Enhancing Design of Visual-Servo Delayed System

Zhi-Ren Tsai | Yau-Zen Chang*

Abstract—A robust adaptive predictor is proposed to solve the time-varying and delay control problem of an overhead crane system with a stereo-vision servo. The predictor is based on the use of a recurrent neural network(RNN) with tapped delays, and is used to supply the real-time signal of the swing angle. There are two types of discrete-time controllers under investigation, i.e., the proportional-integral-derivative (PID) controller and the sliding controller. Firstly, a design principle of the neural predictor is developed to guarantee the convergence of its swing angle estimation. Then, an improved version of the particle swarm optimization algorithm, the parallel particle swarm optimization (PPSO) method is used to optimize the control parameters of these two types of controllers. Finally, a homemade overhead crane system equipped with the Kinect sensor for the visual servo is used to verify the proposed scheme. Experimental results demonstrate the effectiveness of the approach, which also show the parameter convergence in the predictor.

1. Introduction

Intelligent control[1],[2]based on neural networks has attracted much attention from both academic and industrial communities with many successful applications partly because of its absolute robustness to uncertainties. Delay,uncertainty, and disturbance[3],[4]are the major causes of poor performances in many important engineering systems.For these systems, stability analysis and systematic design procedures are still under intensive research.

Among them, image process[5]-[9], neural network[10], and predictive control[11],[12]have been proposed in academic,medicine, traffic, and industrial communities.

In this paper, we propose a neural-based predictor to improve the transient performance of a control system with a significant uncertain feedback delay introduced by visual servo. The manipulation of traditional overhead cranes is affected by the friction, unknown winds, unbalanced load, accidental collision, change of payloads, and variation in string length.

A prototype crane system is built for verification of the proposed approaches. As shown in Fig. 1 (a), two servo motors are installed in the crane head with one to adjust the string length of the load and another one to move the kit on a rack. To provide a reliable estimation of the payload location, the Microsoft Kinect sensor is used. A detailed picture that shows a small wire-rewinding pulley to adjust the string length and the installation of the steel wire is given in Fig. 1 (b). Besides, Fig. 1 (c) shows the engagement of the reduction gear and rack.

The crane can carry goods to any locations along the rack. However, the load swings not only in the direction of the rack but also in the perpendicular direction, if the movement is not properly controlled. Inspired by the adaptive predictive controller for linear systems introduced in [13], we propose a robust predictive control method for this nonlinear system.

Furthermore, the time-varying delay[14]inherent in the stereo-vision servo system deteriorates the system stability, which was typically ignored, as shown in [15] to [17]. For instance, [15] used the sliding mode to control a type of overhead crane, and the particle swarm optimization method was used for the design of the proportionalintegral-derivative (PID) controller for nonlinear systems in [16] and [17].

In recent years, a great interest has been placed on stereo vision devices[18]-[20]that can reliably capture the depth of objects. These devices provide a depth image (D), along with an red, green, blue (RGB) image, thus called as RGB-D sensor. An application of the stereo vision device is proposed for this overhead crane system to estimate the location of the load under string. To ease the measurement, the coordinates of the load center is estimated by calculating its volume center. However, the interface to the Kinect sensor and the calculation of the volume center both introduce a significant time delay which varies with time.

In this study, a neural predictor dedicated for this time-varying delay problem is introduced. The design of the predictor begins with the introduction of a virtual plant of the overhead crane prototype. Its closed-loop stability is enhanced by using the adaptive neural predictor and optimal controller.

To design the controller, an improved version of the particle swarm optimization algorithm, the parallel particle swarm optimization (PPSO) method[21],[22], is used to optimize the control parameters in terms of its transient performance. The PPSO employs the island algorithm to parallelize the standard particle swarm optimization,which shares the particles of other islands through a common pool. Furthermore, re-initialization, also called as the big bang, is applied every ten generations to avoid local optimums.

The rest of the paper is organized as follows. In Section 2, a system description is given, and the proposed neural network application scheme and other related works are presented in Section 3. In Section 4, the controller design is presented in details, and the experiments are stated in Section 5. Experimental results are shown in Section 6. Conclusions and the importance and difficulty of the work are presented in the final section.

2. System Definition

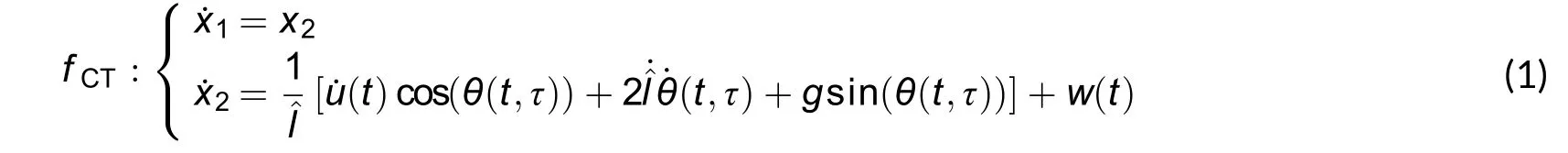

We depict the string length of the overhead crane system aswhereis a constant andis the variation with respect to the nominal length. Besides, if we letrepresent the cart position, the horizontal position of payload can be calculated as

where the continuous time for this nonlinear systemis discretized by settingwithbeing the time index andbeing the sampling time.is the string length,is the dynamics not explicitly modeled,such as friction and disturbance.

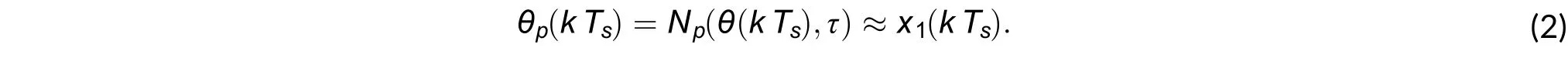

Note that the predictor includes an unknown and probably time-varying delay termwhich is to be implemented by using a recurrent neural network (RNN) with tapped delays, as shown in the overall schematic diagram of Fig. 2, and will be detailed in the next section.

Fig. 2. Stereo-vision-based servo structure with digital optimal controller and RNN predictor for the continuous-time overhead crane system.

3. Neural Predictor

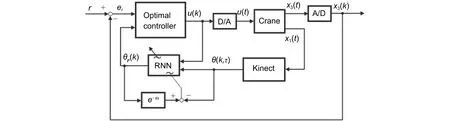

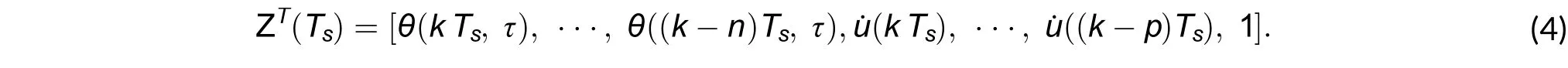

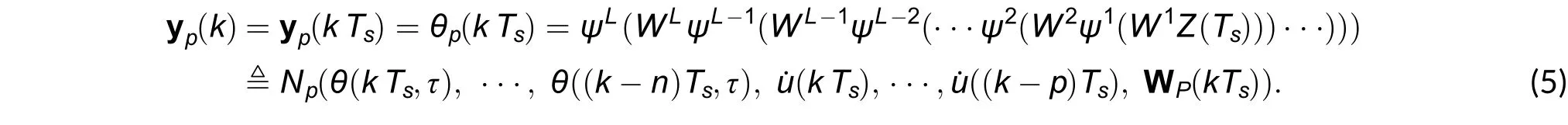

This section is dedicated for the design of the neural predictorin terms of RNN with tapped delays, which is used to estimate

This predictor is equipped withlayers, each having() neurons. The weight matrix ofincluding biases, for the lth layer is written asand the transfer function of the lth layer, denoted asfor the input u in the RNN, which is defined as

The outputs of the neural predictorcan then be derived as

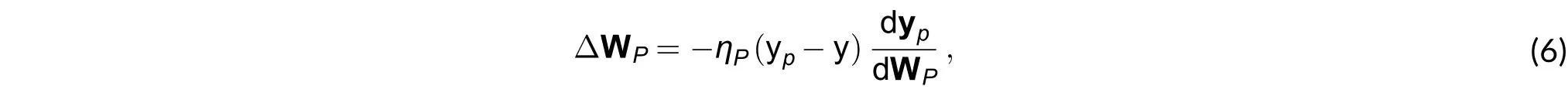

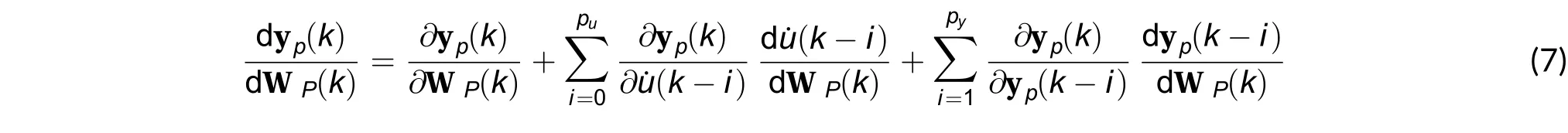

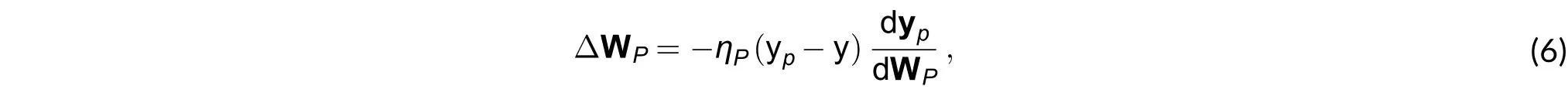

The neural predictor is trained to approximate the nonlinear system. Its complete weight matrix with bias is defined aswhich can be trained gradually by the steepest descend adaptation law:

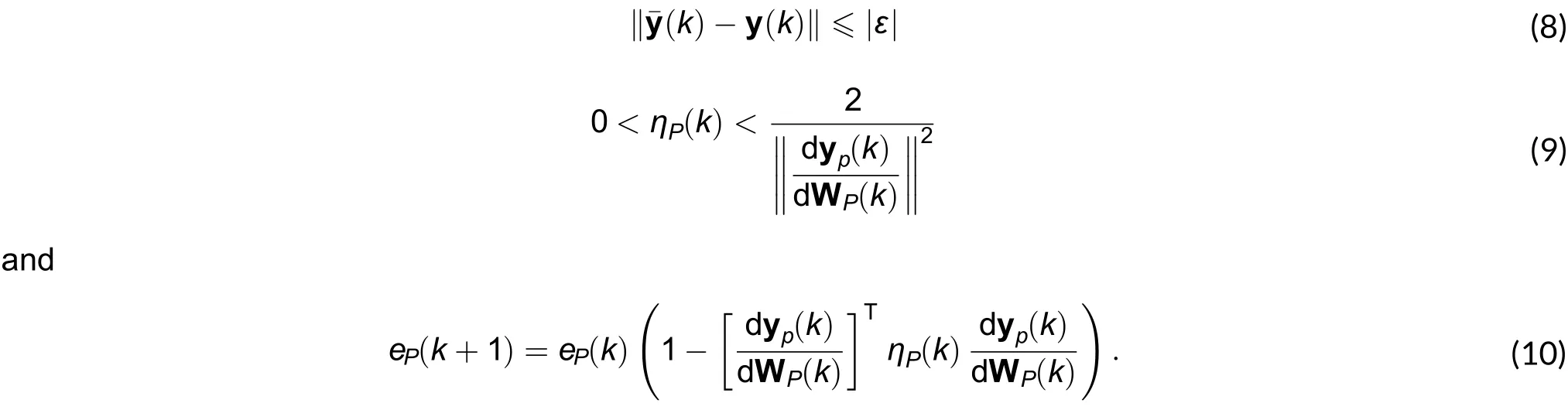

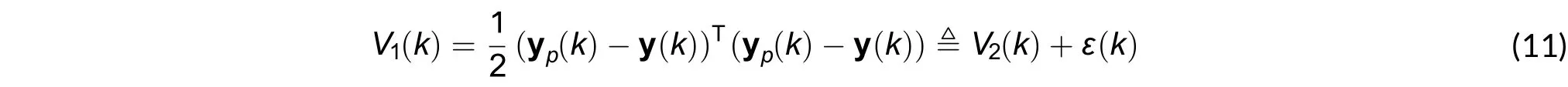

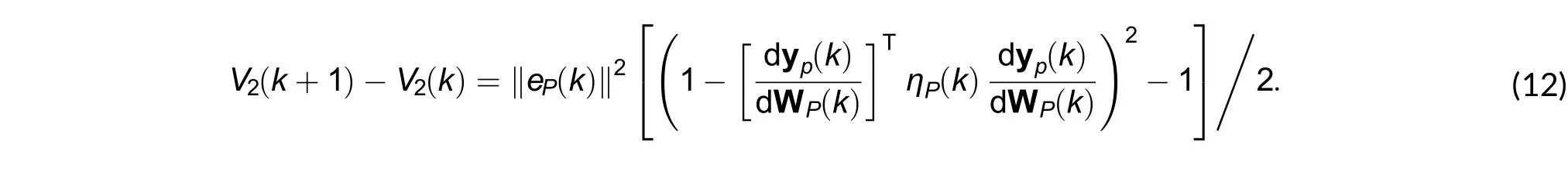

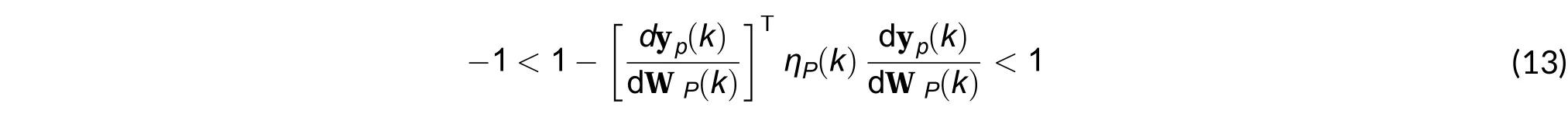

Proof. First, we define a Lyapunov candidatefor this neural predictor:

(10) and (11) as

It is easy to find that if

4. Enhancing Control

This section describes the proposed controller design. We have developed two controller designs. The first is a PID controller, and the second is a sliding controller, both uses the output signal of the neural predictor,as an estimation of the swing angle, as shown in Fig. 2.

Case 1. PID controller

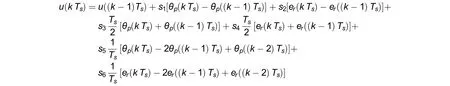

The first control law is in the form of a digital version of the standard PID controller

Case 2. Sliding controller

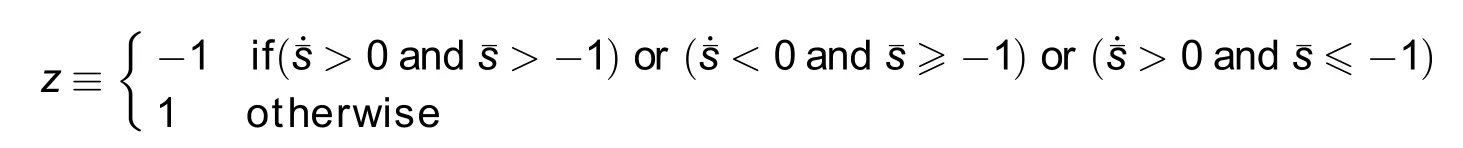

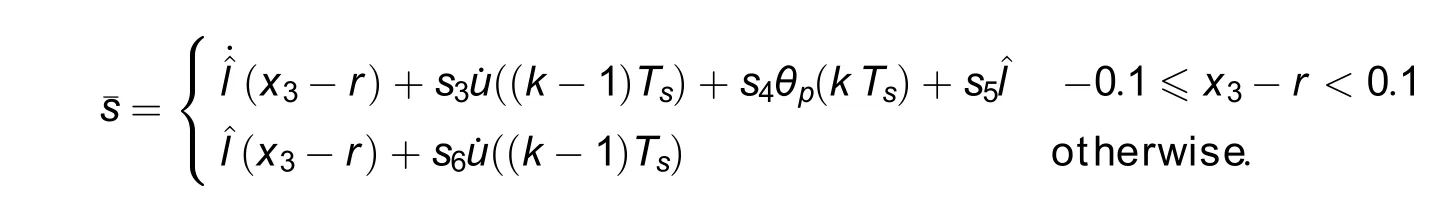

The second control law is in the form of a digital version of a sliding controller

where

with

The gains of the sliding controller,are also optimized by PPSO method[18],[19]through minimizing the cost value

5. Experimental Study

To verify the performance of the proposed neural predictor, several experiments were conducted using the overhead crane system shown in Fig. 1.

There were four control strategies implemented for the performance comparison. In addition to the two cases introduced in Section 4, Case 3 used the sliding controller of [15] and Case 4 used the PID controller of [16] and[17]. Note that both Case 3 and Case 4 were implemented without the neural predictor introduced in Section 3.

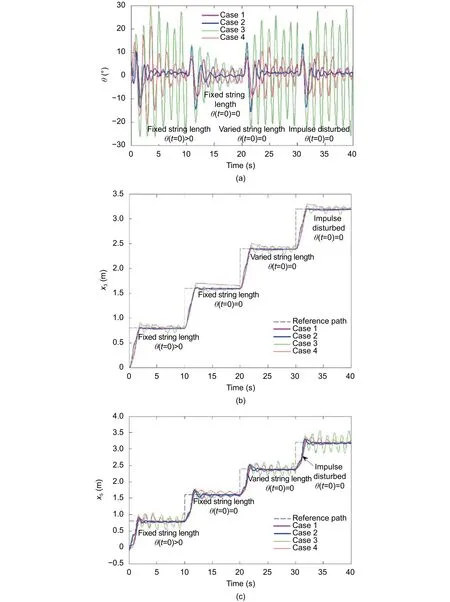

The system was command to move to 4 locations in 40 s. During the manipulation, the load was static at the beginning of each division with the following settings:

Division 1: The string length was fixed at 1.4 m.

Division 2: The string length was fixed at 0.8 m.

Division 3: The string length varied between 1.4 m and 0.8 m.

Division 4: The string length was fixed to 1.4 m, but there was an impact applied at 32 s.

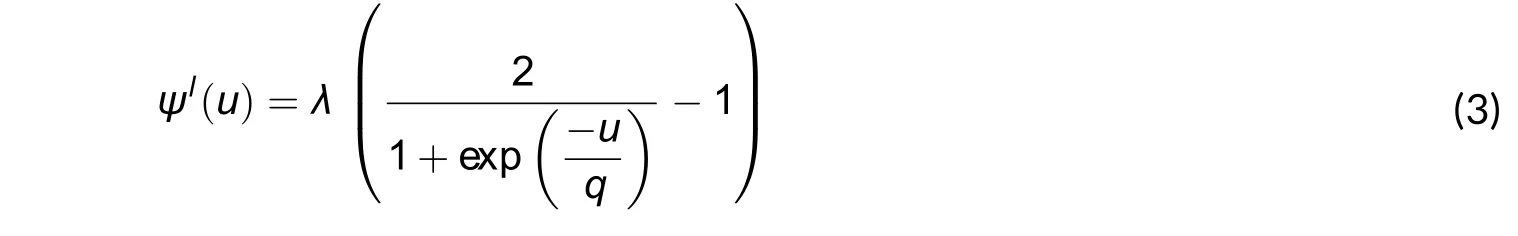

Fig. 3 shows the recorded experimental results, where Fig. 3 (a) depicts the time history of swing anglemeasured by the Kinect sensor, Fig. 3 (b) displays the cart positionand Fig. 3 (c) presents the horizontal position of payload

Fig. 3. Experimental records of state variables and outputs when four control setups were applied: (a) records of the swing angle, (b) records of the cart position, and (c) records of the horizontal position of payload

According to the experimental results, Case 1 and Case 2 outperformed Case 3 and Case 4; with the sliding version, Case 2 achieved the best performance in terms of transient stability.

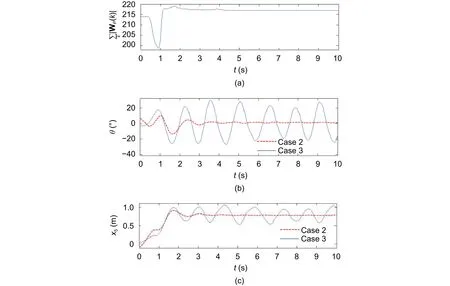

Note that both Case 2 and Case 3 were sliding controllers. The only difference was that Case 2 used the neural predictor. A close comparison of Case 2 and Case 3 demonstrated the contribution of the neural predictor, as shown in Fig. 4.

Fig. 4. Colse comparison of Case 2 and Case 3: (a) record of the summation of the absolute magnitude of in the neural predictor of Case 2, (b) close-up comparison of Case 2 and Case 3 in the swing angle, and (c) comparison in terms of the horizontal position of payload

We summarize the absolute magnitude ofand depicts its change during an experiment of Case 2 in Fig. 4 (a), which shows the quick convergence of the weights of the neural predictor in the first 2 s. The transient performance of the swing angleand the horizontal position of payloadare shown in Figs. 4 (b) and (c),respectively. Again, the Case 2, the sliding controller with the neural predictor, performs better than Case 3, the case without the neural predictor. Fig. 4 clearly demonstrates the adaption of the neural predictor is stable, and the application of the neural predictor can provide enhanced stability.

6. Conclusions

The use of visual servo induces a significant delay to the feedback signal that may deteriorate the system stability. To overcome this problem, we investigate the possibility to design a predictor to forecast the feedback signal using the RNN with tapped delays.

The predictor is used to solve the time-varying and delayed control problem of an overhead crane system with the stereo-vision servo. We build a homemade overhead crane system equipped with the Kinect sensor for the visual servo, which is used to verify the proposed scheme. The neural predictor is developed to supply the feedback swing angle to two types of two discrete-time controllers: The PID controller and sliding controller.

Experimental results show that the sliding controller performs better than the PID controller in the crane manipulation, if both are equipped with the neural predictor. And that the sliding controller cannot suppress the oscillatory swing of the payload if the neural predictor is not applied. These results successfully justify the effectiveness of the neural predictor.

Journal of Electronic Science and Technology2018年3期

Journal of Electronic Science and Technology2018年3期

- Journal of Electronic Science and Technology的其它文章

- Review on Fault-Tolerant NoC Designs

- Adaptive Algorithm for Accelerating Direct Isosurface Rendering on GPU

- Review of Methods of Image Segmentation Based on Quantum Mechanics

- Spatial Channel Sounding Based on Bistatic Synthetic Aperture Radar Principles

- Blood Flow Simulation in the Femoral Artery

- Analysis of RF Feedback Chain Isolation in Wireless Co-Time Co-Frequency Full Duplex