Measuring the Acoustic Properties of Underwater Coating Material under Pressure-Acoustic Impedance Method

PANG Ye-zhen,YU Xiao-li,ZHANG Xiao-wei,YU Meng-sa

(National Key Laboratory on Ship Vibration&Noise,China Ship Scientific Research Center,Wuxi 214082,China)

Measuring the Acoustic Properties of Underwater Coating Material under Pressure-Acoustic Impedance Method

PANG Ye-zhen,YU Xiao-li,ZHANG Xiao-wei,YU Meng-sa

(National Key Laboratory on Ship Vibration&Noise,China Ship Scientific Research Center,Wuxi 214082,China)

A method to measure the acoustic properties of underwater acoustic coating material under pressure based on acoustic impedance matrix is setup.Acoustic impedance matrix is measured to evaluate the absorption and transmission loss of underwater material.The test apparatus are well designed,especially for the tube,driver,backing mass and hydrophones.Isotropic material samples are tested to verify the test apparatus.Impedance matrix of acoustic coating material samples is measured to evaluate the absorption and transmission loss of samples,compared with theoretical results, and hence the acoustic impedance method is verified.

acoustic impedance;sound absorption coefficients;sound transmission loss

0 Introduction

Chung and Blaser(1980)[1-3]developed transfer function method to measure the reflections, input impedance and transmission loss of materials in the air.Goodman(1985)[4]applied for patent using this method to measure the input impedance in water.Wilson(2003)[5-6]described the propagation in the impedance tube filled with water in detail,and use impedance tube to measure the reflections of water layer with bubbles.Tao and Seybert(2001)[7]reviewed three kinds of methods to measure the transmission loss in pipe using transfer function method.

A new method to measure the impedance matrix is developed in these years.Impedance matrix is the unchanged parameter of acoustic material.The impedance matrix could be used to evaluate the acoustic properties with different backings,and it is a more efficient way than measuring the absorption coefficients or transmission loss directly.To measure the acoustic properties of underwater material,Cole and Martini(1994)[8]from Cambridge Acoustical Associates(USA)designed new acoustic impedance tube,PZT-8 piezoelectric rings and a beryllium piston are composed to be a low-frequency driver,transfer function of sound pressure in the tube and vibration of piston are measured to analyze the impedance matrix.Krylov Insti-tute developed the impedance tube to measure the acoustic properties of pipe parts.Akoum and Ville(1998)[9]used Fourier-Lommel transform to develop acoustic impedance test method in the tube.Reflections of plane-wave(0 order)and high-order modes could be analyzed by separating the incidence and reflection wave.Dalmont(2001)[10-11]converted the transfer matrix to impedance matrix.

1 Impedance matrix

1.1 Transfer matrix method

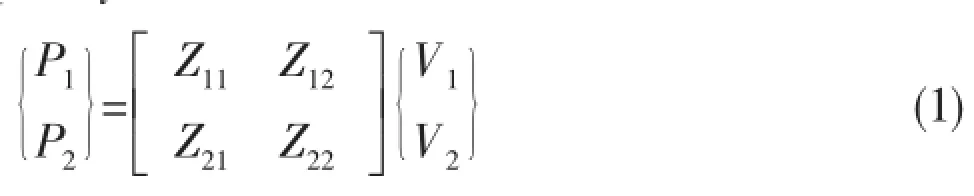

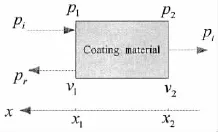

The acoustic material layer could be characterized as a two-port linear system(Fig.1) when the material layer is located in a water filled tube which could be treated as a plane wave sound field in low frequency.

Fig.1 Two-port model

where P1and P2are the sound pressure at input end and output end,V1and V2are the volume velocity at input end and output end,Z11and Z22are the input impedance at input end and output end,Z12and Z21are the transfer impedance at input end and output end,respectively.

The impedance parameters could be determined at special boundary conditions.

To ensure the volume velocity at output end V2=0,the output end should be absolutely rigid,which means that the inertial impedance of output end should be infinity.Practically backing mass made from steel is used to represent the inertial impedance.

1.2 Impedance matrix of isotropic material

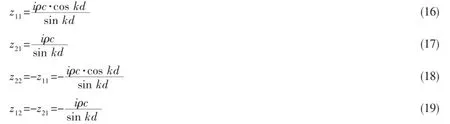

For isotropic material sample,the input impedance and transfer impedance are determined by Eqs.(6-7):

where HLis the thickness of sample,ρLis the density of sample,cLis the sound speed of sample.

1.3 Impedance matrix test method

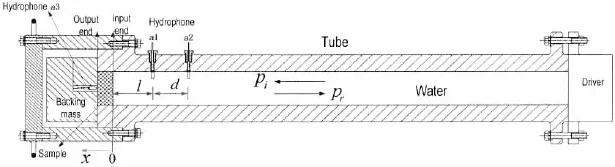

The acoustic tube is shown in Fig.2,P1and P2are the sound pressure at input end and output end,V1and V2are the volume velocity at input end and output end.Two hydrophones are mounted on the wall of the tube,located at l and l+d before the input end to measure the sound pressure Pa1and Pa2,then the sound pressure P1and particle velocity V1of input end could be analyzed.The third hydrophone is mounted at the output end,just at the joints between sample and backing mass.The backing mass is treated as rigid backing,thus the particle velocity at output end V2≈0.

Fig.2 Scheme of acoustic test apparatus

where ρωcωis the characteristic impedance of water.

Thus the pressure and particle velocity at location l could be:

The pressure and particle velocity at location l+d could be:

From Eqs.(12-13),the amplitudes of injective sound and reflective sound,i.e.A and Bcould be solved,thus the sound pressure P1and particle velocity V1at input end are easily obtained,thus the input impedance is:

The transfer impedance is

where H1=Pa2/Pa1,H2=Pa3/Pa1.

2 Apparatus design

The apparatus(Fig.3)is based on an acoustic tube with the same diameter,the lower end is a sound driver which produces sound wave,and the upper end is the material sample and backing mass.The whole acoustic tube is filled with pressured water.

2.1 Tube

The whole tube is made from stainless steel,the diameter of tube is 120 mm,and the wall thickness of tube is 60 mm,first,the tube could be pressured more than 6 MPa,second, the tube is rigid enough to make sure the plane wave exist(Fig.4).

Fig.3 Acoustic impedance test apparatus

Fig.4 Sound speed of plane wave(0-order wave)

To seal the water from air,O-rings are used at both the driver and the top cover.Hydraulic connection locates at the lower part of the tube to fill water,pneumatic connection locates at the top cover to release the gas.

2.2 Driver

A long tonpilz driver(Fig.5)comprised by PZT rings is designed to get wide-band sound power in the tube.The injection sound pressure level is larger than 110 dB in 100-2 000 Hz,and the SNR is more than 20 dB.The driver could be working under the pressure 7 MPa.The driver and the tube are sealed with 2 O-rings.

Fig.5 The scheme figure and photo of driver

2.3 Backing mass

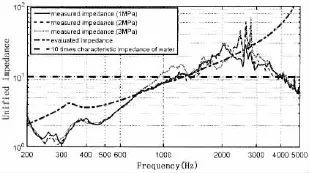

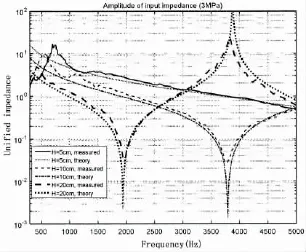

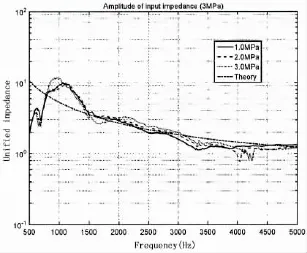

Generally,if the input impedance of backing mass(Fig.6)is ten times larger than the characteristic impedance of water,the backing mass could be treated as rigid backing.The thickness of the whole backing mass is 490 mm,the theoretically input impedance at 600-5 000 Hz is larger than 10 times of characteristic impedance of water,which is verified by using test under several pressure up to 3 MPa(Fig.7).

Fig.6 Steel backing mass

The input impedance of steel mass backing has a very little change with the change of environmental pressure.Because the characteristic impedance changes very little with pressure, so the effect of pressure on measurement system could be negligible.

2.4 Hydrophones

To limit the measurement uncertainty of transfer function,the distance of two hydrophones should be 0.1π<kd<0.8π,where k is the wavenumber,d is hydrophone distance.So the applicable frequency is 0.05c/d<f<0.4c/d.Four hydrophones and three kinds of distances(0.05 m,0.12 m and 0.4 m)are used to cover the whole measurement frequency span 100 Hz~2 kHz.

Fig.7 Theoretical and measured input impedances of multilayer steel backing

Fig.8 Relationship between hydrophone distance d and usable frequency span

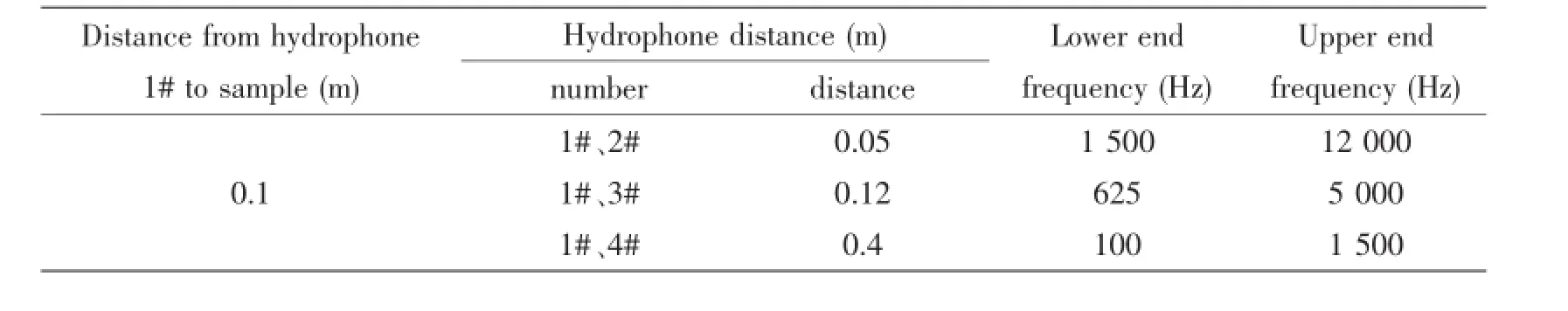

Tab.1 Usable frequency span

3 Using impedance matrix to evaluate the absorption and transmission loss of underwater material

3.1 Absorption parameters using impedance

It is not intuitive to evaluate the properties of acoustic material from the impedance matrix.Usually the sound absorption coefficients and sound transmission loss are used to evaluate the properties of acoustic material,which could be converted from impedance matrix.

Suppose the acoustic material is isotropic material,d is the thickness,characteristic impedance is ρc,the impedance coefficients is:

The surface impedance could be

where zbis the surface impedance of backing structure.

From the surface impedance,the reflection coefficients R is

Thus the sound absorption coefficients is

It is easy to know that,different backing corresponding to Zbwill bring different reflection coefficients.To evaluate the acoustic character of coating materials,the acoustic character should be taken into account.

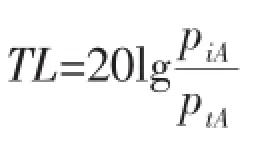

3.2 Transmission loss parameters using impedance

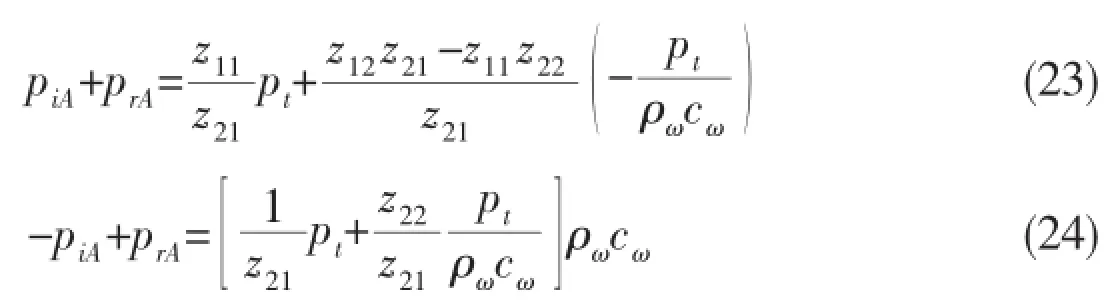

The incident sound pressure piAand reflection sound pressure prAcould be obtained from the impedance matrix and the transmitted sound pressure pt(Fig.9).

Fig.9 The acoustic parameters of coating material

The sound transmission loss could be represented using impedance parameters.

4 Measurement results

4.1 Impedance matrix verification

To verify the method,two kinds of model made by isotropic material water and rubber are measured.The typical impedance matrix of water and rubber could be analyzed using their characteristic impedance.

The water models with three kinds of thickness 50 mm,100 mm and 200 mm,the rubber model with two kinds of thickness 50 mm and 200 mm,are tested(Fig.10).

The input impedance and transfer impedance of water layer(Fig.11)are highly in accordance with theoretical results above 500 Hz-1 kHz,below this frequency span,the test results go to bad because the backing mass is not rigid enough,the input impedance of backing mass does not meet the condition of‘rigid backing’(Figs.12-13).

When the water layer becomes thicker,the lower end of effective frequency span gets lower,the reason is that when the water layer becomes thicker,the phase shift induced by thetransmission in the water gets bigger,the relative measurement error induced by the phase error of test system gets smaller,thus the frequency becomes effective in lower frequency span.

Fig.10 Measured input impedance of water

Fig.11 Measured transfer impedance of water

Fig.12 Theoretical and measured input impedance of rubber sample(50 mm thickness)

Fig.13 Theoretical and measured transfer impedance of rubber sample(50 mm thickness)

The impedance matrix of rubber sample(50 mm thickness)is measured,compared with theoretical impedance,they are well in accordance upon 800 Hz.

4.2 Absorption parameters verification

Using measured impedance matrix of rubber sample to calculate the sound absorption coefficients of rubber sample with steel backing,compared with the directly measured sound absorption coefficients.Measured and converted SAC are highly in accordance,the difference is less than 0.1 from 100 Hz to 5 kHz,and averaging error is less than 5%.

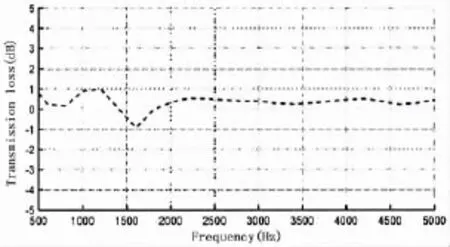

4.3 Transmission loss parameters verification

Water is acoustic transparent,the theoretical transmission loss for acoustic layer is 0 dB. The measurement results show that transmission loss for 10 cm thickness varies between-2 dB to 4 dB from 400 Hz to 5 kHz,especially,the measurement results are less than 1dB different from theoretical results from 2 000 Hz to 5 000 Hz.High pressure bring better results, the measurement results at 3 MPa have much less error than atmosphere.

Fig.14 Measurement results and converted results of incident absorption coefficients

Fig.15 The measurement transmission loss for 10 cm thickness water layer

5 Conclusions

A method to measure the properties of underwater acoustic material under pressure based on acoustic impedance matrix is setup.Acoustic impedance matrix is measured to evaluate the absorption and transmission loss of underwater material.The test apparatus are well designed, especially for the tube,driver,backing mass and hydrophones.Isotropic material samples are tested to verify the test apparatus.Impedance matrix of acoustic coating material samples are measured to evaluate the absorption and transmission loss of samples,compared with theoretical results,the acoustic impedance method is verified.The impedance matrix could be used to evaluate the acoustic properties with different backings,it is a more efficient way than measuring the absorption coefficients or transmission loss directly.

[1]Chung J Y,Blaser D A.Transfer function method of measuring in-duct acoustic properties.I.Theory[J].JASA,1980,68 (3):907-913.

[2]Chung J Y,Blaser D A.Transfer function method of measuring in-duct acoustic properties.II.Experiment[J].JASA,1980, 68(3):914-921.

[3]Chung J Y,Blaser D A.Transfer function method of measuring acoustic intensity in a duct system with flow[J].JASA, 1980,68(6):1570-1577.

[4]Goodman J,43.30.Ky,43.85.Bh Underwater acoustic impedance measuring apparatus[P].Patent Number:4638275,1985. [5]Wilson P S.Sound propagation and scattering in bubbly liquids[D].Doctoral Dissertation,Boston University,2003.

[6]Wilson P S,Roy R A,Carey W M.An improved water-filled impedance tube[J].J Acoust.Soc.Am.,2003,113(6):3245-3252.

[7]Tao Z,Sybert A F.A Review of current techniques for measuring muffler transmission loss[C].SAE Noise and Vibration Conference,2003.

[8]John E Cole,Kyle Martini.A device for measuring the properties of acoustic materials at low frequency under pressure [R].AD Report,1994.

[9]Akoum M,Ville J M.Measurement of the reflection matrix of a discontinuity in a duct[J].J Acoust.Soc.Am.,1998,103 (5):2463-2468.

[10]Dalmont J P.Acoustic impedance measurement,Part I:A review[J].Journal of Sound and Vibration,2001,243(3):427-439.

[11]Dalmont J P.Acoustic impedance measurement,Part II:A new calibration method[J].Journal of Sound and Vibration, 2001,243(3):441-459.

《船舶力学》稿约须知

一、《船舶力学》(月刊)是中国船舶科学研究中心和中国造船工程学会联合主办的国内外公开发行的专业性学术期刊。它以繁荣科技文化,培养科研人才,促进科学技术向生产力转化,为社会主义现代化建设服务为宗旨。本刊着重刊登我国船舶与海洋工程力学界的科学著作、学术论文和创新研究成果以及有关振动与噪声、计算机应用、测试技术和研究综述等,是我国船舶与海洋工程力学界广大学者和中青年科技工作者的一个重要学术园地和论坛。本刊为中文核心期刊;中国科技核心期刊;RCCSE中国核心学术期刊;美国《工程索引》Ei核心期刊。2014年被评为中国精品科技期刊和百种中国杰出学术期刊。本刊同时刊登中、英文论文。欢迎国内外读者踊跃撰搞。

二、稿约要求

1.论点明确、条理清晰、文字简炼、论据充分、数据可靠。学术论文和综述文章一般不超过6000字(包括图、表);

2.欢迎使用打印稿(用A4纸单面打印,打印一式两份),如用网上投稿也应附有打印稿,标点准确,不要使用非正式公布的简化汉字。如用网上投稿,邮件发至:huanggr@cssrc.com.cn,同时邮寄二份打印稿以便与电子邮件发送稿校核;

3.计量单位一律采用《中华人民共和国法定计量单位》;

4.来稿要求附有中、英文摘要,中、英文关键词(Key words)3~8个,并放在论文首页。英文论文稿末页应附有中文题目、中文摘要及关键词;

5.请提供清晰准确的图、表。图中文字不宜太多。图题和表头应同时使用中英文表示。英文稿的图应插入文中,不要集中放在论文最后;

6.参考文献只选用最主要的、公开发表过的,并在文中引用处注明。为便于Ei收录,中文参考文献应附有英文翻译。文后参考文献按文中引用顺序排序,著录格式应符合:

(1)期刊[序号]作者.题名[J].刊名,年,卷(期):起止页码.

(2)专著[序号]作者.题名[M].出版地:出版者,年,起止页码.

(3)学位论文[序号]作者.题名[D].出版地:出版者,年.起止页码.

(4)论文集[序号]作者.题名[C]//出版地:出版者,年.起止页码.

(5)论文集中析出文献[序号]作者.析出文献题名[C]//原文献责任者.原文献题名.出版地:出版者,出版年,起止页码.

(6)国家标准[序号],标准编号,标准名称[S].

(7)专利[序号]专利所有者.题名[P].国别:专利号,出版日期.

7.请在篇首页地脚处写明作者简介,英文论文请用中、英文写明(简介应包括姓名、出生年、性别、籍贯、单位职称和主要从事工作);

8.请在篇首页地脚处注明资助基金名称的中英文全称及基金号;9.请在来稿中注明联系地址、电话(包括E-mail信箱)。

三、本刊已相继加入国内外的一些重要数据库,提供网络信息服务。故凡向本刊投稿者,均视为其文稿刊登后可供国内外刊物或数据库收录、转载并上网发行;其作者文章著作权使用费与稿酬一次付清,本刊不再另付其它报酬。凡有不同意者,请来函或来电声明,本刊将作适当处理,或请另投它刊。

四、凡经《船舶力学》上刊出论文,其版式、版权属于《船舶力学》编辑部,其他单位或个人不得侵权。

五、对录用的稿件编辑部可作适当删改或请作者删改。对未录用稿件编辑不退稿,请作者自行留底。

六、本刊发表学术论文文责(政治、学术、保密)作者自负,请勿一稿两投。

七、论文发表后,请作者随时将国内外的收录、获奖等信息告知编辑部。

加压声学覆盖层声学性能测试—声阻抗方法

庞业珍,余晓丽,张晓伟,俞孟萨

(中国船舶科学研究中心船舶振动噪声重点实验室,江苏无锡214082)

文章建立了一种基于声阻抗传递矩阵方法的加压声学覆盖层声学性能测试方法。测量得到的声阻抗矩阵用于计算声学覆盖层吸声系数与隔声量。对声阻抗测试装置包括声管、声源、背衬和水听器布置等进行了详细介绍。通过测量均匀材料样品声阻抗对测试装置进行了验证,通过测试声学覆盖层样品计算吸声系数与隔声量,并与理论计算结果进行对比,对声阻抗方法进行了试验验证。

声阻抗;吸声系数;隔声量

TB56

:A

庞业珍(1982-),男,中国船舶科学研究中心博士研究生;

1007-7294(2017)03-0372-10

TB56

:A

10.3969/j.issn.1007-7294.2017.03.012

余晓丽(1980-),女,中国船舶科学研究中心高级工程师;

张晓伟(1987-),男,中国船舶科学研究中心工程师;

俞孟萨(1960-),男,中国船舶科学研究中心研究员,博士生导师。

Received date:2016-12-28

Foundation item:Supported by the National Key Research and Development Program of China(Grant No. 2016YFF0200900)

Biography:PANG Ye-zhen(1982-),female,Ph.D.student,E-mail:chaos123@qq.com;

YU Meng-sa(1960-),male,researcher,E-mail:yumengsa@sohu.com.

- 船舶力学的其它文章

- Numerical Study on the Nonlinear Characteristics of Longitudinal Motions and Wave Loads for SWATH Ship in Regular Head Waves

- Coupled Hydrodynamic and Aerodynamic Response Analysis of a Tension-Leg Platform Floating Wind Turbine

- Validation of CFD Simulation for Ship Roll Damping

- Motion Behavior of a Semisubmersible in Freak Waves

- Numerical Investigation of the Side Wall Effects for Two Ship Models Advancing Parallel in Waves

- Three-Dimensional Problem of the Compressible Water-gas Mixture Impacting on Rigid Plates