瓜类蔬菜斜插式嫁接砧木子叶自适应压持机构设计与试验

楼建忠,吴 康,陈骏炀,麻桂杨,李建平,3※

瓜类蔬菜斜插式嫁接砧木子叶自适应压持机构设计与试验

楼建忠1,2,吴 康1,陈骏炀1,麻桂杨4,李建平1,3※

(1.浙江大学生物系统工程系,杭州 310029;2.浙江机电职业技术学院机械技术系,杭州 310053;3.农业部设施农业装备与信息化重点实验室,杭州 310029;4.华纳圣龙(宁波)有限公司 宁波 315104)

针对现有瓜类蔬菜嫁接机在砧木子叶压持过程中容易导致子叶根部折断,或由于压持力过大导致砧木子叶损伤等问题,以葫芦苗为试验对象,通过测定砧木苗子叶特征参数,设计制作了一种适用于瓜类蔬菜嫁接的砧木子叶压持机构,压持机构中的仿形垫块形态曲线与砧木苗子叶自然形态接近,防止子叶根部折断;在子叶压持过程中,压持机构的压辊能在仿形自适应垫块上自动滑移以实现压紧力自动调节,避免砧木子叶表面损伤。取60株苗龄15 d的葫芦苗进行子叶压持试验,并与没有加仿形垫块的砧木子叶压持机构进行比较,试验结果表明:加仿形垫块的压持机构子叶压持成功率为100%,无子叶根部折断和子叶表面损伤现象,生长点去除率达到98.3%,说明所设计的子叶自适应压持机构是可行的,该研究为解决蔬菜嫁接砧木子叶压持提供了设计参考。

农业机械;设计;嫁接;瓜类蔬菜;嫁接机;子叶压持;自适应;仿型

0 引 言

瓜类蔬菜嫁接栽培利用砧木根系发达、耐热、抗病和吸肥力强等特点,能有效克服连茬病害,增强植株的抗病能力,减少施肥量,被广泛用于蔬菜规模化种植中[1-3]。斜插式嫁接法是瓜类蔬菜常用的一种插接方法,嫁接时只需将经切削的穗木苗直接插入已去除生长点并打好孔的砧木中,无需对嫁接苗进行固定,操作简便,可避免贴接法因切除一片砧木子叶使砧木营养成分流失而影响嫁接苗成活率,被广泛应用于瓜类蔬菜嫁接种植中[4-6],而机械嫁接可克服手工嫁接效率低、成活率不高的缺点,减轻农民的劳动强度,提高作业生产率[7-10]。斜插式嫁接机作业时,砧木苗的子叶压持是斜插式瓜类蔬菜嫁接机设计需重点考虑的问题之一。嫁接时,若压持机构设计不合理,将导致砧木子叶在根部折断且损伤砧木子叶表面,直接影响嫁接的作业质量和嫁接苗的成活率[11-15]。

日本和韩国等国家于20世纪后期已对瓜类蔬菜嫁接机各机构进行了研究[16-18];在国内张铁中[19-21]和辜松[22-24]等分别进行了瓜类蔬菜插接式嫁接机的研究,并开发了相应的设备,但由于砧木苗具有较柔软的特性,夹持定位及固定较难、砧木苗子叶压持和压苗过程中易损伤、砧木苗打孔准确性差以及生长点不易去净等问题依然存在[25-26],常规的砧木子叶压持方法容易折断和损伤子叶[8-9]。

本文设计了一种瓜类蔬菜砧木子叶自适应压持机构。通过在作者所设计的交叉夹持机构[8]上加设仿型垫块,适应砧木苗形态特点,在压持过程中,压持机构的压辊能在仿形垫块上沿垫块表面自动滑移以调节压紧力,避免损伤砧木子叶,以期实现砧木苗子叶的无损压持,再利用作者所设计的生长点去除机构[27],成功实现砧木苗生长点的去除。

1 砧木苗形态特征及压持机构原理

1.1 砧木苗形态特征

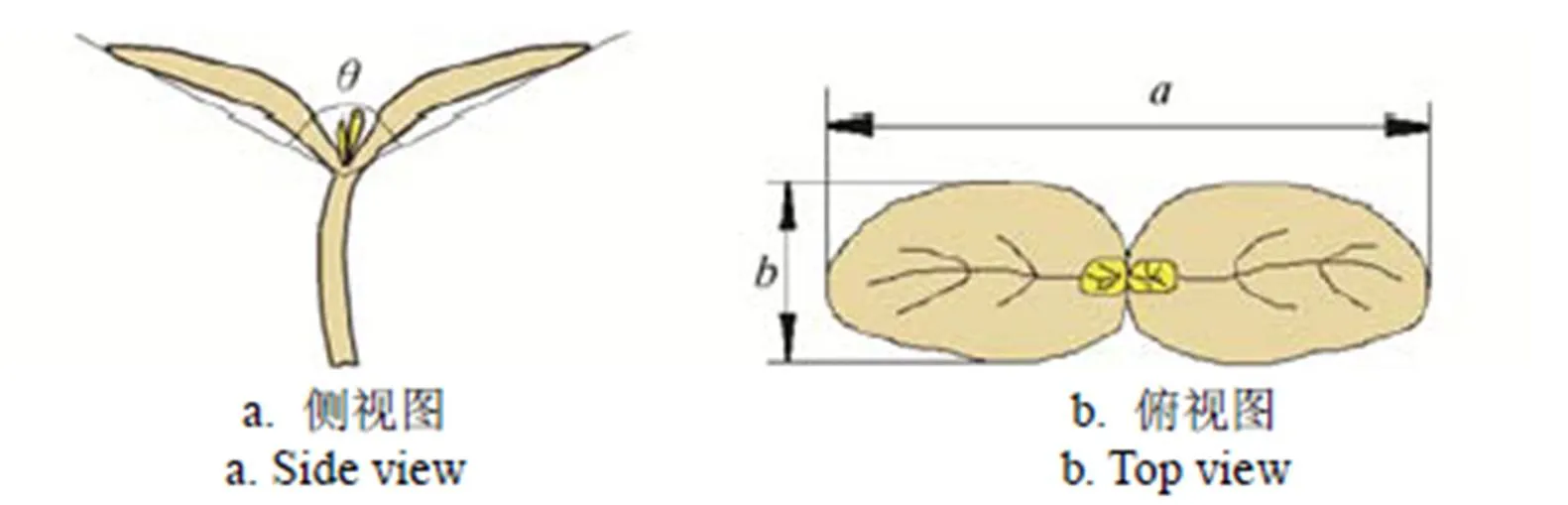

如图1所示为砧木苗实物图,砧木苗由子叶、生长点和苗茎3部分组成。葫芦苗在苗龄在12~15 d时生长点柔嫩且容易被去除,适合于嫁接,但由于砧木苗子叶比较柔嫩,压持时容易受到损伤。苗龄在12~15 d时的砧木苗子叶尚未完全展开,形状呈Y型,由于生长点嵌于两片子叶之间,所以子叶往两边拉伸,将生长点完全暴露于子叶外面,将有助于生长点去除。

1.2 砧木子叶特征参数测定

砧木苗子叶特征参数是砧木子叶压持机构设计的主要依据[28-30]。图2为砧木苗各特征参数示意图,葫芦苗特征参数测量结果见表1。

图1 砧木苗实物图

注:a为砧木子叶伸展跨距,mm;b为砧木子叶宽度,mm;θ为子叶展开角度,(º)

表1 砧木苗子叶特征参数

注:葫芦苗培育时间为15 d,样本数为60。

Note: Seedling age of cucurbit is 15 d, sample number is 60.

2 砧木苗子叶自适应压持机构设计

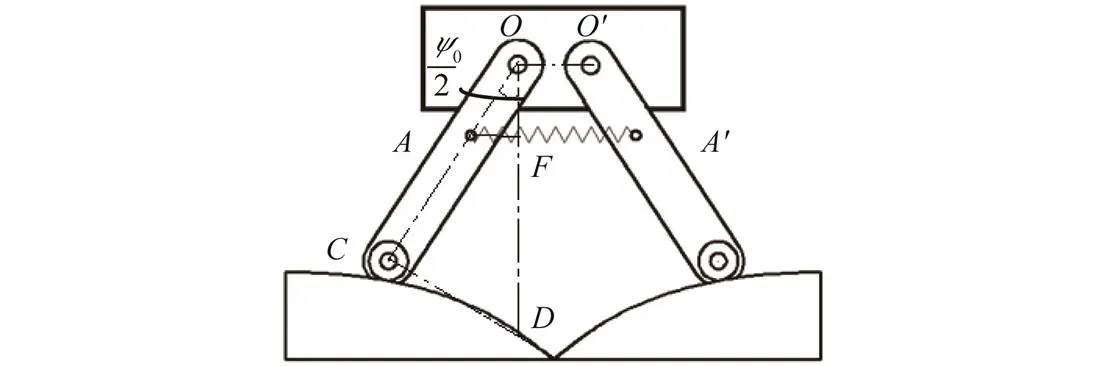

2.1 砧木子叶自适应压持机构原理

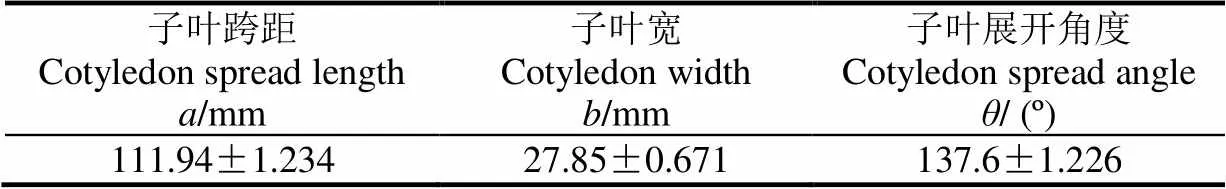

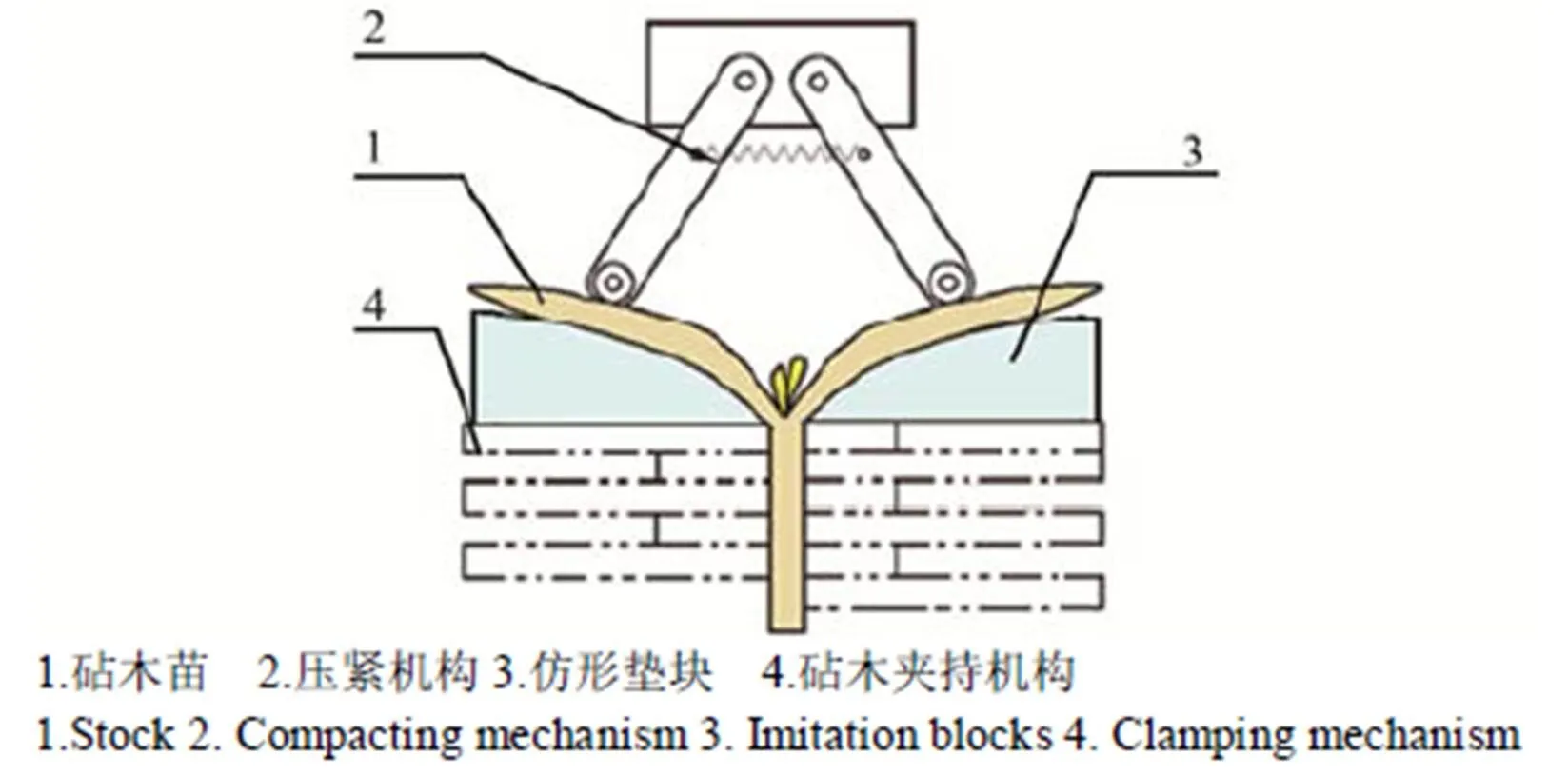

砧木子叶压持机构原理图如图3所示,其结构由仿形垫块、压紧机构两部分组成。仿形垫块由左、右两块组成,采用透明有机玻璃材料制作,在中间部位钻一与砧木苗茎直径大致相同的孔,仿形垫块安装于作者所设计的砧木夹持机构[8]上,随夹持机构一起运动。砧木子叶压紧机构结构如图4所示,砧木子叶压紧机构由压臂、压辊、压块、导套和弹簧等部分组成。

图3 砧木子叶压持机构原理图

压紧机构的压块通过导套安装于导杆上,沿导杆上下滑动,两压臂之间装有弹簧,当压紧机构下降至垫块时,压辊压于子叶上向外滚动,同时促使压臂撑开;当压紧机构上升时,压臂在弹簧作用下收回。压臂通过连接板安装于压块上,连接板上安装有两个限位销,用于限制压臂的位置。

图4 砧木子叶压紧机构结构图

2.2 砧木子叶自适应压持机构力学分析

砧木苗放入夹持机构[8]后,能较好地实现砧木苗茎部的定位对中与夹持固定,但嫁接期的砧木苗子叶展开呈Y型,生长点陷于2片子叶之间,使得生长点去除机构[27]很难将生长点抠除干净,若所设计的压持机构能使子叶往外伸展,则可以使生长点充分暴露于子叶外部,方便将生长点去除。

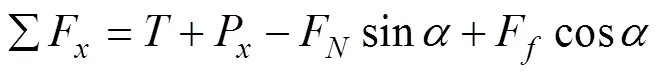

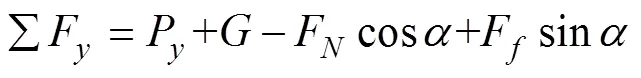

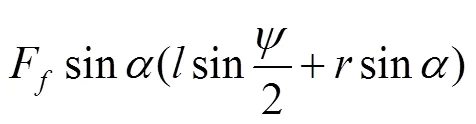

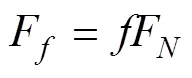

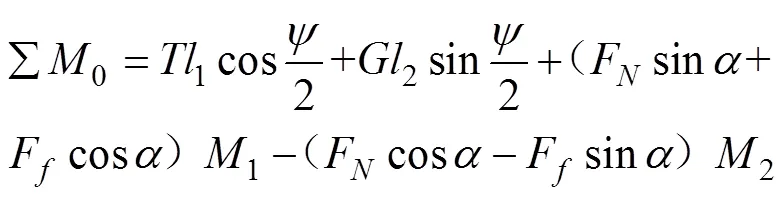

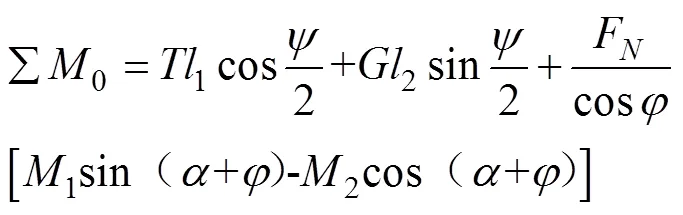

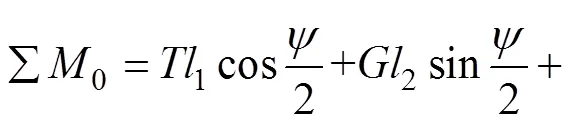

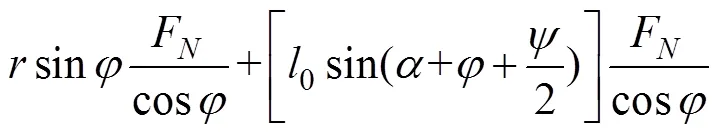

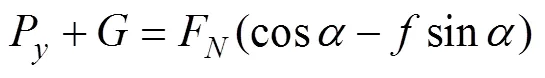

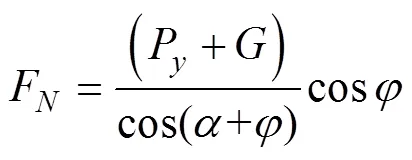

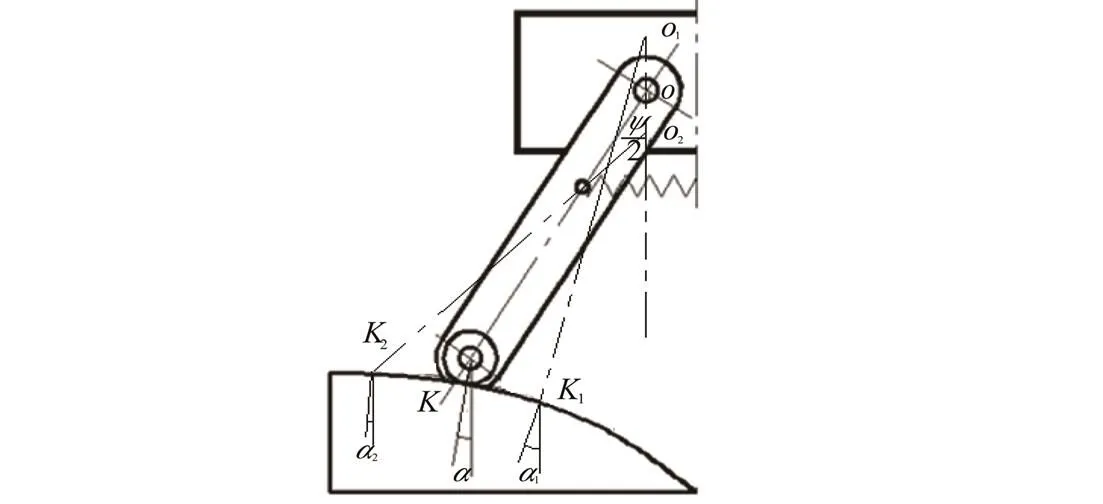

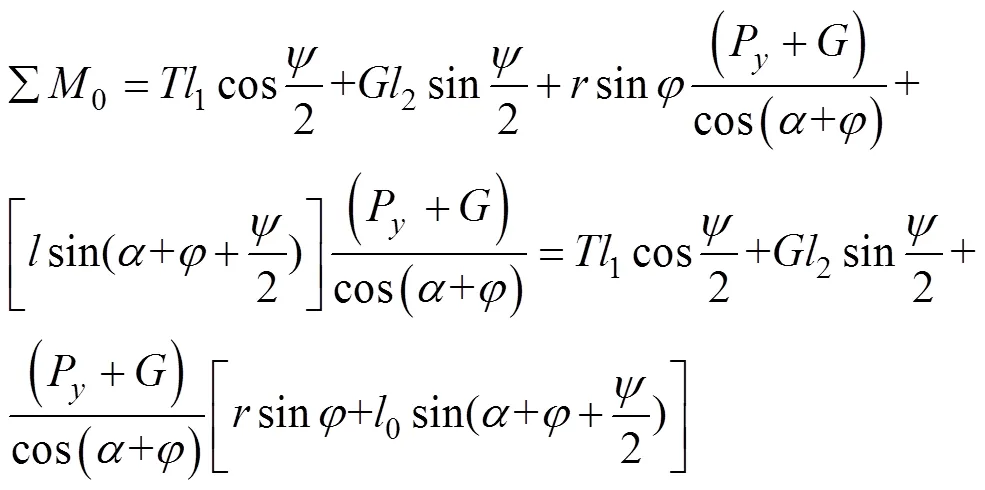

图5为砧木子叶压紧机构受力分析图,则有:

式中ΣF为方向的合力,N;ΣF为方向的合力,N;Σ0为绕点的合力矩,N.m;为弹簧拉力,N;P为方向上作用于压臂的外力,N;P为方向上作用于压臂的外力,N;F为子叶与压辊之间的摩擦力,N;F为子叶对压辊的支撑力,N;为子叶对压辊的支撑力与垂直面之间的夹角,(º);为压臂的重力,N;为压辊的半径,mm;为2压臂所夹的夹角,(º);为压臂的长度,mm;1为的长度,mm;2为的长度,mm。

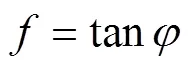

由于

则

则式(5)可简化为

注:G为压块的重力,N;为压臂的重力,N;P为方向上作用于压臂的外力,N;P为方向上作用于压臂的外力,N;F为砧木子叶与压辊之间的摩擦力,N;F为砧木子叶对压辊的支撑力,N;为弹簧拉力,N;为2压臂的夹角,(°);为砧木子叶对压辊的支撑力与垂直面之间的夹角,(°);点为左压臂与压块连接处;点为右压臂与压块连接处;点为压臂与弹簧连接点;点为压臂重心;点为压臂与压辊连接点;l为压臂的长度,mm;1为的长度,mm;2为的长度,mm。

Note:Gis the gravity of pressing block, N:is the gravity of pressing arm, N;Pis the forces acting on the arm indirection, N;Pis the forces acting on the arm indirection, N;Fis the friction between cotyledon and pressing rod, N;Fis supporting force on pressing rod, N;is spring tension, N;is the angle between two clamping arms,(°),is the angle between supporting force on pressing rod and vertical face,(°);is connected point of pressing arm and left pressing block;is connected point of pressing arm and right pressing block;is connected point of pressing arm and spring;is the centre of gravity of pressing arm;is connected point of pressing arm and pressing rod;lis the length of pressing arm, mm;1is the length of, mm;2is the length of, mm.

图5 压紧机构受力分析图

Fig.5 Stress analysis of compacting mechanism

即

则式(6)可简化为

将1、2代入(8)得

由式(2)可得

由式(10)可得

注:O1为压块运动至最高点时压臂与压块连接点;O2为压块运动至最低点时压臂与压块连接点;K1为压块运动至最高点时压辊与垫块接触处;K2为压块运动至最低点时压辊与垫块接触处;K为运动过程中压辊与垫块接触处;α1为压块运动至最高点时压辊与垫块接触处法线方向与垂直方向的夹角,(°);α2为压块运动至最低点时压辊与垫块接触处法线方向与垂直方向的夹角,(°);α即为压辊接触处法线方向与垂直方向的夹角,(°)。

式中

则

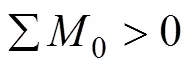

根据作用力与反作用力,压臂上的合力矩S0使得砧木苗子叶获得一个从中心向两边拉叶子的摩擦力(见图7),从图7还可以看出,在子叶向外伸展的过程中,子叶背面与垫块接触处会产生阻碍子叶向外伸展的阻力F2,由于子叶厚度不大,可认为与F2在同一线上,但方向相反,当F>F2时,子叶向外伸展,子叶贴合在仿形垫块上,使生长点充分暴露方便去除。

注:F f1为压辊作用于砧木的摩擦力,N;Ff2为砧木子叶与垫块之间的摩擦力,N;Ff3为砧木苗与夹持片之间的摩擦力,N;FN1为压辊对砧木苗的压力,N;FN2为垫块对砧木苗的支撑力,N;FN3为夹持片对砧木苗的夹紧力,N;G'为砧木的重力,N。

2.3 砧木子叶压持机构结构设计

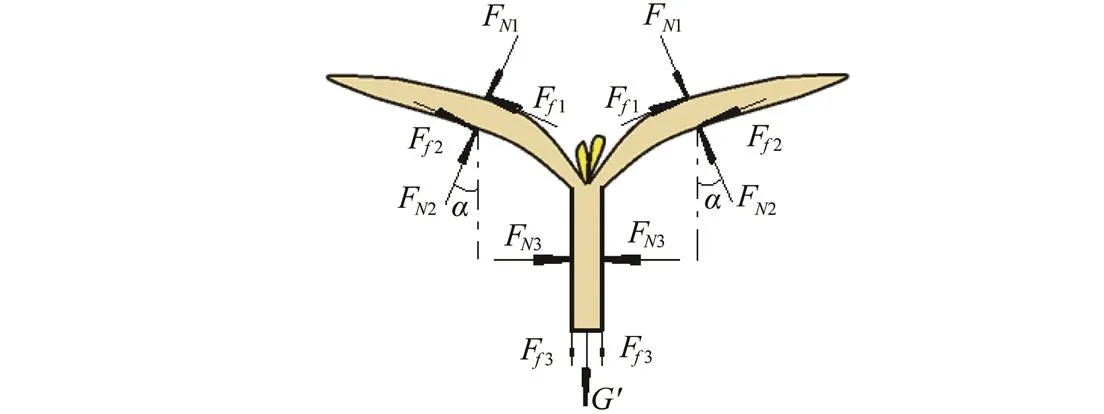

仿形垫块的结构参数对砧木子叶的压持有较大影响,仿形垫块的结构如图8所示。

注: l为左、右2压持垫块闭合后总长度,mm;d为压持垫块的宽度,mm;h为压持垫块的高度,mm。

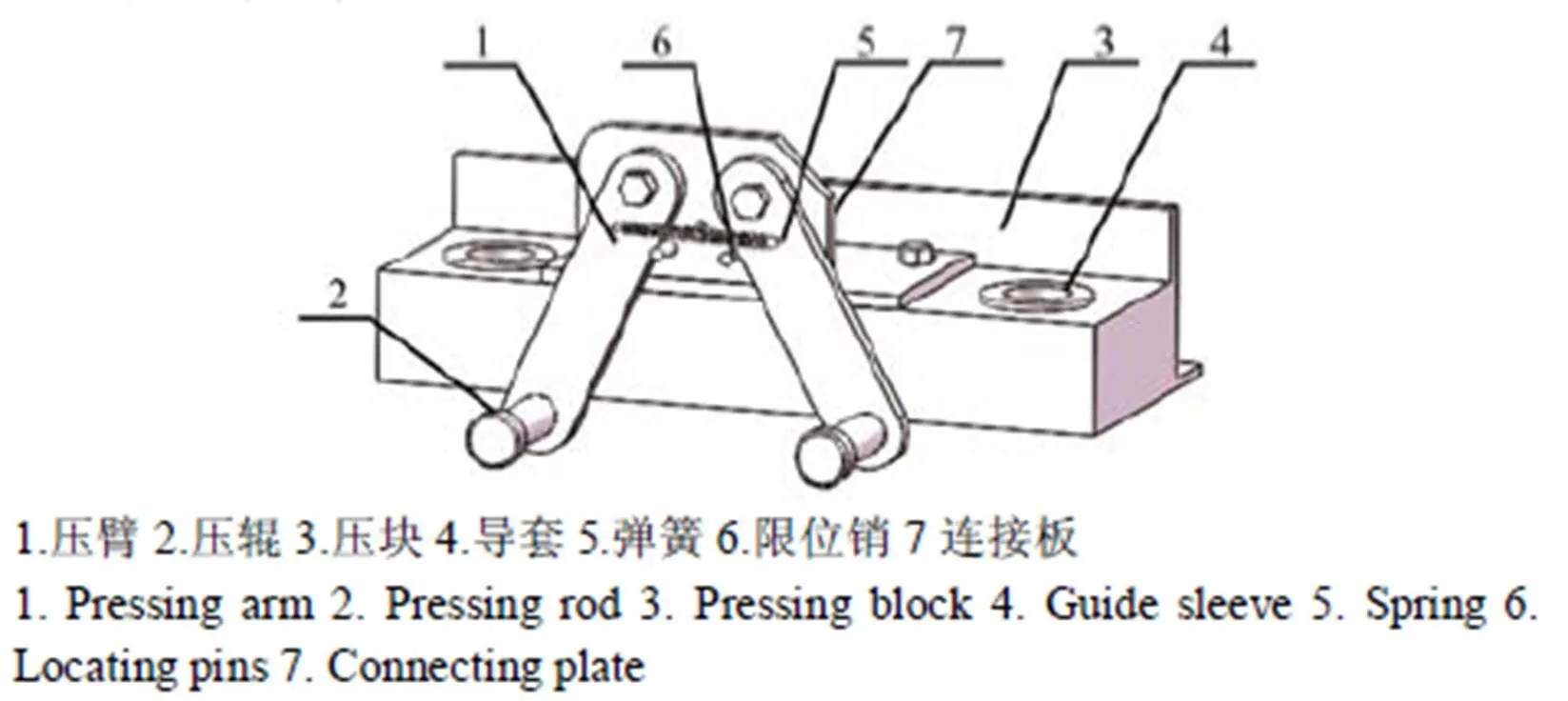

根据表1测定的砧木参数,取左、右两压持垫块闭合后总长度为110mm,宽度为25mm。

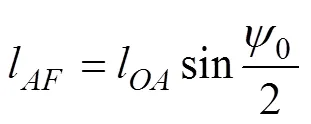

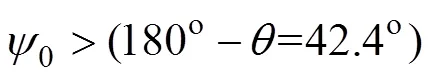

由几何关系

结果分析:从左至右,样品依次编号为1-10号,最右列为2000bp的对照Marker,此电泳结果为B组致病菌的电泳条带:首先所有样品均在1176bp处出现内对照条带。其中1、4、6、8-10号分别在695bp处出现特异性条带,检测结果为大肠埃希氏菌特异性基因。

可得为21.33mm,取高度为20mm。仿形垫块外形与砧木苗子叶舒展时的形态特征。

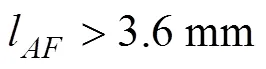

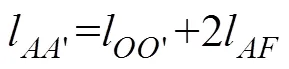

压紧机构的几何关系如图9所示。压辊由销钉和套筒组成,销钉固定于压臂上,选用外径为5mm的套筒套于销钉上,套筒外套0.5mm厚的柔性橡胶套,套筒外套柔性橡胶套目的是防止压辊对砧木子叶的损伤。压紧机构通过凸轮推动压块作周期性运动[9]。

由于仿形垫块表面为曲线,故有

设计l的长度为10mm。

则

由于

其中l为段的长度,mm。设计l'的长度为10 mm。

注:O点为左侧压臂与压块连接处;O'点为右侧压臂与压块连接处;A点为左侧压臂与弹簧连接点;A'点为右侧压臂与弹簧连接点;C点为压臂与压辊连接点;F点为过O点作垂线与弹簧的交点;D为过C点作OC的垂线与OF延长线的交点;为压臂张开角度,(°)。

则

取弹簧自由长度为20 mm,压臂的初始位置通过两侧定位销进行定位(结构见图4)。

3 砧木子叶压持试验

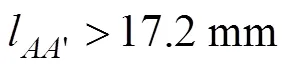

3.1 试验条件与方法

砧木子叶的压持试验如图10所示。取60株苗龄在15 d的葫芦苗,将无仿形垫块压持机构[8](图10a)与加仿形垫块压持机构(图10b)2种压持机构进行比较试验,比较子叶压持成功率、子叶折断率、子叶表面损伤率和生长点去除率。

图10 砧木子叶压持试验

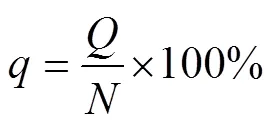

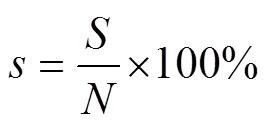

其中:子叶压持成功率为试验中子叶没有扭曲并贴紧仿形垫块的砧木数与用于试验的砧木苗总数之比,%;子叶折断率为压持过程中子叶根部折断的砧木数与用于试验的砧木苗总数之比,%;子叶损伤率为压持过程中子叶表面有明显压痕的砧木数与用于试验的砧木苗总数之比,%;生长点去除率为生长点被成功去除的砧木苗数与用于试验的砧木苗总数之比,%。即

工作时,利用凸轮机构(图10c)顶起子叶压紧机构(图10d),由于仿形垫块安装于夹持片上,当夹持片随夹持机构打开的同时,2片砧木子叶仿形垫块也同时分开,手工放入砧木苗,调整砧木苗子叶展开方向使其与仿形垫块保持一致,利用砧木苗自重控制夹持机构闭合,砧木苗夹持后的状态如图10e所示;压紧机构随凸轮降下压紧子叶,为生长点去除提供有利条件,用本课题组设计的生长点去除机构除去生长点[27]。整体试验装置如图10f所示。

3.2 试验结果

砧木子叶压持试验情况如表2所示。通过试验可知,未加砧木仿形垫块的砧木苗子叶容易折断,其折断率为13.3%,而加仿形压持垫块后砧木子叶在设定的工况下子叶根部无折断现象,子叶压持成功率为100%;未加仿形垫块的砧木苗子叶表面压持损伤率为21.6%,加仿形压持垫块后子叶表面无明显压痕现象;加仿形压持垫块后生长点能较好地被去除,比未加砧木仿形垫块的生长点去除率提高81.6个百分点,达到98.3%,分析生长点未被去除的砧木苗,发现这些砧木苗具有较大的畸变。所设计的砧木仿形自适应压持机构能较好地满足瓜类蔬菜嫁接的要求。

表2 砧木子叶压持试验结果

注:葫芦苗培育时间为15 d,样本数每组60。

Note: Seedling age of cucurbit is 15 d, sample number is 60.

4 结 论

1)通过对砧木苗子叶特征参数的分析,设计了一种应用于瓜类蔬菜嫁接的斜插式砧木子叶自适应压持机构,压持机构的仿形垫块利用砧木苗子叶自然状态时的形态特征,防止了砧木苗子叶在压持过程中根部发生折断。压持机构的压辊能在仿形垫块上沿垫块表面自动滑移调节压紧力,避免损伤砧木子叶,实现了砧木苗子叶的无损压持。

2)通过对压持机构的受力分析可知,随着压持机构的压辊在仿形垫块上由中间往外滚,砧木子叶对压辊的支撑力值越来越小,即压持机构能自动调节压辊对砧木子叶的压力大小,防止砧木子叶表面损伤;同时压辊作用下子叶充分向外伸展,方便生长点去除机构抠除生长点。

3)取苗龄在15 d的葫芦苗进行砧木子叶压持试验,在给定工况下,用加仿形垫块与不加仿形垫块2种压持机构进行比较试验,结果显示,加仿形垫块后压持成功率为100%,子叶根部无折断现象,子叶表面无损伤情况,生长点生长点去除率达到98.3%,表明所设计的砧木自适应压持机构能较好地满足砧木苗的压持要求。

[1] 孙光闻,陈日远,刘厚诚.设施蔬菜连作障碍原因及防治措施[J]. 农业工程学报,2005,21(增刊):184-188.Sun Guangwen, Chen Riyuan, Liu Houcheng. Causes and control measures for continuous cropping obstacles in vegetable cultivation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(Supp.): 184-188. (in Chinese with English abstract)

[2] 邹贵祖,辜松.果蔬机械化嫁接育苗生产[J].农机化研究, 2009(2):235-237.Zou Guizu, Gu Song. The production of vegetables mechanized grafting seedling[J]. Agricultural Mechanization Research. 2009 (2): 235-237. (in Chinese with English abstract)

[3] 范双喜,王绍辉. 高温逆境下嫁接番茄耐热特性研究[J].农业工程学报,2005,21(增刊):60-63.Fan Shuangxi, Wang Shaohui. Endurance to high temperature stress of grafted tomato[J]. Transactions of the Chinese Society of Agricultural Engineering (Transitions of the CSAE), 2005, 21(Supp.): 60-63. (in Chinese with English abstract)

[4] 鹿令军. 黄瓜嫁接苗与自根苗生长状况的比较研究[J].现代农业科技,2011(12):107-108.Lu Lingjun. Comparative study of grafted cucumber seedlings and own root growth conditions[J].Modern agricultural science and technology, 2011(12): 107-108. (in Chinese with English abstract)

[5] 李建平.斜插式蔬菜嫁接装置:CN201010151585.9[P]. 2010-04-20.

[6] 李建平.蔬菜嫁接苗定位夹持机构:CN201010136744.8[P]. 2010-03-30.

[7] 刘爱群,李国强,赵丽丽. 不同苗龄砧木嫁接对黄瓜生长及产量的影响[J]. 辽宁农业科学,2011(3):57-58.Liu Aiqun, Li Guoqiang, Zhao Lili. The effect of different ages rootstocks on the growth and yield of the cucumber [J]. Liaoning Agricultural Sciences, 2011(3) :57-58. (in Chinese with English abstract)

[8] 楼建忠,李建平,朱盘安,等. 斜插式蔬菜嫁接机砧木夹持机构研制与试验[J]. 农业工程学报. 2013,29(7):30-35.Lou Jianzhong, Li Jianping, Zhu Pan’an, et al. Design and test of stock clamping mechanism for vegetable grafting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(7): 30-35. (in Chinese with English abstract)

[9] 楼建忠. 斜插式瓜类蔬菜嫁接装置机理研究及优化设计[D]. 杭州:浙江大学,2014.Lou Jianzhong. Mechanism Study and Optimization Design of Inclined-insert Grafting Device of Cucurbita Vegetable[D]. Hangzhou: Zhejiang University, 2014.

[10] 赵匀,武传宇,胡旭东,等.农业机器人的研究进展及存在的问题[J].农业工程学报,2003,19(1):20-24.Zhao Yun, Wu ChuanYu, Hu Xudong, et a1. Research progress and problems of agricultural robot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2003, 19(1): 20-24. (in Chinese with English abstract)

[11] 楼建忠,李建平,朱盘安,等. 斜插式蔬菜嫁接机穗木气吸吸头优化设计[J]. 农业机械学报,2012,43(2):63-68.Lou Jianzhong, Li Jianping, Zhu Pan'an, et a1. Optimization of suction head of scion clamping mechanism in vegetable grafting[J]. Transactions of the Chinese Society of Agricultural Machinery, 2012, 43(2): 63-68. (in Chinese with English abstract).

[12] 李明,戴思慧,汤楚宙,等. 苗木嫁接机器人切削机构模拟实验[J].农业工程学报.2008,24(6):129-132.Li Ming, Dai Sihui, Tang Chuzhou, et a1. Simulation test on plantlet-cutting mechanism of grafting robot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(6): 129-132.

[13] 索瑞英,邹贵,辜松. 旋转嫁接机的人机工程学设计[J]. 农机化研究.2009,(2):87-89.Shuo Ruiying, Zhou Gui, Gu Song. Design of the rotary grafting machine according to the man-machine engineering[J].Journal of Agricultural Mechanization Research, 2009,(2): 87-89. (in Chinese with English abstract)

[14] 赵燕平,张铁中,王红英. 树苗自动嫁接机砧木切削机构研究[J]. 农业工程学报,2008,24(9):79-83.Zhao Yanping, Zhang Tiezhong, Wang Hongying. Cutting mechanism of root parental stock in automatic machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Translations of the CSAE), 2008, 24(9): 79-83. (in Chinese with English abstract)

[15] 吕谷来. 蔬菜嫁接机器人关键技术的研究[D].杭州:浙江大学,2010.Lv Gulai. Study on the Key Technology of Vegetable Grafting robot[D]. Hangzhou: Zhejiang University, 2010.(in Chinese with English abstract)

[16] Amada H, Buno S, Koga H, et al. Development of a grafting robot[C]//Proc. International Symposium on Automation and Robotics in Bio-production and Processing. Kobe, Japan: 1995:241-248.

[17] Miyanaga T, Fukumori I, Susawa K, et al. Technical report of the institute of agricultural machinery[R]. Omiya, Saitama, Japan. 1998.

[18] Ryu K H, Kim G, Han J S. Development of a robotic transplanter for bedding plants [J]. Agric Eng Res, 2001, 78(2): 141-146.

[19] 赵颖,孙群,张铁中. 营养钵茄苗嫁接机器人机械系统设计与实验[J].农业机械化学报,2007(9):94-97.Zhao Ying, Sun Qun, Zhang Tiezhong. Mechanical system design of grafting robot for nutritional bowl eggplant seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007(9): 94-97. (in Chinese with English abstract)

[20] 杨丽,刘长青,张铁中. 双臂蔬菜嫁接机设计与试验[J].农业机械学报.2009,40(9):175-181.Yang Li, Liu Changqing, Zhang Tiezhong. Design and experiment of vegetable grafting machine with double manipulators[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(9): 175-181. (in Chinese with English abstract)

[21] 徐丽明,张铁中,刘长青.蔬菜自动嫁接机器人系统: 旋转切削机构设计[J]. 中国农业大学学报,2000,2(2):34-36.Xu Liming, Zhang Tiezhong, Liu Changqing. Vegetables automatic grafting robot systems: rotating cutting mechanism design[J]. Journal of China Agricultural University, 2000, 45(2): 34-36. (in Chinese with English abstract)

[22] 辜松,刘宝伟,王希英. 2JC-500型自动嫁接机西瓜苗嫁接效果生产试验[J]. 农业工程学报, 2008,24(12):84-87.Gu Song, Liu Baowei, Wang Xiying, et al. Production test of 2JC-500 automatic grafting machine for watermelon [J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(12): 84-88. (in Chinese with English abstract)

[23] 辜松. 2JC-350型蔬菜插接式自动嫁接机的研究[J], 农业工程学报,2006,22(12):103-106.Gu Song. Development of 2JC-350 automatic grafting machine with cut grafting method for vegetable seeding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(12): 103-106. (in Chinese with English abstract)

[24] 辜松,刘凯,杜月.电磁力在蔬菜自动嫁接机上的应用[J].农业工程学报,2008,24(10):105-109. Gu Song, Liu Kai, Du Yue. Application of electromagnetic force on automatic vegetable grafting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(10): 105-109. (in Chinese with English abstract)

[25] 姜凯,郑文刚,张骞,等. 蔬菜嫁接机器人研制与试验[J].农业工程学报,2012,28(4):8-14. Jiang Kai, Zheng Wengang, Zhang Qian, et al. Development and experiment of vegetable grafting robot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 8-14. (in Chinese with English abstract)

[26] 马稚昱,韦鸿钰,牟英辉,等.顶芽斜插嫁接时砧木插孔角度的确定[J].农业工程学报,2014,30(3):43-49. Ma Zhiyu, Wei Hongyu, Mu Yinghui, et al. Determination of insertion angle of hole-insertion grafting method by grafting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014,30(3): 43-49. (in Chinese with English abstract)

[27] 楼建忠,李建平,朱盘安. 瓜类蔬菜嫁接砧木生长点去除机构设计与试验[J],农业工程学报,2016,32(23):64-69.Lou Jianzhong, Li Jianping, Zhu Pan'an. Design and test on growing point removal mechanism of melon vegetable grafting stock[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(23): 64-69. (in Chinese with English abstract)

[28] 张雷,贺虎,武传宇. 蔬菜嫁接机器人嫁接苗特征参数的视觉测量方法[J]. 农业工程学报,2015,31(9):32-38. Zhang Lei, He Hu, Wu Chuanyu. Vision method for measuring grafted seedling properties of vegetable grafted robot[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(9): 32-38. (in Chinese with English abstract)

[29] 牟英辉,辜松,马稚昱.瓜类嫁接苗生物力学特性的试验分析[J].农业工程学报,2012,28(4):15-20.Mu Yinghui, Gu Song, Ma Zhiyu. Experimental analysis on biomechanical properties of cucurbits grafted seedlings[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 15-20. (in Chinese with English abstract)

[30] 熊丙全. 蔬菜嫁接育苗的主要方法及其技术要点[J]. 四川农业科技,2008(12):30-31.Xiong Bingquan. Grafting methods and cultivation technology of vegetable seedling grafts[J]. Sixhuan Agricultural Science, 2008(12): 30-31. (in Chinese with English abstract)

Design and test of self-adaptive stock cotyledons pressing and clamping mechanism for oblique inserted grafting ofvegetables

Lou Jianzhong1,2, Wu Kang1, Chen Junyang1, Ma Guiyang4, Li Jianping1,3※

(1.,,310029,; 2.,,310053,; 3.,,310029,; 4315104, China)

The grafting and cultivation ofvegetables are characterized by the strong root system, heat resistance, disease resistance and good absorbing ability for soil fertility. Oblique grafting is a common method forvegetables. The pressing and clamping of the stock cotyledons is one of the important issues to be considered in the design of oblique inserted grafting machine. According to the problem that the existingvegetable grafting machine easy to break the petiole of cotyledons or damage the cotyledons in the process of cotyledons pressing, the stock cotyledons pressing and clamping mechanism used invegetable grafting was designed and developed by measuring the characteristic parameters of the cotyledons and by adding an imitation blocks on the cross clamp mechanism designed by the author before to adapt to the morphological characteristics of the stock cotyledons. The shape of the imitation blocks in the pressing and clamping mechanism was close to the natural shape of the cotyledons in order to prevent the breaking of the cotyledon. In the process of pressing the cotyledon, the pressing roll of the pressing and clamping mechanism could automatically slip on the imitation blocks to realize the automatic adjustment of the compression force and to avoid the damage of cotyledon. Then the growth point removal mechanism designed by the authors was used to successfully remove the growth point of rootstock seedlings. Through the force analysis of the pressing and clamping mechanism, it could be seen that the supporting force of the cotyledon to the pressing rod was getting smaller and smaller when the pressing rod rolled from middle to outside on the imitation blocks. That is, the pressing mechanism could automatically adjust the force on the cotyledon and prevent the cotyledon surface damage. At the same time, the pressing rod could extend the cotyledons to outside making the growth point fully exposed and convenient to be removed. The stock cotyledon pressing tests on 60 cucurbit seedlings were carried out by using the self-adaptive pressing and clamping mechanism and compared with that of without imitation blocks. The results showed that the success rate of the stock cotyledon pressing and clamping mechanism with the imitation blocks was 100%. It was also found that cotyledons could easily be broken by using the pressing and clamping mechanism without imitation blocks, and the breaking rate of cotyledons was 13.3%, but cotyledons was totally not broken by using the pressing and clamping with imitation blocks in the same condition. The damage rate of cotyledons surface was 21.6% by using the mechanism without imitation blocks, but it was totally not damaged by using the mechanism with imitation blocks in the same condition. The growth point of stock could easily be removed by using the mechanism with imitation blocks, and the remove rate of growth point was 98.3%, while it was only 16.7% by using the mechanism without imitation blocks. It indicated that the design of the stock cotyledon pressing and clamping mechanism with the imitation blocks was reasonable. It can better meet the requirements of the grafting and cultivation ofvegetables. The study provides a design reference for solving the problems on pressing cotyledons in the process ofvegetable grafting.

agricultural machinery; design, grafting;vegetable; grafting machine; cotyledons pressing and clamping; self-adaptive; imitating

10.11975/j.issn.1002-6819.2018.18.010

S233.74

A

1002-6819(2018)-18-0076-07

2018-04-02

2018-06-08

国家自然科学基金(51775490);浙江省科技厅公益基金项目(2014C32105);浙江省机电集团有限公司项目(2016JD004)联合资助。

楼建忠,男,浙江诸暨人,副教授,博士生,主要从事农业机械的研究。Email:loujz160@163.com

李建平,男,教授,博导,主要从事农业机器人研究。Email:jpli@zju.edu.cn

楼建忠,吴 康,陈骏炀,麻桂杨,李建平. 瓜类蔬菜斜插式嫁接砧木子叶自适应压持机构设计与试验[J]. 农业工程学报,2018,34(18):76-82. doi:10.11975/j.issn.1002-6819.2018.18.010 http://www.tcsae.org

Lou Jianzhong, Wu Kang, Chen Junyang, Ma Guiyang, Li Jianping. Design and test of self-adaptive stockcotyledons pressing and clampingmechanism for oblique inserted grafting ofvegetables[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 76-82. (in Chinese with English abstract) doi: 10.11975/j.issn.1002 -6819.2018.18.010 http://www.tcsae.org