溴诱导法乙烯渣油基高软化点各向同性沥青的制备及表征

葛传长, 孙振龙, 杨海潇, 龙东辉, 乔文明,2, 凌立成

(1.华东理工大学,化学工程联合国家重点实验室,上海200237; 2.华东理工大学,上海市多相结构材料化学工程重点实验室,上海200237)

1 Introduction

High softening point isotropic pitches are complex mixtures of polycyclic aromatic hydrocarbon (PAH) oligomers which exhibit a high molecular weight, high coking value and high softening point of more than 200 ℃. It is well-known that the high softening point isotropic pitches have been extensively used as precursors for making a variety of high-value added products and high performance carbonaceous materials in industrials such as general purpose carbon fibers (GPCF)[1], carbon foams[2], high density isotropic graphite[3], anode materials for lithium ion batteries[4], advanced C/C composites[5,6]and activated carbon materials[7].

Generally high softening point isotropic pitches can be prepared from various feed stocks, such as heavy oils, petroleum pitch or purified coal tar pitch, by methods of solvent extraction[8], air blowing[9,10], thermal treatment[11]and the polymerization of small molecules using catalysts[12,13]. Among these methods, air blowing and thermal treatment are the most efficient and economical ones. It is generally accepted that air blowing greatly increases the softening point by enabling the formation of oxy-radicals and gives cross-linked structures of the pitch[14]. However, the introduced oxygen in the pitch is unstable and would decompose during pyrolysis which will inevitably deteriorate the performance of the final carbon products. Whereas the thermal treatment, which needs to be held at high temperature for long reaction time, is likely to generate more planar and condensed molecules and thus gives rise to the formation of mesophase[15], which will leads to inhomogeneity of the pitch and badly destroys the spinning property of the isotropic pitch for the manufacture of carbon fibers. Moreover, most of the light components are distilled out during the heating treatment, which will results in a low pitch yield. Therefore, how to prepare high purity isotropic pitches with a high yield and softening point using a cheap raw material still remains to be a challenge task.

Ethylene tar (ET), a byproduct from naphtha cracking process, is produced on a large scale each year with the growing need of ethylene. This typical residual oil possesses advantage features of a high solvent solubility, high carbon/hydrogen ratio, high aromaticity and essentially free from heteroatoms and inorganic substances, which make it suitable source for developing carbon materials[16,17]. In this paper, a new facile two-step method to produce a high softening point and homogeneous isotropic pitch from the vacuum distillated ET was developed and the obtained pitches were characterized. First, the vacuum distillated ET was modified via bromination, and then thermally treated under a relatively low temperature to induce dehydrobromination/polycondensation reaction. The effect of bromination temperatures and the amount of the introduced bromine on the composition, physical properties and coking behaviors of the final pitches were investigated. This route should suggest a significant guidance for the effective utilization of ET and potential market can be stimulated by the developing of high-value-added carbon materials.

2 Experimental

2.1 Raw material and pretreatment

ET supplied by Sinopec Shanghai Petrochemical Co. Ltd. (PR China) was used as the starting material. The original ET was subsequently distillated at 250 ℃ under vacuum (0.025 mmHg) to remove the volatile fractions. The obtained solid heavy residue (ET-HR) which takes up ca. 49% of the entire ET was then used as the feed stock for the preparation of the novel high softening point isotropic pitches.

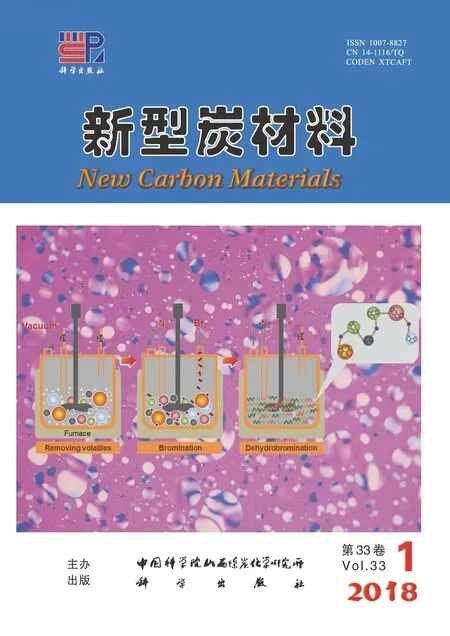

Fig. 1 Schematic diagram of the novel pitch preparation process.

2.2 Pitch preparation

The novel high softening point pitches were prepared by a successive two-step method, the bromination of ET-HR under low temperatures and subsequent dehydrobromination/polycondensation (DP) at 350 ℃. The schematic diagram of the preparation process was shown in Fig. 1. In a typical run, about 120 g coarsely grounded ET-HR (<5 mm particle diameter) was re-melted in a 250 mL Pyrex reactor under vigorous stirring with an N2flow of 150 mL/min. Then the liquid bromine was added to the ET-HR under 200 ℃ at a dropping rate of 0.5 mL/min to form brominated products with a bromine content of 9.25 wt.% (labeled as BP1) and 13.35 wt.% (labeled as BP2). The ET-HR was also brominated at 30 ℃ to form a mixture with bromine content of 12.02 wt.% by using benzene as the solvent (labeled as LBP). After this, the second thermal treatment of BP1, BP2 and LBP were carried out at 350 ℃ for 6 h to induce the dehydrobromination/polycondensation. The resultant pitches were denoted as DBP1, DBP2 and DLP, respectively. For comparison, the direct thermal treatment of ET-HR at 350 ℃ for 6 h in nitrogen atmosphere was also carried out to determine the effect of the thermal treatment itself on characteristics of pitch. This obtained pitch was denoted as TTP. All the pitches were further distillated at 330 ℃ for 20 min under vacuum to remove volatile components. The product yield was calculated by the following equation:

Yield (%) = 100×Mass of resultant pitch/ Mass of the used ET-HR

As-prepared pitches were then carbonized at 800 ℃ using a horizontal tube furnace. About 5 g pitch samples were placed in a quartz crucible, which was then positioned in the constant temperature zone of the furnace. The samples were heated to 800 ℃ at 5 ℃/min and held for 30 min under a N2flow rate of 120 mL/min. The obtained cokes were noted as C-X, where X stands for the corresponding pitches.

2.3 Pitch characterization

The composition of ET-HR was determined by gas chromatography-mass spectrometry (GC-MS) on a Shimadzu GCMS-QP2010 plus instrument operating in an electron ionization (EI, 70 eV) mode. Sample injection (1 μL) was performed in split mode with a split ratio of 1∶30. The oven temperature was initially held at 100 ℃ for 5 min, and then increased to 260 ℃ at a rate of 7 ℃/min and held for 3 min. The ion source temperature was set at 250 ℃, and the samples were scanned from 35 to 800 m/z in TIC mode. The separated components were determined by comparing their mass spectra with those recorded in the National Institute of Standards and Technology (NIST) database. Quantitative analysis of the main components was determined by peak area normalization method.

The elemental compositions of the prepared pitches were determined by an elemental analyzer (vario EL, III ELEMENTAR, Germany) at CHN mode. The oxygen content was determined by the difference. The solubility of the samples was measured by the Soxhlet extraction.

The1H NMR spectra of the samples were performed on a Bruker Avance 400 spectrometer. CDCl3was used as the solvent and tetramethylsilane (TMS) was used as the internal standard.

Laser desorption ionization time-of-flight mass spectrometry (LDI-TOF/MS) analysis was recorded on a 4800 Plus LDI TOF/MS Analyzer (AB Sciex). It was operated in a linear mode which provided a high sensitivity to high molecular weight molecules.

Fourier-transform infrared spectroscopy (FT-IR) of the pitches was performed on a Nicolet 6700 (Thermo Scientific, USA) spectrophotometer in the range of 4 000-500 cm-1at a resolution of 4 cm-1.

The softening point of the pitches was determined by a thermomechanical analyzer (TMA, DMA2980, USA).

The X-ray diffraction (XRD) patterns of the pitch samples were characterized by a Bruker D8 Advance diffractometer with CuKαradiation (λ=0.154 056 nm) and steps of 2θ=0.02°. The aromaticity and crystallite parameters were calculated by the following equations[18,19]:

A comparative estimate of the aromaticity (fa) was determined from the area (A) of resolved peaks for theγand 002 bands using the following formula:

fa=A002/(A002+Aγ)

(1)

The layer distance between the neighboring aromatic sheets,d002, were calculated by the following Bragg equation:

d002=λ/(2sinθ002)

(2)

whereλis the wave length of the CuKαradiation andθ002is the Bragg’s angle in which the peak is centered. The distance between the saturated portions (neighboring aliphatic chains or saturated rings) in the pitch molecules was also determined from the Bragg’s relation and theγband:

dγ=5λ/(8sinθλ)

(3)

The average stack height (Lc) and size (La) of the aromatic sheet were estimated according to the Scherrer equations.

Lc=0.9λ/β002cosθ002

(4)

La=1.84λ/β100cosθ100

(5)

Whereβis the full width at half maximum of the corresponding bands obtained by curve fitting procedures. The number of aromatic sheets per stacked cluster was determined as follows:

N=(Lc/d002)+1

(6)

The optical microstructures of the prepared pitches and cokes were examined by using an Olympus BX51 microscope. The samples were embedded in epoxy resin, which were then smoothed and polished. Representative images of the samples were taken using objective of 20×magnification.

3 Results and discussion

3.1 Analysis of ET-HR

The main properties of ET-HR are summarized in Table 1. Compared with ET, the ET-HR obtained from the vacuum distillation exhibits a higher carbon content and lower hydrogen content. The softening point of the ET-HR has been increased to 101 ℃ after the removal of light fraction. Furthermore, the carbon yield of ET-HR is noticeably higher than that of parent ET, indicating a larger molecular weight of components of the heavy residue.

Table 1 Main characteristics of ET and the derived ET-HR

aBy difference.

bAtomic ratio.

cSoftening point.

dCarbon yield determined by TG at 800 ℃, as shown in Fig. S1.

Although with a high softening point, ET-HR is still completely soluble in toluene. Thus GC-MS techniques are applied to identify and quantify the low-boiling point compounds in the ET-HR. The spectrum is shown in Fig. 2 (a). The main GC-amenable compounds identified as the numbered peaks are listed in Table 2. Results show that ET-HR is a complex mixture, which is composed of phenanthrene, methylanthracene, ethylphenanthrene, pyrene, methylpyrene, benzanthracene, methylchrysene, et al. All the compounds in the ET-HR can be divided into 3-5 rings species with a normalization result of 29.1%, 61.8% and 9.1%, respectively. To be noted, the ET-HR also contains a considerable amount of short alkyl chains as 54.12% of the integrated compounds are substituted by methyls or ethyls.

Fig. 2 (a) GC-MS and (b) LDI-TOF/MS spectra of the ET-HR.

However, the tailing at a longer retention time (after 32 min) on GC-MS might suggest that some high-boiling point PAHs present in the ET-HR are not well resolved on the GC column. Thus the ET-HR is further analyzed by LDI TOF/MS, as shown in Fig. 2(b). As expected, LDI TOF/MS reveals a large number of well-defined peaks corresponding to the high molecular weight PAHs. It is found that the major components in the ET-HR fall in the molecular weight range of 150-600, which contain various heavy PAHs of more than 5 rings. The alkylated chrysenes (242 m/z) and benzopyrenes (252 m/z) are found to comprise the majority of heavy PAHs in the ET-HR. Moreover, the intensity of these peaks is very close, indicating that the heavy PAHs are evenly distributed. The m/z differences between most of the adjacent peaks are near to 15, which suggest an extensive alkylation (multimethyl substitution) in this feedstock.

3.2 Bromination of ET-HR

The bromination of ET-HR is comparably investigated under temperature of 30 ℃ and 200 ℃ by feeding different amounts of liquid bromine, respectively. The compositions of the brominated ET-HR are also determined by LDI-TOF/MS, as shown in Fig. 3. Compared with ET-HR, the low temperature bromination product LBP with a bromine content of 12.02 wt.% has shown a weak increase of the average molecular weight (AMW), which is caused by the combination of bromine atoms to the aromatic carbons of the reactive species[20]. While the high temperature bromination product BP2 with a bromine content of 13.35 wt.% exhibits much larger AMW with the whole spectrum shifting to much higher m/z values. This result suggests that bromination at high temperature would lead to partial polycondensation reactions simultaneously through dehydrobromination. As high temperature could effectively facilitate the bromination on aliphatic chains[20], the resultant molecules with aliphatic C-Br bond of low dissociation energy[21]would preferentially be dehydrobrominated to generate larger molecules with typical methylene bridged structures[22]. According to the results of LDI TOF/MS, some possible oligomers in the bromination product BP2 are proposed in Fig. 3(b).

Fig. 3 (a) LDI TOF/MS spectra and (b) possible structures of the brominated ET-HR.

3.3 Dehydrobromination/polycondensation and general properties of the prepared pitches

The DP process is carried out at a relative low temperature of 350 ℃ after the bromination. The resultant pitches are firstly subjected to characterization by determining the pitch yield, softening point, elemental composition and solubility. The results are listed in Table 3. It is found that two-step method is very effective for obtaining a high pitch yield. The pitches yields were calculated to be 62 wt.%, 65 wt.% and 67 wt.% for DLP, DBP1 and DBP2, respectively, which are much higher than that of TTP prepared from direct thermal treatment. The more bromine introduced, the higher pitch yield obtained.

Table 3 Yields and main properties of the resultant pitches.

aPitch yield.

bTS: Toluene soluble fraction; TI-PS: Toluene insoluble-pyridine soluble fraction; PI-QS: Pyridine insoluble-quinoline soluble fraction; QI: Quinoline insoluble fraction.

The softening points of the DP pitches are all found to higher than 240 ℃ while sample TTP obtained from thermal treatment only exhibits a softening point of 152 ℃. This confirms that the dehydrobromination in the two-step method enhances the polymerization and condensation of aromatics thus facilitates the formation of large molecules. The elemental analysis results show an increase of carbon content and decrease of hydrogen content of all the resultant pitches, indicating an obvious dehydrogenation of both methods during the same thermal treatment under 350 ℃. However, compared with pitch TTP, the higher C/H ratio of the pitches from the two-step method suggests a deeper dehydrogenation through the dehydrobromination reaction. Although the bromination products (LBP and BP2) possess a similar bromine content (ca. 12 wt.%-13 wt.%), considerable different properties can be found in the corresponding DP pitches. This demonstrates that the partial polycondensation during the high temperature bromination which leads to relative higher AMW of the bromination products would play an important role in determining the structure and properties of the final pitches.

The solubility of the resultant pitches is investigated by using a sequential Soxhlet extraction method. The relative contents of typical TS fraction, TI-PS fraction, PI-QS fraction and QI fraction are shown in Table 3. Results show that the TS content of pitch TTP is larger than that of pitch DBP1, DLP and DBP2, suggesting a lower condensation degree of the former one. The lowest TS content of 41.5 wt.% is found in pitch DBP2, indicating that most of the light molecules has been condensed to insoluble molecules during the dehydrobromination/polycondensation reactions[23]. In contrast, the most concerned QI content of the DP pitches are increased with the increase of bromination temperature and the introduced bromine. The highest QI content is found to 35.9 wt.% for pitch DBP2, which furtherly indicates a critical role of the introduced bromine on the construction of new intermolecular C—C bonds. Because of relative low activation energy for the dissociation of C—Br bonds, stable free radicals could be easily formed during the low temperature thermal treatment and thus produce the most polymerized materials.

3.4 Characterization of pitches by 1H NMR

Generally, the hydrogen atoms in the pitches are divided into aromatic hydrogens (Har) and aliphatic hydrogens (Hal) in terms of their chemical shifts. Typical1H NMR spectrum of pitch shows chemical shifts of Harin the region 9.5-6.0 ppm and Halin the region 4.5-0.5 ppm. The Halcan be further subdivided intoαhydrogens (Hα) in the region 4.5-2.0 ppm,βhydrogens (Hβ) in the region 2.0-1.1 ppm andγhydrogens (Hγ) in the region 1.1-0.5 ppm[24,25]. More specifically, the hydrogens in ring-joining methylene which belong to Hαare assigned as HCH2in the chemical shift range of 4.5-3.4 ppm.

Fig. 4 1H NMR spectra of the prepared pitches.

Fig. 4 shows the1H NMR spectra of the prepared pitches in term of the TS fractions. The distribution of the different types of hydrogens is calculated and tabulated in Table 4. It is noted that the Harcontents of all the resultant pitches increase with the Hα, Hβand Hγcontents and decrease gradually after the same thermal treatment. According to the results, high contents of Harcan be also found in the DP pitches, which indicates an obvious dehydrogenative aromatization or cracking reaction at the expenses of aliphatic hydrogen during the thermal treatment[22]. Moreover, the alkyl groups of all the DP pitches are mainlyαandβsubstituents, suggesting that a certain amount of aliphatic chains is still remained inαandβposition of the aromatic rings. The gradually intensification of the HCH2absorption bands in the DP pitches (shown in Fig. 4) indicates a promotion effect of the dehydrobromination on the formation of a methylene bridged structure[20]. Especially, pitch DBP2, which is prepared from the bromination product with a highest introduced bromine content, exhibits the highest HCH2content. In addition, the hydrogen aromaticity index (Har/Hal) is increased in the order of TTP Table 4 Structural parameters calculated from 1H NMR spectra and FT-IR spectra. Fig. 5 shows the FT-IR spectra of the as-prepared pitches. In the well-defined FT-IR spectra, the bands from 2 850 to 2 920 cm-1are assigned to the strong stretching of aliphatic groups suggesting an aliphatic-rich structure of the pitches. While band at 1 600 cm-1is due to the ring vibration of aromatic hydrocarbons and the band at 1 440 cm-1is assigned to the C—H in-plane bending of methylene. Compared with ET-HR, the spectra of all the prepared pitches also show intense bands near 3 040 cm-1, which is due to the stretching vibration of aromatic C—H groups, suggesting a large amount of unsubstituted aromatic rings of the pitches. Fig. 5 FT-IR spectra of the prepared pitches. The molecular weight distribution (MWD) in term of the TS fraction of the prepared pitches is determined by LDI-TOF/MS spectroscopy. Representative mass spectra of the sample TTP, DLP and DBP2 are present in Fig. 6 (a). All the pitches show a very complex component with a continuous MWD, suggesting a series of aliphatic chains or naphthenic groups are present in the pitch molecules. However, some differences between these fractions can be also pointed out. The molecular weight of pitch TTP is mainly distributed in the m/e range of 200-800 with the most intense peak at m/e 440, which is most likely corresponding to the macromolecule condensed from two 4-rings PAHs molecules. The direct thermal polycondensation, which is induced by the cleavage of stable C—H or C—C bonds, is in low reaction rate under the employed temperature of 350 ℃. Such simple thermal treatment could only result in a low polycondensation degree and thus form the polymeric molecules with a relative low molecular weight. This can be also indicated by the solubility of pitch TTP in solvents (79 wt.% of TS fraction and no QI content). In contrast, the MWD of pitch DLP is more like a narrow Gaussian shape distributed from m/e 300 to 800 with the maximum abundance at m/e 420 and 482, respectively, which might suggest one more methyls in the structure. Pitch DBP2 exhibits a MWD mainly in the range of m/e 300-1 000 with the maximum abundance at m/e 584. However, the intensified tailing peaks can be traced to as high as m/e 1 600, indicating a broader distribution of the molecular weight and higher degree of polycondensation. This should be due to the enhanced molecular thermal reactivity that benefit from the relative weak C-Br bonds during the thermal treatment. Much of the structural analysis has indicated that the pitch components are composed of aryl-aryl bonds or ary-alky bonds linked aromatic oligomers, thus based on the results of elemental analysis,1H NMR, FT-IR and LDI-TOF/MS, some possible molecular structures in the prepared pitches are proposed in Fig. 6 (b). Fig. 6 LDI-TOF/MS spectra of the TS fraction of (a) the as-prepared pitches and (b) the corresponding representative model structures. The XRD patterns of the precursor and prepared pitches are shown in Fig. 7. All samples exhibits superimposed broad peaks between 10° and 30°. Peak in the range of 10°-20° is corresponding to theγband that is resulted from the condensed naphthenic rings or the aliphatic chains, while the peak between 20° and 30° is attributable to graphene band (or (002) band) that is resulted from the stacked aromatic molecular structures[18,27]. As can be seen, the intensities of 002 bands in the resultant pitches are sharped instantaneously following the order of TTP The superimposed broad peaks are further fitted in term ofγand (002) bands positioned at approximately 2θ=15° and 25°, as shown in Fig. S2. Based on the fittedγand (002) peaks, the structural parameters of interlayer spacing (dγandd002), crystallite size (Lc), average number of aromatic sheets per stacked cluster (N) and aromaticity (fa) are calculated and listed in Table 5. To be noted, the calculatedfahere is only based on the stack aromatic carbon, thus do not represent the true aromaticity of the pitches[19,23]. It is observed thatdγof all the prepared pitches are increased by different extents as compared with that of ET-HR, which should be due to the cracking and shortening of side chains. On the other hand, the average number of aromatic sheets per stacked cluster (N) is found to increase gradually with the increase of cluster diameter (Lc) and decrease of average inter-aromatic layer distance (d002). Moreover, the larger cluster size of the DP pitches than that of TTP is mainly due to the enhanced polycondensation, dehydrogenation and aromatization during the dehydrobromination reaction. In addition, the calculatedfa, which exhibits the same change tendency with the aromatic indexes obtained from FT-IR, is also increased with the increase of introduced bromine content and the employed bromination temperature. Fig. 7 XRD patterns of as-prepared pitches. Samplesdγ(nm)d002(nm)Lc(nm)NfaET⁃HR0.6580.4110.9742.40.14TTP0.7230.3641.1954.30.32DBP10.7020.3621.3194.60.37DLP0.6870.3601.4044.90.49DBP20.6810.3541.4505.10.58 The microstructures of as-prepared pitches are observed by using optical microscopy, as shown in Fig. 8 (a-d). It can be seen that no mesophase is developed in all of the samples. The presence of total isotropic phase in the pitches should be due to the low thermal treatment temperature employed in this study. To assess the capacity of the pitches to generate mesophase, the samples are carbonized at 800 ℃. The optical textures of the obtained cokes are investigated, as shown in Fig. 8 (e-h). It is observed that large region of coalesced mesophase (domain texture) are formed in the coke C-TTP. Such well-developed mesophase of the coke should be largely benefited from the low polycondensation degree of the precursor pitch. In contrast, coke C-DLP exhibits an optical texture of small domain throughout the sample, suggesting that the highly polymerized pitch from dehyrobromination could be also completely transformed into mesophase after carbonization. While for coke C-DBP1 and C-DBP2, a co-existence of a coarse mosaic texture with small domains and complete fine mosaic texture are observed, respectively. Fig. 8 Optical micrographs of the prepared pitches and cokes obtained from the corresponding pitches The abilities of the obtained pitches transforming to anisotropic cokes can be further verified by the XRD patterns of the cokes as shown in Fig. S3. It is found that the intensity of the graphene band is increased in order of C-TTP>C-DLP>C-DBP1>C-DBP2. The crystallite parameters are calculated and summarized in Table S1. Compared with C-TTP, the gradually increase of layer sizeLaof the DP pitch coke should be largely distributed to the longer linear molecules (mainly linked by single aryl to methyl bonds or aryl to aryl bonds and even cross-linked structures) of the parent pitches. Nevertheless such molecular structures are believed to undergo complex reactions during the carbonization which would deteriorate the optical texture of the DP pitch coke and result in the decrease of crystallitic stack heightLcand increase of interlayer spacingd002. Moreover, the increase of polycondensation degree of the DP pitches, which results in a high methylene content, would cause severe cracking and recombination reactions and thus lead to a high viscosity of the matrix during the carbonization. Such increased viscosity would reduce the mobility of planar aromatic molecules thus hindering the coalescence of mesophase and produce the coke toward the development of a mosaic texture. However, the much higher coke yields of the DP pitches in the range of 57-77 wt.% for DBP1, DLP and DBP2, as shown in Fig. 9, indicate that these novel pitches still could be provided as alternative precursors for the high-value added carbon products. Pitch DLP, which generates coke with an optical texture of small flow domains, might be used as a potential precursor for needle coke[28]. While pitch DBP2, which produces coke with the highest yield and an optical texture of mosaics could be served as a suitable precursor for high-density carbon artifacts[29]. These results highlight the effective utilization of ethylene tar by the novel two-step method for preparing high carbon yield pitches with different microstructures for wide potential applications. Fig. 9 Coke yields of the pitches. We have developed a facile method of bromiantion and subsequent dehydrobromination/polycondensation for preparing high performance isotropic pitches from ET-HR. This novel two-step method exhibits unique advantages during the thermal treatment. Effective polycondensation of the light precursor components at relative low temperature could be realized, and thus can avoid the formation of inhomogeneous composition in the final pitches and prevent the formation of mesophase. Compared with the direct thermal treatment, the novel isotropic pitches obtained by the two-step treatment exhibit much higher product yields (62-67 wt.%), softening point (241-264 ℃) and coking value (57-77 wt.%) according to the bromination temperature and the addition of bromine. The structural analysis indicates that the low temperature dehydrobromination could effectively enhance the aromatization and polymerization of the pitch molecules. All the high softening point isotropic pitches still exhibit thermal reactivity to transform to optical anisotropy during the coking at 800 ℃. The results indicate that such novel two-step treatment method is suitable technique to realize effective utilization of ET and for the production of high performance pitch materials. AppendixA.Supplementarydata TG curves and the fitted XRD patterns can be found in the supplementary data associated with this article. [1] Maeda T, Zeng S M, Tokumitsu K, et al. Preparation of isotropic pitch precursors for general purpose carbon fibers (GPCF) by air blowing—I. Preparation of spinnable isotropic pitch precursor from coal tar by air blowing[J]. Carbon, 1993, 31(3): 407-412. [2] Chen C, Kennel E B, Stiller A H, et al. Carbon foam derived from various precursors[J]. Carbon, 2006, 44(8): 1535-1543. [3] Carlson R K, Ferritto J J. Manufacture of high density, high strength isotropic graphite[P]. United States Patent, 1980, 4226900. [4] Mabuchi A, Tokumitsu K, Fujimoto H, et al. Charge-discharge characteristics of the mesocarbon miocrobeads heat-treated at different temperatures[J]. Journal of the Electrochemical Society, 1995, 142(4): 1041-1046. [5] Manocha L M, Patel M, Manocha S M, et al. Carbon/carbon composites with heat-treated pitches: I. Effect of treatment in air on the physical characteristics of coal tar pitches and the carbon matrix derived therefrom[J]. Carbon, 2001, 39(5): 663-671. [6] Menéndez R, Granda M, Fernández J J, et al. Influence of pitch air-blowing and thermal treatment on the microstructure and mechanical properties of carbon/carbon composites[J]. Journal of Microscopy, 1997, 185(2): 145-156. [7] Suzuki M. Activated carbon fiber: Fundamentals and applications[J]. Carbon, 1994, 32(4): 577-586. [8] Mora E, Blanco C, Prada V, et al. A study of pitch-based precursors for general purpose carbon fibers[J]. Carbon, 2002, 40(14): 2719-2725. [9] Blanco C, Santamara R, Bermejo J, et al. A comparative study of air-blown and thermally treated coal-tar pitches[J]. Carbon, 2000, 38(4): 517-523. [10] Yu B, Wang C, Chen M, et al. Two-step chemical conversion of coal tar pitch to isotropic spinnable pitch[J]. Fuel Processing Technology, 2012, 104: 155-159. [11] Lewis I C. Thermal polymerization of aromatic hydrocarbons[J]. Carbon, 1980, 18(3): 191-196. [12] Mendez A, Bermejo J, Blanco C, et al. Structural characterization of high-softening-point pitches by oxidation with RuO4[J]. Energy & Fuels, 2001, 15(1): 128-134. [13] Yang K S, Choi Y O, Kim Y M, et al. Preparations of carbon fibers from precursor pitches synthesized with coal tar or petroleum residue oil[J]. Fibers and Polymers, 2000, 1(2): 97-102. [14] Zeng S M, Maeda T, Tokumitsu K, et al. Preparation of isotropic pitch precursors for general purpose carbon fibers (GPCF) by air blowing—II. Air blowing of coal tar, hydrogenated coal tar, and petroleum pitches[J]. Carbon, 1993, 31(3): 413-419. [15] Blanco C, Santamara R, Bermejo J, et al. Separation and characterization of the isotropic phase and co-existing mesophase in thermally treated coal-tar pitches[J]. Carbon, 2000, 38(8): 1169-1176. [16] Cheng X, Zha Q, Zhong J, et al. Needle coke formation derived from co-carbonization of ethylene tar pitch and polystyrene[J]. Fuel, 2009, 88(11): 2188-2192. [17] Mochida I, Fei Y Q, Korai Y. A study of the carbonization of ethylene tar pitch and needle coke formation[J]. Fuel, 1990, 69(6): 667-671. [18] Andersen S I, Jensen J O, Speight J G. X-ray diffraction of subfractions of petroleum asphaltenes[J]. Energy & Fuels, 2005, 19(6): 2371-2377. [19] Shirokoff J W, Siddiqui M N, Ali M F. Characterization of the structure of Saudi crude asphaltenes by X-ray diffraction[J]. Energy & Fuels, 1997, 11(3): 561-565. [20] Kim B J, Kil H, Watanabe N, et al. Preparation of novel isotropic pitch with high softening point and solvent solubility for pitch-based electrospun carbon nanofiber[J]. Current Organic Chemistry, 2013, 17(13): 1463-1468. [21] Blanksby S J, Ellison G B. Bond dissociation energies of organic molecules[J]. Accounts of Chemical Research, 2003, 36(4): 255-263. [22] Ge C, Yang H, Miyawaki J, et al. Synthesis and characterization of high-softening-point methylene-bridged pitches by visible light irradiation assisted free-radical bromination[J]. Carbon, 2015, 95: 780-788. [23] Kumar S, Srivastava M. Catalyzing mesophase formation by transition metals[J]. Journal of Analytical and Applied Pyrolysis, 2015, 112: 192-200. [24] Kershaw J R, Black K J T, Jaeger H K, et al. A comparison of mesophase formation under sparging and vacuum[J]. Carbon, 1995, 33(5): 633-643. [25] Guillén M D, Díaz C, Blanco C G. Characterization of coal tar pitches with different softening points by1H NMR: role of the different kinds of protons in the thermal process[J]. Fuel Processing Technology, 1998, 58(1): 1-15. [26] Guillen M D, Iglesias M J, Dominguez A, et al. Semi-quantitative FT-IR analysis of a coal tar pitch and its extracts and residues in several organic solvents[J]. Energy & Fuels, 1992, 6(4): 518-525. [27] Yen T F, Erdman J G, Pollack S S. Investigation of the structure of petroleum asphaltenes by X-ray diffraction[J]. Analytical Chemistry, 1961, 33(11): 1587-1594. [28] Obara T, Yokono T, Miyazawa K, Sanada Y. Carbonization behavior of hydrogenated ethylene tar pitch[J]. Carbon, 1981, 19(4): 263-267. [29] Fanjul F, Granda M, Santamaría R, et al. The influence of processing temperature on the structure and properties of mesophase-based polygranular graphites[J]. Journal of Materials Science, 2004, 39(4): 1213-1220.

3.5 Characterization of pitches by FT-IR

3.6 Characterization of pitches using LDI-TOF/MS

3.7 XRD analysis

3.8 Carbonization behavior of the prepared pitches

4 Conclusions