玉米种子仿生脱粒机性能试验与参数优化

李心平,马 磊,耿令新,王升升,庞 靖,姬江涛

玉米种子仿生脱粒机性能试验与参数优化

李心平,马 磊,耿令新,王升升,庞 靖,姬江涛※

(河南科技大学农业装备工程学院,洛阳 471003)

玉米种子仿生脱粒机是依据鸡喙离散玉米籽粒过程和裸手脱粒玉米籽粒过程的先离散后脱粒原理设计的,其具有低损伤、低破碎率等特点。为了优化玉米种子仿生脱粒机脱粒系统的有关参数,进而降低玉米种子在脱粒过程中的损伤,该文采用二次回归正交旋转组合设计的方法,以籽粒破碎率和脱净率为主要性能指标,选取差速辊转速、离散辊转速、脱粒辊转速和离散辊间隙、脱粒辊间隙为试验因素,对玉米种子仿生脱粒机进行了性能试验。并依据试验结果分别对离散辊转速与脱粒辊转速对破碎率和脱净率的影响,以及离散辊间隙与脱粒辊间隙对破碎率和脱净率的影响进行分析。分析结果表明:当离散辊转速在150~180 r/min和310~350 r/min,脱粒辊转速在270~350 r/min时,破碎率取得较小值;当离散辊转速在230~300 r/min,脱粒辊转速在150~200 r/min范围内时,籽粒脱净率取得最大值100%。当离散辊间隙在0~4 mm,脱粒辊间隙在5~9.2 mm时,籽粒破碎率取得最小值。当脱粒辊间隙在0~2.2 mm时脱净率取得最大值100%。综合以上结论,在试验拟合曲线的基础上按综合评价法进行优化,得到最优参数组合为差速辊转速90 r/min,离散辊转速350 r/min,脱粒辊转速为350 r/min,离散辊间隙4.6 mm,脱粒辊间隙4.6 mm。测得此时破碎率为0.226%,脱净率为99.317%,玉米芯完整度为100%,达到国家标准要求。

农业机械;仿生;种子;玉米;离散;脱粒;破碎率;脱净率

0 引 言

玉米籽粒的破损影响玉米种子储藏。遭受破损的玉米籽粒发芽率低,易生霉菌和虫子、易破碎,而且其市场价值降低。国外玉米脱粒机的研制比较早,整体而言损失率低,脱净率高,但体积设计较为庞大,且价格昂贵。中国目前玉米种子脱粒采用普通商品玉米脱粒的机型,以靠钉齿或窄板齿高速打击玉米果穗而脱粒,滚筒转速在700 r/min以上,脱粒获得的籽粒破损大,严重影响种子发芽率和玉米产量,并且不利于精密播种等精细农业的发展要求。种子安全是关系农业安全的重大问题,因此降低玉米种子脱粒损伤成为机械脱粒的主要问题[1-8]。

基于先离散后脱粒原理的玉米种子仿生脱粒机,具有不伤胚芽,破碎率低、未脱净率低,对各品种玉米适应性强等先进性优点,能够满足种子玉米脱粒的要求。本文是在玉米种子仿生脱粒机[9-10]上对玉米种子进行多因素试验,在试验分析的基础上确定其最佳的各辊转速和间隙,以获得最优的脱粒效果。

1 基本构造和工作原理

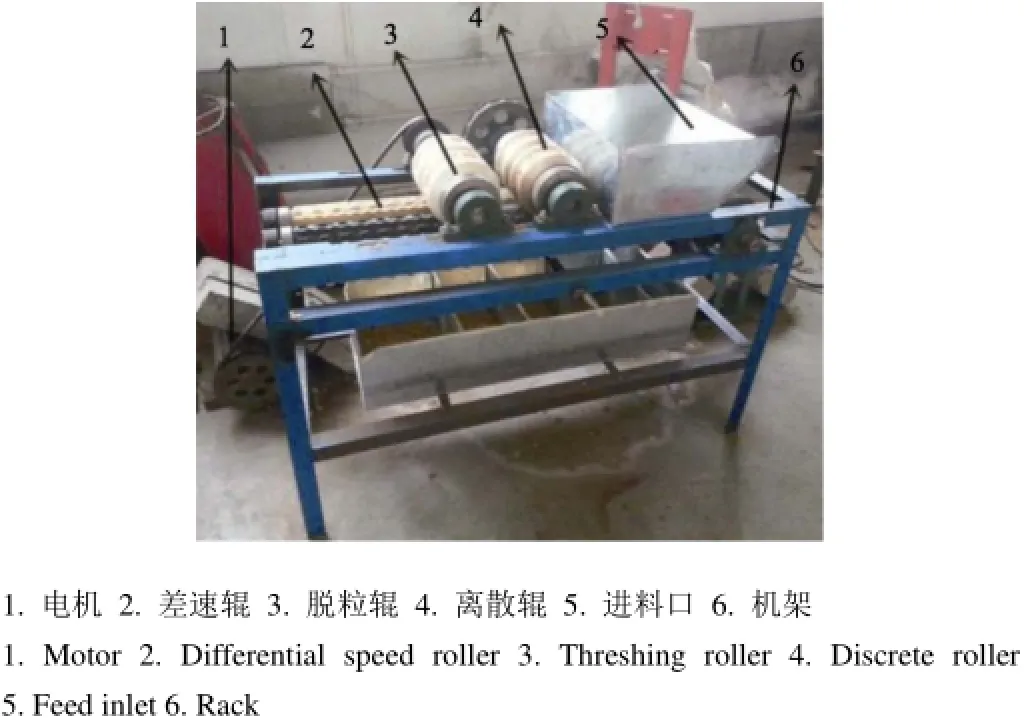

本机由机架、进料口、差速辊、离散辊、脱粒辊、及籽粒回收区等构成,整机结构如图1所示。

图1 仿生玉米脱粒机结构示意图Fig.1 Schematic diagram of seed corn bionic thresher

本机核心部分是差速辊、离散辊和脱粒辊。玉米果穗由进料口随机喂入,果穗与两差速辊轴线不平行,在差速辊前端螺旋推进器轴向分力作用下,玉米果穗逐步矫正自己位置沿平行于两差速辊轴线方向运动,果穗随之被推入工作空间,玉米果穗首先进入离散辊与差速辊组成的离散空间,在离散辊仿鸡喙离散单元作用下,破坏完整玉米果穗籽粒间组砌规律[11],使部分果穗籽粒离散,离散后的玉米果穗再进入脱粒辊与差速辊组成的脱粒空间,在脱粒辊与差速辊共同作用下完成仿裸手低损伤差速脱粒。被脱籽粒穿过差速辊之间缝隙,通过籽粒回收口进行回收;玉米芯沿差速辊轴向排出机外。由于本机脱粒时玉米果穗沿差速辊轴向顺序受力,玉米芯完整无断裂,可节省清选系统,减少功率消耗。

2 试验设备、方法和材料

如图1所示,试验时差速辊、离散辊、脱粒辊分别由3台电机带动,每台电机由YTSP1001L-4-2.2 kW型变频器控制,以调节各辊转速;离散辊间隙、脱粒辊间隙是指离散辊、脱粒辊与差速辊之间的最小间隙,其大小可由固定处轴承座加减垫片来调节[12-15]。试验用玉米果穗选取郑单958,含水率为12.5%。对试验材料玉米果穗进行统计,记录每一个果穗的长度、质量、直径等,挑选差别较小的玉米果穗进行试验,其平均长度为18.7 cm,平均质量为165.8 g,平均直径为4.83 cm。

破碎率的计算公式

式中Y1为样品中损伤籽粒的百分比;n1为样品中损伤籽粒的数量;N1为样品中全部籽粒总数。

脱净率的计算公式

式中Y2为样品中脱掉籽粒的百分比;n2为样品中脱掉籽粒的数量;N2为样品中全部籽粒总数。

3 试验方案的确定

玉米果穗的破碎率和脱净率与间隙和转速有直接关系,因此选取差速辊转速、离散辊转速、脱粒辊转速和离散辊间隙、脱粒辊间隙5个因素[16-20]。参考单因素试验结果和正交试验结果[21],综合考虑选取差速辊转速范围50~150 r/min,离散辊转速150~350 r/min,脱粒辊转速150~350 r/min,离散辊间隙0~9.2 mm,脱粒辊间隙0~9.2 mm。

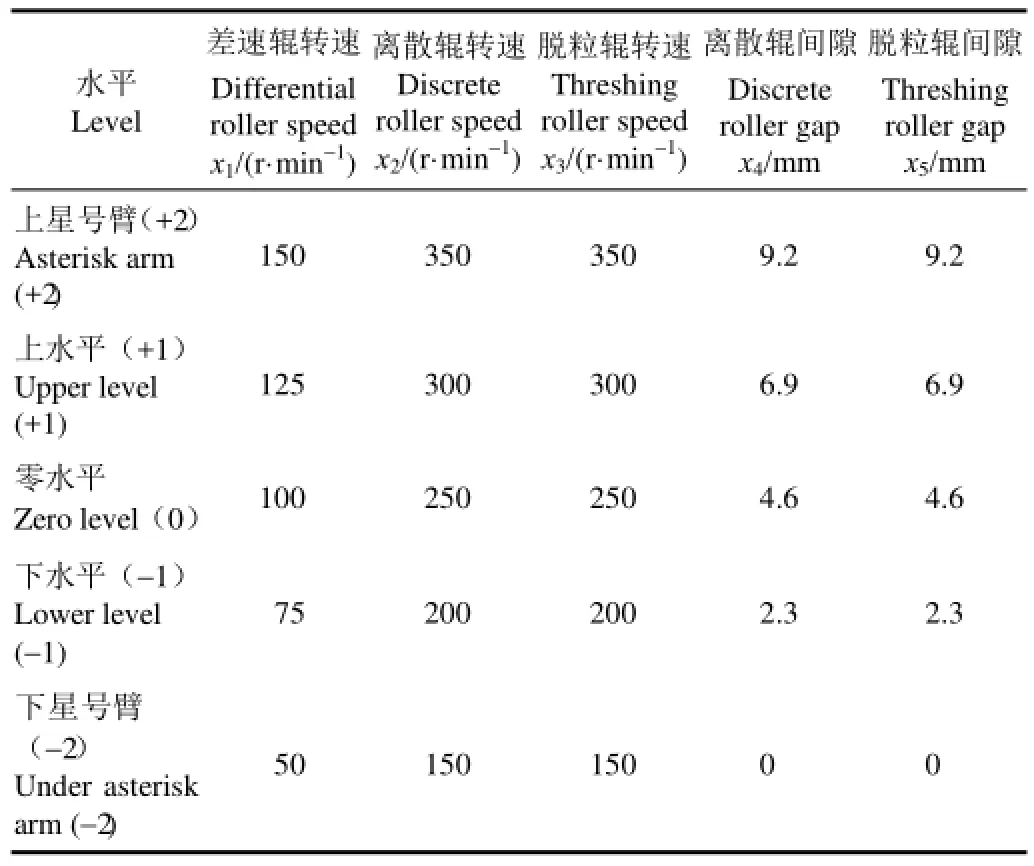

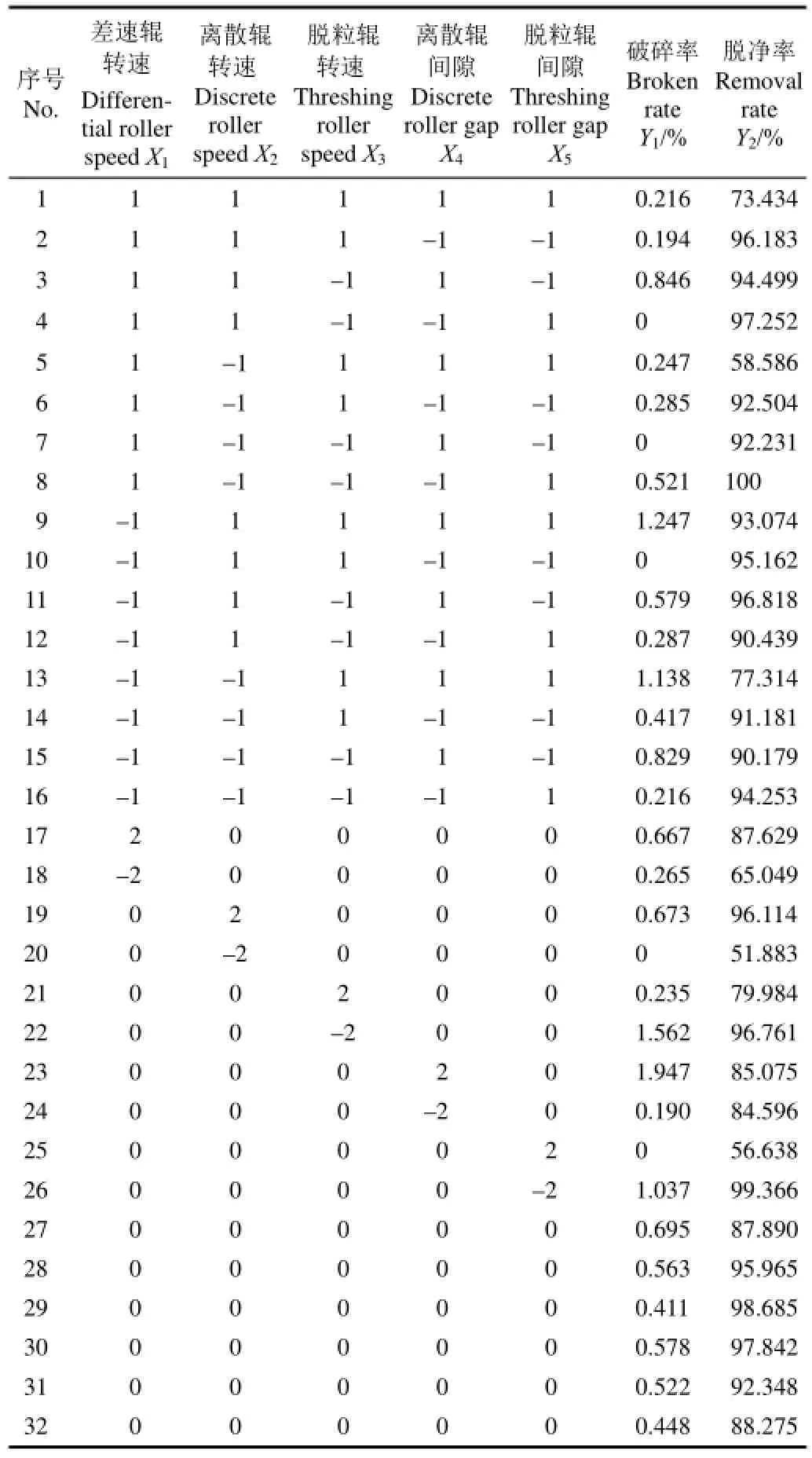

试验采用五元二次回归正交旋转组合设计选取差速辊转速x1、离散辊转速x2、脱粒辊转速x3和离散辊间隙x4、脱粒辊间隙x5共5个因素为试验因素。根据回归试验设计方法安排变量设计水平编码表和二次回归正交旋转组合设计试验表如表1、2,据设计水平编码表其中五因素时γ = 2[22]。试验结果统计发现玉米籽粒清洁度高,玉米芯无破损,因此以破碎率和脱净率为主要指标进行分析。

表1 因素水平编码Table1 Coding of factor levels

表2 二次回归正交旋转组合试验设计Table2 Regression orthogonal rotation combination test design

4 试验因素对试验指标影响的回归分析

4.1 回归分析

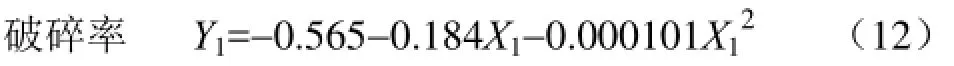

4.1.1 试验因素影响破碎率的回归分析

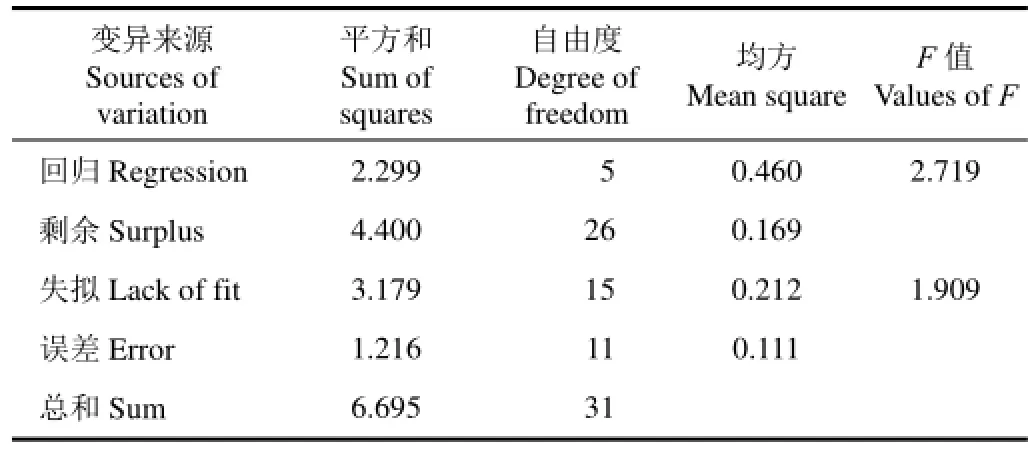

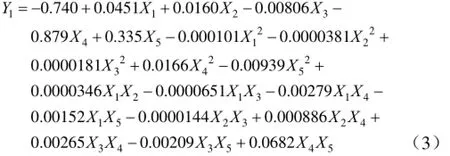

破碎率试验结果进行逐步回归统计分析,求得各试验因素与籽粒破碎率之间关系的回归方程如式(3)所示,破碎率方程分析见表3所示[23-27]。

表3 破碎率方差分析Table3 Results of broken rate variance analysis

式中X1、X2、X3、X4、X5分别为x1、x2、x3、x4、x5的水平值。

查 F 表,F0.05(15,11)=2.72,FLf<F0.05(15,11),说明方程拟合得好;进一步用统计量F回对方程进行检验,已知F0.05(5,26)=2.59,F回>F0.05(5,26),回归方程显著。

4.1.2 试验因素影响脱净率的回归分析

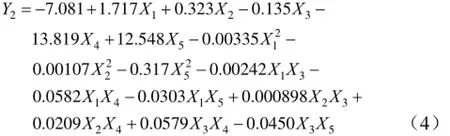

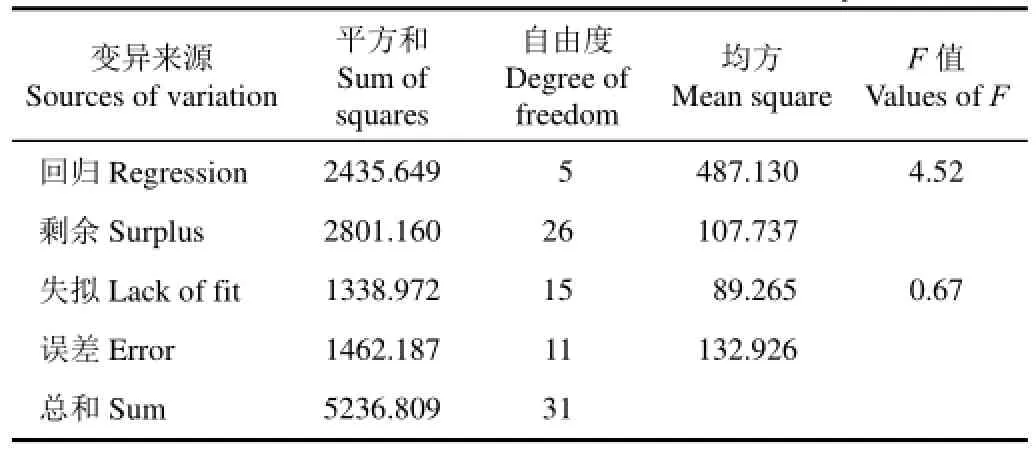

对脱净率试验结果进行逐步回归统计分析,求得各试验因素与果穗脱净率之间关系的回归方程如式(4)所示,破碎率方程分析见表4所示。

查F表,F0.05(15,11)=2.72,FLf<F0.05(15,11),说明方程拟合得好;进一步用统计量F回对方程进行检验,已知F0.05(5,26)=2.59,F回>F0.05(5,26),回归方程显著。

表4 脱净率方差分析Table4 Results of removal rate variance analysis

4.2 双因素影响试验指标的效应分析

4.2.1 离散辊转速和脱粒辊转速对籽粒破碎率的影响效应分析

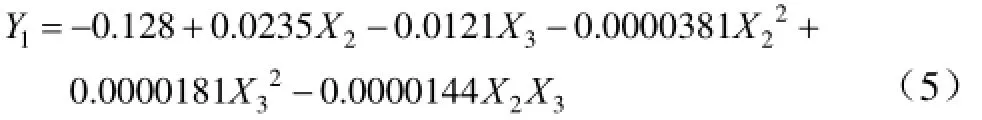

令X1、X4、X5取零水平,得到破碎率与X2、X3的关系式(5)。

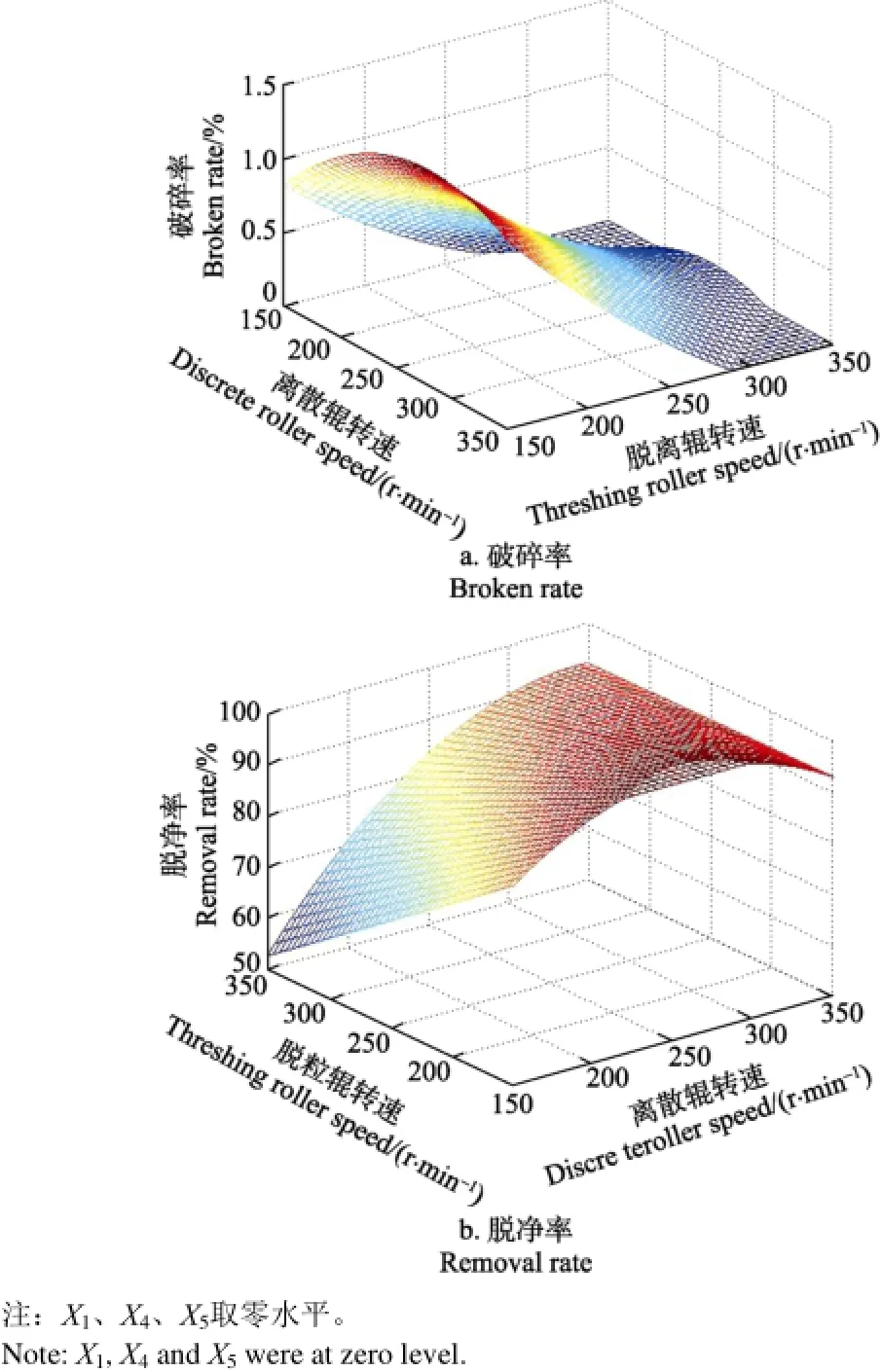

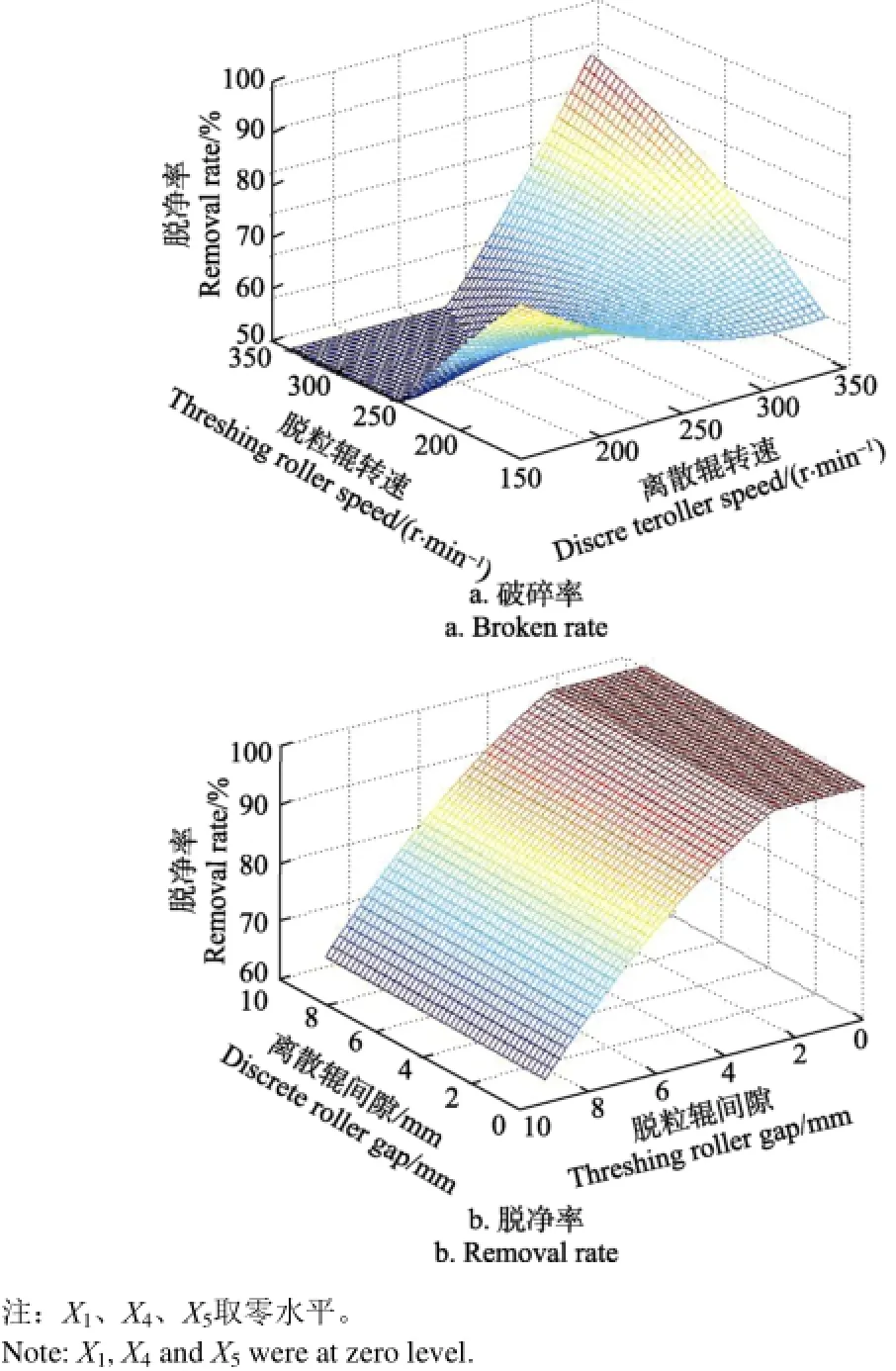

图2a即为脱粒辊转速和离散辊转速对破碎率的影响响应曲面。从图2a可以看出,当脱粒辊转速固定在某一值时,离散辊转速从150 r/min增加到350 r/min时,破碎率先增大后减小。这是因为离散辊转速从150 r/min增加到250 r/min,离散辊对玉米果穗的离散力随之增大,单位时间内的离散单元与玉米果穗接触的次数增加,有利于玉米果穗离散;而离散辊转速在250~350 r/min时,随着转速增加,离散辊离散单元的线速度增大,与玉米果穗接触时带动果穗向后运动,使得脱粒时间减少,破损率减小。

图2 脱粒辊转速和离散辊转速对破碎率和脱净率的影响Fig.2 Effect of threshing roller speed and discrete roller speed on broken rate and removal rate

当离散辊转速固定在某一值时,随着脱粒辊转速的增加,破碎率逐渐下降。这是因为离散后的果穗组砌规律已经被破坏,当转速较低时,玉米籽粒主要由脱粒辊产生的脱粒力而进行脱粒的,破碎率较大;当脱粒辊转速增加时,仿裸手脱粒单元对果穗的冲击力增大,而由裸手脱粒试验可知,力越大时对籽粒间组砌规律破坏越严重[28],籽粒之间相互作用力也增大,少部分籽粒受到的作用力传递到较大范围的籽粒,最后蹦散开来。此时由于只有少部分籽粒直接受力,故破碎率比较小。由图可知当离散辊转速在150~180 r/min和310~350 r/min,脱粒辊转速在270~350 r/min时,籽粒破碎率较低。

4.2.2 离散辊转速和脱粒辊转速对脱净率的影响效应分析

令X1、X4、X5取零水平,得到脱净率与X2、X3的关系式(6)。

图2b为脱粒辊转速和离散辊转速对脱净率的影响响应曲面。从图中可以看出,脱粒辊转速固定在某一值,离散辊转速在150~350 r/min转范围内变化时,脱净率先增大,在250 r/min左右达到最大值,随后维持一段,然后随着离散辊转速继续增加,脱净率减小。因为离散辊转速在150~250 r/min时,转速增加,对果穗的离散程度增大,破坏了玉米籽粒的组砌规律,且单位时间内的离散单元与玉米果穗接触的次数增加,从而有利于玉米果穗的离散;而当转速在250~350 r/min时,随着离散辊转速增加,离散辊离散单元的线速度增大,与玉米果穗接触时带动果穗向后运动,使得离散时间减少,脱净率减小。

而当离散辊转速固定在某一值时,随着脱粒辊转速增大,脱净率逐渐减小。因为脱粒辊线速度增大,与玉米果穗接触后作用力大,果穗未脱粒完成即离开脱粒辊下方,脱粒时间短,脱净率减小。当离散辊转速在230~330 r/min,脱粒辊转速在150~300 r/min范围内时,籽粒脱净率较高。

4.2.3 离散辊间隙和脱粒辊间隙对籽粒破碎率的影响效应分析

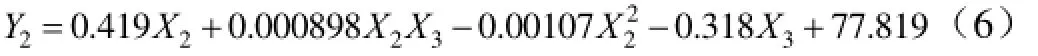

令X1、X2、X3取零水平,得到破碎率与X4、X5的关系式(7)。

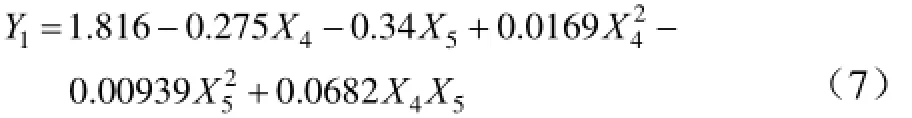

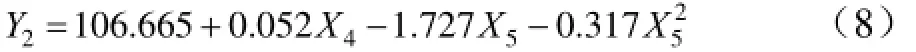

图3a为脱粒辊间隙和离散辊间隙对破碎率的影响响应曲面。由图3a可知,当离散辊间隙固定在0~4 mm之间某一值时,随着脱粒辊间隙的增大,破碎率逐渐减小,间隙超过某一值时破碎率减小到0,随后保持不变。这是因为脱粒辊间隙由0逐渐增大时,脱粒辊与玉米果穗间的相互作用力减弱,籽粒的损伤因而减小,破碎率持续降低,直至减小到0。当脱粒辊间隙在4~9.2 mm之间固定在某一值时,随着脱粒辊间隙的增大,破碎率增大。因离散间隙较大时,离散辊对果穗的离散力减小,不易打破玉米籽粒间由组砌规律产生的相互作用力,对玉米果穗的离散效果不好,进而后续玉米果穗不易脱粒,使破碎率迅速增加。

同理,当脱粒辊间隙固定在0~5 mm之间的某一值时,随着离散辊间隙的增大,破碎率先减小,后逐渐增大。这是因为离散辊间隙增大时,离散辊对玉米果穗的作用力减小,玉米籽粒的损伤减少,碎率先减小;而当间隙持续增加,离散辊的离散效果逐渐变差,籽粒间由组砌规律产生的相互作用力仍大量存在,脱粒辊脱粒时需要很大离散力才能进行脱粒,于是加剧了籽粒的破碎,破碎率逐渐增大。当脱粒辊间隙固定在5~9.2 mm之间的某个值时,随着离散辊间隙的增大,破碎率先保持0不变,随后迅速增大。这是因为离散辊间隙较小时能够充分破坏籽粒间的组砌规律,较好的进行离散,而此时的脱粒辊间隙相对较大,即能以较小的脱粒力将剩余果穗脱粒,又不会造成籽粒破碎,因而破碎率维持在0不变;而随着离散辊间隙继续增加,对果穗作用力减小,不能充分破坏籽粒的组砌规律,离散效果减弱,后续脱粒辊脱粒时困难加大,需要较大的作用力进行脱粒,籽粒破碎率增加。

图3 脱粒辊间隙和离散辊间隙对破碎率和脱净率的影响Fig.3 Effect of the threshing roller gap and discrete roller gap on the broken rate and removal rate

当离散辊间隙在0~4 mm,脱粒辊间隙在5~9.2 mm时,籽粒破碎率取得最小值。

4.2.4 离散辊间隙和脱粒辊间隙对籽粒脱净率的影响效应分析

令X1、X2、X3取零水平,得到破碎率与X4、X5的关系式(8)。

如图3b所示为离散辊间隙和脱粒辊间隙对籽粒脱净率的影响效果响应曲面,当离散辊间隙固定在某一值不变,脱粒辊间隙9.2 mm减到0时,脱净率持续增大,达到100%时保持不变。因为间隙减小,脱粒辊对玉米果穗的脱粒力增大,能够破坏籽粒间组砌规律,脱粒效果好;当脱粒辊间隙降到某一临界值时,脱净率达到100%,而后保持不变。当脱粒辊间隙降到某一临界值时,改变离散辊间隙,对脱净率几乎没有明显影响,说明离散辊间隙对脱净率影响不明显。这是因为离散辊在前,脱粒辊在后,脱粒辊对脱净率起决定性作用。

由图3b中易知,脱粒辊间隙介于0~2.2 mm时,籽粒脱净率取得最大值。

5 参数优化

5.1 优化分析

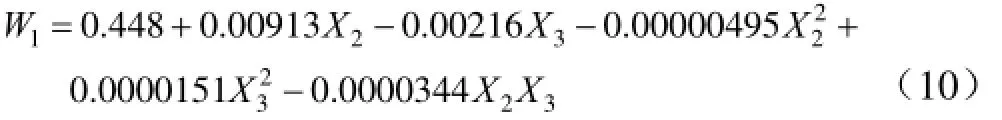

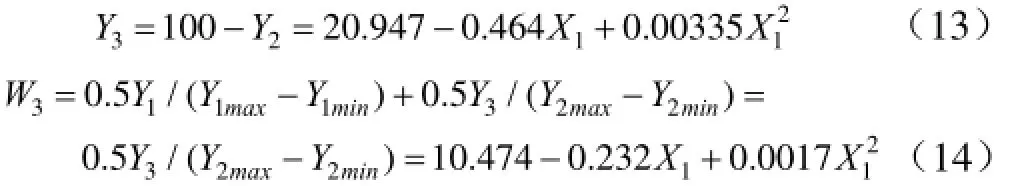

将4.1.1节和4.1.2节中的破碎率和脱净率的回归方程进程按综合评价法进行拟合[29-32]。为便于分析运算,引入未脱净率Y3(即Y3=100-Y2)。破碎率与未脱净率均以权重0.5:0.5的比例进行相加,计算评价值W1拟合的公式如下

5.1.1 选取离散辊最佳转速和脱粒辊最佳转速

令X1、X4、X5取零水平,得到评价值W1关于X2、X3的关系式:

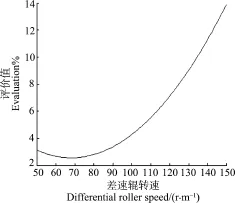

评价值W1为最小值时,即破碎率和未脱净率的值均较小。有图4可知,评价值W1在某一小范围内达到最小值,此时取离散辊转速为350 r/min,脱粒辊转速为350 r/min作为最佳参数组合。

图4 评价值W1的响应曲面Fig.4 Response surface of evaluation value W1

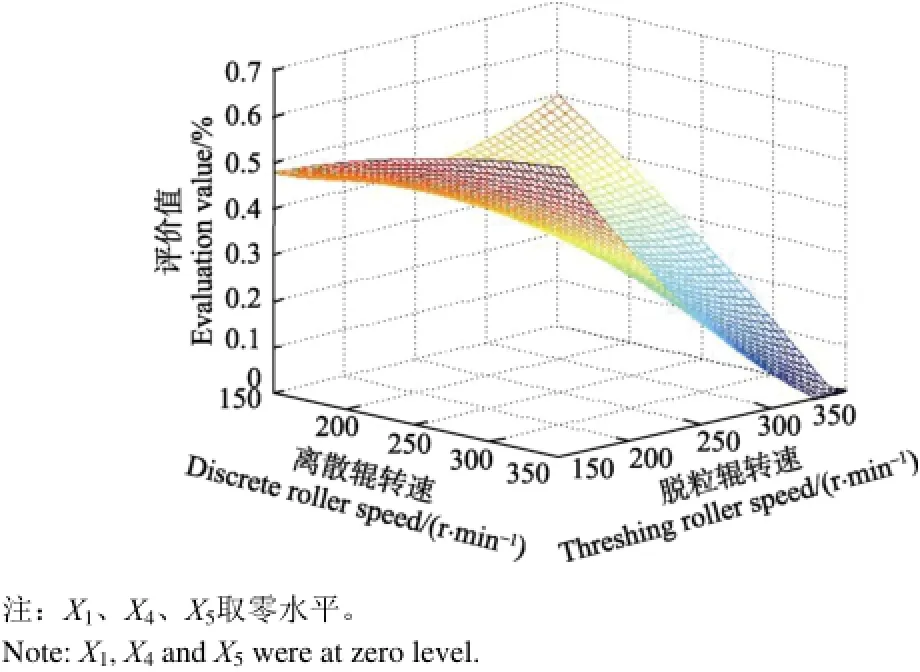

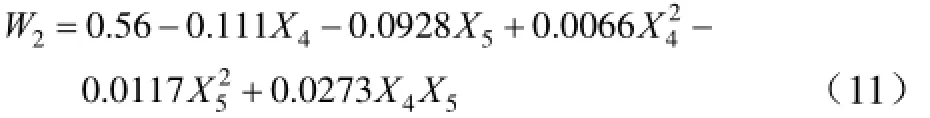

5.1.2 选取离散辊最佳间隙和脱粒辊最佳间隙

利用5.1.1节中已知最佳组合X2为350 r/min,X3为350 r/min,差速辊转速X1取0水平,代入公式(9)得到仅含有X4、X5的评价值,此时该评价值记为W2:

同理,评价值W2越小,说明破碎率越低,未脱净率越低,二者综合值越小。由图5可知,评价值W2为最小值0时,离散辊间隙为4.6 mm,脱粒辊间隙为4.6 mm。

图5 评价值W2的响应曲面Fig.5 Response surface of evaluation value W2

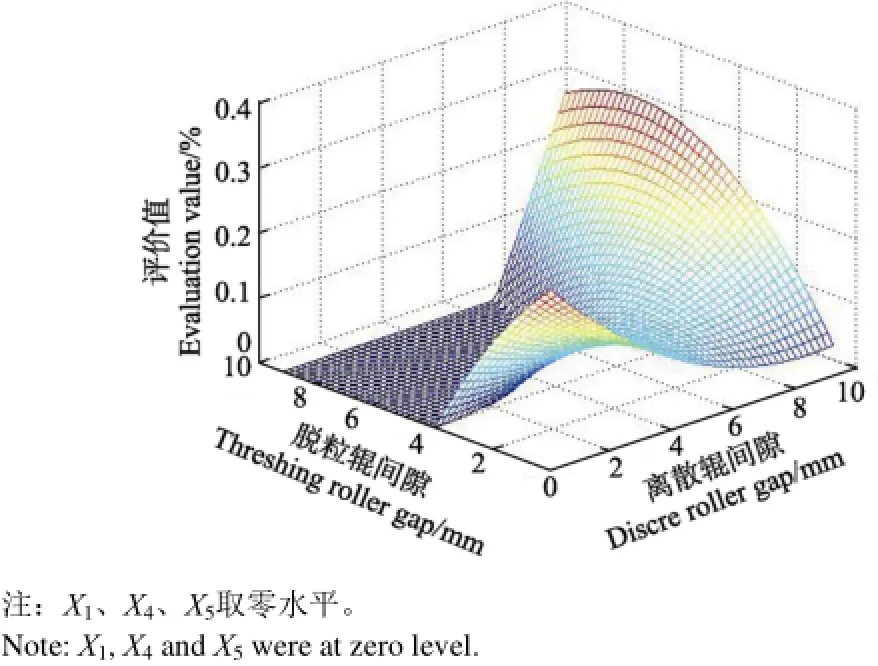

5.1.3 选取差速辊最佳转速

将已得到的最优参数组合X2=350 r/min,X3=350 r/min,X4=4.6 mm,X5=4.6 mm带入4.1.1节和4.1.2节中Y1和Y2的表达式,

而Y1大于等于0,因而在最佳转速与间隙条件下破碎率Y1始终是0;考虑未脱净率Y3,以及此时仅余未知量X1的综合评价值,记为W3:

由图6可知,当差速辊在50 r/min~90 r/min范围内,评价值W3变化缓慢,说明差速辊转速对脱净率和破碎率综合影响效果不大,而考虑到差速辊转速决定了单位时间内玉米果穗输送量,为在较低的破碎率和较高脱净率情况下提高生产率,取转速90 r/min。

图6 评价值W3的响应曲面Fig.6 Response surface of evaluation value W3

5.2 优化结果验证试验

在最佳条件差速辊转速90 r/min,离散辊转速350 r/min,脱粒辊转速为350 r/min,离散辊间隙4.6 mm,脱粒辊间隙4.6 mm条件下进行验证试验,测得此时破碎率为0.226%,脱净率为99.317%,玉米芯完整度为100%,达到破碎率小于1%、未脱净率小于1%的国家标准要求[33]。

6 结 论

1)对基于先离散后脱粒原理的玉米种子仿生脱粒机进行试验。分析离散辊转速和脱粒辊转速对破碎率和脱净率的影响,当离散辊转速在150~180 r/min和310~350 r/min,脱粒辊转速在270~350 r/min时,籽粒破碎率达到最小值;当离散辊转速在230~300 r/min,脱粒辊转速在150~200 r/min范围内时,籽粒脱净率达到最大值。

2)分析试验结果中离散间隙和脱粒间隙对破碎率和脱净率的影响效果,当离散辊间隙在0~4 mm,脱粒辊间隙在5~9.2 mm时,籽粒破碎率取得最小值;脱粒间隙对脱净率影响效果较明显,脱粒辊间隙介于0~2.2mm时,籽粒脱净率取得最大值。

3)运用综合评价法对结果进行优化,得到整机性能参数的最优参数组合为差速辊转速90 r/min,离散辊转速350 r/min,脱粒辊转速为350 r/min,离散辊间隙4.6 mm,脱粒辊间隙4.6 mm。以最优参数组合进行验证试验,破碎率为0.226%,脱净率为99.317%,玉米芯完整度为100%,达到低损伤脱粒的目的,为进一步降低玉米种子脱粒过程中的机械损伤提供参考。

[1] Petkevichius S, Shpokas L, Kutzbach H D. Investigation of the maize ear threshing process[J]. Biosystems Engineering, 2008, (99): 532-539.

[2] 罗锡文,廖娟,胡炼,等. 提高农业机械化水平促进农业可持续发展[J]. 农业工程学报,2016,32(1):1-11.

Luo Xiwen, Liao Juan, Hu lian, et al. Improving agricultural mechanization level to promote agricultural sustainable development[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 1-11. (in Chinese with English abstract)

[3] 罗锡文,臧英,周志艳.精细农业中农情信息采集技术的研究进展[J]. 农业工程学报,2006,22(1):167-173.

Luo Xiwen, Zang Ying, Zhou Zhiyan. Research progress in farming information acquisition technique for precision agriculture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(1): 167-173. (in Chinese with English abstract)

[4] 朱明,陈海军,李永磊. 中国种业机械化现状调研与发展分析[J]. 农业工程学报,2015,31(14):1-7.

Zhu Ming, Chen Haijun, Li Yonglei. Investigation and development analysis of seed industry mechanization in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 1-7. (in Chinese with English abstract)

[5] Folarin A, Kosemani A, Babajide S. Development of a guinea corn thresher[C]//American Society of Agricultural and Biological Engineers Annual International Meeting, ASABE 2011, 2: 1281-1288.

[6] Tastra I K. Designing and testing an improved maize sheller [J]. Ama Agricultural Mechanization in Asia, Africa and Latin America, 2009, 40(1):12-17.

[7] 徐立章,李耀明,王显仁. 谷物脱粒损伤的研究进展分析[J]. 农业工程学报,2009,25(1):303-307.

Xu Lizhang, Li Yaoming, Wang Xianren. Research development of grain damage during threshing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(1): 303-307. (in Chinese with English abstract)

[8] 李心平,李玉柱,高吭,等. 种子玉米籽粒仿生脱粒机理分析[J]. 农业机械学报,2011,42(2):99-103.

Li Xinping, Li Yuzhu, Gao Hang, et al Bionic threshing process analysis of seed corn kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(2): 99–103. (in Chinese with English abstract)

[9] 李心平,马义东,金鑫,等. 玉米种子仿生脱粒机设计与试验[J]. 农业机械学报,2015,46(7):97-101.

Li Xinping, Ma Yidong, Jin Xin, et al. Design and test of seed corn bionic thresher[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 97-101. (in Chinese with English abstract)

[10] Li Xinping, Wu Kang, Ma Yidong. Quantitative analysis of geometric structures and experimental evaluation of rooster beak[J]. Bio Automation, 2016, 20(2): 205-214

[11] 李心平,刘赢,马义东,等. 玉米果穗籽粒间缝隙走向对其循环力衰败的影响[J]. 农机化研究,2015,37(1):183-187.

Li Xinping, Liu Ying, Ma Yidong, et al. Effect of gap direction among corn ear kernels on the circulating dint decline[J]. Journal of Agricultural Mechanization Research, 2015, 37(1): 183-187. (in Chinese with English abstract)

[12] 罗锡文,刘涛,蒋恩臣,等. 水稻精量穴直播排种轮的设计与试验[J]. 农业工程学报,2007,23(3):108-112.

Luo Xiwen, Liu Tao, Jiang Enchen, et al. Design and experiment of hill sowing wheel of precision rice directseeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(3): 108-112. (in Chinese with English abstract)

[13] 赵武云,王广万,刘国春,等. 低破碎玉米种子脱粒机的研制[J]. 机械研究与应用,2010,23(1):132-134.

Zhao Wuyun, Wang Guangwan, Liu Guochun, et al. Research and design on low damage corn seed sheller[J]. Machine research and Application, 2010, 23(1): 132-134. (in Chinese with English abstract)

[14] 贾洪雷,赵佳乐,姜鑫铭,等. 行间免耕播种机防堵装置设计与试验[J]. 农业工程学报,2013,29(18):16-25.

Jia Honglei, Zhao Jiale, Jiang Xinming, et al. Design and experiment of anti-blocking mechanism for inter-row notillage seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(18): 16-25. (in Chinese with English abstract)

[15] 何树国,车刚,万霖.5TY-10A型玉米种子脱粒机的研制与试验研究[J].黑龙江八一农垦大学学报,2006,18(3):55-58.

He Shuguo, Che Gang, Wan Lin. Manufacture and study on 5TY-10A type corn seed thresher[J]. Journal of Heilongjiang August First Land Reclamation University, 2006, 18(3): 55-58. (in Chinese with English abstract)

[16] 史嵩,张东兴,杨丽,等. 气压组合孔式玉米精量排种器设计与试验[J]. 农业工程学报,2014,30(5):10–18.

Shi Song, Zhang Dongxing, Yang Li, et al. Design and experiment of pneumatic maize precision seed-metering device with combined holes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(5): 10-18. (in Chinese with English abstract)

[17] 韩长杰,杨宛章,张学军,等. 穴盘苗移栽机自动取喂系统的设计与试验[J]. 农业工程学报,2013,29(8):51-61.

Han Changjie, Yang Wanzhang, Zhang Xuejun, et al. Design and test of automatic feed system for tray seedlings transplanter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(8): 51-61. (in Chinese with English abstract)

[18] 吴良军,杨 洲,洪添胜,等. 荔枝树枝力学特性的试验研究[J]. 农业工程学报,2012,28(16):68-73.

Wu Liangjun, Yang Zhou, Hong Tiansheng, et al. Experimental study on mechanical properties of litchi branches[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(16): 68-73. (in Chinese with English abstract)

[19] 张国忠,臧英,罗锡文,等. 水稻气力式排种器导向型搅种装置的设计与试验[J]. 农业工程学报,2013,29(12):1-8.

Zhang Guozhong, Zang Ying, Luo Xiwen, et al. Design and experiment of oriented seed churning device on pneumatic seed metering device for rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(12): 1-8. (in Chinese with English abstract)

[20] 丛锦玲,廖庆喜,曹秀英,等. 油菜小麦兼用排种盘的排种器充种性能[J]. 农业工程学报,2014,30(8):30-39. Cong Jinling, Liao Qingxi, Cao Xiuying, et al. Seed filling performance of dual-purpose seed plate in metering device for both rapeseed & wheat seed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(8): 30-39. (in Chinese with English abstract)

[21] Li Xinping, Wu Kang. Design and experiment of bionic discrete devices based on corn threshing system[J]. Chemical Engineering Transactions, 2016, 51(5), 127-132.

[22] 李云雁,胡传荣.试验设计与数据处理[M]. 北京:化学工业出版社,2004.

[23] 李心平,高连兴. 差速式玉米种子脱粒机的性能试验[J].农业工程学报,2009,25(12):102-106.

Li Xinping, Gao Lianxing. Performance test on corn thresher with different-speed threshing parts[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(12): 102-106. (in Chinese with English abstract)

[24] 王晶,聂影,宫元娟,等. 玉米对生种子脱粒机试验[J],农业机械学报,2011,42(2):104-108.

Wang Jing, Nie Ying, Gong Yuanjuan, et al. Experiment on thresher of maize pair seeds[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(2): 104-108. (in Chinese with English abstract)

[25] 白晓虎,林静,吕长义,等. 免耕播种机圆盘破茬刀工作性能分析与试验[J]. 农业工程学报,2014,30(15):1-9.

Bai Xiaohu, Lin Jing, Lü Changyi, et al. Analysis and experiment on working performance of disc coulter for no-tillage seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(15): 1-9. (in Chinese with English abstract)

[26] 曹玉华,李长友,张增学,等. 蓖麻蒴果剥壳装置关键部件改进设计与试验[J]. 农业工程学报,2012,28(18):16-22.

Cao Yuhua, Li Changyou, Zhang Zengxue, et al. Improvement design and test to key components of castor capsule hulling device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(18): 16-22. (in Chinese with English abstract)

[27] 杨有刚,刘迎春. 仿生式开沟机设计理论的研究[J]. 农业机械学报,2004,35(1):65-68.

Yang Yougang, Liu Yingchun. Design of a bionic ditch digger[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(1): 65-68. (in Chinese with English abstract).

[28] Li Xinping, Du Zhe, Ma Yidong, et al. Bare hand threshing experiment on corn ear kernel[J]. International Agricultural Engineering Journal, 2014, 23(3): 74-80.

[29] 李耀明,周伟,徐立章,等. 单切双横流脱粒分离装置参数试验与优化[J]. 农业机械学报,2015,46(5):62–67,92.

Li Yaoming, Zhou Wei, Xu Lizhang, et al. Parameter test and optimization of tangential-horizontal-horizontal threshing and separating device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 62-67, 92. (in Chinese with English abstract)

[30] 李耀明,乔明光,徐立章,等. 纵轴流复脱分离装置设计与试[J].农业机械学报,2009,40(11):50-54.

Li Yaoming, Qiao Mingguang, Xu Lizhang, et al. Development and performance experiments on axia-l rethreshing with axial feeding[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(11): 50-54. (in Chinese with English abstract)

[31] 楚杰,路海东,薛吉全,等. 玉米宽窄行深旋免耕精量播种机田间试验及效果[J]. 农业工程学报,2014,30(14):34-41.

Chu Jie, Lu Haidong, Xue Jiquan, et al. Field experiment and effect of precise mechanical sowing of maize based on wide-narrow row deep rotation and no-tillage technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(14): 34-41. (in Chinese with English abstract)

[32] 李汝莘,耿爱军,赵何,等. 碎玉米秸秆卷压过程的流变行为试验[J]. 农业工程学报,2012,28(18):30-35.

Li Ruxin, Geng Aijun, Zhao He, et al. Rheologic behavior of chopped corn stalks during rotary compression[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(18): 30-35. (in Chinese with English abstract)

[33] JB/T 10749-2007: 玉米脱粒机[S]. 北京: 机械工业出版社, 2008.

Performance test and parameter optimization of corn seed bionic thresher

Li Xinping, Ma Lei, Geng Lingxin, Wang Shengsheng, Pang Jing, Ji Jiangtao※

(College of Agricultural Equipment Engineering, Henan University of Science and Technology, Luoyang 471003, China)

Corn seed bionic thresher was designed based on the principle of first discretizing and then threshing, which imitated the process of chicken beak discretizing corn grain and bare hand threshing, and had the advantages of low damage, low broken rate, and so on. In order to optimize the parameter of corn seed bionic threshing system, and then reduce the damage in the course of threshing of corn seed, this paper adopted the method of the quadratic regression orthogonal rotation combination design. Grain broken rate and removal rate were taken as the main performance indicators, differential roller speed, discrete roller speed, threshing roller speed, discrete roller gap, and threshing roller gap were selected as experimental factors, and the performance test of the corn seed bionic thresher was carried out. According to the test results, the influence of discrete roller speed and threshing roller speed on the broken rate and removal rate was respectively analyzed, as well as the influence of discrete roller gap and threshing roller gap on the broken rate and removal rate. Analysis results showed that when the threshing roller speed was fixed at a certain level, and the discrete roller speed increased from 150 to 350 r/min, the broken rate first increased and then decreased; when the discrete roller speed was fixed at a certain level, with the increasing of the threshing roller speed from 150 to 350 r/min, the broken rate decreased gradually; when the discrete roller speed was in 150-180 and 310-350 r/min, and the threshing roller speed was in 270-350 r/min, the broken rate was 0, which reached the lowest. The threshing roller speed was fixed at a certain level, and the discrete roller speed changed in the range of 150-350 r/min, the removal rate first increased and then decreased; when the discrete roller speed was fixed at a certain level, with the increase of threshing roller speed, the removal rate decreased gradually; when the discrete roller speed was in 230-330 r/min, and the threshing roller speed was in 150-300 r/min, the removal rate reached 100%, which was the highest. When the discrete roller gap was in 0-4 mm, and the threshing roller gap was in 5-9.2 mm, the broken rate was 0, reaching the lowest. When the discrete roll gap was fixed at a certain level, and the threshing roller gap reduced from 9.2 to 0 mm, the removal rate continued to increase; when the threshing roller gap was in 0-2.2 mm, the removal rate was 100%, which was the highest. On the basis of the experimental curve, through the optimization with the comprehensive evaluation method, the optimal combination of parameters was obtained: the differential roller speed of 90 r/min, the discrete roller speed of 350 r/min, the threshing roller speed of 350 r/min, the discrete roller gap of 4.6 mm, and the threshing roller gap of 4.6 mm. The verification test was carried out on the basis of these optimal conditions. It was found that the breaking rate was 0.226%, the net removal rate was 99.317%, and the corncob integrity was 100%. All the results meet the requirements of the national standard.

agricultural machinery; bionics; seeds; corn; discrete; threshing; broken rate; removal rate

10.11975/j.issn.1002-6819.2017.05.009

S226.1

A

1002-6819(2017)-05-0062-08

李心平,马 磊,耿令新,王升升,庞 靖,姬江涛. 玉米种子仿生脱粒机性能试验与参数优化[J]. 农业工程学报,2017,33(5):62-69.

10.11975/j.issn.1002-6819.2017.05.009 http://www.tcsae.org

Li Xinping, Ma Lei, Geng Lingxin, Wang Shengsheng, Pang Jing, Ji Jiangtao. Performance test and parameter optimization of corn seed bionic thresher[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(5): 62-69. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.05.009 http://www.tcsae.org

2016-05-25

2017-01-05

国家自然科学基金与河南人才培养联合基金资助项目(U1204514)

李心平,男,博士,副教授,主要研究方向为农产品收获与加工机械研究。洛阳 河南科技大学农业装备工程学院, 417003。

Email:aaalxp@126.com

※通信作者:姬江涛,男,河南偃师人,博士,教授,博士生导师,研究方向为智能化农业装备。洛阳 河南科技大学农业装备工程学院,417003。

Email:jjt0907@163.com