Cement-lime stabilization of crude oil contaminated kaolin clay

Opeyemi E. Oluwatuyi, Oluwapelumi O. Ojuri, Arman Khoshghal

a Department of Civil Engineering, Landmark University, Omu-Aran, Nigeria

b Department of Civil and Environmental Engineering, Federal University of Technology, Akure, Nigeria

c School of Civil and Environmental Engineering, University of New South Wales (UNSW), Sydney, Australia

Keywords:Cement-lime Consolidation Contaminated clay Crude oil Stabilization

A B S T R A C T The present study examines the effect of stabilization on the geo-environmental properties of crude oil contaminated kaolin clay. Lime and cement were mixed in a ratio of 1:2 and added to the simulated crude oil contaminated kaolin clay at different percentages(5%,10%,15%,and 20%)as a stabilizing binder.Parameters investigated include consistency limits, unconfined compressive strength (UCS), and direct shear, and compressibility and leaching characteristics of the untreated and stabilized soils. The experimental testing reveals a decrease in the consistency limits with addition of the stabilizing binder.Maximum UCS values occurred for 15%cement-lime stabilized kaolin clay at different curing periods(i.e.0 d, 7 d,14 d, and 28 d). By increasing the cement-lime content from 5% to 15%, the UCS values of the stabilized clay increase from 185 kPa to 350 kPa and from 785 kPa to 1160 kPa for uncured and 28 dcured samples,respectively.Both the compression and recompression indices of the contaminated kaolin clay from the consolidation test decrease by 40% and 50%, respectively, with 20% stabilizing binder addition. The leachability of the contaminated clay also reduces with incorporation of cement and lime.According to the scanning electron microscope (SEM) test, addition of stabilizing binder transforms the dispersed structure of contaminated kaolin clay into a knitted flocculated structure.The study shows the effectiveness of cement-lime mix in stabilizing the contaminated kaolin clay and the possible use of stabilized contaminated kaolin clay as an alternative construction material.

1. Introduction

Crude oil contamination like any other forms of hydrocarbon contamination has an effect on the soil's mechanical strength(Ojuri and Oluwatuyi, 2014; Onyelowe, 2015; Oluwatuyi et al., 2019),stiffness (Al-Adili et al., 2017), microstructural (Izdebska-Mucha et al., 2011), microbial (Labud et al., 2007), physical and chemical(Wang et al., 2013) properties. Although the presence of these hydrocarbons including naphthalene,diesel oil,gasoline and crude oil may increase the soil strength and stiffness (Onyelowe, 2015; Al-Adili et al., 2017; Oluwatuyi et al., 2019), they often have detrimental effects on the soil's microstructural,microbial,physical and chemical properties. Studies on the adverse changes in soil properties as a result of contamination and the related soil remediation techniques have been a subject of interest for many researchers.The remediation techniques used to improve the crude oil contaminated soil include bioremediation (Yan et al., 2015),chemical remediation (Ola et al., 2015), soil washing (Urum et al.,2005), solvent extraction (Li et al., 2012), stabilization (Akinwumi et al., 2016) and thermal extraction (Li et al., 2009). All these remediation techniques (with the exception of stabilization) are based on the permanent removal of the crude oil (contaminant)from the contaminated soil. Through these researches, crude oil contaminated soil is gradually emerging as a construction material for buildings(Abousnina et al.,2015)and road pavements(Hassan et al., 2005; Nasr, 2014).

The focus of most studies performed in the past was mainly focusing on crude oil contaminated sand(Atuanya,1987;Puri et al.,1994; Al-Sanad et al.,1995; Ojuri and Epe, 2016). This is generally because granular materials are more suitable for most geotechnical engineering projects (Nnochiri et al., 2017; Owamah et al., 2017;Ojuri and Oluwatuyi, 2018; Ola et al., 2018; Oluwatuyi et al.,2018). Contaminated fine-grained materials are often considered as unsuitable construction materials. However, fine-grained soils are prevalent in the tropical regions like Nigeria (Ajibade et al.,2019) and therefore, contaminated fine-grained soils areinevitably found in these regions. The fine-grained soils hold/absorb contaminants for a longer period because of their chemical sensitivity to these contaminants (Ojuri et al., 2016, 2017a). For example, studies on the Olomoro flow station in Delta State and Ogoniland in Rivers State,Nigeria,showed that the fine-grained soil on the site was contaminated with crude oil (Tanee and Albert,2011; Lindén and Pålsson, 2013). Disregarding the contaminated fine-grained soils is costly and ineffective, necessitating study on remediation or stabilization techniques for contaminated finegrained soils as better alternative techniques for treatment.

Table 1 Properties of uncontaminated and crude oil contaminated kaolin clays.

Several studies have been performed on remediation/stabilization of oil contaminated fine-grained soils (Adenipekun and Fasidi, 2005; Ayotamuno et al., 2006; Khosravi et al., 2013; Liu et al., 2015; Estabragh et al., 2017; Ghasemzadeh and Tabaiyan,2017; Ghadyani et al., 2019). One common conclusion from all these studies on soil contamination and its stabilization is that contaminated soil could still be remediated for construction rather than being discarded.Stabilization with chemical additives(e.g. cement and lime) is a viable option for restoring or rather improving the geomechanical properties of oil contaminated clay.The use of cement and lime together as a stabilizing additive for fine-grained soil has been commonly practiced(and investigated)over the past few decades (Onitsuka et al., 2001; Lemaire et al.,2013; Khemissa and Mahamedi, 2014). Cement-lime stabilized fine-grained soil could be used as an engineering material for backfill and highway pavement(Ojuri et al.,2017b).The use of this technique (stabilization) to counteract the adverse effects of soil contamination, however, is still rare.

This study attempted to explore the influence of adding cement and lime on the geotechnical and leaching properties of clay contaminated with crude oil. Consistency limits, unconfined compressive strength (UCS), direct shear and consolidation tests were conducted on the contaminated and stabilized samples of the clay. Leaching tests were performed on the contaminated and stabilized samples to determine the immobilizing effect of the cement and lime on the contaminant in the soil.Scanning electron microscope (SEM) was also used to explore the microstructural alteration in the contaminated clay and the stabilized contaminated clay samples. To this end, stabilization of crude oil contaminated fine-grained soils with cement and lime is the main objective of this study.

2. Materials and their characterization

The materials used in this context include uncontaminated soil(kaolin clay), contaminant (crude oil), and stabilizing binder(cement and lime).

2.1. Soil

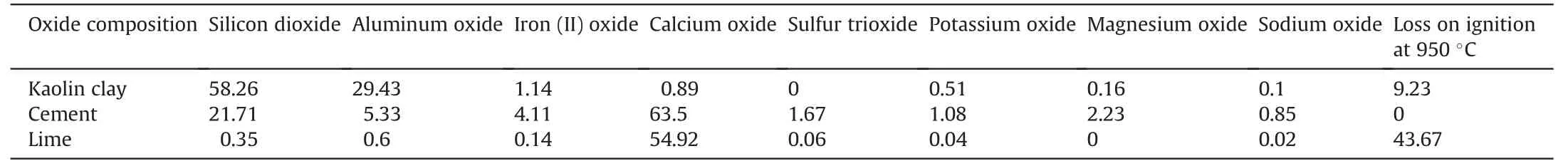

The soil material was commercial kaolin clay supplied by a retailer in Ibadan,Nigeria.It was characterized as lean clay(CL),i.e.clay of low plasticity according to ASTM D2487-17 (2017). The geotechnical properties of the uncontaminated kaolin clay including specific gravity, consistency limits, cohesion and UCS were obtained in accordance with ASTM D854-14 (2014), ASTM D4318-17e1 (2017), ASTM D3080/D3080M-11 (2011) and ASTM D2166/D2166M-16 (2016), respectively, and are listed in Table 1.The geotechnical properties of the soil were obtained from three trials for each individual property. The particle size distribution(PSD) of the uncontaminated kaolin clay obtained from the sieve and hydrometer analyses(ASTM D422-63(2007)e2,2007)is shown in Fig.1.The kaolin clay used in this study was a light brown colored soil classified as A-7-6 and CL according to American Association of State Highway and Transportation Officials (AASHTO) and Unified Soil Classification System (USCS), respectively (Table 1). From the chemical composition of the kaolin clay, lime and cement presented in Table 2, the main oxides in the soil were silicon dioxide(58.26%) and aluminum oxide (29.43%).

2.2. Contaminant

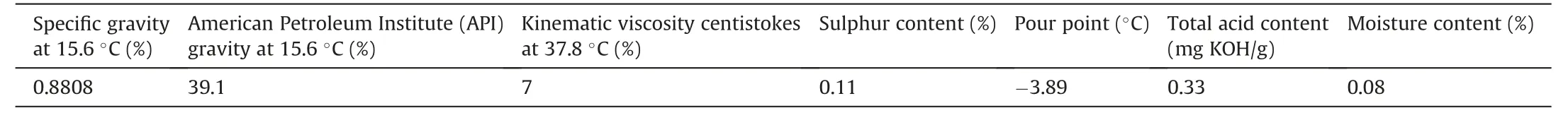

The crude oil was sampled from the Afiesere-Iwhrenene crude oil pipeline station,owned by the Nigerian Petroleum Development Company, the upstream arm of the Nigerian National Petroleum Corporation (NNPC) located in Ughelli North Local Government Area(LGA),Delta State,Nigeria.The crude oil sample was the same batch as the one used by Ojuri and Epe (2016) and its properties evaluated by the authors are listed in Table 3.The specific gravity of the crude oil at 15.6°C was 0.8808 (Table 3) with a low moisture content of 0.08%,which will not affect the moisture content of the crude oil contaminated kaolin clay.

2.3. Stabilizing binder

Locally produced ordinary Portland cement (OPC) of grade 43 and hydrated lime(Ca(OH)2)were purchased from a retailing outlet and used as a stabilizing binder. The chemical properties of thelime,cement and uncontaminated kaolin clay are listed in Table 2.Calcium oxide (which aided in soil strengthening) was the main oxide presented in cement (63.5%) and lime (54.92%).

Table 2 Chemical composition (%) of lateritic soil, cement and lime.

Table 3 Crude oil properties (Ojuri and Epe, 2016).

3. Sample preparation

For the crude oil contaminated samples, crude oil with weight equal to 10%of the dry kaolin clay representing the maximum level of crude oil contamination(Shah et al.,2003;Akinwumi et al.,2016)was poured on the kaolin clay and manually fused to form a homogenous mixture. The homogeneity allows for easy control and comparison, unlike the naturally contaminated sample that is heterogeneous and will complicate analysis. The homogeneous mixture was stored in an airtight bag for a contact time of 4 weeks(Khamehchiyan et al.,2007)and mixed every now and then during this period to ensure evenness of the contaminant in the soil pore spaces. The properties of the contaminated kaolin clay alongside the uncontaminated kaolin clay are listed in Table 1.

A mixture of lime and cement in a ratio of 1:2 (Ojuri et al.,2017b) was added to the aged contaminated soil samples at varying portions of 0%,5%,10%,15%,and 20%by weight of the artificially contaminated soil sample(Al-Rawas et al.,2005).The ratio(1:2)of lime and cement represents an optimized ratio commonly adopted for uncontaminated clay stabilization (Khemissa and Mahamedi,2014). The cement-lime stabilized samples were stored in secured containers for several target periods of time(0 d,7 d,14 d,and 28 d) to allow for different degrees of balance and uniformity before the commencement of experimental testing. It should be noted that the 0 d-cured samples had a lull(period between sample preparation and testing)not exceeding 100 min.

4. Experimental testing

The procedures for consistency limit tests were in accordance with ASTM D4318-17e1 (2017). Consistency limits (liquid and plastic limits)were obtained based on soil samples sieved through a 0.425 mm sieve. The liquid limit was determined using the Casagrande apparatus. The plastic limit was determined as the gravimetric water content at which a soil sample can be rolled by hand into a thread of about 3.2 mm in diameter without breaking.Samples used for UCS, direct shear, and consolidation tests were prepared by static compaction in three layers at their respective optimum moisture contents to obtain the maximum dry unit weight. The UCS tests were performed on uncured samples and those cured under controlled conditions (constant room temperature of 23°C and relative humidity condition of 100%)for 7 d,14 d and 28 d to observe the rate of strength development in the cured samples. The UCS tests were performed on cylindrical samples having a diameter of 40 mm and a height of 81 mm in accordance with ASTM D2166/D2166M-16(2016).A strain rate of 0.5 mm/min was maintained throughout the UCS test.The direct shear test can be determined according to ASTM D3080/D3080M-11(2011)using the shear box apparatus.Shear strength parameters(cohesion and angle of internal friction) of the samples were investigated. Since there were no arrangements for measuring pore pressure in the shear box apparatus,only drained tests were conducted.Hence,the horizontal shear force was applied at a slow constant strain rate of 0.0025 mm/min to avert development of excess pore water pressure. Samples were examined at the normal stresses of 13.9 kPa,27.8 kPa and 41.7 kPa.

Consolidation tests were conducted using fixed ring oedometer and loading frame on samples having a diameter of 6.35 cm and a thickness of 2 cm in accordance with ASTM D2435/D2435M-11(2011). The samples for the consolidation tests were allowed to equilibrate with distilled water for 24 h before commencement of the test. The normal pressures of 25 kPa, 50 kPa,100 kPa,200 kPa and 400 kPa were applied on the sample in series. After the laboratory test,a semi-logarithmic graph of the void ratio(e)against the logarithm of pressure (log10p) was plotted for the loaded and unloaded parts. The compression index (Cc) and recompression index (Cs) were then calculated from the graph. The coefficient of permeability, k, for each sample was inferred from the consolidation tests.

Leaching test was conducted on the contaminated and stabilized kaolin clay samples in accordance with the procedure outlined by Oluwatuyi and Ojuri(2017).The procedure imitates what happens to crude oil contaminated soil when rain falls.The total petroleum hydrocarbon (TPH) of leachate during the leaching test was measured using gas chromatography with flame ionization detector (GC-FID). GC-FID analyses were performed using a GC122 gas chromatograph (Shanghai, China) with a double FID detector that supports both packed and capillary column injections. Nitrogen was used as carrier gas while hydrogen and oxygen were used as FID gases. A software package (RS-232 interface and N-2000 chromatogram workstation) was used for data acquisition and processing. The microstructure and morphology of the uncontaminated, contaminated and stabilized contaminated kaolin clay samples were determined using the SEM apparatus (Hitachi S4500).

5. Results and discussion

The consistency limits of the kaolin clay increased and the strength of the kaolin clay decreased when the contaminant(crude oil) was added. The increase in consistency limits can perhaps be attributed to the interlayer expansion within the clay minerals and extra cohesion due to the viscous properties of the crude oil contamination (Akinwumi et al., 2016). The decrease in strength may be attributed to the greasy coating of the soil by the crude oil,increasing the probability of inter-particle slippage. The crude oil viscosity could have facilitated the sliding of soil particles under unconfined loading conditions.

Fig. 2. Consistency limits of uncured stabilized crude oil contaminated kaolin clay samples.

Fig. 3. Mean values of plasticity index against liquid limit for crude oil contaminated kaolin clay and stabilized contaminated kaolin clay samples on (a) AASHTO and (b)USCS plasticity charts.

5.1. Consistency limits

The plot of the consistency limits of the cement-lime stabilized crude oil contaminated kaolin clay for various amounts of the stabilizing binder is displayed in Fig.2.All the data are for uncured samples. The liquid limit, plastic limit, and plasticity index all decreased with addition of cement-lime to the crude oil contaminated clay.The decrease could be credited to the chemical reactions between the soil and the binder. These chemical reactions are classified into cation exchange,flocculation and pozzolanic reaction(Soltani et al., 2017). The application of the binder (cement and lime) to the contaminated clay results in exchange of monovalent cations in the contaminated clay with divalent higher charged cations(such as Ca2+)presented in the binder.This brings about the formation of an attractive force between the soil particles and the binder, leading to particle flocculation and a decrease in the plasticity(consistency limits)of the stabilized soil.The mean values of liquid limit decreased from 66.7%to 28.9%,plastic limit from 33.3%to 10.1%, and plasticity index from 33.4% to 18.8%, which were in agreement with those obtained by Du et al. (2014). The liquid and plastic limit values of the stabilized clay were less than 50% and 30%, respectively, hence they were appropriate for use as a subgrade material in pavement construction according to Federal Ministry of Works and Housing (FMW&H) (1997). The mean values of liquid limit against plasticity index were plotted on the AASHTO and USCS plasticity charts (Fig. 3). The data points on both plots moved to the lower left with addition of the stabilizing binder. The 15% and 20% cement-lime stabilized crude oil contaminated clays were classified as A-6 and CL according to AASHTO and USCS plasticity charts, respectively.

5.2. Strength

Results of the UCS tests performed on stabilized crude oil contaminated kaolin clay samples after 0 d, 7 d,14 d and 28 d of curing are displayed in Fig. 4. Results of direct shear tests performed on stabilized crude oil contaminated kaolin clay samples after 28 d of curing are presented in Fig.5.Both plots(Figs.4 and 5)show an increase in the strength(UCS and cohesion values)as more quantity of stabilizing binder is added to the contaminated clay.The UCS value of the unstabilized contaminated clay was 116 kPa.Based on the UCS results,by increasing the cement-lime content from 5%to 15%,the UCS values of the stabilized clay increased from 185 kPa to 350 kPa and from 785 kPa to 1160 kPa for uncured and 28 dcured samples, respectively. Strength increase of uncured samples could be attributed to the reaction between the stabilizing binder and clay during the period between sample preparation and testing to form the cementation product (Geiman, 2005). The reaction between the stabilizing binder and the contaminated clay starts with a cation exchange and particle aggregation, which is almost immediate and perhaps the main reason for strength gain in the uncured samples(Eades and Grim,1960;Geiman,2005;Oluwatuyi and Ojuri, 2017; Baldovino et al., 2018). The differences in the optimum moisture content and maximum unit weight for each sample may also have contributed to the increasing strength.

Fig. 4. UCS values of stabilized crude oil contaminated kaolin clay samples cured for 0 d, 7 d,14 d and 28 d.

Thereafter,the influence of the stabilizing binder(cement-lime)slightly reduced. At 20% cement-lime, the UCS values of the stabilized clay decreased to 347 kPa and 1152 kPa for uncured and 28 dcured samples, respectively. This decrease, albeit minor, showed that 15% cement-lime stabilized contaminated clay was the optimized quantity of lime and cement in the ratio of 1:2 for the stabilization of artificially contaminated kaolin clay.The UCS values of the stabilized clay with 15% cement-lime (initially uncured) were approximately 3 and 10 times higher than that of the untreated contaminated clay after 28 d curing,respectively. The stabilization treatment was effective because the UCS values of the stabilized sample were higher than the minimum value of 345 kPa stipulated by ASTM D4609-08 (2008). The strength values have the same range and show similar trends to those presented by Shah et al.(2003). The decrease in the angle of internal friction with increase in the amount of the stabilization mixture is attributed to the binder effect, which increases the strength of the sample through cementation, and reduces the sensitivity of the shear strength to the confining pressure.

5.3. Stiffness

Fig. 5. Cohesion and angle of internal friction of stabilized crude oil contaminated kaolin clay samples cured for 28 d.

Fig.6. Secant modulus values of stabilized crude oil contaminated kaolin clay samples cured for 0 d, 7 d,14 d and 28 d.

The secant modulus is a significant design parameter for soil materials which describes the average stiffness of the soil. The secant modulus is the ratio of the deviatoric stress to the corresponding axial strain at a particular point on the stress-strain curve (Chogueur et al., 2018; Paimushin et al., 2018; Wang et al.,2019; Zhou et al., 2019). The secant modulus can be defined corresponding to a certain level of strain or stress. In this study, for each sample,the secant modulus was calculated based on the point corresponding to half of the UCS of the sample (Ma et al., 2014;Saberian et al., 2017). The secant modulus of the samples, Es, is plotted against the varying percentage of cement-lime added to the soil in Fig.6.As can be seen in this figure,the secant modulus value of the contaminated clay was estimated at 2.21 MPa.By increasing the cement-lime content from 5%to 15%,the secant modulus values of the stabilized clay increased from 3.12 MPa to 3.8 MPa and from 21.33 MPa to 35.26 MPa for uncured and 28-d cured samples,respectively. At 20% cement-lime, the secant modulus values (like the UCS value from which it was estimated) of the stabilized clay decreased to 3.52 MPa and 33.68 MPa for uncured and 28-d cured samples,respectively.

Fig. 7. Coefficients of permeability and consolidation of stabilized crude oil contaminated kaolin clay samples cured for 28 d.

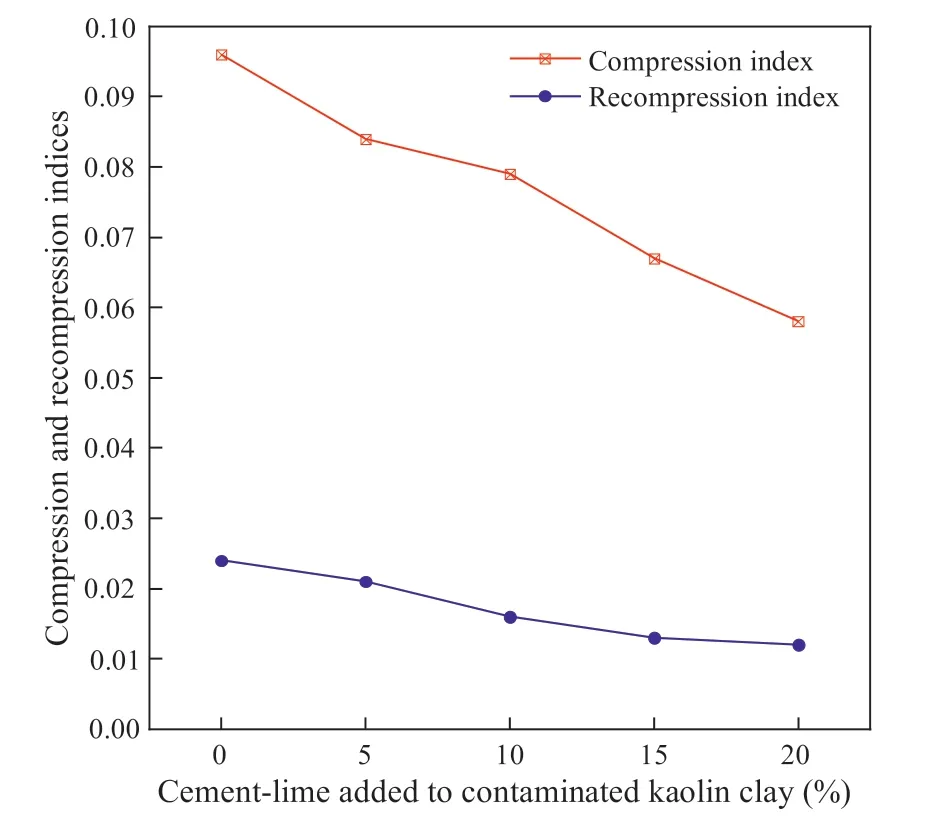

Fig. 8. Compression and recompression indices of stabilized crude oil contaminated kaolin clay samples cured for 28 d.

5.4. Compressibility

Consolidation tests were conducted using fixed ring oedometer and loading frame on relatively undisturbed samples having a diameter of 6.35 cm and a thickness of 2 cm. The coefficient of consolidation indicates the rate of compression, that is, the time period over which consolidation settlement will take place. This was estimated using the square root of time method. The coefficient of consolidation was thereafter used in calculating the coefficient of permeability. Both values were plotted against the percentage of cement-lime added to the contaminated kaolin clay(Fig. 7) after 28 d of curing. Both coefficients of consolidation and permeability decreased with an increase in the quantity of the stabilizing binder. The decrease in the coefficient of permeability may be due to the effect of the stabilizing binder on reducing the void ratio of the samples. The values of the coefficient of permeability were in the same range as the ones obtained by Akinwumi et al. (2016). The decrease in the coefficient of consolidation was due to the increase in the stiffness of the stabilized soil and the decrease in its permeability as more quantity of the cement-lime mixture is added to the sample.

The compression and recompression indices were derived respectively from the slopes of the linear portion and the unloading portion of the curve of the void ratio against the logarithm of pressure. The derived values of compression and recompression indices for each stabilized contaminated clay sample are presented in Fig.8 for samples cured for 28 d.Both indices decreased with an increase in the quantity of the stabilizing binder: the compression index decreased from 0.096 to 0.058 while the recompression index decreased from 0.024 to 0.012. A decrease in compression index will result in smaller consolidation settlement while a decrease in recompression index will lead to lower rebound heights after load removal. The decrease in both indices could be attributed to the stabilizing binder,forming a closed structure with the crude oil contaminated soil.

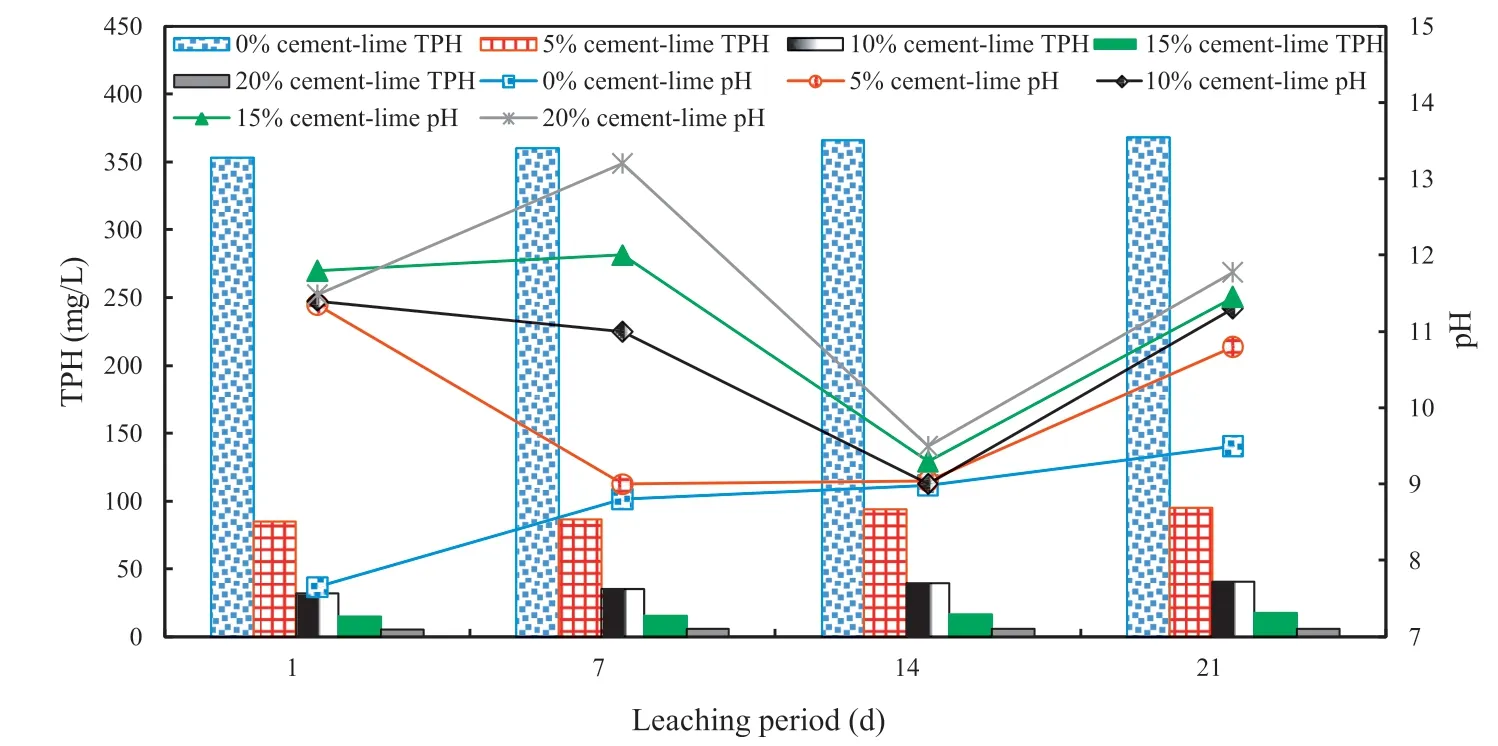

5.5. Leachability

Results of the TPH and pH value from the leaching test conducted on the stabilized samples cured for 28 d are presented in Fig. 9. TPH contains many organic substances, however, it can be assumed as an indicator for the release of crude oil (a petroleum hydrocarbon) from the stabilized soil matrix (Suja et al., 2014).Fig.9 shows that the leachability of the crude oil contaminated soil increased with time, however, the leachability decreased with addition of stabilizing binder. The decrease may be due to the closed structure formed by the addition of the binder, which subsequently prevents the free flow of the contaminant(crude oil)into the leachate. The TPH values of all the stabilized contaminated sample leachates were all below 100 mg/L. The pH values of the leachates all range between neutral and basic values.

5.6. Soil structure

The engineering properties of clay soils are strongly dependent on soil microstructure (Choobbasti and Kutanaei, 2017). The SEM was used in this study to observe the modification effect of crude oil contamination and cement-lime treatment on morphological and chemical (calcium localization) structures of the kaolin clay. SEM images of uncontaminated (Fig. 10a), 10% crude oil contaminated(Figs. 10b), and 20% cement-lime treated crude oil contaminated kaolin clay (Fig.10c) show very distinct particle arrangement and pore space.The particles of the kaolin clay in Fig.10a show a slightly flocculated structure. When the crude oil contamination is added(Fig. 10b), the link between the soil grains is weakened, causing particles to become extremely dispersed with loose aggregations of randomly arranged particles. The stabilization treatment of the crude oil contaminated clay (Fig. 10c) shows a more flocculated structure(compared to Fig.10a),mainly as a result of an increase in calcium ions (due to the binder addition). This image matches the earlier discussion regarding the effect of the binder on the consistency limits, coefficient of permeability, and strength of the stabilized contaminated sample.

Fig. 9. TPH and pH from leaching test on stabilized crude oil contaminated kaolin clay samples cured for 28 d.

Fig.10. SEM images of(a) kaolin clay,(b)10%crude oil contaminated kaolin clay,and (c)20%cement-lime stabilized crude oil contaminated kaolin clay(cured for 28 d)samples.

6. Conclusions and recommendations

6.1. Conclusions

This study aimed at studying the lime and cement(in a ratio of 1:2)stabilization treatment of a crude oil contaminated kaolin clay.Adverse effects of the crude oil contamination on the geotechnical properties of the clay samples were discussed. It was also shown that such effects are generally reversed with addition of the stabilizing binder (cement and lime). In particular, consistency limits decreased, soil mechanical strength increased, and soil compressibility and permeability decreased when the contaminated soil was treated with stabilization mixture. For contaminated soil potentially used as construction material, it is not likely that leaching of its contaminant to groundwater could occur,thus posing no risk to the public and environment as stabilizing the contaminated soil significantly reduced its leachability. Therefore, the suggested stabilization treatment of the contaminated soil could be considered as an effective approach, making the soil useful as a building and highway construction material. The results of the study showed that the optimum amount of the stabilization mixture is about 15%(by weight of the contaminated clay)as the benefit gained after this amount was negligible.

6.2. Limitations and future research directions

This study was limited to stabilization of crude oil contaminated clay using a lime and cement mixture of ratio 1:2. The microstructural analyses were limited to samples cured for up to 28 d.Only one type of clay(i.e.kaolin)and one specific stabilizing agent were studied due to time limitations. While the effect of stabilization on many geomechanical and geoenvironmental characteristics such as strength, stiffness and leachability were studied,many others including permeability, erodibility and long-term behavior were not considered due to time and resource limitations.

More researches are hence required to generalize the outcome of this study to other fine-grained soils and stabilization agents.Furthermore,exploring the most economical approach in applying the results of this study to geotechnical engineering practice is needed.

Declaration of Competing Interest

The authors wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Journal of Rock Mechanics and Geotechnical Engineering2020年1期

Journal of Rock Mechanics and Geotechnical Engineering2020年1期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- On the use of 1g physical models for ground movements and soil-structure interaction problems

- Ground behaviour analysis, support system design and construction strategies in deep hard rock mining - Justified in Western Australian's mines

- Prediction of TBM jamming risk in squeezing grounds using Bayesian and artificial neural networks

- Multi-scale modelling of gas flow in nanoscale pore space with fractures

- Three-dimensional double-rough-walled modeling of fluid flow through self-affine shear fractures

- Numerical study on tensile failures of heterogeneous rocks