Effects of conditioners (single-layer, double-layer and retentionconditioner) on the growth performance, meat quality and intestinal morphology of growing and finishing pigs

DUAN Hai-tao, LI Jun-guo, XUE Min YANG Jie DONG Ying-chao LIANG Ke-hong, QIN Yu-chang

1 Feed Research Institute, Chinese Academy of Agricultural Sciences, Beijing 10081, P.R.China

2 Key Laboratory of Feed Biotechnology, Ministry of Agriculture, Beijing 10081, P.R.China

3 Institute of Food and Nutrition Development, Ministry of Agriculture, Beijing 10081, P.R.China

1. Introduction

Livestock diet preparation has evolved from a simple “grind and mix” feed to more advanced hydro-thermal processes,such as pelleting, expanding, and even extruding feeds prior to animal consumption (Lundbladet al. 2011b). Traditional feed processing technology includes receiving, grinding,batching, mixing, conditioning, pelleting, and packaging procedures. These practices are most commonly used for diet preparation in farrow-to-finish pig operations (Boroojeniet al. 2016). Of these measures, the conditioning step is crucial to the feed grade value as it provides time for steam or liquids to be absorbed in the pellets as well as promotes uniformity of the feed. The manner in which the materials are conditioned plays a large role in determining the durability of the feed pellets (Zimonja and Svihus 2009).High temperature conditioning or long-term conditioning has been shown to greatly improve pellet quality (Lundbladet al.2009). A recent study investigated the effects of various feed processing techniques on pig growth performance and nutritional digestibility. It found that heat processing of the cereal improved digestibility and growth rate only during the first 10 days post-weaning while pelleting the diet improved digestibility and feed conversion but not growth rate (Medelet al. 2004). Another study indicated that efficient extrusion processing, utilizing larger particles from milled grains and recombining with finer ground grains, improved energy utilization in monogastric feeds (Al-Rabadiet al. 2011).Furthermore, numerous research studies have explored the effect of hydro-thermal processing on feed quality or growth performance of young piglets (Vanschoubroeket al. 1971; van der Poelet al. 1990; Vranjeset al. 1994;Lundbladet al. 2009; Zimonja and Svihus 2009). However,studies are seldom to take concern to the effects of various hydro-thermal conditioner preparations on meat quality of finishing pigs.

In this study, feed underwent hydro-thermal conditioning with different conditioners prior to pig consumption. We hypothesized that the pigs fed diets that endured longer retention-conditioner processing will have a greater growth performance than pigs fed traditionally processed feed with a single-layer conditioner treatment. To test our hypothesis,feeds were created using different hydro-thermal methods and fed to pigs throughout the growing phase (0 to 6 weeks)and into the finishing phase (6 to 17 weeks). The different feed effects on growth performance, meat quality, and intestinal morphology were investigated.

2. Materials and methods

This study was approved by the Animal Welfare and Animal Experimental Ethical Inspection Committee of Feed Research Institute, Chinese Academy of Agricultural Sciences (Beijing, China).

2.1. Diets and hydro-thermal conditioning treatments

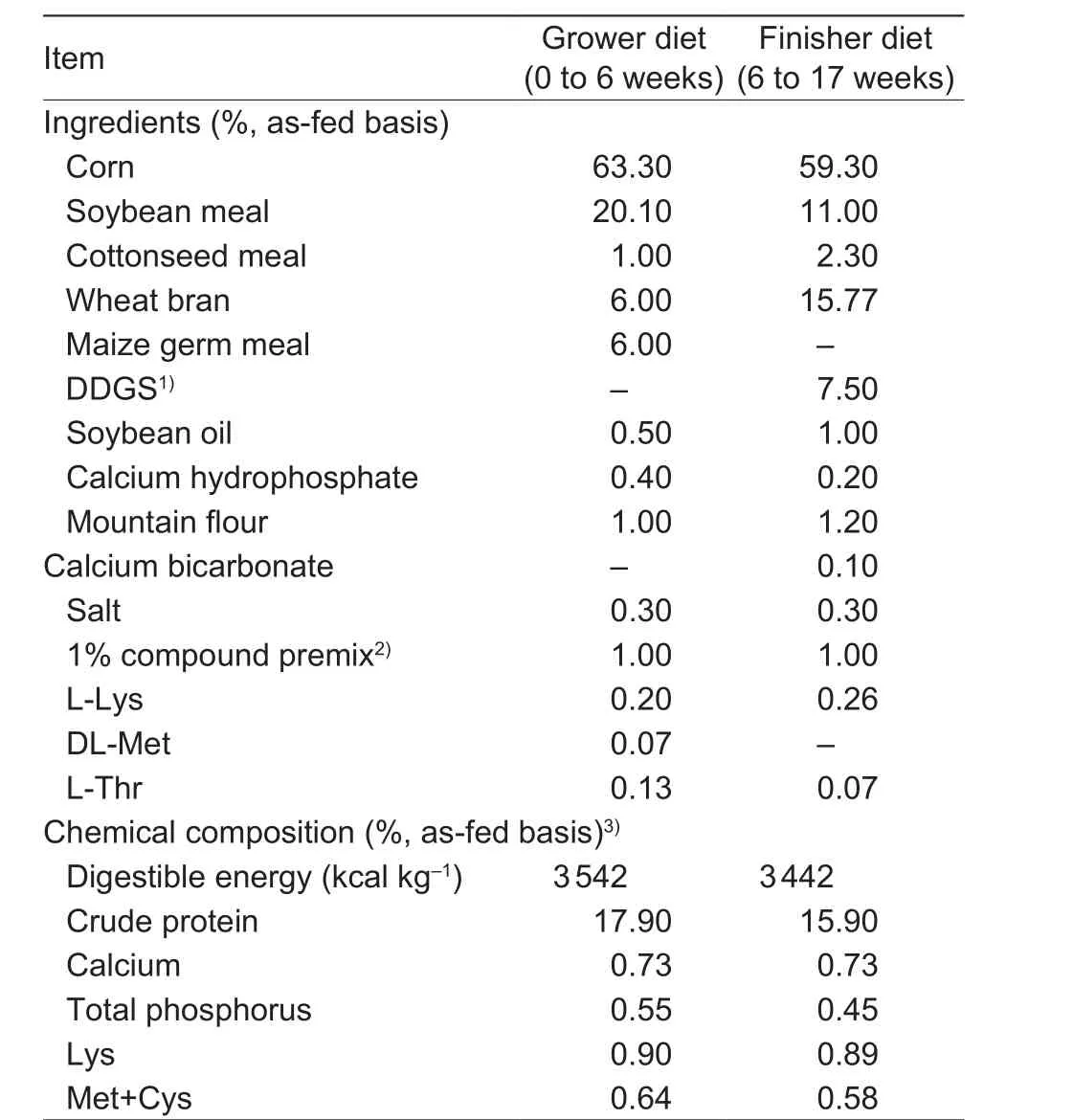

Two diets both based on corn, soybean meal, cottonseed meal, and wheat bran were formulated to meet or exceed NRC (2012) requirements for pigs (grower and finisher).Grower diet was used during the growing phase (0 to 6 weeks) and finisher diet was used during the finishing phase (6 to 17 weeks). Although diets were comprised of the same constituents, the diets differed in final ingredient and chemical composition percentages (Table 1).

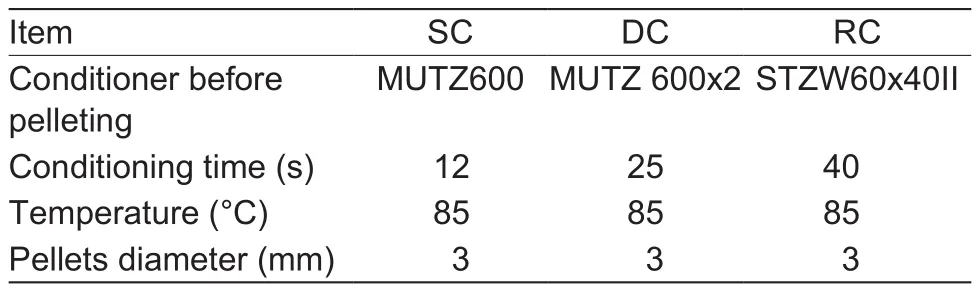

Macro materials, including corn, soybean meal,cottonseed meal, and wheat bran, were ground to a mean particle size of 535 μm through a 2.0-mm screen and mixed with vitamins as well as other ingredients in three separate batches prior to further processing. The treatments were:(1) single-layer conditioner (85°C for 12 s before pelleting,MUTZ600, Muyang, China; SC); (2) double-layer conditioner(85°C for approximately 25 s before pelleting, MUTZ600x2,Muyang, China; DC); and (3) retention-conditioner (85°C for approximately 40 s before pelleting, STZW60x40II,Muyang, China; RC). All treatments were pelleted to the same diameter (Table 2).

Table 1 Experimental diet ingredients and chemical compositions (air-dry basis)

2.2. Animal management and experimental design

Total of 96 pigs (Duroc×Landrace×Yorkshire; initial bodyweight (28.70±3.20) kg) were randomly distributed into three treatment groups. The complete random design had eight pigs (four sows and four barrows) per replicate with four replicates per treatment.

Barrows were provided withad libitumaccess to water and feed. The ration was divided into two equal-sized feedings at 08:00 and 16:00. The amount of feed provided was recorded at each feeding. Orts were removed and weighed after each meal and daily feed consumption was calculated. Ambient temperature was maintained at(22±2)°C to maximize pig growth.

2.3. Sample and analysis

Pellet durability was presented as pellet durability index(PDI). PDI was measured using the “P-fost” method and expressed as a percentage (Thomas and van der Poel 1996). Around 500 g of sieved pellets were placed in a drum (30.5 cm×30.5 cm×12.7 cm) and tumbled for 10 min at 50 r min–1. After tumbling, the pellets were screened with a sieve (US Sieve Size 6 with 2.36 mm diameter) to determine the amount of pellets that could not pass through the sieve. The pellet durability index was calculated as follows: PDI=Weight of pellets after tumbling/Weight of pellets before tumbling×100%.

The starch gelatinization degree (SGD) is one of the most important indicators evaluating the quality of pellet feed processing. The SGD was measured using the“enzyme reaction” method and expressed on a percentage basis (Xiong 2000). Approximately 0.20 g of mash feed was placed in a boiling water drum with a glass test tube(25 mL) and boiled for 1 h. A total of 1 mL amyloglucosidase(SIGMA180 U, USA) was added to the boiled samples for 1 h at 40°C. A total of 20 μL phosphomolybdic acid and 0.02 mL copper hydroxide were added to all samples. The samples were then measured at an absorbance of 420 μm using a spectrophotometer (Multiskan MK3, China). The starch gelatinization was calculated as follows: SGD=(Samples absorbance under 420 μm–Blank absorbance under 420 μm)/(Curing samples absorbance under 420 μm–Blank absorbance under 420 μm)×100%.

Twelve pigs were randomly selected from each of the 12 replicates (three treatments with four replicates each)and killed by thiopental injection (50 mg kg–1body weight,China). Pork samples of 36 cm2(6 cm×6 cm) and 2.5 cm thickness were cut from thelongissimus dorsimuscle and stored at 4°C for 3 d before texture profile analysis using a texture analyzer (XT2, Surrey, England). The analysis was carried out using an aluminum compression probe (5 mm diameter). The compression rate was set to 0.8 mm s–1and the strain to 60%. Samples were compressed twice,30 s apart. Six texture parameters, including chewiness,gumminess, cohesiveness, springiness, shear force and resilience were calculated according to previously described methods (Gineset al. 2004).

Further samples (2 cm×3.5 cm×5 cm) were cut from the center of thelongissimus dorsiand weighed (W1). Each sample was hung in an inverted paper cup (250 mL volume)and stored at 4°C for 3 d. Samples were then reweighed,after wiping off the surface diffusate (W2). Drip loss (DL) was calculated using the equation: DL (%)=[(W1–W2)/W1]×100

Tissue samples (approximately 1 cm) were collected from the duodenum, jejunum, and ileum of each euthanized pig.Samples were preserved in 20% formaldehyde and were analyzed for morphological characteristics (crypt depth and villus height and width). Tissue sections (thickness:6 mm; three slices from each sample) were stained with hematoxylin/eosin. The five longest villi from each slice and the thickness of five randomly selected muscle layers were measured using a light microscope (Leica DM2500,Leica, Solms, Germany).

2.4. Statistical analysis

All data were analyzed using the Statistical Analysis System(SAS 2008: version 114 9.2). Each replicate was considered an experimental unit during the analysis of feed quality,performance, meat quality and intestinal morphological data.Data were analyzed under a completely randomized design using the general linear model procedures of SAS followed by the Duncan’s multiple range test. Values are presented as least square means±the standard deviation. Significant differences were declared atP<0.05.

Table 2 Parameters for feed processing treatments1)

3. Results

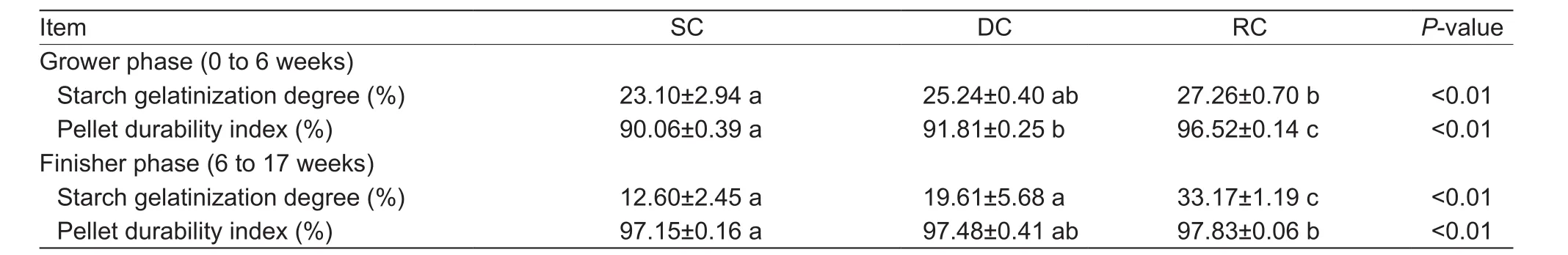

3.1. Feed quality

Feed quality parameters SGD and PDI were measured for the SC, DC and RC treatments in the growth and finishing diets (Table 3). In the growing phase, the SGD of the RC group was significantly higher (P<0.05) than that of the SC group. Furthermore, the PDI of the RC group was significantly higher (P<0.05) than that of the other treatment groups. In the finishing phase, the SGD of the RC group was significantly higher (P<0.05) than that of the other treatment groups. The PDI of the RC group was significantly higher(P<0.05) than that of the other treatment groups.

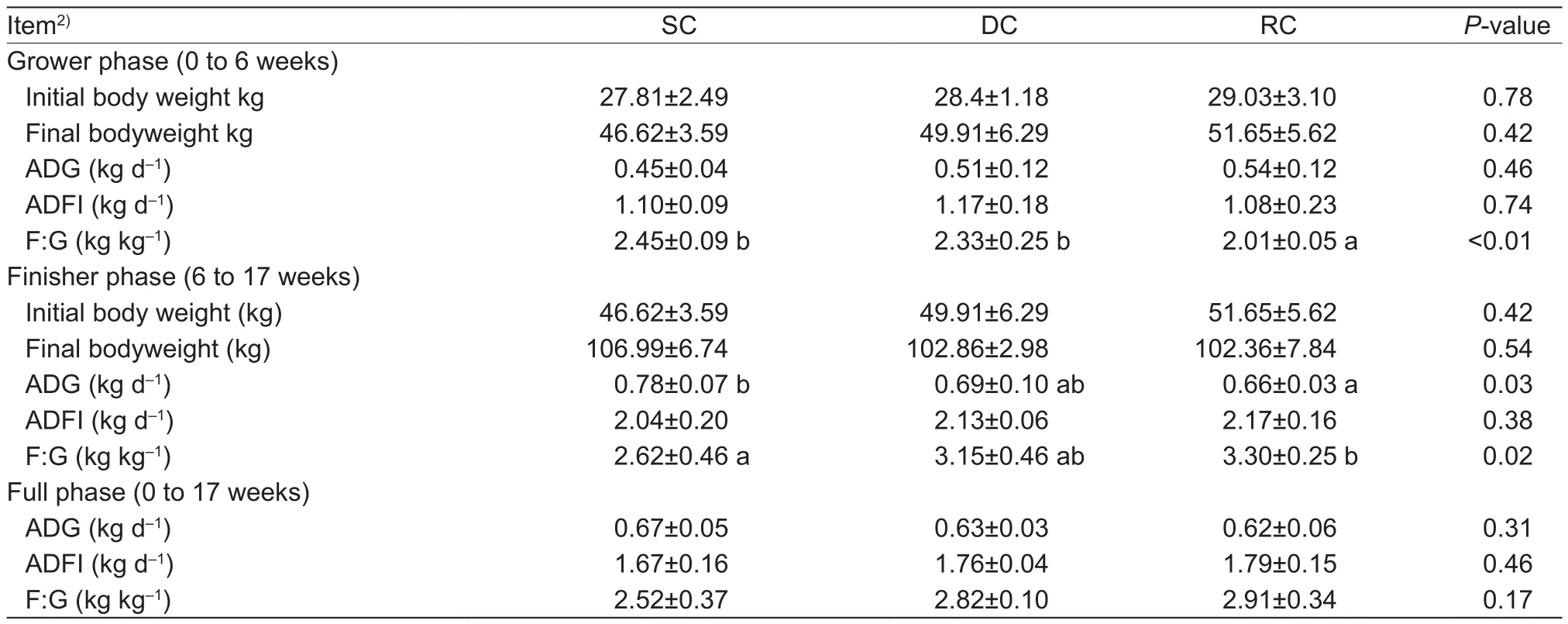

3.2. Pig performance

During the growing phase, there were no significant (P>0.05 for all; Table 4) differences in initial body weight, final body weight, average daily feed intake (ADFI) or average daily gain (ADG) among the different conditioner treatments.However, the feed to gain index (F:G) of the RC group was significantly lower (P<0.05) than that of the SC and DC group. Additionally, there was no significant difference in the F:G during the grower phase (P>0.05) between the DC and SC groups (Table 4). In the finishing phase, the three different conditioners showed no significant (P>0.05)differences in initial body weight, final body weight or ADFI(Table 4). The ADG of the RC group was significantly lower(P<0.05) than that of SC group and the F:G of the SC group was significantly lower (P<0.05) than that of the RC group.Overall, the three different conditioner treatments showed no significant (P>0.05) effect on ADG, ADfiand F:G from growing until slaughter.

3.3. Meat quality

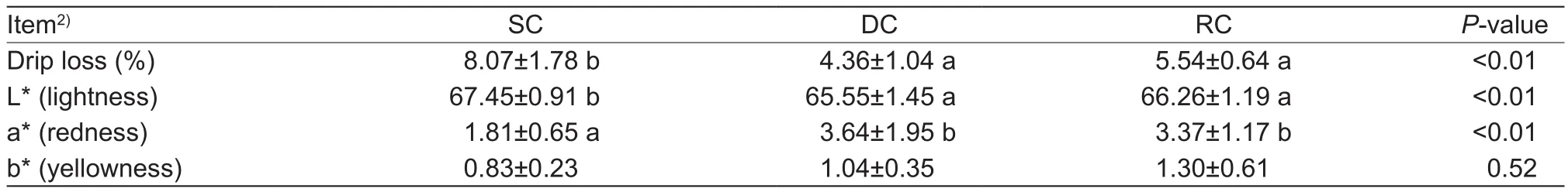

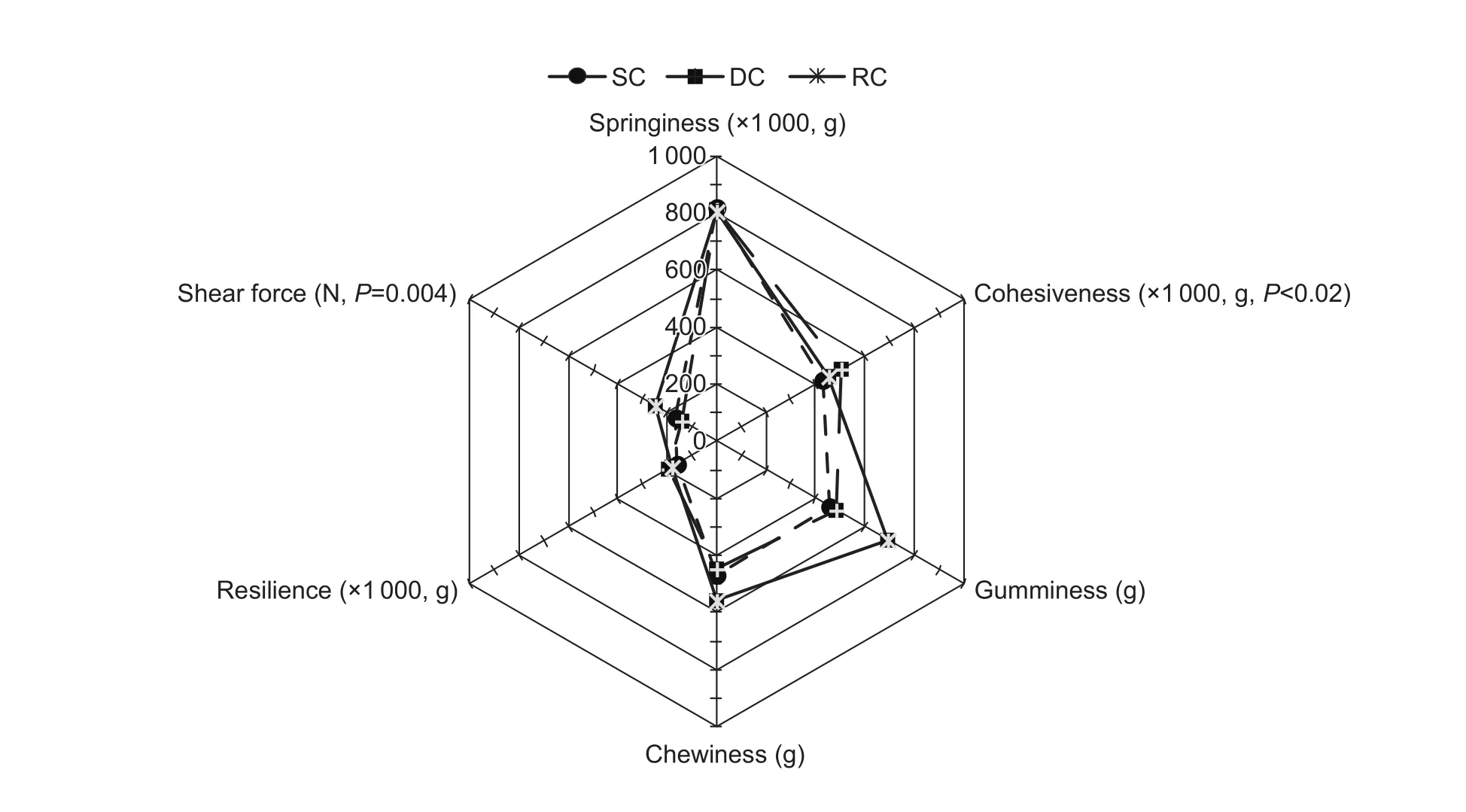

Meat quality was assessed using a texture profile analysisafter storage at 4°C for 3 d. The DL was significantly lower inlongissimus dorsitissue collected from pigs fed the RC diet than in tissue collected from pigs fed the SC diet,whereas DL did not differ between pigs fed the DC diet and those fed the RC diet (Table 5). The lightness (L*) value of the SC group was significantly higher (P<0.05) than that of the other groups, whereas, the redness (a*) value of the SC group was significantly lower (P<0.05) than that of the other groups. There was no significant difference(P>0.05) between the a* value of the DC group and that of the RC group. The shear force of longissimus dorsi tissue was higher (P=0.004; Fig. 1) in pigs fed the RC diet than in those fed other diets. Furthermore, the cohesiveness of thelongissimus dorsitissue collected from pigs fed the DC diet was higher (P=0.02) than that of tissue collected from pigs fed the SC diet. There were no significant differences (P>0.05) in springiness, resilience, chewiness and gumminess among the three groups.

Table 3 Effect of different feed conditioners on feed quality parameters1)

Table 4 Effect of different feed conditioner treatments on growth performance1)

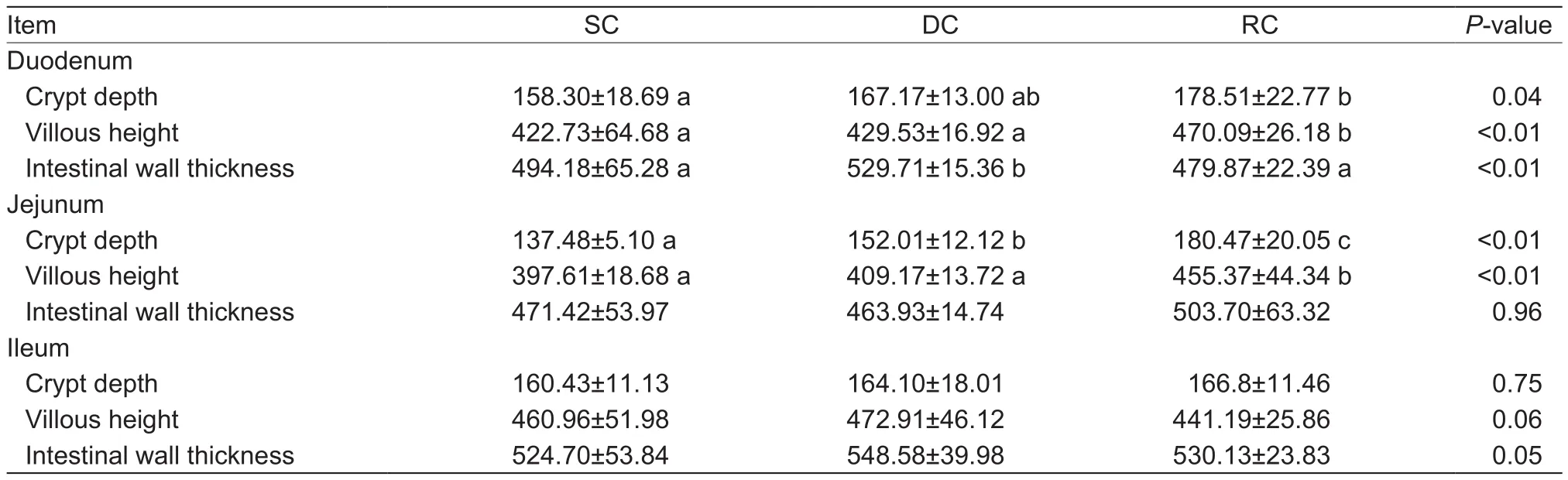

3.4. Intestinal morphological measurements

The crypt depth and villus height in duodenum tissues from the SC group were slightly greater (P<0.05) compared to the same tissues from the RC group (Table 6). The intestinal wall thickness was significantly higher (P<0.05) in the DC group than in the SC and RC groups. The crypts depth and villus height in jejunum tissues from the RC group were significantly deeper (P<0.05) than those in the SC and DC groups. However, there was no significant difference(P>0.05) in intestinal wall thickness between the three groups. In the ileum, no significant differences (P>0.05)were determined in crypt depth, villus height and intestinal wall thickness among the three groups.

4. Discussion

With ongoing livestock feed preparation studies, conditioningtechnology has progressed from single-layer conditioning to multi-layer conditioning techniques. Existing research shows that conditioning improves feed quality, enhances starch gelatinization, digestibility, and nutrient utilization(Liuet al. 2016; Steinet al. 2016). Studies have shown that pellets produced by expansion practices are harder and more durable than pellets produced using steam conditioning treatments (Lundbladet al. 2011b). The effect of SGD on feed quality was minor owing to the high SGD of unprocessed meal. There were three different feed conditioners (single-layer, double-layer and retentionconditioner) in this experiment. The higher SGD of the RC diet compared to the SC diet may be explained by the longer conditioning time and the abundant water content during processing. Our findings corresponded to previous studies with similar results (Zimonja and Svihus 2009). It has been shown that when temperature is limited, longer conditioning time is needed to gelatinize starch (Johnstonet al. 1999a). Moreover, it has been reported that the SGD of pellets produced either by extruder or expander techniques are significantly higher than that of pellets produced by hydro-thermal techniques (Lundbladet al.2011a). The generally higher PDI found in the RC diet in our study coincided with observations in several other studies(Johnstonet al. 1999b; Steidingeret al. 2000) and can be explained by the higher starch gelatinization found in this treatment. Starch gelatinization is the process of breaking down the intermolecular bonds of starch molecules in the presence of water and heat and improves adhesion and surface properties, allowing the hydrogen bonding sites to engage more water (Thomas 1996). Additionally, higher starch gelatinization has been shown to be affected by the application of high temperature, pressure, and humidity(Thomas 1998; Bampidis and Christodoulou 2011).

Table 5 Texture profile analysis measuring the effects of different feed conditioners on meat profiles1)

Fig. 1 Effect of different feed conditioners on meat quality properties. SC, control using hydro-thermal single-layer conditioning prior to pelleting; DC, hydro-thermal double-layer conditioning prior to pelleting; RC, hydro-thermal retention-conditioner prior to pelleting.

Feed quality is an important factor that highly influences pig growth performance. In this study, we measured SGD,PDI, ADFI, ADG, and F:G. The F:G decreased in growing pigs fed the RC diet compared to the DC diet. This may be explained by the feed quality in the different formulations as both the SGD and PDI were higher for the RC diet than the DC diet. Reduced feed waste may explain the improved utilization of nutrient digestibility (van der Poel 1997; Lundbladet al. 2011a). It has been shown that a reduction in starch and non-starch polysaccharide viscosity may shift the site of nutrient metabolism to more proximal regions of the gut, thereby reducing substrate availability for the microflora of the distal GI tract (Kim and Baker 2003).During the finishing phase, the ADfiin finishing pigs was not significantly different among the three groups, however,the ADG in finishing pigs fed the SC diet was significantly higher than that of RC diet. The decreased feed utilization in finishing pigs fed RC diet compared to SC diet could be explained by the excessive hydro-thermal processing, as confirmed by the markedly increased SGD and PDI in the RC diet fed pigs (Table 3). Long-term conditioner of the feed may induce the Maillard reaction which reduces nutrition utilization and causes heat-sensitive ingredients in the diet to degrade. At the same time, our study showed that the digestion and absorption systems of the finishing pigs increased with age and the feed quality requirements had become lower. Therefore, the growth performance of the finishing pigs fed SC diet was better than those fed RC diet.

Many factors determine pork meat quality, including genetic and environmental components that affect muscle color, water holding capacity, and palatability (Sukumaranet al. 1983; Hovenier 1992; Cannon 1996; Ellis 1999;Breweraet al. 2002). Research has shown that the incorporation of dried pomace in the diet improves several measures of meat quality while fattening pigs (Pieszkaet al. 2017). In the present study, we found that differentconditioners significantly affected meat quality differentially.The drip loss of pigs fed RC and DC diets was lower than that of pigs fed SC diet. Drip loss is inversely correlated with commercial value and consumer preference (Fredericket al. 2006; Dodenhoffet al. 2011; Alonsoet al. 2012;Athaydeet al. 2012). Meanwhile, texture profile analysis is a subjective measurement based on the preference of people chewing food (Wuet al. 2014). The shear force of thelongissimus dorsitissue was higher in pigs fed the RC diet than in those fed other diets. For each treatment, the bigger the area of the meat quality parameters is measured (Fig. 1),the higher the meat quality is. Currently, there are limited resources explaining the effects of feed processing on meat quality in livestock. However, studies have suggested that dietary nutrient levels significantly affect pork quality, and that high caloric energy, or reduced protein:energy ratio will significantly increase intramuscular fat (Souzaet al. 2003;Tanget al. 2010). Intramuscular fat content and muscle fiber type are two major factors influencing the quality of pork. The SGD of the RC diet was the highest in this study,however, the growth rate of finishing pigs fed the RC diet was lower, illustrating that more energy was applied to the formation of myofibroblasts and intramuscular fat content rather than improving growth performance. A higher SGD in the RC diet may also promote the expression of generative-associated genes in muscle tissue and stimulate the development of muscle fibers (Wang 2012). It has been shown that the shear force and drop loss parameters are closely related to the size or number of muscle fibers and intermuscular fat content (Breweraet al. 2002). Thus, the conditioner treatments in our study improved feed quality,in turn improving overall meat quality.

Table 6 Effect of different feed conditioners on the intestinal morphological measurements (μm)1)

Lastly, we studied intestinal tissues to understand nutrient absorption differences in the pigs fed the differently conditioned diet treatments. The intestine is the main organ for digestion and absorption in mammals (Choiet al. 2013;Gaoet al. 2013; Al-Fataftah and Abdelqader 2014; Oliveiraet al. 2014; Hanet al. 2015). It has been shown that the gut morphology of pigs fed feed-processed diets is more efficient at extracting nutrients than that of pigs fed unprocessed diets (Mikkelsen and Jensen 2001). Similarly, it has been reported that the ileal villi grow longer in broilers fed a dry diet than that of broilers fed a wet diet (Akinolaet al. 2015).Further research suggests that an increase in intestinal crypt depth corresponds with an increase in digestive and absorptive capacity (Yanget al. 2001; Zhao 2012; Hanet al.2015). The higher crypt depth and villus height measured in the duodenum of finishing pigs fed the RC diet compared to those fed the SC diet may be explained by the greater absorption in these tissues. This could be further explained by the greater SDG measurements from the RC diet than that from the SC diet. Unfortunately, information regarding multiple conditioners and intestinal morphology is scarce and no references could be used for comparison purposes.However, we do know that starch gelatinization breaks down the intermolecular bonds of starch molecules and increases the glucose content. Intestinal microflora can utilize glucose as a carbon source for acetic acid, butyric acid and other volatile fatty acid production (Fuet al.2017; Luoet al. 2017). Butyric acid is the main source of epithelial cell growth and can repair damage to promote the development of normal epithelial cells (Knudsenet al. 2012).Furthermore, it has been reported that glucose increases villus size and villus height ratio (Mathlouthiet al. 2002).Thus, the diet conditioner treatments that showed increased SDG and improved intestinal morphology could be a result of increased tissue area production and absorption.

5. Conclusion

Our results have demonstrated that the retention-conditioner treatment decreased the feed to gain index in growing pigs, improved intestinal morphology and enhanced meat quality in the finishing pigs. However, retention-conditioner treatments had a negative impact on growth performance in finishing pigs.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China(2016YFF0201800), the National Natural Science Foundation of China (31572631, 31372539), the Beijing Technology System for Sturgeon and Salmonids, China(SCGWZJ 20171103-1), the National Basic Research Program of China (2014CB138600), the Fundamental Research Funds of China (1610382016010), and the Special Scientific Research Fund of Agriculture Public Welfare Profession of China (201203015). We thank all the people who offered many useful suggestions and guidance in the experimental procedures.

Akinola O S, Onakomaiya A O, Agunbiade J A, Oso A O.2015. Growth performance, apparent nutrient digestibility,intestinal morphology and carcass traits of broiler chickens fed dry, wet and fermented-wet feed.Livestock Science,177, 103–109.

Al-Fataftah A R, Abdelqader A. 2014. Effects of dietaryBacillus subtilison heat-stressed broilers performance, intestinal morphology and microflora composition.Animal Feed Science and Technology, 198, 279–285.

Al-Rabadi G J, Torley P J, Williams B A, Bryden W L, Gidley M J. 2011. Effect of extrusion temperature and pre-extrusion particle size on starch digestion kinetics in barley and sorghum grain extrudates.Animal Feed Science and Technology, 168, 267–279.

Alonso V, Provincial L, Gil M. 2012. The impact of short-term feeding of magnesium supplements on the quality of pork packaged in modified atmosphere.Meat Science, 90,52–59.

Athayde N B, Dallaosta O A, Roca R O, Guidoni A L. 2012.Meat quality of swine supplemented with ractopamine under commercial conditions in Brazil.Journal of Animal Science,90, 4604–4610.

Bampidis V A, Christodoulou V. 2011. Chickpeas (Cicer arietinumL.) in animal nutrition: A review.Animal Feed Science and Technology, 168, 1–20.

Boroojeni F G, Svihus B, Reichenbach H G, Zentek J. 2016.The effects of hydrothermal processing on feed hygiene,nutrient availability, intestinal microbiota and morphology in poultry - A review.Animal Feed Science and Technology,220, 187–215.

Brewera M S, Jensen J, Sosnicki A A, Fields B, Wilson E, McKeith F K. 2002. The effect of pig genetics on palatability,color and physical characteristics of fresh pork loin chops.Meat Science, 61, 249–256.

Cannon J E, Morgan J B, Schmidt G R, Tatum J D, Sofos J N,Smith G C, Delmore R J, Williams S N. 1996. Growth and fresh meat quality characteristics of pigs supplemented with vitamin E.Journal of Animal Science, 74, 98–105.

Choi S C, Ingale S L, Kim J S, Park Y K, Kwon I K, Chae B J. 2013. Effects of dietary supplementation with an antimicrobial peptide-P5 on growth performance, nutrient retention, excreta and intestinal microflora and intestinal morphology of broilers.Animal Feed Science and Technology, 185, 78–84.

Dodenhoff J, Schuster M, Wittmann W, Littmann E, Lindner J P,Gotz K U. 2011. Data recording and genetic evaluation of drip loss for pigs in Bavaria.Zuchtungskunde, 83, 142–152.Ellis M, Mekeith F K, Miller K D. 1999. The effects of genetic and nutritional factors on pork quality.Journal of Animal Science, 12, 261–270.

Frederick B R, Heugten E V, Hanson D J, See M T. 2006. Effects of supplemental magnesium concentration of drinking water on pork quality.Journal of Animal Science, 84, 185–190.

Fu H, Yang S T, Wang M, Wang J, Tang I C. 2017. Butyric acid production from lignocellulosic biomass hydrolysates by engineeredClostridium tyrobutyricumoverexpressing xylose catabolism genes for glucose and xylose coutilization.Bioresource Technology, 234, 389–396.

Gao Y, Han F, Huang X, Rong Y, Yi, H, Wang Y. 2013.Changes in gut microbial populations, intestinal morphology,expression of tight junction proteins, and cytokine production between two pig breeds after challenge with K88: A comparative study.Journal of Animal Science, 91,5614–5625.

Gines R, Valdimarsdottir T, Sveinsdottir K, Thorarensen H. 2004. Effects of rearing temperature and strain on sensory characteristics, texture, colour and fat of Arctic charr (Salvelinus alpinus).Food Quality and Preference,15, 177–185.

Han B, Long W Q, He J Y, Liu Y J, Si Y Q, Tian L X. 2015. Effects of dietaryBacillus licheniformison growth performance,immunological parameters, intestinal morphology and resistance of juvenile Nile tilapia (Oreochromis niloticus) to challenge infections.Fish Shellfish Immunol, 46, 225–231.

Hovenier R, Kanis E, Asseldonk T, Westerink N G. 1992.Genetic parameters of pig meat quality traits in a halothane negative population.Livestock Production Science, 32,309–321.

Johnston S L, Hancock J D, Hines R H, Kennedy G A, Traylor S L, Chae B J, Han I K. 1999a. Effects of conditioners(standard, long-term and expander) on pellet quality and growth performance in nursery and finishing pigs.Asian-Australasian Journal of Animal Sciences, 12, 558–564.

Johnston S L, Hancock J D, Hines R H, Kennedy G A, Traylor S L, Chae B J, Han I K. 1999b. Effects of expander conditioning of corn- and sorghum-based diets on pellet quality and performance in finishing pigs and lactating sows.Asian-Australasian Journal of Animal Sciences, 12,565–572.

Kim S W, Baker D H. 2003. Use of enzyme supplements in pig diets based on soyabean meal.Pig News and Information,24, 91–95.

Knudsen K E B, Hedemann M S, Laerke H N. 2012. The role of carbohydrates in intestinal health of pigs.Animal Feed Science and Technology, 173, 41–53.

Liu H, Wan H F, Xu S Y, Fang Z F, Lin Y, Che L Q, Li J, Li Y,Su X, Wu D. 2016. Influence of extrusion of corn and broken rice on energy content and growth performance of weaning pigs.Animal Science Journal, 87, 1386–1395.

Lundblad K K, Hancock J D, Behnke K C, Prestløkken E,McKinney L J, Sørensen M. 2009. The effect of adding water into the mixer on pelleting efficiency and pellet quality in diets for finishing pigs without and with use of an expander.Animal Feed Science and Technology, 150, 295–302.

Lundblad K K, Issa S, Hancock J D, Behnke K C, McKinney L J, Alavi S, Prestløkken E, Fledderus J, Sørensen M. 2011a.Effects of steam conditioning at low and high temperature,expander conditioning and extruder processing prior to pelleting on growth performance and nutrient digestibility in nursery pigs and broiler chickens.Animal Feed Science and Technology, 169, 208–217.

Lundblad K K, Issa S, Hancock J D, Behnke K C, McKinney L J, Alavi S, Prestløkken E, Fledderus J, Sørensen M. 2011b.Ileal digestibility of crude protein, amino acids, dry matter and phosphorous in pigs fed diets steam conditioned at low and high temperature, expander conditioned or extruder processed.Animal Feed Science and Technology, 172,237–241.

Luo G, Zhang L, Chen T, Yuan W, Geng Y. 2017. Butyric acid fermentation in xylose and glucose byClostridium tyrobutyricum.Bioresources, 12, 2930–2940.

Mathlouthi N, Lailles J P, Lepercq P, Juste C, Larbier M.2002. Xylanase and beta-glucanase supplementation improve conjugated bile acid fraction in intestinal contents and increase villus size of small intestine wall in broiler chickens fed a rye-based diet.Journal of Animal Science,80, 2773–2779.

Medel P, Latorre M A, Deblas C, Lazaro R, Mateos G G. 2004.Heat processing of cereals in mash or pellet diets for young pigs.Animal Feed Science and Technology, 113, 127–140.

Mikkelsen L, Jensen B B. 2001. Feeding liquid diets to pigs.Recent Developments in Pig Nutrition, 3, 379–398.

NRC (National Research Council). 2012.Nutrient Requirements of Swine.11th revised ed. The National Academies Press,Washington D.C., USA.

Oliveira L, Madrid J, Ramis G, Martínez S, Orengo J, Villodre C,Valera L, López M J, Pallarés F J, Quereda J J, Mendonça L, Hernández F. 2014. Adding crude glycerin to nursery pig diet: Effect on nutrient digestibility, metabolic status,intestinal morphology and intestinal cytokine expression.Livestock Science, 167, 227–235.

Pieszka M, Szczurek P, Bederska-Lojewska D, Migdal W,Pieszka M, Gogol P, Jagusiak W. 2017. The effect of dietary supplementation with dried fruit and vegetable pomaces on production parameters and meat quality in fattening pigs.Meat Science, 126, 1–10.

van der Poel A F B, Fransen H M P, Bosch M W. 1997. Effect of expander conditioning and or pelleting of a diet containing tapioca pea and soybean meal on the total tract digestibility in growing pigs.Animal Feed Science and Technology,66, 289–295.

van der Poel A F B, Hartog L A D, Stiphout W A A V, Bremmers R, Huisman J. 1990. Effects of extrusion of maize on ileal and faecal digestibility of nutrients and performance of young piglets.Animal Feed Science and Technology, 29,309–320.

Souza D, Pethick D W, Dunshea F R. 2003. Nutritional manipulation increases intramusclar fat levels in the longissimus muscle of female finisher pigs.Australian Journal of Agricultural Research, 54, 745–749.

Steidinger M U, Goodband R D, Tokach M D, Dritz S S,Nelssen J L, McKinney L J, Borg B S, Campbell J M. 2000.Effects of pelleting and pellet conditioning temperatures on weanling pig performance.Journal of Animal Science, 78,3014–3018.

Stein H H, Lagos L V, Casas G A. 2016. Nutritional value of feed ingredients of plant origin fed to pigs.Animal Feed Science and Technology, 218, 33–69.

Sukumaran P K, Nakatsuji A L, Reese J G, Gilman P, Huisman T H. 1983. DNA sequence variants in the G gamma-, A gamma-, delta- and beta-globin genes of man.Nucleic Acids Research, 32, 4635–4643.

Tang R Y, Yu B, Zhang K. 2010. Effects of nutritional level on pork quality and gene expression of mu-calpain and calpastatin in muscle of finishing pigs.Meat Science, 85,768–771.

Thomas T, van der Poe A F B. 1996. Physical quality of pelleted animal feed. 1. Criteria for pellet quality.Animal Feed Science and Technology, 61, 89–112.

Thomas T, van der Poe A F B. 1998. Physical quality of pelleted animal feed. 3. Contribution of feedstuff components.Animal Feed Science and Technology, 70, 59–78.

Vanschoubroek F, Coucke L, Spaendonck R V. 1971. The quantitative effect of pelleting feed on the performance of piglets and fattening pigs.Nutrition Abstracts and Reviews,41, 1–9.

Vranjes M V, Pfirter H P, Wenk C. 1994. Influence of processing treatment and type of cereal on the effect of dietary enzymes in broiler diets.Animal Feed Science and Technology, 46,261–270.

Wang J. 2012. Meat quality comparison between pig breeds and its interaction with nutrition. Ph D thesis, Sichuan Agricultural University, China. pp. 1–144. (in Chinese)

Wu D, Wang D S, He Y. 2014. Novel non-invasive distribution measurement of texture profile analysis (TPA) in salmon fillet by using visible and near infrared hyperspectral imaging.Food Chemistry, 145, 417–426.

Yang J S, Jung H J, Xuan Z, Kim J, Kim D, Chae B, Han K.2001. Effects of feeding and processing methods of diets on performance, morphological changes in the small intestine and nutrient digestibility in growing-finishing pigs.Asian-Australasian Journal of Animal Sciences, 14, 1450–1459.

Xiong Y Q. 2000. Determinate starch gelatinization degree in feed.Feed Industry, 21, 30–31. (in Chinese)

Zhao Y, Bin S, Yan S, Yu P, Liu X, Guo Y, Xu Y, Xu Z. 2012.Comparative study between the tethered-type feeding and scattered-type feeding styles on slaughter performance and meat quality in beef cattle.Chinese Journal of Animal Science, 48, 63–67. (in Chinese)

Zimonja O, Svihus B. 2009. Effects of processing of wheat or oats starch on physical pellet quality and nutritional value for broilers.Animal Feed Science and Technology, 149,287–297.

Journal of Integrative Agriculture2018年4期

Journal of Integrative Agriculture2018年4期

- Journal of Integrative Agriculture的其它文章

- Climate change and Chinese farmers: Perceptions and determinants of adaptive strategies

- Estimating the average treatment effect of adopting stress tolerant variety on rice yield in China

- lmmunogenicity and protective efficacy of DHBV DNA vaccines expressing envelope and capsid fusion proteins in ducks delivered by attenuated Salmonella typhimurium

- Sub-lethal effects of Beauveria bassiana (Balsamo) on field populations of the potato tuberworm Phthorimaea operculella Zeller in China

- Regionalization of wheat powdery mildew oversummering in China based on digital elevation

- Streptomyces sp. RP1A-12 mediated control of peanut stem rot caused by Sclerotium rolfsii