室温热电材料研究进展

朱航天, 任武洋, 张勤勇, 任志锋

(1.休斯敦大学物理系、德克萨斯超导中心,德克萨斯州 休斯敦 77204美国; 2.西华大学先进材料及能源研究中心, 四川 成都 610039)

The direct conversion between temperature differences and electricity energy can be realized through materials with thermoelectric effect. The efficiency of this conversion no matter for cooling or power generation is determined by the materials’ dimensionless figure-of-merit, ZT=SσT/(κlat+κele), whereSis the Seebeck coefficient,σthe electrical conductivity,κlatthe lattice thermal conductivity,κelethe electronic thermal conductivity, andTthe absolute temperature.

Room temperature thermoelectric materials has broad and important applications, including portable cooling system,energy sourcefor remote sensor,and microelectronics temperature control, etc[1]. However, more widespread use requires further improving of the conversion efficiency. The coefficient of performance (COP) of thermoelectric module that determines the cooling ability can be expressed as

(1)

Figure 1 The coefficient of performance of thermoelectric module with various average ZT (The COP is calculated with fixed hot-side temperature of 300 K. Household refrigerators and air conditioner is compared in this picture[5])

Due to the bigmarket of cooling device and the promising potential of thermoelectric materials in solid-staterefrigeration, the room temperature thermoelectric materials have attracted a great attention for decades[1,6]. The new strategies for thermoelectric performanceenhancement has been developed, and new promising room temperature materialshave been discovered[7-14]. However, the improvement is difficult, because all the transport parameters are strongly interrelated and cannot be controlled independently. Especially, room temperature thermoelectric materials with fixed operating temperature range can only be enhanced by Z value. Z value is a more critical parameter to judge the thermoelectric materials, which is only related to the intrinsic transport properties of the material. The room temperature thermoelectric materials have higher Z value than the materials working at mid-or high-temperature. A high Z value requires a very lowκlat,suitable carrier concentration, best band structure, and idea microstructure, which is a very rare combination in real materials leading to limited candidates for room temperature application.

In this work, the most promising room temperature thermoelectric materials including Bi2Te3-based materials,α-MgAgSb, and high power factor half-Heusler compounds are reviewed, and the general strategies for improving the power factor and lowering the lattice thermal conductivity are summarized. The common traitsunderline the room temperature thermoelectric materials may shed light on how to optimize the balance between phonon and electronscattering, which will guide us to further enhance the performance of the existing candidates and seek for new thermoelectric materials.

1 Bi2Te3 based materials

Since sixty years ago, Bismuth telluride (Bi2Te3) and its alloyswere recognized as the best candidates for thermoelectric refrigeration working near room temperature[15-16]. Intensive theoretical and experimental stu-dies have demonstrated the great potential of Bi2Te3-based thermoelectric device in refrigerating applications[1,6,17-20]. More importantly, the corresponding commercial products can provide a maximum temperature drop (△Tmax) of ~70 K with 298 K hot side[21]. As mentioned above, the efficiency of refrigeration can be evaluated by the materials’ intrinsic property,Z=S2σ/(κL+κe), which is usually multiplied byTappearing in its dimensionless form ZT. Thus improvement of ZT has been the goal for the thermoelectriccommunity. However, at low-temperature range (near the room temperature), a highZis essential, which is the most important character of Bi2Te3-based thermoelectric materials[14,22-27]. Table 1 summarizes the achieved encouraging ZT values forboth p-type and n-type Bi2Te3-based materials which are of great significance in the thermoelectric field. It is worthwhile pointing out that the typical p-type Bi2Te3alloys are

Table 1 Reported ZT values of p-type and n-type

Bi2Te3-based materials.

(Bi2Te3)-(Sb2Te3)pseudobinary compounds while the most n-type materials are alloys along the (Bi2Te3)-(Bi2Se3) pseudobinary line[19].

1.1 Crystal and electronic structure of Bi2Te3

1.2 p-type Bi2Te3-based thermoelectric materials

Since 1950, p-type Bi2Te3alloy has been regar-

Figure 2 Crystal and band structures of Bi2Te3((a)Crystal structure, and (b)band structure of Bi2Te3[46]. (c)Band related properties as a function of composition x for (Bi1-xSbx)2Te3at 300 K[26]. Reproduced with permission from ref. [46] Copyright 2009American Physical Society and ref. [26] Copyright of 2017 Elsevier Ltd.)

ded as the most important thermoelectric materials, of which ZT has remained around 1 for more than sixty years[15,19-20]. However, the recent decade has witnessed a significant progress in thermoelectric field by introducing nanostructure engineering[51-55]. The original idea of nanostructure engineering was suggested by Prof. Dresselhaus to utilize the quantum effect to enhance the performance of Bi2Te3quantum-well structure[56]. Based on this idea, a noticeable experimental result was reported by Venkatasubramanianet al., where a ZT as high as 2.4 at 300 K was reported for p-type Bi2Te3/Sb2Te3superlattices[28]. In this work, the explanation for such high performance is the contribution of phonon-blocking/electron-transmitting transport properties. The difference is that Prof. Dresselhaus proposed quantum effect responsible for adjusting the electronic density of state while Dr. Venkatasubramanian mainly focused on the lattice thermal conductivity reduction[57]. Due to the extremely reduced mean free path of phonons (~2.2 Å), the lattice thermal conductivity of the superlattices is only ~0.22 Wm-1K-1, which is 2.2 times smaller than that of Bi0.5Sb1.5Te3alloy(~0.49 Wm-1K-1). Unfortunately, this high ZT has never been reproduced. But the strategy to improve ZT via tuning the phonon transport, enlightened other researchers to develop nanocomposites. An important breakthrough came from Ren and Chen’s joint work, who reported room temperature ZT of 1.2 and peak ZT of 1.4 at 373 K in nanocrystalline p-type Bi0.4Sb1.6Te3(Figure 3)[14]. According to the microstructure analysis (inset of Figure 3), the grains are nanosized which increases the phonon scattering by dense grain boundaries, and the high crystallinity for each grain minimizes the detrimental effects on carrier mobility. This kind of nanostructured materials were easily prepared by using high-energy ballmilling (the size of ball milled nanoparticles mainly ranges from 5 to 50 nm) and fast sintering process. More detailed content about thermoelectric nanocomposites was discussed in ref.[51].Thus the thermoelectric nanocompositesby ball milling and hot pressing opened up a new venue for ZT improvement. Later many efforts were made to investigate various kinds of p-type Bi2Te3thermoelectric nanocomposites[22,24,26-27,31-32,40-41,43,45,58-60]. For instance, Terry M.Tritt et al. obtained a peak ZT of 1.56 at 300 K in Bi0.52Sb1.48Te3bulk material with unique microstructures, where 5-15 nm fine nanocrystalline domains were embedded in an amorphous matrix[22]. In addition, the sintered bulk materials from Bi0.5Sb1.5Te3nanoplates which consist of dense boundaries and dislocations, also showed good performance. Significantly reduced lattice thermal conductivity which is derived from a wide-frequency phonons scattering leads to room temperature ZT of 1.2[27]. Accordingly, on the basis of hierarchical phonon scattering, a dramatically enhanced ZT of 1.86 at 320 K was reported in Te-rich Bi0.5Sb1.5Te3alloy[43],which was investigated by other group independently but not reproduced[45]. Usually, grain boundaries and Bi-Sb atomic disorder targeted low-and high-frequency phonon scattering, respectively, whereas the mid-frequency phonons around 0.63 THz, which carry 74% of the heat, can avoid scattering from point defects and grain boundaries. In their opinion, high density of dislocationarrays formed by an unconventional liquid-phase compaction are responsible for scattering these mid-frequency phonons causing a greatly reduced lattice thermal conductivity (only 0.33 W m-1K-1at 320 K), but only have amarginal impact on the carrier mobility. According to this remarkable result, the whole thermoelectric industry may be revolutionized. Recently, a systematic reinvestigation on this Te-rich Bi0.5Sb1.5Te3alloy was performed by X. F. Tang’s group[45]. They propose the significantly enhanced ZT is ascribed to the anisotropic structure, where the charge and thermaltransport properties along and across two orthonormal directions are distinctly different, rather than the mid-frequency phonon scattering from dislocation networks. Figure 4 shows the electrical and thermal properties of the Te-rich Bi0.5Sb1.5Te3alloys for both directions, where the maximum ZT is of 1.24 at 350 K. Another interesting thing is that high-performance p-type (Bi1-xSbx)2Te3compounds are usually obtained asxaround 0.75. Previously, many researchers assumed this is due to the sudden flattening of the valence band to increase the band effective mass[61]. However, G. J. Snyder et al. proposed a two-band transport model which can explain the correspondingly experimental thermoelectric transport data more satisfactorily[26]. Based on thesemi-empirical band model, the convergence of first and second valence band is shown in Figure 2c. Therefore, the unique band structure, together with the persistent efforts to reduce thermal conductivity, contributes to the high thermoelectric performance of p-type BixSb2-xTe3alloys.

Figure 3 Temperature-dependent ZT of nanocrystalline p-type Bi0.4Sb1.6Te3material (The inset is the high-magnification TEM image of this p-type material showing thenanosized grains, high crystallinity, randomorientation, and clean grain boundaries[14]. Reproduced with permission from ref. [14] Copyright 2009 the American Association for the Advancement of Science).

Figure 4 Temperature-dependent thermoelectric properties of Bi0.5Sb1.5Te3withxwt% excess of Te in different directions[43,45]((a) Electrical conductivity, (b) Seebeck coefficient, (c) thermal conductivity, and (d) ZT value.Reproduced with permission from ref. [45] Copyright 2018 the American Association for the Advancement of Science).

1.3 n-type Bi2Te3-based thermoelectric materials

As mentioned above, the most n-type Bi2Te3alloys are (Bi2Te3)-(Bi2Se3) pseudobinary compounds[20]. Unlike the p-type materials with an isotropic ZT (electrical and thermal properties have same anisotropy), the n-type compounds are complicated for their anisotropic thermoelectric properties[23,62]. Therefore, it is easier to utilize nanostructure engineering for p-type materials than for n-type materials. At first, the performance improvement of Bi2Te3-xSexfailed to live up to the expectation by simply going nanoscale[34-35,38-39,42,63-64]. But by promoting the anisotropy via a two-steps sintering process[23], X. Yan et al. reported an enhanced ZT (over 1.0 around 373 K). Furthermore, a preferentially aligned Bi2(Te0.93Se0.07)3alloy was fabricated by directly hot deforming the commercially zone-melted ingots with peak ZT reaching 1.2 at 357 K (Figure 5a)[25]. In this work, increasing the number of hot deforming created dense dislocations, which resulted in a greatly reduced in-plane thermal conductivity. More importantly, a much higher quality factorB(∝μm*3/2/κL) was achieved in this highly aligned material compared with the one prepared by ball-milling and hot-pressing shown in Figure 5b. This preferentially aligned n-type material provides an opportunity for tackling the challenge on seeking good n-type Bi2Te3-based alloys matching with the peak ZT>1.2 in p-type. Another difference between n-and p-type Bi2Te3-based alloys is about doping. Note that single crystal Bi2Te3, Sb2Te3, and Bi2Se3are intrinsic p-type,degenerated p-type, anddegenerate n-type, respectively[20]. Thus the hole concentration of p-type (Bi2Te3)-(Sb2Te3)pseudobinary alloys can be tuned by manipulating the native defects, while the role of doping in n-type (Bi2Te3)-(Bi2Se3)pseudobinary alloys is to increase the electron concentration[19]. As a result, enhancing the performance of n-type materials via extrinsic dopants seems more reasonable, such as, peak power factor of 32 μWm-1K-2and peak ZT of 1.06 obtained in Cu0.01Bi2Te2.7Se0.3[33], and peak power factor of 55 μWm-1K-2and peak ZT of 1.1 obtained in 0.08wt% I-Bi2Te2.85Se0.15[36]. From Table 1, it can be concluded that the peak ZT of p-type materials is usually higher than that of the n-type, which is mainly due to the following reasons. First, the high-performance p-type (Bi2Te3)-(Sb2Te3)pseudobinary alloys is due to strong phonon scattering by Bi/Sb atomic disorder at the ratio of Bi/Sb of 0.5/1.5 and convergence of two valence bands. Second, the p-type materials has an isotropic ZT because both thermal and electrical conductivityhas the same anisotropy, which facilitates effective nanostructure engineering for further thermal conductivity reduction.

Figure 5 Thermoelectric properties of Bi2Te2.79Se0.21with orientation[25]((a)Temperature-dependent of ZT for all Bi2Te2.79Se0.21bulk materials with different processing methods. (b)Quality factorB(∝μ(m*/m0)3/2/κph) at 300 K of the n-type Bi2Te2.79Se0.21as a function of hot deformation number.Reproduced with permission from ref. [25] Copyright 2015 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim).

2 MgAgSb based materials

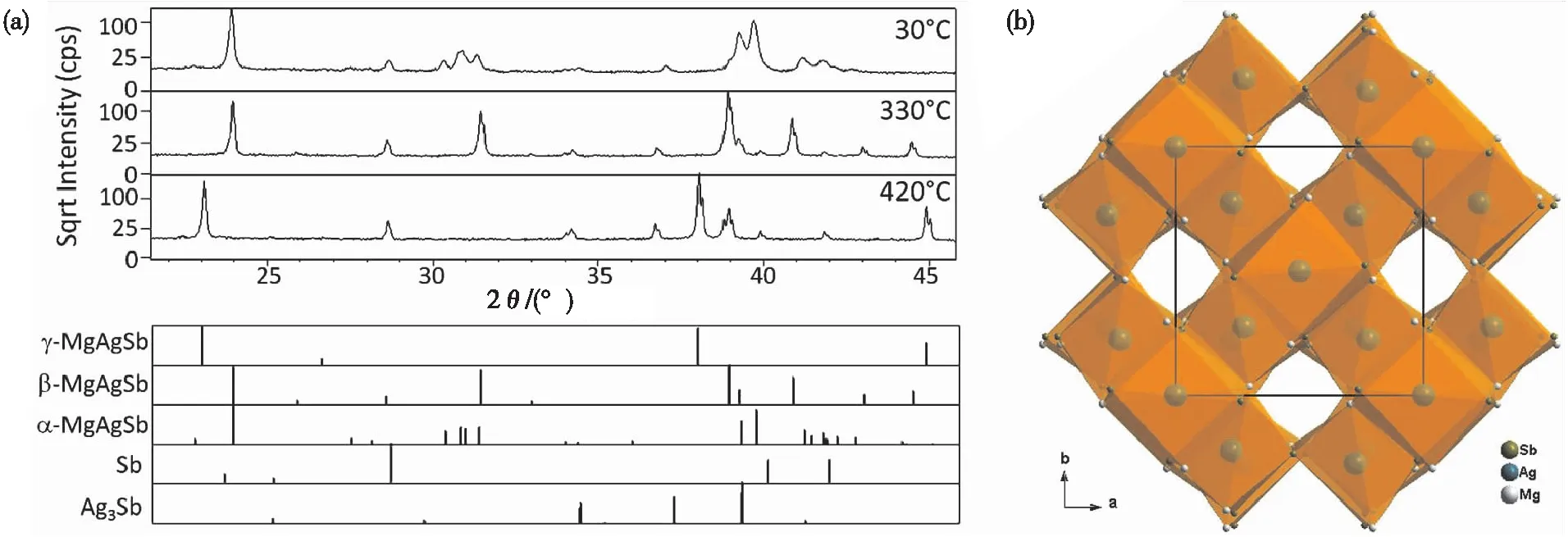

As a 1 ∶1 ∶1 compound with 8 electrons per formula, MgAgSb was expected to have cubic half-Heusler structurewith promising thermoelectric performance[65].However, MgAgSb experiences two complicate phase transitions at 610 and 682 K reported by Kirkham et al., shown by the XRD in Figure6. The room temperature MgAgSb with a tetragonal structure (Figure 6b)is defined as α-phase which transforms to β phase (tetragonal structure) at 610 K, and the cubic γ phase emerges and becomes the main phase beyond 682 K which has been identified as half-Heusler structure or CaF2structure[65-66].

Figure 6 Phase transition and structure of MgAgSb ((a)XRD pattern of α-, β-, and γ- MgAgSb at different temperatures[65]. (b) The crystal structure of α-MgAgSb, with the hollow structure clearly seen.Reproduced with permission from ref. [65] Copyright 2012 American Physical Society).

Due to the activechemical properties of elemental Mg and the complicated phase change, the pure phase has been found very difficult to be prepared by traditional synthesis method[65,67-68]. The impurities significantly inhibit the thermoelectric performance of the compound. Luckily Zhao et al. discovered a two-step ball-milling and hot-pressing method to successfully achieve pure phase in 2014[12],which largely improved the quality of the α-MgAgSb sample and enabled the outstanding room temperature thermoelectric performance to be discovered[12,68-76].

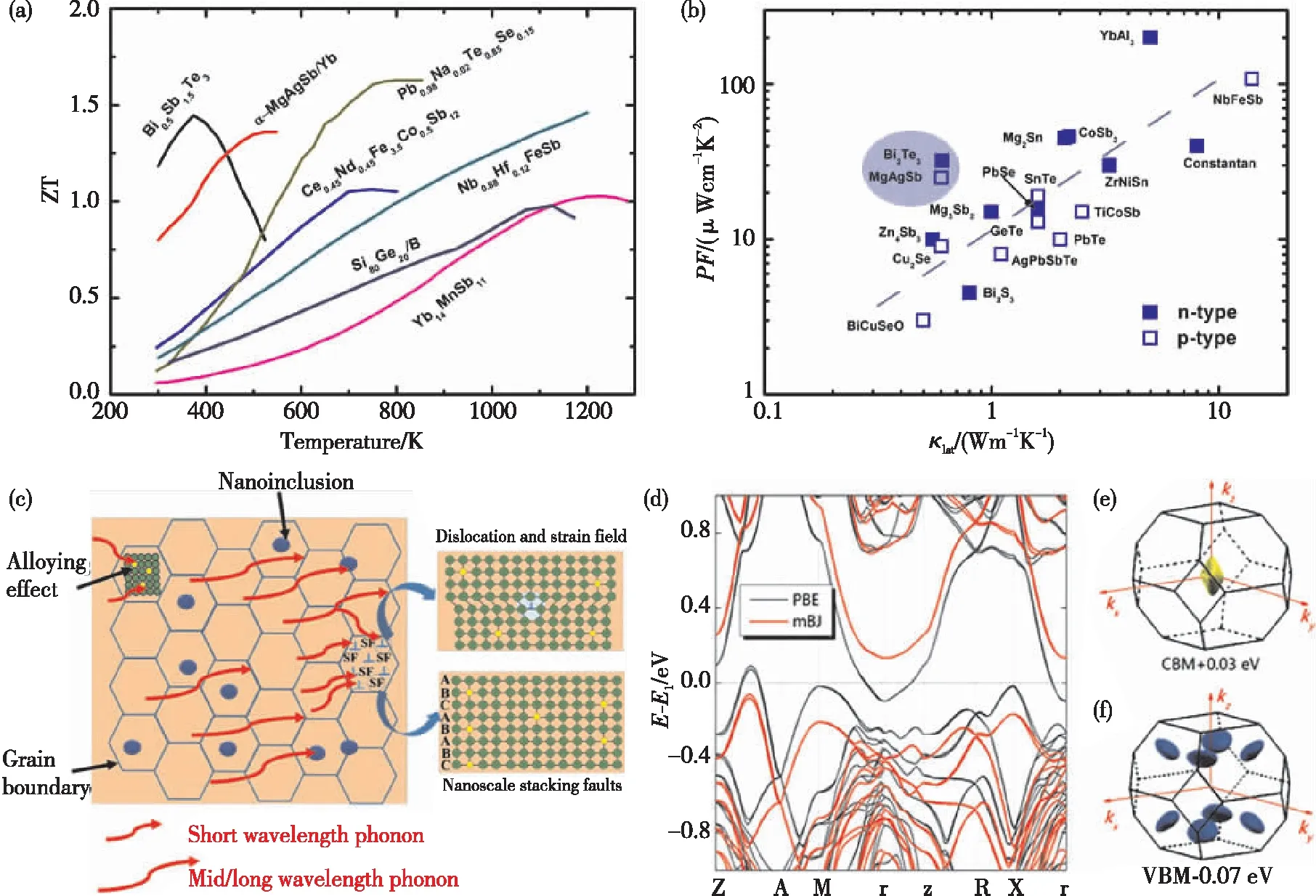

Compared with state-of-the-art thermoelectric materials, shown in Figure7a, α-MgAgSb after further adjusting the carrier concentration via doping and controlling the microstructure and defect with different hot-pressing temperatures, a peak ZT up to 1.4 with an average ZT of 1.2 was achieved[68-70,72-73,75-77].Such a high room temperature performance originates from the high Z value, which means a large ratio of power factor to lattice thermal conductivity. As shown in figure 7b, all the promising room temperature material have higher ratio of power factor to lattice thermal conductivity, which can be regarded as a key factor to identify the materialsfor room temperature applications.

α-MgAgSb as a degenerate semiconductor can be considered as one of the typical examples following the concept of “phonon glass electron crystal” (PGEC). The PGEC concept requires phonon scattering as strong as in a glass, and at the same time the electron propagation as easy as in a perfect crystal.

Figure 7 The extraordinary room temperature thermoelectric performance and “phonon glass electron crystal” behavior of α-MgAgSb (The ZT value (a)and lattice thermal conductivity versus power factor (b) of α-MgAgSb compared with state-of-the-art thermoelectric materials[67]. (c)The schematic diagram for broad frequency phonon scattering by the hierarchical microstructure of α-MgAgSb[78]. The calculated band structure (d), the electron pocket (e) and hole pockets (f)[78]. Reproduced with permission from ref. [67,73], and [78]. Copyright of 2018 The Royal Society of Chemistry, 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim, and 2017 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim).

Thermal transport in material is by all phonons with different frequencies[43].The scattering mechanisms that can effectively reduce lattice thermal conductivity are usually frequency selected. The point defect targets at high frequency phonons, and the grain boundary scattering is more effective for phonons with low frequencies.However, the hierarchical microstructure of α-MgAgSb, as shown in Figure 7c, enables the effective suppression of the phonon propagation with broad frequency. Due to weak Ag-Sb bonding,Ag vacancy is the dominant intrinsic point defect in α-MgAgSb[72]. Compared with other point defects, vacancy has the largest mass difference leading to the strongest high frequency phonon scattering. In addition, the concurrent ion migration for Ag+and Mg2+has also been verified, which induce the softening transverse phonon mode and low lattice thermal conductivity[80].The high density of micro-nanoscale boundaries and interfaces provide scattering for low frequency phonons[73]. By careful TEM investigation, nanoprecipitates of ~10 nm and large quantity of dislocations have also been observed, which may further reducing the lattice thermal conductivity by mid-frequency phonons. The broad frequency phonon scattering through hierarchical microstructure of α-MgAgSb is the leading reason for the low lattice thermal conductivity.

In addition to the glass like phonon transportproperties arising from the distinctive crystal structure and the multiscale microstructure, the unique band structure realized the electron crystal features of α-MgAgSb and the high power factor.Among the various approaches for power factor enhancement, band convergence is particularly effective[9,81]. The optimized electronic performance of a TE material mainly depends on the weighted mobility, whereμ,mDOS, andm0are the carrier mobility, the density-of-state effective mass, and free electron mass, respectively[8-9,82]. Moreover, the density-of-state effective mass (mDOS) is related to the valley degeneracy numberNvthroughmDOS=Nv2/3mb, wherembis the effective mass of a single valley. However, highermbis unfavorable for optimizing power factor due to its adverse effect on the carrier mobilityμ∝mb-5/2, meanwhile higherNvcould effectively enhancemDOSwithout underminingμ, therefore beneficial to boost the power factor. As shown in the calculated band structure (Figure 7d), the conduction band minimum locates at Г point and valence band maximum of α-MgAgSb locates between Z and A point. Therefore, the band degeneracy number for conduction band and valence band is quite different. As shown in Figure 7e and 7f, there is only one electron pocket but 8 hole pockets, which give a highNvof 8 resulting in the high electrical performance of p-type α-MgAgSb[74,78,83-84].Therefore, the high valley degeneracy number is very beneficial for realizing the high power factor of α-MgAgSb.

α-MgAgSb has a large effective mass of 2.3m0, which requires a high carrier concentration of ~9 ×1019cm-3to optimize the power factor. However, the carrier concentration of pristine α-MgAgSb is only 2.7× 1019cm-3, which is about 3 times lower than the optimized value. In order to improve the power factor, various dopant has been studied in α-MgAgSb system[68-71,73]. The thermoelectric performance of α-MgAgSb with different dopants is shown in Figure 8. The carrier concentration can be significantly increased by doping with Li, Na, Cu, Ca, and Yb at Mg site as well as tuning the Sb content. Among all the dopants, Li is particularly effective, and a maximum carrier concentration of ~1.2 ×1020cm-3was obtained by 2% doping, which is more than 4 times that of the pristine sample, as shown in Figure 8a. This may be attributed to the small ionic radius of Li+[73].Upon doping, the power factor has been substantially improved (Figure 8b). The room temperature power factor is ~18 μW cm-1K-2for pristine sample and it is ~24 μW cm-1K-2for Li doped α-MgAgSb. The peak power factor of ~25 μW cm-1K-2has been reached by Li doping. Due to the alloying scattering of dopant elements, the lattice thermal conductivity has been suppressed (Figure 8c). Combined with the enhanced power factor and reduced lattice thermal conductivity, the ZT value of Yb doped sample is noticeably higher in the whole temperature range with the peak ZT reaching ~1.4 at 550 K[77]. As a result, average ZT has also been enhanced, which are 1.1 for both Ca[75]and Li[73]dopingand 1.2 for Yb[77]doping (Figure 8d).

Owing to the outstanding room temperature performance, good mechanical properties as well as low cost of the elements, α-MgAgSb has a great potential for real application at near room temperatures. The single leg device can be easily prepared by hot-pressing samples with silver powder as the contacts[85], as shown in Figure 9a. The clean and well-defined interface between the α-MgAgSb material and contact layer were revealed by the SEM investigation (Figure 9b). The small contact resistance of ~10 μΩcm2was measured by a home-made scanning voltage probe as shown in Figure 9c[67].Figure 9d shows therecord high heat-to-electricity conversion efficiency of 8.5 % at a temperature difference of 225 K measured on a single leg α-MgAgSb device, which outperforms the p-type Bi2Te3-based device in the temperature above 425 K[85].

3 Half-Heuslers

Among various high-performance thermoelectric materials, half-Heusler compounds, with the formula ABZ, where A can be an early transition metal or a rare-earth element, B is a less electropositive transition metal, and Z is a main group element, are identified as one of the promising materials for power generation due to the excellent thermo-mechanical stability[86-87]and intrinsically high power factor[88-92]. Recently, J. W. Zhou et al. disclosed that the origin of the noticeably high power factors in half-Heusler compounds is mainly due to their strongly suppressed electron-acoustic phonon coupling, where the common belief is that

Figure 8 Thermoelectric performance of α-MgAgSb-based materials with different dopant (The carrier concentration (a), temperature-dependentpower factor(b), and lattice thermal conductivity(c), and average ZT(d) of α-MgAgSb-based materials with different dopants).

Figure 9 α-MgAgSb devicewith silver contact layer and the measured heat-to-electricity conversion efficiency ((a)Single leg device prepared by hot-pressing α-MgAgSb powder sandwiched with silver powder. (b)SEM image showing the clean and well-defined interface between α-MgAgSb and sliver contact layer. (c)Contact resistance measurement showing good electrical contact. (d)The measured efficiency based on the fabricated α-MgAgSb single leg device[67,85]. Reproduced with permission from ref. [67] Copyright 2015 The Royal Society of Chemistry and ref. [85] Copyright 2018 The Royal Society of Chemistry).

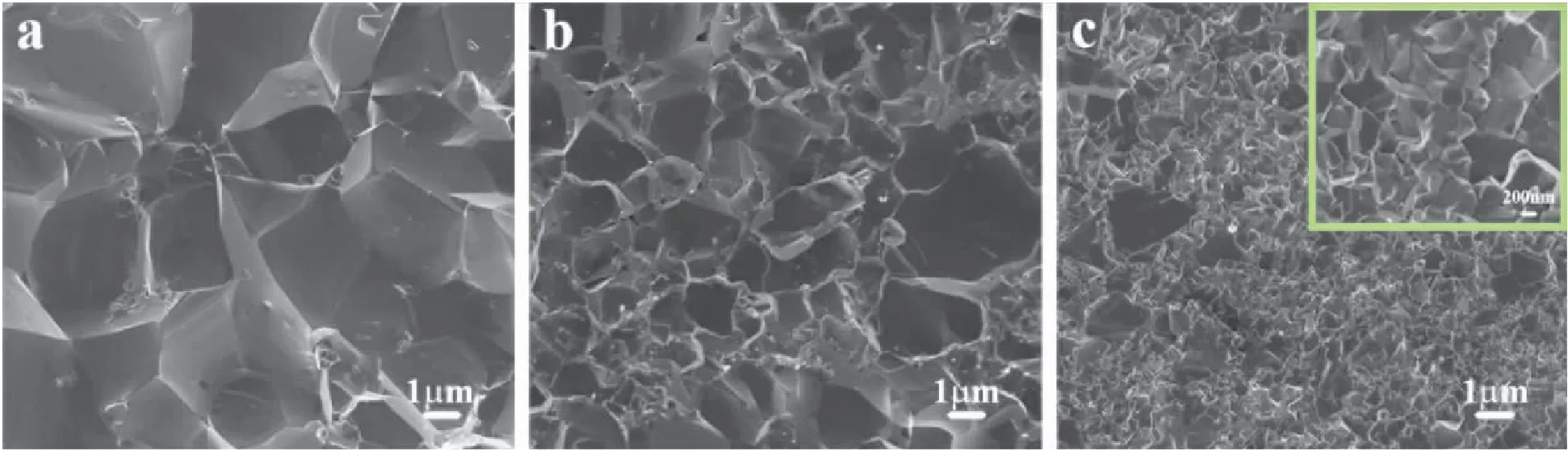

the acoustic phonon scattering dominates the electron transport in these materials. This weak coupling is enabled by the crystal symmetry-protected nonbonding orbitals at the band edge[92]. This finding makes half-Heusler very unique among the electronic materials. Although p-type ZrCoSb and n-type ZrNiSn were reported with high power factor of ~30[93-95]and ~50 μW cm-1K-2 [96-102], respectively, p-type NbFeSb attracted much more attentions due to its ultrahigh power factors[103-110]. Power factor as high as 100 μW cm-1K-2at room temperature were achieved in a series of materials Nb0.95M0.05FeSb (M=Ti, Hf, Zr)[108,110]. However the thermal conductivity of these materials are also high (Figure 10a) leading to ZT less than 0.3 at room temperature that is not high enough (Figure 10b). If thermal conductivity at room temperature could be reduced to the same level of Bi2T3, a record ZT of~3 would be possible (Figure 10b). However, it is very challenging to achieve this. The main challenge is on controlling the grain growth. As reported, this material system is unique for the rapid diffusion and grain growth under high-temperature heat treatment, where the grain size increases from hundreds of nanometers to a few micrometers shown in Figure 11. We believe that half-Heusler compounds have the potential in thermoelectric refrigeration by deeply understanding their intrinsic properties, and then enhancing room temperature ZT via the modern nanotechnology.

Figure10 Thermoelectric properties of Nb0.95M0.05FeSb (M=Hf, Ti, Zr)[108,110]((a)Temperature-dependent power factor (left) and thermal conductivity (right). (b) Temperature-dependent ZT. Pentagram and dot refer to room temperature ZTs by assuming room temperature thermal conductivity of 3 and 1 W m-1K-1, respectively, with the ultrahigh power factor (100 μW cm-1K-2) remained).

Figure 11 SEM images of Nb0.95Hf0.05FeSb[110]((a)-(c) hot pressed at 1323 K, 1273 K, and 1173 K, respectively. The inset of (c) is at higher magnification for easier reading of the grain size.Reproduced with permission from ref. [110] Copyright 2018 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim).

4 Challenges/Outlook

In spite of the advantage such as no moving part, compact size, and high reliability, the utilization of thermoelectric cooling device is limited due to the relatively low performance and small COP. The COP is the function of the average ZT, which is determined by the thermoelectric properties of both p-type and n-type materials in the whole module. The module design requires the matching of thermal expansion, thermal conductivity, and electrical conductivity of both of the materials. Therefore, the high performance of both p-type and n-type materials based on one parent compound is vital for the high COP in real application.

Due to the anisotropic thermoelectric properties of the n-type Bi2Te3alloys,it is difficult to realize the significant enhancement in n-type samples by nanocrystalline as what have been achieved in p-type Bi2Te3alloys. The key challenges for Bi2Te3-based alloys is how to reduce the thermal conductivity in preferentially aligned n-type Bi2Te3materials in order to match the high performance of p-type Bi2Te3with ZT> 1.2. The p-type α-MgAgSb is an outstanding thermoelectric material near room temperature which has been verified by the record high conversion efficiency. However, until now, the n-type α-MgAgSb has not been found. Therefore, developing n-type α-MgAgSb or seeking for n-type counterpart with comparable thermoelectric and mechanical properties is the indispensable task for commercial utilization of this material. The ultra-high power factors up to 100 μW cm-1K-2with a record power density of~22 W cm-1at room temperature has been realized in Nb0.95M0.05FeSb (M=Ti, Hf, Zr) half-Heulers system. However, in order to obtain a competitive ZT value, the high thermal conductivity need to be drastically reduced,and at the same time the high mobility and power factorhave be to reserved.Additionally, it is also necessary to discovera comparable n-type ultra-high power factor half-Heulers to make a thermoelectric couple for this material system.

5 Conclusion

Room temperature modules for cooling and waste heat recoveryare important applications for thermoelectric materials. Therefore, improving the performance near room temperature and identifying new room temperature candidate materials is critical. In this review, we focused on the best and well developed Bi2Te3-based materials system and the recently developed novel p-type MgAgSb system, as well as the new Nb0.95M0.05FeSb (M=Ti, Hf, Zr)half-Heulers showing ultra-high power factors. The unique crystal structure, band structure,and microstructure of these systemslead to the high performance, especially high power factors. It is hopeful a significant progress could be made in especially the half-Heulsers if the high thermal conductivity could be drastically reduced. For each system, there are still many issues preventing them from high performance applications. Persistent and intensive research efforts are very much needed for these promising materials to be advanced to real applications.

Acknowledgements

The work is supported by the U.S. Department of Energy, Office of Basic Energy Sciences under Award Number:DE-SC0010831.

Additionalinformation

The authors declare no competing financial interest.

†These authors contributed equally to this work.

校友作者介绍

任志锋(1963—),男,四川南部人,西华大学(原成都农机学院铸造专业)1980级本科生,1987年获华中工学院(现华中科技大学)硕士学位,1990年获中国科学院物理研究所博士。1990-1999年在美国纽约州立大学布法罗分校(SUNY at Buffalo)任副教授,1999-2013年在美国波士顿学院(Boston College)任副教授、教授,2013年至今,在美国休斯敦大学任M. D. Anderson讲席教授。美国发明家科学院院士,美国科学促进会、物理协会会士。发表论文460余篇,授权专利30余项,被引用54080余次,H因子75,出版专著2部,《Material Today Physics》创刊人、主编,Science、Nature Materials、Nature Nanotechology、Appl.Phys. Lett.、Nano Letters、Advanced Materials、Angewandte Chemie、Journal of American Chemical Society、Small、Nanotechnology、Physica C等杂志特邀审稿人。