Impacts of different drying strategies on drying characteristics,the retention of bio-active ingredient and colour changes of dried Roselle☆

Thing Chai Tham ,Mei Xiang Ng ,Shu Hui Gan ,Lee Suan Chua ,Ramlan Aziz ,Luqman Chuah Abdullah ,Sze Pheng Ong ,Nyuk Ling Chin ,Chung Lim Law ,*

1 Department of Chemical Engineering,The University of Nottingham,Malaysia Campus,Jalan Broga,43500 Semenyih,Selangor D.E.,Malaysia

2 Institute of Bioproduct Development,Universiti Teknologi Malaysia,UTM,Johor Bahru,81310 Skudai,Malaysia

3 Department of Chemical and Environmental Engineering,Universiti Putra Malaysia,UPM,43400 Serdang,Selangor,Malaysia

4 Department of Process and Food Engineering,Universiti Putra Malaysia,UPM,43400 Serdang,Selangor,Malaysia

1.Introduction

1.1.Roselle and its medicinal uses

Roselle(Hibiscus sabdariffa L.)is recognized as a tropical shrub which belongs to the family Malvaceae.Roselle can be found in tropic and subtropic regions such as India,Indonesia and Malaysia.This herbaceous subshrub can grow up to 2.4 m tall with cylindrical red stems.The flowers of Roselle are typically red in calyx consisting of five large sepals with a collar(epicalyx)of8 to 12 pointed bracts around the base[1].The fleshy base of the flower(the calyx)can be processed into food products[2,3]to make syrup,refreshing drinks,jellies,wine,jams and natural food colourants[4-6].Roselle has been widely used in local medicines and food.The leavesorcalyces are traditionally prepared in fusion asthey are rich in anthocyanins,which have antioxidant property and are useful in diuretic and sedative treatment[7-10].In fact,the flavonoid compounds of Roselle vary between studies,probably due to genetic,environmental,ecology and harvest conditions of the plant[11].Studies have reported that the concentration of ascorbic acid of Roselle is 2.5,3 and 9 times higher compared to that of blackcurrant,grapes and citrus,respectively[12].It is also recommended to use Roselle as a folk remedy for abscesses,bilious conditions,cancer,cough,debility,dyspepsia,dysuria,scurvy and strangury[13,14].Roselle contains polyphenols of the flavonol and flavanol type in simple or polymerized form.Protocatechuic acid(PCA),a phenolic compound containing a 3,4-dihydroxy substructure,is a compound that naturally occurs in the dried flower of Roselle.

It has demonstrated strong healing functions owing to its strong antioxidant and antitumor promotion effects[15,16].Besides,the antibacterial effects of PCA against food spoilage bacteria were investigated by Chao and Yin[17].Other than PCA,this research paper also considers another type of flavonoid,named as catechin.Catechin is a flavan-3-ol,a type of natural phenol,antioxidant as well as plant secondary metabolite.

Cocoas and teas,especially those species derived from the tea plant Camellia sinensis are rich in catechin[18,19].Catechin,the naturally occurring flavonoid has been proven in preventing human plasma oxidation[20]and inhibiting the oxidation of low density lipoprotein[21].Moreover,other researchers highlighted the potent antioxidant of catechin in cardiovascular and metabolic health[22].In this paper,the effects of drying techniques on the retention of two bio-active compounds i.e.PCA and catechin in dried Roselle were examined and presented.

1.2.Drying of Roselle

Over the years,solar energy is well-known as an economical and clean method for the preservation of agricultural product[23,24].Roselle is dried traditionally using solar greenhouse drying(SD)method in which the calyces are naturally dried by spreading over mats or plastic sheets placed directly on the open floor area[25].With SD method,the calyces are gathered up and kept securely in store during sundown or rainy day and the similar drying process is repeated on the next day until the weather gets better.A typical SD will take approximately three to four days to dehydrate the crops as it is dependent on ambient condition such as temperature and relative humidity,RH[2,26].Nevertheless,the quality of the dried crop from this drying technique is questionable due to the exposure to contaminations,dirt,pestinfestation and otherexternal calamities such as rain,and loss by birds.According to Plotto[27]and EcoCrop[28],rain or high humidity during the drying process can lower the quality and yield of the calyces.Thus,a change in weather condition can result in poor productivity and inconsistency in drying quality of dried products.Thus far,Roselle's drying technique still dominant by SD[2]and following by hot air drying(HA)[26,29].However,there is a lack of research in advanced drying technique to alleviate the aforementioned issues.In this paper,heat pump system(HP)is considered as an alternate drying solution for Roselle.Unlike SD,HP is able to operate independently and maintain the optimum drying condition for a drying chamber.This will help to mitigate those adversities found in SD.Positive resultshave been reported from variousdrying investigationson different products including biomaterials with HP[30-33].Similarly,HP has been utilized for herb drying such as Jew's mallow,spearmint and parsley[34].

Although dried Roselle have been used and consumed extensively in pharmaceutical or food industry for a long period,literature review shows a lack of information about raw material processing,especially the drying process.Hence,the present work aims atinvestigating the drying characteristic of Roselle with SD,SIHP,HAand HP.In this case study,a locally built low temperature heat pump-assisted dryer was developed to support the drying of Roselle with and without solar drying system.Besides,this research outlines the influence of both ambient condition and drying location on the drying rate of Roselle which are discussed in the following section.With the applications of four different types of drying techniques,this paper:(a)examines the drying kinetics of Roselle calyxes and petals and(b)investigates the colour change of dried Roselle and(c)the retention of bio-active ingredient compounds in Roselle.

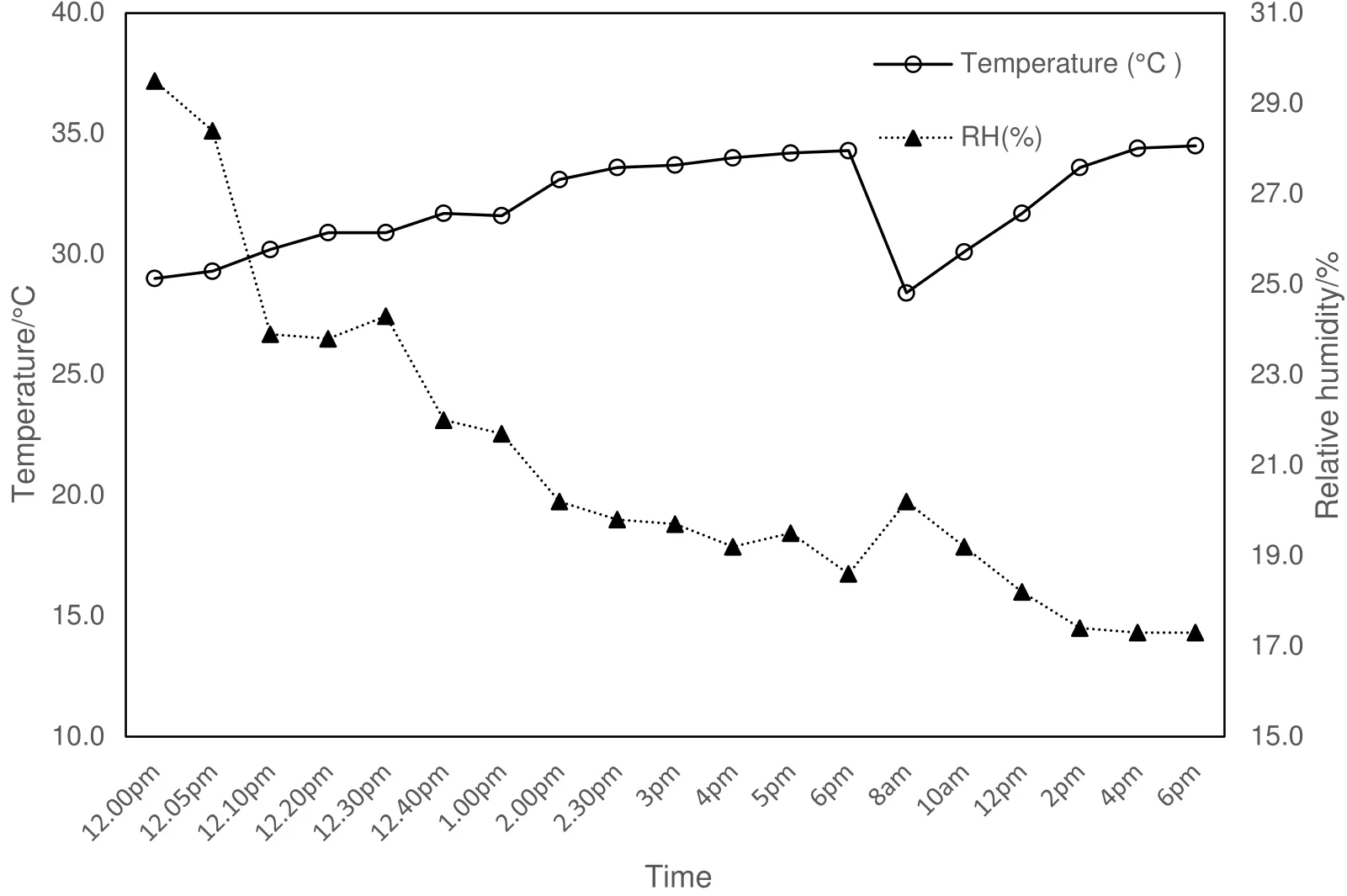

1.3.Weather condition

A tropical country like Malaysia experiences warm-humid equatorial climate,characterized by both high temperature and high humidity throughout the year.Temperature at sea level ranges from 21°C to 32°C,while the annualrainfallvaries from2000 mmto 2500 mm[35].Furthermore,Malaysia has RH ranges between 70%and 90%[36].It is rare to have a fullday with complete clearsky although this nation has abundant sunshine.On average,Malaysia receives about 6 h of sunshine per day[37].Therefore,the effect of change in weather,especially changes in ambient condition must be taken into account to relate the drying rate of the sample.Effects of weather change on both temperature and RH were measured and recorded.

2.Materials and Methods

2.1.Preparation of material

Fresh Roselle of the variety Terengganu(UMKL-1)with a harvest maturity(approximately 85-100 days after sowing)were purchased from the local farmer located at Senggarang,Johor,Malaysia.The seed's capsule is removed from the fresh calyx with a seed capsule removal tool.Then,fresh Roselle's calyces are preserved in a chest freezer(CFR 400B,Ardo,minimal freezing temperature:-24°C,UK)with a room temperature controlled below 10°C.Forcomparison,the Roselle's calyx is fur the r processed into two forms:one group as whole(remain uncut)and another group is cut into petals with a pair of scissors.The dimension of the Roselle was measured with Vernier callipers(Kern Germany,with an accuracy of±0.01 mm).The calyx consisting of five large sepals has a dimension of(5±1.5)cmlong and(2.5±0.5)cm of base width.The petal has a thickness of(3.4±0.3)cmofsepaland(6.0±0.2)cm long.During the experiment,the Roselle calyx and petals were prepared with an initial sample mass of(20±1.5)g(each sample has three replications)and spread evenly on the stainless steel fine wire mesh tray for drying.

2.2.Drying strategies

The experiments are carried out in four different types of operating conditions with various dryers including SD,SIHP,HP and HA.Temperature for each experiment was maintained below 45°C to define the low temperature drying for Roselle calyx and petals.On the other hand,the RH of dryers was recorded below 40%in average during the experiment.

2.2.1.First condition:solar drying(SD)and solar with intermittent heat pump drying(SIHP)

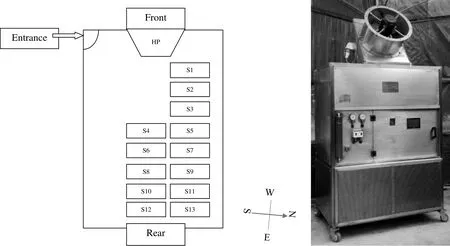

SDfor Roselle was conducted in a solargreenhouse dryer(SGD)located at Sendayan Commodity Development Centre(SCDC),Seremban,Malaysia.The SGD is designed as natural convection mode with no active air provided to the system.A hemisphere SGD was built with steel structure and covered with transparent thin sheet made from polyethylene.The transparent sheet captures the incoming solar radiation and acts as a heat collector.According to Abdullah and Mursalim[38],solar radiation is transmitted into the entire drying chamber through the transparent structure and since the resulting long wave radiation created within the chamber is opaque to the transparent wall and roof,the accumulated energy will heat the incoming air from the ambient thereby increasing the chamber temperature.The accumulated heat that transferred and conducted to the interior of room is used for diffusion activities of water and vapour from the centre to the surface of drying specimen.Meanwhile,the remaining amountofenergy is applied for the water evaporation at the surface or lost to the ambient by radiation or convection.Under ambient condition,this process continues until the dried product reaches equilibrium moisture content.On the other hand,a heat pump was introduced in SGD to improve the drying time and efficiency.As shown in Fig.1,the heat pump included an evaporator(refrigerant:R-134a),a condenser unit(waterand air cooled),an expansion valve,compressorand an axialblower.The systemtakes in moisture laden air inside the SGD where the humid air is directed toward the cool surface of the evaporator.Then,the moist air is cooled down to its dew point and liquid water is removed.After the water removal,the process air becomes dry.The temperature ofthe dry air is increased by hotwater flowing through a heat exchanger.An axial blower is supplying constant dry airto the system.The blowertilts approximately 45°from a horizontal position to ensure the dry air is distributed across the drying shelves inside the SGD.In intermittent mode,the HP ceases to operate if room RH falls below 50%.The layout of the SGD and drying shelves was illustrated in Fig.1.Basically,the even span SGD facial facing 266°west and 13 units of drying shelves are arranged in series and parallel inside the SGD.Meanwhile,the sample coding in both SD and SIHP is labelled in RR XYZ,where RR:Roselle sample;X:the shelf's number(2,7&11);Y:calyx(1)or petal(2)and Z:sample's number.

2.2.2.Second conditions:low temperature heat pump assisted dryer(HP)

A locally built vertical two chamber HP was applied to examine the drying process of Roselle.As shown in Fig.2,the HP has an evaporator(BEM-013,refrigerant:R-134a),a condenser unit(water cooled and air cooled),an expansion valve(TEN 2,Danfoss,Denmark),bi-cylinder compressor for cooling(2 hp,TFH 4525Y,coolant:R134a,manufacturer:Tecumseh,France)and a 2 hp axialblower.Similarly,the main objective of HP is to maintain drying chamber's RH and temperature at optimal conditions by extracting excess humid air from wet product inside the drying chamber.The system takes in moisture laden air inside the drying chamber which the moist air was directed to the cool surface of the evaporator.Then,the moist air was cooled down to its dew point and condensate which later turns into dehumidi fied dry air.Waste heat is recovered from the condenser to increase the dry air temperature.If necessary,temperature of the dry air can be elevated through an auxiliary heater.This extra heat from dry air creates more vapour pressure that enhances the water diffusion from the product.Meanwhile,an embedded blower is blowing constant flow of dry air at high volume to remove the free water from the product.Additionally,the vertical drying chambers are air tight to prevent any potential heat losses to the ambient.The HP is equipped with a user-friendly logic panel and user can pre-set drying parameters for respective experiment.In this HP experiment,the desired RH was set at a minimum of 20%,and room temperature is controlled by an auxiliary heater.

Fig.1.The layout of SGD(from top view),location of drying shelves and heat pump.

Fig.2.Low temperature heat pump assisted dryer(HP).

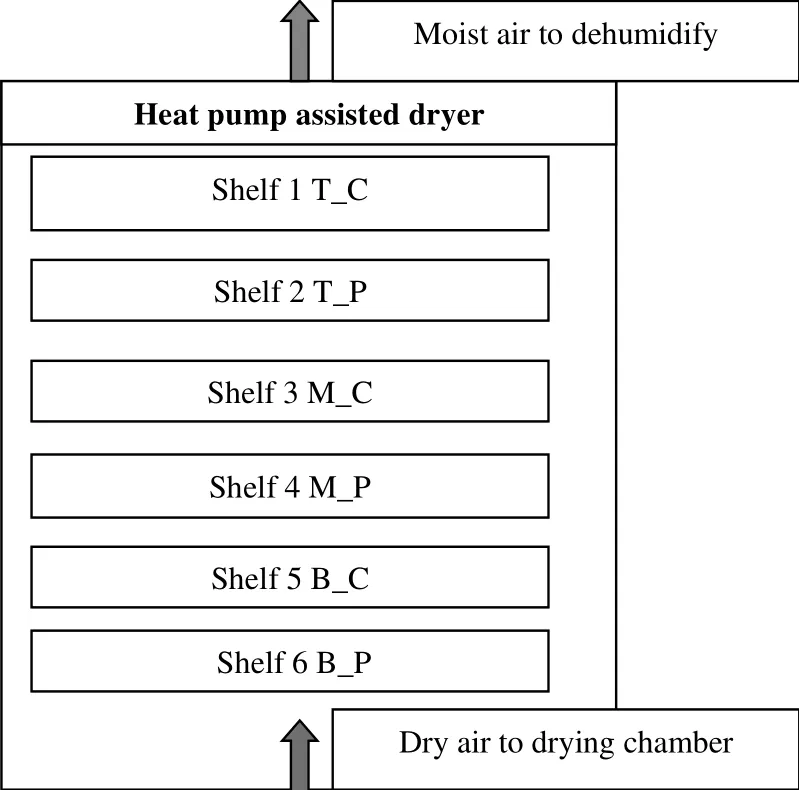

The arrangement of Roselle calyx,C and petal,P inside the HP was illustrated in Fig.3;T,M and B are referring to the top,middle and bottom of the HP,respectively.The air flow circulates inside the dryer from bottom to top across the drying shelves.

2.2.3.Third conditions:hot air drying(HA)

HA was performed in a laboratory scale hot air circulation universal oven(UNB 500,Memmert,Germany,range:30-220°C with an accuracy of0.5 °C).The drying temperature was controlled at35 °C,40 °C and 45 °C respectively and(31±0.5)%for oven humidity.The temperature and RH inside the oven were assumed constant throughout the drying process.

Fig.3.Position of Roselle samples and direction of air flow.

2.3.Measurement of drying room temperature and humidity

The drying parameters including temperature and RHwere measured with sets of thermo-hygrometer.Two sets of thermohygrometer(EE220,E+E Elektronik GES.M.B.H.,Austria,measuring range(0…100%RH,accuracy±1.5%RH)/(-40…80°C,accuracy±0.1°C);HygroFlex3-HF3,Rotronic AG,Switzerland,measuring range(0…100%RH,accuracy±2.0%RH)(-10…60 °C,accuracy ±0.3 °C)were installed at both front and rear of SGD to measure temperature and RH over drying time.For HP,a thermo-hygrometer(Omniport 30,multifunctional hand held meter with logprobe,E+E Elektronik GES.M.B.H.,Austria,logprobe 31,for RH(0…100%RH,accuracy ±2%RH);temperature(-40…180°C,accuracy±0.2°C),was used to measure the temperature and RHinside the chamber.

2.4.Drying characteristic and kinetic profiling

Each drying sample has three replications and the moisture content loss is determined in accordance to AOAC standard[39].An analytical balance(ME204;sensitivity 0.1 mg,Mettler Toledo,USA)was used for consecutive mass measurement of the Roselle's samples.Later,the water activity of dried sample was measured with a water activity meter(Pawkit,AquaLab,USA;accuracy:±0.2).Meanwhile,dried Roselle sample weighed 2 g each from respective drying test which was carried out in a universal laboratory oven(UNB 500,Memmert,Germany)at 105°C for 24 h to obtain bone dry mass and determine the moisture content in dry basis(db.)

The moisture content,Xd(%,dry basis)of Roselle was determined with reference to the bone-dry mass,Wdexpressed in Eq.(1)as shown below:

For the purpose of graphical presentation,the moisture ratio was defined based on the moisture content(Eq.(2))[40].Consequently,the comparison between various sets of drying conditions can be done.The moisture ratio,∅of Roselle during drying experiments was calculated by the following equation:

X0,represents the original moisture content,Xiis the moisture content at time t,and Xeqis the equilibrium moisture content.Xeqis determined when three consecutive readings were obtained from the experiment.The initial and final moisture contents were tabulated respectively in Table 1.

Table 1 Corresponding water activity,initial and final moisture content of calyx and petals in different drying techniques

The drying rate(g H2O·(g DM)-1·min-1)was determined by approximation of the derivatives to finite differences as shown in Eqs.(3)and(4)[41,42].

Drying rate at t=t0( first point),

where t is time(min)and X0and Xfare the moisture content(g H2O·(g DM)-1·min-1)at initial and equilibrium conditions,respectively.

2.5.Colour determination

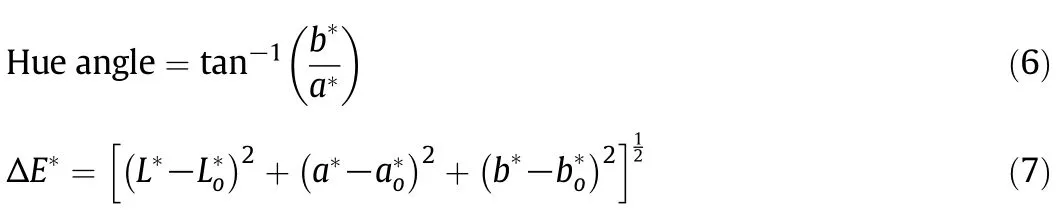

Various types of drying techniques will have different effects on the physicochemical properties of a dried product[43,44].In this study,the physical property of Roselle i.e.colour is measured with a handheld colour meter(LC100,The Tintometer Ltd.,England).Colour was measured at three different sides of Roselle calyx with three replications each on the sample and averaged to obtain the mean and standard deviation reading.Colour data of Roselle calyces and petals is expressed in L∗,a∗and b∗values where L∗presented as the lightness coefficient which ranges from(0 for black to 100 for white),in a∗a positive value of 60 indicates redness,and a negative value of-60 indicates greenness.Meanwhile,in b∗a positive value of 60 indicates yellowness while a negative value of-60 indicates blueness.Then,a∗and b∗were further derived into hue angle via Eq.(6).Generally,fresh Roselle has positive a∗and b∗indicating redness and yellowness of the calyces.Total colour change of the sample was calculated by using Eq.(7)[45,46].

in which a high degree of colour degradation of dried product was expressed by a high value of ΔE∗.

2.6.Statistical analysis

The data of colour and retention of bio-active ingredients were reported in mean±standard deviation(SD)of triplicate determination.Statistical calculation by SPSS version 22.0 software(IBM Corp,USA)was carried out.Significant differences(p<0.05)between means were evaluated by one way ANOVA and Tukey's range test.

2.7.Quality analysis for bio-active ingredient of Roselle

2.7.1.Extraction process

Bio-active ingredients from dried Roselle were extracted by re flux extraction method.Re flux extraction method is the most commonly used method to obtain bio-active ingredient from herbs[47,48].Dried Roselle was grinded into powder form prior to the extraction.Two grammes of powder was added into 100 ml methanol in a 250 ml round bottom flask equipped with a cooling condenser followed by boiling for 60 min.The supernatant was kept dry and filtered by using a membrane filter to get a clear extract.The extracts were kept in a tight glass bottle and then stored in fridge for further analysis[49].

2.7.2.HPLC-PDA

Dried extract was dissolved in methanol(2.5 ml)and 10 μl was taken for injection.All sample extracts were filtered with 0.45 μm nylon filters prior to injection.Two bio-active ingredients i.e.PCA and catechin were analysed by a high-performance liquid chromatography(Waters Alliance e2695,Milford,MA)system combined with a photo diode array(Waters 2998,Milford,MA).A C18 reversed phase Xbridge column(5 μm pore size,4.6 mm×250 mm)was used for the separation process.The elution solvents were classified as mobile phase-A(0.1%acetic acid in distilled water)and mobile phase-B(acetonitrile),respectively.The samples were eluted according to the following binary gradient:0-6.5 min—20%B,6.5-10 min—80%B,10-15 min,80%B,15-16 min,20%B,and 16-20 min,20%B.Each sample extract was analysed at the mobile phase with the flow rate of 0.8 ml·min-1and detector wavelength at 30°C.Data were integrated by the software of Empower 3(Waters Corporation,USA).All bio-active ingredients were quantified using the external standard method.Quantification was based on the peak area[50].A series of standard solutions with different concentrations ranging from 1 to 500×10-6was prepared for calibration curve.

3.Results and Discussion

3.1.Drying characteristic of Roselle

In this study,the drying profile of Roselle comprising the reduction of moisture content and the change of drying rate with time was reported.From Table 1,the initial moisture content for both calyx and petal for each respective experiment was indifferent.However,petal of HP and HA have higher initial moisture content in comparison with both SIHP and SDsamples.Whereas,calyx of SDhad the lowest initial moisture content among others.The initial moisture content of Roselle samples varied between studies,probably due to harvest conditions,ecology,conditions of crop,soil type,and environmental effect such as rainfall[11,51,52].

In terms of final moisture content,both HP and HAsamplesshow consistent results for both calyx and petal.This is because the sample was dried in a controlled and confined environment i.e.minimuminterruption from ambient change.Conversely,both SD and SIHP samples have bigger variance in final moisture content when environmental factor such as weather change in fluences the stability of final moisture content at the end of drying period.As shown in Table 1,corresponding water activities for SIHP and SD were both 0.51;whereas HA and HP were measured at 0.52 and 0.54,respectively.Despite slight difference of final moisture content bet ween various drying strategies,however,all the dried samples have approximate water activities well below the maximum threshold(aw<0.60).These results showed that the low temperature drying was able to reduce the moisture contents to a safe level that could prevent microbial spoilage and minimize deteriorative reactions[53].

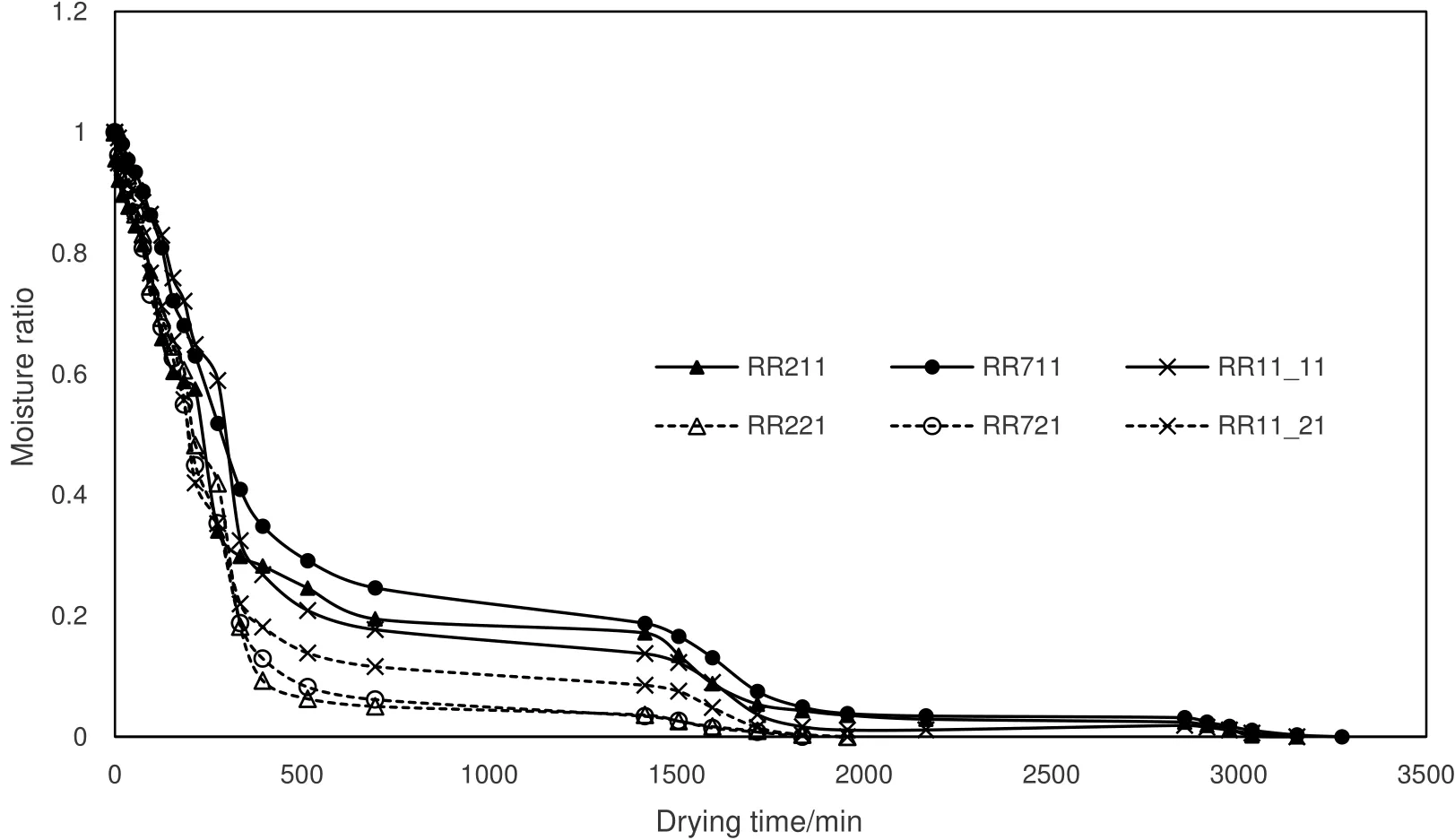

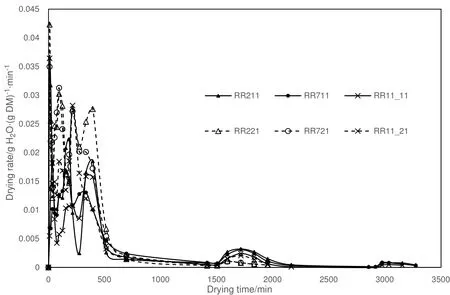

3.2.SD

In Fig.4,the dried Roselle demonstrated five different stages of moisture reduction trend.The first400 min shows a drastic reduction of moisture followed by modest reduction at between 500 and 1500 min.Again,the moisture loss was reported in between 1500 and 2000 min before a steady plateau was formed near the end of the drying session.A significant change in moisture content for the first 400 min was recorded for petals whereas calyx has a slightly lower moisture reduction rate.This drastic change was due to petals(RR721 and RR11_21)receiving higher coverage of solar irradiation especially in the middle and rear of SGD.Additionally,the available surface of petals exposed to the sunlight is bigger than the calyx.According to Fatouh et al.[34],whole plants required longer drying time than that of leaves and drying time increased with increasing surface area and small size herbs exhibited short drying hour.By comparison,more water loss can be observed from petals than calyx sample.On the contrary,drying temperature was the key parameter that significantly influenced the drying rate[54-56].Hence,the SGD's temperature also contributes to the rapid drying of sample.In Fig.5,the temperature of SGD was above 40°C between 12 pm and 5 pm while the highest temperature was recorded during 2 pm to 3 pm.Similar outcome was reported by Rabha et al.[57]where the ambient temperature was found highest during 11 am to 2 pm.In this hour,the solar irradiation position is directly vertical to the sample at noon while slightly slanted during late afternoon.

In terms of drying rate,both calyx and petal in front of SGD(RR211 and RR221)recorded the highest drying rate at 0.036 g H2O·(g DM)-1·min-1and 0.042 g H2O·(g DM)-1·min-1,respectively at the first20 min of drying.In Fig.6,the sharp increase in drying rate within a short duration was in fact due to the sample position at the SGD in which samples received maximum amount of solar irradiation causing temperature rise and rapid water losses.In the meantime,calyx samples only have proximate moisture reduction trend and slower moisture loss rate when compared to that of petals.

It was observed that an unsteady drying rate trend happened from 0 to 335 min.The major cause for this unusual trend was due to weather interference such as cloudy day and rainfall that will increase the room RH.Besides,this phenomenon can be explained by the shifting of solar irradiation pointing from west of SGD(refer to Fig.1)during late afternoon.In this case study,increasing trend of drying rate,which was observed in subsequent days,falls between 1500 and 2000 min and at 3000 min,respectively as an effect of hot weather during the mid-day.However,these drying rates were insignificant in comparison with the drying rate obtained from the first day of drying as most of the free moisture was removed.Low drying rate was observed at 695-1500 min and 2100-2800 min,respectively suggested the sample's moisture migration was dominated by internal diffusion.On the other hand,the total drying time for petals was 67.5%shorter than the calyx in the same drying condition.In fact,agricultural product dried with SD usually consumed longer drying hours e.g.four days for tomato[58],35 h for Roselle[59],and 193 h for ghost chili pepper[57].

Fig.7 illustrated the variation of temperature and relative humidity recorded in SGD when SD was employed.Average temperature recorded from the SGD from SD was(40.16± 7.24)°C,whereas RH was(37.56±15.06)%.As aforementioned,the interference of cloudy weather has an adverse effect toward the drying temperature and RH[60].A reduction of SGD temperature is causing the increase of RH.Indirectly,this will slow down the whole drying process.It was observed that the room RH can reach more than 70%overnight as shown in Fig.5.This is not an ideal drying environment for hygroscopic material such as herb or spices due to its susceptibility to reabsorb moisture from the surrounding air when humidity is high[61].The risk of microbial contamination is high if drying by rain or slow drying rate[62].

3.3.SIHP

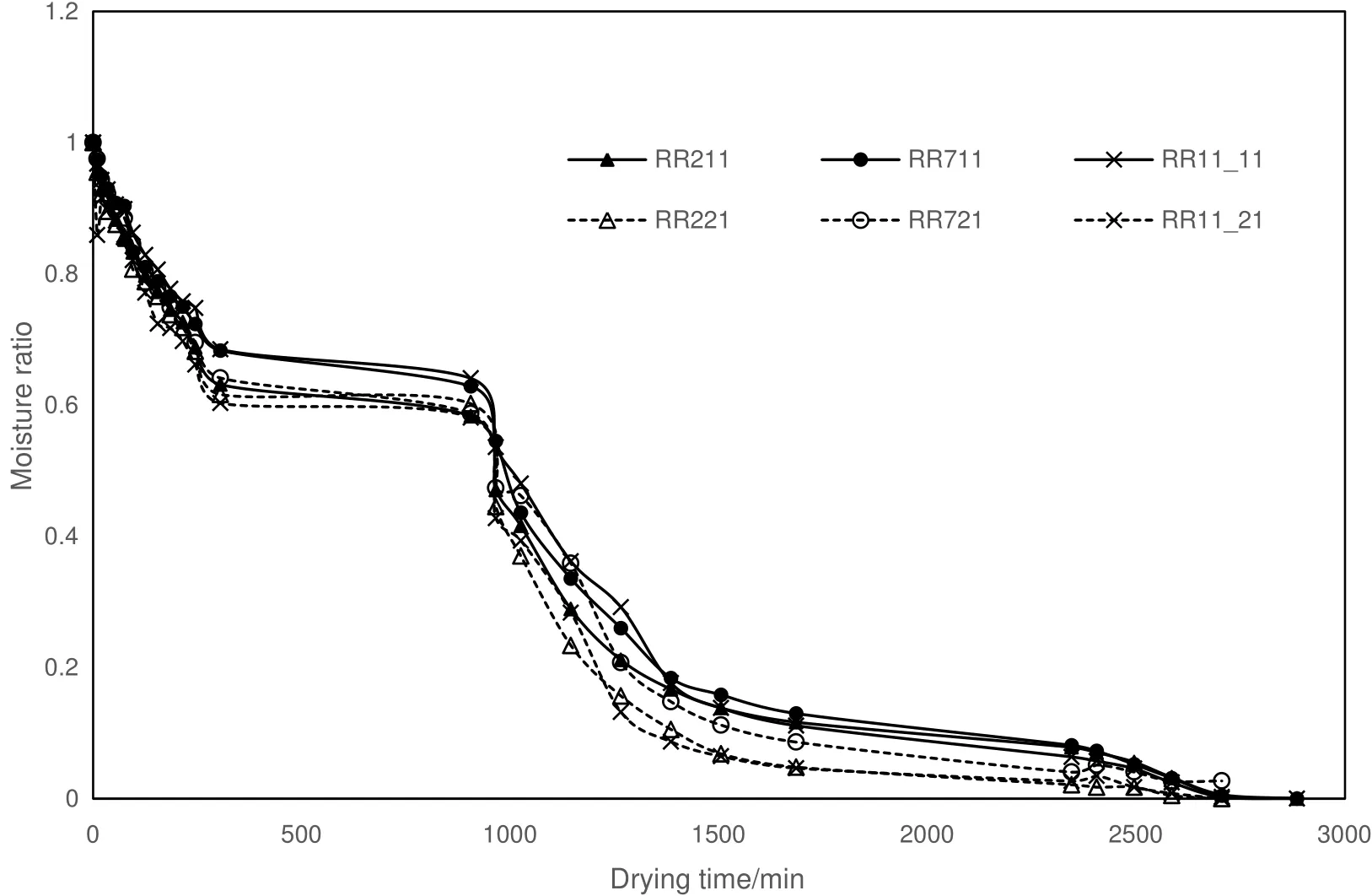

The performance of a SIHP was influenced by four ambient parameters such as solar irradiation,ambient relative humidity,ambient wind velocity and ambient temperature[63].Moisture loss profile of both petals and calyx in Fig.8 exhibited four major falling rate periods with a sharp moisture reduction in the first 300 min and followed by a constant plateau.The constant plateau indicated a gradual decrease of moisture removal from samples especially at night.Obvious moisture reduction with a steep slope was recorded on the next day of drying and similar pattern occurred in the third and fourth drying periods due to overnight drying.Similar result to SD in terms of quicker moisture removal rate of petal than calyx was found in SIHP too.

Fig.4.Changes in moisture ratio with time using SD strategy.

Fig.9 depicted the highest drying rate was achieved by petal located at the middle(RR721)with 0.059 g H2O·(g DM)-1·min-1;however,calyx exhibited a lower drying rate despite sharing the same drying location.In comparison to SD,SIHP's sample had a consistent drying rate in the first 300 min.In addition,the fluctuation of drying rate has been minimized and average drying rate for both petal and calyx was slightly higher than SD's samples.On the next day,the drying rate for both calyx and petal once again increased and reached as high as 0.017 g H2O·(g DM)-1·min-1for petal and calyx located at the middle section.Similar trend of drying rate was formed in other samples and drying rate of calyx was marginally improved thereafter.Unlike SD,SIHP drying shows a constant drying rate in the 1700-2400 minute region followed by a small increase of drying rate before it reached equilibrium moisture content.This slow drying process can be explained by the domination of internal moisture diffusion mechanism over the external free surface evaporation[63].With SIHP,the room's RH was maintained at desired lower level and hence the water removal rate was consistent even at night drying[34,64].Evi dently,the drying rate of SD with heat pump assistance had higher drying rate than SD alone.

In this case study,the heat pump was set up to operate intermittently when drying room RH rises above 55%.This has assisted in the continuity ofthe drying operation atnight.When using the SIHP strategy,the average temperature and RH inside the SGD were measured at(40.0±6.97)°C and(37.96±14.17)%respectively.The SGD's drying condition for SIHP was fairly similar to SD deduced a fair comparison between these two experiments.In Fig.5,the room's RH with HP operated intermittently measured at 57.8%-67%(during night)which was slightly lower than SD(58.4%-75.5%).On the other hand,a huge spike of RH measured at 75.5%was due to heavy rain that caused higher ambient RH in that particular drying period.In a nutshell,solar dryer integrated with heat pump warrants sustainable drying performance and shorter drying time with controlled drying condition at low RH.Additionally,the drying rate was extended beyond sunset.Similar observation with different products was reported by Yahya et al.[65],Gan et al.[66],Best et al.[67]and Şevik et al.[68].

Fig.6.Changes in drying rate with time using SD strategy.

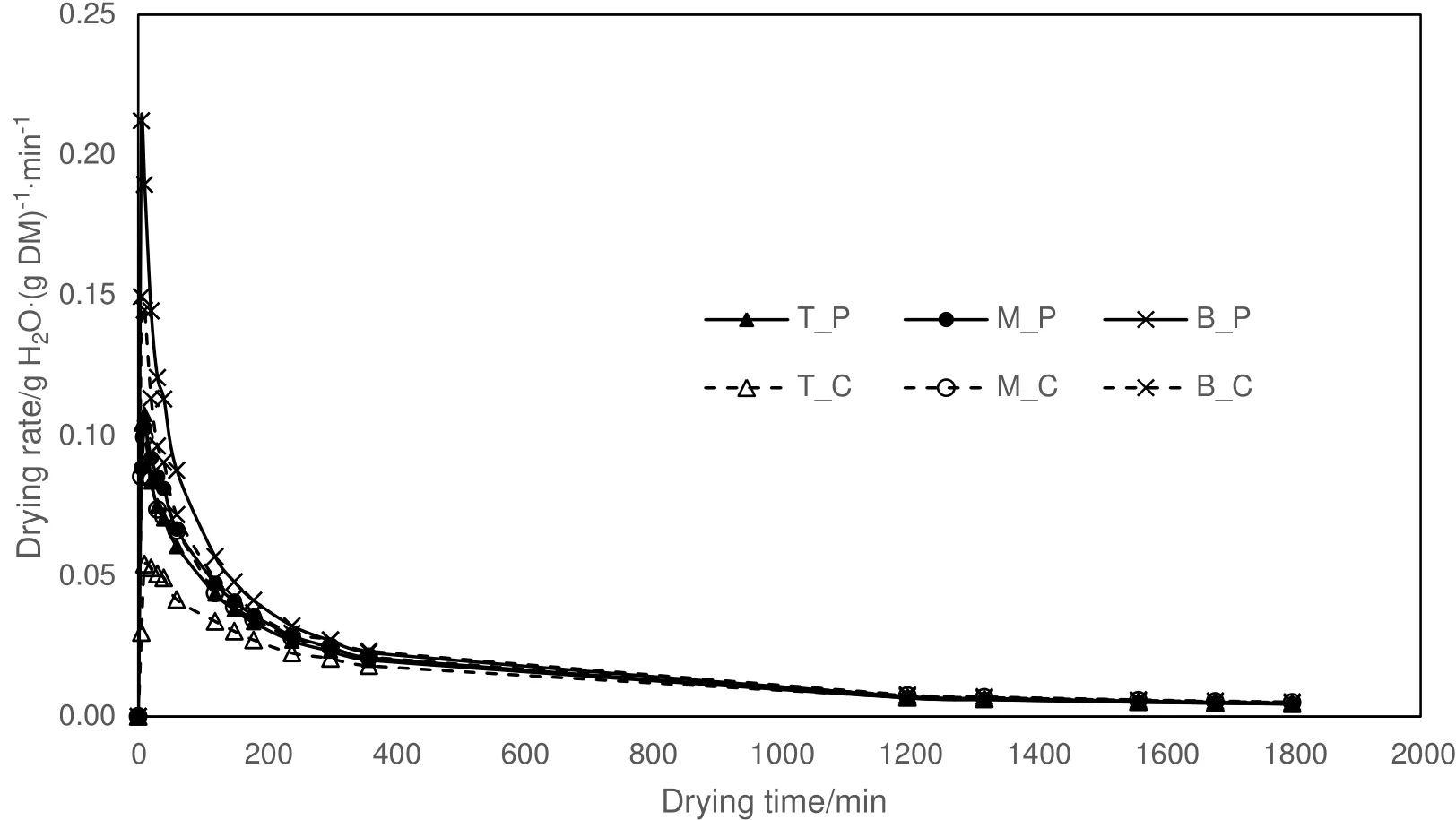

3.4.HP

In this experiment,a vertical type two chamber HP was applied to dry Roselle sample without exposing them to solar irradiation.As shown in Fig.10,petals demonstrated faster moisture reduction rate in comparison to the calyx flower which have similar outcomes obtained from both SD and SIHP strategy.Besides,it is noteworthy to highlight that the moisture reduction rate was higher for those samples located near the bottom shelf of HP,especially at the first 1000 min.At this stage,moisture particles were picked from surface by convective heat transfer.In the air flow design of HP(Fig.3),samples located at the bottom shelf received fresh dry air and greater air flow than the top sample.The air turbulence created by recirculating fan inside the dryer helps in moisture removal[69,70].Eventually,this sample experiences rapid water migration and loss of moisture content.After 1200 min of drying hours,the moisture reduction showed insignificant variation as the dried sample either top or bottom has gradually approached equilibrium moisture content.With HP,the drying time of calyx was shorter by 45.04%and 37.60%in comparison with SD and SIHP respectively.This was supported by the fact that lowering air relative humidity in the drying air would create a greater drying force for moisture removal on the solid surface hence,the increase the drying rate and shorter drying hours[71,72].

Fig.8.Changes in moisture ratio with time using SIHP strategy.

Both petals and calyx were subjected to substantial drying rate as shown in Fig.11.Petals exhibited significant drying rate ranging from 0.103 g H2O·(g DM)-1·min-1to 0.212 g H2O·(g DM)-1·min-1followed by calyx which was slightly lower than petals.Similarly,the average drying rate for top petal and calyx was lower than the bottom sample due to air flow design as aforementioned[70].However,this phenomenon was only apparent in the beginning of the drying test.The drying rate of petals and calyx approximate to each other as soon as the drying time reached 400 min and above.In other words,the Roselle samples were reaching the falling rate drying period in which the change of moisture was insignificant.In a nutshell,the average drying rate for HP was found two to three-fold faster than SD and SIHP strategy.Other successful testimonials with HP drying were demonstrated by Minea[73],Chua et al.[74]and Fatouh et al.[34],respectively.

For herb application,HP is recommended to operate at temperature lower than 50°C[75,76].It was clearly shown from Fig.12 that the HP chamber humidity well controlled between(21.1±3.52)%and drying room temperature at(32.1± 2.0)°C.The temperature and RH trend demonstrated an increasing and decreasing trend,respectively during the drying test.However,there was a slightdrop in temperature measured in the morning(8 am)of the second day of drying due to a lower ambient temperature at the test venue.Also,the RH recorded below 20%before the sample reached equilibrium moisture content.A sustainable low RH and controlled temperature environment has enhanced the dehydration process of Roselle,thus,accelerated the drying rate and reduced the drying time.A reduction in drying time using HP was also reported by Phoungchandang et al.[77]in the drying of lime leaf too.Moreover,the HP helps in minimizing the rehydration issue,especially overnight drying through continuous drying at controlled environment.

Fig.9.Changes in drying rate with time using SIHP strategy.

Fig.10.Changes in moisture ratio with time using HP strategy.

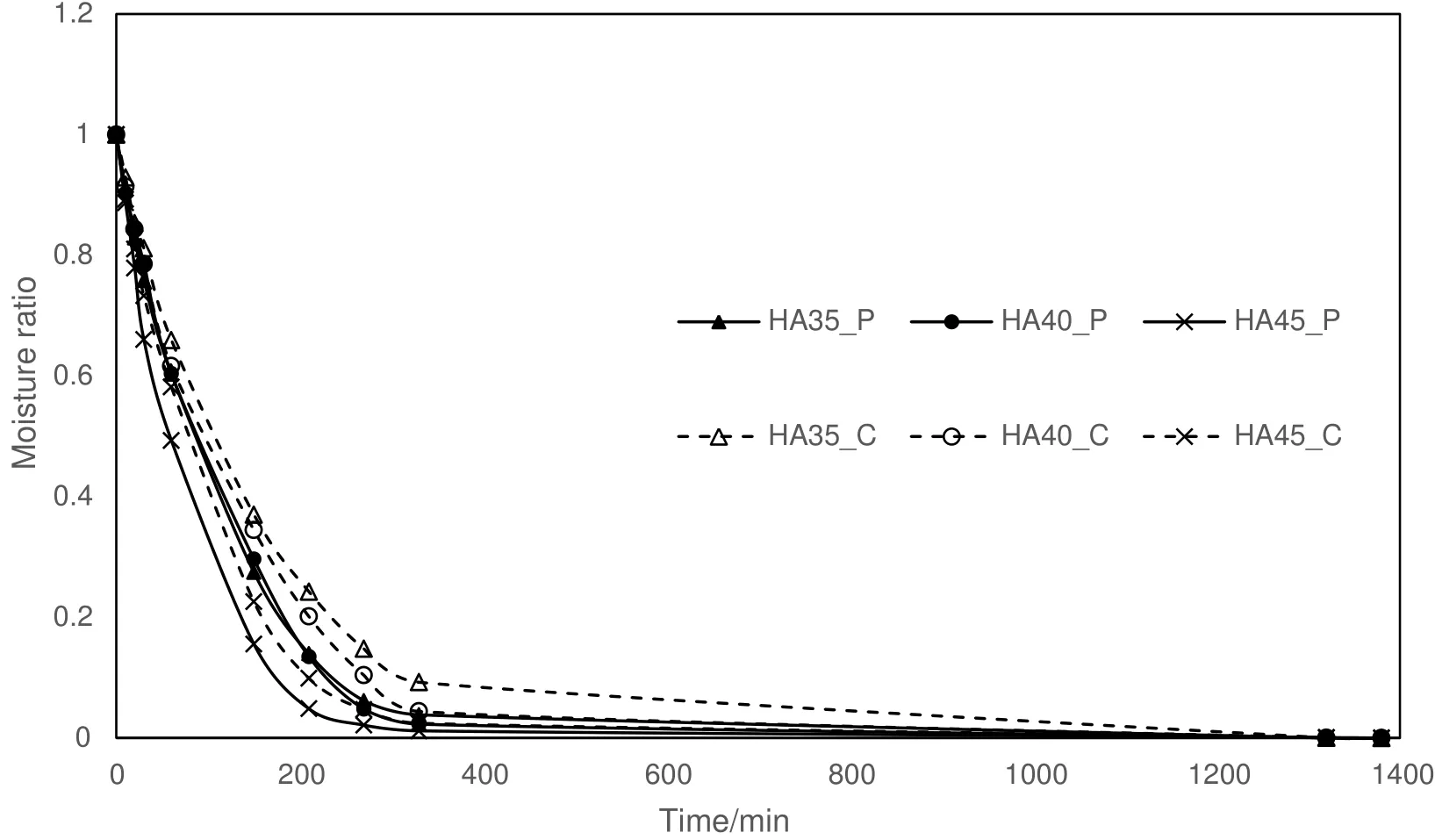

3.5.HA

A universal drying oven(HA)has 30%shorter drying time in comparison with HP.The oven's humidity level and temperature were assumed constant over the drying period.The variation of moisture ratio demonstrated that the higher the drying temperature,the faster the moisture reduction in the sample.As illustrated in Fig.13,petal has a faster moisture removal rate at 45°C,however there was no difference in terms of moisture reduction rate in between 35 °C and 40 °C.Saeed et al.[29]reported that at different temperatures(35,45,55 and 65°C),the drying time was reduced with increased temperature.This suggested that temperature beyond 40°C can improve the moisture removal rate for Roselle.

On the other hand,the drying rate of petals was substantial in the first 30 min as illustrated at Fig.14.This was mainly due to the continuous hot air circulation inside the oven which removes the surface water from the petals which have bigger area exposed to hot air in comparison to calyx.Similarly,the drying rate for the petals dried at 45°C reached highest at 0.11 g H2O·(g DM)-1·min-1.This was followed by the petal and calyx drying at 40 °C and 45 °C respectively with a drying rate in the range of 0.10 g H2O·(g DM)-1·min-1or a 10%dropped in the average drying rate.Likewise,the drying impact of HA was more prominent in petal than the calyx which also applied to SD,SIHP and HP strategies.

Fig.11.Changes in drying rate with time using HP strategy.

Fig.12.Temperature and moisture evolution trend in the HP chamber.

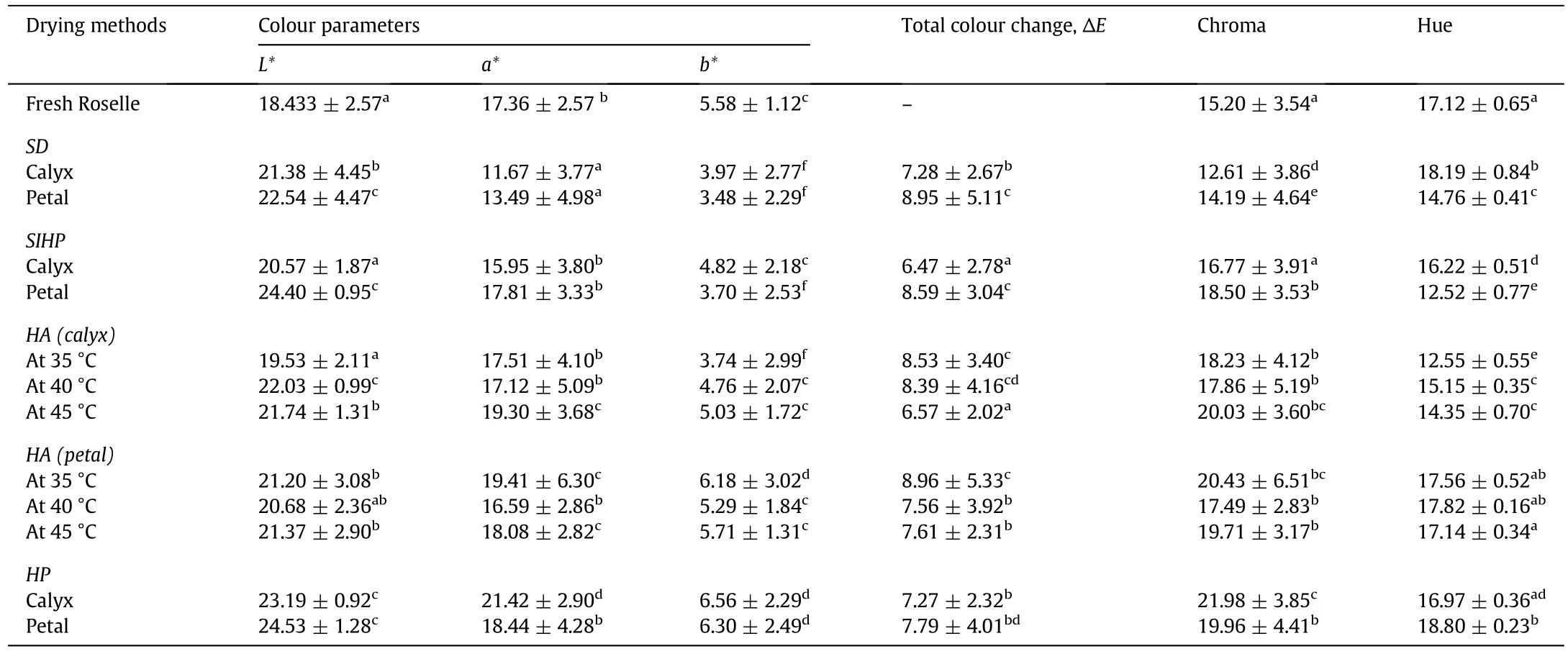

3.6.Colour analysis of dried Roselle

Table 2 demonstrated the colour parameters CIE L*,a*and b*values and other derived parameters such as total colour change(ΔE),chroma and hue from different drying methods.Total colour changes,ΔE from solar drying(both SD and SIHP)exhibited marginal difference between calyx and petal.Both experiments suggested higher colour change was found in Roselle petal.Conversely,total colour change from HA's dried calyx was slightly higher(both 35 °C and 40 °C)than SD and SIHP's dried calyx.Whereas,HA's petals exhibited lower colour changed when 40 °C and 45 °C were applied,respectively in drying.Instead,the HP dried Roselle are showing consistent colour results particularly in L*,b*and ΔE regardless calyx or petal(p > 0.05).The degree of redness(a*)from HP dried sample was higher than sample from other drying strategies,especially with SD's sample.According to Wong et al.[78],the calyces comprise of brilliant red pigments of four anthocyanins including delphinidin 3-sambubioside and cyanidin 3-sambubioside as the major pigments and delphinidin 3-glucoside and cyanidin 3-glucoside as the minor ones.The anthocyanins are derivatives of the basic flavylium cation structure which are highly reactive and involve in decolourization of the anthocyanin pigments.The rate of anthocyanin decomposition depends on factors such as temperature,oxygen,and temperature[79,80].Similarly,drying temperature significantly induced the increase of a*and b*colourimetric parameters due to non-enzymatic browning reaction,which turned the samples more reddish and yellowish when the temperature rose[44].This phenomenon was further demonstrated by HA Roselle calyx whereby the a*and b*increased proportionally with temperature.On the other hand,the increase of chroma value from all the samples was due to the presence of high level of oxygen which stimulated the enzymatic browning reaction between the oxygen[45,81].The hue value fordried Roselle measured atbetween 12°and 19°was indicating a dark red colour of final product.In conclusion,low temperature drying for Roselle warrants a total colour change within 10%(mean value)whereas HP assures consistency of colour for both petals and calyx.

Fig.13.Changes in moisture ratio with time using HA strategy.

Fig.14.Changes in drying rate with time using HA strategy.

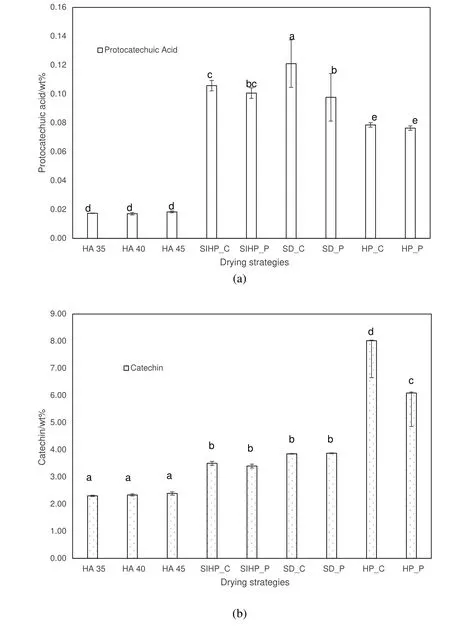

3.7.Quality analysis

In Fig.15(a),HA yields the lowest percentage solution of PCA in comparison with other drying methods.The average PCA%was merely(0.0176±0.0006)wt%.The reason for this is unknown but probably caused by the reaction change such as oxidative degradation during the drying period.Literature reviews suggested that the stability of polyphenols compound can be altered by different conditions such as light,high temperature,oxygen,solvents,the presence ofenzymes,proteins,metallic ions,or association with other food constituents[82].Cheng's investigation in phenolic compound in high temperature water suggested the decomposition of PCA increased with rising temperature and the acids became less stable with longer heating time[83].In this case study,both SIHP and SD demonstrated high retention of PCA with a highestpercentage solution from calyx measured at SIHP:0.1058 wt%and SD:0.1211 wt%,respectively.From Fig.15(b),it was noticed that the catechin retention from HP was two to three times higher than other drying strategies.SD and SIHP have average catechin content in both calyx and petals whereas HA recorded low catechin value.According to Li et al.,catechin degradation kinetics was affected by RH and temperature,but temperature was the dominantfactor[84].Thus,with lower RHand consistent low drying temperature,the HP can retain more bio-active compounds.By comparing different drying strategies,HA is a less desirable drying method particularly when higher retention of bio-active ingredient is desired.On the other hand,while retaining good amount of PCA content,HP's dried Roselle also contain high retention of catechin acid among the other drying techniques.Alternately,the solar drying(both SD and SIHP)produced balanced compound retention between PCA and catechin acid respectively as exemplified in Fig.15.

Table 2 Colour kinetics under different drying conditions and parameters

Fig.15.Retention of PCA(a)and catechin(b)in dried Roselle calyx and petals under differentdrying strategies.Oven drying with differenttemperatures(HA35,HA40,HA45);SIHP(solar with intermittent heatpump drying for Roselle calyx,C and petal,P);SD(solar drying for Roselle calyx,C and petal,P)and HP(heat pump drying for Roselle calyx,C and petal,P).Vertical bar and line graph indicated with the same letter are not significantly different(p>0.05).

4.Conclusions

By comparing the drying kinetics of four different drying methods,the highest drying rate was achieved by HP,followed by HA,SIHP and SD.The results suggested a confined dryer such as HP and HA can speed up the drying process and increase the output of the product,meanwhile SD has poor drying performance due to environmental factor e.g.weather condition and product rehydration during overnight drying.Likewise,HP had yield consistent red colour of dried Roselle for both calyx and petal which is an added value property to finished product.Although HA had significantly reduced the total drying time of Roselle,the retention of bio-active ingredient was undesirable.HPLC analysis revealed that both SD and SIHP have significantretention of PCA in dried Roselle(p<0.05)whereas higher catechin acid was detected in HP(p<0.05),followed by SD and SIHP,respectively.Overall,HP or heat pump assisted solar drying(SIHP)is a better drying option for Roselle as dried Roselle could have better colour quality and high retention of bio-active compounds.

[1]I.A.Ross,Medicinal Plants of the World:Chemical Constituents,Traditional and Modern Medicinal Uses,vol.1,Humana Press Inc.,NY,2003.

[2]Tjukup Marnoto,Endang Sulistyowati,P.Budiyastuti,P.Sumarwoto,M.Syahri,Bambang Sugiarto,Yusuf Hana fi,Girman,Kristianingrum,Drying of Rosella(Hibiscus sabdariffa) flower petals using solar dryer with double glass cover collector,Int.J.Sci.Eng.7(2)(2014)150-154.

[3]O.A.Ashaye,Studies on moisture sorption isotherm and nutritional properties of dried Roselle calyces,Int.Food Res.J.20(1)(2013)509-513.

[4]J.A.Duke,Handbook of Energy Crops,Center for New Crops And Plants Products:Purdue University,Indiana,1983.

[5]W.B.Esselen,G.M.Sammy,Applications for roselle as red color food colorant,Food Prod.Dev.9(1975)37-40.

[6]C.I.Beristain,H.S.García,A.Vazquez,Foam mat dehydration of Jamaica(Hibiscus sabdariffa L.)instant drink,Dry.Technol.11(1993)221-228.

[7]O.Carbajal,S.M.Waliszewski,D.M.Barradas,Z.Orta,P.M.Hayward,C.Nolasco,O.Angulo,R.Sanchez,R.M.Infanzon,P.R.L.Trujillo,The consumption of Hibiscus sabdariffa dried calyx ethanolic extract reduced lipid profile in rats,Plant Food Hum.Nutr.60(2005)153-159.

[8]A.A.Akindahunsi,M.T.Olaleye,Toxicological investigation of aqueous-methanolic extract of the calyces of Hibiscus sabdariffa L,J.Ethnopharmacol.89(2003)161-164.

[9]S.Fernández-Arroyo,I.C.Rodríguez-Medina,R.Beltrán-Debón,F.Pasini,J.Joven,V.Micol,A.Segura-Carretero,A.Fernández-Gutiérrez,Quantification of the polyphenolic fraction and in vitro antioxidant and in vivo anti-hyperlipemic activities of Hibiscus sabdariffa aqueous extract,Food Res.Int.44(5)(2011)1490-1495.

[10]S.Patel,Hibiscus sabdariffa:an ideal yet under exploited candidate for nutraceutical applications,Biomed.Prev.Nutr.4(2014)23-27.

[11]I.Da-Costa-Rocha,B.Bonnlaender,H.Sievers,I.Pischel,M.Heinrich,Hibiscus sabdariffa L.—a phytochemical and pharmacological review,Food Chem.165(2014)424-443.

[12]Y.Musa,E.A.Engku Ismail,H.Yahaya,Manual of Roselle's Cultivation Technology(Manual Teknologi Penanaman Rosel),Institut Penyelidikan dan Kemajuan Pertanian Malaysia(MARDI),Kuala Lumpur,2006.

[13]C.C.Hsieh,M.Y.Lee,C.C.Chen,J.J.Hsu,H.K.Lu,C.J.Wang,Hibiscus protocatechuic acid supplementation reduces oxidative stress induced by exhaustive exercise in rat muscle,J.Exerc.Sci.Fit.4(1)(2006)59-64.

[14]S.Kakkar,S.Bais,A review on protocatechuic acid and its pharmacological potential,ISRN Pharmacol.2014(2014)1-9.

[15]T.H.Tseng,C.J.Wang,E.S.Kao,H.Y.Chu,Hibiscus protocatechuic acid protects against oxidative damage induced by tert-butylhydroperoxide in rat primary hepatocytes,Chem.Biol.Interact.101(1996)137-148.

[16]T.H.Tseng,J.D.Hsu,M.H.Lo,F.P.Chou,C.L.Huang,C.Y.Chu,C.J.Wang,Inhibitory effect of Hibiscus protocatechuic acid on tumor promotion in mouse skin,Cancer Lett.126(1998)199-207.

[17]C.Y.Chao,Yin,M.C.,Antibacterial effects of roselle calyx extracts and protocatechuic acid in ground beef and apple juice,Foodborne Pathog.Dis.6(2)(2009)201-206.

[18]J.F.Hammerstone,S.A.Lazarus,H.H.Schmitz,Procyanidin content and variation in some commonly consumed foods,J.Nutr.130(2000)2086S-2092S.

[19]X.Z.Han,T.Shen,H.Lou,Dietary polyphenols and their biological significance,Int.J.Mol.Sci.8(9)(2007)950-988.

[20]S.B.Lotito,C.G.Fraga,Catechin prevents human plasma oxidation,Free Radic.Biol.Med.24(1998)435-441.

[21]H.Mangiapane,J.Thomson,A.Salter,S.Brown,G.D.Bell,D.A.White,The inhibition of oxidation of low density lipoprotein by(+)-catechin,a naturally occurring flavonoid,Biochem.Pharmacol.43(1992)445-450.

[22]S.d.P.Teresa,D.A.Moreno,C.G.Viguera,Flavanols and anthocyanins in cardiovascular health:a review of current evidence,Int.J.Mol.Sci.11(2010)1679-1703.

[23]O.Prakash,A.Kumar,Historical review and recent trends in solar drying systems,Int.J.Green Energy 10(7)(2013)690-738.

[24]A.C.Miranda,R.C.Miranda,J.M.Jimenez,Solar drying system for the agro-products dehydration,J.Agric.Soc.Sci.4(2008)135-140.

[25]C.Mady,Literature Review and Background Information of Bissap(Hibiscus sabdariffa L.),2010 9.

[26]D.L.Daniel,B.E.Huerta Barragan,I.Anaya Sosa,M.G.Mendoza Vizcarra,Effect of fixed bed drying on the retention of phenolic compounds,anthocyanins and antioxidant activity of roselle(Hibiscus sabdariffa L.),Ind.Crop.Prod.40(2012)268-276.

[27]A.Plotto,Hibiscus:Post Production Management for Improved Market Access,FAO:Food and Agriculture Organization,2004.

[28]EcoCrop,Hibiscus sabdariffa var.sabdariffa,FAO:Food and Agriculture Organization,2007.

[29]I.E.Saeed,K.Sopian,Z.Zainol Abidin,Thin layer drying of Roselle(I):mathematical modeling and drying experiments,Agric.Eng.Int.X(2008)1-25.

[30]O.Alves-Filho,I.Strommen,Application of heat pump in drying of biomaterials,Dry.Technol.14(1996)2061-2090.

[31]H.Li,Review of the Heat Pump Technologies and Applications,Sheffield University,2011 1-64.

[32]T.Kivevele,Z.Huan,A review on opportunities for the development of heat pump drying system in South Africa,S.Afr.J.Sci.110(5/6)(2014)1-11.

[33]F.Fayose,Z.Huan,Heat pump drying of fruits and vegetables:principles and potentials for sub-Saharan Africa,Int.J.Food Sci.2016(2016)9673029.

[34]M.Fatouh,M.N.Metwally,A.B.Helali,M.H.Shedid,Herbs drying using a heat pump dryer,Energy Convers.Manag.47(15-16)(2006)2629-2643.

[35]SelectiveAsiaLtd,Peninsular Malaysia:weather&when to go[cited 2015 3 August];Available from:http://www.selectiveasia.com/malaysia-holidays/weather 2010.

[36]U.Romer,Climate of the world:Malaysia[cited 2015 4 August];Available from:http://www.weatheronline.co.uk/reports/climate/Malaysia.htm 2015.

[37]MetMalaysia,General climate of Malaysia:sunshine and solar radiation[cited 2015 4 August];Available from:http://www.met.gov.my/web/metmalaysia/climate/generalinformation/malaysia?p_p_id=56_INSTANCE_zMn7KdXJhAGe&p_p_lifecycle=0&p_p_state=normal&p_p_mode=view&p_p_col_id=column-1&p_p_col_pos=1&p_p_col_count=2&_56_INSTANCE_zMn7KdXJhAGe_page=3 2015.

[38]K.Abdullah,Mursalim,Drying of vanilla pods using a greenhouse effect solar dryer,Dry.Technol.15(2)(1997)685-698.

[39]AOAC,Of ficial Methods of Analysis,Association of Of ficial Analytical Chemists,Arlington,VA,1996.

[40]C.L.Hii,C.L.Law,C.Michael,S.Suzannah,Improving Malaysian cocoa quality through the use of dehumidi fied air under mild drying conditions,J.Sci.Food Agric.91(2011)239-246.

[41]C.L.Hii,C.L.Law,M.Cloke,S.Suzannah,Thin layer drying kinetics of cocoa and dried product quality,Biosyst.Eng.102(2)(2009)153-161.

[42]R.P.F.Guiné,R.M.C.Fernandes,Analysis of the drying kinetics of chestnuts,J.Food Eng.76(3)(2006)460-467.

[43]N.Izli,E.Isik,Color and microstructure properties oftomatoes dried by microwave,convective,and microwave-convective methods,Int.J.Food Prop.(2014)(null-null).

[44]N.Djendoubi Mrad,N.Boudhrioua,N.Kechaou,F.Courtois,C.Bonazzi,In fluence of air drying temperature on kinetics,physicochemical properties,total phenolic content and ascorbic acid of pears,Food Bioprod.Process.90(3)(2012)433-441.

[45]S.P.Ong,C.L.Law,Microstructure and optical properties of salak fruitunder different drying and pretreatment conditions,Dry.Technol.29(16)(2011)1954-1962.

[46]C.H.Chong,C.L.Law,M.Cloke,L.C.Abdullah,W.R.Wan Daud,Drying models and quality analysis of sun-dried ciku,Dry.Technol.27(9)(2009)985-992.

[47]S.Sasidharan,Y.Chen,D.Saravanan,K.M.Sundram,L.Yoga Latha,Extraction,isolation and characterization of bioactive compounds from plants'extracts,Afr.J.Tradit.Complement.Altern.Med.8(1)(2011)1-10.

[48]H.Yao,X.Li,Y.Liu,Q.Wu,Y.Jin,An optimized microwave-assisted extraction method for increasing yields of rare ginsenosides from Panax quinquefolius L,J.Ginseng Res.40(4)(2016)415-422.

[49]A.Escarpa,M.C.González,Approach to the content of total extractable phenolic compounds from different food samples by comparison of chromatographic and spectrophotometric methods,Anal.Chim.Acta 427(1)(2001)119-127.

[50]P.Mattila,J.Kumpulainen,Determination of free and total phenolic acids in plantderived foods by HPLC with diode-array detection,J.Agric.Food Chem.50(13)(2002)3660-3667.

[51]F.D'Heureux-Calix,N.Badrie,Consumer acceptance and physicochemical quality of processed red sorrel/roselle(Hibiscus sabdariffa L.)sauces from enzymatic extracted calyces,Food Serv.Technol.4(2004)141-148.

[52]J.F.Morton,Fruits of Warm Climates,Echo Point Books&Media,Vermont,USA,2013 550.

[53]S.P.Ong,C.L.Law,Drying kinetics and antioxidant phytochemicals retention of salak fruit under different drying and pretreatment conditions,Dry.Technol.29(4)(2011)429-441.

[54]Z.Chen,F.M.Lamb,Analysis of the vacuum drying rate for red oak in a hot water vacuum drying system,Dry.Technol.25(3)(2007)497-500.

[55]S.Arora,S.Bharti,V.K.Sehgal,Convective drying kinetics of red chillies,Dry.Technol.24(2)(2006)189-193.

[56]A.Lingayat,V.P.Chandramohan,V.R.K.Raju,Design,development and performance of indirect type solar dryer for banana drying,Energy Procedia 109(2017)409-416.

[57]D.K.Rabha,P.Muthukumar,C.Somayaji,Experimental investigation of thin layer drying kinetics of ghost chilli pepper(Capsicum Chinense Jacq.)dried in a forced convection solar tunnel dryer,Renew.Energy 105(2017)583-589.

[58]K.Sacilik,R.Keskin,A.K.Elicin,Mathematical modelling of solar tunnel drying of thin layer organic tomato,J.Food Eng.73(3)(2006)231-238.

[59]M.W.Kareem Habib,Thermal performance study of a multi-pass solar air heating collector system for drying of Roselle(Hibiscus sabdariffa),Renew.Energy 113(2017)281-292.

[60]S.F.Dina,H.Ambarita,F.H.Napitupulu,H.Kawai,Study on effectiveness of continuous solar dryer integrated with desiccant thermal storage for drying cocoa beans,Case Stud.Therm.Eng.5(2015)32-40.

[61]K.King,Packaging and storage of herbs and spices,in:K.V.Peter(Ed.),Handbook of Herbs and Spices,Woodhead Publishing Limited,Cambridge,England 2006,pp.86-101.

[62]S.Janjai,P.Tung,Performance of a solar dryer using hot air from roof-integrated solar collectors for drying herbs and spices,Renew.Energy 30(14)(2005)2085-2095.

[63]M.Mohanraj,Performance of a solar-ambient hybrid source heat pump drier for copra drying under hot-humid weather conditions,Energy Sustain.Dev.23(2014)165-169.

[64]V.Minea,Overview of heat-pump-assisted drying systems,Part II:data provided vs.results reported,Dry.Technol.33(5)(2015)527-540.

[65]M.Yahya,A.Fudholi,H.Ha fizh,K.Sopian,Comparison of solar dryer and solarassisted heat pump dryer for cassava,Sol.Energy 136(2016)606-613.

[66]S.H.Gan,L.S.Chua,R.Aziz,M.R.Baba,L.C.Abdullah,S.P.Ong,C.L.Law,Drying characteristics of Orthosiphon stamineus Benth by solar assisted heat pump drying,Dry.Technol.(2017)1-10.

[67]R.Best,W.Soto,I.Pilatowsky,L.J.Gutierrez,Evaluation of a rice drying system using a solar assisted heat pump,Renew.Energy 5(1)(1994)465-468.

[68]S.Şevik,M.Aktaş,H.Doğan,S.Koçak,Mushroom drying with solar assisted heat pump system,Energy Convers.Manag.72(2013)171-178.

[69]H.R.Gazor,S.Minaei,In fluence oftemperature and airvelocity on drying time and quality parameters of pistachio(Pistacia vera L.),Dry.Technol.23(12)(2005)2463-2475.

[70]A.Vega-Galvez,et al.,Effect of temperature and air velocity on drying kinetics,antioxidant capacity,total phenolic content,colour,texture and microstructure of apple(var.Granny Smith)slices,Food Chem.132(1)(2012)51-59.

[71]S.V.Jangam,V.S.Joshi,A.S.Mujumdar,B.N.THorat,Studies on dehydration of sapota(Achras zapota),Dry.Technol.26(3)(2008)369-377.

[72]M.K.Krokida,V.T.Karathanos,D.Marinos-Kouris,Z.B.Maroulis,Drying kinetics of some vegetables,J.Food Eng.59(2003)391-403.

[73]V.Minea,Heat-pump-assisted drying:recent technological advances and R&D needs,Dry.Technol.31(10)(2013)1177-1189.

[74]K.J.Chua,S.K.Chou,W.M.Yang,Advances in heat pump systems:a review,Appl.Energy 87(12)(2010)3611-3624.

[75]K.H.Lee,O.J.Kim,J.Kim,Investigation on drying performance and energy savings of the batch type heat pump dryer,Dry.Technol.28(5)(2010)683-689.

[76]V.Sosle,G.S.V.Raghavan,R.Kittler,Low-temperature drying using a versatile heat pump dehumidi fier,Dry.Technol.21(3)(2003)539-554.

[77]S.Phoungchandang,W.Srinukroh,B.Leenanon,Kaf fir lime leaf(Citrus hystric DC.)drying using tray and heat pump dehumidi fied drying,Dry.Technol.26(12)(2008)1602-1609.

[78]P.K.Wong,S.Yusof,H.M.Ghazali,Y.B.C.Man,Physico-chemical characteristics of roselle(Hibiscus sabdariffa L.),J.Nutr.Food Sci.32(2002)68-73.

[79]P.Chumsri,A.Sirichote,A.Itharat,Studies on the optimum conditions for the extraction and concentration of roselle(Hibiscus sabdariffa Linn.)extract,Songklanakarin J.Sci.Technol.30(Suppl.1)(2008)133-139.

[80]P.Bridle,C.F.Timberlake,Anthocyanins as natural food colours—selected aspects,Food Chem.58(1-2)(1997)103-109.

[81]S.Palzer,C.Dubois,A.Gianfrancesco,Generation ofproduct structures during drying of food products,Dry.Technol.30(1)(2011)97-105.

[82]A.Castañeda-Ovando,M.d.L.Pacheco-Hernández,M.E.Páez-Hernández,J.A.Rodríguez,C.A.Galán-Vidal,Chemical studies of anthocyanins:a review,Food Chem.113(4)(2009)859-871.

[83]Y.Cheng,Q.Z.Xu,J.Liu,C.S.Zhao,F.M.Xue,Y.Z.Zhao,Decomposition of five phenolic compounds in high temperature water,J.Braz.Chem.Soc.25(11)(2014)2102-2107.

[84]N.Li,L.S.Taylor,L.J.Mauer,Degradation kinetics of catechins in green tea powder:effects of temperature and relative humidity,J.Agric.Food Chem.59(2011)6082-6090.

Chinese Journal of Chemical Engineering2018年2期

Chinese Journal of Chemical Engineering2018年2期

- Chinese Journal of Chemical Engineering的其它文章

- Transport hindrances with electrodialytic recovery of citric acid from solution of strong electrolytes

- Experimental investigation on CO2-light crude oil interfacial and swelling behavior

- Biosynthesis of 4-hydroxyphenylpyruvic acid from L-tyrosine using recombinant Escherichia coli cells expressing membrane bound L-amino acid deaminase☆

- Process development for producing a food-grade glucose solution from rice straws

- Carbon dioxide induced degradation of diethanolamine during absorption and desorption processes

- Biodegradation of natural and synthetic estrogens in moving bed bioreactor