Fabrication and Property of Yb:CaF2 Laser Ceramics from Co-precipitated Nanopowders

WEI Jia-Bei,TOCI Guido,PIRRI Angela,PATRIZI Barbara,FENG Ya-Gang,VANNINI Matteo,LI Jiang

(1.Key Laboratory of Transparent Opto-Functional Inorganic Materials,Shanghai Institute of Ceramics,Chinese Academy of Sciences,Shanghai 200050,China;2.Center of Materials Science and Optoelectronics Engineering,University of Chinese Academy of Sciences,Beijing 100049,China;3.Istituto Nazionale di Ottica,Consiglio Nazionale delle Ricerche,CNR-INO,50019 Sesto Fiorentino (Fi),Italy;4.Istituto di Fisica Applicata “Carrara”,Consiglio Nazionale delle Ricerche,CNR-IFAC,50019 Sesto Fiorentino (Fi),Italy;5.Istituto Nazionale di Ottica,Consiglio Nazionale delle Ricerche,CNR-INO,56124 Pisa(Pi),Italy)

Abstract:Transparent ytterbium doped calcium fluoride ceramics (Yb:CaF2) were successfully fabricated by vacuum sintering and hot pressing post-treatment from coprecipitated powders.In-line transmittance of 5at% Yb:CaF2 transparent ceramics fabricated by pre-sintering at 600 ℃ for 1 h and hot pressing post-treatment at 700 ℃ for 2 h,reaches 92.0% at the wavelength of 1200 nm.Microstructure,spectroscopic characteristics and laser performance of the ceramics were measured and discussed.The sample shows a homogeneous microstructure with average grain size of 360 nm.Furthermore,the absorption cross section at 977 nm and the emission cross section at the 1030 nm of the ceramics are calculated to 0.39×10-20 cm2 and 0.26×10-20 cm2,respectively.Finally,the laser behavior was tested,finding a maximum output power of 0.9 W while the highest slope efficiency was 23.6%.

Key words:Yb:CaF2;co-precipitation synthesis;two-step sintering;laser ceramics;optical property

In recent years,solid state lasers have been widely used in many fields,such as inertial confinement fusion,medical science and manufacturing.The gain medium is an important part of the laser system.The common materials used as gain media include glass,transparent ceramics and single crystals.Polycrystalline transparent ceramics have attracted considerable attention over the last few years.Compared with traditional optical glass,transparent ceramics show obvious superiorities on mechanical and thermal property.Generally transparent ceramics exhibit advantages over single crystals in many aspects,such as lower cost in preparation,higher homogeneity of the dopant and larger size[1-4].Many kinds of transparent ceramics have been studied and great achievements have already been acquired,such as YAG[5-9],sesquioxides[10-15],and fluorides[16-18].In the case of fluoride ceramics,the current progress of the researches and development fall behind oxide ceramic materials,although the first laser ceramics,Dy:CaF2,were fabricated by Hatch,et alin 1964[19].

Fluoride crystalline hosts,such as CaF2and its Sr and Ba based isomorphs (i.e.SrF2and BaF2) possess excellent property such as broad range of transmittance,lower phonon energy and low refraction index than garnets and sesquioxides;in these hosts Yb3+features a very broad absorption and emission bands (useful for the generation and amplification of ultrashort laser pulses) and long fluorescence lifetime that ensures efficient energy storage for the laser operation[20-21].In addition,Yb:CaF2has a negative thermo-optical coefficient which is suitable for the high output power in lasers due to mitigation of the thermal lens effect[22-23].Due to these characteristics,crystalline CaF2is a widely used host for efficient Yb doped[20,24-27]and Nd doped materials for laser applications[28].

The success of crystalline CaF2as laser host has stimulated the development of ceramics with the same composition for laser applications,in particular with Yb3+doping[18,21-22].

A large number of scientific literatures have been published on Yb:CaF2transparent ceramics and some progresses have been made.Basiev,et al[17,29-30]successfully fabricated Yb:CaF2laser ceramics with high optical quality by the hot forming method and reported the laser operation.But this hot forming method needs corresponding single crystal as the starting material and therefore it does not have the general advantages of ceramics preparation,such as short sintering time and low fabrication cost.Mortier,et al[18,31-33]has investigated the fabrication of Yb:CaF2transparent ceramics by sintering under vacuum atmosphere combined with the hot pressing method and the reported laser oscillation.Li,et al[34]prepared Yb:CaF2by vacuum hot pressing and spark plasma sintering respectively.In 2015,Aballea,et al[35-36]reported the fabrication of Yb:CaF2transparent ceramics by sintering at moderate temperature in air and without any pressure assistance;moreover they demonstrated the laser operation of nano-powder based Yb:CaF2ceramics.In 2017,Kitajima,et al[37]studied Yb,La:CaF2transparent ceramics sintered by hot isostatic pressing (HIP) method.They reported the laser operation of the Yb3+- doped CaF2-LaF2ceramics with a maximum output power of 4.36 W and a maximum slope efficiency of 69.5%.

In this study we report on the fabrication,spectroscopic investigation and laser behavior of a 5at%Yb:CaF2transparent ceramic obtained by vacuum sintering and hot pressing post-treatment.The nano-powders were synthesized by the co-precipitation method.Then the FT-IR spectrum,phase composition and morphology of these powders were measured.The microstructure and in-line transmittance of the samples were investigated.Meanwhile,the fundamental spectroscopic characteristics of 5at% Yb:CaF2transparent ceramics were systematically studied.Finally,we test the laser characteristic of the sample finding encouraging results.

1 Experimental

5at% Yb:CaF2nano-scale powders were synthesized by the co-precipitation method.Commercially available chemical reagent included hydrated calcium nitrate(99.90%,Sinopharm Chemical Reagent Co.,Ltd.,Shanghai,China),hydrated potassium fluoride (99.90%,Sinopharm Chemical Reagent Co.,Ltd.,Shanghai,China),Ytterbium oxide (99.99%,Alfa Aesar,USA).Ca(NO3)2solution and KF solution were prepared by dissolving hydrated calcium nitrate and hydrated potassium fluoride in deionized water,respectively.The Yb(NO3)3solution was obtained by dissolving Yb2O3powders in nitric acid at 80 ℃.Then the solutions were filtered to remove the undissolved particles and impurities with 0.3 µm aperture size filter paper.The solution of potassium fluoride was added to the mixed solution of calcium nitrate and yttrium nitrate using a peristaltic pump under magnetic stirring.Next,the obtained solution was aged for 12 h at room temperature.The suspension was washed and centrifuged with deionized water for several times.Subsequently,the washed suspension was dried at 70 ℃ for 48 h in an oven,and the dried powders were sieved through a 74-μm screen.Finally,5at% Yb:CaF2nanopowders were obtained.

The synthesized nano-powders were dry-pressed in a 34 mm diameter die at 20 MPa,followed by cold isostatic pressing (CIP) at 250 MPa.The green body was sintered under vacuum at 600 ℃ for 1 h.Then,the presintered sample was hot pressed at 700 ℃ with 30 MPa pressure under vacuum.The obtained Yb:CaF2ceramic sample was polished into 1.5 mm for the further characterizations.

The phase of the powders was determined by X-ray diffraction (XRD,Model D/max2200 PC,Rigaku,Japan)in the range of 2θbetween 10° and 80° using nickelfiltered Cu-Kα radiation.Fourier transform infrared spectroscopy (FT-IR) was performed on an infrared spectrometer (FT-IR,Bruker VERTEX 70 spectrophotometer,Ettlingen,Germany) using the standard KBr method in the range of 4000-400 cm-1.The specific surface area (SBET) of the powders was performed by Norcross ASAP 2010 Micromeritics with N2as the absorption gas at 77 K.The morphologies of powders and microstructures of the fracture surfaces of ceramics were observed by a scanning electron microscope (FESEM,SU8220,Hitachi,Japan).The absorption intensity and in-line transmittance of the transparent ceramics were measured by a UV-VIS-NIR spectrophotometer (Model Cray-5000,Varian,CA,USA).The emission spectrum excited by a 915 nm laser beam was measured by a low temperature absorption spectrometer (FLS980,Edinburgh Instruments,Edinburgh,UK) at room temperature.The decay curve of the ceramics was measured using a pulsed Ti:Sapphire laser at 900 nm for excitation,using the so-called pinhole method for the correction of the radiation trapping effects[38-39].The laser emission of 5at% Yb:CaF2transparent ceramics was tested in an end pumped cavity,using a fiber coupled diode laser as pumping source.

2 Results and discussion

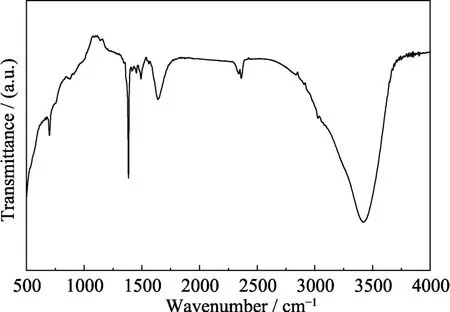

Fig.1 shows the FT-IR spectrum of 5at% Yb:CaF2powders.The wide absorption band around 3420 cm-1is related to the stretching vibrations of OH-group.The band around 1644 cm-1corresponds to H-O-H bending mode.Nevertheless,the hygroscopic property of matrix material KBr must be taken into consideration when analyzing the information provided by OH-and H-O-H vibration band during the measurements,which affects the test results.The absorption peak at 2364 cm-1is caused by the adsorption of CO2in the air and provides no information as a consequence.The absorption peak at 1383 cm-1is due to NO3-elongation mode.An effective washing process can decrease absorbed nitrate content and impurity ions like K+ions in the powders.The residual nitrates and absorbed water in the powders are decomposed during pre-sintering process.

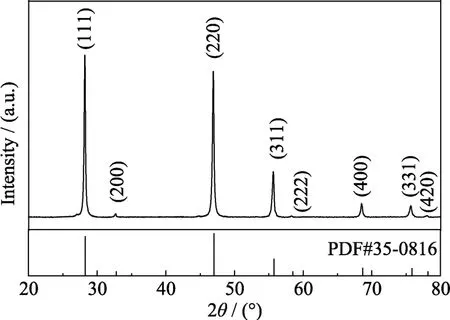

Fig.2 shows the XRD pattern of 5at% Yb:CaF2powders.It can be seen that all diffraction peaks of the powders are well matched with those of the cubic CaF2phase(PDF# 35-0816) and no secondary phase can be detected.Meanwhile,all the peaks of the powders shift to a lower angle,which reveals that the lattice parameter increases.This occurs because Yb3+enters into the CaF2structure by substituting for a Ca2+and creating an extra F-for charge compensation;as a consequence,the charge repulsion between F-ions increases the lattice parameter.The grain size (DXRD) of the powders can be calculated by the Scherrer equation:

whereβis the full width at half-maximum (FWHM) of a diffraction peak at Bragg angleθandλis the wavelength of CuKα radiation used in the measurements.The calculated average grain size of 5at% Yb:CaF2powders is 32 nm.

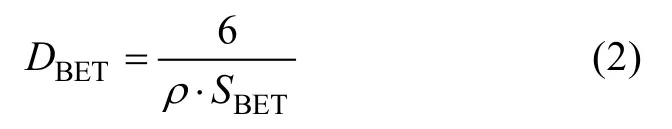

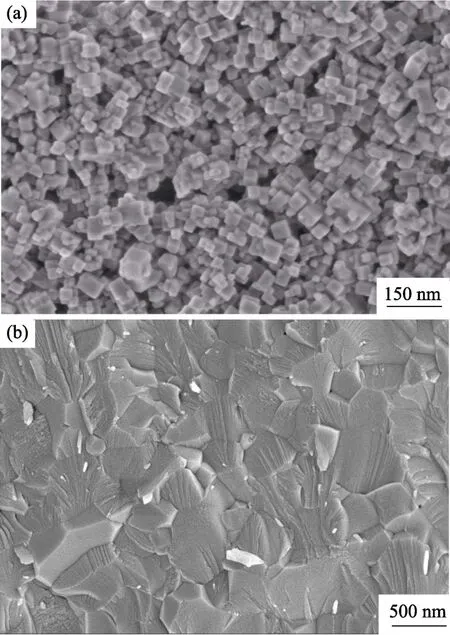

Fig.3(a) shows the SEM micrograph of 5at% Yb:CaF2powders.It appears that the powders are well-distributed and slightly agglomerated.The shape of the small particles is close to cubic.The average particle size (DBET) is 45 nm,which is calculated from the following formula

Fig.1 FT-IR spectrum of 5at% Yb:CaF2 powders

Fig.2 XRD pattern of 5at% Yb:CaF2 powders

Fig.3 SEM micrographs of 5at% Yb:CaF2 powders (a) and the fracture surface of 5at% Yb:CaF2 ceramics (b)

where (ρ=3.473 g/cm3) is the theoretical density of the powders calculated from their lattice parameters.SBETis the specific surface area determined by BET measurement.Meanwhile,it can be found that the size of 5at%Yb:CaF2powders calculated by BET method is larger than the value calculated by the Scherrer equation,indicating the existence of weak agglomerates,which can be observed from SEM micrograph of the powders.

Fig.3(b) shows the SEM micrograph of the fracture surface of 5at% Yb:CaF2transparent ceramics fabricated by vacuum pre-sintering at 600 ℃ for 1 h and hot pressing at 700 ℃ for 2 h.It reveals that the ceramics have an homogeneous structure and the average grain size is about 360 nm.The fracture mode is mainly transgranular.Moreover,it can be observed that some residual pores exist at the grain boundaries.It is known that these residual pores cause scattering loss in the transparent ceramics,which can decrease their optical quality.The work in future will focus on the complete elimination of the residual pores by HIP post-treatment.

The in-line transmittance and the photograph of 5at%Yb:CaF2transparent ceramics are shown in Fig.4.As it can be seen in the inset of Fig.5,the size of ceramics is 16 mm×6.8 mm while the thickness is 1.5 mm.At a visual inspection,ceramics have good transparency and the letters on the underlying paper can be clearly recognized.

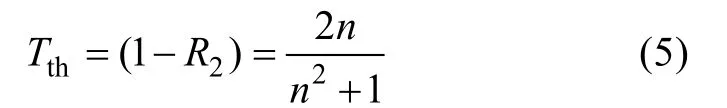

According to Krell[40],without scattering or absorption losses,the theoretical maximum of transmission is 100%minus reflection on both surfaces of a window.At normal incidence,the reflectionR1on one surface is governed by the refractive indexnas:

Fig.4 The in-line transmittance and the photograph of 5at%Yb:CaF2 transparent ceramics

Fig.5 Absorption coefficient and emission spectra of 5at%Yb:CaF2 transparent ceramics at room temperature

And the total reflection loss (including multiple reflection) is:

Thus,the theoretical limit is:

It is well known that the refractive index of CaF2single crystal decreases as the wavelength increases.At 1200 nm,the un-doped CaF2single crystal has a refractive index of 1.4277[41].Based on the above equation,the theoretical transmittance of CaF2single crystal is 93.97%at 1200 nm.The transmittance of 5at% Yb:CaF2transparent ceramics we have prepared reaches 92.0%,which is very close to the theoretical value.However,at the wavelength of 400 nm,the transmittance is 74.3%.The transmittance in visible range decreases rapidly,which can be attributed to the residual nanoscale pores in the ceramics.

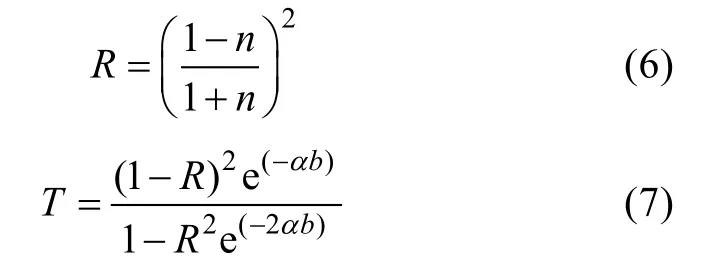

The room temperature absorption coefficient and emission spectrum of 5at% Yb:CaF2transparent ceramics are shown in Fig.5.The pump source used to excite the sample to measure the emission spectrum is a fibercoupled laser diode (LD) with center wavelength at 915 nm.It can be seen that the spectrum has broad absorption band.There are two main strong absorption peaks at 925 and 977 nm,corresponding to the transition from the ground state2F7/2to the excited state2F5/2of Yb3+ions.The absorption coefficient is calculated by the following equations:

WhereTis the transmittance of the ceramics,αandbare the absorption coefficient and the thickness of the sample,respectively.At 977 nm,the absorption coefficient is 4.8 cm-1,which is suitable for pumping by high powder InGaAs laser diodes.The emission spectrum has a broad emission band,ranging from 960 nm to 1040 nm.The main emission peaks that can be seen are near 977,1010,1030 nm,which can be attributed to2F5/2→2F7/2transition of Yb3+ions.

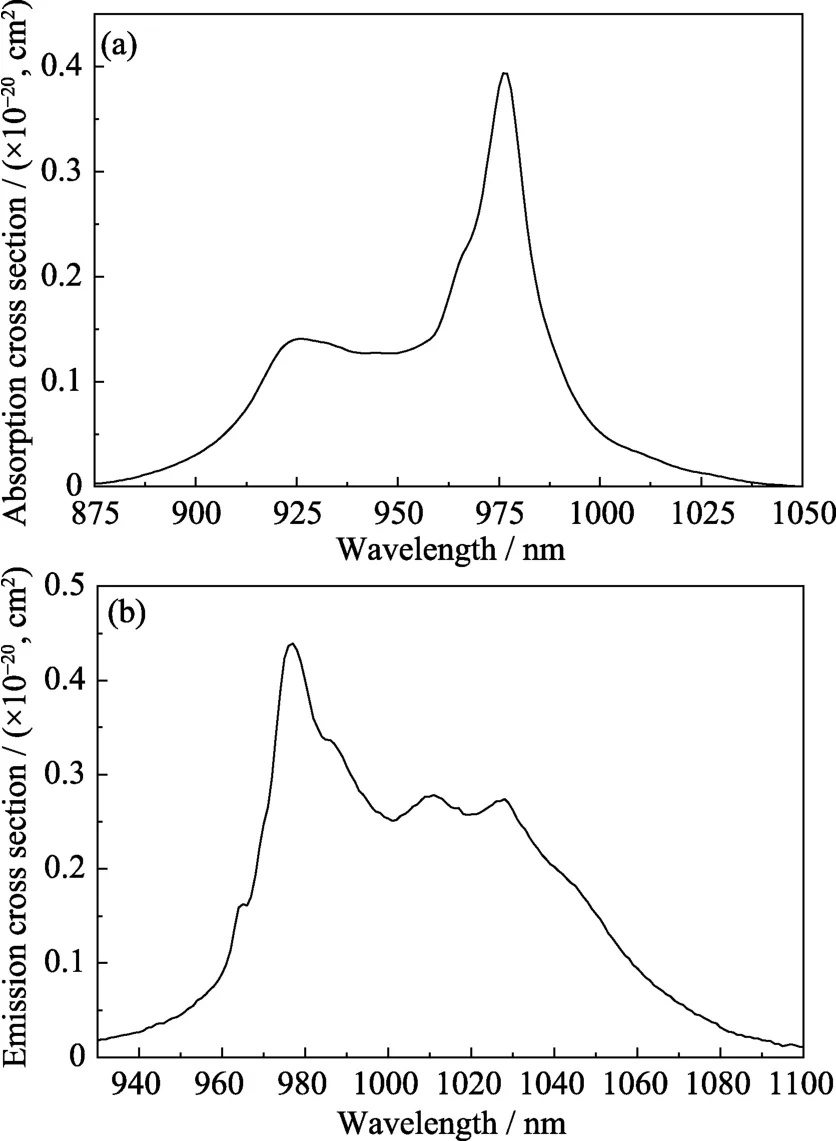

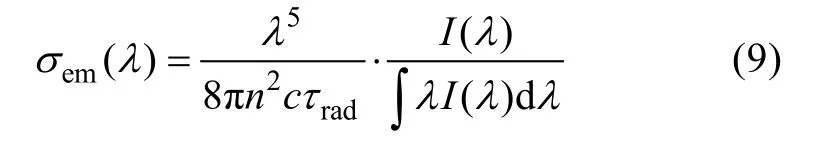

Fig.6 (a) shows the absorption cross section spectrum of 5at% Yb:CaF2transparent ceramics at room temperature.The absorption cross sectionσabscan be calculated by the following formula:

Fig.6 Absorption cross section spectrum (a) and emission cross section spectrum (b) of 5at% Yb:CaF2 transparent ceramics at room temperature

Whereαis the absorption coefficient calculated above;Nis the number of the doping ions per unit volume.The absorption cross section at 977 nm is calculated to 0.39×10-20cm2.

The Fuchtbauer-Ladenburg equation was used to calculate the emission cross section,with the expression of the Eq.(9).

Wherecis light speed:3.0×108m/s;λis wavelength;nis the refractive index;τradis upper level radiation lifetime:2.4 ms[42];I(λ) is fluorescence intensity at a certain wavelength in the fluorescence spectrum.The emission cross section spectrum of 5at% Yb:CaF2transparent ceramics is showed in Fig.6(b).The value of the emission cross section at the 1030 nm is 0.26 ×10-20cm2.

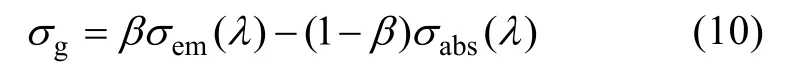

The gain cross section of 5at% Yb:CaF2transparent ceramics was calculated by the formula:

Whereβis particle inversion number.The gain cross section with differentβare reported in Fig.7.It can be observed that the gain cross-section curves show wide and flat shapes,which are very helpful to realize broadband tuning and ultra-short pulse laser output.

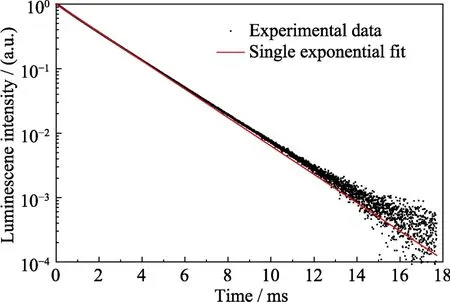

For the measurement of the upper laser level lifetime,the sample was excited using a pulsed Ti:Sapphire laser emitting at 900 nm with a pulse duration of about 100 ns FWHM.To correct for radiation trapping effects,the fluorescence was excited and detected through a small pinhole placed in contact with the surface of the sample,following the method outlined in Ref.[38-39].Several pinholes with diameters from 1.1 mm to 200 µm were used,and the lifetime of the detected fluorescence was calculated by fitting the temporal decay with a single exponential function (Eq.(11)).

Fig.7 The calculated gain cross section of 5at% Yb:CaF2 ceramics

Fig.8 The fluorescence decay curve of 5at% Yb:CaF2 transparent ceramics at room temperature.The time constant τ of the fitting curve is 1.974 ms

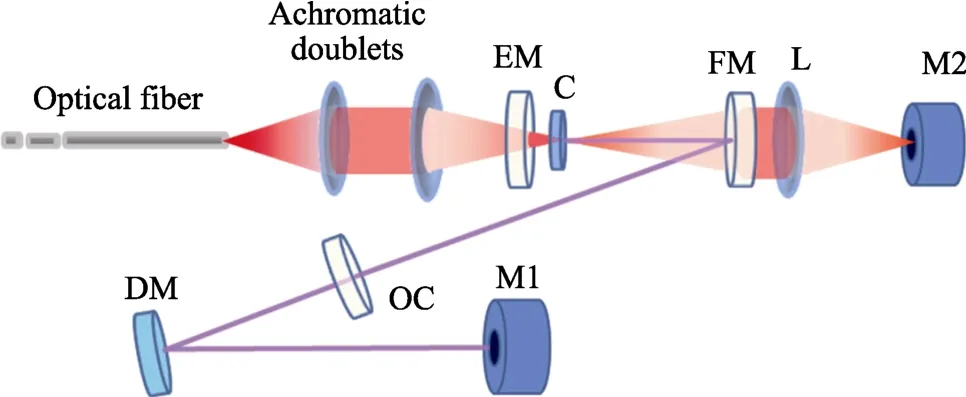

Fig.9 Experimental set-up

WhereIandI0are the fluorescence intensities at the timetand 0.

The actual lifetime was calculated as the extrapolation to null pinhole diameter of the decay times obtained with the different pinholes[38-39].The resulting value of the upper level lifetime was 1.95 ms.

Fig.8 shows the room temperature fluorescence decay curve of 5at% Yb:CaF2transparent ceramics obtained with a pinhole with 200 µm diameter.The small deviation from a pure single exponential decay is due to radiation trapping effects[39].

Finally,we tested the laser emission property of the sample.It was tested using the laser cavity layout shown in Fig.9.The cavity is end pumped.The sample used in the experiments had a thickness of 1.5 mm and it was welded by a sheet of indium on a copper heat-sink and cooled by water at 19 ℃.The sample was pumped by a fiber-coupled laser-diode which emits at 929.4 nm with a Gaussian pump intensity distribution in the region of the focal plane (i.e.waist radius around 65 µm at 1/e2,measured with a CCD camera),numerical aperture of the pump beam 0.22.The other elements of the cavity are EM:End-Mirror,dichroic (high transmission for the pump wavelength,high reflection for the laser wavelength);FM:Folding-Mirror (spherical,ROC 100 mm);OC:Flat Output Coupler mirror;M1 and M2:Power Meters,DM:Dichroic Mirror.The distance between EM and FM was 60 mm,while the distance between FM and OC was 270 mm.

The sample was pumped in Quasi-CW mode (QCW),with rectangular pump pulses at 10 Hz of repetition rate with a Duty Factor of DF=20%,in order to limit the thermal load into the sample.As the samples had different thickness and thus different absorption,the maximum incident pump power was adjusted to have about the same pump absorption for both samples.The sample absorbed about 14% of the incident pump,under lasing conditions.The maximum absorbed pump power was about 5 W for the sample (peak value during the pump on period),corresponding to about 38 W of incident pump power for the sample (peak values under the pump on period).

Several OC mirrors were used,with different values of transmission (fromToc=2% toToc=12%),to find the optimal output coupling transmission.

The lasing wavelength was measured by means of a grating spectrometer equipped with a multichannel detector head,with a resolution of about 0.4 nm.

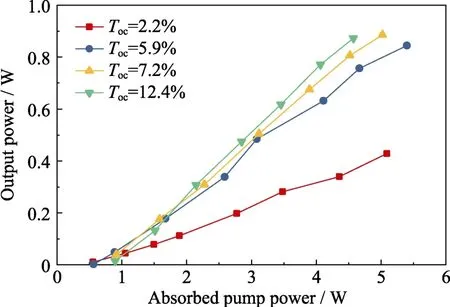

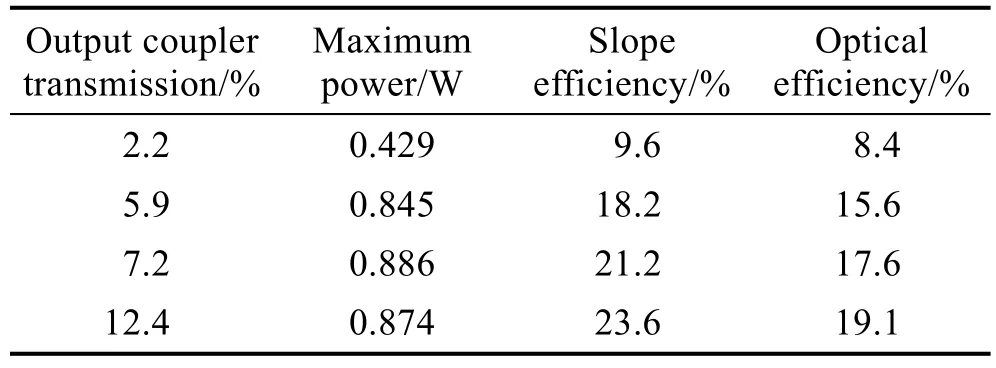

The graph of Fig.10 shows the output power as a function of the absorbed pump power for the sample under test.The actual value of the absorbed pump power was assessed under lasing conditions,by means of the auxiliary power meter M2 shown in Fig.9.The reported values of the pump and of the output power correspond to the value during the “on” period of the pump.For the sample,and in all the output coupling conditions the free running lasing wavelength is about 1028.5 nm.In QCW pumping conditions the maximum output power is 0.9 W,corresponding to an optical to optical efficiencyηO=17.6%,obtained with a value ofToc=7.2%.The maximum value of the slope efficiency isηS=23.6% obtained withToc=12.4%.The main parameters of the laser emission are reported in Table 1.

Fig.10 Laser output power vs.incident pump power for different values of the output coupler mirror transmission Toc

Table 1 Main laser emission parameters with slope efficiency being calculated with respect to the absorbed pump power

3 Conclusion

In this work,5at% Yb:CaF2transparent ceramics were successfully fabricated by vacuum sintering at 600 ℃ for 1 h and hot pressing post-treatment at 700 ℃ for 2 h from powders synthesized by the co-precipitation method.An effective washing process is necessary to remove some impurity ions in the powders.The used powders are pure cubic phase without secondary phase.The grain size of the powders is calculated to be 32 nm and the powders are agglomerated slightly.5at% Yb:CaF2transparent ceramics have the homogeneous microstructure and the average grain size is about 360 nm.The in-line transmittance of the sample with the thickness of 1.5 mm reaches 92.0% at the wavelength of 1200 nm,which is close to the theoretical value.Furthermore,5at%Yb:CaF2transparent ceramics have broad absorption and emission band.The strongest absorption and emission peaks are both at 977 nm.Meanwhile,the absorption cross section at 977 nm and the emission cross section at the 1030 nm of the ceramics are 0.39×10-20and 0.26×10-20cm2,respectively.The lifetime of the5F5/2level of the Yb3+is 1.95 ms.In the laser experiment,the maximum slope efficiency of 23.6% and the maximum output power of 0.9 W under QCW pump conditions were obtained from the ceramics.

- 无机材料学报的其它文章

- C/SiOC Composites by a Modified PIP Using Solid Polysiloxane:Fabrication,Microstructure and Mechanical Properties

- Preparation of CeO2/Flake-like CdS Composites as High-performance Photoanodes for Photoelectrochemical Cathodic Protection

- TiO2@SiO2复合材料的制备及其光催化与抗菌性能的研究

- NH2-UIO-66负载RuCuMo纳米催化剂的制备及其催化产氢

- 一步法合成特异性pH响应碳量子点及其发光机理研究

- 高质量水系钠离子电池正极Fe4[Fe(CN)6]3的合成及其电化学性能