granule size. In general, the granule sizes of starch obtained from spring-sown plants (11.4 μm) were greater than those of starch obtained from summer-sown plants(10.5 μm).

Table 1–Effects of high temperature and N rate on grain yield of fresh waxy maize.

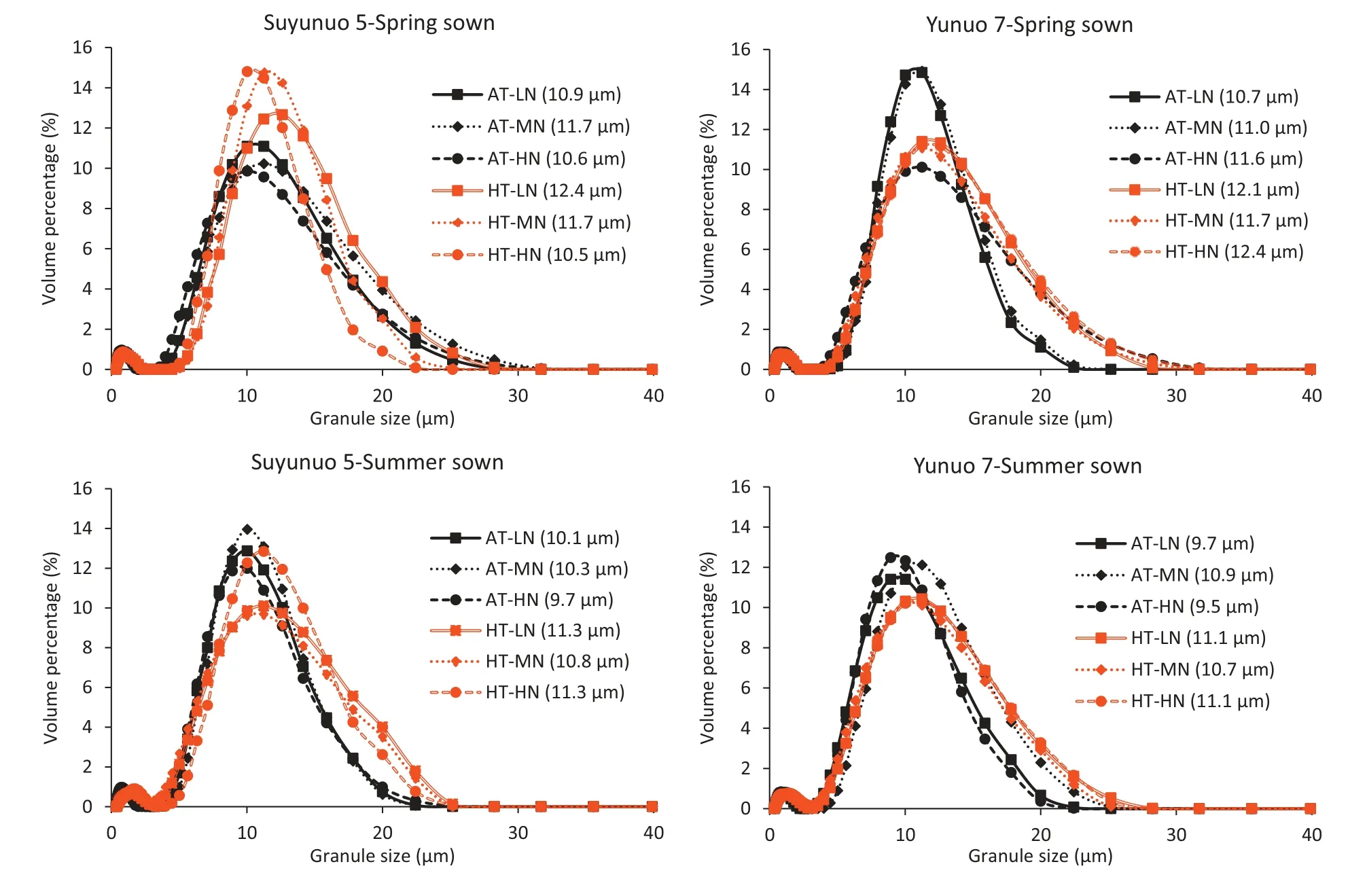

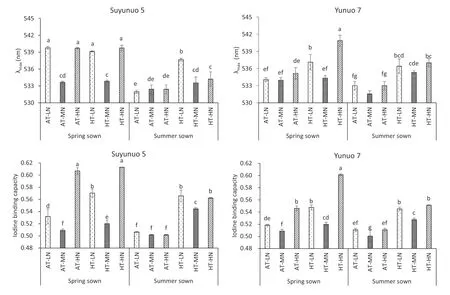

3.4. Starch iodine staining

The λmaxand IBC of the grain starch under the different treatments ranged from 531.6 to 539.8 nm and 0.5005 to 0.6127, respectively, presenting a typical waxy character (Fig.4). The SYN5 starch λmaxat HT was lowest under MN among the three N rates for both sowing dates. The λmaxat AT was low under MN and high under HN in spring-sown grain,but it was unaffected in summer-sown grain. The YN7 starch λmaxwas unaffected by the N rate at AT, but it was low with MN and high with HN at HT. IBC initially decreased and then increased with increasing N rate under both temperature regimes for the two hybrids under the two sowing dates except for SYN5 under summer sowing at AT,whose IBC was similar among the three N rates. In general,HT increased the values of λmaxand IBC, implying that HT-ripening grain had a high ratio of long amylopectin chains. The low λmaxand IBC under MN at HT suggest that MN could alleviate the detrimental effect of HT.

Fig.2– Effects of high temperature and N rate on grain starch and protein content of fresh waxy maize.AT,ambient temperature;HT,high temperature;LN,1.5 g N plant−1;MN,4.5 g N plant−1;HN,7.5 g N plant−1.Mean values within each hybrid followed by different letters are significantly different at P <0.05.

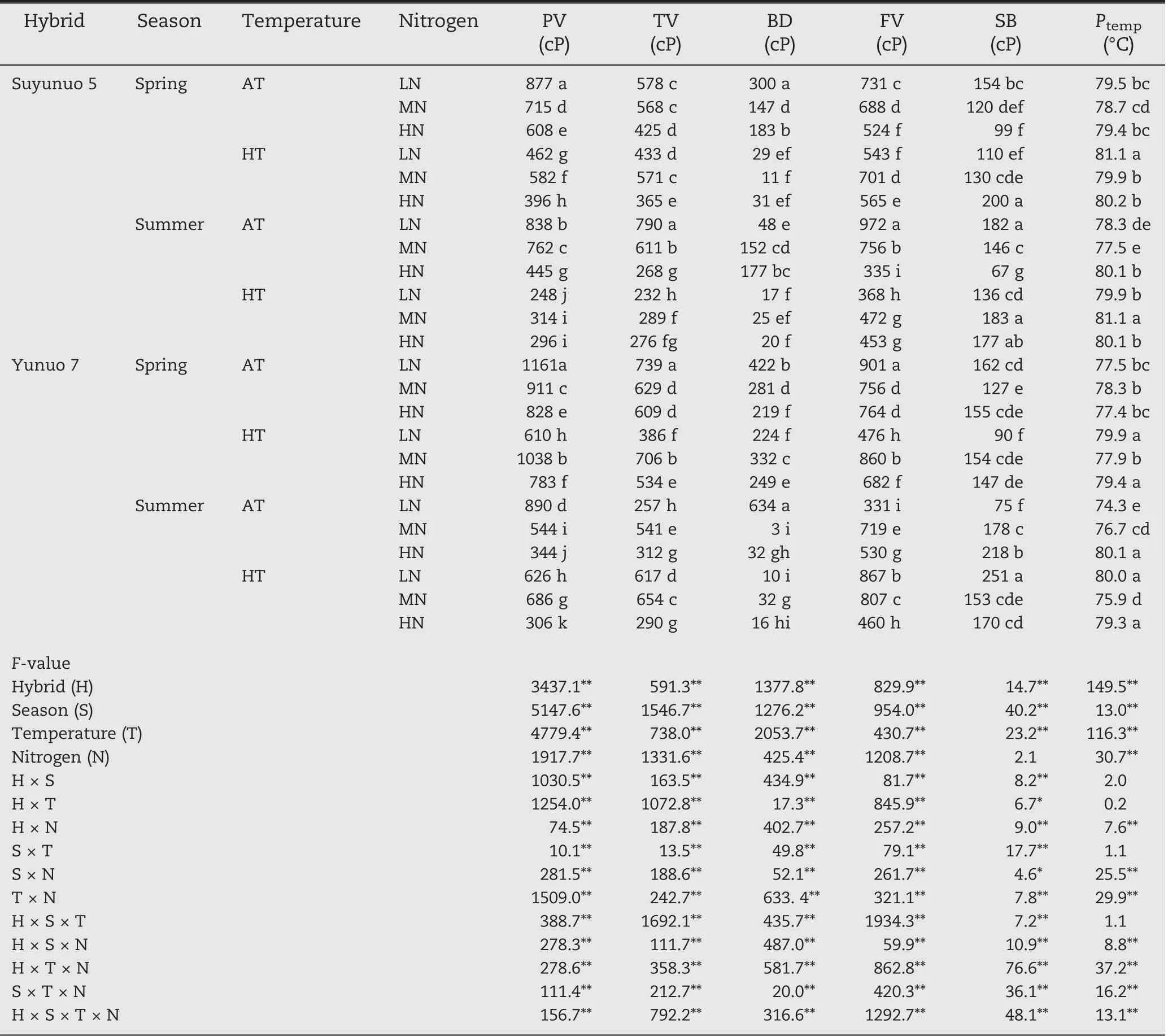

3.5. Pasting properties

Grain pasting characteristics in response to HT and N rate depended on the hybrid and sowing date (Table 2). The setback viscosity (SB) ranged from 75 to 251 cP, indicating a typical waxy character. The peak viscosity (PV) of the two hybrids gradually decreased with increasing N rate at AT. However, PV was higher under MN than under LN and HN at HT. Trough (TV), final (FV), and breakdown (BD)viscosities (means of two hybrids under two sowing dates) presented similar trends to those of PV in general.The pasting temperature (Ptemp) significantly increased at HT under all LN rates. The Ptempwas increased only by HT in summer-sown SYN5 under MN, and that under HN was increased only in spring-sown YN7 and unaffected by HT under other treatments. In SYN5, the PV and BD were decreased at HT regardless of the N rates. By comparison,HT increased the PV and BD of YN7 under MN and reduced them under LN and HN, respectively. The low BD at HT indicated that the starch granules were hardly broken during heating. The TV and FV in response to HT were dependent on hybrid, N rate, and sowing date. The viscosities of grain harvested from spring-sown plants were higher than those of grain from summer-sown plants. The viscosities of YN7 were higher, but the Ptemplower, than those of SYN5.

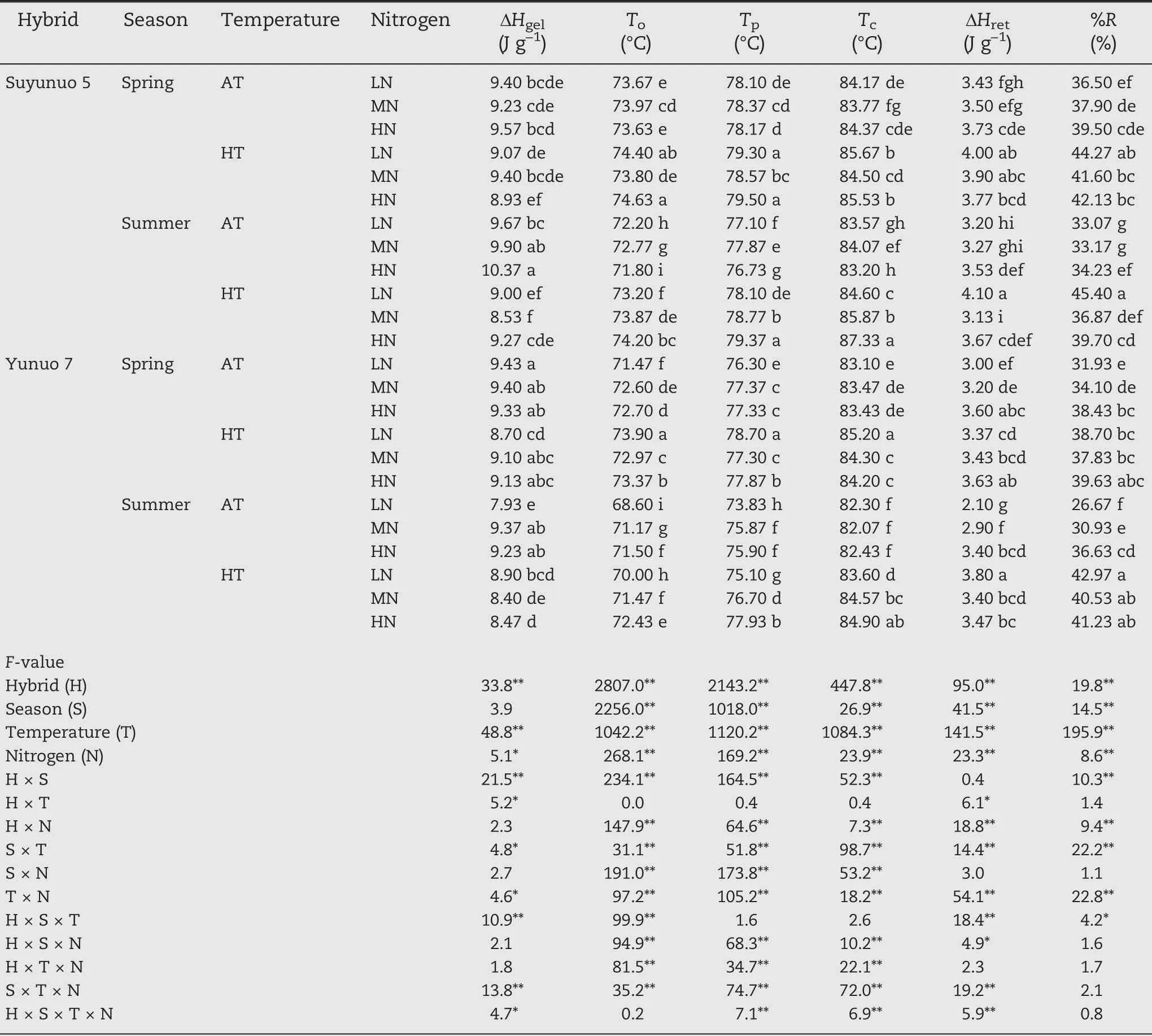

3.6. Thermal properties

Grain thermal properties were significantly affected by temperature,N rate,and sowing date(Table 3).Gelatinization enthalpy(ΔHgel)in both hybrids from spring-sown plants was unaffected by N rate under both temperature regimes.Under the summer-sown condition, ΔHgelin SYN5 was similar between MN and LN and highest under HN at both temperature regimes. The ΔHgelin YN7 was unaffected by N rate at HT,but the value at AT was similar between MN and HN and lowest under LN. Gelatinization temperatures increased at HT at all N rates in general. Onset (To), peak (Tp), and conclusion (Tc) temperatures in response to N rate were dependent on hybrid,temperature regime,and sowing date.In general, To, Tp, and Tcwere similar for LN and MN and highest under HN at HT.At AT,Toand Tpwere highest under MN and lowest under LN, and Tcwas similar among three N rates.

Fig.3–Effects of high temperature and N rates on grain starch granule volume distribution of fresh waxy maize.AT,ambient temperature;HT,high temperature; LN,1.5 g N plant−1;MN,4.5 g N plant−1;HN,7.5 g N plant−1.

Retrogradation occurred after gelatinized samples were stored at 4 °C for 1 week. Retrogradation enthalpy(ΔHret) and percentage (%R) at AT were highest under HN(3.6 J g−1and 37.2%, respectively) and lowest under LN(2.9 J g−1and 32.0%, respectively). However, at HT, they were lowest under MN (3.5 J g−1and 39.2%, respectively)and highest under LN (3.8 J g−1and 42.8%, respectively)among three N rates in general.The ΔHretin YN7 was increased at HT in all treatments.The ΔHretin SYN5 was also increased at HT in all treatments except in the summer-sown plants under MN, which was similar between two temperature regimes.The value of %R was increased at HT irrespective of N rate.Summer-sown plants at AT produced grain with low gelatinization temperatures and retrogradation tendency,especially in YN7.

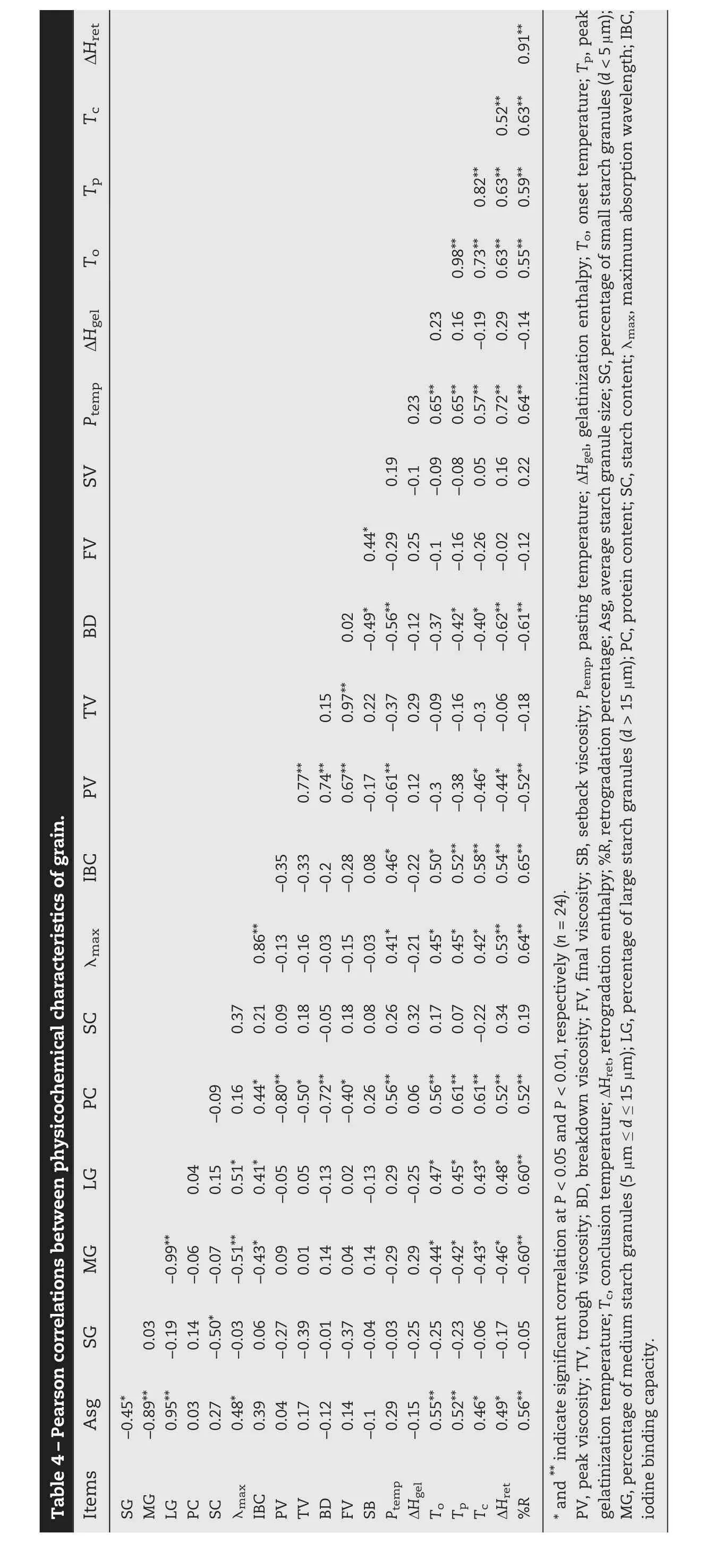

3.7. Correlation analysis

Mean starch granule size was positively correlated with the percentage of large starch granules and λmaxbut negatively correlated with the percentage of medium granules (Table 4).PV, TV, BD, and FV were negatively correlated with protein content.Ptempwas positively correlated with protein content,λmax, and IBC. To, Tp, Tc, ΔHret, and %R were positively correlated with mean starch granule size,percentage of large starch granules, IBC, λmax, and protein content. However,these factors were negatively correlated with percentage of medium starch granules. ΔHretand %R were positively correlated with Ptempbut negatively correlated with PV and BD.

4. Discussion

4.1.Interaction effects of N and temperature on grain yield and starch and protein accumulation

In comparison with AT, HT reduced grain yield, with the highest yield under MN among the three N rates irrespective of temperature, hybrid, and sowing date, indicating that MN alleviated the negative effect of HT. The highest grain yield under MN perhaps due to optimal N application relieved the negative effects of HT by promoting biomass accumulation[4], increasing kernel set [5], enhancing photosynthetic capacity, and retarding senescence [6]. As the main component of the grain, the change of grain starch content among different treatments was similar to that of grain yield. Under both temperature regimes, the highest starch content occurred under MN. A possible explanation is that moderate N application favors an increase in the number of endosperm cells and starch granules by promoting the activities of starch synthetic enzymes[38].

The low grain moisture content (mean 57.7%) at HT suggested that fresh waxy maize grown in hot climates should be harvested earlier, given that its optimal moisture content is 59–64% at harvest [39]. In rice [22] and maize [30],low grain moisture content at HT indicated an accelerated filling rate. In the present study, the grain moisture content under MN was generally the highest among three N rates at both temperature regimes, perhaps because appropriate N application moderated grain filling rate and amyloplast development [22].

Fig.4–Effects of high temperature and N rate on grain starch iodine staining of fresh waxy maize.AT,ambient temperature;HT,high temperature;LN,1.5 g N plant−1;MN,4.5 g N plant−1;HN,7.5 g N plant−1.Mean values within each hybrid followed by different letters are significantly different at P< 0.05.

Grain protein content gradually increased with N rate under both temperature regimes, as previously reported in cereals[14,15,18].The high protein content may have resulted from high activities of nitrate reductase and glutamine synthetase [40]. HT increased protein content under all N rates, a result consistent with previous findings [29,41].However, the increase was only a concentration effect, as starch and protein yields at HT decreased by 34.9 and 25.6%,with the greater decrease in starch leading to the relative high protein concentrations [40,42]. The grain protein contents of the spring-sown plants were lower than those of summersown ones. With grain development, protein concentration gradually decreases and accelerated grain filling of springsown plants (showing a low grain moisture content) leads to lower grain protein contents than those in summer-sown ones[43,44].

4.2. Interaction effects of N and temperature on starch physicochemical properties

The mean starch granule size among the three N rates was greatest under MN at AT and least under MN at HT.The large starch granule size under the MN + AT conditions is possibly due to proper N fertilization,which facilitates the transport of carbon that is assimilated by developing grain to promote starch deposition and enlargement [45]. A similar result was reported in normal maize [13]. The large starch granule size under the LN + HT conditions was observed likely because N starvation[46]and HT[47]restrict amyloplast formation.The interactions between these conditions intensify their individual effects[22].The available substrate is diverted toward the surviving starch granules to enlarge them. The starch granules gradually enlarge with development [42–44], and the accelerated filling rate under stress(low moisture content in the present study) also leads to large granule size. This finding was confirmed by the finding that the starch granule size of spring-sown plants was greater than that of summersown plants. Although the percentage of the small starch granules (d < 5 μm) differed among the treatments, the low percentage (2.8%–11.4%) did not affect the pasting and thermal properties of grain; a finding similar to previous findings in mature waxy maize[48].

IBC is an index that reflects amylopectin chain length. A high value at HT indicates a long amylopectin chain [42]. IBC was lowest under MN among the three N rates under both temperature regimes, perhaps because high branching enzyme activity under MN disrupts a long chain of glucoses to produce two or more shorter chains [19,49]. IBC was highest under the HT + HN condition among all treatments, mainly because starch under this condition has a high proportion of large granules(Table 4) [50].

Table 2–Effects of high temperature and N rate on grain pasting properties of fresh waxy maize.

In previous studies,HT[29,30]and MN[28]reduced the PV of fresh waxy maize.In several studies of cereals[19,51,52],PV was reduced by an increased N rate. %R in response to N rate and HT showed no distinct trend in our early field trial[28]or in rice [19,53]. In the present study, PV gradually decreased with increasing N rate at AT and was highest under MN among three N rates at HT in general.%R gradually increased with N rate at AT, but was lowest under MN at HT.Thus, MN application in hot climates could alleviate PV and %R deterioration caused by HT. %R increased at HT in general,as shown by early reports on waxy maize [29,42,50]. The correlation results indicated that the large amounts of protein coating on the starch granules have a relatively stable structure that is difficult to break, resulting in low PV and BD[44]. The denatured protein leads to aggregation during reheating,resulting in high%R[50].Starch with large granules and long branched chains is easily retrograded [54,55].

5. Conclusions

Grain weight, yield, and starch content of fresh waxy maize were reduced by post-silking HT, but this reduction was alleviated by MN.The low moisture content of grain under HT and/or LN/HN conditions suggests that plants grown under adverse environmental conditions should be harvested early.HT increased protein content. Protein content gradually increased with N rate, irrespective of hybrid, temperatureregime, and sowing date.Grain starch under the MN condition comprised smaller starch granules and shorter amylopectin chains than starch under LN and HN conditions at HT. PV gradually decreased and%R gradually increased with N rate at AT.At HT,MN produced grain with higher pasting viscosity and lower retrogradation tendency than LN and HN.In hot climates,moderately increasing N application rates could increase grain yield and improve the quality of fresh waxy maize.

Table 3–Effects of high temperature and N rate on grain thermal properties of fresh waxy maize.

Acknowledgments

This work was supported by the National Key Research and Development Program of China (2016YFD0300109,2018YFD0200703), the National Natural Science Foundation of China (31771709), Jiangsu Agriculture Science and Technology Innovation Fund (CX[19]3056), the Priority Academic Program Development of Jiangsu Higher Education Institutions, and High-end Talent Support Program of Yangzhou University.

Author contributions

Dalei Lu and Weiping Lu conceived and designed the study.Jue Wang and Pengxiao Fu conducted the experiment. Jue Wang analyzed the data and prepared the original draft.Dalei Lu edited the manuscript. All authors read and approved the final manuscript.

Appendix A. Supplementary data

Supplementary data for this article can be found online at https://doi.org/10.1016/j.cj.2019.11.007.

- The Crop Journal的其它文章

- Genetic dissection of husk number and length across multiple environments and fine-mapping of a major-effect QTL for husk number in maize(Zea mays L.)

- Identification of a novel planthopper resistance gene from wild rice(Oryza rufipogon Griff.)

- Genome-wide linkage mapping of QTL for root hair length in a Chinese common wheat population

- Comparative analysis of the photosynthetic physiology and transcriptome of a high-yielding wheat variety and its parents

- Metabolic profiling of DREB-overexpressing transgenic wheat seeds by liquid chromatography–mass spectrometry

- Haplotype variations in QTL for salt tolerance in Chinese wheat accessions identified by markerbased and pedigree-based kinship analyses