Sound Character Calculation and Analysis of Sound Barrier Based on Acoustoelectric Analogy

ZHUCongyun,WURui(吴睿),HUANGPanxu,DINGGuofang,HUANGQibai

1 School of Mechanical Science & Engineering, Zhongyuan University of Technology, Zhengzhou 450007, China2 School of Mechanical Science & Engineering, Huazhong University of Science and Technology, Wuhan 430074, China

Abstract: A new acoustic barrier structure with resonant sound of micro-perforation board absorption structure and impedance composite sound-absorption structure is proposed. The acoustic impedance and the sound-absorption coefficient of the acoustic structure are calculated via means of equivalent circuit. MATLAB is used to calculate the relationship between the parameters of the ontology structure and the sound-absorption coefficient and the sound insulation. It is revealed that the sound barrier of the new ontology structure is 7.65-9.80 dB, which is more than the sound barrier of the traditional reflective structures. The relationships among the parameters of sound-absorption structure, sound-absorption coefficient, and sound insulation performance are obtained. In addition, the parameters can be transformed to satisfy the noise reduction requirements of various road sections, which has a admirable adaptability. The acoustic barrier can have tremendous acoustic performance only if there is a splendid sound insulation in the traffic noise frequency band.

Key words: acoustic barrier; micro-perforation board; sound-absorption coefficient; sound insulation

Introduction

With the development of the society, the means of transportation are also increasing gradually. Traffic noise has seriously interfered with people’s normal life and work, and even endangered people’s health. It is extremely urgent to take measures to quell the harm of traffic noise to people. According to the survey, traffic noise in China is almost over 70 dB(A), and few noise reduction measures are adopted[1]. Noise barrier is one of the most convenient and effective means because of its small footprint, obvious effect of noise reduction, convenient maintenance and low cost. The initial sound barrier is just a simple sound insulation board, and the noise reduction effect is not ideal. After extensive and in-depth research via researchers, three ways have been formed: reflection and diffusion sound barrier, absorption and resonance sound barrier and active noise reduction sound barrier[2]. Many domestic and overseas experts have done a lot of research on acoustic barriers, including the calculation of insertion loss, structural design, structural improvement and landscape design. Yang and Ye[3]expounded the design method of sound barrier from the acoustic perspective, and through the comparative study of the performance of diverse acoustic components of the sound barrier, proposed that the sound-absorption resonance variety is the future development direction of highway sound barrier. Through theoretical analysis, Sun[4]deduced the calculation formula of the insertion loss of finite length acoustic barrier. Maoetal.[5]proposed a new sound barrier with a top sound absorbing cylinder based on the resonant sound absorbing structure of the micro perforation. Yu[6]put forward a variety of sound barrier with micro-perforation of gradually changing cavity, and deduced the calculation method of insertion loss of the sound barrier based on the theory of micro-perforation sound-absorption. Miki[7]studied the attenuation effect of sound absorbing materials on multiple reflections and diffracted sounds between parallel sound barriers. Hothersalletal.[8]studied the influence of geometric shape and ground reflection on acoustic characteristics of the sound barrier through a finite element method. Li[9]established a scattering mathematical model of sound-absorption barrier, and theoretically analyzed the impact of sound-absorption material performance on the sound barrier insertion loss. Based on the studies of the above scholars, it can be seen that the noise reduction effect of the sound barrier with micro-perforated plates or sound absorbing materials has been improved to some extent, but it still fails to meet the ideal requirements due to various noise sources and environmental restriction.

Based on the comparative analysis of the existing sound barrier performance and considering the special requirements of urban traffic noise on the sound barrier, a new sound barrier body structure is designed, which is a combination of a micro-perforated resonance sound-absorption structure and a impedance composite sound-absorption structure. A micro-perforated plate structure is a sound-absorption structure composed of micro-perforated panel with low perforation rate and cavity behind the plate. The micro-perforated panel was put forward by Ma[10-11], and he proposed basic theory and accurate, successively. Compared with the ordinary perforated plate, the micro-perforated plate has the characteristics of high sound-absorption coefficient and sound-absorption bandwidth. At the same time, it can be made from a variety of materials with advantages of cleanness, no pollution, no environmental restrictions and so on. The micro-perforated plate can not only make up for the defects of sound absorbing material, but also act as the protective layer of sound absorbing material. When acoustic wave is incident on the surface of the composite structure, a parallel helmholtz resonator is formed between the micro-perforated plate and the cavity layer behind the plate. The sound waves continue to transmit to the sound-absorbing material which consumes some of the sound energy through the friction of the material and attenuates it again. According to the characteristics of sound-absorption materials suitable for sound-absorption processing of medium and high frequency noise[13], and the resonance structure of micro-perforated plate suitable for low frequency noise processing, they are combined to form the body structure of sound barrier. As revealed in the figure, the structure of "resonance structure, sound-absorption layer, resonance cavity" is formed. The cavity layer close to the rigid wall is to save sound absorbing material and quell cost without reducing sound absorbing effect.

Firstly, the structural form of the new structure acoustic barrier is proposed, and the acoustic impedance of the new structure acoustic barrier is calculated via the method of acoustoelectric equivalent circui[13,15,17], and the sound- absorption coefficient of the body sound-absorption structure is obtained. The noise reduction formula of sound-absorption variety sound barrier[12-14]is substituted to obtain the sound insulation quantity of the new structure sound barrier. Via changing the sound-absorption structure, sound-absorption coefficient and sound insulation quantity of micro-perforated plate with diverse cavity depth, pore diameter, perforation rate, thickness, sound-absorption material, thickness of sound-absorption material and cavity thickness were compared,so as to research the corresponding relationship.

1 Resonant Sound-Absorption Structure of Micro-perforated Plate, Cavity, Sound Impedance of Sound-Absorption Material

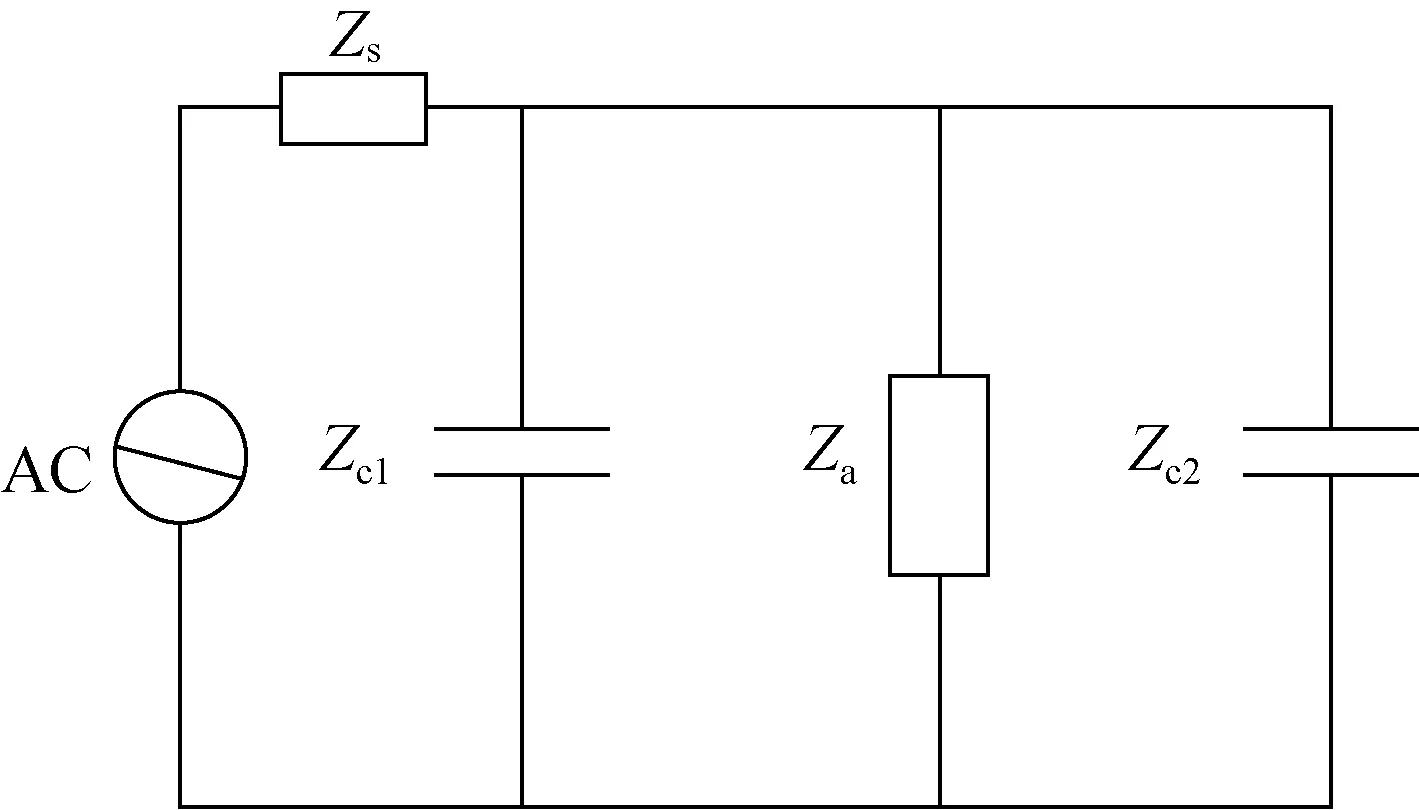

The new composite sound-absorption structure model is revealed in Fig. 1. The first layer is a micro-perforated plate, the second and the fourth layers are cavities, and the third layer is sound-absorption material with rigid walls behind. Its equivalent circuit diagram is revealed in Fig. 2, whereZsis the acoustic impedance of the micro-perforated plate,Zais the acoustic impedance of sound absorbing material, andZc1andZc2are the acoustic impedance of the left and right cavities.

Fig. 2 Equivalent circuit of the structure

The impedance calculation formula of this structure is as follows. The calculation formula of acoustic impedance of micro-perforated plate sound-absorbing structure[13]is

(1)

where,mis the relative sound mass;ris relative acoustic resistance;ωis the angular frequency;Dis the cavity depth;C0is the speed of sound.

In Eq. (1), the relative sound mass and the relative sound resistance are

(2)

(3)

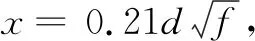

wherehis the thickness of the perforated plate(mm);pmis the perforation rate(%);kris acoustic resistance coefficient, and

kmis the acoustic reactance coefficient, and

The calculation formula of acoustic impedance of sound-absorption material layer[13]is

(4)

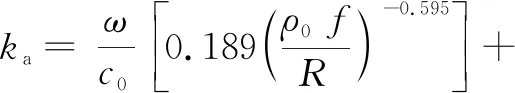

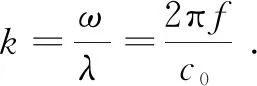

The empirical formulas of sound propagation constant and characteristic impedance of sound absorbing materials are:

(5)

(6)

whereρ0is air density,c0is the air sound velocity,fis the frequency of sound wave,tais the thickness of sound absorbing material, andRis the flow resistance of sound absorbing material.

The calculation formula of acoustic impedance of the cavity layerDis[15]

Zc1=ρ0c0coth(kctc1),

(7)

The formula is for calculating the acoustic impedance of the cavity layer c2 of the rigid wall[15]:

Zc2=-jρ0c0cosh(ktc),

(8)

Then, the calculation formula of total impedance is

(9)

2 Theoretical Calculation of Sound-Absorption Coefficient about Sound Barrier

The acoustic impedanceZof the sound-absorption structure can be obtained from the previous derivation, andZcan be expressed in the form of the relative acoustic resistivity:

Z=ρ0c0(r+jx),

(10)

where,rrepresents the relative acoustic resistance to air;xrepresents the relative acoustic resistance to air; and the obtainedrandxare substituted into the formula for the sound-absorption coefficient of the sound-absorption structure:

(11)

The sound-absorption coefficientαof sound absorbing material under regular incidence can be calculated; And the formula for calculating the sound insulation of the acoustic barrier with infinite length of sound-absorption variety[16,18-19]is substituted:

ΔLp=

(12)

where, the sound-absorption and noise reduction of sound barrier sound-absorption structure is

(13)

whereLiis the sound pressure level before sound-absorption in each frequency band;δ0=A+B-d, is sound path distinction.

3 Numerical Calculation and Experiment

Structure parameters: sound velocityc0=340 m/s, temperature is 20℃, air densityρ0=1.29 kg/m3,d=0.5 mm,t=1.5 mm,pm=1%,d=20 mm,ta=20 mm,tc=20 mm, acoustic path differenceδ0=0.3 m, andR=16 000 N/m4. The porous sound-absorption material is composite rock wool board.

The experimental results of sound-absorption coefficient are measured via a standing-wave tube method, and the structural parameters are revealed in the corresponding table of each item. The experimental data of sound insulation are measured in an echoic chamber.

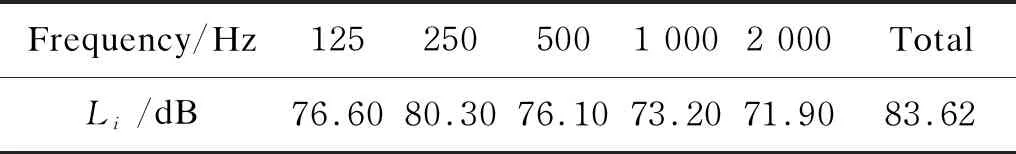

Table 1 Spectral sound level values of urban road noise

The sound-absorption coefficient, sound insulation quantity difference and insertion loss (IL) obtained through MATLAB calculation are revealed in Figs. 1-7.

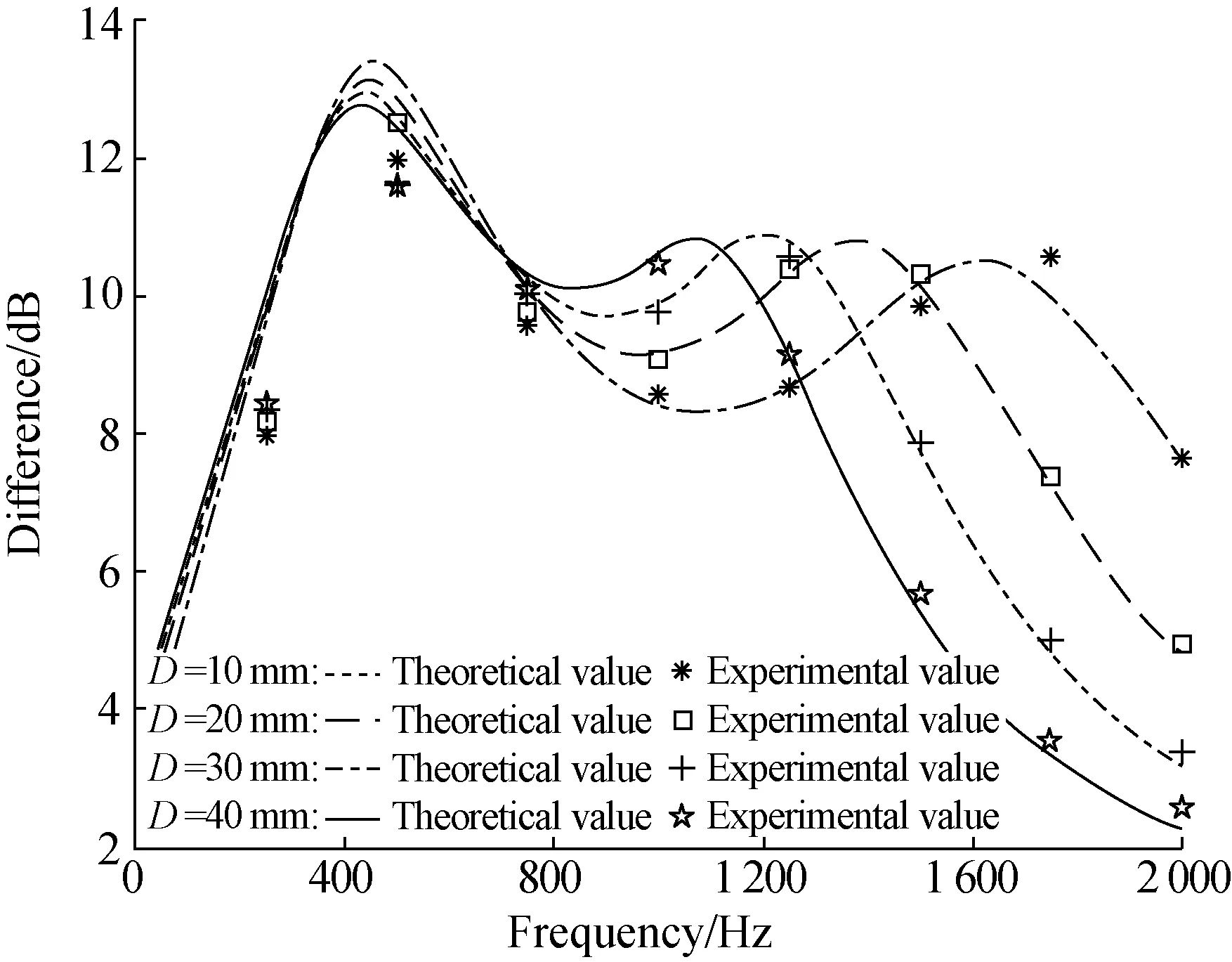

The sound-absorption coefficient of the micro-perforated panel with diverse depths and the distinction of noise reduction between the sound-absorption barrier and the reflective sound barrier are revealed.

3.1 Variation of cavity depths

It can be seen from Fig. 3 and Table 2 that the micro-perforation plate cavity depth increase will not change the maximum absorption coefficient of sound absorbing structure, and the sound-absorption structure on the sound-absorption coefficient of low frequency change is little. The middle and lower frequencies of sound insulation quantity distinction also have no obvious change. For more than 700 Hz frequency band, the larger absorption coefficient covering range, the smaller the distinction of sound insulation quantity cover band is decreased. Road traffic noise is mainly concentrated in the vicinity of 500 Hz, and the change of cavity depth has little impact on the overall sound insulation volume of the sound barrier.

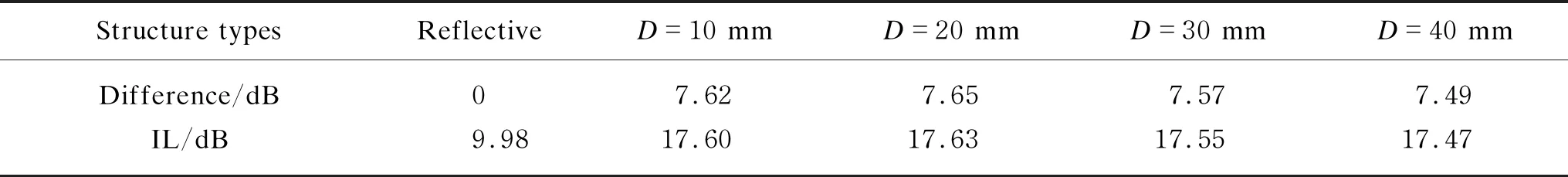

3.2 Variation of apertures

The sound-absorption coefficient of the micro-perforated panel with diverse apertures and the distinction of noise reduction between the sound-absorption barrier and the reflective sound barrier are revealed.

(a) Acoustic absorption coefficients (b) Sound insulation difference

Structure typesReflectiveD=10 mmD=20 mmD=30 mmD=40 mmDifference/dB07.627.657.577.49IL/dB9.9817.6017.6317.5517.47

From Fig. 4 and Table 3, as the pore size of the micro-perforated plate increases, the overall sound-absorption coefficient of the sound-absorption structure becomes smaller, and the corresponding sound barrier sound insulation decreases.

Fig. 4 Micro-perforated plate with diverse apertures

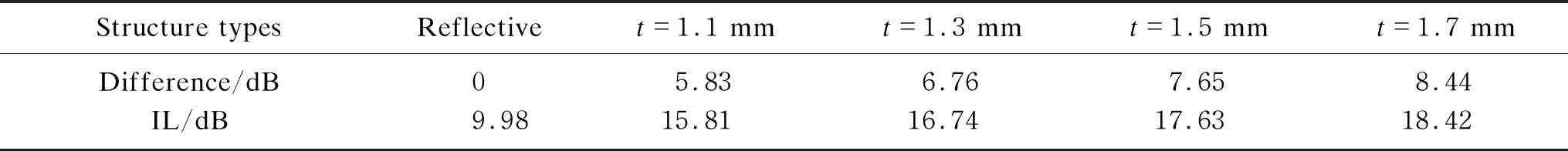

As can be seen from Fig. 5 and Table 4, the greater the thickness of the micro-perforated plate is, the lower the frequency band around 700 Hz will be. The sound-absorption coefficient will gradually increase, and the distinction of the corresponding sound insulation quantity will also increase. For the frequency band above 700 Hz, the sound-absorption coefficient will gradually decrease, and the distinction of the corresponding sound insulation quantity will also gradually decrease. The overall sound insulation volume of the sound barrier increases gradually, mainly because road traffic noise is concentrated around 500 Hz. The contribution of sound insulation volume increase caused by sound-absorption coefficient increase is larger than that caused by sound-absorption coefficient decrease.

Fig. 5 Micro-perforated plate with diverse thicknesses

3.3 Variation of thickness of panel

The sound-absorption coefficient of the micro-perforated panel with diverse thicknesses and the distinction of noise reduction between the sound-absorption barrier and reflective sound barrier are revealed.

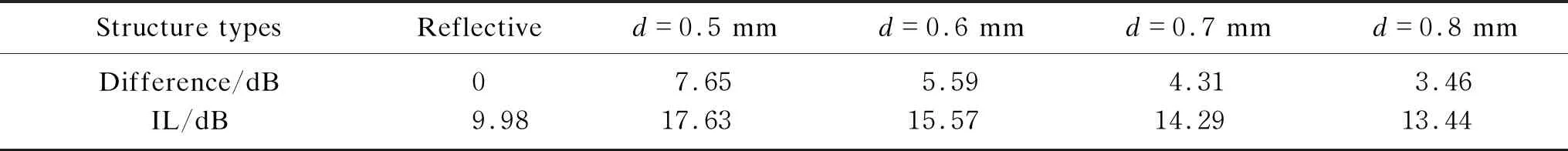

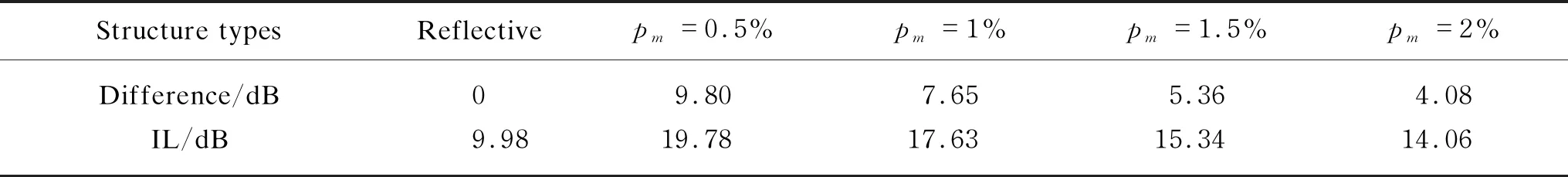

3.4 Variation of perforation rates

The sound-absorption coefficient of the micro-perforated plate with diverse perforation rates and the distinction of noise reduction between the sound-absorption barrier and the reflective sound barrier are revealed.

As can be seen from Fig. 6 and Table 5, the changes in the rate of micro-perforated plate perforation caused by the change of the absorption coefficient and sound insulation quantity resemble the changes caused by the changes of thickness. About the frequency band below 700 Hz, the greater the perforation rate, the smaller sound-absorption coefficient, the larger sound-absorption coefficient in the case of frequency band above 700 Hz. Meanwhile, the contribution of sound insulation caused by the increase of sound-absorption coefficient is smaller than that caused by the decrease of sound insulation coefficient.

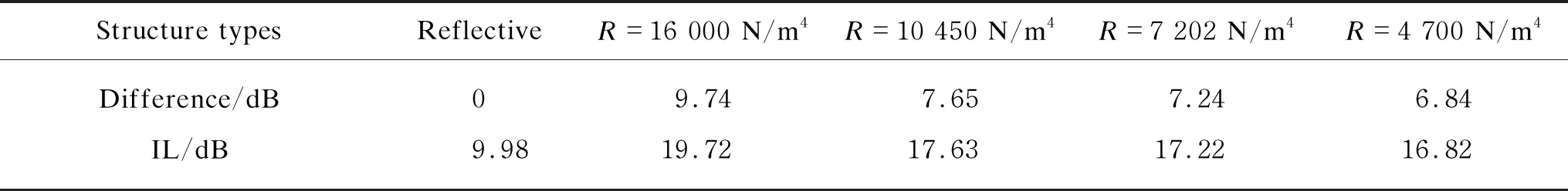

3.5 Variation of sound-absorption material

The distinction between sound-absorption coefficient of diverse sound-absorption materials and noise reduction of the reflective sound barrier is revealed.

As can be seen from Fig. 7 and Table 6, the larger the flow resistance of sound absorbing material is, the larger the sound-absorption coefficient of middle and low frequency band will be, the smaller the sound-absorption coefficient of high frequency band will be, and the sound insulation of the overall sound barrier will gradually increase.

Table 5 Synthetic sound insulation and distinction values of micro-perforated plates with diverse perforation rates

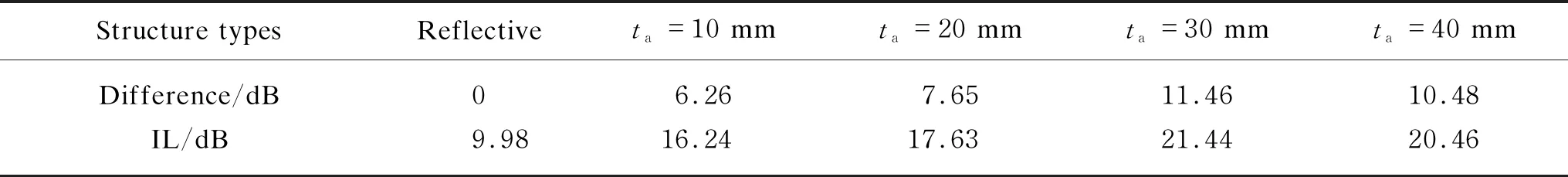

3.6 Variation of thickness of sound-absorption material

The sound-absorption coefficient of the micro-perforated panel with diverse sound-absorption material and the distinction between the sound-absorption barrier and the reflective sound barrier are revealed.

As can be seen from Fig. 8 and Table 7, the smaller the thickness of sound-absorption material is, the more the maximum sound-absorption coefficient of sound-absorption structure will shift to the lower frequency band. The excessive thickness will lead to the reduction of the maximum sound-absorption coefficient, and the corresponding sound insulation of sound barrier will reach the maximum when the material thickness is moderate.

3.7 Variation of thickness of sound-absorption material

The sound-absorption coefficient of the micro-perforated panel with different thicknesses of sound-absorption material and the distinction of noise reduction between the sound-absorption barrier and reflection sound barrier are revealed.

Fig. 6 Micro-perforated plate with diverse perforation rates

Fig. 7 Micro-perforated plate of diverse sound-absorption materials

Fig. 8 Micro-perforated plate of sound-absorption material with diverse thicknesses

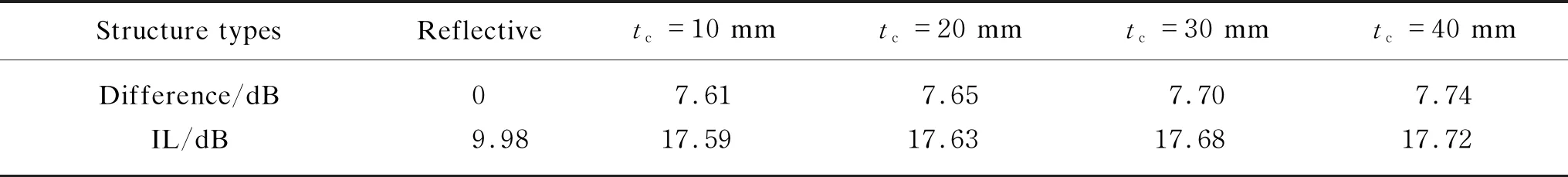

It can be seen from Fig. 9 and Table 8 that the changes in sound-absorption coefficient and sound barrier sound insulation caused by changes in cavity layer thickness are similar to the changes in cavity depth of micro-perforated plate, with almost no influence in the middle and low frequency band. With the increase of cavity thickness, between 800 Hz and 1 500 Hz frequency, absorption coefficient decreases, and the corresponding sound insulation quantity distinction also decreases, and more than 1 500 Hz, high frequency sound-absorption coefficient increases gradually, the corresponding sound insulation quantity distinction increases gradually, mainly because the cavity layer is to save the sound-absorption material, plays a role in replacing the sound-absorption material high-frequency sound-absorption. The contribution of sound insulation volume increase caused by sound-absorption coefficient increase is slightly greater than that caused by sound insulation volume decrease caused by sound-absorption coefficient decrease.

In general, the experimental results display that the difference between the absorption coefficient and the sound insulation capacity is quite consistent with the calculated values. The difference between the sound barrier with different structural parameters and the vertical rigid sound barrier is used to avoid the influence of other interference factors such as side diffraction and sound source.

Fig. 9 Micro-perforated plate of diverse cavity thickness

4 Conclusions

In this paper, a new sound barrier is designed according to the defects of existing reflective sound barrier and the special demand of road traffic noise for sound barrier. With MATLAB for the new ontology structure parameters of highway noise barrier made a detailed comparative analysis, it showed that its sound barrier, sound insulation quantity has large improvement compared with the traditional refleltive sound barrier which improved about 7.65-9.8 dB. Also all parameters which of ontology acoustical absorption and sound barrier of amount of noise spectrum can be abtained. In a word, the parameters of this composite structure can be transformed to cope with various noises and meet the noise reduction requirements of its road. The noise reduction evaluation has tremendous flexibility and adaptability. For example, when the sound barrier thickness is required, the same noise reduction effect can be achieved by transforming other parameters.

For the sound-absorption structure, the resonant structure of micro-perforated plate makes up for the shortcomings that the sound-absorption material can absorb low and medium frequency noise poorly. For the sound insulation of sound barrier, the average sound-absorption coefficient of sound-absorption structure must be paid attention to. The characteristics of road traffic noise should be noted, and a fantasic sound insulation quantity within the frequency band should be provided to optimize the acoustic performance of the sound barrier.

Journal of Donghua University(English Edition)2019年4期

Journal of Donghua University(English Edition)2019年4期

- Journal of Donghua University(English Edition)的其它文章

- Parameter Estimation for Complex Ornstein-Uhlenbeck Processes

- Elastic Predictions of 3D Orthogonal Woven Composites Using Micro/meso-scale Repeated Unit Cell Models

- Tool Health Condition Recognition Method for High Speed Milling of Titanium Alloy Based on Principal Component Analysis (PCA) and Long Short Term Memory (LSTM)

- Upper Bound Solution of Soil Slope Stability under Coupling Effect of Rainfall and Earthquake

- Exploring the Performance of Magnetic Immobilized Lysozyme on Sludge Hydrolysis and Mechanism of Improving Dewaterability of Excess Sludge

- Mesoporous ZSM-5 Crystals Synthesized by a Novel Amphiphilic Organosilane Soft Template