Optical coatings for projection objective immersion lithography

BI Dan-dan, ZHANG Li-chao, SHI Guang

(1.Engineering Research Center of Extreme Precision Optics,Changchun Institute ofOptics,Fine Mechanics and Physics,Chinese Academy of Sciences,Changchun 130039,China;2.University of Chinese Academic of Sciences,Beijing 100049,China;3.Changchun National Extreme Precision Optics Co. Ltd.,Changchun 130039,China)

Abstract: The deep ultraviolet lithography is currently a main method for integrated circuit manufacture. The immersive projection objective must be used to increase resolution of the optical system for realization of smaller component feature dimensions. Therefore a number of rigorous requirements for optical coating component are put forward. In this paper we present designs of the film material and film system applicable to immersive lithographical system as well as the large angle polarization-maintaining film system required for optical systems at high NA. Key issues about immersion environment adaptability, hydrophobicity and anti-contamination of the immersion coating most critical to the objective are discussed. Laser irradiation lifetime of the coated components especially in the immersion environment that is an important factor to evaluate performance of the immersive lithographical system is analyzed.

Key words: immersion lithography;optical coatings;coating system design;environmental adaptability;lifetime under laser irradiation

1 Introduction

引 言

New process nodes need to be reached according to Moore′s Law to increase integration of the integrated circuit components involved in the semiconductor technology. Its key issue lies in how to improve the lithographical resolution. In consideration of the fact that the resolution of lithographical projection objective is directly proportional to the exposure wavelengthλand the process factorkand inversely proportional to the numerical aperture of lithographical projection objective NA[1], the value of objective NA can be increased to improve the lithographical resolution only with full immersion between the last objective component and the silicon wafer in case that the main exposure wavelength is fixed as 193 nm and the process factor has been minimized[2].

在半导体技术中,为增加集成电路器件的集成度,需要按照摩尔定律不断推进到新的工艺节点,其核心问题在于如何提升光刻分辨率。考虑到光刻投影物镜的分辨率与曝光波长λ及工艺因子k成正比,并与投影光刻物镜的数值孔径NA成反比[1],在主流曝光波长固定在193 nm,工艺因子已经缩小到极限的情况下,只能通过将物镜最后一片元件与硅片之间充满浸液的方式来提高物镜的NA值,进而提高光刻分辨率[2]。

The value of projection objective NA can be increased to 1.3-1.4[3]with objective immersion to meet the requirement 10x nodes. But the application of the objective immersion technology makes the corresponding optical design and manufacture processes face more rigorous technology issues, and even thin-film optical components of the objective have to face a number of issues such as realization of optical indices, adaptability to the immersion environment and security of the laser irradiation lifetime. The objective specifications such as component transmittance and polarization aberration[4]must be strictly met. Design and preparation of the large angle polarization-maintaining film system will face extreme challenges[5]. The last system component has to be immersed into a liquid environment for years, and its characteristics such as anti-etching[6]and hydrophobicity[7]represent particular requirements that regular optical coatings have never faced. At the same time, film-coated components need to maintain optical capabilities in a liquid immersion environment and under the laser irradiation for years[8].

通过物镜浸液的方式,可以使投影物镜的NA值增大到1.3~1.4[3],满足十几纳米光刻技术节点的要求,但应用物镜浸液技术使得相应的光学设计与制造面临更多苛刻的技术难题。而物镜中的薄膜光学元件,更面临着光学指标的实现、浸液环境的适应、激光辐照寿命的保障等众多问题:物镜中元件的透过率、偏振像差[4]等指标必须得到严格满足,其大角度保偏膜系设计及制备将面临极大挑战[5];系统最后一片元件需数年浸泡在液体环境下,其防刻蚀[6]、疏水[7]等特性是常规光学薄膜未面临的特殊要求;同时,镀膜元件需在浸液环境以及长达数年的激光辐照环境下保持光学性能[8]。

The above issues relate to the fields of optics, chemistry, materials science,etc. They can be solved systematically only through the multi-disciplinary technical cooperation. To this end, systematic researches on the lithography were carried out began from end of the last century, under the leadership of the research of integrated circuit manufacturing technology, the lithography machine and the projection objective manufacturer as the main force, with the cooperation of optical materials manufacturers and related universities and research institutes. The optical capability, liquid immersion and irradiation lifetime of mask aligner, particularly immersion projection objective provide severe limitation of the overall design and operation stability. Therefore, mask aligner suppliers such as ASML and Nikon are dedicated to solving the contamination in an objective application environment and building up Marathon test devices for evaluation of the long-term irradiation lifetime of components and thin films[9]. Material suppliers such as Corning and Heraeus have commenced the long-term testing to evaluate the laser irradiation lifetime of optical materials such as fused quartz and calcium fluoride, and also created foundational damage models to evaluate the long-term practicability[10]. Furthermore, some research institutes have also conducted continual in-depth investigations under organizing by industry unions such as SEMATECH in United States and ASET in Japan[11]. For example, Lincoln Laboratory at MIT has conducted systematic researches on DUV(193 nm)/VUV(157 nm) laser irradiation and liquid immersion lifetime of optical materials and thin films[8]. In addition, projection objective manufactures such as Zeiss and Nikon are dedicated to researches on security of optical capability of high NA projection objectives, control of the polarization aberration and manufacture of extremely high-precision coated optical components[5,12]. Layout of the above multi-level researches has effectively supported fundamental and applied studies on the immersive lithographical objective. Capabilities of the immersive mask aligner that first emerged since 2004(ASML-XT1250i) have been constantly improved and now can meet the requirement for 1Xnm nodes.

上述问题涉及光学、化学、材料学等领域,需要跨学科技术协作才能够获得系统解决。为此,自上世纪末起,在集成电路制造技术研发需求的牵引下,以光刻机与投影物镜制造商为主力,在光学材料厂商以及各相关大学、研究所的协同配合下,开展了光刻机的系统研究工作。光刻机尤其是浸没式投影物镜的光学性能、浸液和辐照寿命严重限制了整机的设计及使用稳定性,因此ASML、尼康等光刻机供应商主要致力于解决物镜应用环境下的污染问题,并搭建马拉松实验装置来评价元件、薄膜的长期辐照寿命[9]。康宁、贺利氏等材料供应商则开展了长期实验,对融石英、氟化钙等光学材料进行激光辐照寿命评估,建立基础损伤模型以评价其长期实用性[10]。另外,在美国SEMATECH和日本ASET等产业联盟的组织下,一些研究机构也进行了持续的深入研究[11],例如MIT林肯实验室在十余年的时间内,针对DUV(193 nm)/VUV(157 nm)光学材料、薄膜进行了激光辐照、浸液环境寿命的系统研究[8]。另外,蔡司、尼康等投影物镜制造商致力于高NA投影物镜光学性能保障、偏振像差的控制以及极高精度薄膜光学元件制造等方面的研究[5,12]。上述多层次研究布局有效支撑了浸液光刻物镜的基础及应用研究,自2004年首次问世以来(ASML-XT1250i),浸没式光刻机的性能不断得到提升,目前已满足1Xnm节点需求。

Chinese studies in this field began from 2007. Changchun Institute of Optics, Fine Mechanics and Physics carried out research and development of the lithographical projection objective technology towards than 90 nm[13]nodes and much smaller nodes. Systematic research progresses in terms of ArF laser irradiation lifetime of thin-film components and immersive material protection interface have been obtained[14-16]to provide a good foundation for further apply of the projection objective.

该领域的研究在我国始于2007年。在国家科技重大专项的支持下,长春光机所开展了面向90 nm[13]及以下节点的光刻投影物镜技术研发,在薄膜元件ArF激光辐照寿命、浸液材料防护界面等研究方面取得了很大进展[14-16],为投影物镜的进一步实用化奠定了良好基础。

2 Design and Realization Approach of the Large Angle Film System for Immersive Lithographical Objective Components

浸没式光刻物镜元件的大角度膜系设计及实现途径

2.1 Design of the broad angle antireflection(BAAR) film system

宽角度减反(BAAR)膜系的设计

There are two particular difficulties for the immersive projection objective. First, a high NA causes increase of the light incidence angle on the component surface. NA1.35 can be used as an example the water refraction index is 1.437 corresponding to the objective system NA0.94. In such case, some components need to reduce the residual reflectance within 0-70°[17]. The optical coating for immersive projection objective faces severer issues in terms of the large angle incidence than those for dry objective(NA0.75). In addition and from the view of film system design, film systems designed with materials such as MgF2, AlF3, LaF3, GdF3and SiO2[18-19]prepared in traditional thermal evaporation and ion beam sputtering methods are insufficient to ensure the extremely low residual reflectance and S/P polarization split at a large angle incidence, when an ArF excimer light source with the operating wavelength of 193nm is used. Some common methods that eliminate the polarization[20-21]cannot be compatible with the requirement for large angle incidence and need to pursue better solutions.

对浸没式投影物镜来说,存在两个特殊的难题:首先,高NA导致了光线在元件表面入射角的增加,以NA1.35为例,水的折射率为1.437,相当于物镜系统NA0.94,这种情况下,部分元件需要在0~70°[17]范围内减少剩余反射,相对干式物镜(NA0.75)而言,浸没式投影物镜光学薄膜面临的大角度入射问题更加严峻。另外,从膜系设计的角度考虑,当工作波长为193 nm的ArF准分子光源时,使用传统热蒸发和离子束溅射方法制备的MgF2、AlF3、LaF3、GdF3和SiO2[18-19]材料所设计的膜系很难保证在大角度入射时仍具有极低的剩余反射和S/P偏振分离,另外一些常见消偏振方法[20-21]无法兼顾大角度入射需求,需要寻求更好的解决办法。

From the view of film system design, the above broad angle antireflection(BAAR) film system can be realized with two ideas. On one hand, the best solution of a film system design depends on materials with high/low refraction indices known from the maximum value principle in mathematics. The larger refraction index difference results in better optical capabilities of a film system[22]. The BAAR film system with more superior capabilities can be designed with importing film layers that have a lower refraction index. As shown in Fig.1, lower the refractive index of the outermost material in the design, the smaller the residual reflectance and polarization separation when the film is incident at a large angle. On the other hand, a film system design within 0-70° has approached to the so-called “omni-directional antireflection film”. An ideal solution uses the film system where the refraction index is shaded from the substrate to the air side, which has no interface and reflection and can effectively eliminate the polarization split[23-24]. However, an ideal film system with shaded refraction index is hard to be realized. The film system with shaded refraction index can be substituted approximately with the film system that has a gradient refraction index only according to the principle of Snell′s Law and following the rule that the film system interface with a smaller refraction index variation results in a larger initial incidence angle that begins to cause the polarization split. To realize both the above ideas, many possible attempts have been made in practice to prepare film layers with extremely low and adjustable refraction indices[25-26].

从膜系设计的角度看,可以通过两种思路实现上述宽角度减反(Broad Angle Anti-Reflection,BAAR)膜系:一方面,由数学上的极大值原理可知,一个膜系设计的最优解由高/低折射率材料所决定,其折射率差值越大,膜系的光学性能越好[22],因此可以通过引入折射率更低的膜层设计出性能更加优异的BAAR膜系,如图1所示,在设计中最外层材料折射率越低,膜系大角度入射时的剩余反射率和偏振分离越小;另一方面,0~70°的膜系设计已接近所谓的“全向减反膜”,理想的解决方案是采用从基底到空气端折射率渐变的膜系,这样的膜系无界面、无反射,能够有效消除偏振分裂[23-24],然而理想的折射率渐变膜系很难实现,只能根据斯涅耳定律的原理,遵循膜系界面折射率突变越小发生偏振分离的起始入射角越大的规律,采用梯度折射率膜系近似替代折射率渐变膜系。为实现以上两种思路,制备出超低折射率膜层和折射率可调的膜层,人们在实践中尝试了多种可能[25-26]。

2.2 Realization approach of BAAR film layer materials

BAAR膜层材料的实现途径

2.2.1Filmlayerwithanextremelylowrefractionindexpreparedinthesol-gelmethod

溶胶-凝胶法制备超低折射率膜层

Among regular film-coated materials, MgF2and cryolite have the lowest refraction index. MgF2has the refraction index of approximately 1.44 at 193 nm. The cryolite has a lower refraction index, but it is not suitable for use in the objective due to its worse environmental adaptability. In addition, traditional PVD processes are not convenient to realize the refraction index adjustment. Thus only other methods can be pursued to realize an extremely low refraction index. It can be known from the equivalent medium approximation(EMA) model that a pore structure needs to be introduced into the film layer to reduce the film layer refraction index. Main methods to prepare film layers with an extremely low refraction index include template and sol-gel methods. In recent years, many technologies to prepare thin films with the template method use copolymer as the template where film layers with the refraction index of 1.11 in a visible range as well as a certain anti-friction capability can be prepared. But the high-temperature calcination at more than 450 ℃ shall be used for this method. It is insufficient to meet the requirement on film-coated component surface shape index for the lithographical objective(less than 1 nm for a single component). Compared with the template method, the sol-gel method has been widely used in recent years due to its simple reaction principle, relatively low preparation temperature(~200 ℃), and favorable surface hydrophobic modification[27-28].

在常规镀膜材料中,MgF2和冰晶石具有最低的折射率,其中MgF2在193 nm处的折射率约为1.44,冰晶石虽然具有更低的折射率,但由于其环境适应性较差而不适合在物镜中使用。另外,传统PVD工艺不便于实现折射率的调控,因此超低折射率的实现只能寻求其他方法。由等效介质近似(EMA)模型可知,为降低膜层折射率,需要在膜层内引入孔隙结构,主流的超低折射率膜层制备方法有模板法和溶胶-凝胶法。近年来模板法制备薄膜的技术多采用异量分子聚合物(copolymer)为模板,可以制备出可见范围内折射率1.11的膜层,并且具有一定的抗摩擦性能,但该方法在工艺上需采用450 ℃以上的高温煅烧工艺,很难保障光刻物镜对镀膜元件面形指标的要求(单个元件1 nm以下)。相对于模板法,溶胶-凝胶法因其反应原理简单、制备温度(~200 ℃)相对较低、利于进行表面疏水修饰的工艺优势,近年来被广泛采用[27-28]。

For optical coatings on the lithographical objective, the regular sol-gel method uses MgF2as a base material to prepare materials with an extremely low refraction index. Different reaction paths can be adopted in realization[29]. But the essential idea is basically consistent. The MgF2sol material is obtained through reaction between the weak acidic salt or alcoholate that contains magnesium and the fluoric acid. Generally this material consists of self-organized nanometer particles that can form the MgF2bubble structure after treatment with an autoclave or aging treatment. In addition, the catenulate tree structure is formed through hydrolytic polycondensation of TEOS. It wraps the bubble MgF2particles to constitute an irregular tree structure. The sol sample obtained is used for thin film preparation through Czochralski method[30]or the spin-coating method. Finally pore film layers are prepared to realize a refraction index lower than that of the lumpy MgF2. The refraction index of film layers obtained finally can be adjusted with parameters in the reaction. The lowest refraction index that can be realized with this method is slightly more than 1.1, but the mechanical strength of film layers is frequently low. To solve this problem, Ishizawaetal.[31]use the viscous SiO2solution for spinning on the MgF2film layer prepared and heat to 100-200 ℃ to form the amorphous SiO2between MgF2particles, which makes mechanical strength of the film layer increase from approximately 25 MPa to about 135 MPa. In addition to the extremely low refraction index of the sol-gel film layer, its another advantage lies in a high resistance to laser damage that makes the film layer maintain integrity after exposure to the ArF laser irradiation at 5×107pulses and the energy density of 600 mJ/cm2/pulse[32].

对于光刻物镜光学薄膜,为制备出超低折射率材料,常规的溶胶-凝胶方法均以MgF2为基础材料,可以采用不同的反应路径[29],但其本质思路基本一致:通过含镁的弱酸盐或醇盐与含氟酸反应获得MgF2溶胶原材料,这种材料通常是自组织的纳米颗粒,通过高压釜处理或老化处理形成MgF2水泡结构,另外,通过TEOS的水解缩聚反应,形成链状的树形结构,并将水泡状MgF2颗粒包裹其中,成为无规则的树状结构。得到的溶胶样品通过提拉法[30]或旋涂法制备薄膜,最终制备出含孔隙的膜层,实现了低于块状MgF2的折射率,最终获得的膜层折射率可由反应过程中的各参数进行调控来获得。采用该方法可实现的最低折射率略大于1.1,但通常膜层机械强度较低,为解决这一问题,Ishizawa等人[31]在制备完成的MgF2膜层上,用SiO2粘合溶液甩胶并加温100~200 ℃,使MgF2粒子之间形成了非晶SiO2,将膜层的机械强度由~25 MPa提升至~135 MPa。溶胶-凝胶膜层除了具有超低折射率,另一优势在于其具有较高的抗激光损伤能力,在能量密度为600 mJ/cm2/pulse的条件下经历5×107脉冲的ArF激光辐照后,膜层仍然保持完好[32]。

As shown in Fig.1, the MgF2antireflection film prepared with the sol-gel method or traditional PVD film system with the sol-gel coated MgF2film layer has good optical capacities at the vacuum ultraviolet waveband and deep ultraviolet waveband.

如图1所示,溶胶-凝胶方法所制备的MgF2减反膜,或在传统PVD膜系上增镀溶胶-凝胶MgF2膜层,在真空紫外与深紫外波段,都有良好的光学性能。

2.2.2Mixedfilmlayermaterial

混合膜层材料

When the two materials of high/low refractive index are co-evaporated, a specific refractive index film layer between the two materials can be realized by adjusting the ratio of the two materials. Realization can be made with two methods. One is the gaseous phase mixture method where two separate evaporation sources each evaporate one material and the required proportions are obtained by changing deposition rates of both materials. The other one is used to directly mix materials as per designated proportions in one evaporation source for evaporation, which is called the liquid phase mixture. The former is flexible for refraction index adjustment and is more applicable to cases where continuous adjustment of the refraction index is required. But its defects are also evident. Proportions of two materials are different in space distribution. Thus it is not suitable for the preparation of large diameter components. The latter can be used only to realize particular proportions of materials, but it can be used for large-caliber components with curved surface and is applicable more extensively.

当高/低折射率的两种材料共同蒸发时,可以通过调控两种材料的配比,实现介于两种材料之间的特定折射率膜层。具体实现可以采用两种方法:一种是气相混合,即两个独立的蒸发源各自蒸发一种材料,通过改变两种材料的沉积速率获得所需的配比;另一种是直接按照指定配比将材料混合在同一蒸发源中再蒸发,即所谓的液相混合。其中前一种方法对折射率的调整较为灵活,更适用于需要连续调节折射率的情形,但其缺陷也比较明显,即两种材料的配比具有空间分布的差异性,因此无法实现大口径元件的制备;后一种方法只能实现特定材料配比,但可用于具有曲面形状的大口径元件,具有更广泛的适用性。

What needs to be pointed out specifically is that any refraction index between 1.20 and 1.44 can be realized with the aforesaid sol-gel method where the molar ratio between Si and Mg in two sols of MgF2and SiO2are controlled. The schematic diagram for mixture of two sols in different proportions and the corresponding refraction index are shown in Fig.2. Recently, Xu Yaoetal.[33-34]have prepared the antireflection film system with a gradient refraction index by controlling the molar ratio between mixed materials, which is potential to meet broad wavebands or the demand for broad angle antireflection.

另外需要特殊指出的是,在前面所述的溶胶-凝胶法中,通过控制MgF2和SiO2两种溶胶Si和Mg的摩尔比,也可以实现折射率从1.20到1.44的任意折射率,图2为两种溶胶不同比例混合示意图及其对应折射率。最近,徐耀等人[33-34]通过控制混合材料摩尔比制备出了梯度折射率减反射膜系,具有满足宽波段或宽角度减反需求的潜力。

Fig.2 Realization of the adjustable refraction index with mixture of two sols(MgF2 and SiO2) at different Si/Mg molar ratios 图2 两种溶胶(MgF2和SiO2)不同Si/Mg摩尔比混合实现可调折射率

2.3 Security of objective system indices with the BAAR film system

BAAR膜系对物镜系统级指标的保障

Design and realization approach of the BAAR film system have been presented in the above. Now indices of objectives NA0.75 and NA1.35 are used as an example to explain how to evaluate objective system indices. Impact of the objective on the incident light can be expressed with Jones Matrix. The pupil expressed with Jones Matrix is called Jones Pupil, components of which are not certain in physical significance. It is not easy to distinguish indices because of combination of different influence factors. Thus it is broken down into the form of physical pupil, components of which are independent from each other and certain in physical significance. They can be expressed with parameterization in the directional Zernike Polynomials. The objective′s Jones Pupil can be described with five pupil functions that have certain physical significances after simplification and decomposition:

上述内容介绍了BAAR膜系的设计及实现途径。现以NA0.75和NA1.35物镜的指标为例,说明物镜系统级指标如何评估。物镜对入射光的影响可用琼斯矩阵表示,用琼斯矩阵表示的光瞳称为琼斯光瞳。琼斯光瞳各个分量的物理意义不明确,不同影响因素交织在一起,不易进行具体指标的划分,因此将其分解成物理光瞳的形式。物理光瞳的各分量相互独立且物理意义明确,并可用方向泽尼克多项式进行参数化表征。通过简化与分解,物镜的琼斯光瞳可以由5 个具有明确物理意义的光瞳函数进行描述:

J≈t·ei·Φ·Jdia(d,θ)·

Jrot(α)·Jret(φ,β)

The diattenuationJdiaand the retardationJretare two main influence factors of the polarization aberration, which correspond respectively to amplitude and phase splits. Generally it is required in the immersive projection objective with NA1.35 that the diattenuation is less than 0.5% and the retardation is less than 2 nm. It is also required that the apodization uniformity corresponding to each viewing field of the system is not less than 90% and the transmittance is not less than 60%.

式中,二次衰减(diattenuation,Jdia)和延迟(retardation,Jret)为偏振像差的两个主要影响因素,分别对应振幅分离和相位分离,在NA1.35的浸没式投影物镜中,一般要求其二次衰减<0.5%,延迟<2 nm。另外要求系统各个视场对应的切趾均匀性(apodization uniformity,t)≥90%,透过率≥60%。

Impact of the polarization aberration caused by film system on the imaging cannot be ignored at a certain extent of the objective numerical aperture. Shang Hongboetal. use the objective system with NA0.75 for studies on the intensive lines imaging at 90 nm intervals and the imaging contrast. It is found through comparison between common and BAAR film systems in terms of diattenuation, retardation, apodization uniformity, transmittance and intensive line contrast at 90 nm intervals that the system retardation has been reduced significantly from 1.55 nm to 1.2 nm after use of the BAAR film system. In addition, the intensive line contrast at 90 nm intervals in the objective is increased from 0.08 to 0.89 by adjusting the objective system design simultaneously[35].

当物镜数值孔径达到一定程度时,膜系所引起的偏振像差对成像的影响不容忽视。尚红波等采用NA0.75物镜系统对90 nm密集线条成像,并对成像的对比度进行研究,通过对比普通膜系和BAAR膜系对应的二次衰减、延迟、切趾均匀性、透过率和90 nm密集线条对比度等指标,发现采用BAAR膜系后,系统的延迟显著降低,由1.55 nm降到1.2 nm。另外,通过调整物镜系统设计,使物镜90 nm密集线条对比度由0.08提升至0.89[35]。

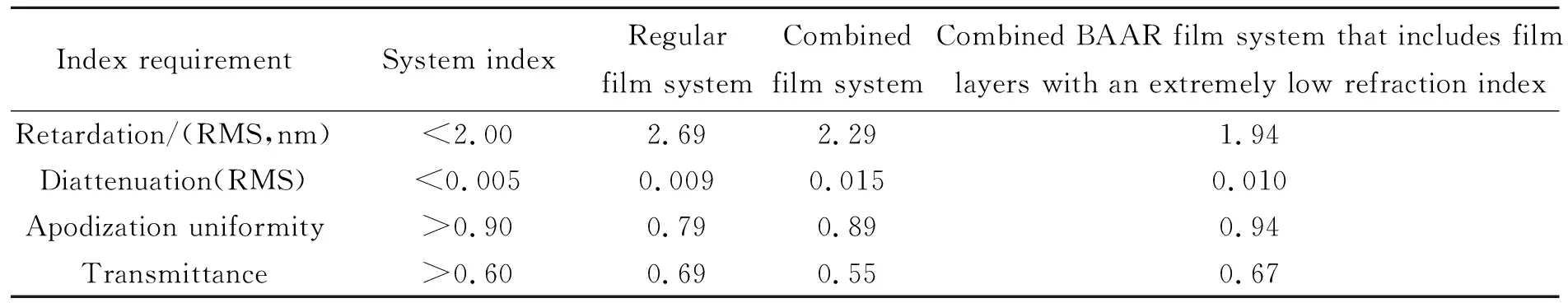

The film system has a bigger impact on the polarization aberration in an immersive objective with higher numerical aperture. System indices corresponding to different film systems such as regular film system, combined film system and combined BAAR film system that includes film layers with an extremely low refraction index are shown in Tab.1.

在数值孔径更高的浸没式物镜中,膜系对偏振像差的影响更大。表1是不同膜系对应的系统指标,一种是常规膜系,一种是组合膜系,另一种是应用超低折射率膜层构成的组合BAAR膜系。

Tab.1 System indices corresponding to different schemes 表1 不同方案对应的系统指标

It can be seen from the table that retardation, apodization uniformity and transmittance of the film system have been increased significantly after use of film layers with the extremely low refraction index of 1.1 and the requirement for objective system indices can be met.

从表中可以看出,膜系中应用折射率为1.1的超低折射率膜层后,系统延迟、切趾均匀性和透过率均有较大提升,能够满足物镜系统级指标要求。

3 Lifetime of Film-coated Components in an Immersion Environment

浸液工况环境下的镀膜元件寿命

The practice used to increase numerical aperture of an optical system with immersion of the last component has a long history. For example, this method has been being used in a high-NA microscopic objective. Use of the dry lens cannot realize the system-required imaging resolution at the minimum optical exposure image resolution of a mask aligner that is less than 45 nm. Therefore the immersion lithography is naturally put forward. The system resolution at 193 nm can be increased by 44.3% through objective immersion when other conditions of the objective system are not changed. However, use of the immersion lithography technology will make the last component of the objective be immerged in water for a long term. Service lifetime of the immerged component must be fully considered.

通过对最后一片元件进行浸液可以提高光学系统数值孔径,这种做法由来已久,例如高NA显微物镜一直采用这种方法。当光刻机光学曝光的最小图形分辨率达到45 nm以下时,采用干式镜头已无法实现系统要求的成像分辨率,浸没式光刻由此自然而然地被提出。在193 nm处,在物镜系统其它条件不变的情况下,仅通过将物镜浸液的方式就可将系统分辨率提升44.3%。然而如果采用浸没式光刻技术,物镜最后一个元件需要长时间浸没在水中,必须充分考虑浸没元件的使用寿命。

3.1 Waterproofness of the last-window component

下窗口元件的防水性能

The objective immersion is realized by adding an immersion liquid supply and recovery device between the last-window objective component and the silicon wafer, which will continuously inject fresh water into the gap between last window and silicon wafer and recover it. Thus the last-window component has to be continuously subjected to washing by the immersion liquid when the objective is operating. The requirement for anti-etching and hydrophobicity is put forward therefrom.

物镜浸液通过在物镜下窗口元件与硅片之间增设浸液供给与回收装置提供,该装置将持续不断地向下窗口与硅片之间的间隙处注入新鲜的纯水并回收。因此在物镜工作期间,下窗口元件将会持续承受浸液的冲刷,由此对元件产生了防刻蚀与疏水的要求。

The objective itself does not move together with the silicon wafer workbench during exposure. The flow field on the last window surface forms a nearly lateral flow at approximately 60 mm/s. The component will be subjected to the shearing force and etched constantly. Anti-etching characteristics of the component depend mainly on the material itself at the pure water condition. Use of CaF2as the last-window component material will result in its un-ignorable dissolution in water, and it will be etched easier at a certain flow field. Thus coating of a protective film system is required in use. The fused quartz material is much solider than it. Weissenriederetal[6]have carried out a detailed research on material etching and given reference indices. The dissolution/etching rate of the surface exposed to immersion liquid(that may be the non-film coated optical material or outermost layer of film layer material) in an immersion environment shall be less than 0.01 mg/(cm2·day) or even less than 0.005 mg/(cm2·day) or 0.002 mg/(cm2·day). The film system for immerged component must contain protective film layers including the barrier layer and wearing layer. The barrier layer does not have pores that penetrate film layers, and there is at least one layer that cannot be permeated by the immersion liquid. The wearing layer is outermost layer exposed to the immersion liquid, which shall have a sufficiently low etching rate.

由于物镜本身在曝光期间并不随硅片工件台移动,下窗口表面上的流场为~60 mm/s的近横向流动,元件将承受剪切力而被不断刻蚀。在纯水的条件下,元件防刻蚀特性主要取决于材料本身:如果采用CaF2作为下窗口元件材料,其在水中会发生不可忽视的溶解,在一定的流场下则更易被刻蚀,因此使用时需要增镀保护膜系。相对而言,融石英材料则坚固得多。Weissenrieder等人[6]对材料的刻蚀情况进行了详细的研究,给出了参考指标:与浸液接触的表面(可能是未镀膜的光学材料或是膜层材料的最外层)在浸液环境下的溶解/刻蚀速率应当小于0.01 mg/(cm2·day),甚至小于0.005 mg/(cm2·day)或0.002 mg/(cm2·day),并且浸液元件的膜系必须包含具有保护功能的膜层,包括阻挡层和磨损层,其中阻挡层不含有贯穿膜层的孔隙,并至少有一层无法被浸液渗透,磨损层为与浸液接触的最外层,应具有足够低的刻蚀速率。

In practice, the barrier layer in a protective film system can be prepared with the plasma enhanced chemical vapor deposition(PECVD) method. Generally it consists of pore-free SiO2film layers. It must be ensured that overall optical capabilities of the film system do not vary with thickness of the wearing layer gradually reduced over time. The wearing layer can use a protective flat panel consisting of body material(e.g. fused quartz). The barrier layer can be prepared with hydrophobic material, e.g. Merck′s WR series materials or polytetrafluoroethylene(PTFE). The film system with protective layers can be also applied. The liquid material or lubricating material is applied together with the flat panel made of body material. Bai Jingjianetal.[36]have investigated solubility of various materials in water(the flow field in this test is not provided at the lithographical condition, so the test result shall be static solubility of the material). It is found that thicknesses of the SiO2film layer and the LaF3film layer prepared on crystal surface of the CaF2substrate (111) are not changed. The index at which solubility of the film layer in the pure water shall be less than 2×10-12g/mL is given. Burnetal.[37]have summarized the index from the view of practice, at which thickness reduction of the anti-corrosion coating at operating conditions shall be less than 10-5/h and indicated possible materials including SiO2, ITO, polymer and non-sensitive resin for photoresist.

在实践中,保护膜系中的阻挡层可以采用等离子体增强化学气相沉积(PECVD)方法来制备,一般为无孔的SiO2膜层。对于磨损层,由于其膜厚随时间逐渐减小,必须保证膜系的整体光学性能不因磨损层厚度而变化,磨损层可以采用由体材料构成的保护平板(例如融石英)。阻挡层可以利用具有疏水性的材料制备,如默克的WR系列材料或聚四氟乙烯(PTFE),还可以应用保护层膜系,即液体材料或具有润滑性的材料与体材料平板配合应用。白井健等人[36]考察了各种材料在水中的溶解度(在该实验中未按光刻工况提供流场,所以测试结果应为材料的静态溶解度),发现在70 ℃恒温的纯水中浸泡3 h前后,SiO2膜层与CaF2基底(111)晶面的上制备的LaF3膜层的厚度均未发生改变,并给出膜层对纯水的溶解度应小于2×10-12g/mL的指标。Burn等人[37]也从实践角度总结出抗腐蚀膜系(Anti-Corrosion Coating,ACC)在工况下厚度的减少量需要低于10-5/h的指标,并指出了可能的材料,包括SiO2、ITO、聚合物和光致抗蚀剂的非感光树脂。

Some solutions for preparation of the pore-free optical coating are provided. Pazidisetal.[38]use SiO2prepared through chemical reaction to fill or partially fill pores in the film layer. The reaction substance can be trimethylfluorosilane, hexamethyldisilazane, hydroxytrimethylsilane or hexamethylcyclotrisiloxane. Bai Jingjianetal.[36]use high homogeneity and backfilling of the wet film forming method to fill pores in the film layer for increase of the anti-permeation ability of the film-coated component. In addition, there are also solutions to address the problem with film-coating and polishing cycles[6]. The first coated film layer is polished to remove a part of thickness and then the removed thickness with polishing is compensated through subsequent coating. The probability that defects are generated at the same location in two times of coating is relatively small. Pores that penetrate film layers can be removed completely through a number of coating and polishing cycles to realize waterproofness of film layers.

针对如何制备出无孔隙的光学薄膜,人们也提出了一些方案:Pazidis等人[38]采用化学反应制备出的SiO2来填充或部分填充膜层中的孔隙,其反应原料可以是三甲基氟硅烷、六甲基二硅氮烷、三甲基硅醇或者六甲基环丙硅烷;白井健等人[36]利用湿式成膜法的高均质性和高填埋性来填充膜层中的孔隙,以提高镀膜元件的抗浸透能力;另外,还有采用镀膜-抛光循环流程[6]解决问题的方案,即当首层薄膜镀制后,对其抛光去除一部分厚度,然后再通过后续镀膜补足被抛光去除的厚度,由于两次镀膜时缺陷生长在同一位置的几率相对较小,通过若干次镀膜-抛光循环就可以完全去除贯穿膜层的孔隙,实现膜层的防水。

3.2 Leaching contamination and hydrophobicity of the immerged component

浸液元件的浸析污染与疏水特性

The silicon wafer with coated photoresist needs to be exposed and etched repetitively for manufacture of devices on the mask aligner. There will be many contamination factors in more than 100 manufacture processes, which lead to defective devices that make the transmittance fall down. Furthermore in comparison with the dry lithographical technology, the possibility for contamination of the last window on the immersive objective is extremely increased due to continuous flow of the immersion liquid between the last window and the silicon wafer. Thus the immersive lithographical objective must meet the anti-contamination and superficial hydrophobicity requirements.

在光刻机制造器件时,需要对涂布光刻胶的硅片进行反复曝光-刻蚀,在上百道制造流程中会存在众多引起污染的因素,这将导致器件出现缺陷而透过率下降。另外,与干式光刻工艺相比,由于浸液在下窗口与硅片之间持续流动,极大增加了浸没式物镜下窗口被污染的可能性。因此浸没式光刻物镜必须同时满足防污染与表面疏水要求。

Contamination of the last window on objective results mainly from leaching[39-40]and viscosity[41]of the photoresist. It is very possible for photo-acid generator(PAG), quencher and small-molecule group in the photoresist that are dissolved in the immersion liquid to adhere to the last surface of objective window at the flow field. Accumulation of these leached substances with a very small amount in years of the operating period will lead to lens hazing[42]on the objective that increases system stray lights and decreases the transmittance.

对于物镜下窗口,污染主要来自于光刻胶的浸析(leaching)[39-40]和粘附性状态[41],光刻胶中的光酸产生剂(PAG)、猝灭剂(quencher)和小分子基团等溶解于浸液,在流场中极有可能吸附到物镜窗口的下表面。虽然这些浸析物的剂量非常微小,但在长达数年的使用期内积累在下窗口表面,将使物镜产生“镜头起雾(lens hazing)”[42]问题,导致系统杂散光增加、透过率下降。

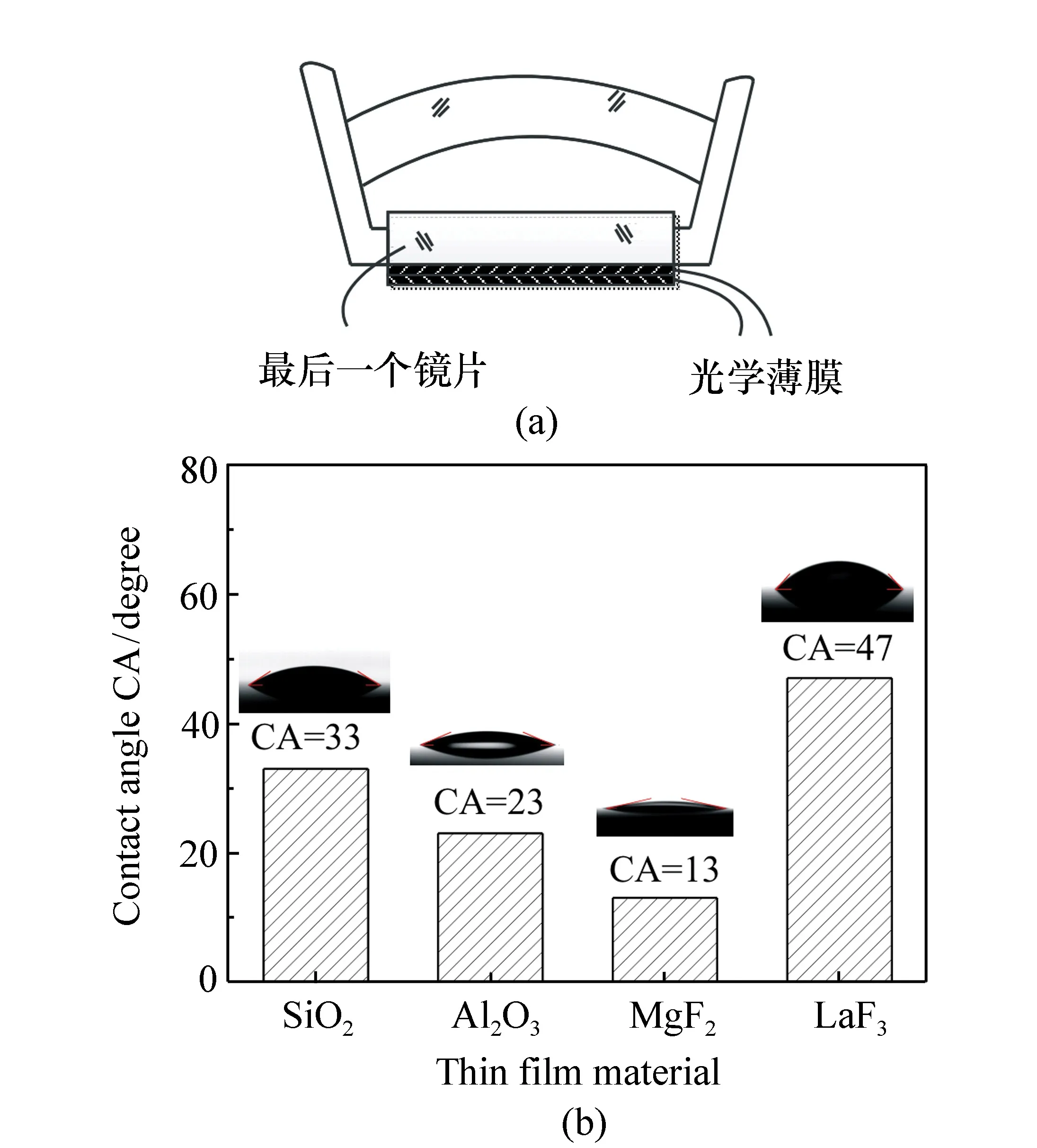

The immersive lithographical contamination can be eliminated by increasing the contact angle of the objective last-window component surface, which needs to be controlled at the minimum of approximately 70°[43]for restraint of the defect quantity within an allowable range and prevention of contaminants from adherence to the component surface along with water flow. The result of contact angle measurement for common last-window components and film layer materials is shown in Fig.3. The contact angle of SiO2[44], Al2O3, MgF2and LaF3film layers is less than 50°. It is mush insufficient to meet operating requirements.

浸没式光刻污染问题可以通过提高物镜下窗口元件表面的接触角解决。在浸液高速流动的情况下,为将缺陷数量限制在允许范围内,接触角至少需要控制在~70°[43],防止污染物随水的流动在元件表面附着。图3显示常用下窗口元件及膜层材料的接触角测量结果,SiO2[44]、Al2O3、MgF2、LaF3膜层的接触角均小于50°,远远不能满足使用要求。

Fig.3 (a)Last optical element of the lithography objective; (b)Contact angle of the film layer material 图3 (a)常用光刻物镜下窗口元件;(b)膜层材料的接触角

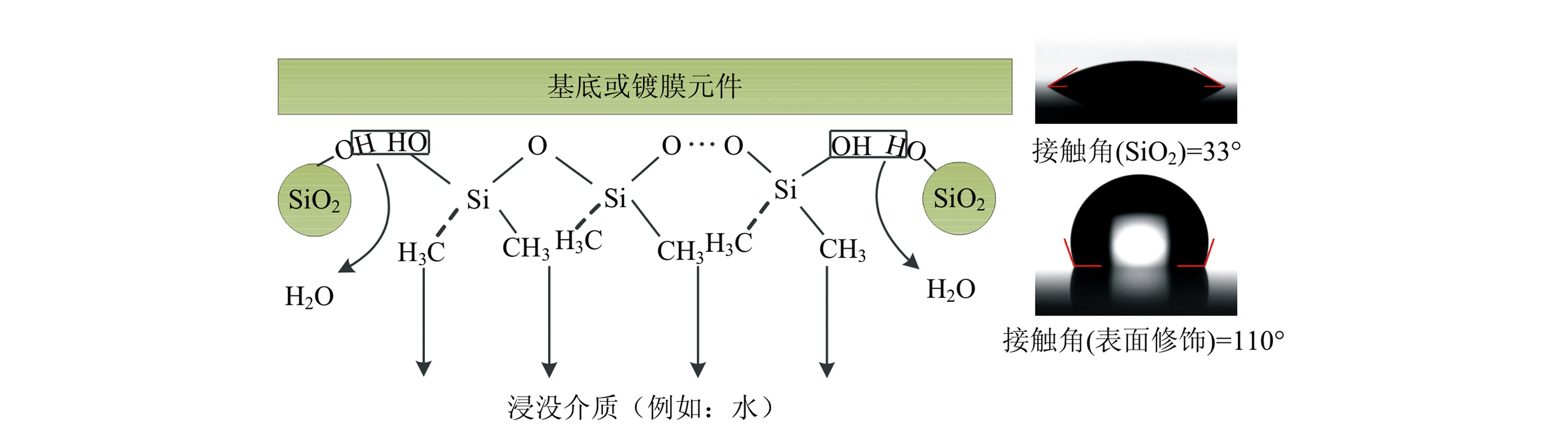

To solve this problem, it is necessary to modify the surface of the coated component to increase the contact angle by using last surface energy group, such as the small molecule fluoride, methyl or the like. This case is exhibited in Fig.4. Contact angle of the film surface can be increased to approximately 110° with surface modifying, which meets the hydrophobicity requirement. But the contact angle may be decreased to a certain extent during the long-term laser irradiation[45]. Therefore, it is worthy to further study stability of the film layer surface hydrophobicity at the laser irradiation condition.

Fig.4 Increase of the material surface hydrophobicity with surface trimming 图4 通过表面修饰提高材料表面疏水性能

为解决这一问题,需要对镀膜元件的表面进行修饰,通过增加小分子氟化物、甲基等表面能较低的基团来提高接触角。图4展示了这种情况:通过表面修饰,可使薄膜表面的接触角提升到~110°,满足疏水性的要求。但其在长期激光辐照过程中,接触角可能发生一定程度的降低[45],因此膜层表面疏水性能在激光辐照条件下的稳定性问题值得进一步研究。

4 Laser Irradiation Lifetime of the Optical Film Component

薄膜光学元件的激光辐照寿命

Optical film components of the lithographical objective need to withstand several ten billion pulses in operating period of the mask aligner that is 7-10 years. Repetitive frequency of a laser source is 4-6 kHz[46]. Energy density of a single pulse is between 0.1 mJ/cm2and several mJ/cm2. The energy density at this extent is 2-3 magnitudes lower than the classical laser induced damage threshold(LIDT)[47]of optical coatings. But the long-term laser irradiation will still result in absorption, adherence and optical thinning of the film-coated component[11]and even a combined variation brought by both the laser irradiation and the immersion environment.

在光刻机7~10年的使用周期内,光刻物镜中的光学薄膜元件需要承受数百亿个脉冲,并且激光光源的重复频率在4~6 kHz之间[46],单脉冲能量密度在0.1 mJ/cm2至数个mJ/cm2之间。虽然这种程度的能量密度较光学薄膜的经典激光损伤阈值(Laser Induced Damage Threshold,LIDT)[47]低2~3个数量级,但是长期激光辐照仍然会使镀膜元件产生吸收、粘附性和光致变薄的问题[11],甚至产生激光辐照与浸液环境共同作用所带来的复合变化。

4.1 Laser irradiation lifetime of the deep ultraviolet optical coating component

深紫外薄膜光学元件的激光辐照寿命

Optical path of the basic test device for online monitoring of continuous variation of the component transmittance during irradiation is as shown in Fig.5. In addition, accessories can be added into the evaluation device to detect the sample's laser-induced fluorescence(LIF) spectrum or perform the online/offline ellipsometric measurement. These results together with the online transmittance result are used for comprehensive evaluation of the irradiation lifetime.

用于在线监测元件透过率在辐照过程中持续变化的基本实验装置光路如图5所示。除此之外,还可以在评估装置内增加附件,检测样品激光诱导荧光光谱(LIF),或对样品进行在线/离线椭偏参量测量,利用这些结果与在线透过率结果进行辐照寿命的综合评估。

Fig.5 Optical path of in-situ transmission measurement while laser irradiation 图5 激光辐照过程中在线透过率检测光路图

There is a non-linear relationship between the extinction coefficient of Al2O3film subjected to asynchronous excitation of the laser at 193 nm and the repetitive laser frequency[48]. Thus what needs to be first considered in the laser irradiation lifetime evaluation is impact of the repetitive frequency on the component lifetime. So far, similar phenomena have not been found in fluoride materials(including the fluoride film), and the single photon absorption mode is still presented. Thus the value of irreversible component damage(the increased absorption) is linearly correlated to the repetitive frequency and energy density, as shown in Fig.6.

鉴于193 nm激光对Al2O3薄膜产生异步激励影响,使其消光系数与激光重复频率之间呈现非线性关系[48]。因此,激光辐照寿命评估中首先需要考虑的是重复频率对元件寿命的影响。迄今为止,尚未在氟化物材料(包括氟化物薄膜)中发现类似的现象,仍显示为单光子吸收模式,因此元件不可逆损伤(吸收的增加)的数值与重复频率、能量密度都呈线性关系,如图6所示。

Fig.6 Relationship between the value of irreversible component damage and the repetitive frequency and energy density 图6 元件不可逆损伤的数值与重复频率、能量密度的关系

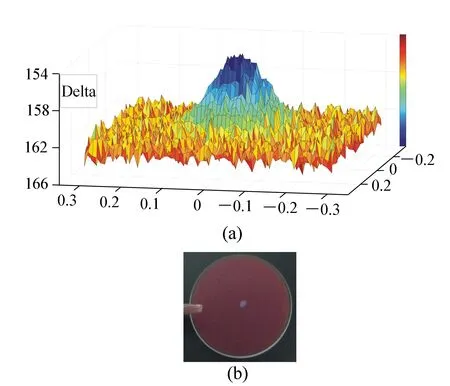

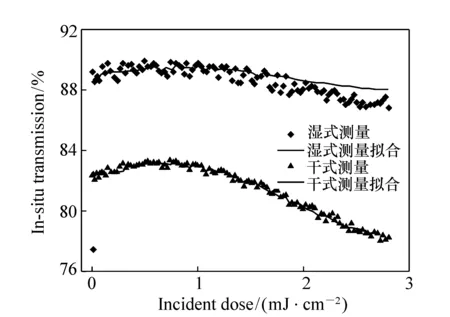

Intuitive recognition of the component damage progress can be based on online tracking and measurement of the component's wide-spectrum ellipsometric parameters. Mapping distribution of ellipsometric parameters that were initiatively not featured tends gradually to be same as the irradiation facula shape along with dose accumulation in the irradiation. As shown in Fig.7, variation of a film system can be fit dynamically by using changes ofΔandΨover time. Liberman et al have created the dynamic film layer thinning model based on the assumption of surface film-layer laser irradiation densification in accordance with the film system fitting result, assuming that the film thickness changes continuously at a constant rate in the irradiation environment. This model agrees very well with the online film-system transmittance fitting results[8], as shown in Fig.8.

通过对元件的宽光谱椭偏参量进行在线跟踪测试,可以对元件的损伤历程建立直观认识:在辐照过程中,随着剂量的累积,原本无特征的椭偏参量mapping分布逐渐与辐照光斑形状趋同,如图7所示,利用Δ和Ψ随时间的变化可以动态拟合膜系的变化。Liberman等跟据膜系拟合结果,基于“表面膜层激光辐照致密化”的假设,建立了膜层动态减薄模型,假设薄膜的厚度在辐照环境下持续发生变化,并且变化速度是恒量,这种模型与膜系在线透过率拟合结果吻合得非常好[8],如图8所示。

Fig.7 (a)Delta space distribution for the film-coated component after laser irradiation; (b)Laser irradiation sample 图7 (a)镀膜元件在激光辐照后的空间Delta分布;(b)激光辐照样品

Fig.8 Relationship between the transmittance(solid lines) in dynamic film-layer thinning model and the transmittance(scattered points) measured actually during irradiation 图8 膜层动态减薄模型透过率(实线)与辐照过程中实测透过率(散点)关系

4.2 Laser irradiation lifetime of components in the immersion environment

浸液环境下的元件激光辐照寿命

The last-window surface exposed to water in the immersive lithographical projection objective is subjected to both the immersion liquid and the laser irradiation. Its service lifetime is different from that in the pure immersion or laser irradiation. Liberman et al had evaluated the laser irradiation lifetime of products provide by main suppliers of lithographical film-coated components and obtained the result showing multiple degenerations including film dissolution, film layer falloff, complete transmittance disappearance in a un-irradiated area, surface roughness increase, film layer thickening/densification, film blackening and discoloration in an irradiated area that can be found only at the reflective observation condition[49].

在浸没式光刻投影物镜中,与水接触的下窗口表面同时受浸液与激光辐照的双重影响,其使用寿命有别于单纯的浸液或激光辐照。Liberman等人曾对主流光刻镀膜元件供应商的产品进行激光辐照寿命的评估,结果显示了多种退化现象,包括薄膜溶解、膜层脱落、未辐照区域透过率完全消失、表面粗糙度增加、膜层变薄/致密、薄膜发黑、仅在反射观察条件下能够发现的辐照区域变色等[49]。

The above result has shown complication of the issue. Immersion irradiation lifetime of the component is closely related to the immersion environment(including contamination) and irradiation condition. The water quality and leaching contamination have a considerable impact. Liberman el al have built up an ultrapure water treatment cycle system to strictly control indices in the part of immersion liquid in contact with component surface including conductivity(>18 MΩ) and total carbon content(<2×10-9g/mL)[8], and further studied contamination effects at different doses brought by contaminants such as isopropanol, acetone, methylbenzene and silicone on the above basis. Contaminants at the content of several ppb to more than one hundred ppm are injected into the immersion liquid and cycled for observation of immersion irradiation characteristics of the fused quartz substrate[50]. Surprisingly, film layers that can be considered as contaminants and have a refraction index different from the substrate have not been found in all samples. The reason is explained such that a water film was formed on surface of the fused quartz to inhibit formation of surface contaminants at the interface between water and component.

上述结果显示了问题的复杂性,元件的浸液辐照寿命与浸液环境(包括污染)、辐照条件均紧密相关,其中水质与浸析污染等具有相当大的影响。Liberman等人搭建了超纯水处理循环系统,对浸液中与元件表面接触部分的电导率(>18 MΩ)、总碳含量(<2×10-9g/mL)等指标进行了严格的控制[8],并在此基础上针对异丙醇、丙酮、甲苯、硅酮等污染物进行了不同剂量的污染效果研究,将数个ppb至上百个ppm含量的污染物注入浸液中进行循环,并对融石英基底的浸液辐照特性进行了观察[50]。令人意外的是,在所有的样品中,都未发现可被视为污染物以及折射率异于基底的薄膜层。并解释其原因为:在融石英表面形成了一层水膜,抑制了表面污染物在水/元件二者界面上的形成。

To further identify the contamination mechanism, the contaminant content and pure water flow will be strictly controlled at quasi-working conditions in the next test. Having studied the bare fused quartz substrate and film-coated CaF2sample, a more complicate anti-intuitive phenomenon is found. Samples have not been contaminated in the laser irradiation area but have been severely contaminated at upstream of the water flow outside the irradiation area, and even the transmittance disappeared completely at some locations[51]. On basis of these phenomena, Liberman et al point out that: first, the contamination shall not be a pure adherence and shall result from competition between both the adherence and cleaning mechanisms; second, the laser appears not only as a negative player but also as a participant in the complicated photochemical reaction to make foreign matters become contaminants on one hand and facilitate generation of the cleaning catalyst with water participation on the other hand, where the component surface maintains cleaned at a bigger action of the latter than the former; and finally, the severe contamination at upstream of the component and the unchanged optical capabilities at downstream can be explained as excessive intermediate products with the cleaning effect that gather at downstream along with water flow while no such products at upstream. The above result constitutes a very important reference to effectively controlling immersion irradiation lifetime of the component.

为了进一步明确污染机制,在接下来的实验中,污染含量、纯水流量等被严格控制于准工况下。经过对融石英裸基底与镀膜CaF2样品进行研究,发现了更加复杂的反直觉现象:在激光辐照的区域内,样品是无污染的;但在辐照区域外水流方向的上游侧,则出现了比较严重的污染,某些位置甚至透过率完全消失[51]。基于这些现象,Liberman等指出:首先,污染不应该是一个单纯的吸附过程,而是吸附与清洁两种机制竞争产生的结果;其次,激光的出现也不仅仅起负面作用,而是参与了复杂的光化学作用,一方面使外来杂质形成污染物,另一方面,在水的参与下促使清洁催化剂的生成,当后者的作用超过前者时,元件表面仍然呈现为清洁状态;最后,元件上游污染严重、下游光学性能未变的原因可以解释为伴随着水的流动,下游聚集了过多的具有清洁作用的中间产物,而上游则没有。上述结果为有效控制元件的浸液辐照寿命提供了非常重要的参考依据。

5Conclusions

结 论

The immersive lithography technology represents currently the upmost optical manufacture, which imposes requirements on the thin-film mainly from two respects. Rigorous requirements such as large incidence angle and inhibition of the polarization split are brought by high numerical aperture of the projection objective. New film layer materials together with corresponding processes need to be developed to meet demands for shaded refraction index, film layer with an extremely low refraction index, etc, realize the large angle polarization-maintaining film system and satisfy the system image quality requirement. The optical coating component works at highly repetitive frequency and high cumulative energy density conditions, and even the last component needs to be immerged in the immersion environment during the full life cycle. Satisfaction of the requirements for waterproofness, hydrophobicity and resistance to laser irradiation constitutes a precondition to apply the immersive projection objective. The relevant research progresses to the above issues were presented and the relevant technologies were discussed in this paper to point out a technical direction for optical coating components to better satisfy the demand for immersive projection objective.

浸没式光刻代表了目前光学技术的制造极限,对薄膜的要求主要来自两方面:投影物镜的高数值孔径带来了大入射角、抑制偏振分离等苛刻要求,为此需要开发新型膜层材料与配套工艺,以满足渐变折射率、超低折射率膜层等需求,实现大角度保偏膜系,满足系统像质要求;薄膜光学元件工作在高重频、高能量密度的工况下,甚至最后一片元件还需在全寿命周期内浸泡在浸液环境中,同时满足防水、疏水、抗激光辐照的要求是浸没式投影物镜实际应用的前提条件。本文针对上述问题,对相关研究进展进行了介绍,对相关技术进行了讨论,为薄膜光学元件更好地满足浸没式投影物镜的需求指明了技术方向。