Analysis of Wastewater Membrane Pollutants in Joint Station and Research on Biological Control Technology

WANG Zhijian; PAN Yongqiang; YU Dandan; CHEN Chao; ZHANG Naifeng

[a] Xinjiang Xinchun Petroleum Development Co., Ltd, Sinopec,Dongying,China.

[b] Shengli Oilfield Petroleum Engineering Technology Research Institute, SINOPEC, Dongying, China.

[c] Steam Injection Technology Service Center,SINOPEC, Dongying,China.

Abstract In view of the serious membrane pollution and short stable operation period of the existing heavy oil wastewater treatment process in a combined station of an oil field, the organic pollution is determined to be the main cause of the membrane pollution on the basis of the analysis of the wastewater quality and membrane pollutants. In view of the characteristic pollutants in heavy oil wastewater, the efficient degrading bacteria were screened by restrictive culture technology, and the strains were identified as Pseudomonas and Bacillus. The effects of environmental conditions on the growth of bacteria and the degradation of heavy oil by bacteria were investigated. In the existing process, biological treatment unit was added, simulation process was established, and long-term operation experiment was carried out. The results show that after biological treatment, the oil content of wastewater is less than 1 mg/L, COD is less than 100 mg/L, suspended matter is less than 1 mg/L, and the median particle size is 0.92 um, which is better than the first kind of water injection index (SY/T 5329-2012). Biological treatment effectively degraded organic pollutants in heavy oil wastewater and delayed membrane fouling. The loss rate of membrane flux was less than 15%. The microscopic morphology of membrane surface also showed that membrane fouling was effectively suppressed.

Key words: Membrane fouling; Heavy oil degrading bacteria; Biological treatment; Membrane flux

Low permeability oilfields require strict injection water quality and need fine treatment. Because of the difficulty of heavy oil wastewater treatment and the imperfection of front-end deoiling process, the quality of fine filtration effluent is not up to the standard, and the suspended solid content is more than 5 mg/L, which is much higher than the 1.0 mg/L required for water injection in low permeability oilfields. At the same time, the stable operation period of the process is short, and the fine filter components need to be replaced once in 1-2 years.Therefore, on the basis of biological and chemical analysis of heavy oil wastewater, the main reasons for fouling blockage of fine filtration membrane were identified; the effective removal of organic pollutants such as petroleum in wastewater was realized by screening and constructing high-efficient degrading bacteria group for membrane pollutants, and the impact on subsequent fine filtration treatment facilities was fundamentally solved; finally,a set of fine filtration treatment facilities was formed.The biochemical/fine treatment process suitable for the characteristics of heavy oil wastewater lays a foundation for the low permeability and up-to-standard reinjection of oilfield wastewater

1. EXPERIMENTAL MATERIALS AND METHODS

1.1 Experimental Materials

1.1.1 Testing Drugs

Petroleum ether, n-heptane, toluene; potassium dihydrogen phosphate, potassium dihydrogen phosphate,sodium chloride, magnesium chloride hexahydrate,ammonium sulfate, zinc sulfate heptahydrate, ferrous sulfate heptahydrate, calcium chloride, manganese sulfate,agar, phenanthrene, cyclohexane, hexadecane.

1.1.2 Equipment

Quantitative filter paper, glycerol bath, extraction device,vacuum drying box, Carry 50 ultraviolet spectrophotometer,analytical balance, XRD diffraction instrument. E14130 electronic balance, HZQ-X100 oscillation incubator,HZS-H water bath oscillator, WH-Z micro-eddy mixer,vertical pressure steam sterilizer, SMZ1500 anatomical mirror, deionized water meter, VS-840-KU clean table,pHS-3C precise pH meter, BX50 microscope.

1.1.3 Test Sample

The experimental water is taken from the oil-water separation effluent of the existing treatment process of a combined station, and the experimental oil is taken from the dehydrated crude oil transported from the combined station.

1.2 Experimental Method

1.2.1 Membrane Pollutant Analysis Method

One of the membrane contaminants was analyzed by energy spectrum and the other was weighed and distilled in glycerol bath. Then the solid phase was dried in vacuum.The residual was dissolved and refluxed with n-heptane to determine the soluble substances. Residual insoluble matter is extracted by toluene and refluxed to determine asphaltene content. The final insoluble solids were analyzed by XRD.

1.2.2 Screening Methods of Bacteria

In the screening process of petroleum hydrocarbon degrading bacteria, the target microorganisms needed were screened according to the steps of separation,primary screening and re-screening in accordance with comprehensive, efficient and strict criteria. Samples were added to the enrichment medium and cultured in a shaker at 40 and 140 rpm for 7 days. After the culture medium was turbid, 2 mL culture medium was absorbed and re-transferred into fresh culture medium. The culture conditions were the same as those mentioned above,and then transferred and enriched for three times. 2 mL enriched medium was absorbed and inoculated into different selective medium for bacterial isolation.

(1) Liquid medium for enrichment:

KH2PO40.5g,K2HPO4·3H2O 0.5g,MgCl2·6H2O 0.3g,(NH4)2SO41g,trace element solution10 mL,combined station sewage 1000mL,crude oil 5g,pH=7.5.

(2) The isolation medium was liquid inorganic salt medium with 1.5% agar for enrichment.

(3) Screening medium for bacteria degrading direct alkanes or naphthenes:

KH2PO4 0.5 g,K2HPO4·3H2O 0.5 g,MgCl2·6H2O 0.3 g,(NH4)2SO4 1 g,trace element solution 10 mL,NaCl 5 g,distilled water 1000 mL,pH=7.5-8.0,N-hexadecane or n-hexane is the only carbon source.

Trace element solution:ZnSO4·7H2O 0.2 g,FeSO4·7H2O 0.5 g,CaCl2 3 g ,MnSO4·H2O 0.06 g,distilled water 1000 mL.

(4) Screening medium for aromatic hydrocarbon degrading bacteria:

KH2PO4 0.5 g,K2HPO4·3H2O 0.5 g,MgCl2·6H2O 0.3 g,(NH4)2SO4 1 g,trace element solution 10 mL,NaCl 5 g,distilled water 1000 mL,pH=7.5-8.0,Phenanthrene is the only carbon source.

trace element solution:H3BO3 0.057 g,(NH4)6Mo7O24·4H2O 0.037 g,MnSO4·7H2O 0.043 g,ZnSO4·7H2O 0.043 g,CuSO4·5H2O 0.04 g,Co(NO3)2·6H2O 0.025 g,distilled water 1000 mL。

(5) Screening medium for asphalt degrading bacteria:

KH2PO4 0.5 g,K2HPO4·3H2O 0.5 g,MgCl2·6H2O 0.3 g,(NH4)2SO4 1 g,NaCl 5 g,Trace element solution 10 mL (same (4) trace element solution), distilled water 1000 mL, pH=7.5-8.0, chloroform asphalt as the only carbon source.

(6) General medium:

Glucose 3g, peptone 3g, yeast powder 3g KH2PO4 0.5 g,K2HPO4·3H2O 0.5 g,MgCl2·6H2O 0.3 g,(NH4)2SO4 1g,NaCl 5 g,蒸馏水1000 mL,pH=7.5-8.0.

Trace element solution:ZnSO4·7H2O 0.2g,FeSO4·7H2O 0.5g,CaCl2 3g ,MnSO4·H2O 0.06g,distilled water 1000 mL.

1.2.3 Identification of Bacteria

At present, 16S rDNA sequence analysis is mainly used to identify bacteria. The steps are as follows:

(1) Extraction of bacterial DNA

The extraction of bacterial DNA was carried out according to the instructions of TIANGEN’s bacterial genomic DNA extraction kit.

(2) PCR amplification of 16SrDNA gene

Primers amplified by PCR:

27f: Forward primer 5,AGAGTTTGATCMTGGCTCAG3.

1492r: Reverse primer 5,GGCTACCTTGTTACGACTT3.

In 25 L reaction volume, 1 L template DNA, 0.5 L 27 F and 0.5 L 1492r (final concentration is 0.4 L), 2 L dNTP(final concentration is 0.2 mM for each NTP), 2 L MgCl2(final concentration is 2 mM), 2.5 L 10 * PCR buffer and 0.2 LTaq polymerase (5U) were added. The conditions of PCR amplification were 94 5 min, 94 30 S, 61 - 65 30 S,72 1 min, 30 cycles, and the last 72 10 min.

After electrophoresis with agarose gel, the gel was cut off under ultraviolet lamp. The gel was added to the centrifuge tube, and then sterilized MILLIPORE water 20 L,placed at 24 h in 4 degree refrigerator. Re-press the above step of PCR and send the product out for sequencing.

1.2.4 Analysis of Degradation Characteristics of Heavy Oil by Bacteria

5% of the selected bacteria were inoculated into the medium containing 2% of the dehydrated crude oil from the combined station and placed in a shaking incubator at 37 C for 7 days. The residual oil was extracted and the group composition was analyzed by alumina adsorption column chromatography.

2. RESULTS AND DISCUSSION

2.1 Cause Analysis of Membrane Pollution

The existing sewage treatment process of the combined station is: oil-water separation-sewage modificationflocculation sedimentation-multi-media filtrationsterilization, corrosion inhibition, scale inhibitionmembrane filtration-reinjection of low permeability oilfields. At present, there are some problems, such as the fast attenuation of membrane flux, the fast replacement frequency of membrane formation and the unsatisfactory quality of effluent.

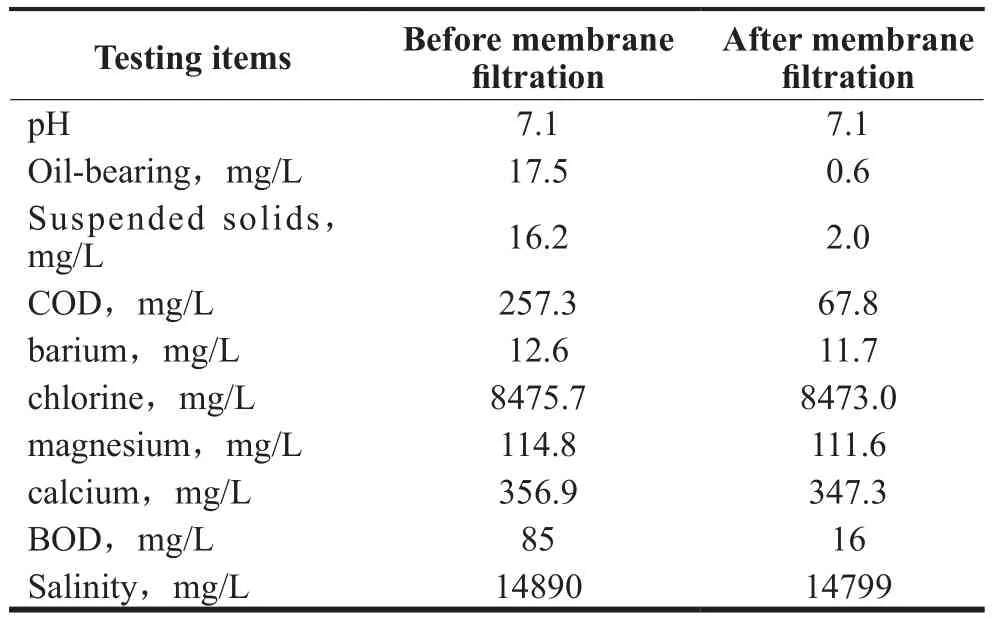

2.1.1 Water Quality Analysis

From the analysis of water quality before and after membrane filtration, it can be seen that the oil content and COD in the influent of membrane filtration are higher,most pollutants are adsorbed on the surface of membrane,blocking the membrane pore, causing a rapid decline in membrane flux, shortening the cleaning cycle and the life of membrane. At the same time, because the B/C of membrane water is 0.33, the accumulation of pollutants on the membrane surface causes bacterial growth, bacterial metabolism produces extracellular polymers, which aggravates membrane fouling. There are scaling ions and inorganic contamination in sewage. See Table 1.

Table 1 Water Quality Analysis Before and After Membrane Filtration

2.1.2 Observation on the Micromorphology of Polluted Membrane Surface

Scanning electron microscopy (SEM) showed that a large number of pollutants were accumulated on the surface of the membrane, and the surface was dense, and the main phase was organic pollution. At the same time,we can see the interlaced stretching of cords, which is due to the growth of viscous extracellular polymers by bacteria on the membrane surface. These macromolecules containing active groups interact with petroleum and inorganic scaling ions to form a contaminated layer on the membrane surface, as shown in Figure 1.

Figure 1 Scanning electron microscope of contaminated membrane

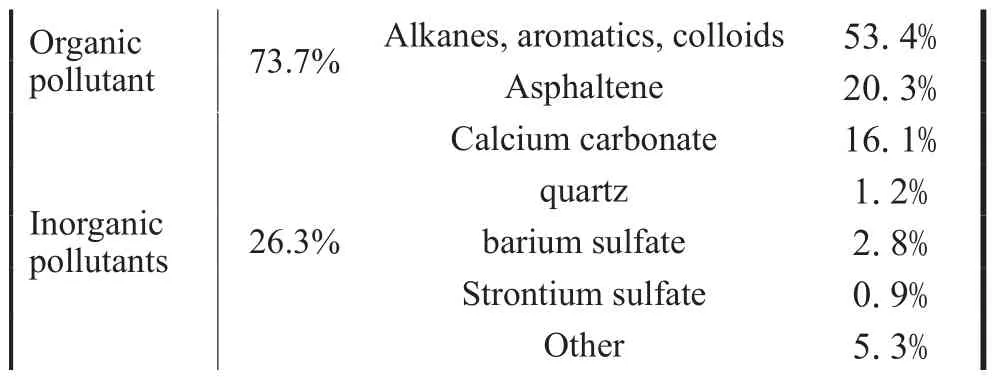

2.1.3 Component Analysis of Pollutants

Energy spectrum analysis showed that the main elements of membrane pollutants were carbon and oxygen,accounting for more than 85% of the elements, and there were also calcium, sulfur, barium, silicon and other elements. The results of specific component analysis of pollutants are shown in Table 2. It can be seen that organic pollution is the main cause of membrane fouling.The main reason is that the removal efficiency of organic pollutants in sewage by flocculation and sedimentation,multi-media filtration and other processes is not high,resulting in the adsorption of pollutants on the membrane surface, resulting in membrane fouling blockage.Although the content of inorganic pollutants is not high,inorganic ions form insoluble inorganic salts and deposit on the membrane surface, accelerating pollution.

Table 2 Composition Analysis of Membrane Pollutants (mass fraction)

2.2 Breeding of High-Efficient Degrading Bacteria and Their Degradation Characteristics for Heavy Oil

2.2.1 Breeding of Highly Degrading Bacteria

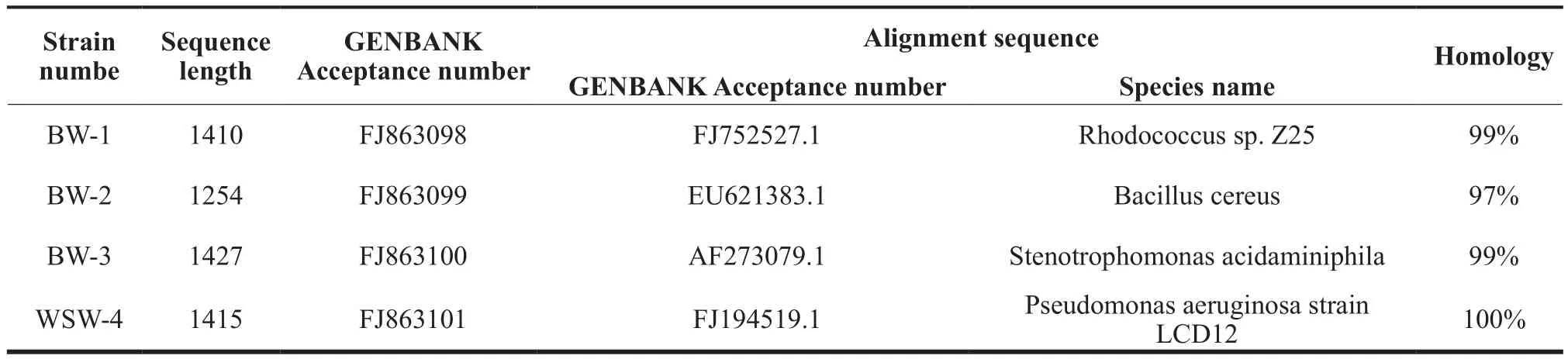

Eight strains of heavy oil degrading bacteria were screened by selective culture technology. Three dominant strains BW-1, BW-2 and BW-3 with good growth and stable characteristics were selected. Another strain WSW-4 with high degrading efficiency was selected from the unit strain bank for bacterial flora construction.Preliminary identification showed that BW-1 and BW-3 were Pseudomonas, BW-2 and WSW-4 were Bacillus(Pan, et al., 2016). The results of 16S rDNA sequence comparison of four strains are shown in Table 3.

Table 3 Comparison of 16S rDNA Sequences of Pure Bacteria by BLAST

2.2.2 Effects of Environmental Conditions on the Growth of Strains

The degradation rate of organic matter in sewage by bacteria was affected by temperature, dissolved oxygen and pH. The growth of mixed bacteria at different temperatures, dissolved oxygen and pH was investigated.

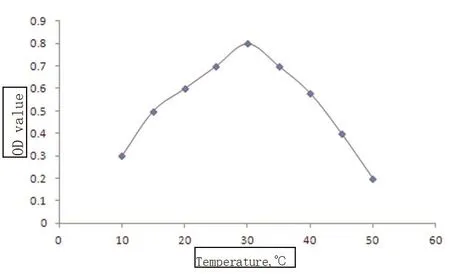

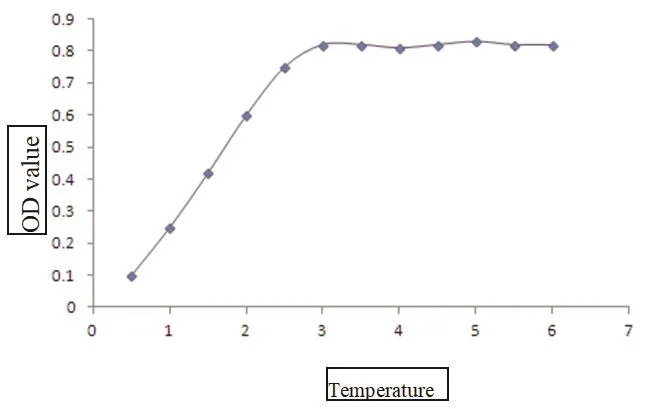

(1) The effect of temperature

Temperature is one of the most important factors affecting microbial growth. The effects of temperature on microorganisms are as follows: affecting enzyme activity, temperature change affecting enzymatic reaction rate, ultimately affecting cell synthesis; affecting cell membrane fluidity, high temperature fluidity, conducive to material transport. Therefore, temperature changes affect the absorption and metabolism of nutrients, and then affect the growth rate.

For the selected mixed bacteria group, the OD value(optical density) of 8 h growth at different temperatures was measured to evaluate the effect of temperature on their growth. The results are shown in Figure 2.

Figure 2 8h OD value of bacteria at different temperatures

From the above table, it can be seen that the bacterial density reaches a high level after 8 hours of bacterial growth at 20-40 C. Therefore, the suitable growth temperature of this group is 20 - 40 C, belonging to the normal temperature group.

(2) Effect of dissolved oxygen

Because the selected bacteria group is aerobic microorganism, the amount of oxygen is very important to its growth. The low dissolved oxygen inhibits the aerobic biochemical reaction, and the activity of bacteria becomes worse. The high dissolved oxygen has no effect on the degradation activity of bacteria, but it will cause the waste of kinetic energy. The effect of dissolved oxygen on bacterial growth is shown in Figure 3.

From the Figure 3 different dissolved oxygen conditions, bacterial growth, bacterial density with the increase of dissolved oxygen level, showing a rapid rise first, then tends to stabilize the law. When dissolved oxygen reaches more than 3 mg/L, the increase of dissolved oxygen has no obvious effect on the increase of bacterial density. Therefore, the optimum dissolved oxygen for the growth of this group is 3 mg/L.

Figure 3 Bacterial growth under different dissolved oxygen

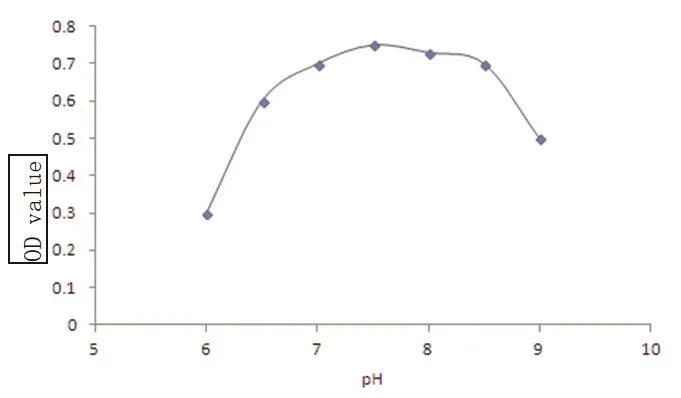

(3) The influence of pH value

PH value is an important factor affecting the growth of strains and COD degradation. Appropriate pH value can not only promote the growth of microorganisms, but also better degrade organic matter. The effect of pH on bacterial growth is shown in Figure 4.

Figure 4 Effect of pH value on bacterial growth

According to the above test results, the optimum pH of the degrading bacteria group was 7-8.5.

2.2.3 Degradation of Heavy Oil by Microflora

The changes of heavy oil group composition after microbial action are shown in Table 4. It can be seen that the relative content of saturated hydrocarbon and aromatic hydrocarbon decreases, while the content of nonhydrocarbon and asphaltene increases. This is due to the selective consumption of different components in crude oil by bacteria, resulting in changes in the composition of group components.

Table 4 Changes in Relative Content of Heavy Oil Group Components Before and After Bacterial Degradation (%)

2.3 Inhibitory Effect of Biological Treatment on Membrane Fouling

The biological treatment unit (Du, et al., 2012)was added after the existing treatment process of oil-water separation-sewage modification-flocculation sedimentation-multi-media filtration-sterilization,corrosion and scale inhibition-fine filtration-reinjection in the combined station, and an experimental process with a treatment scale of 1 m3/d was established. See Figure 5,the inhibition effect of biological treatment on membrane fouling was evaluated.

Biochemical process access bacteria: BW-1, BW-2,

Figure 5 1m3/d pilot flow of combined station

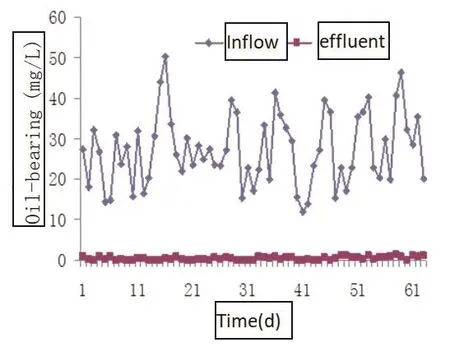

2.3.1 Effect of Biological Treatment on Sewage Treatment

After the establishment of biochemical system, the removal effect of oil content, COD and suspended matter in sewage is shown in figs. 6, 7 and 8. After treatment,the oil content in sewage is less than 1 mg/L, COD is less than 100 mg/L, suspended matter is less than 1 mg/L,the median particle size is 0.92 um, and the particle size distribution is shown in Figure 9. It can be seen from the figure that the process has a good removal effect on oil,COD and suspended solids in sewage. This is because the growth and reproduction of bacterial flora form microbial flora mainly composed of microbial micelles. The crude oil and other pollutants in sewage can be captured by biological coagulation and adsorption, so that the water quality can be purified. The suspended matter can be controlled by membrane unit less than 1 mg/L, so that the effluent meets the first water standard.

Figure 6 Removal of oil by biological treatment

Figure 7 Removal of COD by biological treatment

Figure 8 Removal of suspended solids by biological treatment

Figure 9 Distribution chart of suspended particle size

2.3.2 Stable Change of Membrane Flux

Membrane fouling can lead to rapid attenuation of membrane flux, so membrane flux is the main parameter to investigate the effect of pretreatment. The effects of biological treatment units on membrane flux and periodic backwashing on membrane permeation flux were investigated experimentally. As can be seen from Figure 10, with the addition of biological treatment units, the flux decline rate of each cycle is slowed down, and the flux loss is less than 15%. The recovery effect of hydraulic backwash flux is obviously improved, and the biological treatment can keep the membrane running steadily for a long time. This is because biological treatment removes petroleum and other pollutants which lead to membrane fouling, slows down the adsorption of pollutants on the membrane surface, and removes the substrate which can be used biologically in sewage, eliminating the biological pollution on the membrane surface.

Figure 10 The effect of biological treatment on membrane flux

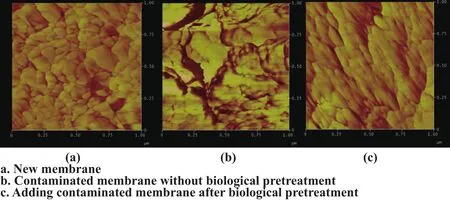

2.3.3 Micromorphological analysis of Membrane Surface

Dismantling the membrane module, atomic force microscopy was used to observe the surface of the new membrane, the contaminated membrane without biological pretreatment and the contaminated membrane with increased biological pretreatment, and roughness and contact angle were measured. See Figure 11 and Table 6.

It can be seen that the fouled membrane separation layer without biological pretreatment adheres to a large number of pollutants, and aggregates into clusters, fouling and plugging the membrane pore. The surface roughness of the membrane increases from 10.786 to 36.512. With the increase of biological pretreatment, the membrane fouling decreases significantly, and the surface roughness rises to 19.238. This is because biological pretreatment removes most of the petroleum and other pollutants in sewage and slows down membrane fouling. Membrane contact angle measurements also showed that the contact angle of contaminated membranes without biological pretreatment increased significantly because hydrophobic petroleum and other organic pollutants adhered to the membrane surface, resulting in the weakening of hydrophilicity of the membrane and the decrease of membrane flux.

Figure 11 Micromorphology of membrane surface

Table 6Comparison of Surface Roughness and Contact Angle

CONCLUSION

(1) The analysis of water quality, microscopic morphology of membrane surface and pollutant composition in the existing process of the combined station determined that organic pollution was the main cause of membrane pollution. At the same time, the accumulation of biologically available organic pollutants on the membrane surface caused bacterial growth and aggravated membrane pollution by viscous extracellular polymers.

(2) In view of the characteristic pollutants in heavy oil wastewater, four strains of highly efficient degrading bacteria were screened by restrictive culture technology and identified as Pseudomonas and Bacillus. Bacteria can degrade saturated hydrocarbons and aromatics in heavy oil wastewater.

(3) Adding biological treatment units to the existing treatment process can effectively inhibit membrane fouling, and the membrane flux is stable for a long time.This is because biological treatment removes pollutants such as petroleum, which lead to membrane fouling,slows down the adsorption of pollutants on the membrane surface, while biological treatment removes the substrate which can be used biologically in sewage and eliminates the biological fouling on the membrane surface.

Advances in Petroleum Exploration and Development2019年1期

Advances in Petroleum Exploration and Development2019年1期

- Advances in Petroleum Exploration and Development的其它文章

- The Natural Gas Composition is Key in Hydrate Formation

- Performance of Combined Process of Air Flotation- Sedimentation- Biological Contact Oxidation - Membrane Biological Reactor Treating Heavy Oil Wastewater

- Water Content of Sweet Natural Gas: A Simplified Formula-Based Approach

- Study and Application of Diagnosis Curves of Water Channeling Patterns for Horizontal Well in Bottom-Water Heavy Oil Reservoir

- Performance Evaluation of a Biomaterial in an Aqueous-Based Drilling Mud at High Pressure High Temperature

- Research on Sesmic Attribute Reservoir Prediction Method: Taking the Shang Block 2 of Sanzhao Sag as an Example