On the characterization of microstructure and fracture in a high-pressure die-casting Al-10 wt%Si alloy

Xingyi Jio,Chofeng Liu,Jun Wng,Zhipeng Guo,b,∗∗,Junyou Wng,Zhuoming Wng,Junming Go,Shoumei Xiong,b,∗

a School of Materials Science and Engineering,Tsinghua University,Beijing 100084,China

b Key Laboratory for Advanced Materials Processing Technology,Tsinghua University,Beijing China

c Hong Bang Die Casting (NanTong) CO.,LTD China

ABSTRACT Microstructure and fracture behavior in a high-pressure die-casting Al-10 wt%Si alloy have been investigated using optical microscope(OM),scanning electron microscope(SEM)and a high-resolution laboratory computed tomography (CT).The results showed that a typical heterogeneous microstructure of the alloy comprised α-Al rich region,eutectic silicon band region and porosity.The microstructure patterns highly dependent on fluid convection and rapid solidification.Under high filling speed,externally solidified crystals (ESCs) and the growing dendrites migrated in center and formed α-Al rich region.Si particles was discharged and enriched in the final solidified liquid,forming eutectic silicon band.Hard Si particles and brittle Fe-rich phases served as obstacles prevented dislocation migration,causing local stress concentration.Due to large movable slip systems in α-Al rich region,the propagation path of the crack was greatly extended.Net-shrinkage that induced by dense impinging dendrites led to the microcracks along the boundary of dendrites which promoted intergranular fracture.

Keywords:Fracture Hypoeutectic Al-10Si Microstructure heterogeneity High-pressure die-casting

1.Introduction

Hypoeutectic Al-10 wt%Si alloys are extensively applied in automotive industry due to low density,good formability and high specific strength [1,2].Structural components manufactured using Al-10 wt%Si alloys have promising mechanical properties because of the narrow solidification freezing range.Zhang et al.[3]found that Al-10-Si-1.2Cu-0.7Mn exhibited excellent tensile properties,such as,the YS of 206 MPa,the UTS of 331 MPa and the elongation (EI) of 10%.

High pressure die casting (HPDC) is one of the most popular methods to produce complex thin-wall components [4].However,the rapid filling and fast solidification can lead to the formation of particular microstructure.The so-called externally solidified crystals (ESCs)normally form in the shot sleeve during the slow-shot stage.The defect band normally exhibited in HPDC components and its formation was highly dependent on melt flow[5].In addition,massive pores existed in castings,which was affected by the air entrapment in shot sleeve.

Outmani et al.[6]found that the porosity level was a key factor to decrease elongation of Al-Si-Cu HPDC castings.Lu et al.[7]found that the initiation and expansion of the fatigue crack were highly sensitive to geometry,size and distribution of the porosity.Niklas et al.[8]considered that the existence of gas porosity made it difficult to apply heat treatment in die casting because surface blistering occurred during solution and heat treatment.Most studies have been performed to investigate the effect of ESCs and defect band on the casting performance[9].The macroscopical defects,such as,large shrinkages network in a casting,normally served as the crack initiation source.These defects can induce stress concentration followed by crack initiation and propagation when the external stress exceeded the yield strength.Using insitu tensile test,Li et al.[10]found that the specimen was fractured by connecting defects at the section with minimum effective force bearing area.In addition,the interface between Al and Si also provided the path for crack propagation.Lee et al.[11]found that the microporosity was induced at the phase interface between Al and eutectic Si particles during deformation.These microporosity would then act as crack initiation source and promote crack expansion,similar finding in Refs.[12-14].

This paper investigates the relation of the microstructure and fracture of a high-pressure die-casting Al-10 wt%Si alloy.The 3-D large size reconfiguration of fracture morphology was proposed using high-resolution computed tomography (CT) equipped with a software namely Avizo.

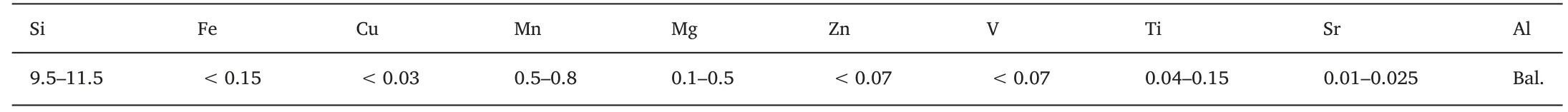

Table 1 Chemical composition of AlSi10MnMg hypoeutectic Al-Si alloy (wt.%).

2.Experimental procedures

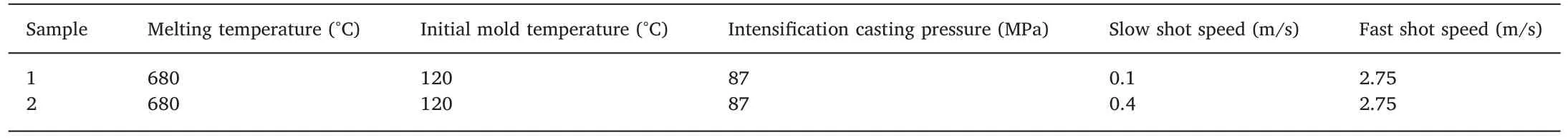

A commercial hypoeutectic aluminum alloy,AlSi10 MnMg,was used,and its chemical composition is shown in Table 1.The liquidus and solidus temperature of this alloy was 595°C and 550°C,respectively.Fig.1a shows the configuration of the specific casting including three tensile test bars and one plate.Standard tensile testing bars with a diameter of 6.4 mm (see Fig.1b) were produced by a TOYO BD-350V5 cold chamber die casting machine,the detail of which can be found in the previous study [15].The sample location for OM and SEM analysis was marked in Fig.1b.Table 2 shows the key processing parameters adopted in HPDC experiment.Two samples with different slow shot speeds (VL) were produced to obtain different HPDC microstructure.

In metallography observation of the microstructure,SiC papers of#400,#800,#1200,#1500 and #2000 were used in order.After mechanically mounted,ground,polished and ultrasound cleaning,the microstructure was observed using OM and SEM.A software,namely Image-Pro Plus 6.0,was used to identify phases in samples.A highresolution laboratory CT,Nanotom m manufactured by GE,was used to study the 3-D fracture morphology in samples.The voltage and electric current were set to be 110 kV and 100 μA,respectively.

Tensile tests were performed on a WDW electronic universal testing machine with a loading rate of 2 mm/min.Standard HPDC test bar(see Fig.1b) was prepared to determine stress-strain curve and three dog bone bars with the same processing parameters and the same position(see Fig.1a) were employed to ensure the accuracy of the tensile test results.The elongation was recorded by a knife-edge extensometer fixed in the range of gauge length.All tests were performed at ambient temperature.

3.Results

3.1.Microstructure heterogeneity

Fig.2 shows the optical micrograph of the rod with different slow shot speeds for the HPDC AlSi10MnMg alloy.Particular microstructure patterns including α-Al rich region and eutectic silicon band were present in Fig.2a and b,namely,α-Al enriched in central region while eutectic silicon-rich region surrounded the α-Al rich region with a ring shape.A large volume fraction of pores (gas pore and shrinkage) were exhibited across the sample.

In slow shot sleeve,metal liquid turbulence was caused by the plunger movement enforced more gas in the casting.These gases were sealed to form large size gas pores.Below a circular cross section,the square cross section shows the cutaway view along height direction.The finding confirms that α-Al rich region and eutectic silicon-rich region were consistent with the results.The spacing of two eutectic silicon band was about 3 mm.The thickness of each eutectic silicon band was about 500 μm.According to Ref.[16],the position and thickness of the eutectic segregation bands depended on thermal gradients (ΔT) as well as the solid fraction gradient ().In other words,the eutectic segregation bands were changeable affected by die temperature and ESCs content.In Fig.2b,the particular α-Al rich region marked by red frame existed and it even appeared out the eutectic silicon band.

Fig.3 shows the microstructure of α-Al rich region and eutectic silicon band region.In α-Al rich region (Fig.3a and b),the microstructure comprised ESCs,fine α-Al grains,eutectic.Coarse ESC with the size over 30 μm was present when VL=0.1 m/s,while fine ESCs with average grain size about 10 μm when VL=0.4 m/s.In addition,the shrinkage with a size about 2 μm formed along grain boundary and developed into network in Fig.2b.Contrary to the formation of the gas pores,the shrinkage was caused by feeding failure in impinging dendrites.

Fig.3c and d shows the eutectic silicon-rich region of HPDC Al-Si10MnMg at different slow shot speeds.The eutectic silicon band zone comprised Fe-rich phase and eutectic silicon phase.Fe-rich phase behaved in thick needle-plate shape,while eutectic silicon was more fiberand rod-like.Since the preferred growth orientation of Si particles was<110>or<211>located on {111} planes,Si particles exhibited a facet characteristic with sharp edges.0.02 wt%Sr in this alloy was gathered in twins and dislocations of Si particles,inhibiting the growth of Si particles.Fine silicon particles were preserved,as shown inFig.3c and d.

Table 2 Processing parameters during HPDC.

Fig.4 shows the type of Fe-rich phases in HPDC AlSi10MnMg alloy.Two types of Fe-rich phases,including bulk Fe-rich phase and lath Ferich phase,could be identified.The bulk Fe-rich phase distributed random,and its size varied considerably.The lath Fe-rich phase was surrounded by eutectic and segregated in strip shape.According to Al-Si-Fe diagram [17],β-Al5FeSi nucleated preferentially in liquid phase and further expanded to form large flake-shape under low cooling speed of~1°C/min.In die-casting process,β-Al5FeSi preferentially formed in slow shot sleeve under lower cooling rate,and then the flake β-Al5FeSi was broken affected by high speed fluid,to form bulk Fe-rich phase in Fig.4a.When the melt was injected into the die cavity,the precipitation of Fe affected by high cooling rate was restricted,and the final solidification of Fe was at the eutectic interface,to form δ-Al4FeSi2(lath Ferich phase),as shown in Fig.4b.Because of massive precipitation of β-Al5FeSi in HPDC initial stage,higher Mn content (25.59%) and Fe content (3.62%) were in bulk Fe-rich phase.Nevertheless,higher Si content (~13.9%) was in lath Fe-rich phase because of the final solidification combined with eutectic.

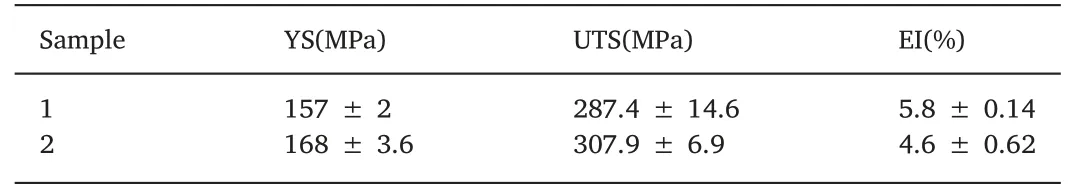

Table 3 Mechanical properties of HPDC AlSi10MnMg alloy.

3.2.Fracture feature

Table 3 lists the mechanical properties of HPDC AlSi10MnMg alloy.In comparison with the casting under lower slow shot speed (0.1 m/s),Sample 2 with higher slow shot speed of 0.4 m/s exhibited the improved strength,while the decreased elongation,such as,the higher YS of~7%,the higher UTS of~7%,the lower EI of~21%.

Fig.5a and b shows the whole crack surface with high field depth.Compared with that in Fig.2,α-Al rich region and eutectic silicon band were marked in Fig.5.Caused by the connected shrinkages,penetrated porous inclusions existed in center,to cause the rough fracture surface and tortuosity of the crack path.In eutectic band zone,the fracture surface was relatively flat.Fig.6a and b shows the whole 3-D fracture morphology contour map of the undulation height of the fracture surface with 3700 slices piled up.The half of total crack fluctuation is defined as the baseline to determine the fracture level.Based on the level of crack fluctuation,the 3-D fracture surface was classified into ridge(red),basin(blue)and plain(green)areas.Large crack fluctuation existed at edge.The cracks were relatively flat at the center of sample.Since deep central pit and tortuous crack surface exhibited in center when VL=0.4 m/s,it indicates a longer crack propagation path.The rise and fall of the flat propagation surface was measured to be 1320 μm when VL=0.1 m/s.Because of large volume of shrinkage in center,the whole height of crack fluctuation was highly improved and reached 2064 μm when VL=0.4 m/s.When the main crack passed through the shrinkages region,the crack propagation direction changed along shrinkage network.Accordingly,the crack fluctuation increased.The microcracks around the shrinkage converged on the main failure crack,and propagated together with the main crack.

4.Discussion

4.1.The formation of heterogeneous microstructure

In the process of die-casting,the solidification contained two stages.In the first stage,ESCs nucleated in slow shot sleeve and grew with the motion of the plunger.Lower slow shot speed would extend the duration of the melt in the shot sleeve,and increase the size and area fraction of ESCs.In Fig.7a,coarser ESCs with the shape of dendrite was present due to the longer stay time in shot sleeve.At the end of the first stage,ESCs and liquid formed semi-solid state.The second stage happened in die cavity.The cooling rate in die cavity was much higher,such as the interfacial heat transfer coefficient between the metal and die in die cavity could approach~104-105 W m−2K−1and the cooling rate could be~100 K s−1.Therefore,the nucleation rate was much high in metal liquid,which restricted the growth of α-Al grains.When the metal liquid was injected in die cavity,explosive nucleation of α-Al grains happened in remaining liquid,forming large quantity fine α-Al grains,as shown in Fig.7.In addition to rapid solidification,the high speed liquid flow also contributed to the heterogeneous microstructure.Due to the disperse effect of high filling speed,coarse ESCs distributed in every position along the radius direction.However,relative dense distribution of ESCs was in center to form α-Al rich region.According to the previous study [18],the ESCs and growing dendrites tended to migrate toward the center instead of attaching to the solidification layer during filling.The eutectic segregation band was presumed to come from the last solidified liquid.According to Li et al.[19],this segregation band followed the contour of melt flow in liquid filling,which can contribute to the feeding in interdendritic gap.

The dendrites growing along the wall were fused and dissociated in center.Equipped with ESCs,α-Al rich region formed in center.While the compact chilled crystal formed in surface affected by chill effect of die cavity [20-22].The middle region between α-Al rich region and surface chilling shell provided the path for metal liquid filling.Because of massive precipitation of α-Al,the last solidified liquid in middle region would have high silicon concentration.Therefore,the eutectic silicon band formed.

4.2.Effect of pores and Fe-rich phases on the fracture

The main Cracks originated from the surface and changed direction in the course of expansion.The second cracks were constantly sprouted up during the expansion process.

The pores in HPDC aluminium alloy comprised gas pores and shrinkage pores.Gas pores were induced by the air entrapment in shot sleeve,while shrinkage pore were induced by the feeding failure during solidification.In Fig.8a,the shape of gas pore was nearly spherical and its size was about 60 μm.However,the size of shrinkage pore was smaller and less than 5 μm.The shrinkage pore distributed along the Al grain boundary and its shape was narrow ribbon due to the solidify contraction.The worse roundness of shrinkage was easy to cause stress concentration,leading to microcrack initiation around its tip.According to Ref.[23],the increase of porosity increased the degree of maximum stress(σmax).The expression was as follow:

where K was the stress concentration factor of the porosity,which was related to the size and shape of pores;F was tensile force; A0was cross section area;f was the volume fraction of pores.The gas pore with large volume fraction increase the f while the shrinkage with irregular shape increase the K.Compared with gas pore,the effect of shrinkage with smaller size on fracture could be ignored,but the shrinkage was interconnected in α-Al rich region forming large shrinkage network.It was proposed by Li et al.[24]and named net-shrinkage.By 3-D CT image reconstruction,they concluded that net-shrinkage was the dominant sources for crack initiation because of a much lower sphericity causing high stress intensity.Microcracks tended to originated around worse roundness of the shrinkage and further expanded along the boundary of the dendrites.Seen from Fig.5a and b,net-shrinkage region was located in center and covered the whole α-Al rich region.The fracture of net-shrinkage became rough,as shown in Fig.8e,indicating the microcracks covering Al dendrite boundary and a long crack propagation path.

In Fig.8c,the bulk Fe-rich phase distributed random in cross section of sample and contributed to the failure of tensile test bar.Because of natural brittle property and poor deformation compatibility,the bulk Fe-rich phase was broken into several pieces,as shown in Fig.8f.According to Zhu et al.[25],the coarse Fe-rich phases inhibited the dislocation motion and acted as stress raisers to weaken the coherence.Meanwhile,the local stress concentration made brittle Fe-rich phases easy to crack along the definite crystallographic structural planes.

4.3.Effect of eutectic silicon-rich region and α-Al rich region on fracture expansion

The hindering effect of the eutectic silicon on dislocation motion determines the strength of hypoeutectic Al-Si alloy.According to Orowan mechanism,the smaller the particle spacing (d) and the larger the volume fraction (f),the more obvious the strengthening effect is.The expressions were as follow:

wherebwas burgers vector;r was particle size;α depended on the type of dislocation.As shown in Fig.9a and c,Sample 2 with higher density of eutectic silicon owns smaller particle spacing and larger volume fraction.Table 3 provides the reason for higher strength of Sample 2.However,when the dislocations encounter with the obstacles e.g.the eutectic silicon or Fe-rich phase,the motion of the dislocations will be stopped.The dislocations piled up along{111}planes can lead to stress concentration in phase interface,and then microcracks begin to germinate and extend along the interface of Al and Si.According to Lee[26],the eutectic silicon rotated to form micropores because of incongruity of deformation between Al and Si in tensile test.The weak incoherent interface provided a path for the crack growth.

Many researchers have found that part of eutectic silicon is ruptured in tensile fracture.The broken particles generate new surfaces and increase the interfacial energy.The increased critical shear stress (Δτa)could be expressed:

whereσwas interface energy.Similarly,the smaller size (r) and large fraction of eutectic silicon will increase extra strength.Man[27]found that the fracture Si particles increased with stress improvement,and Si particles with large length-width ratio were easier to fracture.Wang[28]discovered the probability (p) of silicon fracture to be conformed to Weibull:

wheremwas Weibull modulus;VandσPwere particle volume and the actual force applied in particle,respectively.Voandσowere related to microstructure of hypoeutectic Al-Si alloy.The greater ofVandσPvalue,the fraction silicon fracture will be higher.Since denser Si particles distribution in Sample 2 lead to more broken Si particles and higherΔτa,the overall strength is therefore improved.

In Fig.10a and b,the quasi-cleavage fracture morphology consists of tearing edges,micropores and the exposed lath Fe-rich phases,which was present in eutectic silicon band region.Meanwhile,the large cleavage steps formed,indicating the change of main crack propagation direction.In the process of main crack propagation,when the tip of the crack was in contact with the eutectic silicon band region,the growth of cracks was hindered by dense eutectic silicon particles,which improved the strength of alloy.However,many broken Fe-rich phase and micropores existed in the sample,as shown in Fig.10a.As for lath Ferich phase,it was easy to be broken affected by the nature brittle,and could not provide the effective strength for inhibiting crack propagation[29].High stress intensity around these defects would occur,which promoted the generation and propagation of the microcracks.

The α-Al rich region had also an important influence on the expansion of the crack.Coarse ESCs were soft and easy to deform.These grains acted as a stress buffer,if the cracks passed the interior of the grain.When the energy was consumed and the crack growth was volatile affected by alternating sliding {111}<110>,according to the FCC crystal structure.The continuous change of the lattice plane and crystal direction during sliding was the key factor to increase the crack propagation path.As shown in Fig.9b and d,the coarse ESCs and fine α-Al grains were common existence in center region.Higher density of ESCs in Sample 1 would increase the deformability.However,the denser and smaller α-Al in Sample 2 increased the density of boundaries and provided more sites for shrinkages.Fig.9e shows the quantity statistics of α-Al grains size from 0 μm to 120 μm.The grain sizes less than 8 μm were account for the majority.The maximum grain size in Sample 1 was 108 μm,far greater than that in Sample 2 (92 μm).The largest size of ESCs was typical dendritic crystal,as shown in Fig.9e.In the crack surface in Fig.10c and d,the dendrites and tearing dendrites presented,which was related to intergranular fracture and transgranular fracture,respectively.Transgranular fracture surface with small dimple and tearing ridge was rough while intergranular fracture surface was smooth.Net-shrinkage induced by the impinging dendrites was the reason for the intergranular crack propagation.Because of dense α-Al dendrites in Sample 2,a large amount of shrinkages increased the possibility of intergranular fracture.Meanwhile,the edge of shrinkage endured the high local stress intensity,which was easy to induce microcracks,and promotes the crack growth.

5.Conclusions

(1) Particular heterogeneous microstructure,including α-Al rich region and eutectic silicon band region,exhibit in the HPDC AlSi10MnMg alloy.

(2) Bulk Fe-rich phases and lath Fe-rich phases exist in HPDCAlSi10MnMg alloy.All brittle phases can contribute to crack propagation.

(3) Dense silicon particles in eutectic silicon band region inhibit the crack propagation,while coarse ESCs and dense α-Al in center increase the crack propagation path.

(4) Interdendritic shrinkages connect to each other to form the netshrinkage in α-Al rich region.This net-shrinkage is the dominant sources for microcrack initiation and propagation.

Acknowledgement

The authors would like to thank the National Natural Science Foundation of China (Grant No.51775297),the National Science and the Tsinghua University Initiative Scientific Research Program(20151080370) and UK Royal Academy of Engineering/Royal Society through the Newton International Fellowship Scheme.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.pnsc.2019.04.008.

Progress in Natural Science:Materials International2020年2期

Progress in Natural Science:Materials International2020年2期

- Progress in Natural Science:Materials International的其它文章

- Introduction of manganese based lithium-ion Sieve-A review

- Hollow bismuth ferrite combined graphene as advanced anode material for sodium-ion batteries

- Magnetically separable and visible light-active Ag/NiCo2O4 nanorods prepared by a simple route for superior photodegradation of atrazine in water

- Solid electrolyte composite Li4P2O7-Li3PO4 for lithium ion battery

- Wearable supercapacitor self-charged by P(VDF-TrFE) piezoelectric separator

- Enhanced superconducting performance in solution-derived YBCO-BaZrO3 composite film