Development of Innovative Reagents for Processing Phosphate Ores Worldwide

WANG Guoxin,GU Zhengxing

Arr-Maz Products,LP,FL 33860,USA

Development of Innovative Reagents for Processing Phosphate Ores Worldwide

WANG Guoxin,GU Zhengxing

Arr-Maz Products,LP,FL 33860,USA

With the depletion of easily processed phosphate reserves,the phosphate which remains useable must be extensively processd to recover the useable phosphate,by rejecting gangue impurities prior to its use in phosphoric acid manufacturing.The characteristics of phosphate ores from different sources can vary significantly.The impurities associated with phosphate reserves include clay,silica quartz,silicates,carbonate minerals,iron oxide minerals,organics,etc..Among the technologies for processing phosphate ores,flotation technology is most often used in the process to separate phosphate from those impurities to obtain the marketable concentrate.There is no“universal”reagent,reagent scheme or flowsheet capable of beneficiating phosphate ores from different sources.ArrMaz has made a great effort in developing new reagents for processing phosphate ores around the globe including in China.The examples using ArrMaz CustoFloat®(CF)and CustAmine®(CA)collectors will be presented.

flotation technology;processing reagent;CustoFloat®anionic colector;CustoFloat®cationic collector

Among various mineral processing methods,flotation is considered as the most widely used approach to separate phosphate from its impurities.There is no“one-for-all” process to separate phosphate from its impurities,because ofthe different characteristics of the ore body.So,the beneficiation process must be customized based on the different flotation response of the phosphate ores from differentmines or locations.The typical flotation processes applied in phosphate industry include directflotation,direct-reverse flotation,reverse-direct flotation,double reverse flotation,etc..In direct flotation,phosphate is floated with fatty acid or soap collector,while the sink is discarded as waste.Direct flotation has been used in many regions of the world,such as Russia,South Africa and South America.In the phosphate industry in Florida U.S.A.,a double flotation process,known as the“Crago”process,isused.In thisprocess,phosphateis recovered via direct rougher flotation followed by cleaner reverse flotation of silica.The direct-reverse flotation can also be applied for phosphate ores with both siliceous and carbonaceous impurities.In such a case,phosphate is floated with some carbonates using a fatty acid type collector at alkaline pH to reject siliceous waste. The carbonate impurities are separated from phosphate with or without a collector in acidic pH.For phosphate ores with siliceous and carbonaceousimpurities,doublereverseflotation process is also widely practiced.With double reverse flotation process,carbonaceous impurities are floated with a carbonate collector at acidic pH followed by floating silica using a cationic collector at neutral pH.

As a world leader in mining chemicals,Arr-Maz has made great efforts in developing new reagents for processing different phosphate ores worldwide,including in China.In this paper,examples will be discussed to illustrate the application of Arr-Maz CustoFloat®(CF)and CustAmine®(CA)collectors for beneficiating different phosphate ores with various processes[1-5].

1 Direct Flotation of Phosphate Ore

1.1 A phosphate mine,Yunnan,China

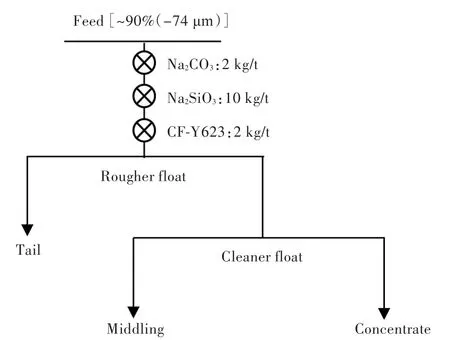

The phosphate ore from the mine is weathered rock with low MgO content.It contains about 22.48%P2O5and 0.2%-1.0%MgO.In order to achieve good liberation,the ROM rock was ground to the size range of 90%passing 74 μm.Soda ash was used as pH modifierand sodium silicate wasused as depressant.CustoFloat®Y623(CF-Y623)was used as a collector for phosphate flotation.The flowsheet of lab testing is shown in Fig.1 and the flotation results are listed in Tab.1.

Fig.1 Lab flotation flowsheet for the phosphate ore with CF-Y623

Tab.1 Lab and plant flotation results of the weathered ore with CF-623

In 2009,a plant test was conducted at the Phosphate Mine,Yunnan,China and the plant test results are also given in Tab.1.A phosphate concentrate with 30.03% P2O5wasachieved at 73.77%recovery from this low MgO weathered feed in plant test.

1.2 Another phosphate mine,Yunnan,China

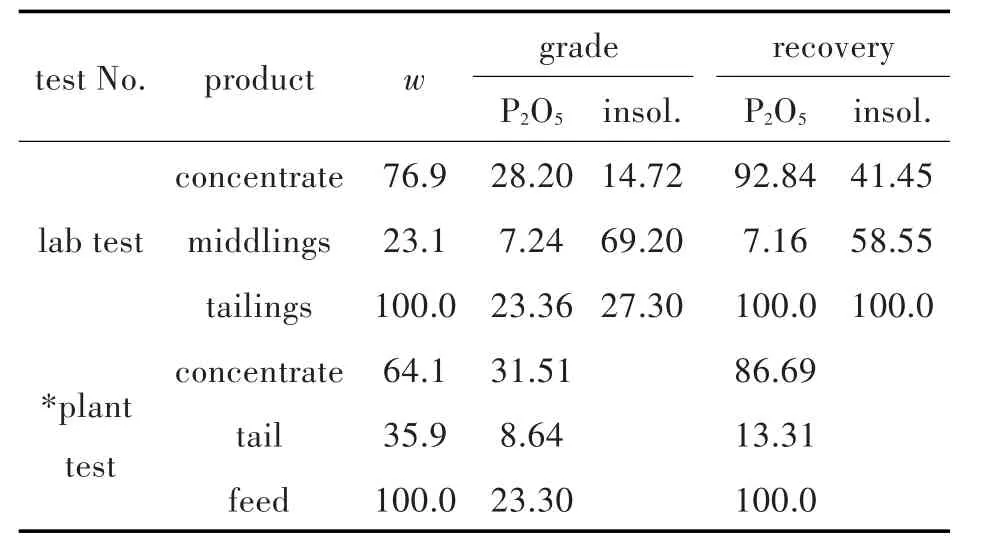

TheROM rock from thephosphatemine contains about 23.36%P2O5and 27.30%insol.A collector,CF-623A,was developed to float phosphate away from the major siliceous impurities for this feed and satisfactory flotation performance was achieved in plant test.Fig.2 shows the open circuit of one stage rougher flotation with reagent conditions used in lab testing.Plant test was run with the flowsheet of one rougher,one scavenger and one cleaner.Lab and plant test results are summarized in Tab.2.

Fig.2 Flotation flowsheet for the phosphate ore

Tab.2 Lab and plant flotation results with CF-Y623 (%)

2 Reverse Silica Flotation Process

2.1 Reducing silica content in concentrate product from China

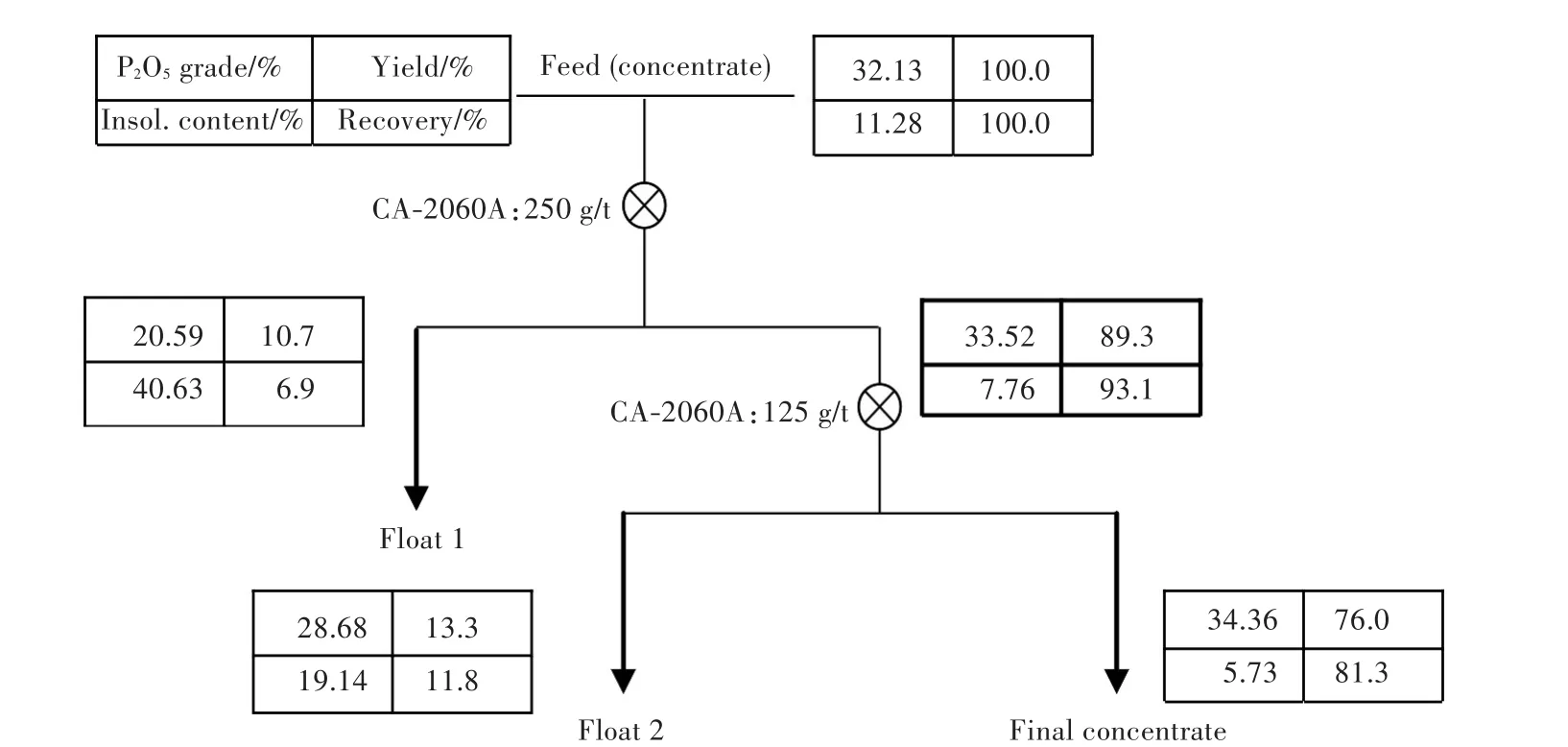

This is a concentrate product from east Yunnan,China with 32.13%P2O5and 11.28%insol..It is in size range of 80%passing 74 μm without desliming.In order to further lower the insol.content in the product,an amine collector,CA-2060A,was used and the material balance sheet in the flotation process is shown in Fig.3.

As can be seen from Fig.3,CA-2060A could float some insol.out from this fine feed with the sacrifice of recovery.With two stage flotation,a final concentrate with 34.36%P2O5and 5.73%insol.can be obtained at 81.3%recovery.This approach may be taken into consideration only if the product of high P2O5grade and low insol.is needed.The tails from this float can be recycled back to the original concentrate product for general purpose,such as manufacturing SSP,TSP,etc..

Fig.3 Reducing insol.in a concentrate from China

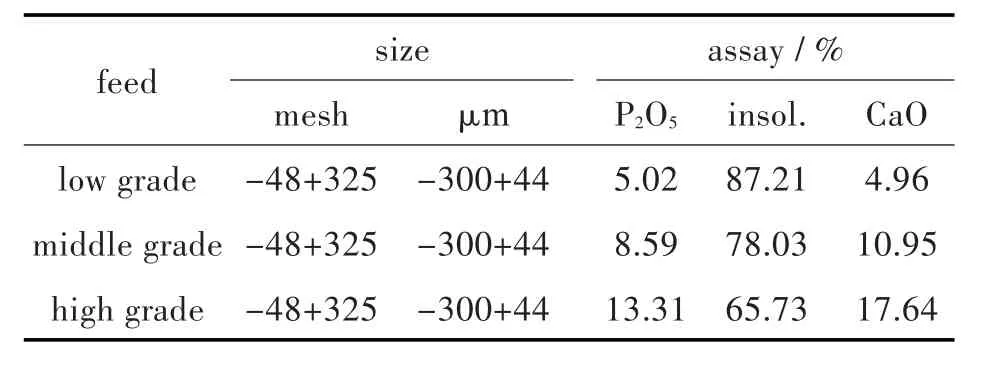

2.2 Beneficiating high insol.phosphate feed from Africa with amine collector

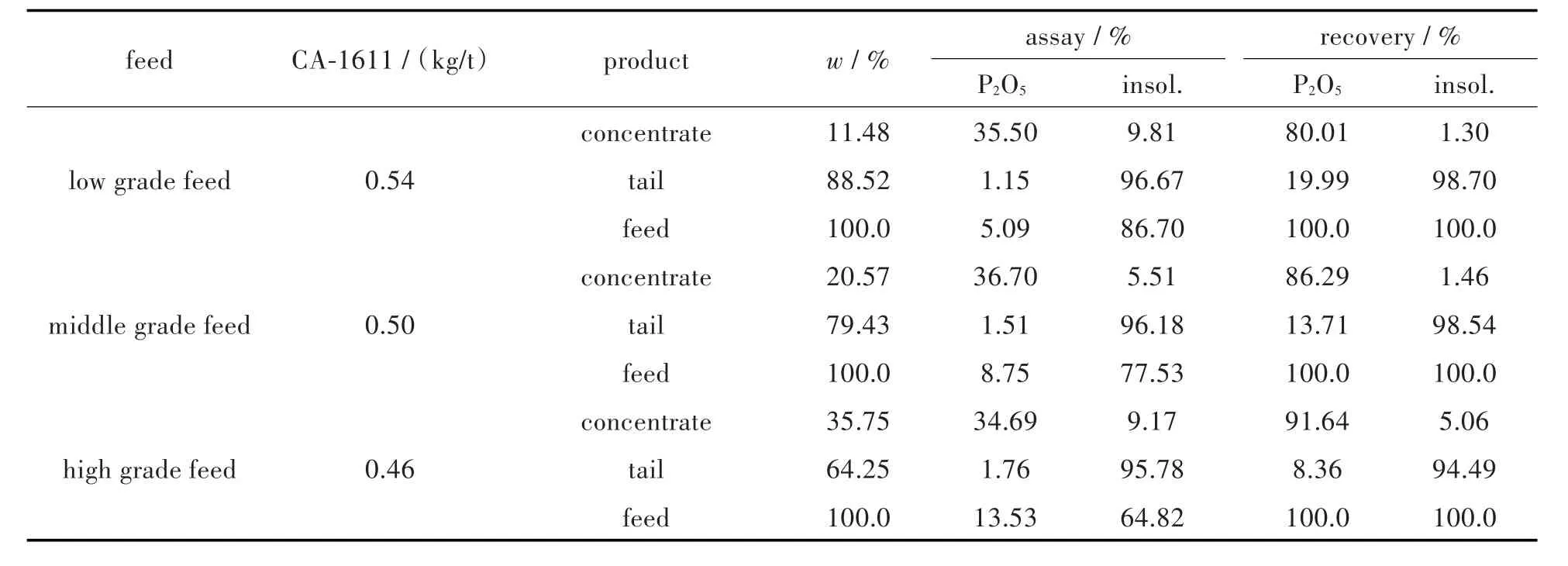

The samples received from Africa were prepared from the waste stock piles in an existing phosphate preparation plant.Based on the P2O5content in the feed,the samples were identified as low grade,middle grade and high grade,respectively.The feed analysis is listed in Tab.3.As can be seen from the feed analysis that all of the feed are associated with very high insol.content.

Tab.3 Analysis of high insol.feed from Africa

Based on the characteristics of the rock,a cationic collector,CA-1611,was used to float silica out of the feed.The results with one step amine flotation are shown in Tab.4.It can be seen from Tab.4 that all the three feed can be easily upgraded to high P2O5grade through single stage flotation at relatively low reagent consumption.

Tab.4 Flotation results of high insol.feed from Africa

3 Reverse Flotation of Carbonates

3.1 Calcite flotation for phosphate ore from Middle East

This phosphate ore contains about 50%phosphate,3%insol.,3%dolomite and 40%calcite.The ore was ground to pass 300 μm for good mineral liberation,and deslimed at 37 μm to remove low P2O5grade slimes.In orderto obtain a marketable phosphate concentrate from thisfeed,carbonate impurities,particularly calcite,must be rejected.For this purpose,a new carbonate collector,CustoFloat®XT collector was developed.

The feed was conditioned in acidic pH<5.5 with phosphoric acid as pH modifier and depressant.Afterone step reverse flotation,the floatwas discarded as waste,and the sink was collected as concentrate.The collectordosagesand flotation results are plotted in Fig.4.

Fig.4 Collector dosages and flotation results for phosphate ore from Middle East

We can see from Fig.4 that a final concentrate with over 32%P2O5and around 90%recovery can be obtained and the reagent dosage of the CustoFloat®XT collector is only 1.2 kg/t.

3.2 Dolomite flotation for phosphate ore from Yunnan,China

The ore body has three recoverable phosphate beds with average P2O5grade approximately 24%.The MgO content in the feed to the plant fluctuates widely from 6.5%to 9.0%.The majority of the impurity is carbonate,such as dolomite,calcite,etc.,and silica,which is less than 2%.In order to obtain high grade concentrate from this high MgO ore,a very strong and selective carbonate collectoris required.

In beneficiation plant,sulfuric acid was used as pH modifier and phosphate depressant was used.The process flowsheet involves one rougher and one scavenger as shown in Fig.5.The plant flotation results with three different feeds are summarized in Tab.5.

Fig.5 Flowsheet for processing phosphate ores in Yunnan Province

Tab.5 Plant flotation results of three phosphate ores in Yunnan Province (%)

As shown in Tab.5,CF-813 is a very strong carbonate collector with good selectivity. A concentrate product with less than 1%MgO and over 33%P2O5can be obtained after one rougher and one scavenger flotation at relatively low consumption of CF-813 collector.The final P2O5recovery can be achieved between 88.49%and 93.92%.

4 Double Reverse Flotation

4.1 Double reverse flotation for phosphate ore from Middle East

The flotation feed was prepared in the size range of-212 μm+38 μm.The chemical analysis of the feed sample is given in Tab.6.It can be seen from the feed analysis that the feed contains low MgO,Al2O3,Fe2O3,while the majority of the impurities is carbonate,particularly calcite.

Tab.6 Chemical analysis of flotation feed from Middle East

The feed was first conditioned with anionic collector CCS-502A at acidic pH 5.0-5.5 using H3PO4as depressant and pH modifier. The conditioned slurry was subjected to the first reverse flotation to reject carbonate as waste from the float.The sink was conditioned with cationic collector CustAmine®1208(CA-1208)at pH between 6.5 and 7 by using soda ash as pH modifier.The simplified flowsheet is shown in Fig.6 with the flotation results in Tab.7.

Fig.6 Simplified flotation flowsheet for phosphate ore from Middle East

Tab.7 Double reverse flotation results of the feed from Middle East

It can be seen that a phosphate concentrate with 33.0%P2O5can be obtained at 85.4%recovery from the feed of 20.2%P2O5,by applying double reverse flotation process.The silica flotation stage can be eliminated ifa concentrate productwith insol.content of 7%-8%can be accepted.

4.2 Double reverse flotation for phosphate ores from North Africa

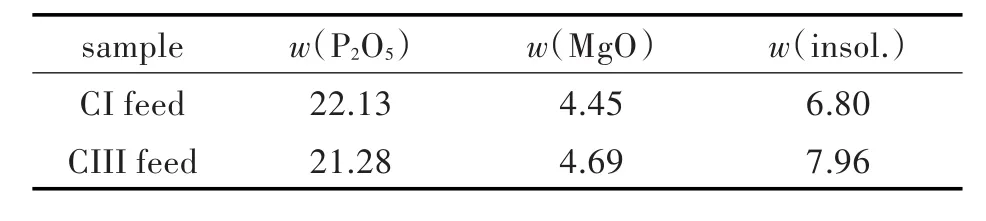

There are two feed samples,CI and CIII,with the analysis shown in Tab.8.The feed samples contain a considerably elevated amountoffine particles with the particle size below 150 μm.The impurity minerals include both carbonate and silica,and the majority of carbonate mineral is dolomite.Both dolomite and silica must be removed to achieve an acceptable phosphate concentrate.

Tab.8 Chemical analysis of the samples (%)

The simplified flotation flowsheet for this feed is illustrated in Fig.7.The feed was conditioned with depressant CP550 and collector CustoFloat®714(CF-714)at pH 5.3 for carbonate flotation.The rougher carbonate tail was refloated at pH 5.3.Two underflows of carbonate flotation were combined and sized at 25 μm.The plus 25 μm fraction was conditioned with an amine collector(CA-2060A)for silica flotation,while the minus 25 μm fine fraction was combined with the underflow of silica flotation as a composite concentrate.The flotation results of two samples were summarized in Tab.9.

As can be seen from Table 9,the final product grade of 30.1%P2O5and 83.8%recovery can be obtained for sample CI and a composite phosphate concentrate with 29.0%P2O5was achieved at 82.8%recovery from sample CIII.

Fig.7 Flotation flowsheet for the samples from North Africa

Tab.9 Flotation results of the samples from North Africa

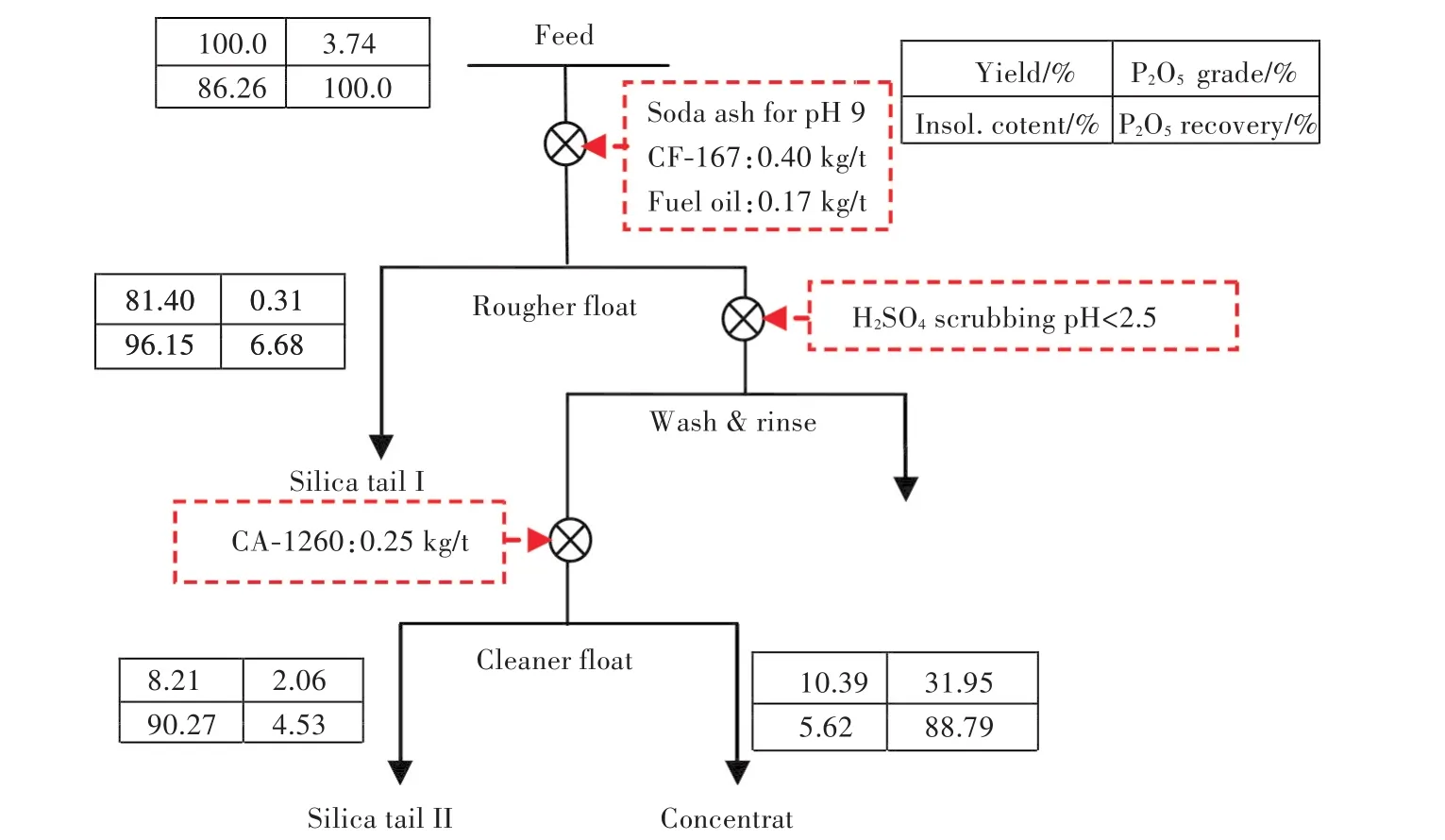

5 “Crago”Double Float Process in eastern USA

“Crago” double floatprocess iscommonly practiced in Eastern US phosphate industry.The sized feed,such as-600 μm +105 μm,is conditioned at about 70%or higher solids with fatty acid/fuel oil at pH > 9 using pH modifier,such as soda ash or ArrMaz Custo pH product line.The phosphate is floated to produce a rougher concentrate and a sand tailing.Usually rougher concentrate can't be directly used as a product for downstream process,because a significant amount of fine sand is also floated with phosphate in this step.Therefore,the rougher concentrate will proceed through dewatering,acid-scrubbing and washing to remove reagents from phosphate surfaces,which is known as“deoiling”.The deoiled rougher concentrate is subjected to amine flotation at neutral pH to remove silica as waste.The following is a typical example in which CustoFloat®167(CF-167),a fatty acid collector,was used for rougher phosphate flotation,and CustAmine®1260(CA-1260),a cationic collector for silica flotation.The simplified flowsheet,conditions and flotation results for a typical phosphate feed are shown in Fig.8.It can be observed that a phosphate concentrate containing over 31.95% P2O5can be achieved at 88.79%recovery from a low grade feed of 3.74%P2O5.

Fig.8 Simplified double float process for recovering phosphate in eastern USA

6 Conclusions

ArrMaz has made significant efforts in developing flotation reagents for processing phosphate ores worldwide.A variety of anionic and cationic collectors have been developed and successfully applied for various flotation processes,such as direct flotation of phosphate,reverse flotation of silica,reverse flotation of carbonates,double reverse flotation of carbonates and silica,etc.The marketable phosphate concentrate product can be achieved from those phosphate ores through flotation processes with ArrMaz CustoFloat®and CustAmine®collectors.

[1] GU Z X,WANG G X,SULDICKAS J.Improving dolomite/francolite separation performance using new reagents[M]//ZHANG P,MILLER J,EI-SHALL H.Beneficiation of Phosphates, New Thought, New Technology,New Development.Englewood Colorado:Society for Mining,Metallurgy,and Exploration,2012:329-333.

[2] OSWALD G,GRUBER G,GUAN C.How to conduct a‘Standard’Florida phosphate lab flotation test[M]//ZHANG P,SWAGER K,FILHO LAURINDO LEAL,et al.Beneficiation of Phosphates,Technology Advance and Adoption. Littleton Colorado:Society for Mining,Metallurgy,and Exploration,2010:337-344.

[3] WANG G X.Application ofCustoFloat carbonate collectors in beneficiating phosphate ores in China[M]//ZHANG P, MILLER J, WINGATE E, etal.Beneficiation of Phosphates,Comprehensive Extraction,Technology Innovations, Advanced Reagents.Englewood Colorado:Society for Mining,Metallurgy,and Exploration,2016:147-150.

[4] WANG G X,LI Y J,GU Z X,et al.Development of Custofloat® Collector for processing Yunnan sedimentary dolomitic phosphate ore[M]//ZHANG P,SWAGER K,FILHO LAURINDO LEAL,etal.Beneficiation of Phosphates,Technology Advance and Adoption.Littleton Colorado: Society forMining,Metallurgy,and Exploration,2010:169-174.

[5] WIEGEL R.Phosphate rock beneficiation practice in Florida[M]//ZHANG P,EI-SHALL H,WIEGEL R,et al.Beneficiation of Phosphates,Advance in Research and Practice.Littleton Colorado:Society for Mining,Metallurgy,and Exploration,1999:271-276.

1674-2869(2017)06-0529-07

新磷矿选矿药剂的开发利用

王国欣,顾正兴

美国阿麦仔公司,佛罗里达 33860,美国

随着易选磷矿资源的日益枯竭,必需大规模开发利用剩余的难选磷矿资源,以满足磷酸生产的需求.不同产地的磷矿性质的差异很大,对选矿工艺的要求也不相同.与磷矿共生的脉石矿物主要有石英、硅酸盐、碳酸盐、铁铝氧化物、黏土矿物、有机质等.在磷矿选矿工艺中,主要还是通过浮选工艺脱除磷矿中的杂质矿物,以获得可以利用的磷酸盐精矿.目前,还没有“通用”的药剂、药剂条件或浮选流程,可以用来浮选不同产地的磷矿.作为选矿药剂公司,阿麦仔致力于根据磷矿石的特性开发新的浮选药剂,用于选别不同地区的磷矿资源,包括中国.本文将介绍使用阿麦仔CustoFloat®(CF)类阴离子捕收剂和CustAmine®(CA)类阳离子捕收剂浮选不同地区磷矿的一些实例.

浮选工艺;选矿药剂;CustoFloat®阴离子捕收剂;CustAmine®阳离子捕收剂

TD923+.1

A

10.3969/j.issn.1674-2869.2017.06.002

苗 变

2017-05-31

*Corresponding author:WANG Guoxin,doctor,Research Associate.E-mail:gwang@arrmaz.com

:WANG G X,GU Z X.Development of innovative reagents for processing phosphate ores worldwide[J].Journal of Wuhan Institute of Technology,2017,39(6):529-535.