基于三维扫描的织物悬垂形态分析

王鹏程 李永贵 刘基宏

摘要: 为了从三维尺度上分析织物悬垂形态,文章选取了27块不同悬垂风格织物,将三维扫描仪采集的织物悬垂体点云数据作为研究对象,预处理后沿着模型Y轴方向等距离截取得到多条悬垂轮廓曲线,经椭圆傅里叶描述后,建立起具有多层悬垂特征曲线的椭圆傅里叶拟合悬垂模型,然后对所构建的悬垂模型进行主成分和模糊C均值聚类分析。实验结果表明,该方法可有效地将不同悬垂形态织物分为3类,且各类之间界限清晰;通过对比分析3类悬垂形态特点,描述了各类悬垂形态在褶皱线条、波数和波形形状的差异。

关键词: 三维扫描;悬垂形态;椭圆傅里叶描述;主成分分析;模糊C均值聚类

中图分类号: TS101.923.1 文献标志码: A 文章编号: 1001-7003(2019)05-0034-06 引用页码: 051106

Abstract: In order to analyze fabric drape form in 3D scale, 27 fabrics with different drape styles were selected, and point cloud data of fabric drape collected by 3D scanner were taken as the research object. After preprocessing, several vertical contour curves were obtained by intercepting along the Y axis of the model at equal distance. After elliptical Fourier description, an elliptical Fourier fitting drape model with multilayer drape characteristic curves was established. Then, the principal component analysis and fuzzy C-means clustering analysis were carried out for the drape model. The experimental results showed that this method could effectively classify different kinds of drape fabrics into three categories, and the boundary between them was clear. By comparing and analyzing the characteristics of three kinds of drape forms, the differences in fabric folds, the number of waves and the form of the waveform were described.

Key words: 3D scanning; fabric drape form; elliptic Fourier description; principal component analysis; fuzzy C-mean clustering

織物悬垂形态是织物因自重下垂而形成圆滑流畅的曲面形态,是影响服装造型美感的一项重要指标[1]。在主观悬垂评定中,不单考虑织物下垂后的遮光面积同时还需考虑悬垂后的整体形态[2]。目前,对织物悬垂形态的客观测量多是采用伞式投影法[3-5],该方法是在悬垂体俯视投影轮廓的基础上计算出相应的二维悬垂指标,但具有不同三维悬垂形态的织物通常也会形成相同的投影形状。因此,仅通过俯视投影是无法表现织物悬垂的三维特性,同时通过投影降维也丢失了大量的悬垂形态信息。

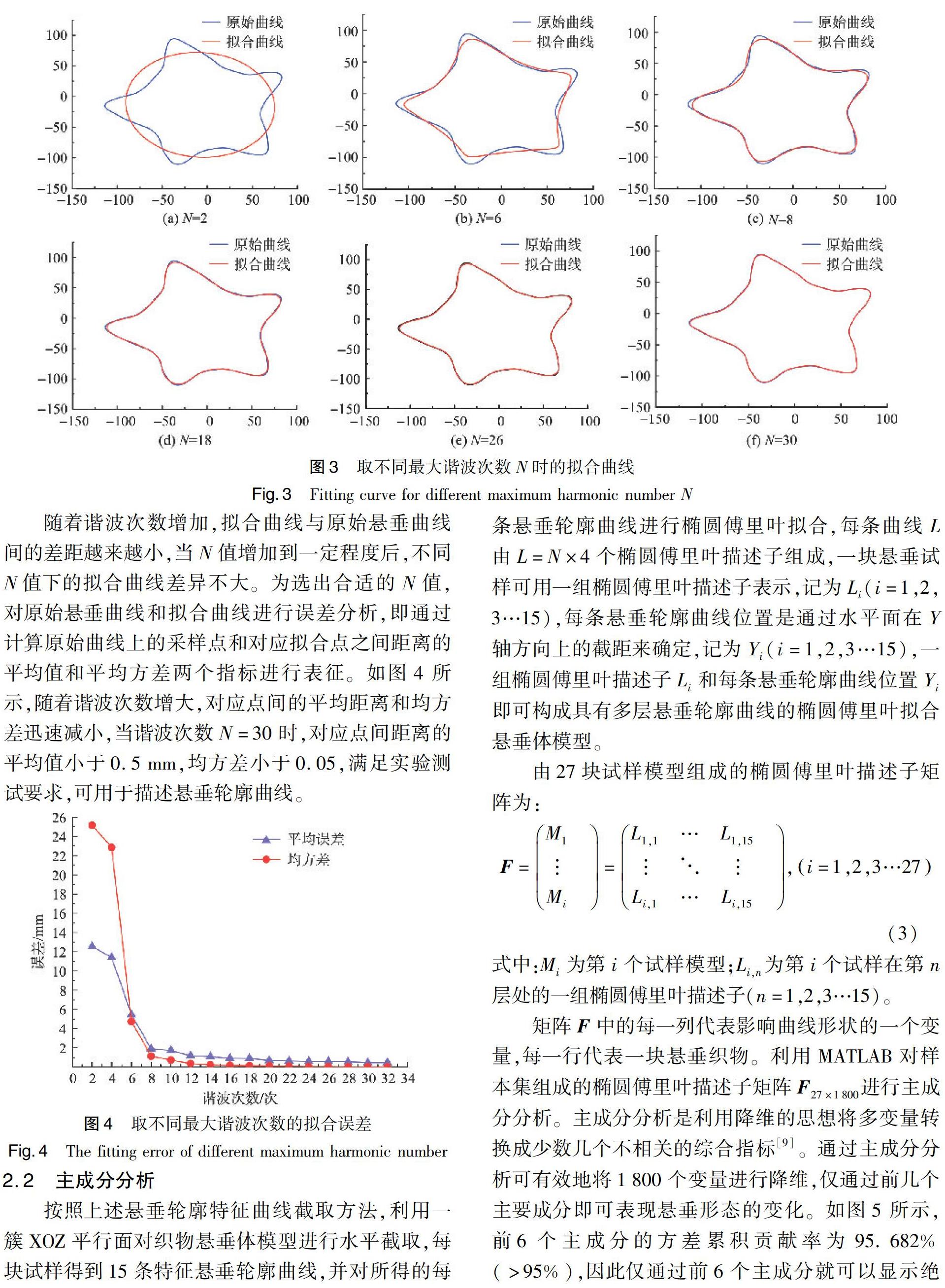

为了能更好、更全面地评价织物悬垂性,本文利用非接触式三维扫描仪采集织物悬垂体表面数据,经过点云去噪、曲面修补、摆正模型坐标等预处理后,利用一簇XOZ水平面等间距截取悬垂体,得到多条特征悬垂轮廓曲线,并对多条特征悬垂轮廓曲线进行椭圆傅里叶拟合,然后建立具有多层特征曲线的椭圆傅里叶拟合悬垂体模型。通过对拟合模型进行主成分分析和模糊C均值聚类分析,可有效地将不同悬垂形态织物进行划分,为服装设计中面料的选择提供理论依据。1 实 验

1.1 试样准备

选取27块市面销售的不同悬垂风格面料,各块织物的规格如表1所示。根据GB/T23329—2009《纺织品 织物悬垂性的测定》将测试面料裁剪成直径为24cm圆形试样,开始实验前,按照GB/T6529—2008《纺织品 调湿和试验用标准大气》对所有测试试样进行预调湿处理。

1.2 数据采集与预处理

实验设备为先临三维公司生产的Einscan-s非接触式三维扫描仪,采用两个130万分辨率摄像头和一个白光光栅投影装置作为扫描单元。基于三维扫描仪自行搭建织物悬垂形态数据采集平台[6],该测试平台可在3min内完成一块织物的数据采集。

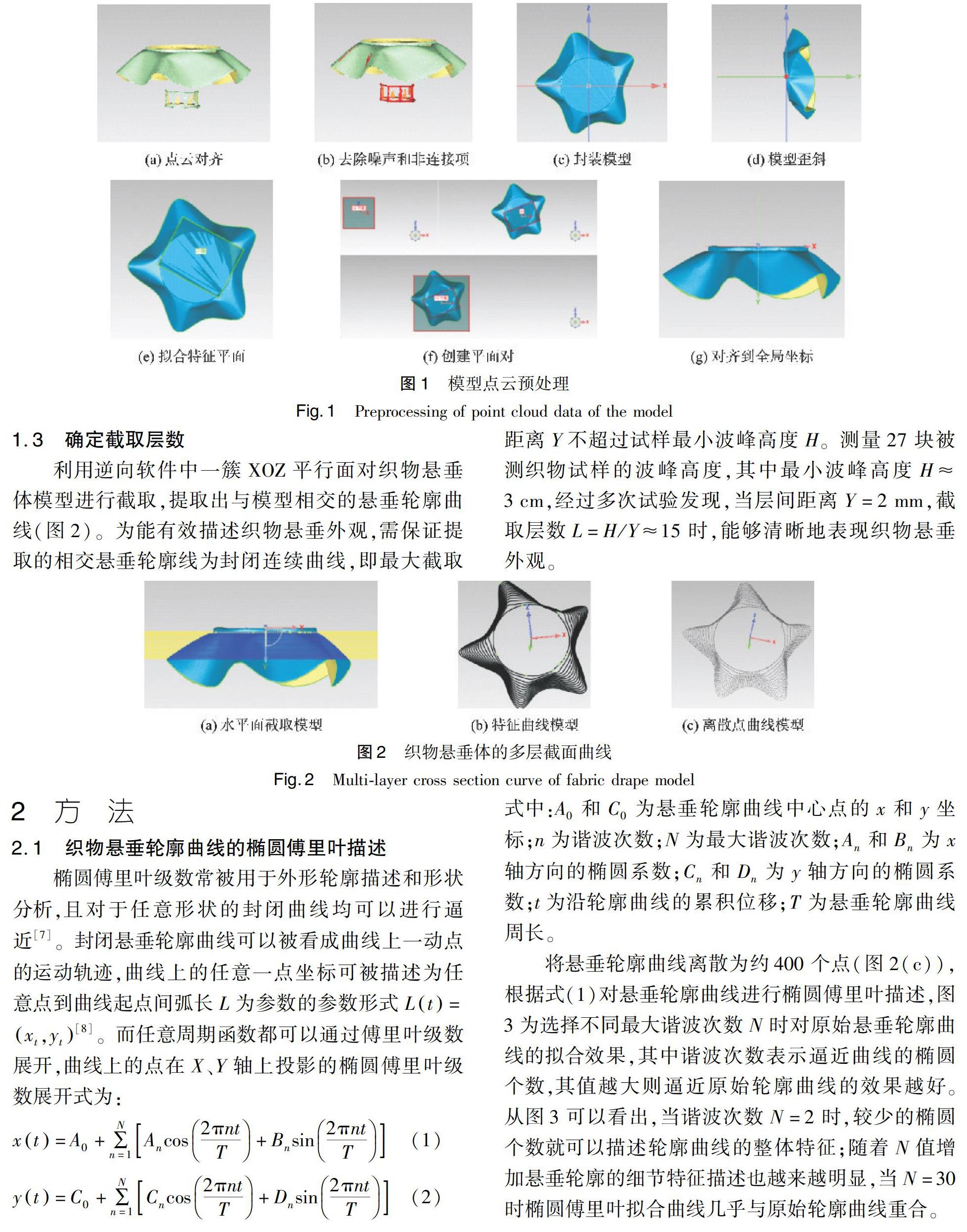

一个完整的织物悬垂体点云数据是由多块不同视角下的点云数据组成,因此需要先将多块点云数据进行全局对齐。扫描过程中除了被测物体的点云数据外,不可避免地存在噪声和采集到其他物体的点云信息,有必要对模型进行点云去噪、优化处理。由于织物悬垂测试平台难以保证绝对水平,经扫描导入Geomagic后,悬垂体点云数据不能很好地与逆向软件坐标系对齐,因此利用特征平面命令,以支撑圆盘面为基面拟合基准平面,并建立基准平面与坐标平面间的对应关系来摆正悬垂模型(图1),为下一步精确截取悬垂体做准备。

参考文献:

[1]韩剑虹, 周衡书, 武世锋, 等. 基于三维人体形态的织物立体悬垂测试方法与表征[J]. 纺织学报, 2018,39(1): 39-44.

HAN Jianhong, ZHOU Hengshu, WU Shifeng, et al. Test method and characterization of 3-D drape for fabrics based on human body form[J]. Journal of Textile Research, 2018,39(1): 39-44.

[2]纪峰, 李汝勤, 郭永平, 等. 织物悬垂性研究的追踪与展望[J]. 纺织学报, 2003(1): 72-74.

JI Feng, LI Ruqin, GUO Yongping, et al. The past and future of fabric drapability [J]. Journal of Textile Research, 2003(1): 72-74.

[3]云畅, 张辉. CLO3D下的经纬异性织物悬垂性模拟研究[J]. 北京服装学院学报(自然科学版), 2017,37(2): 33-39.

YUN Chang, ZHANG Hui. Study on draping simulation of the fabric with difference in warp and weft in CLO3D [J]. Journal of Beijing Institute of Clothing Technology(Natural Science Edition), 2017,37(2): 33-39.

[4]黄新林, 李汝勤. 织物悬垂性图像测试方法[J]. 纺织学报, 2006, 27(11): 14-17.

HUANG Xinlin, LI Ruqin. Image test method for fabric drape[J]. Journal of Textile Research, 2006, 27(11): 14-17.

[5]戴济晏, 徐伯俊, 张洪,等. 粘胶仿真丝织物的服用性能测试与分析[J]. 丝绸, 2017, 54(1): 9-14.

DAI Jiyan, XU Bojun, ZHANG Hong, et al. Wearability test and analysis of viscose silk-like fabric [J]. Journal of Silk, 2017, 54(1): 9-14.

[6]王鹏程, 刘基宏. 基于3D扫描技术的织物悬垂性测试方法[J]. 丝绸, 2018, 55(6): 25-30.

WANG Pengcheng, LIU Jihong. Method of fabric drape test based on 3D scanning technology [J]. Journal of Silk, 2018, 55(6): 25-30.

[7]夏凤勤, 毋戈, 谢昊洋, 等. 基于人体纵截面特征曲线的体型分类[J]. 纺织学报, 2017, 38(6): 86-91.

XIA Fengqin, WU Ge, XIE Haoyang, et al. Classification of body shape based on longitudinal section curve [J]. Journal of Textile Research, 2017, 38(6): 86-91.

[8]夏明, 陈益松, 张文斌. 基于椭圆傅里叶的人体胸围断面形状研究[J]. 纺织学报, 2014, 35(7): 107-112.

XIA Ming, CHEN Yisong, ZHANG Wenbin. Shape analysis of bust slice using elliptic fourier [J]. Journal of Textile Research, 2014, 35(7): 107-112.

[9]苟捷, 刘建立, 高卫东. 应用主成分分析的原棉可纺性指数构建[J]. 纺织学报, 2015, 36(8): 16-21.

GOU Jie, LIU Jianli, GAO Weidong. Construction of raw cotton spinnability index based on principal component analysis [J]. Journal of Textile Research, 2015, 36(8): 16-21.

[10]楊晓波. 基于模糊C均值聚类的织物平整度等级评定[J]. 计算机应用与软件, 2006,23(9): 43-44.

YANG Xiaobo. Fabric wrinkle grade assessment based on fuzzy cmedian cluster [J]. Computer Applications and Software, 2006,23(9): 43-44.