混凝土及预应力混凝土结构抗火研究现状与展望

郑文忠,侯晓萌,王 英

(1.结构工程灾变与控制教育部重点实验室(哈尔滨工业大学),哈尔滨 150090;2.哈尔滨工业大学 土木工程学院,哈尔滨 150090)

混凝土及预应力混凝土结构抗火研究现状与展望

郑文忠1,2,侯晓萌1,2,王 英1,2

(1.结构工程灾变与控制教育部重点实验室(哈尔滨工业大学),哈尔滨 150090;2.哈尔滨工业大学 土木工程学院,哈尔滨 150090)

为拓展混凝土及预应力混凝土结构抗火的研究思路与方法,论述了普通钢筋、预应力筋、混凝土等结构材料的抗火性能,凝炼了混凝土及预应力混凝土结构构件的抗火性能,介绍了火灾后混凝土结构加固修复技术,指出了混凝土及预应力混凝土结构抗火研究中存在的一些问题,展望了其发展趋势.分析表明:混凝土高温爆裂临界温度随强度变化而变化,掺钢纤维或聚丙烯纤维可有效防止混凝土火灾下爆裂;合理考虑名义拉应力和混凝土强度影响的爆裂判别方法,可有效降低火灾下预应力结构混凝土爆裂风险;混凝土及预应力混凝土结构应满足火灾时不爆裂、火灾下不坍塌、火灾后可修复的抗火设计目标;火灾下防爆裂混凝土合理纤维掺量、混凝土及预应力结构构件高温爆裂机理及预测模型、活性粉末混凝土(RPC)高温爆裂规律、RPC热-力耦合本构关系及其结构构件抗火性能、温度-荷载路径对结构构件高温性能的影响、高层混凝土结构和地下空间结构抗火性能等方面应予关注.关键词: 钢筋混凝土;预应力混凝土;爆裂;抗火性能;抗火设计

火灾是高频灾种[1-2],中国每年发生建筑火灾约15万起,全世界每年发生建筑火灾约360万起.火灾常导致结构严重损伤甚至坍塌.2003年湖南衡阳衡州大厦在火灾中突然整体坍塌,夺去了20位消防官兵的宝贵生命.2009年央视北配楼火灾、2015年哈尔滨“1.2”火灾,无不影响巨大,损失惨重.混凝土工程量大面广,高温影响材料性能和结构内力,温度和荷载有耦合作用,温度-荷载路径对材料本构关系和构件受力性能有影响,火灾下预应力构件混凝土可能发生爆裂.混凝土及预应力混凝土的研究,经历了由构件到体系,由静力到动力,由一般作用到极端作用的多个阶段.火灾对混凝土及预应力混凝土结构影响研究,成为近年来土木工程行业研究热点之一.世界各国对结构抗火日益关注,结构抗火学会(SIF)是国际上著名的学术团体,该组织定期举行结构抗火学术会议,中国建筑学会结构抗火专业委员会每两年举办一次全国结构抗火研讨会,积极推进中国结构抗火水平的提升.

本文论述了混凝土、预应力混凝土及活性粉末混凝土抗火性能的研究现状,介绍了火灾后混凝土结构加固修复技术,指出了混凝土及预应力混凝土结构抗火研究中尚存的一些问题,并展望了其发展趋势.

1 材料的高温力学性能

1.1 普通钢筋高温力学性能

钢筋的合金成分和生产工艺不同,将导致高温下钢筋力学性能有所差别.高温下,钢筋内部金属晶体结构改变,致使力学性能变化.陆洲导等[3-4]对屈服强度为401 MPa的热轧螺纹钢筋进行了恒温加载试验,发现400 ℃之前钢筋极限抗拉强度下降不明显,温度高于500 ℃后,下降明显,提出了高温下钢筋理想弹塑性的本构关系模型;过镇海等[5]完成了HPB235级、HRB335级、HRB400级和RRB400级普通钢筋恒温加载试验,提出了高温下普通钢筋的极限抗拉强度、屈服强度统一计算式;李明等[6]通过恒温加载试验研究了月牙纹钢筋、光圆钢筋和高强碳素预应力钢丝强度变化规律,发现预应力钢丝极限强度退化快于普通钢筋,提出了高温下预应力损失计算公式,该公式适用于温度不高于500 ℃的情况;王孔藩等[7]完成了光圆钢筋、螺纹钢筋、冷拔钢丝和冷轧扭钢筋恒温加载试验,发现高温下不同种类钢筋极限抗拉强度退化并不相同,冷拔钢丝强度退化更快;吴波等[8]对国内所完成的高温下普通钢筋、钢材的屈服强度进行了统计分析,提出了具有95%保证率的普通钢筋高温屈服强度计算公式.

Ingberg等[9]采用恒温加载试验研究了屈服强度250 MPa的结构钢高温力学性能,获得了其高温下应力-应变关系曲线;Harmathy等[10]完成了ASTM A36(屈服强度246 MPa)、CSA G40.12(屈服强度300 MPa)低碳结构钢及ASTM A421-65 (条件屈服强度1 550 MPa)预应力钢丝的恒温加载试验,获得了3种钢材的高温应力-应变曲线;Lie[11-12]基于上述试验结果,给出了高温下结构钢、热轧钢筋应力-应变曲线计算式,并被美国土木工程协会(ASCE)结构防火手册[13]采纳,但该式钢筋应力-应变曲线无下降段[5,14].

美国混凝土抗火设计规范ACI 216-07[15]给出了高温下热轧钢筋、合金高强钢筋和冷拉预应力筋屈服强度的退化规律.

欧洲混凝土抗火设计规范EC2-1-2[16-17]给出的高温下热轧钢筋、冷拔钢丝受拉应力-应变关系曲线,分为弹性段、非线性段、塑性段和下降段四部分.该公式给出的钢筋极限拉应变(钢筋极限应力对应的应变)及破断点应变(钢筋被拉断时应力对应的应变)与温度无关,这与高温下钢筋应变发展规律不符.Elghazouli等[18]采用恒温加载方法,完成的热轧钢筋、冷拉钢筋的力学性能试验表明,高温下钢筋的屈服强度、极限强度退化与欧洲混凝土抗火设计规范的建议值基本一致,但高温下钢筋极限应变高于规范建议值.

为比较ASCE防火手册、欧洲抗火设计规范给出的高温下普通钢筋受拉应力-应变计算模型的差别,以屈服强度为400 MPa的热轧钢筋为例,高温下其受拉应力-应变曲线见图1.温度为20、300、500、700 ℃时,按ASCE手册计算钢筋受拉应力-应变关系为曲线1、2、3、4;按欧洲抗火设计规范计算钢筋受拉应力-应变关系为曲线5、6、7、8.ASCE防火手册考虑了钢筋受拉强化段,按ASCE防火手册计算常温下钢筋极限强度大于按欧洲抗火设计规范计算值,温度低于500 ℃时,ASCE防火手册给出的钢筋应力-应变曲线强度退化较快.

图1 高温下钢筋应力-应变关系

Fig.1 Stress-strain relationships of reinforcing steel bars under high temperatures by ASCE and EC2-1-2 model

钢筋高温蠕变影响火灾下结构反应.钢材熔点约为1 400 ℃,一般认为,恒载升温状态下,当钢筋温度超过其熔点的30%时,高温蠕变明显,即钢筋温度超过400 ℃时,应合理考虑高温蠕变的影响[19].Dorn[20]基于恒温、恒应力高温蠕变试验,提出了不同种类结构钢高温蠕变模型.Harmathy[21]对Dorn高温蠕变模型进行了修正,期望使之适用于变应力状态下结构钢的高温蠕变计算,Dorn-Harmathy模型经参数标定后也可用于计算钢筋高温蠕变[22].Kodur等[23]研究表明:当用Dorn-Harmathy模型计算变应力状态下结构钢、钢筋的高温蠕变时,会产生较大偏差.过镇海等[5]完成了HRB335级钢筋应力水平为0.2~0.8,温度为200~600 ℃的高温蠕变试验.

国内外对普通钢筋高温性能的研究表明,温度不高于200~300 ℃时,普通热轧钢筋的屈服强度、极限强度基本不降低,温度超过400 ℃时,钢筋的屈服强度、极限强度急剧降低,600 ℃时,屈服强度、极限强度分别为常温下强度的30%、45%.钢筋强度退化规律有一定差别,这可能是钢筋合金成分、生产工艺(产地)[24]及试验条件的差别所致.不同文献给出钢筋应力-应变计算模型有一定差异,部分模型的计算应变与高温下钢筋实际应变不符,因此,在进行结构抗火分析时,应合理选择钢筋应力-应变计算模型.

1.2 预应力筋高温力学性能

中国每年有逾百万吨高强预应力钢丝/钢绞线用于预应力工程建设,预应力钢丝/钢绞线抗火性能是预应力结构抗火性能的关键影响因素之一.

Day等[25]对预应力钢丝进行了恒载升温和高温蠕变试验,结果表明,预应力钢丝应力水平(拉应力与极限抗拉强度之比)为0.6时,温度升高至400 ℃,钢丝被拉断,高温蠕变引起较大的预应力损失;Abrams等[22]进行了预应力钢绞线(抗拉强度标准值fptk=1 860 MPa)恒温加载试验,获得了高温下钢绞线极限抗拉强度退化规律,结果表明:温度为427 ℃时,钢绞线极限抗拉强度降低至50%;过镇海等[5]采用恒温加载方法,完成了用于预应力混凝土结构的消除应力钢丝(直径5 mm,条件屈服强度为1 274 MPa)高温性能试验,提出了高温下消除应力钢丝应力-应变计算公式,发现与HPB235~RRB400级普通钢筋相比,消除应力钢丝极限抗拉强度退化更快,故应更重视预应力混凝土结构的抗火性能;范进等[26-27]进行了预应力钢丝(fptk=1 670 MPa)、钢绞线(fptk=1 860 MPa)的恒温加载试验,获得了其极限强度、条件屈服强度和弹性模量随温度的变化规律;陈礼刚等[28-29]完成了fptk=1 570 MPa预应力钢丝、fptk=1 410 MPa预应力钢丝、77B螺旋肋钢丝(fptk=1 120 MPa)和LL650 冷轧带肋钢丝(fptk=650 MPa)恒温加载和恒载升温试验,提出了高温下预应力钢丝应力-应变关系曲线的二折线模型.发现经过冷拔和回火热处理后的fptk=1 570 MPa预应力钢丝、fptk=1 410 MPa预应力钢丝和77B螺旋肋钢丝,高温下强度下降更快,这主要是当温度高于300 ℃以后,热处理所造成的金属晶体框架的畸变逐渐被解除,热处理作用基本消失所致.此外,恒载升温路径下,经热处理钢丝的极限抗拉强度略高于恒温加载路径下钢丝的强度,而两种路径下LL650冷轧带肋钢丝强度基本一致,这主要是恒温加载路径减弱了钢筋热处理作用所致.

PC钢棒(fptk=800 ~970 MPa)是近年来发展的新型预应力钢种.侯晓萌等[30]完成了PC钢棒高温下力学性能试验,建立了其高温下应力-应变计算公式,发现高温下PC钢棒强度退化慢于预应力钢丝,这主要是PC钢棒中锰、钒含量较高,提高了其耐火性能所致.为揭示火灾下低松弛高强预应力钢丝的本构模型,郑文忠等[31-32]采用恒温加载方法,完成了fptk=1 770、1 860 MPa的低松弛高强预应力钢丝的高温力学性能试验,基于试验结果建立了两种强度级别的高温下低松弛高强预应力钢丝的本构关系.热轧钢筋、PC钢棒、预应力钢丝高温下极限强度退化见图2.

图2 高温下不同钢筋极限抗拉强度退化规律

Fig.2 Comparison of ultimate tensile strength of different reinforcing steel bars under high temperatures

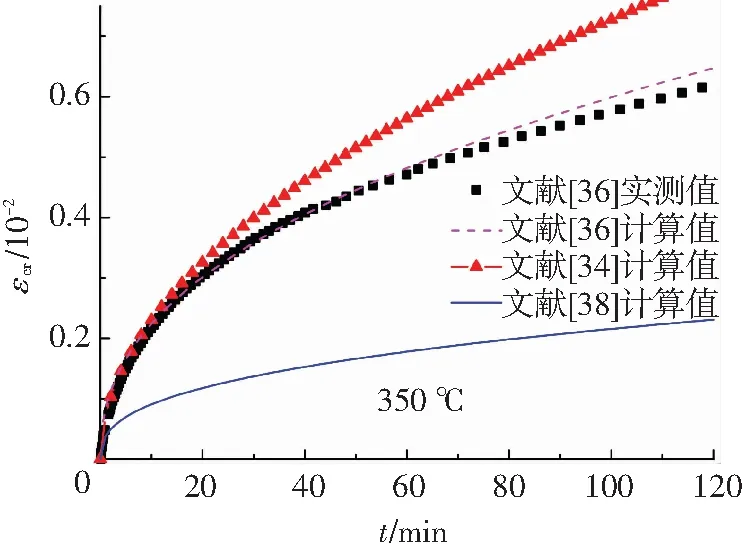

火灾下预应力结构的钢丝、钢绞线处于高应力状态,产生显著的应力松弛(或蠕变)[33],使结构中预应力明显降低,变形增大.华毅杰[34]、蔡跃等[35]进行了fptk=1 570 MPa预应力钢丝的高温拉伸和高温蠕变(εcr)试验,提出了高温蠕变计算公式.

为揭示火灾下预应力筋应力、应变变化规律,张昊宇等[36]开展了52个fptk=1 770 MPa低松弛高强预应力钢丝试件的高温蠕变试验、应力松弛试验,提出了低松弛高强预应力钢丝的高温蠕变、高温松弛计算公式.

周焕廷等[37-38]开展了高温下预应力钢绞线(fptk=1 860 MPa)强度、蠕变性能试验,并提出了钢绞线高温蠕变计算公式.发现预应力钢丝高温蠕变低于钢绞线高温蠕变,这主要是钢绞线捻制完成之后,又经历一次回火所致.

文献[34-38]均是基于恒温、恒应力下的高温蠕变试验结果,提出的预应力钢丝/钢绞线高温蠕变计算公式,且公式计算结果差异较大.以fptk=1 770 MPa的预应力钢丝/钢绞线为例,常温下应力为751 N/mm2、温度为350℃时,文献[34,36,38]给出的高温蠕变计算值和实测值对比见图3.用预应力钢丝高温蠕变公式计算钢绞线高温蠕变,将偏于保守.

图3 预应力钢丝/钢绞线高温蠕变计算值和实测值对比

Fig.3 Comparison of creep curves of prestressing steel wires/stands under high temperatures

为研究温度-荷载路径对预应力混凝土结构受力性能的影响,郑文忠等[39]考虑了低松弛高强预应力钢丝温度变化过程中蠕变、温度膨胀、应力变化及变形模量变化对钢丝应变的影响,将任意温度-荷载路径分解为恒温加载和恒载升温两种路径,建立了高温下低松弛高强预应力钢丝考虑温度-时间路径的应变和应力计算方法.

1.3 混凝土高温力学性能

国内外学者对高温下混凝土的抗压强度、弹性模量、抗拉强度、本构关系、高温膨胀、高温徐变、瞬态热应变等进行了研究.对高温下普通混凝土(混凝土强度等级≤C50,NSC)力学性能的研究表明[5,40-46]:在温度低于150 ℃时,混凝土强度降低,在温度为150~300 ℃时,混凝土抗压强度稍有提高,甚至大于常温下强度,温度大于400 ℃时,混凝土强度快速下降.

Thienel等[47]研究了高温下NSC双轴受压时的本构关系,结果表明,高温下双轴受压强度高于单轴受压强度,双轴受压强度退化规律与单轴受压强度退化规律相似.高温下混凝土抗压强度与混凝土骨料、配合比、升温速率、应力水平等有关[48-49].高温与荷载作用下,混凝土游离水先被蒸发,在200 ℃左右,结合水开始分解,在350 ℃左右,发生硅酸钙和铝酸钙等脱水,在550 ℃左右,氢氧化钙开始分解,导致水泥石破坏.针对这一问题,Gawin等[50]建立了化学反应-温度-应力混凝土本构数值模型,但模型需要高温下混凝土渗透系数张量、热扩散率张量等众多参数,即使是常温下,这些参数还难以准确确定.

近年来,不少学者对高温下高强混凝土(C55-C95,HSC)力学性能进行了研究[51-52],高强混凝土掺入矿渣粉、硅灰等,与NSC相比,微观结构更为致密,高温下易发生爆裂[53-54].高温下NSC、HSC抗压强度随温度变化归一化曲线见图4.其中,文献[5]采用100 mm×100 mm×300 mm棱柱体试件,棱柱体抗压强度15~35 MPa,文献[43-45]分别采用φ75 mm×150 mm、φ51 mm×102 mm和φ80 mm×300 mm圆柱体试件,圆柱体抗压强度分别为28、31和33 MPa,文献[45,51-52]分别采用φ80 mm×300 mm、φ50 mm×100 mm和φ100 mm×310 mm圆柱体试件,圆柱体抗压强度分别为107、69~118和60 MPa.

图4 高温下混凝土抗压强度随温度变化

Fig.4 Variation with temperature of concrete compressive strength under high temperatures

NSC抗拉强度约为抗压强度的10%,而HSC抗拉强度与抗压强度之比更小.火灾下混凝土抗拉强度对结构构件的受弯承载力贡献极小[5],但混凝土抗拉强度影响构件的开裂,对混凝土的高温爆裂性能也有显著影响[54].过镇海等[5]给出的NSC抗拉强度随温度升高而线性降低(20~1 000 ℃).高温下HSC混凝土抗拉强度退化规律与NSC相似,但还受到纤维种类和掺量的影响,有待进一步研究.

受混凝土强度、骨料类型、混凝土配合比、养护条件、升温条件的影响,不同学者给出的高温下混凝土力学性能试验结果有一定差异,但宏观变化趋势一致:随着温度的升高,混凝土弹性模量的降低速率通常比强度更大[55],混凝土的峰值应变逐渐增大,混凝土的单轴应力-应变曲线趋于扁平.

高温下混凝土应变主要包括应力引起的应变、自由膨胀应变、高温徐变和瞬态热应变.混凝土在持续应力作用下发生徐变.混凝土的高温徐变远大于常温徐变,Bazant等[56]、Harmathy等[57]开展了混凝土高温徐变研究,但最高温度为140 ℃,不能满足混凝土结构抗火分析需要.Khoury[58]提出了混凝土高温徐变计算公式,高温徐变随受火时间、应力水平的增加而增大.过镇海等[5]基于恒温、恒应力状态下的NSC高温徐变试验结果,提出了混凝土高温徐变计算模型(适用于温度不大于700 ℃,应力水平不大于0.6的NSC),并引入了等效时间,使其可用于恒温-变应力状态下的徐变计算,但混凝土高温徐变计算值明显小于按文献[58]的计算值,这可能是混凝土骨料类型、配合比、试件尺寸等差异所致.混凝土强度等级对高温徐变的影响还有待于进一步研究[59].

高温下混凝土无应力时的伸长为自由膨胀变形,在压应力作用下,混凝土高温变形可能伸长或缩短,将混凝土压应力作用下的变形与自由膨胀变形的差值,定义为瞬态热应变.瞬态热应变与混凝土常温下应力水平和自由膨胀相关,发生的机理尚不清楚.Anderberg等[60]、南建林等[61]分别给出了NSC瞬态热应变计算公式,温度大于200 ℃时,瞬态热应变可达混凝土高温徐变的数倍.胡海涛等[62-63]给出了HSC瞬态热应变计算公式,结果表明随混凝土强度提高,瞬态热应变降低.过镇海等[5]研究了恒温加载和恒载升温两种基本温度-荷载路径下混凝土的力学性能退化规律,基于这两种基本路径,将混凝土高温应变进行分解,提出了混凝土温度-应力耦合本构关系.高温徐变、瞬态热应变会影响结构变形,且受火时间越长,影响越显著;对超静定结构,还将影响结构的极限荷载,因此应在结构抗火设计时予以重视.

2011年,中国颁布第一本混凝土结构耐火设计技术规程[55],规程中高温下普通钢筋屈服强度、弹性模量计算公式采用了文献[8]的研究成果;预应力筋极限强度、高温应力松弛和高温蠕变计算公式分别采用了文献[31-32,34]的研究成果;NSC和HSC高温力学性能分别采用了文献[5,63]的研究成果.

1.4 混凝土高温爆裂

高温下混凝土可能发生爆裂.爆裂不仅导致受力钢筋暴露于烈火之中,而且使构件受力截面减小,结构耐火性能急剧降低.如何实现火灾下混凝土不爆裂,一直是混凝土结构抗火研究所关注的问题.混凝土高温爆裂机理仍有争议[64].蒸汽压力理论认为高温下混凝土内部水蒸汽难以逃逸,混凝土孔隙内部产生蒸汽压力,当蒸汽压力超过混凝土的抗拉强度时发生爆裂.热应力理论认为,高温下混凝土变形受到约束而产生热应力,热应力超过混凝土抗拉强度时,发生爆裂.

吴波[65]对混凝土高温爆裂的研究表明,混凝土表面温度在200~500 ℃时,易发生爆裂.为研究纤维种类和掺量对HSC柱爆裂性能的影响,Kodur等[66]完成了4根HSC(标准立方体抗压强度81~108 MPa)和1根NSC方柱四面受火试验,结果表明:掺0.54%钢纤维或0.1%掺聚丙烯(PP)纤维可缓解HSC高温爆裂,钙质骨料HSC较硅质骨料HSC爆裂程度低,这主要是由于温度大于600 ℃时,钙质骨料发生分解,导致混凝土比热容增大,进而降低爆裂所致;编制了考虑高温爆裂影响的HSC柱抗火性能分析程序[67],提出混凝土爆裂临界温度为350 ℃,为抗火分析中考虑混凝土高温爆裂提供了基础.Xiao等[68]研究表明:强度等级为C50、C80、C100的混凝土,爆裂临界温度分别为800、400、500 ℃.以上研究表明爆裂临界温度随着混凝土强度和组成的变化而变化.

为避免混凝土高温爆裂,不少学者建议掺PP纤维(纤维长度6~30 mm,直径50~200 μm)以避免混凝土高温爆裂,掺PP纤维混凝土在美国、欧洲、日本等得到了应用[69-70].研究表明,温度为160~170 ℃时,PP纤维熔化,在混凝土内形成水蒸汽逃逸的孔道,可减缓混凝土爆裂.例如,对强度等级C60-C80混凝土,添加不少于2 kg/m3的短切PP纤维可避免爆裂[55],欧洲混凝土抗火设计规范(EC2-1-2)[16]建议,对标准立方体抗压强度73~113 MPa的混凝土,添加不少于2 kg/m3的PP纤维可避免爆裂.

针对掺PP纤维会降低混凝土和易性及常温下抗压强度的问题,不少学者提出在混凝土内合理单掺钢纤维,不仅可防止混凝土高温爆裂,还可以提高混凝土强度;钢纤维在混凝土中是随机分散的,具有较大的热传导性,有利于混凝土内部各处温度的传递,可以减少应力造成的内部损伤,由此减缓混凝土爆裂风险.Chen等[71]研究表明:标准立方体抗压强度为85 MPa的混凝土,掺0.6%钢纤维可推迟初爆时刻,但仍发生爆裂;Poon等[72]研究表明:标准立方体抗压强度为79~105 MPa的混凝土,掺1%钢纤维,可防止高温爆裂.

事实上,防爆裂用纤维掺量应随着混凝土抗压强度的变化而变化.应进一步研究不掺纤维或低纤维掺量的混凝土爆裂临界温度,防止火灾下不同强度的混凝土爆裂,所需PP纤维或钢纤维适宜掺量.

1.5 活性粉末混凝土高温性能

Richard等[73]研制了一种超高强水泥基复合材料,以细度较大的石英砂(粒径小于0.6 mm)代替粗骨料,由于掺入了具有较高活性的火山灰质材料,被称为活性粉末混凝土(RPC),其抗压强度可达800 MPa[73-75].RPC(100 mm×100 mm×100 mm立方体抗压强度标准值不低于100 MPa)受到其抗火性能的严峻挑战,制约了RPC的发展与应用.2010年以来,国内外学者对RPC材料的高温性能进行了探索.Ju等[76]实测了常温至250 ℃时,钢纤维RPC热工参数,结果表明:RPC导热系数低于NSC.郑文忠等[77]实测了常温至900 ℃时掺纤维RPC热工参数,发现RPC导热系数高于NSC和HSC,且高温下RPC热工参数受其组成成分的影响.

刘红彬[78]完成了钢纤维体积掺量为0%、1%和2%的RPC高温爆裂试验,结果表明:100 mm×100 mm×100 mm立方体试件中心温度为250 ℃时,RPC发生爆裂,钢纤维对RPC爆裂临界温度的提高效果不明显,但可降低RPC爆裂程度;陈强[79]研究表明:RPC初爆温度为420~583 ℃,随湿含量的增加,RPC爆裂概率和爆裂损伤程度逐渐增大,湿含量(试件所含可蒸发水的质量与试件饱水状态下所含可蒸发水的质量比)低于63%时,水胶比由0.16增大至0.20时,试件爆裂概率降低,这主要是由于水胶比增大,RPC强度降低、渗透性降低所致;郑文忠等[80-81]通过试验研究了含水率、升温速度、试件尺寸、防火涂料、恒温时间和纤维种类及掺量对RPC高温爆裂性能的影响,发现未施加荷载时,单掺2%钢纤维RPC(试件尺寸为70.7 mm×70.7 mm×70.7 mm)爆裂临界含水率为0.85%;合理涂抹防火涂料可防止高温下RPC爆裂.在RPC不爆裂的基础上,采用恒温加载方法,研究了高温下钢纤维体积掺量分别为1%、2%和3%的RPC力学性能,结果表明:随温度升高,钢纤维RPC棱柱体抗压强度和弹性模量迅速下降,峰值应变逐渐升高,200、400、600和800 ℃时钢纤维RPC的抗压强度分别降为常温时的76%~82%、53%~62%、33%~42%和14%~19%,提出了高温下钢纤维RPC单轴受压本构模型.Aydin等[82]进行了20~800 ℃下两种类型RPC高温力学性能试验,研究表明:温度超过300 ℃时常规RPC易爆裂,而高温下碱矿渣RPC不爆裂,其耐火性能优于常规RPC.Canbaz[83]的研究表明:先对RPC施加80 MPa压应力,再用90 ℃热水养护3天,常温下RPC强度可达200 MPa,掺1%的PP纤维降低了RPC强度,但可避免高温下爆裂.Ju等[84]用COMSOL软件分析了高温下RPC热应力,采用主拉应力和Von Mises应力判别RPC高温爆裂,为环境温度20~500 ℃的RPC爆裂预测提供了参考,但该数值模型未考虑高温下RPC蒸气压力对爆裂的影响,假定RPC发生塑性变形后,应力不再变化,这一假定尚缺乏试验验证,爆裂判别方法的适用性还有待商榷.

国内外对RPC高温性能的研究表明,高温下RPC易发生爆裂,一般通过掺钢纤维或PP纤维来避免高温爆裂.RPC构件抗火性能的试验研究尚未见报道.

2 混凝土结构抗火性能

在材料高温性能研究的基础上,国内外学者开展了钢筋混凝土构件抗火性能试验研究,取得如下成果.

2.1 高温下钢筋与混凝土间粘结性能

钢筋与混凝土间的可靠粘结性能是两者共同工作的基础.Diederichs等[85]、Morley等[86-87]完成了20~800 ℃高温下中心拔出试验,结果表明:钢筋与混凝土间粘结强度随温度升高而降低,退化规律与混凝土抗拉强度相似.火灾下变形钢筋粘结强度退化慢于光圆钢筋粘结强度退化,光圆钢筋粘结强度退化快于混凝土抗拉强度的退化.袁广林等[88]研究表明:受热温度不超过450 ℃时,粘结强度下降不超过20%;受热温度达到650 ℃时,高温下试件的粘结强度约下降40%.胡克旭[89]完成了高温下中心拔出试验,获得了不同温度下的钢筋-混凝土的粘结-滑移曲线,分别给出了火灾下光圆钢筋、变形钢筋与混凝土粘结强度退化影响系数计算式.

Huang[90]、Gao等[91]建立了考虑火灾下钢筋-混凝土粘结滑移影响的有限元模型,分析了火灾下钢筋混凝土梁截面应力、跨中变形.结果表明:若忽略火灾下钢筋-混凝土粘结滑移的影响,混凝土梁、板变形计算值可能偏小.

这里需要指出,由于混凝土的组分不同,不同学者间给出的高温下钢筋与混凝土间粘结强度退化离散较大.

2.2 混凝土板抗火性能

1950年以来,国内外学者开展了钢筋混凝土简支板耐火极限的试验研究,考察了保护层厚度、板厚、荷载水平对耐火极限的影响.基于ASTM119标准升温曲线,以背火面混凝土平均温度超过121 ℃或任意点温度超过163 ℃作为板耐火极限的标志,Thompson[92]完成了荷载水平为0.5、计算跨度为3 650 mm、板厚为150 mm的钢筋混凝土简支板耐火试验,该板耐火极限大于3 h.Gustaferro等[93-94]的研究表明:梁、板支座约束可提高其耐火极限;膨胀页岩轻质骨料混凝土耐火性能高于普通硅质、钙质骨料混凝土;混凝土含水率越高,由温度控制的板耐火极限越长.混凝土板背火面设置多孔混凝土、珍珠岩混凝土或蛭石混凝土等防火措施,可提高板的耐火极限,且混凝土密度越低,耐火极限越高[95].Lie[96]编制了混凝土板温度场计算程序,给出了由温度控制的板耐火极限计算式,结果表明:随板厚、保护层厚度的增大,板耐火极限增大.陈正昌[97]完成了混凝土空心简支板抗火性能试验,结果表明:相同板厚、相同承载力的钢筋混凝土空心板耐火性能优于预应力空心板,保护层厚度增加、荷载水平降低,耐火极限增大.

2004年以来,国内外学者开始进行混凝土连续板、双向板抗火试验与数值模拟.陈礼刚等[98-100]完成了6块三跨钢筋混凝土连续板抗火试验,分别研究了边跨受火、中跨受火和相邻两跨受火下板的支座反力变化规律,结果表明:火灾下连续板发生明显内力重分布,在负弯矩钢筋截断处出现集中裂缝.Bailey等[101]完成了48块钢筋混凝土简支双向板抗火性能试验,发现常温下混凝土被压碎的试验板,火灾下因钢筋被拉断而破坏,这是由于钢筋高温下强度降低,由适筋板变为少筋板所致.

王滨等[102-103]完成了2块四边简支和1块四边固支钢筋混凝土双向板抗火性能试验,结果表明:四边固支双向板在板顶出现椭圆形裂缝.杨志年等[104]对3层3×3跨钢框架三层顶角部钢筋混凝土双向板进行了抗火试验,双向板受火面积为4.2 m×4.2 m.王勇等[105]对该钢框架二层2×2区格双向板进行了抗火试验,受火面积为8.4 m×8.4 m,结果表明:相邻构件的约束作用提高了钢筋混凝土双向板抗火性能.

为模拟混凝土双向板火灾反应,Huang等[106-108]考虑了几何非线性和材料非线性的影响,提出了火灾下混凝土双轴破坏判别准则,编制了考虑火灾下板薄膜效应有限元程序.Zhang等[109]编制了双向板火灾反应分析程序,结果表明轴向约束能减少火灾下双向板的变形,但分析过程中未考虑混凝土瞬态热应变、高温徐变的影响.Wang等[110]提出了火灾下双轴受力混凝土瞬态热应变的计算方法,并编制了双向板抗火性能有限元分析程序,与Huang等[106]方法相比,火灾下双向板变形计算值与实测值吻合更好.

2.3 混凝土梁抗火性能

Ellingwood等[111-113]完成了6根钢筋混凝土伸臂梁抗火试验,实测了火灾下混凝土梁温度场分布,获得了基于ASTM119标准升温曲线和高强度火灾[111]两种升温曲线下混凝土梁变形,发现不同升温条件对钢筋混凝土梁变形有明显影响,基于火灾下混凝土、钢筋热工参数和应力-应变关系,编制了火灾下钢筋混凝土梁变形分析程序,但变形计算值小于实测值.Dotreppe等[114]、Wu等[115]也开展了火灾下钢筋混凝土简支梁、板抗火性能试验与数值模拟.

Lin等[116]完成了11根单跨两端伸臂梁抗火试验,结果表明:由于梁下部区域的膨胀变形大于梁的上部区域,使梁顶拉应力增大,进而使得火灾下梁支座负弯矩增大,结构抗火设计时应合理考虑火灾下内力重分布的影响.过镇海等[5]完成了拉区受火、压区受火钢筋混凝土梁力学性能试验,结果表明,压区受火适筋梁极限荷载降低慢于拉区受火,提出了高温下梁板受弯承载力简化计算方法;完成了4根双跨升温、2根单跨升温的两跨钢筋混凝土连续梁抗火性能试验,实测了不同荷载水平下连续梁支座反力变化,发现连续梁抗火性能优于简支梁.陆洲导等[117]完成了12根钢筋混凝土简支梁一面、二面、三面受火试验,计算了高温下简支梁弯矩-曲率关系和跨中变形,发现当荷载水平大于0.5时,简支梁耐火极限降低明显.冯雅等[118]提出了考虑火灾下混凝土湿热变化的温度场数值模拟方法,并得到试验结果的验证.向延念等[119]、张威振[120]利用电炉完成了8根b×h=250 mm×400 mm钢筋混凝土简支梁抗火试验与数值分析,结果表明:在一定受火时段内,随受火时间延长,纵向受拉钢筋应力增大.时旭东等[121]完成了12根钢筋混凝土简支梁抗火试验,其中6根为恒温加载路径,6根为恒载升温路径,结果表明:温度-荷载路径不仅影响构件截面应力分布,而且影响结构极限荷载.

苗吉军等[122]完成了7根带初始裂缝的钢筋混凝土简支梁抗火性能试验,结果表明:初始裂缝宽度越大,梁耐火性能越差;考虑初始裂缝对梁截面温度场的影响,提出了带裂缝梁受弯承载力简化计算方法.该方法同样适用于研究经氯离子侵蚀后带裂缝钢筋混凝土梁抗火性能[123].查晓雄等[124-125]完成了4根GFRP筋混凝土简支梁在ISO834标准升温曲线下受力性能试验,高温下GFRP筋抗拉强度退化快于普通钢筋,GFRP筋混凝土梁裂缝开展高度明显大于钢筋混凝土梁.

钢筋混凝土梁抗火性能数值模拟通常采用以下两种方法:一种是基于截面弯矩-曲率关系,分析火灾下梁反应[96,117,126],该方法可较方便揭示截面承载力退化规律;一种是有限元分析方法[114,127-129].Kodur等[126]基于截面分析方法,提出了考虑混凝土高温徐变、瞬态热应变和钢筋高温蠕变影响的简支梁抗火性能数值模拟方法,分析了荷载水平、升温条件、混凝土保护层厚度对梁抗火性能的影响,结果表明:以受拉钢筋温度超过593 ℃或梁达到承载能力极限状态计算确定耐火极限,可能大于变形控制的耐火极限.

实际工程中构件可能受到不同程度的边界约束,Dwaikat等[130]提出了火灾下考虑支座约束和混凝土高温爆裂影响的钢筋混凝土梁抗火性能数值分析方法,但该程序假定混凝土爆裂临界温度为350 ℃,未考虑不同混凝土爆裂温度不同的影响;Dwaikat等[131-132]完成了2根NSC梁和4根HSC梁抗火性能试验,其中NSC和HSC梁中各有一根施加端部轴向约束.结果表明:带轴向约束梁耐火极限高于简支梁;HSC梁耐火极限低于NSC梁,与NSC相比,火灾下HSC爆裂更严重;吴波等[133-134]通过8根同时具有端部轴向和转动约束的混凝土梁抗火试验和3 744种工况的计算分析,考察了端部约束梁升降温全过程轴力及梁端弯矩的变化,提出了相应的实用计算方法;徐明等[135]等完成了3根超高韧性水泥基复合材料(ECC,抗压强度实测值34.6 MPa)约束梁和3根钢筋混凝土(抗压强度实测值29.8 MPa)约束梁耐火性能试验,结果表明:跨度相同、截面相同、截面承载力相同的ECC梁截面温度低于钢筋混凝土梁,ECC约束梁跨中变形、跨中及支座截面弯矩均小于钢筋混凝土梁.

2.4 混凝土柱抗火性能

1976年以来,美国硅酸盐水泥协会和加拿大国家研究院合作,完成了31根轴压柱和6根偏压柱在ASTM 119标准升温曲线下四面受火试验[136-138],结果表明:钙质骨料混凝土柱耐火性能优于硅质骨料混凝土柱;截面尺寸、柱端约束是影响柱抗火性能的主要因素;截面尺寸越小、荷载水平越高、纵筋配筋率越低,耐火极限越低.轴向荷载水平相同时,偏压柱耐火极限低于轴压柱.Dotreppe等[139]完成了6根NSC轴压柱在ISO 834标准升温曲线下四面受火试验,提出了火灾下轴压柱承载力简化计算公式.过镇海等[5]完成了三面、二面受火NSC轴压柱、偏压柱抗火性能试验,揭示了该类柱火灾下轴向变形和侧向变形发展规律,给出了高温下极限轴力-弯矩包络图;发现三面受火轴压柱发生偏心受压破坏,恒载升温柱极限轴力大于恒温加载柱,两面受火柱抗火性能优于三面受火柱.Tan等[140-141]提出了一面至四面受火NSC轴压、偏压柱耐火极限简化计算方法.

2003年以来,国内外学者进行了HSC柱抗火性能试验与数值模拟.为研究箍筋形式对HSC柱爆裂的影响,Kodur等[142]完成了6根HSC(28 d圆柱体强度81~107 MPa)轴压方柱四面受火试验,结果表明:截面尺寸为305 mm×305 mm、406 mm×406 mm的方柱,当箍筋末端做成90°弯钩时(箍筋2φ8,间距406 mm,屈服强度414 MPa),混凝土全截面均可能爆裂;当箍筋末端做成135°弯钩时(箍筋为2φ6,间距为76~152 mm),仅箍筋外侧混凝土发生爆裂,而核心区混凝土不爆裂;加密箍筋间距,可减轻爆裂.吴波等[143]完成了5根HSC方柱(混凝土棱柱体强度66~74 MPa)和2根NSC(混凝土棱柱体强度33 MPa)方柱四面、三面和两面受火试验,结果表明,随受火面的增加,柱耐火极限降低,相同条件下HSC柱的耐火极限低于NSC柱,这主要是由于HSC柱高温爆裂更严重所致;建立了HSC方柱耐火极限和火灾下正截面承载力计算式[144].完成了4根端部约束高强混凝土柱抗火试验[145],揭示了端部约束柱火灾行为时变机理,提出了火灾下考虑端部约束影响的柱轴力和弯矩计算方法,发现适当增大端部约束可提升HSC柱的耐火性能.

异形柱表体比大,受火时其内部温度相对常规柱上升更为迅速.针对这一问题,Xu等[146]进行了12根NSC(试验当天混凝土棱柱体强度35~38 MPa)异形柱的抗火试验以及6 632种工况的高温反应分析,考察了荷载水平、荷载角、计算长度、偏心率等对异形柱耐火性能的定量影响,研究了高温下异形柱广义中性轴位置、极限承载力、极强中心、极限轴力-弯矩包络图等的演变趋势,提出了混凝土异形柱的耐火设计方法.吴波等[147]完成了16根端部约束异形柱的抗火试验和8 331种工况的计算分析.实现了可同时在柱伸长和缩短阶段施加端部约束的异形柱全过程明火试验,突破了以往只在柱伸长阶段施加约束而无法在柱缩短阶段实施约束的局限.揭示了端部轴向和转动约束对异形柱高温行为的影响规律,建立了定常端部约束下异形柱高温下轴力和弯矩时变过程的定量描述,并拓展至了非定常端部约束情况.

2.5 混凝土结构抗火性能

过镇海等[5]完成了5榀单层单跨钢筋混凝土框架三面受火试验,实测了火灾下框架梁、柱变形和框架柱内力,结果表明,混凝土框架火灾下发生明显的内力重分布;基于平截面假定,给出了混凝土、钢筋热-力耦合本构关系,推导了适用于任意温度-荷载路径的平衡方程,编制了杆系有限元析程序NARCSLT.陆洲导等[148]完成了5榀单层双跨混凝土框架在600 ℃、800 ℃单跨受火、双跨受火试验,编制了火灾下框架受力性能的非线性分析程序.Bailey[149]在Cardington建筑结构实验室完成了7层混凝土平板柱底层局部受火试验,平板柱横向为3×7.5 m,纵向为4×7.5 m,底层层高4.2 m,其余各层层高3.75 m,中柱截面尺寸为400 mm×400 mm,边柱截面尺寸为250 mm×400 mm,板厚250 mm,作用荷载为9.25 kN/m2.底层局部受火区域为沿横向两个柱距、沿纵向中间两个柱距所辖区域,面积为15 m×15 m.板混凝土28 d立方体抗压强度实测值为61 MPa,含水率为3.8%.火灾下板混凝土爆裂,导致试验设备损坏,仅获得了受火25 min内混凝土楼板中心点的变形值.结果表明:火灾下板迎火面混凝土爆裂面积超过75%,部分受力钢筋被烧断,但由于双向板薄膜效应的有利影响,板并未坍塌.刘永军[150]建立了高温下混凝土双轴应力下的本构模型,开发了平面应力单元和杆单元,编制了非线性有限元分析程序STRUFIRE,实现了钢筋混凝土梁、板、框架的抗火性能分析.吴波等[151]编制了混凝土框架杆系有限元分析程序,并完成了单层3跨钢筋混凝土框架的火灾反应分析,结果表明:火灾下框架梁轴力和梁端弯矩变化明显.陈适才等[152]推导了梁单元非线性应变位移矩阵,编制了基于纤维梁模型的混凝土框架火灾反应非线性分析程序,分析了三层三跨混凝土平面框架的火灾反应,结果表明:受火位置不同,框架结构破坏形式不同.闫凯等[153-154]应用ABAQUS有限元软件,引入考虑材料各向异性的砖砌体弹塑性模型,建立了底部框架砖房抗火性能有限元模型,结果表明:火灾下框架梁轴向膨胀变形和向下挠曲变形对墙拱传力机制不利,使框架梁轴向压应力显著增大,加速边柱顶端外侧纵向钢筋受拉屈服,内侧混凝土被压碎.

以上研究表明,荷载水平、截面尺寸、保护层厚度、配筋型式及约束条件、混凝土强度、骨料种类、升温条件及受火位置和区域、混凝土爆裂等均影响混凝土结构抗火性能.尽管相关规范[16]对混凝土结构耐火极限做出了规定,但一方面规范考虑的影响因素较少,一方面是这些规定仅适用于混凝土不爆裂的情况.

3 预应力混凝土结构抗火性能

预应力混凝土结构跨度大、截面小、功能好,近30年来在中国得到了迅速发展.然而,由于火灾下预应力筋强度损失大、应力退化快,火灾引起的预应力混凝土内部的水蒸汽难以逃逸,混凝土具有受火爆裂易发性;因爆裂而暴露于烈火之中的钢筋迅速退出工作,结构可能会突然失效.预应力混凝土耐高温性能和抗火设计受到关注.

3.1 预应力混凝土结构构件抗火性能

1953年,Ashton等[155]完成了37根缩尺有粘结预应力T形NSC梁恒载升温试验,升温曲线接近ISO 834 标准升温曲线,实测了火灾下预应力钢丝、混凝土温度变化,结果表明:钢丝的升温速率对梁受弯承载力有显著影响,当张拉控制应力与极限抗拉强度之比为0.6,钢丝温度超过400 ℃时,预应力混凝土梁发生正截面承载力破坏;部分试验梁因混凝土爆裂而破坏更早.Gustaferro等[156]完成了按ASTM 119标准升温曲线升温的11块有粘结预应力混凝土简支板抗火性能试验,以火灾下板达到正截面承载力极限状态的时刻作为耐火极限,结果表明:其他条件相同时,膨胀页岩轻骨料混凝土板耐火极限高于NSC板(φ152 mm×305 mm圆柱体抗压强度24 MPa),预应力筋保护层厚度越大、荷载水平越低,板耐火极限越长.Abrams等[157]研究了不同种类和厚度的防火涂料对预应力混凝土简支板、双T梁、T形梁抗火性能的影响,结果表明:喷涂防火涂料可有效提高预应力混凝土简支构件耐火性能,火灾下防火涂料与混凝土粘结性能较好,给出了对应2 h、3 h耐火极限的防火涂料厚度建议值.Joseph等[158]完成了无粘结预应力混凝土板的试验,研究了预应力筋保护层厚度、荷载和端部约束对板耐火性能的影响.

Herberghen等[159]完成了8块两端伸臂无粘结预应力混凝土板抗火性能试验,发现火灾下预应力板混凝土爆裂,配置纵横向非预应力钢筋的板爆裂程度小于全预应力板,提出了增配支座负弯矩钢筋的建议.袁爱民等[160]完成了4块无粘结预应力混凝土简支板抗火性能试验,结果表明:保护层厚度越大,板耐火极限越长,预应力度(0.4~0.6)对板的耐火极限影响不明显.Bailey等[161-162]进行了后张无粘结预应力混凝土单向板抗火性能试验,研究了钙质骨料和硅质骨料、板端自由转动和固定两种边界条件对其抗火性能的影响,结果表明:火灾下硅质骨料试验板变形大于钙质骨料板,板端自由转动较固定的板变形大,无粘结预应力板的耐火极限高于相关抗火规范BS 8110的规定[163].

袁爱民等[164-167]完成了9块三跨无粘结预应力混凝土板边、中跨同时受火、边跨受火和中跨受火试验,考察了预应力度、负筋长度等因素对无粘结预应力混凝土连续板耐火性能的影响,结果表明,不同跨受火对无粘结预应力混凝土连续板的抗火性能有重要影响,热膨胀是火灾初期第一内支座两侧控制截面弯矩增大的主要原因.王中强等[168-169]完成了26根无粘结预应力混凝土简支扁梁抗火性能试验,并编制了无粘结预应力混凝土梁抗火性能非线性分析程序NAUPCLF,结果表明:荷载水平越大,综合配筋指标(0.38~0.87)越小,扁梁抗火性能越差.

基于混凝土、非预应力筋和预应力筋的热-力耦合本构关系[175],用t时刻混凝土应力计算t+1时刻混凝土的瞬态热应变和高温蠕变,完成了火灾下预应力混凝土梁板截面的弯矩-曲率关系的计算,基于纤维梁单元模型,用割线刚度法对连续梁板支座反力进行迭代求解,计算梁板在曲率与支座反力共同作用下的弯矩、挠度和支座位移,实现了火灾下有粘结预应力混凝土连续梁、板的非线性有限元分析.提出了考虑荷载水平、保护层厚度和梁板截面尺寸影响的预应力混凝土结构抗火设计方法[176-178].

Venanzi等[179]完成了4块预应力膨胀粘土轻骨料高性能混凝土(立方体抗压强度标准值60 MPa)空心简支板抗火性能试验,结果表明:火灾下预应力空心板迎火面混凝土爆裂,且出现纵向贯通裂缝,导致板破坏;延长板在干燥环境的养护时间,可减缓板火灾下爆裂;Shakya等[180]完成了5块简支和1块施加轴向约束的预应力NSC空心板抗火试验,并用ANSYS有限元软件实现了预应力混凝土空心板抗火性能数值模拟[181],结果表明:施加轴向约束的试验板耐火极限更长,火灾下硅质骨料试验板比钙质骨料试验板更易爆裂;周绪红等[182]完成了4块简支、4块连续预制叠合板抗火性能试验与有限元分析,结果表明:火灾下预应力叠合板迎火面均发生爆裂,预应力叠合板耐火极限小于等强配筋的非预应力叠合板,连续板耐火极限大于简支板.

与预应力梁、板抗火性能研究相比,预应力框架抗火性能研究较少.陆洲导等[183]完成了5榀单层单跨无粘结预应力混凝土框架抗火性能试验,实测了火灾下框架梁变形和无粘结预应力筋应力变化,结果表明,火灾下预应力筋的预应力损失大,是导致框架梁跨中开裂、变形增大的原因,预应力度越高(0.64~0.7),框架抗火性能越不利.

综上,以往抗火试验多基于标准升温曲线,但标准升温曲线与真实火灾升温曲线有较大差别[184],应重视真实火灾下结构构件火灾反应的研究.受试验条件限制,预应力混凝土梁和框架结构抗火性能试验尺寸偏小,宜进一步开展足尺预应力混凝土结构抗火性能的研究.

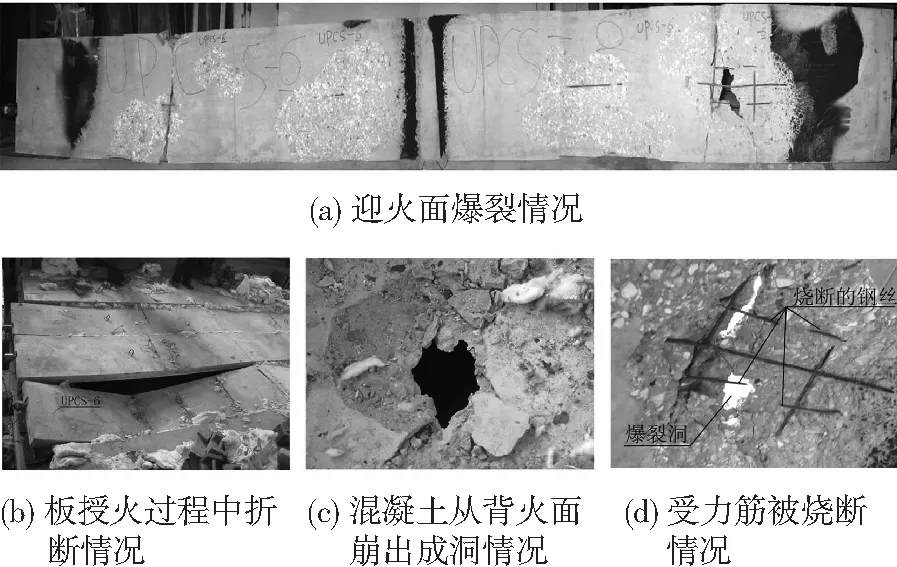

3.2 预应力混凝土高温爆裂与防爆裂验算

使用过程中,预应力构件的预压区可能存在压应力,即使在使用荷载下预压区受拉,拉应力水平也较低.一定的压应力或较小的拉应力,使得在使用荷载下梁板迎火面难以出现裂缝,在火灾下内部水蒸汽难以逃逸,造成相对较高的蒸汽压,易使蒸汽引起的混凝土内部拉应力达到混凝土抗拉强度而引发预应力构件迎火面混凝土爆裂.郑文忠等[185]对38个预应力混凝土梁板火灾下的爆裂情况进行总结,15块简支单向板中有8块发生了不同程度的爆裂,9块连续单向板中有3块发生了不同程度的爆裂,试件爆裂见图5.发现作为迎火面的预压区压应力水平越高或拉应力水平越低、混凝土抗压强度及含水率越高,混凝土就越容易发生爆裂或爆裂越严重.

图5 火灾下预应力连续板混凝土爆裂

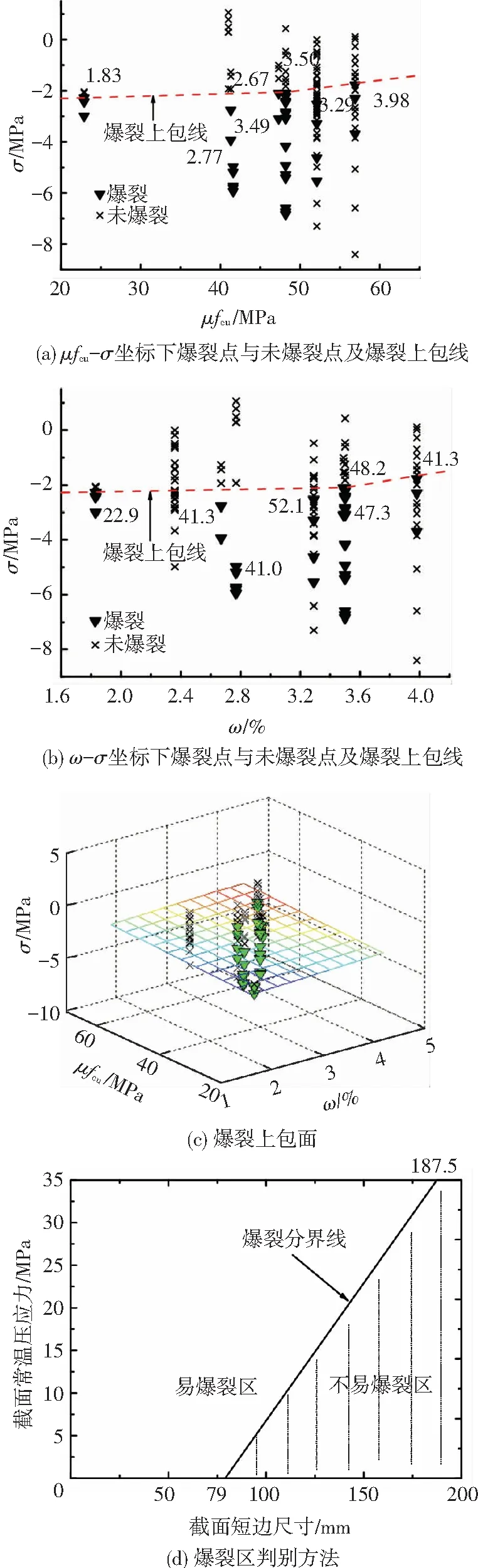

将常温下名义拉应力(压为正)引入预应力板混凝土爆裂判别方法,提出了如图6(a)、(b)所示爆裂上包线,为综合考虑名义拉应力、混凝土抗压强度及含水率的影响,提出了如图6(c)所示的预应力板混凝土爆裂上包面.对于预应力板,用σct≤1.36ftk-2.3来验算迎火面混凝土爆裂,其中,σct为迎火面混凝土的常温名义拉应力下限值(MPa),ftk为混凝土常温抗拉强度标准值(MPa);对预应力梁,用图6(d)方法判别爆裂区.该公式被新一轮行业标准《无粘结预应力混凝土结构技术规程》[186]所采纳,为合理判别火灾下预应力梁板混凝土爆裂提供了参考依据.

图6 预应力混凝土梁板爆裂判别方法

需要指出,基于爆裂试验数据提出的预应力混凝土梁板爆裂判别方法为经验方法,宜开展火灾下预应力梁板爆裂机理、爆裂预测模型的研究.

4 火灾后混凝土结构加固修复技术

混凝土结构火灾后可能比火灾下更危险.其火灾后损伤评估实现由定性到定量发展,是迫切需求.吴波[65]考虑火灾荷载密度、通风因子和房间热工特性的影响,建立了简洁实用的室内火灾温度发展全过程计算模型,解决了复杂模拟在工程中应用不便的难题.吴波等[187]、郑文忠等[188-192]分别完成了混凝土试件高温后力学试验,获得了火灾后掺纤维HSC、RPC表面历经最高温度与损伤特征的关系.吴波[65]提出了确定构件内部最高温度场的简便方法.获得了高温后主导预应力筋[193]、环向约束高强混凝土等剩余力学性能[194],使高温后环向约束高强混凝土相比无约束时20%~40%的强度增幅得以有效利用.对中等和轻微损坏的过火结构,提出了凿除受火温度500 ℃以上混凝土之后进行有效修复的技术[65].建立了火灾后混凝土构件的抗震恢复力模型[195],提出了火灾后混凝土构件评价方法,实现了火灾后混凝土结构损伤评估由定性到定量的跨越.郑文忠等[196-198]提出了火灾后梁板中预应力筋剩余应力和极限应力的计算方法,发现火灾下预应力筋强度退化快于锚具锚固性能退化,火灾后退下的锚具不能重新使用[199].针对环氧类有机胶软化温度只有60~80 ℃的不足,发明了600 ℃内强度不降低的耐高温植筋胶[200-204],用其植筋锚固长度计算公式lab=0.065(fy/ft)d,其中fy为带肋钢筋抗拉强度设计值,ft为混凝土抗拉强度设计值,d为钢筋直径[205].以上研究成果为火灾后混凝土及预应力混凝土结构的损伤评估与加固修复提供了技术支撑.

5 结论与展望

1)钢筋的合金成分和生产工艺不同,是高温下钢筋力学性能差异的主要原因.高温下混凝土可能发生爆裂,加剧其力学性能退化.高温下混凝土力学性能还受到混凝土组分、配合比和升温速度等的影响.

2)以往抗火试验多基于标准升温曲线,但标准升温曲线与真实火灾下升温曲线有较大差别,应重视真实火灾下结构构件抗火性能的研究.受试验条件限制,混凝土及预应力混凝土结构抗火性能试验尺寸偏小,宜进一步开展足尺结构构件抗火性能的研究.提出的混凝土及预应力爆裂判别方法为经验方法,尚宜继续开展火灾下混凝土及预应力结构构件爆裂机理、爆裂预测模型的研究.

3)混凝土及预应力混凝土结构应满足火灾时不爆裂、火灾下不坍塌、火灾后可修复的抗火设计目标.

4)国内外学者对高温下RPC爆裂温度、防爆裂纤维掺量等进行了研究,但对RPC爆裂的影响因素、定量表达和防爆裂措施缺乏系统研究,高温下RPC爆裂的数值模拟鲜见报道,宜开展考虑渗透性、含水率、RPC强度等影响的RPC高温爆裂数值预测方法研究.对高温下RPC的立方体抗压强度、轴心抗压强度、抗拉强度和弹性模量等研究较多,还未开展高温下RPC热-力耦合本构关系研究.宜开展RPC结构构件抗火性能研究.

5)混凝土高温瞬态热应变、高温徐变和钢筋高温蠕变的数值较大,温度-荷载路径不仅影响构件截面应力分布,同时影响结构极限荷载.应进步一开展考虑温度-荷载路径影响的结构构件抗火性能研究.

6)高层混凝土结构和地下空间结构可有效利用建筑用地.高层混凝土结构火灾蔓延迅速、火势难以控制;地下空间结构构件的耐火极限要求一般为4 h,是地上结构构件的一倍以上.应开展高层混凝土结构和地下空间结构的火灾环境与火灾反应研究,进一步研究提升整体结构抗火性能的设计方法.

[1] 吴波,唐贵和. 近年来混凝土结构抗火研究进展[J]. 建筑结构学报,2010,31(6):110-121. WU Bo, TANG Guihe. State-of-the-art of fire-resistance study on concrete structures in recent years[J]. Journal of Building Structures,2010,31(6):110-121.

[2] 郑文忠,闫凯,王英. 预应力混凝土结构抗火研究进展[J].建筑结构学报,2011,32(12):52-61. ZHENG Wenzhong, YAN Kai, WANG Ying. Progress in fire resistance of prestressed concrete structures [J]. Journal of Building Structures , 2011,32(12):52-61.

[3] 钮宏, 陆洲导, 陈磊.高温下钢筋与混凝土本构关系的试验研究[J]. 同济大学学报,1990,18(3):287-297. NIU Hong, LU Zhoudao, CHEN Lei. An experimental study of constitutive relationship between reinforced bar and concrete under elevated temperature [J]. Journal of Tongji University, 1990,18(3):287-297.

[4] 朱伯龙, 陆洲导, 胡克旭.高温(火灾)下混凝土与钢筋的本构关系[J].四川建筑科学研究,1991,17(1):37-43. ZHU Bolong, LU Zhoudao, HU Kexu. Strain-stress relationship of reinforced bar and concrete under elevated temperature(fire)[J]. Sichuan Building Science, 1991,17(1):37-43.

[5] 过镇海,时旭东.钢筋混凝土的高温性能及其计算 [M] . 北京:清华大学出版社,2003:10-223. GUO Zhenhai, SHI Xudong. Behavior of reinforced concrete at elevated temperature and its calculation [M] . Beijing:Tsinghua University Press,2003:10-223.

[6] 李明,朱永江,王正霖.高温下预应力筋和非预应力筋的力学性能[J] .重庆建筑大学学报,1998,20(4):73-77. LI Ming, ZHU Yongjiang, WANG Zhenglin. The mechanical behaviors of prestressed and non-prestressed steel rebars under high temperature [J]. Journal of Chongqing Jianzhu University, 1998,20(4):73-77.

[7] 王孔藩,许清风,刘挺林.高温下及高温冷却后钢筋力学性能的实验研究[J]. 施工技术, 2005, 34(8):3-5. WANG Kongfan, XU Qingfeng, LIU Tinglin. Experimental research on mechanics performance of steel bar after high temperature and cooled down from high temperature [J]. Construction Technology, 2005, 34(8):3-5.

[8] 吴波,梁悦欢.高温下混凝土和钢筋强度的统计分析[J].自然灾害学报,2010,19(1):136-142. WU Bo, LIANG Yuehuan. Statistic analysis of strengths of concrete and steel bars at elevated temperature[J]. Journal of Natural Disasters, 2010,19(1):136-142.

[9] INGBERG S H, SALE P D. Compressive strength and deformation of structural steel and cast-iron shapes at temperatures to 950 ℃[J]. Proceedings of the American society for testing and materials,1926,26:33-55.

[10]HARMATHY T Z, STANZAK W W. Elevated-temperature tensile and creep properties of some structural and prestressing steels[J]. ASTM Special Technical Publication,1970,464:186-207.

[11]LIE T T. A Procedure to calculate fire resistance of structural members[J]. Fire & Materials, 1984, 8(1):40-48.

[12]LIE T T. Fire resistance of circular steel columns filled with bar-reinforced concrete[J].Journal of structural Engineering,1994,120(5):1489-1509.

[13]LIE T T. Structural fire protection. ASCE Manuals and reports on engineering practice No.78[R].New York: American Society of Civil Engineering,1992.

[14]郑文忠,侯晓萌,闫凯.预应力混凝土高温性能及抗火设计[M].哈尔滨:哈尔滨工业大学出版社,2012:3-22. ZHENG Wenzhong, HOU Xiaomeng, YAN Kai. Fire resistance of prestressed concrete and its fire safety design[M].Harbin:Harbin Institute of Technology Press, 2012:3-22.

[15]American Concrete Institute 216. Code Requirements for Determining Fire Resistance of Concrete and Masonry Construction Assemblies: ACI 216.1-07/TMS-216-07 [S]. Farmington Hills, MI: American Concrete Institute,2007.

[16]British Standards Institution. Eurocode 2: Design of Concrete Structures-Part 1.2: General Rules-Structural Fire Design: EN 1992-1-2 [S]. London: British Standards Institution, 2004.

[17]侯晓萌, 郑文忠. 欧洲规范中混凝土结构抗火设计主要内容(一)——火灾下荷载效应、抗力效应、材料性能与基于表格的抗火设计方法[J]. 工业建筑, 2008,38(4):98-103. HOU Xiaomeng, ZHENG Wenzhong. Introduction of the main contents of structural fire design in eurocode of design of concrete structures (Ⅰ)-effects of actions and design resistance in the fire situation, material properties and fire design method based on tabulated data[J]. Industrial Construction, 2008,38(4):98-103.

[18]ELGHAZOULI A Y, CASHELL K A, IZZUDDIN B A. Experimental evaluation of the mechanical properties of steel reinforcement at elevated temperature[J]. Fire Safety Journal,2009,44(6):909-19.

[19]KODUR V K R, DWAIKAT M M S. Effect of high temperature creep on the fire response of restrained steel beams[J]. Materials and structures, 2010,43(10):1327-41.

[20]DORN J E. Some fundamental experiments on high temperature creep[J]. Journal of the Mechanics and Physics of Solids,1955, 3(2):85-116.

[21]HARMATHY T Z. A comprehensive creep model[J]. Journal of Basic Engineering,1967,89(3):496-502.

[22]ABRAMS M S, CRUZ C R. The behavior at high temperature of steel strand for prestressed concrete [J].Journal of the PCA Research and Development Laboratories,1961,3(3):8-19.

[23]KODUR V K R, DWAIKAT M B. A numerical model for predicting the fire behavior of reinforced concrete beams[J]. Cement & Concrete Composites, 2008, 30(5):431-443.

[24]FELICETTI R, GAMBAROVA P G, MEDA A. Residual behavior of steel rebars and R/C sections after a fire[J]. Constr Build Mater,2009,23(12):3546-55.

[25]DAY M F, JENKINSON E A, SMITH A I. Effect of elevated temperatures on high-tensile-steel wires for prestressed concrete[J]. Proceedings Instituting of civil Engineers, 1960,16(5): 55-70.

[26]范进, 吕志涛. 高温(火灾)下预应力钢丝性能的试验研究[J]. 建筑技术,2001,32(12): 833-834. FAN Jin, LÜ Zhitao. Experimental research on performance of prestressed steel wire in high temperature environment (fire) [J]. Architecture Technology,2001,32(12): 833-834.

[27]范进, 吕志涛. 受高温作用时预应力钢绞线性能的试验研究[J]. 建筑结构,2002,32(3):50-63. FAN Jin, LÜ Zhitao. Experimental research on performance of prestressed steel strand in high temperature[J]. Building structure, 2002,32(3):50-63.

[28]陈礼刚,袁建东,李晓东,等.高温下预应力钢丝的应力应变关系[J]. 重庆建筑大学学报,2006,28(4):47-50. CHEN Ligang, YUAN Jiandong, LI Xiaodong, et al. The stress-strain curve of prestressed steel wires at elevated temperature[J]. Journal of Chongqing Jianzhu University, 2006,28(4):47-50.

[29]陈礼刚,高立堂,袁建东.不同温度-应力途径下预应力钢丝的强度试验研究[J]. 建筑结构,2007,37(6):99-101,104. CHEN Ligang, GAO Litang, YUAN Jiandong. Experimental investigation of strength of prestressed steel wires under different temperature-stress paths[J]. Building structure, 2007,37(6):99-101,104.

[30]HOU Xiaomeng, ZHENG Wenzhong, KODUR V K R, et al. Effect of temperature on mechanical properties of prestressing bars[J]. Construction and Building Materials,2014,61(30):24-32.

[31]郑文忠, 胡琼, 张昊宇. 高温下及高温后1770级φP5低松弛预应力钢丝力学性能试验研究[J].建筑结构学报, 2006,27(2): 120-128. ZHENG Wenzhong, HU Qiong, ZHANG Haoyu. Experimental research on the mechanical properties of prestressing steel wires at and after high temperature[J]. Journal of Building Structures, 2006,27(2): 120-128.

[32]张昊宇, 郑文忠. 1860级低松弛钢绞线高温下力学性能[J]. 哈尔滨工业大学学报, 2007, 39(6): 861-865. ZHANG Haoyu, ZHENG Wenzhong. Mechanical property of steel strand at high temperature[J]. Journal of Harbin Institute of Technology, 2007, 39(6): 861-865.

[33]张爱林,武丽英.预应力钢丝钢绞线的高温蠕变性能研究[J]. 钢结构,2008,23(1):6-9. ZHANG Ailin, WU Liying. Study on the thermal creep strain property of prestressed steel wire and stranded wire[J]. Steel Construction,2008,23(1):6-9.

[34]华毅杰. 预应力混凝土结构火灾反应及抗火性能研究[D]. 上海,同济大学,2000. HUA Yijie. Fire resistance performance of prestressed concrete structures[D]. Shanghai: Tongji University,2000.

[35]蔡跃,黄鼎业,熊学玉. 预应力混凝土结构材料高温下的力学性能及模型[J]. 四川建筑科学研究,2003,29(4):82-84. CAI Yue, HUANG Dingye, XIONG Xueyu. Material behaviors and mechanical model of prestressed concrete structure at high temperature[J]. Sichuan Building Science,2003,29(4):82-84.

[36]张昊宇, 郑文忠. 高温下1770级φP5钢丝蠕变及应力松弛性能试验研究[J]. 土木工程学报, 2006, 39(8): 7-13. ZHANG Haoyu, ZHENG Wenzhong. An experimental study on the creep and stress relaxation properties of 1 770-φP5 prestressing steel wires at high temperatures[J].China Civil Engineering Journal, 2006, 39(8): 7-13.

[37]周焕廷,李国强,蒋首超. 高温下钢绞线材料力学性能的试验研究[J]. 四川大学学报(工程科学版),2008,40(5):106-110. ZHOU Huanting, LI Guoqiang, JIANG Shouchao. Experimental studies on the properties of steel strand at elevated temperatures [J]. Journal of Sichuan University (Engineering Science Edition) ,2008,40(5):106-110.

[38]周焕廷,聂河斌,李国强,等. 高温作用下1860级预应力钢绞线蠕变性能试验研究[J]. 建筑结构学报,2014,35(6):123-129. ZHOU Huanting, NIE Hebin, LI Guoqiang, et al. Experimental research on creep properties of prestressed steel strand in 1 860 MPa at high temperature[J]. Journal of Building Structures ,2014,35(6):123-129.

[39]郑文忠, 张昊宇, 胡琼. 基于温度历程的高强钢丝应变及应力计算方法[J]. 建筑材料学报,2007, 10(3): 288-294. ZHENG Wenzhong, ZHANG Haoyu, HU Qiong. Stress and strain calculated methods of high strength steel wire considering temperature-time path[J]. Journal of Building Materials, 2007, 10(3): 288-294.

[40]MALHOTRA H L. The effect of temperature on the compressive strength of concrete[J]. Magazine of Concrete Research,1956,8(23): 85-94.

[41]CRUZ C R. Elastic proprieties of concrete at high temperature[J]. Journal of PCA Research and Development Laboratories, 1966,8(1):37-45.

[42]BALDWIN R,NORTH M A. A stress-strain relationship for concrete at high temperatures[J].Magazine of Concrete Research,1973,25(85):208-212.

[43]ABRAMS M S. Compressive strength of concrete at temperatures to 1600F[J]. Temperature and Concrete, American Concrete Institute, 1971(SP25):33-58.

[44]CASTILLO C, DURRANI A J. Effect of transient high temperature on high-strength concrete[J]. ACI Materials Journal, 1990, 87(1): 47-53.

[45]DIEDERICHS U, JUMPPANEN U M, SCHNEIDER U. High temperature properties and spalling behavior of high strength concrete[C]// Proceedings of 4th Weimar Workshop on High Performance Concrete: Material Properties and Design. Weimar, German:HAB, 1995: 219-236.

[46]SCHNEIDER U. Concrete at high temperatures-A general review[J].Fire Safety Journal, 1988,13(1):55-68.

[47]THENIEL K-CH, ROSTARY F S. Strength of concrete subjected to high temperature and biaxial stress: Experiments and Modeling[J]. Materials and Structures, 1995,28(10):575-581 [48]ARIOZ O. Effects of elevated temperatures on properties of concrete[J]. Fire Safety Journal, 2007,42(8): 516-522.

[49]KODUR V K R, DWAIKAT M M S, DWAIKAT M B. High temperature properties of concrete for fire resistance modeling of structures[J]. ACI Materials Journal, 2008,105(5): 517-527.

[50]GAWIN D, PESAVENTO F, SCHREFLER B A. Modelling of hygro-thermal behavior of concrete at high temperature with thermo-chemical and mechanical material degradation[J]. Computer Methods in Applied Mechanics and Engineering, 2003,192(13/14):1731-1771.

[51]FURUMURA F, ABE T, SHINOHARA Y. Mechanical properties of high strength concrete at high temperatures[C]// Proceedings of 4th Weimar Workshop on High Performance Concrete: Material Properties and Design. Weimar, German:HAB, 1995: 237-254.

[52]HAMMER T A. High strength concrete phase 3, compressive strength and E-modulus at elevated temperatures [R]. Trondheim, Norway: Report No.6.1,SINTEF structures and concrete, STF70 A95023,1995:3-7.

[53]XIAO Jianzhuang, KÖNIG G. Study on concrete at high temperature in China-an overview[J]. Fire Safety Journal, 2004,39(1): 89-103.

[54]KODUR V K R. Properties of concrete at elevated temperatures[J]. ISRN Civil Engineering,2014,2014:1-15.

[55]广东省住房和城乡建设厅.建筑混凝土结构耐火设计技术规程: DBJ/T 15-81—2011 [S].北京:中国建筑工业出版社,2011. Guangdong Housing And Urban-Rural Construction Office. Code for fire resistance design of concrete structures in buildings: DBJ/T 15-81—2011 [S].Beijing:China Architecture & Building Press,2011.

[56]BAZANT Z P, PANULA L. Practical prediction of time-dependent deformations of concrete-Part IV: Temperature effect on basic creep[J]. Materials and Structures, 1978,11(66):424-434.

[57]HARMATHY T Z. Fire safety design and concrete( Concrete design and construction series)[M]. UK: Longman, 1993:3-23.

[58]KHOURY G A. Deformation of concrete and cement paste loaded at constant temperatures from 140 to 724 ℃[J]. Materials and Structures, 1986, 110(19): 97-104.

[59]邢万里,时旭东,倪健刚.基于试验的混凝土高温短期徐变计算模型[J]. 工程力学,2011,28(4):158-163. XINGWanli, SHI Xudong, NI Jian’gang. Short-term thermal creep model of concrete based on experiments[J]. Engineering Mechanics, 2011,28(4):158-163.

[60]ANDERBERG Y, THELANDERSSON S. Stress and deformation characteristics of concrete at high temperatures, 2-Experimental investigation and material behavior model[R]. Bulletin of Division of Structural Mechanics and Concrete Construction, Bulletin 54. 1976:1-84.

[61]南建林,过镇海,时旭东.混凝土的温度-应力耦合本构关系[J]. 清华大学学报(自然科学版),1997,37(6):89-92. NAN Jianlin, GUO Zhenhai, SHI Xudong. Temperature-stress coupling constitutive relationship of concrete[J].Journal of Tsinghua University(Sci&Tech),1997,37(6):89-92.

[62]胡海涛,董毓利. 高温时高强混凝土瞬态热应变的试验研究[J]. 建筑结构学报,2002,23(4):32-35+47. HU Haitao, DONG Yuli. Experimental research on the transient thermal strain of high strength concrete at elevated temperature[J]. Journal of Building Structures, 2002,23(4):32-35,47 [63]胡海涛,董毓利. 高温时高强混凝土强度和变形的试验研究[J]. 土木工程学报,2002,35(6):44-47. HU Haitao, DONG Yuli. Experimental research on strength and deformation of high-strength concrete at elevated temperature[J]. China Civil Engineering Journal, 2002,35(6):44-47.

[64]DWAIKAT M B, KODUR V K R. Hydrothermal model for predicting fire-induced spalling in concrete structural systems[J].Fire safety Journal,2009,44:425-434 [65]吴波.火灾后钢筋混凝土结构的力学性能[M].北京:科学出版社,2003:18-23. WU Bo. Performance of reinforced concrete structures after fire [M]. Beijing:China science press,2003:18-23.

[66]KODUR V K R, CHENG F, WANG T, et al. Effect of strength and fiber reinforcement on the fire resistance of high strength concrete columns[J]. Journal of Structural Engineering, ASCE, 2003,129(2):1-22.

[67]KODUR V K R, WANG T, CHENG F. Predicting the fire resistance behavior of high strength concrete columns[J]. Cement Concrete Composite. 2004,26(2):141-53.

[68]XIAO Jianzhuang, FALKNER H. On residual strength of high-performance concrete with and without polypropylene fibres at elevated temperatures[J]. Fire Safety Journal, 2006, 41(2): 115-121.

[69]BREITENBÜCKER R. High strength concrete C105 with increased fire resistance due to polypropylene fibres[C]// 4th International Symposium on the Utilization of High-Strength/High-Performance Concrete. Paris, France:[s.n.], 1996,571-577.

[70]KALIFA P, CHENE G, GALLE C. High-temperature behavior of HPC with polypropylene fibres: From spalling to microstructure[J]. Cement and concrete research, 2001, 31(10): 1487-1499.

[71]CHEN Bing, LIU Juanyu. Residual strength of hybrid-fiber-reinforced high-strength concrete after exposure to high temperatures[J]. Cement and Concrete Research, 2004, 34(6): 1065-1069.

[72]POON C S, SHUI Z H, LAM L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures[J]. Cement and Concrete Research, 2004, 34(12): 2215-2222.

[73]RICHARD P, CHEYREZY M. Reactive powder concrete with high ductility and 200 MPa-800 MPa compressive strength [J]. ACI Special Publication, 1994(SP 144): 507-518.

[74]郑文忠,吕雪源. 活性粉末混凝土研究进展[J]. 建筑结构学报,2015,36(10):44-58. ZHENG Wenzhong, LV Xueyuan. Research development of reactive powder concrete[J]. Journal of Building Structures,2015,36(10):44-58.

[75]吕雪源,王英,符程俊,等. 活性粉末混凝土基本力学性能指标取值[J]. 哈尔滨工业大学学报,2014,46(10):1-9. LÜ Xueyuan, WANG Ying, FU Chengjun, et al. Basic mechanical property indexes of reactive powder concrete[J]. Journal of Harbin Institute of Technology, 2014,46(10):1-9.

[76]JU Yang, LIU Hongbin, LIU Jinhui, et al. Investigation on thermo physical properties of reactive powder concrete [J]. Science China: Technological Sciences, 2011,54(12):3382-3403.

[77]郑文忠,王睿,王英.活性粉末混凝土热工参数试验研究[J].建筑结构学报,2014,35(9):107-114. ZHENG Wenzhong, WANG Rui, WANG Yin. Experimental study on thermal parameter of reactive powder concrete [J]. Journal of Building Structures, 2014,35(9):107-114.

[78]刘红彬. 活性粉末混凝土的高温力学性能与爆裂的试验研究[D]. 北京:中国矿业大学, 2012. LIU Hongbin. Experimental study on the mechanical properties and explosive spalling of reactive powder concrete exposed to high temperatures[D].Beijing:China University of Mining and technology,2012.

[79]陈强.高温对活性粉末混凝土高温爆裂行为和力学性能的影响[D].北京:北京交通大学, 2010. CHEN Qiang. The influence of high temperature on explosive spalling behavior and mechanical properties of reactive powder concrete [D].Beijing:Beijing Jiaotong University,2010.

[80]ZHENG Wenzhong, LUO Baifu, WANG Ying. Microstructure and mechanical properties of RPC containing PP fibres at elevated temperatures [J]. Magazine of Concrete Research, 2014, 66(8): 397-408.

[81]ZHENG Wenzhong, LUO Baifu, WANG Ying. Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures[J]. Construction and Building Materials, 2013, 41: 844-851.

[82]AYDIN S, BARADAN B.High temperature resistance of alkali-activated slag-and Portland cement-based reactive powder concrete[J]. ACI Materials Journal,2012,109(4):463-470.

[83]CANBAZ M. The effect of high temperature on reactive powder concrete[J]. Construction and Building Materials,2014,15(70):508-513.

[84]JU Yang, LIU Jinhui, LIU Hongbin, et al. On the thermal spalling mechanism of reactive powder concrete exposed to high temperature: Numerical and experimental studies[J]. International Journal of Heat and Mass Transfer, 2016,98:493-507.

[85]DIEDERICHS U, SCHNEIDER U. Bond strength at high temperature[J]. Magazine of Concrete Research,1981,33(115):75-84.

[86]MORLEY PD, ROYLES R. Response of the bond in reinforced concrete to high temperature[J]. Magazine of Concrete Research,1983,35(123):67-74.

[87]ROYLES R, MORLEY P D. Further responses of the bond in reinforced concrete to high temperatures[J].Magazine of Concrete Research, 1983,35(124):157-163.

[88]袁广林,郭操,吕志涛. 高温下钢筋混凝土粘结性能的试验与分析[J].工业建筑,2006,36(2):57-60. YUAN Guanglin, GUO Cao, LÜ Zhitao. Experimental study on bond property of reinforced concrete at high temperatures[J]. Industrial Construction,2006,36(2):57-60.

[89]胡克旭.高温下钢砼粘结滑移性能及钢砼门式框架抗火性能研究[D].上海:同济大学,1989. HU Kexu. Researches on the behavior of bond-slip between concrete and steel to high temperatures and the fire resistance of reinforced concrete portal frames[D].Shanghai:Tongji University,1989.

[90]HUANG Zhaohui. Modelling the bond between concrete and reinforcing steel in a fire[J].Engineering Structures, 2010,32(11): 3660-3669.

[91]GAO Wanyang, DAI Jianguo, TENG Jinguang, et al. Finite element modeling of reinforced concrete beams exposed to fire[J].Engineering Structures, 2013,52: 488-501.

[92]THOMPSON J P. Fire Resistance of Reinforced Concrete Floors[J]. Journal of the American Concrete Institute, 1953,24 (7):677-680.

[93]GUSTAFERRO A H. Factors influencing the fire resistance of concrete[J]. Fire Technology,1966, 2:187-195.

[94]ABRAMS M S, GUSTAFERRO A H. Fire endurance of two-course floors and roofs. Journal of the American Concrete Institute[J]. 1969,66(2):92-102.

[95]GUSTAFERRO A H, ABRAMS M S,LITVIN A. Fire resistance of lightweight insulating concretes[R]. PCA research and development Bulletin (RDO04.01B).Portland:Portland Cement Association,1970. [96]LIE T T. Calculation of the fire resistance of composite concrete floor and roof slabs[J]. Fire Technology, 1978,14(1):28-45 [97]陈正昌. 钢筋混凝土楼板的耐火性能[J]. 消防科技,1983(1):23-27,32. CHEN Zhengchang. Fire resistance performance of reinforced concrete slabs[J]. Fire science and Technology,1983(1):23-27,32.

[98]陈礼刚,李晓东,董毓利.钢筋混凝土三跨连续板边跨受火性能试验研究[J]. 工业建筑,2004, 34(1):66-68,75. CHEN Ligang, LI Xiaodong, DONG Yuli. Test study on performance of the reinforced concrete three-span continuous slabs under fire-fire in side span.

[J]. Industrial Construction,2004, 34(1):66-68,75.

[99]陈礼刚,董毓利,李晓东.钢筋混凝土三跨连续板中跨受火试验研究[J]. 建筑结构,2004,34(4):39-41,53. CHEN Ligang, DONG Yuli, LI Xiaodong. Test study on performance of the reinforced concrete three-span continuous slabs with middle span in fire. Building structure, 2004,34(4):39-41,53.

[100]陈礼刚,高立堂,李晓东,等 两邻跨受火RC三跨连续板抗火性能试验研究[J]. 西安建筑科技大学学报(自然科学版),2006,38(1):100-104. CHEN Ligang, GAO Litang, LI Xiaodong, et al. Study on the fire resistance of the 3-span RC continuous slabs when the two adjacent spans are on fire[J]. Journal of Xi’an University of architecture & technology(Natural Science Edition) ,2006,38(1):100-104.

[101]BAILEY C G, TOH W S. Small-scale concrete slab tests at ambient and elevated temperatures[J].Engineering Structures,2007,29(10): 2775-2791.

[102]王滨,董毓利.四边简支钢筋混凝土双向板火灾试验研究[J]. 建筑结构学报,2009,30(6):23-33. WANG Bin, DONG Yuli. Experimental research of four-edge simple support two-way reinforced concrete slab under fire[J]. Journal of Building Structures, 2009,30(6):23-33.

[103]王滨,董毓利.钢筋混凝土双向板火灾试验研究[J]. 土木工程学报,2010,43(4):53-62. WANG Bin, DONG Yuli. Experimental study of two-way reinforced concrete slabs under fire[J]. China Civil Engineering Journal,2010,43(4):53-62.

[104]杨志年,董毓利,吕俊利,等. 整体结构中钢筋混凝土双向板火灾试验研究[J]. 建筑结构学报,2012,33(9):96-103. YANG Zhinian, DONG Yuli, LV Junli, et al. Experimental study of two-way reinforced concrete subjected to fire in a whole structure[J].Journal of Building Structures, 2012,33(9):96-103.

[105]王勇,董毓利,彭普维,等. 足尺钢框架结构中楼板受火试验研究[J]. 建筑结构学报,2013,34(8):1-11. WANG Yong, DONG Yuli, PENG Puwei, et al. fire test on floor of full-scale steel-framed structure[J].Journal of Building Structures,2013,34(8):1-11.

[106]HUANG Zhaohui, BURGESS I W, PLANK R J. Nonlinear analysis of reinforced concrete slabs subjected to fire[J]. ACI Structural Journal,1999,96(1):127-135.

[107]HUANG Zhaohui, BURGESS I W, PLANK R J. Modelling membrane action of concrete slabs in composite buildings in fire i: theoretical development[J]. Journal of Structural Engineering, ASCE, 2003,129(8):1093-1102.

[108]HUANG Zhaohui, BURGESS I W, PLANK R J. Modelling membrane action of concrete slabs in composite buildings in fire. ii: validations[J]. Journal of Structural Engineering, ASCE, 2003,129(8):1103-1112.

[109]ZHANG Y X, BRADFORD M A. Nonlinear analysis of moderately thick reinforced concrete slabs at elevated temperatures using a rectangular layered plate element with timoshenko beam functions[J].Engineering Structures,2007,29(10):2751-2761.

[110]WANG Yong, DONG Yuli, ZHOU Guangchun. Nonlinear numerical modeling of two-way reinforced concrete slabs subjected to fire[J]. Computers & Structures,2013,12(29): 23-36.

[111]ELLINGWOOD B, SHAVER J R. Effects of fire on reinforced concrete members[J]. Journal of the Structural Division,ASCE,1980,106(11): 2151-2166.

[112]LIN T D, ELLINGWOOD B, PIET O. Flexural and shear behavior of reinforced concrete beams during fire tests[R]. Report no. NBS-GCR-87-536, Center for Fire Research, National Bureau of Standards,1987:3-15.

[113]ELLINGWOOD B, LIN T D. Flexural and shear behavior of concrete beams during fires[J]. Journal of Structural Engineering,ASCE, 1991,117(2):440-58.

[114]DOTREPPE J C, FRANSSEN J M. The use of numerical models for the fire analysis of reinforced concrete and composite structures [J]. Engineering Analysis,1985,2(2):67-74.

[115]WU H J, LIE T T, HU J Y. Fire resistance of beam-slab specimens-experimental studies[R]. Internal Report No. 641, Institute for Research in Construction, National Research Council Canada, 1993.

[116]LIN T D, GUSTAFERRO A H, ABRAMS M S. Fire endurance of continuous reinforced concrete beams[R]. R & D Bulletin RD 072.01B. IL(USA): Portland Cement Association, 1981.

[117]陆洲导,朱伯龙,周跃华. 钢筋混凝土简支梁对火灾反应的试验研究[J]. 土木工程学报,1993,26(3):47-54. LU Zhoudao, ZHU Bolong, ZHOU Yuehua. Experimental study on fire response of simple supported reinforced concrete beams[J].China Civil Engineering Journal,1993,26(3):47-54.

[118]冯雅,陈启高,王尔其. 钢筋混凝土火灾下热湿耦合热过程研究[J]. 重庆建筑大学学报,1999,21(3):41-44. FENG Ya, CHEN Qigao, WANG Erqi. Coupled heat and moisture transfer progress of reinforced concrete under fire disaster[J]. Journal of Chongqing Jianzhu University,1999,21(3):41-44.

[119]向延念,李守雷,徐志胜. 钢筋混凝土简支梁高温力学性能的试验研究[J]. 华北科技学院学报,2006,3(1):57-61. XIANG Yannian, LI Shoulei, XU Zhisheng. Experimental study on mechanics performance of the simple RC beams after high temperature[J].Journal of North China Institute of Science & Technology,2006,3(1):57-61.

[120]张威振. 高温下足尺钢筋混凝土梁试验研究及数值分析[J]. 哈尔滨工业大学学报,2009,41(2):198-201. ZHANG Weizhen. Experimental investigation and numerical analysis for RC beams under elevated temperature[J]. Journal of Harbin Institute of Technology,2009,41(2):198-201.

[121]SHI Xudong, TAN T H. Effect of force-temperature paths on behaviors of reinforced concrete flexural members [J]. Journal of Structural Engineering, ASCE,2002 ,128 (3) :365-373.

[122]苗吉军,陈娜,侯晓燕,等. 使用损伤与高温耦合作用下钢筋混凝土梁火灾试验研究与数值分析[J]. 建筑结构学报,2013,34(3):1-11. MIAO Jijun, CHEN Na, HOU Xiaoyan, et al. Experimental research and numerical simulation on fire resistance performance of RC beams with damages caused by service loading[J]. Journal of Building Structures,2013,34(3):1-11.

[123]苗吉军,刘芳,刘延春,等. 考虑海洋环境损伤的钢筋混凝土梁抗火性能试验研究[J]. 建筑结构学报,2014,35(9):64-71. MIAO Jijun, LIU Fang, LIU Yanchun, et al. Experimental research on fire resistance performance of RC beams with damages caused by marine environment[J]. Journal of Building Structures,2014,35(9):64-71.

[124]查晓雄,王晓璐,谢先义. GFRP筋混凝土梁耐火性能的试验研究[J]. 防灾减灾工程学报,2012,32(1):50-55. ZHA Xiaoxiong, WANG Xiaolu, XIE Xianyi. Fire performance of GFRP reinforced concrete beams[J]. Journal of Disaster Prevention and Mitigation Engineering,2012,32(1):50-55.

[125]王晓璐,查晓雄,朱庸. GFRP筋混凝土梁耐火性能计算方法[J]. 建筑结构学报,2014,35(3):119-127. WANG Xiaolu, ZHA Xiaoxiong, ZHU Yong. Calculation methods for fire resistance of GFRP reinforced concrete beams[J]. Journal of Building Structures, 2014,35(3):119-127.

[126]KODUR V K R, DWAIKAT M. A numerical model for predicting the fire resistance of reinforced concrete beams[J]. Cement and Concrete Composites, 2008,30(5): 431-443.

[127]BRATINA S, PLANINC I, SAJE M, et al. Non-linear fire-resistance analysis of reinforced concrete beams[J]. Structural Engineering and Mechanics,2003,16(6):695-712.

[128]BRATINA S, SAJE M, PLANINC I, et al. The effects of different strain contributions on the response of RC beams in fire[J]. Engineering Structures, 2007;29(3):418-30.

[129]ZHA Xiaoxiong. Three-dimensional non-linear analysis of reinforced concrete members in fire[J]. Building and Environment, 2003,38(2): 297-307.

[130]DWAIKAT M, KODUR V K R. A numerical approach for modeling the fire induced restraint effects in reinforced concrete beams[J]. Fire Safety Journal, 2008, 43(4): 291-307.

[131]DWAIKAT M, KODUR V K R. Response of restrained concrete beams under design fire exposure[J]. Journal of Structural Engineering, ASCE, 2009,135(11):1408-1417.

[132]DWAIKAT M, KODUR V K R. Fire induced spalling in high strength concrete beams[J]. Journal of Fire Technology, 2010,46(1): 251-274.

[133]WU B, LU J Z. A numerical study of the behavior of restrained RC beams at elevated temperatures[J]. Fire Safety Journal, 2009, 44(4): 522-531.

[134]吴波,乔长江. 混凝土约束梁升降温全过程的耐火性能试验[J].工程力学,2011,28(6):88-95. WU Bo, QIAO Changjiang. Experimental study on fire behaviors of RC restrained beams under heating and cooling phases[J].Engineering Mechanics,2011,28(6):88-95.

[135]徐明,杨大峰,尹万云,等. 钢筋增强超高韧性水泥基复合材料约束梁耐火性能试验研究[J]. 建筑结构学报,2016,37(3):29-35. XU Ming, YANG Dafeng, YIN Wanyun, et al. Experimental research on fire resistance of steel reinforced engineered cementitious composites restrained beams[J]. Journal of Building Structures,2016,37(3):29-35.

[136]LIE T T, LIN T D, ALLEN D E,et al. Fire Resistance of Reinforced Concrete Columns[R].National Research Council of Canada, Division of Building Research, NRCC 23065, Ottawa, Canada, 1984.

[137]LIE T T. Fire resistance of reinforced concrete columns: a parametric study[J].Journal of Fire Protection Engineering,1989,1(4):121-129.

[138]苏南,林铜柱, LIE T T. 钢筋混凝土柱的抗火性能[J]. 土木工程学报,1992,25(6):25-36. SU Nan, LIN Tongzhu, LIE T T. Fire resistance of reinforced concrete columns[J]. China Civil Engineering Journal,1992,25(6):25-36.

[139]DOTREPPE J C, FRANSSEN J M, BRULS A, et al. Experimental research on the determination of the main parameters affecting the behavior of reinforced concrete columns under fire conditions[J].Magazine of Concrete Research,1997, 179(49): 117-127.

[140]TAN K H, YAO Y. Fire resistance of four-face heated reinforced concrete columns[J]. Journal of Structural Engineering, ASCE,2003,129(9):1220-1229.

[141]TAN KH, YAO Y. Fire resistance of reinforced concrete columns subjected to 1-, 2-, and 3-Face heating[J] Journal of Structural Engineering, ASCE,2004,130(11): 1820-1828.

[142]KODUR V K R, MCGRATH R C. Fire endurance of high strength concrete columns[J].Fire Technology,2003,39 (1):73-87.

[143]吴波,唐贵和,王超. 不同受火方式下混凝土柱耐火性能的试验研究[J]. 土木工程学报,2007,40(4):27-31,72. WU Bo, TANG Guihe, WANG Chao. Experimental study on fire resistance of RC columns with different faces exposed to fire[J]. China Civil Engineering Journal,2007,40(4):27-31,72.

[144]WU Bo, ZHOU Hong, TANG Guihe, et al. Fire resistance of reinforced concrete columns with square cross section.

[J].Advances in Structural Engineering, 2007, 10(4): 353-369.

[145]WU Bo, LI Yihai, CHEN Shuliang. Effect of heating and cooling on axially restrained RC columns with special-shaped cross section[J]. Fire Technology, 2010, 46(1): 231-249.

[146]XU Yuye, WU Bo. Fire resistance of reinforced concrete columns with L-, T- and +-shaped cross sections[J].Fire Safety Journal, 2009, 44(6): 869-880.

[147]WU Bo, XU Yuye. Behavior of axially-and-rotationally restrained concrete columns with ‘+’-shaped cross section and subjected to fire[J].Fire Safety Journal, 2009, 44(2): 212-218.

[148]陆洲导,朱伯龙, 姚亚雄. 钢筋混凝土框架火灾反应分析[J].土木工程学报,1995, 28(6):18-27. LU Zhoudao, ZHU Bolong, YAO Yaxiong. Fire response analysis of reinforced concrete frames[J]. China Civil Engineering Journal,1995, 28(6):18-27.

[149]BAILEY C G. Holistic behavior of concrete buildings in fire[J]. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 2002,152(3):199-212.

[150]刘永军. 钢筋混凝土结构火灾反应数值模拟及软件开发[D].大连:大连理工大学,2002. LIU Yongjun. Modeling and programming of reinforced concrete structures exposed to fires [D]. Dalian :Dalian University of Technology,2002.

[151]吴波,何喜洋. 高温下钢筋混凝土框架的内力重分布研究[J].土木工程学报,2006,39(9):54-61. WU Bo, HE Xiyang. A study on the redistribution of internal forces in reinforced concrete frames under high temperature[J]. China Civil Engineering Journal, 2006,39(9):54-61.

[152]陈适才,陆新征,任爱珠,等. 基于纤维梁模型的火灾下多层混凝土框架非线性分析[J].建筑结构学报,2009,30(6):44-53. CHEN Shicai, LU Xinzheng, REN Aizhu, et al. Nonlinear analysis of multi-story concrete frame under fire with fiber beam model[J]. Journal of Building Structures,2009,30(6):44-53.

[153]YAN Kai, ZHENG Wenzhong, WANG Ying. Elasto-plastic analysis of masonry with anisotropic plasticity material model [J]. Journal of Harbin Institute of Technology,2011, 18(5): 74-80.

[154]YAN Kai, ZHENG Wenzhong, WANG Ying. Modelling and analysis of the bottom frames of multi-story masonry buildings exposed to fire [J].Advanced Materials Research,2011, 255-260: 704-708.

[155]ASHTON L A, MALHOTRA H L. The fire resistance of prestressed concrete beams[R]. Fire Research Notes 65,1953.

[156]GUSTAFERRO A H, SELVAGGIO S L. Fire endurance of simply-supported prestressed concrete slabs [J]. Journal of the Prestressed Concrete Institute,1967,12(1):37-52.

[157]ABRAMSM S, GUSTAFERRO A H. Fire endurance of prestressed concrete units coated with spray-applied insulation[J]. Journal of the Prestressed Concrete Institute,1972,17(1):82-103.

[158]JOSEPH T R, SON I. Report on unbonded post-tensioned prestressed, reinforced concrete flat plate floor with expanded shale aggregate[J]. Journal of the Prestressed Concrete Institute,1968,13(2):45-56.

[159]HERBERGHEN P V, DAMME M V. Fire resistance of post-tensioned continuous flat floor slabs with unbonded tendons[R]. FIP Notes ,1983: 3-11.

[160]袁爱民,孙宝俊,董毓利,等. 无粘结预应力混凝土简支板火灾试验研究[J]. 工业建筑,2005,35(4):38-42. YUAN Aimin, SUN Baojun, DONG Yuli, et al. Experimental investigation of unbounded prestressed concrete simply-supported slab subjected to fire[J]. Industrial Construction,2005,35(4):38-42.

[161]BAILEY C G, ELLOBODY E. Fire tests on unbonded post-tensioned one-way concrete slabs[J]. Magazine of Concrete Research,2009,61(1):67-76.

[162]ELLOBODY E, BAILEY C G. Modelling of unbonded post-tensioned concrete slabs under fire conditions[J]. Fire Safety Journal. 2009, 44(2):159-167.

[163]Civil engineering and building structures standards committee. Structural use of concrete, Code of Practice for Special Circumstances: BS8110-2[S]. London:British Standards Institution, 1985.

[164]袁爱民,董毓利,戴航,等. 无粘结预应力混凝土三跨连续板火灾试验研究[J]. 建筑结构学报,2006,27(6):60-66. YUAN Aimin, DONG Yuli, DAI Hang, et al. Experimental investigation of unbounded prestressed concrete continuous slab subjected to fire[J]. Journal of Building Structures,2006,27(6):60-66.

[165]高立堂, 董毓利, 袁爱民. 无粘结预应力混凝土连续板边中两跨受火试验[J]. 哈尔滨工业大学学报, 2009, 41(8): 179-182. GAO Litang, DONG Yuli, YUAN Aimin. Experimental investigation on behaviors of continuous slabs of unbounded prestressed concrete with end-middle span under fire[J]. Journal of Harbin Institute of Technology, 2009, 41(8): 179-182.

[166]高立堂, 陈礼刚, 李晓东,等. 无粘结预应力混凝土连续板火灾行为的试验分析[J]. 混凝土, 2006 (9): 80-83. GAO Litang, CHEN Ligang, LI Xiaodong, et al. Analysis of the behaviors of unbounded prestressed concrete continuous slabs under fire[J]. Concrete, 2006 (9): 80-83.

[167]袁爱民, 董毓利, 戴航, 等. 预应力混凝土连续板不同跨受火火灾行为[J]. 哈尔滨工业大学学报, 2008, 40(10): 1633-1638. YUAN Aimin, DONG Yuli, DAI Hang, et al. Behaviors of unbounded prestressed concrete continuous slabs middle span and edge span subjected to fire in_order[J]. Journal of Harbin Institute of Technology, 2008, 40(10): 1633-1638.

[168]王中强,余志武. 高温下无粘结预应力混凝土扁梁试验研究[J]. 建筑结构学报,2011,32(2):98-106. WANG Zhongqiang, YU Zhiwu. Experimental research on unbounded prestressed concrete flat beams under high temperature[J]. Journal of Building Structures,2011,32(2):98-106.

[169]王中强,余志武. 高温下无粘结预应力混凝土受弯构件的非线性有限元分析[J]. 土木工程学报,2011,44(2):42-49. WANG Zhongqiang, YU Zhiwu. Nonlinear finite element analysis of unbounded prestressed concrete flexural members at high temperature[J]. China Civil Engineering Journal,2011,44(2):42-49.

[170]ZHENG Wenzong, HOU Xiaomeng. Experiment and analysis on the mechanical behavior of pc simply-supported slabs subjected to fire[J].Advances in Structural Engineering,2008,11(1):71-89.

[171]HOU Xiaomeng, KODUR V K R, ZHENG Wenzhong. Factors governing the fire response of bonded prestressed concrete continuous beams[J]. Materials and structures,2015,48(9):2885-2900.

[172]HOU Xiaomeng, ZHENG Wenzong, KODUR V K R. Response of unbonded prestressed concrete continuous slabs under fire exposure[J]. Engineering Structures,2013,56(11):2139-2148.

[173]胡琼,许名鑫,郑文忠.火灾下混凝土构件正截面承载力估算方法[J].哈尔滨工业大学学报,2006,38(1):56-58,66. HU Qiong, XU Mingxin, ZHENG Wenzhong. Estimation method for normal section load-bearing capacity of concrete members subjected to fire[J]. Journal of Harbin Institute of Technology,2006,38(1):56-58,66.

[174]胡琼,许名鑫,郑文忠. 火灾下无粘结预应力筋应力-应变全过程分析[J]. 计算力学学报,2011,28(6):891-897. HU Qiong, XU Mingxin, ZHENG Wenzhong. Analysis on stress-strain complete process of unbounded prestressing tendons in concrete subjected to fire[J]. Chinese Journal of Computational Mechanics,2011,28(6):891-897.

[175]侯晓萌, 郑文忠. 预应力混凝土连续梁板抗火性能非线性分析[J].哈尔滨工业大学学报,2011,43(12):36-41. HOU Xiaomeng, ZHENG Wenzhong. Nonlinear finite element analysis of fire resistance performance for prestressed concrete continuous beam and slab[J].Journal of Harbin Institute of Technology, 2011,43(12):36-41.

[176]郑文忠,侯晓萌. 混凝土及预应力混凝土结构抗火设计建议[J]. 建筑科学,2013,29(5):67-70,76. ZHENG Wenzhong,HOU Xiaomeng. Proposition for Fire Resistance Design of Concrete and Prestressed Concrete Building Structures[J].Building Science, 2013,29(5):67-70,76.

[177]ZHENG Wenzhong, OUYANG Zhiwei. Influence of key factors on deflection of bonded prestressed concrete simply supported slabs subjected to fire[J]. Journal of Harbin Institute of Technology, 2010,17(5):615-621.

[178]ZHENG Wenzhong, HOU Xiaomeng, XU Mingxin. Research into rational concrete cover of prestressed concrete beams and slabs for fire resistance[J]. Journal of Harbin Institute of Technology,2009,16(5):99-106.

[179]VENANZI I, BRECCOLOTTI M, D’ALESSANDRO A, et al. Fire performance assessment of HPLWC hollow core slabs through full-scale furnace testing[J]. Fire Safety Journal, 2014,69:12-22.

[180]SHAKYA A M, KODUR V K R. Response of precast prestressed concrete hollowcore slabs under fire conditions[J]. Engineering Structures, 2015,87(15):126-138.

[181]KODUR V K R, SHAKYA A M. Modeling the response of precast prestressed concrete hollowcore slabs exposed to fire[J]. PCI Journal,2014,59(3):78-94.

[182]周绪红,邓利斌,吴方伯,等. 预制混凝土叠合楼板耐火性能试验研究及有限元分析[J]. 建筑结构学报,2015,36(12):82-90. ZHOU Xuhong, DENG Libin, WU Fangbo, et al. Experimental research and FEA on fire resistance performance of precast concrete composite slabs[J]. Journal of Building Structures,2015,36(12):82-90.

[183]陆洲导,李刚,许立新.无粘结预应力混凝土框架火灾下结构反应分析[J]. 土木工程学报,2003,36(10):30-35. LU Zhoudao, LI Gang, XU Lixin. Analysis for structural response of unbounded prestressed reinforced concrete frames in fire environments[J]. China Civil Engineering Journal,2003,36(10):30-35.

[184]GALES J, BISBY L A, GILLIE M. Unbonded post tensioned concrete in fire: A review of data from furnace tests and real fires[J].Fire Safety Journal, 2011,46(4):151-163.

[185]ZHENG Wenzhong, HOU Xiaomeng, SHI Dongsheng, et al. Experimental study on concrete spalling in prestressed slabs subjected to fire[J]. Fire Safety Journal,2010,45(5):283-297.

[186]中华人民共和国住房和城乡建设部.无粘结预应力混凝土结构技术规程:JGJ92—2016 [S]. 北京:中国建筑工业出版社,2016. Ministry of Housing and Urban-Rural Development of China.Technical specification for concrete structures prestressed with unbounded tendons: JGJ92—2016 [S].Beijing:China architecture & building press,2016.

[187]WU Bo, SU Xiaoping, LI Hui, et al. Effect of high temperature on residual mechanical properties of confined and unconfined high-strength concrete[J]. ACI Materials Journal, 2002, 99(4): 399-407.

[188]ZHENG Wenzhong, LI Haiyan, WANG Ying. Compressive behavior of hybrid fiber-reinforced reactive powder concrete after high temperature[J]. Materials & Design, 2012, 41: 403-409.

[189]郑文忠, 李海艳, 王英. 高温后不同聚丙烯纤维掺量的活性粉末混凝土力学性能试验研究[J]. 建筑结构学报, 2012, 33(9): 119-126. ZHENG Wenzhong, LI Haiyan, WANG Ying. Mechanical properties of reactive powder concrete with different dosage of polypropylene fiber after high temperature[J]. Journal of Building Structures, 2012, 33(9): 119-126.

[190]李海艳, 郑文忠, 罗百福. 高温后RPC立方体抗压强度退化规律研究[J]. 哈尔滨工业大学学报, 2012, 44(4): 17-22. LI Haiyan, ZHENG Wenzhong, LUO Baifu. Experimental research on compressive strength degradation of reactive powder concrete after high temperature [J]. Journal of Harbin Institute of Technology, 2012, 44(4): 17-22.

[191]李海艳, 王英, 解恒燕, 等. 高温后活性粉末混凝土微观结构分析[J]. 华中科技大学学报(自然科学版), 2012, 40(5): 71-75. LI Haiyan, WANG Ying, XIE Hengyan, et al. Microstructure analysis of reactive powder concrete after exposed to high temperature[J]. Journal of Huazhong University of Science & Technology(Natural Science Edition),2012,40(5): 71-75.

[192]郑文忠, 李海艳, 王英. 高温后混杂纤维RPC单轴受压应力-应变关系[J].建筑材料学报,2013,16(3):388-395. ZHENG Wenzhong, LI Haiyan, WANG Ying. Compressive stress-strain relationship of hybrid fiber-reinforced reactive powder concrete after exposure to high temperature[J]. Journal of Building Materials,2013,16(3):388-395.

[193]经建生,侯晓萌,郑文忠. 高温后预应力钢筋和非预应力钢筋的力学性能[J].吉林大学学报(工学版),2010, 40(2):441-446. JING Jiansheng, HOU Xiaomeng, ZHENG Wenzhong. Experimental research on the mechanical properties of prestressing steel wire and non-prestressed steel bar after elevated temperature[J].Journal of Jilin University(Engineering and Technology Edition),2010,40(2):441-446.

[194]吴波,宿晓萍,李惠,等. 高温后约束高强混凝土力学性能的试验研究[J]. 土木工程学报,2002,35(2):26-32. WU Bo, SU Xiaoping, LI Hui, et al. Experimental study on mechanical properties of confined high-strength concrete after high temperature[J]. China Civil Engineering Journal,2002,35(2):26-32.

[195]吴波,马忠诚,欧进萍. 高温后钢筋混凝土柱抗震性能的试验研究[J]. 土木工程学报,1999,32(2):53-58. WU Bo, MA Zhongcheng, OU Jinping. Experimental study on seismic properties of RC columns after high temperature[J]. China Civil Engineering Journal,1999,32(2):53-58.

[196]郑文忠, 侯晓萌, 陈伟宏. 火灾后预应力混凝土简支板力学性能试验[J]. 哈尔滨工业大学学报, 2011, 43(2): 8-13. ZHENG Wenzhong, HOU Xiaomeng, CHEN Weihong. Experiment and analysis on mechanical performance of prestressed concrete simply-supported slab after elevated temperature[J].Journal of Harbin Institute of Technology, 2011,43(2):8-13.

[197]侯晓萌, 郑文忠. 火灾后预应力混凝土连续板力学性能试验与分析[J]. 湖南大学学报(自然科学版), 2010, 37(2): 6-13. HOU Xiaomeng, ZHENG Wenzhong. Experiment and analysis on mechanical performance of unbonded prestressed concrete continuous slab after elevated temperature[J].Journal of Hunan University(Natural Sciences), 2010,37(2):6-13.

[198]郑文忠, 陈伟宏, 侯晓萌. 火灾后配筋混凝土梁受力性能试验与分析[J]. 哈尔滨工业大学学报, 2008, 40(12), 1861-1867. ZHENG Wenzhong, CHEN Weihong, HOU Xiaomeng. Experiment and analysis on mechanical properties of reinforced concrete beam after fire[J].Journal of Harbin Institute of Technology, 2008,40(12):1861-1867.

[199]侯晓萌,郑文忠,孙洪宇.火灾作用下锚具对预应力钢棒锚固性能退化规律研究[J]. 建筑结构学报,2014, 35(3):110-118. HOU Xiaomeng, ZHENG Wenzhong, SUN Hongyu. Research on deterioration of anchoring performance between anchorages to steel bars for prestressed concrete under fire [J]. Journal of Building Structures,2014, 35(3):110-118.

[200]郑文忠,陈伟宏,王英. 碱矿渣胶凝材料的耐高温性能[J]. 华中科技大学学报(自然科学版),2009, 37(10):96-99. ZHENG Wenzhong, CHEN Weihong, WANG Ying. High-temperature resistance performance of alkali-activated slag cementitious materials[J]. Journal of Huazhong University of Science & Technology(Natural Science Edition),2009, 37(10):96-99.

[201]郑文忠,陈伟宏,徐威,等. 用碱激发矿渣耐高温无机胶在混凝土表面粘贴碳纤维布试验研究[J].建筑结构学报,2009, 30(4):138-144. ZHENG Wenzhong, CHEN Weihong, XU Wei, et al. Experimental research on alkali-activated slag high temperature resistant inorganic adhesive pasting CFRP sheets on surface of concrete[J]. Journal of Building Structures, 2009, 30(4):138-144.

[202]万夫雄, 郑文忠. 无机胶粘贴碳纤维布加固板防火涂层厚度取值[J]. 哈尔滨工业大学学报, 2012, 44(2): 11-16. WAN Fuxiong, ZHENG Wenzhong. Thickness value of fireproof coating for slabs strengthened with Carbon Fiber Sheet bonded with an inorganic adhesive[J]. Journal of Harbin Institute of Technology, 2012, 44(2): 11-16.

[203]郑文忠, 万夫雄, 李时光. 用无机胶粘贴CFRP布加固混凝土板抗火性能试验研究[J]. 建筑结构学报, 2010, 31(10):89-97. ZHENG Wenzhong, WAN Fuxiong, LI Shiguang. Experimental research of fire performance on reinforced concrete slabs strengthened with CFRP sheets bonded with inorganic adhesive[J]. Journal of Building Structures, 2010, 31(10):89-97.

[204]郑文忠, 朱晶. 无机胶凝材料粘贴碳纤维布加固混凝土结构研究进展[J]. 建筑结构学报, 2013, 34(6): 1-12. ZHENG Wenzhong, ZHU Jing. Progress of research on concrete structures strengthened with CFRP sheets with inorganic adhesive[J]. Journal of Building Structures, 2013, 34(6): 1-12.

[205]郑文忠,陈伟宏,张建华. 碱矿渣胶凝材料作胶粘剂的植筋性能研究[J]. 武汉理工大学学,2009, 31(14):10-14. ZHENG Wenzhong, CHEN Weihong, ZHANG Jianhua. Experimental research on performance on bonded rebars with alkali-activated cementitious material[J].Journal of Wuhan University of Technology,2009, 31(14):10-14.

(编辑 赵丽莹)

Progress and prospect of fire resistance of reinforced concrete and prestressed concrete structures

ZHENG Wenzhong1,2, HOU Xiaomeng1,2,WANG Ying1,2

(1.Key Lab of Structures Dynamic Behavior and Control (Harbin Institute of Technology), Ministry of Education,Harbin 150090, China; 2. School of Civil Engineering, Harbin Institute of Technology, Harbin 150090, China)

In this chapter, the fire resistance of reinforced concrete and prestressed concrete structures are outlined to expend further research. The progress and prospect in fire resistance of reinforced concrete (RC) structures and prestressed concrete(PC) structures and its repair technology after fire is presented, and some issues that still need to be investigated are discussed. The progress mainly includes mechanical properties of materials at elevated temperatures, fire resistance of RC and PC structures, and fire-induced spalling of concrete. The results show that spalling critical temperature of concrete varies with compressive strength of concrete. Adding steel fibers or polypropylene (PP) fibers is able to prevent fire-included spalling of concrete effectively. The criteria considering nominal stress of concrete and concrete strength is effective for judging fire-induced spalling, which is capable for reducing the possibility of fire-induced spalling of concrete in PC members. The requirements that concrete structures will not collapse or spalling during fire and can be repaired after fire should be satisfied in fire safety design. Rational fibers dosage to prevent fire-included spalling of concrete, fire-included spalling and its prediction model on RC and PC members, fire-induced spalling of RPC, temperature-stress coupling strain-stress relation of RPC and fire resistance of RPC members, effect of force-temperature paths on behaviors of structures and members, fire resistance of high-rise buildings and underground structures are the main problems which need to be studied in the future.

reinforced concrete; prestressed concrete; spalling; fire resistance; fire safety design

10.11918/j.issn.0367-6234.2016.12.001

2016-02-27

国家自然科学基金(51578184,51478142); 黑龙江省博士后科研启动基金(LBH-Q15058)

郑文忠(1965—),男,长江学者特聘教授,博士生导师; 侯晓萌(1982—),男,副教授,博士生导师

侯晓萌,houxiaomeng_hit@126.com

TU378.1

A

0367-6234(2016)12-0001-18