Tin-based metal bath heat treatment:an efficient and recyclable green approach for Pinus massoniana wood modification

Kufre Edet Okon•Fengcai Lin•Yandan Chen•Biao Huang

Abstract Pinus massoniana L.was thermally treated with low melting point alloy as heating medium to investigate the strength properties changes.Contact angle,color and scanning electron microscopy were recorded to assess the effectiveness of the treatment.Samples were pre-treated in a micro-wave for 5 min followed by metal bath heat treatment at 150,180,and 210°C for 2,4,and 8 h,respectively.Strength properties of metal bath treated wood were decreased with increase temperature and time.Density,modulus of rupture,impact bending,modulus of elasticity were reduced for all treatments.Maximum compressive strength slightly increased at 150°C for 4 h followed by gradual reduction.The Janka hardness was reduced in the tangential and radial directions.Treatment of the wood at 210°C for 8 h caused the wood to become brittle and rupture.The contact angle was considerably higher after thermal treatment.The color of the wood became darker with increasing temperature of thermal treatment.Micrographs of the heat-treated samples showed damage to the cell wall with increase in temperature.Metal bath heat treatment of wood was carried out successfully and some strength properties were reduced.

Keywords Metal bath heat treatment·Strength properties·Pinus massoniana·Color·Contact angle

Introduction

Wood thermal modification is a non-biocidal method for improvement of wood properties such as dimensional stability,biological durability and is an environmentally friendly method for wood preservation(Homan and Jorissen 2004;Hill 2007;Aytin and Korkut 2016).Favourable changes in the properties of wood after heat treatment,makes the modified wood suitable for use in outdoor furniture,claddings on wooden buildings, floor material,musical instruments and a diversity of other outdoor and indoor applications(Yildiz and Gümüs¸kaya 2007).

The first heat-treatment plant was established in Finland in the middle of the last century and since then wood modification technology has attracted attention because it is environmentally benign.Wood heat-treatments have become well-established,and there are growing numbers of industrial thermal modification methods in various countries in Europe and Canada,such as Thermowood in Finland,Plato wood in Holland,Rectification and Bois-Perdure in France and Oil Heat Treatment(OHT)in Germany(Esteves et al.2007;Boonstra 2008).New thermal treatment processes have been established in Denmark(WTT)and Austria(Huber Holz)(Aytin and Korkut 2016).While some of these thermal treatment processes are in development stages,others are already operating in full production capacity(Esteves et al.2008).Heat treatment is usually applied at different temperature levels(between 160 and 260°C)from 15 min to 24 h.The treatments differ in processes conditions such as the presence of shielding gas(steam or nitrogen vacuum)or humid or dry processes and the use of oils(Pétrissans et al.2011;Candelier et al.2013;Salca and Hiziroglu 2014).The growing market demand for thermally modified wood challenges wood industries to develop faster and more reliable methods for the modification of wood.Existing studies have shown that physical,hygroscopic and structural properties of heat-treated wood were modified during thermal modification(Aytin and Korkut 2016;Sevim Korkut and Guller 2008;Tjeerdsma et al.1998;Akguuml 2012).The application of heat results in the degradation of hemicellulose content.The change in the color of wood is mainly attributed to the degradation of hemicelluloses and oxidation of phenolic compounds(Tuong and Li 2010;Hon and Minemura 2000).Heat treatment reduces the mechanical properties of wood,such as hardness and bending stiffness depending on the intensity of the treatment(Wikberg and Maunu 2004).

We used a low melting point alloy as a heating medium for the treatment of Chinese pine wood.The main ingredients of the alloy is bismuth(0.69%)and tin(0.26%)and the melting point is 97°C.Low melting point alloys are potential phase change thermal storage materials and heat transfer agent due to its excellent property such as high thermal conductivity and storage density,excellent thermal stability,low melting point and high boiling point.It presents much higher thermal conductivity than most other heating media used in thermal wood modification by excluding oxygen from the treated wood and minimizing thermal degradation of some wood constituents(Dubey et al.2012).Low melting point alloy can be considered to be a more sustainable,cost effective,energy-saving and green approach to wood modification,which causes equal and fast heat transfer within treated wood.It is a nonflammable,non-toxic,tasteless and odorless material.In addition,the wide availability of low melting point alloys makes it the most preferred heating medium for use in thermal modification of wood and currently,there is a growing environmental awareness and legislative pressure discouraging the use of biocides based wood treatment methods(Homan and Jorissen 2004).Metal bath heat treatment(MBHT)could be an alternative environmental friendly wood modification method since no toxic chemical is used and almost no information is available on the use of low melting point alloy bath for wood modification.This lack of information has limited its development and application.This study intends to explore the effects of MBHT method on strength properties,contact angle and color of Chinese pine wood grown in China.

Materials and methods

Materials

Tin-based alloy was purchased from Suzhou Chuangmao Metal Materials,Suzhou,China.Twenty five-year-old Chinese pine(Pinus massoniana L.)was purchased from local wood dealer in Fuzhou,Fujian Province,China.The moisture content of the wood samples was approximately 20–25%prior to treatment.

Wood sample preparation

Samples were prepared in the College of Material Engineering,Fujian Agriculture and Forestry University.Test samples with dimension 20 mm×20 mm×60 mm(tangential× radial× longitudinal)were cut for density,20 mm×20 mm×300 mm for bending strength and modulus of elasticity,20 mm×20 mm×30 mm for maximum compressive strength parallel to the grain,20 mm×20 mm×300 mm for impact bending strength and 50 mm×50 mm×70 mm for hardness according to Chinese standards (GB/T) and 20 mm×20 mm×60 mm for color measurement and the samples were kept in conditioning chamber at 65%relative humidity and 20°C until they attained 12%moisture content.

Metal bath heat treatment(MBHT)

MBHT of test samples was performed in a laboratory metal bath filled with tin-based molten alloy as heating medium.The samples were pre-treated in a micro-wave for 5 min to ease heat transfer within the wood.After pre-treatment,samples were transferred and immersed in a pre-heated metal bath at 150,180,and 210°C for 2,4,and 8 h.During heat treatment of samples,the metal bath was covered to sustain the heat flow,while the operating temperature was maintained constant within ±1°C.After MBHT,the samples were wiped,and cooled in a silica gel desiccator and then conditioned in a climate chamber for 65± 5%RH and(20± 2)°C for 8 weeks until 12%MC was attained.The dimension and mass of each sample was measured at accuracy of 0.01 mm and 0.01 g to determine density(ASTM D 2395-14 1991).

Strength properties test

To evaluate the effect of MBHT on the strength properties of the samples,ten treatments were adopted for this study,one treatment was set as untreated(control)and nine MBHT.Ten samples were used for each treatment.Three point bending test(MOR)and modulus of elasticity(MOE)were performed according to GB/T(1936.1-2009;1936.2-2009).The load deformation data were used to determine MOR and MOE.Maximum compressive strength parallel to grain(MCS)and impact bending were obtained according to GB/T(1935-2009;1940-2009).Janka hardness test was conducted in tangential,radial and longitudinal directions by driving a steel hemisphere with a diameter of 11.2 mm into test samples according to GB/T(1941-2009).

Color measurement

Color measurements were taken on the surface of the samples by using X-rite spectrophotometer.The CIELAB system was characterized by three parameters L*,a*and b*.L*axis represents the lightness,+a*represent red,-a*represent green,+b*represent yellow,-b*represent blue and L*varying between 100 which represent white to zero which represent black.The L*,a*and b*color coordinates of each sample before treatment and the differences in lightness ΔL*,chroma corresponding to Δa*and Δb*after heat-treatment was used to calculate the total color difference ΔE*according to Zwinkels(1996).

Scanning electron microscopy(SEM)analysis

Scanning electron microscopy of the control and metal bath treated samples were conducted on SU8010 Scanning Electron Microscope(Tokyo,Japan).25 μm thin sections were cut from the samples by using a Reichert-Shandon microtome(USA).The sliced samples were mounted on sample holders using double-sided adhesive tape and coated with a gold sputter,before the morphological properties observation.

Statistical analysis

The density,strength properties,contact angle and the color data were analyzed using Analysis of Variance(ANOVA)and the means were separated using Student–Newman–Keuls(SNK)test at a significance level of P<0.05.Percentages were arcsine-transformed before subjecting the data to ANOVA.All the analyses were implemented in R version 3.1.1 statistical software(R Development Core Team 2014).

Results and discussion

Density and strength properties analysis

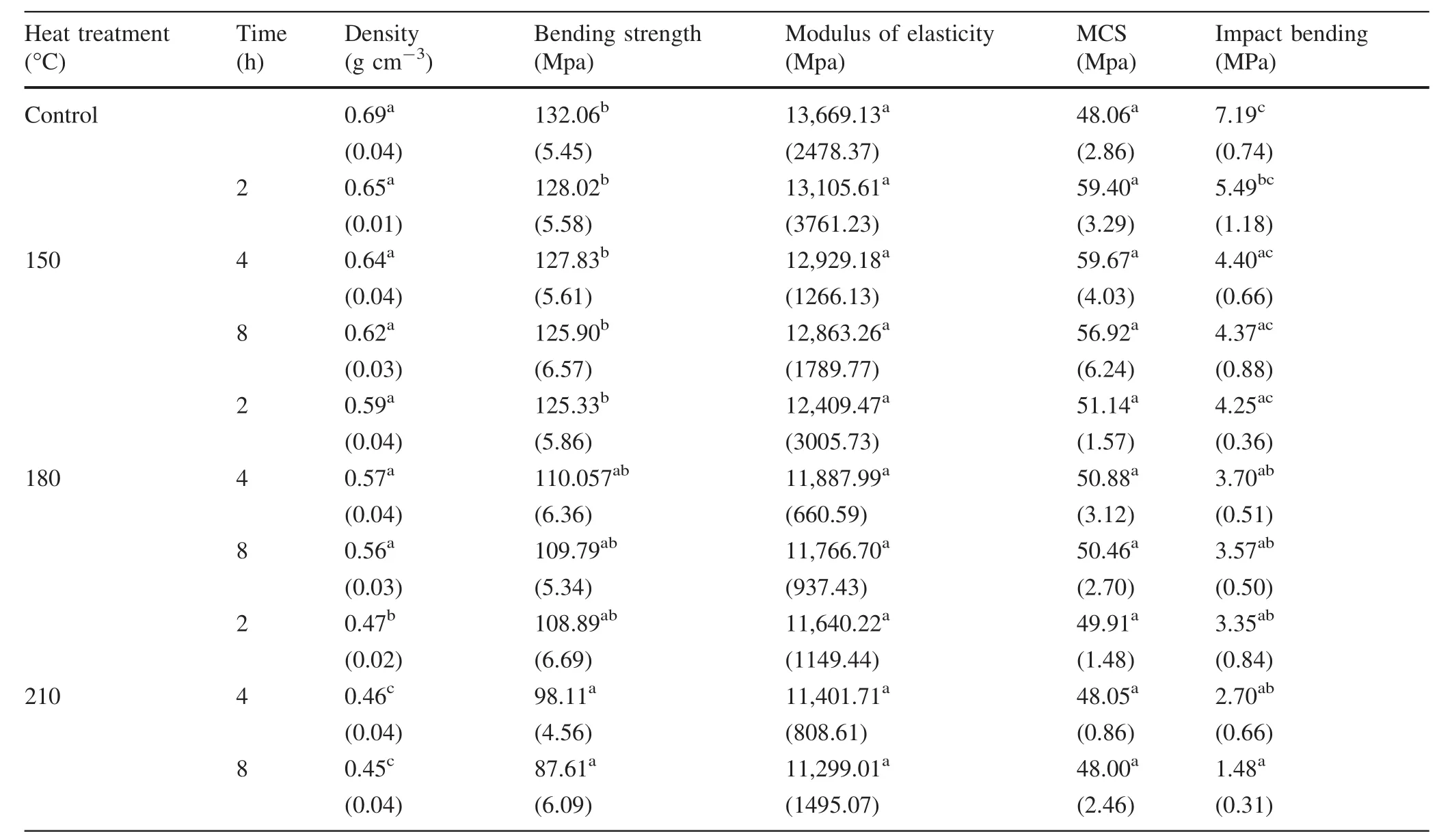

According to Table 1,the mean density obtained from metal bath treated samples was significantly different compared to the control samples(F=2.41,p′0.0162).The density of the control samples was 0.69 g cm-3,indicating that the control samples had higher density compared to metal bath treated samples.The wood density decreased slightly from 0.65 g cm-3in the heat treated at 150 °C for 2 h to 0.45 g cm-3in samples treated at 210 °C for 8 h.The density of metal bath treated wood was reduced by 0.06%at 150°C for 2 h compared to 34.78%at 210°C for 8 h(Table 1).The reduction in density of MBHT wood with increasing temperature is in line with previous study by Metsä-Kortelainen et al.(2006).They reported that the increase in temperature played a significant role on the reduction in wood density of heat treated Scot pine and Norway spruce.The reduction in density of the wood after thermal treatment can be attributed to the modifications of the chemical composition and structure of some of its elements(Shangguan et al.2016;Homan et al.2000).The mass loss of organic volatile components in thermally modified wood has a negative impact on the mechanical properties,as a result of the degradation of hemicellulose and cellulose in the wood cell wall(Kamperidou et al.2013;Kasemsiri et al.2012).Furthermore,heat treatment reduces the hydrophilic behavior of modified wood(Homan et al.2000;Boonstra et al.2007).

The strength properties of the control and metal bath treated wood were evaluated(Table 1).The bending strength(MOR)(F=6.426,p<0.0001),impact bending(F=4.723,p<0.0001),modulus of elasticity(MOE)(F=27.31,p<0.0001)and MCS(F=2.089,p<0.01)of metal bath treated samples were significantly different compared to control samples(Table 1).The MOR,MOE and impact bending of the wood decreased with increasing MBHT temperature.Compared to the control samples,MOR,MOE and impact bending of the treated wood at 150°C for 2 h were reduced by 3.05,4.12,and 23.64%and those treated at 210°C for 8 h reduced by 33.66,17.3 3,and 79.28%,thus suggesting that the strength properties of the wood were remarkably affected after MBHT.This results are in line with previous studies which reported reduction in strength properties with increase in heat treatment temperature(Boonstra 2008;Unsal and Ayrilmis 2005).The MCS of the control was 48.06 MPa.However,after MBHT it increased to 59.67 MPa at 150°C for 4 h which was the maximum increase,then followed by gradual decrease with increase of heat treatment temperature(Table 1).The relative increase in MCS of metal bathtreated wood could be attributed to the density of the wood ranging from 0.69 to 0.45 g cm-3.According to(Korkut et al.2008)appropriate heat treatment process could have a positive effect on compression strength in relation to the actual density of the wood.

Table 1 Mean density,bending strength,modulus of elasticity,maximum compression strength parallel to grain(MCS)and impact bending of metal bath treated Chinese pine wood

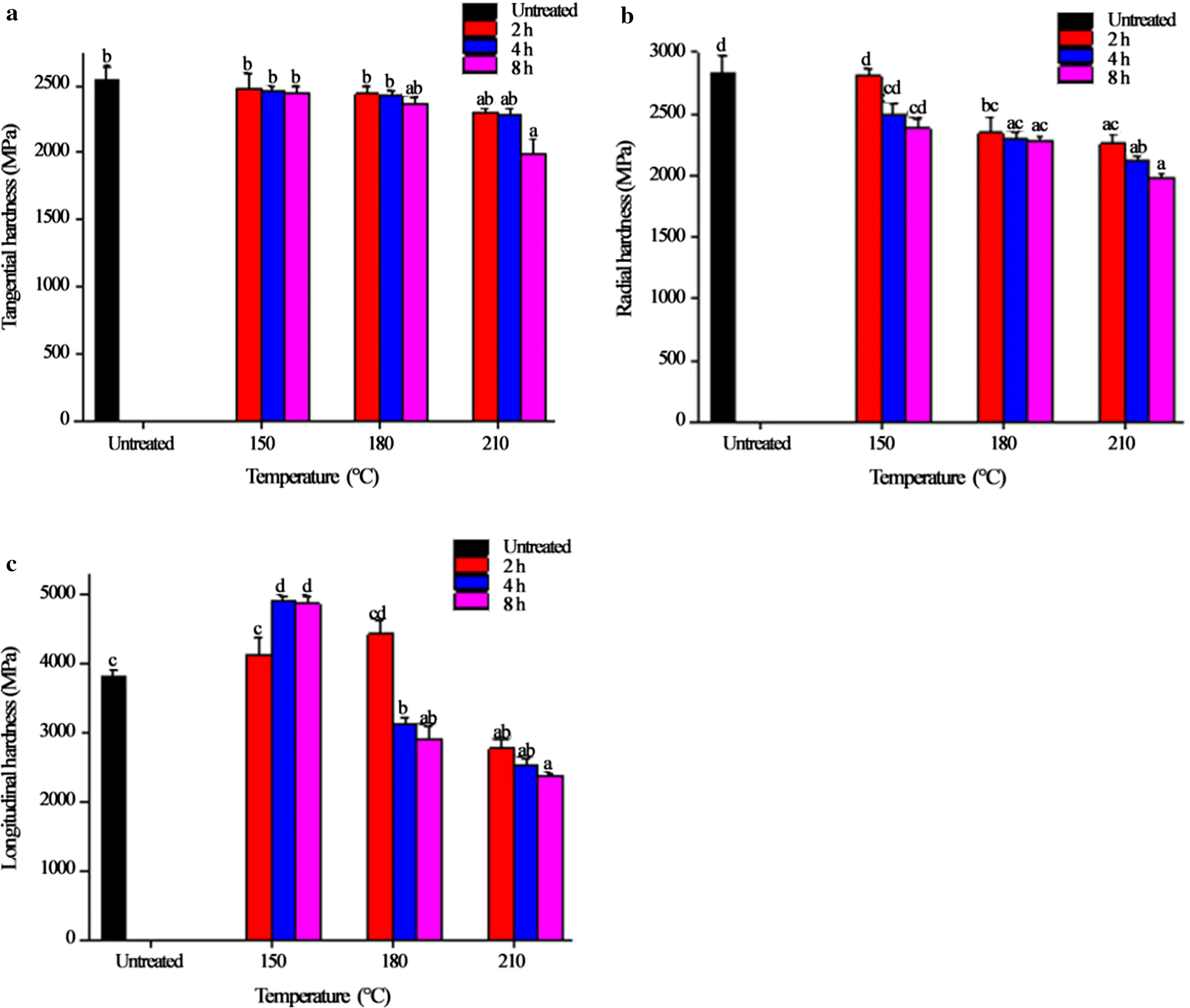

The Janka hardness of metal bath treated compared to control wood,determined in three directions is shown in(Fig.1).The tangential(F=5.455,p<0.0001),radial(F=10.82,p<0.0001)and longitudinal Janka hardness(F=46.33,p<0.0001)of the metal bath treated samples were significantly different compared to the control(Fig.1).The hardness of the control were 2540.93,2824.44,and 3814.45 MPa along the three directions.After MBHT of the wood at 150°C for 2 h,the tangential(2472.31 Mpa)and radial(2808.33 Mpa)hardness slightly reduced while longitudinal hardness increased to 4111.789 MPa,then gradually reduced with increasing temperature.The considerable increase in longitudinal hardness of the treated wood at 150°C for all the time cannot be explained in this study.However,previous work reported that lower temperature and time caused increase in the hardness value of heat treated wood while higher temperature and time decreased the hardness(Karamanoğlu and Akyıldız 2013).The hardness of metal bath treated wood at 210°C for 8 h reduced by 22,30,and 60% in tangential,radial and longitudinal directions respectively.The decrease in the hardness of the wood after MBHT,may be cause by the reduction of equilibrium moisture content,caused by heat treatment and its associated reduced reactivity of hydroxyl(Standfest and Zimmer 2008).Wahab(2004)attributed it to decrease in density along with the structure damage of the native hierarchical fine structure of the heat treated wood.

In general the strength properties of metal bath treated Chinese pine were affected,thus resulting to the wood becoming more brittle.The alteration in the strength properties of thermally treated wood was mainly due to thermal degradation of wood cell wall polymer(Hillis 1984),especially hemicelluloses which are the most thermal-chemical sensitive component of wood primarily responsible for initial strength loss(Rusche 1973;Metsä-Kortelainen and Viitanen 2012)which can be chemically changed at high temperature.The reduction in strength properties were severe as the heating temperature was increasing particularly at 210°C for 8 h and this can be linked to the formation of carboxylic acids which promote the hydrolysis of carbohydrate polymers(Rusche 1973)which lead to thermal degradation and losses of substance during treatment(Kotilainen 2000).The findings of this study is in line with previous work which reported that wood density and several important mechanical properties were reduced following heat treatment compared to the untreated controls(Scheiding et al.2005).

Fig.1 Mean Janka hardness of untreated and metal bath treated Chinese pine wood.a Tangential hardness,b radial hardness,and c longitudinal hardness.Bars with the same letter indicate that there was no significant difference between specimens at p≤0.05

Contact angle

Figures 2 and 3 show the contact angle of control and metal bath treated wood.There was significant difference between the contact angle of the control compared to metal bath treated samples(F=97.21,p<0.0001).The treated wood showed higher contact angle with regards to control(Fig.2b).The control had mean contact angle of 63.51°,the low contact angle recorded was due to spreading because of its high hydrophilicity.Metal bath treated wood at 150 °C for 2 h had mean contact angle of 128.99°and those treated at 210°C for 8 h had mean contact angle of 130.54°.There was no significant difference in contact angle value among treatments as the increments was low over treatment time(Fig.3).The significant increase in the contact angle of the wood after MBHT is favorable for reducing moisture absorption.Implying that MBHT modified the hydrophilic properties of the wood into hydrophobic.Esteves et al.(2007)reported reduced wettability in pine and eucalypt after thermal modification at 150–190 °C.The reduction in wettability of the treated wood may be due to the modification of conformational arrangement of wood biopolymers and plasticization effect of lignin which leads to reorganization of lignocellulosicpolymeric components of the wood(Johansson and Morén 2006).This results suggested that MBHT generally enhanced the hydrophobicity of the wood.

Fig.2 Contact angle of deionized water on the surface of Chinese pine wood a control sample,b metal bath treated sample at 210°C for 8 h

Fig.3 Mean contact angle of untreated and metal bath treated Chinese pine wood.Bars with the same letter indicate that there was no significant difference between specimens at p≤0.05

Color change

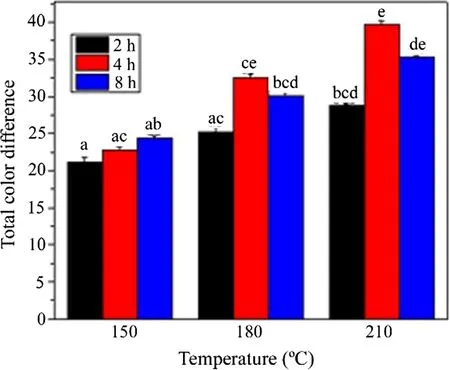

Metal bath treated Chinese pine wood at 210°C for 8 h were found to be darker in color(Table 2).An increase in the treatment temperatures necessitated color changes of the wood.The metal bath treated samples indicatednegative lightness(ΔL*).This means that the samples changed their color from cream white to dark brown.The mean ΔL*of the samples ranged from-18.71 at 150 °C for 2 h to-33.50 at 210°C for 8 h.Noticeable changes occurred on the wood especially at higher temperature,thus turning the color to be more darkening.Similarly,the Δb*of metal bath treated wood was increased(Table 2),indicating slight variation in the yellow coordinate as a result of the treatment.Contrarily,Bekhta and Niemz(2003)reported the b*coordinate of thermally modified birch wood being unchanged at 175°C for different times.The total color difference ΔE*of metal bath treated wood was significantly different between treatments(F=12.24,p<0.0001)(Fig.4).The ΔE*of treated wood was increased from 21.10 at 150 °C for 2 h to 35.31 at 210 °C for 8 h(Fig.4).The ΔE*of wood is temperature and time dependent.As the treatment temperature and time was increased,it might have contributed to darkening of the wood because different oxidative and hydrolytic discoloring reactions took place in wood during thermal treatment(Sundqvist 2004).Phenolic and lignin extractives are the primary molecules which affect color changes in heattreated wood.The colored by-products formed by the thermal degradation of hemicelluloses could also contribute to color change of thermally modified wood(Rusche 1973;Sundqvist 2004).It can be concluded that aesthetic value was added to the color of metal bath treated Chinese pine wood and this may enable the wood to compete with other wood species of higher quality.

Table 2 Mean values of color change of metal bath treated Chinese pine wood

Fig.4 Total color difference(ΔE*)of metal bath treated Chinese pine wood.Bars with the same letter indicate that there was no significant difference between specimens at p≤0.05

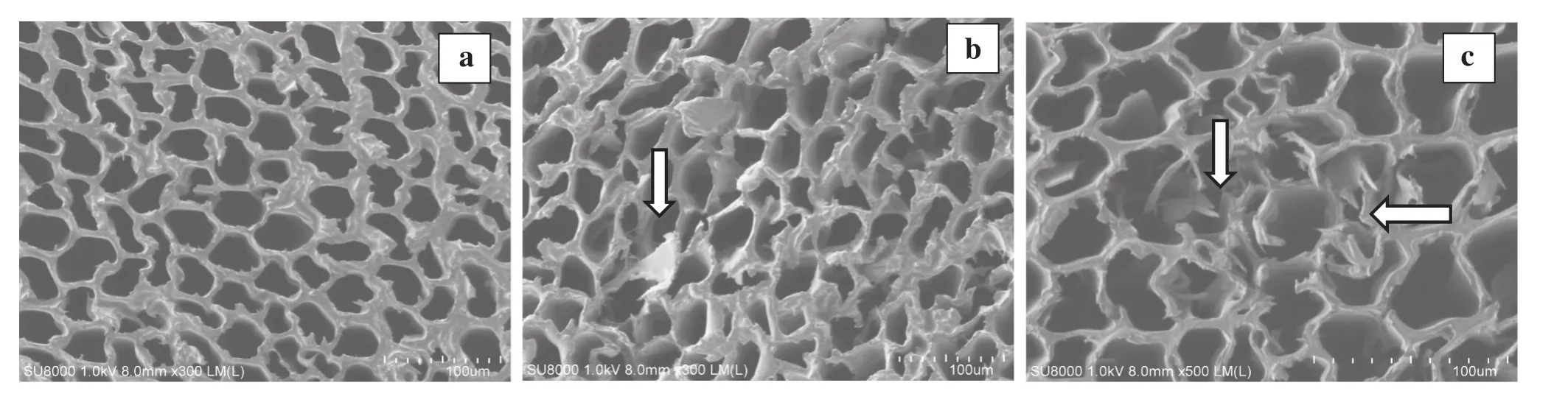

Fig.5 Micrographs of cross section of Chinese pine wood a untreated,b metal bath treated sample at 180°C for 8 h,c metal bath treated at 210°C for 8 h

SEM analysis

Figure 5 shows the cross section of the control and metal bath treated wood.The cell walls and the porous structure of the control was not altered(Fig.5a),but damages were observed in the cell walls of the metal bath treated wood at 180 °C for 8 h and 210 °C for 8 h(Fig.5b,c).The volume of void spaces in metal bath treated wood was reduced.The treated wood became brittle and abrupt(Fig.5b,c),compared to the control(Fig.5a).Nevertheless,structural changes due to MBHT were not obvious and plasticization of cell material may had occurred to some extend(Huang 2012;Bekhta and Niemz 2003).The reduction in strength properties found in this study could be attributed to the damages observed on cell walls of the wood(Priadi and Hiziroglu 2013),as heat treatment adversely influences the strength properties of wood.Oak wood subjected to heat treatment was reported to have some cracks and distortions in the cell wall(Sundqvist 2004).Furthermore,the parenchyma cells and epithelial cells of Chinese pine were not damage after MBHT contrary to the report by Boonstra and Tjeerdsma(2000),they asserted that radiata pine suffer damages after thermal treatment.

Conclusion

This research demonstrated that metal bath heat treatment of Chinese pine wood significantly affected its strength properties,contact angle and color.The strength properties such as density,bending strength,modulus of elasticity,impact bending and Janka hardness decreased with increasing heat treatment temperature and time.

The contact angle of metal bath treated wood was remarkably higher compared to the untreated,suggesting more powerful water-resistance performance of the heat modified wood.

The color of the wood became darker with increase in MBHT temperature,therefore enabling Chinese pine to compete favorably with other wood species of higher quality.Increase in heat treatment temperature particularly at 210°C for 8 h severely affected the properties of the wood.

Tin-based alloy with low melting point as metal bath heating medium was herein verified to be a promising efficient and recyclable physical approach for wood modification.

Further studies would be conducted to determine decay resistance and physical properties such as water absorption and swelling of metal bath treated Chinese pine wood with regards to treatment temperature and time to have a better understanding of the effects of MBHT.

Journal of Forestry Research2018年6期

Journal of Forestry Research2018年6期

- Journal of Forestry Research的其它文章

- Black locust(Robinia pseudoacacia L.)as a multi-purpose tree species in Hungary and Romania:a review

- The impact of the environmental factors on the photosynthetic activity of common pine(Pinus sylvestris)in spring and in autumn in the region of Eastern Siberia

- Osmoregulators in Hymenaea courbaril and Hymenaea stigonocarpa under water stress and rehydration

- Effect of nitrogen levels on photosynthetic parameters,morphological and chemical characters of saplings and trees in a temperate forest

- Free amino acid content in trunk,branches and branchlets of Araucaria angustifolia(Araucariaceae)

- Exogenous application of succinic acid enhances tolerance of Larix olgensis seedling to lead stress