ICP工艺参数对刻蚀Pyrex玻璃影响的实验研究*

张迪雅,梁 庭*,刘雨涛,王涛龙,李旺旺,姚 宗,熊继军

(1.中北大学仪器科学与动态测试教育部重点实验室,太原030051;2.中北大学电子测试技术国防科技重点实验室,太原030051)

ICP工艺参数对刻蚀Pyrex玻璃影响的实验研究*

张迪雅1,2,梁庭1,2*,刘雨涛1,2,王涛龙1,2,李旺旺1,2,姚宗1,2,熊继军1,2

(1.中北大学仪器科学与动态测试教育部重点实验室,太原030051;2.中北大学电子测试技术国防科技重点实验室,太原030051)

影响ICP刻蚀的工艺参数包括反应室压力,偏置射频功率,氩气流量比率。通过正交试验的方法,以CHF3和Ar的混合物作为反应气体,利用电感耦合等离子体技术刻蚀Pyrex玻璃。并采用回归分析方法建立了二次回归方程模型描述腐蚀速率和三个因素之间的关系。实验结果表明,氩气的流量比率(总气体流量(CHF3+Ar)是恒定的)对刻蚀速率的影响最大,影响程度的主次顺序为氩气的流量比率,反应室压力,偏置射频功率。腐蚀速率和三个因素之间的数学表达式为:腐蚀速率= 532.680 0+2.055 6×Ar+0.012 7×(偏置射频功率)-0.964 1×压力-0.065 5×Ar2-0.006 7×Ar×(偏置射频功率)+0.021 7×(偏置射频功率)×压力-0.050 4×(压力)2,实验结果证明数学拟合结果良好。

感应耦合等离子刻蚀;Pyrex玻璃;正交试验;刻蚀速率;数学拟合

Pyrex 7740 glass are commonly used in many Micro Electron Mechanical System(MEMS)device applications including microfluidic,RF and wave-guide due to its significant properties such as high electric insulation,good bio-compatibility and excellent optical transmission and so on[1-2].

Most applications require the glass wafers they use to be etched.There are three major technologies for glass etching:mechanical machining,dry etching and wet etching[3-4].Dry etching provides wafer level processing and many other advantages,such as high aspect ratio,an improved etching ratio control,preciseetching size and sidewall practicality.Several dry etching systems with high-density plasma sources including inductively coupled plasma(ICP),electron cyclotron resonance(ECR)have been reported to etch glass substrates[5-6].Two major advantages with ICP reactors are the ability to deliver high density of ions,electrons and radicals with good uniformity over wafer diameter of 200mm,and it allows both ion bombardment energy and plasma density to be controlled independently of each other,leading to increase flexibility in designing etch products[7-8].

In this paper,the CHF3/Ar gas mixture was used as the etch gas based on ICP dry etching principle[9],and the influence and significance of three key factors on etching rate,including reaction chamber pressure,bias RF and Ar flow rate ratio were studied and the mechanism of effect were explained.Meanwhile the numerical relation between the etching rate and three factors was calculated and analyzed by the regression analysis method.

1 Experiments

Pyrex glasses were etched using an ICP system (NMC GSE200 plus,China)equipped with a process module and a transfer module.The vacuum of the process chamber is generated by a turbo molecular pump and a dry pump to obtain process pressures range from 2 m to 80 mTorr.To control the heat generated during the etching process and keep chemical etching reaction steady,the wafer is held by an electrostatic chuck and He gas is used as a heat exchange medium between the wafer and the chuck[10].A fluid flowing from the chiller is circulated through the chuck to cool.The chuck can be RF biased at 13.56 MHz in order to control ion bombardment energy to the wafer.High density plasma was generated by a coil located on top of the main chamber that is connected to a 13.56 MHz RF power supply[11].

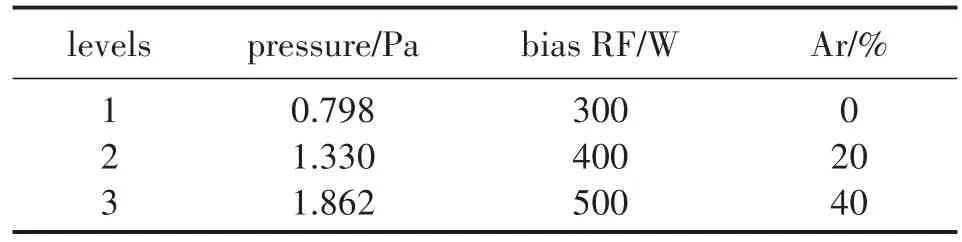

The factors which affect the etching rate are reaction chamber pressure,bias RF,source RF,reactant flow rate,substrate temperature and so on in ICP etching system.In this paper,CHF3/Ar mixture had been adopted for ICP etching of Pyrex glass and process parameters including reaction chamber pressure,bias RF and Ar flow rate ratio on etching rate were investigated by the orthogonal experiment design method and L9(34) orthogonal table was selected for this experiment.Take the pressure,bias RF and Ar flow rate ratio as three factors and each factor includes three levels.The orthogonal experiments which incorporate three factors and three levels were carried out.The factor level table of the experiment was shown in Table 1.The Other etching process was performed under fixed parameters:a source RF of 1 000 W,the total flow rate of CHF3/Ar was a 100 scam(standard-state cubic centimeter per minute)and a substrate temperature of 20℃.Aluminum film,which was prepared by magneto sputtering was selected as an etching mask.Etching rates were obtained from measuring positions both near the center and edge of the etched samples by KLA Content P-7 stylus profiteering after the removal of the Aluminum pattern by thermal phosphoric acid.

In order to reduce the influence of system error caused by the human factors,we conducted the experiments randomly in L9(34)table.

Table 1 Factor level table

2 Results and Discussion

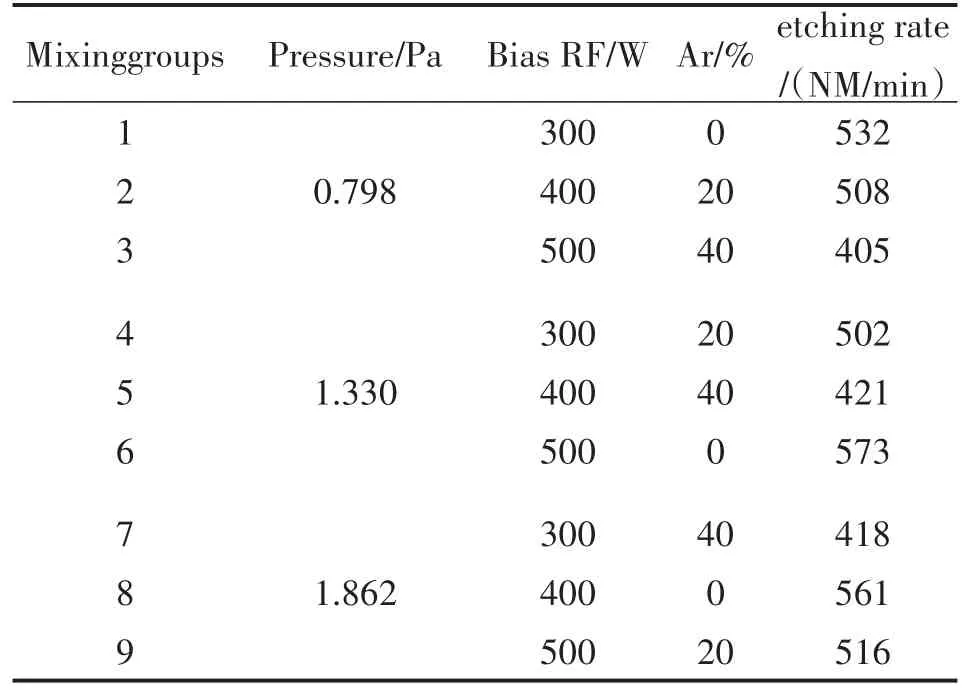

The results of the etching rate of orthogonal experiments were listed in Table 2.

Table 2 The orthogonal experimental results table

2.1Significance analysis of process parameters influenced on etching rate

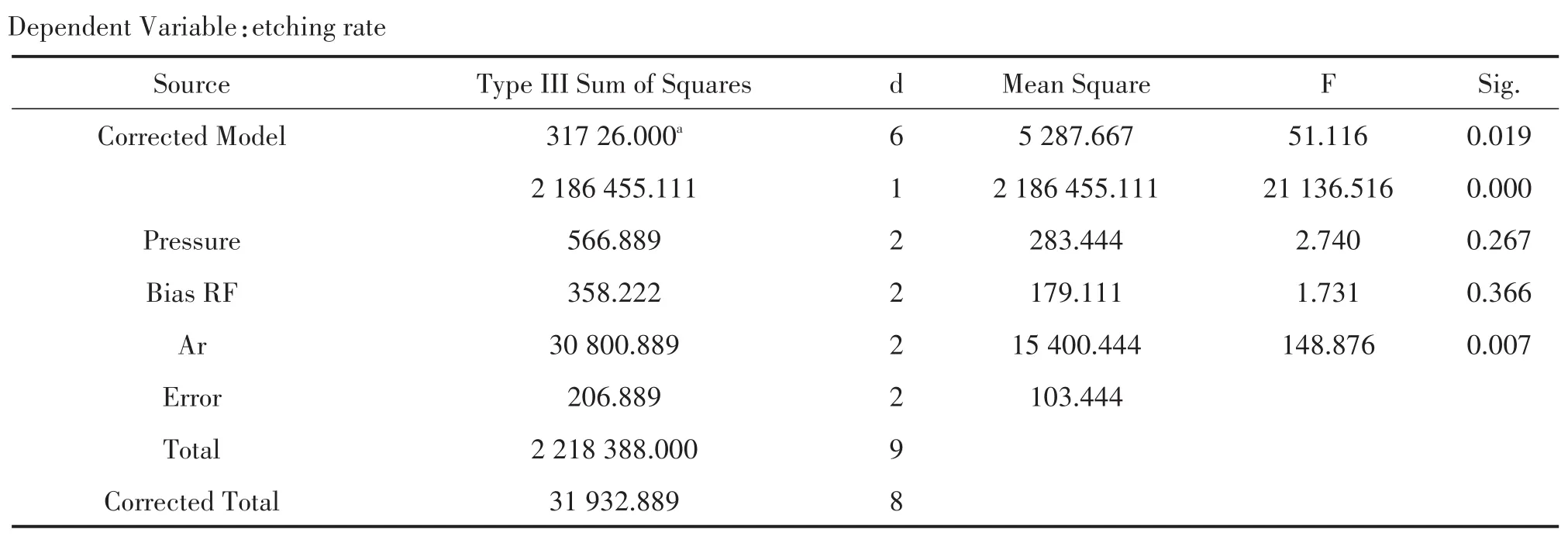

According to the orthogonal experimental data of Table 2,single dependent variable factor analysis of variance was calculated by SPSS software and the maineffect analysis of variance test results were presented in table 3.

We can see from table 3 that the mean square deviation of the error term is 103.444,mean square Error of the pressure is 283.444,mean square deviation of bias RF is 179.111 and mean square deviation of the Ar flow rate ratio is 15 400.444.Obviously,mean square deviation of the error term is less than mean square deviation of three factors,which shows that the differences between the experimental results are caused by different levels of the factors,not by the error,which explains the experiment design is reasonable and accurate.

Table 3 The variance analysis of orthogonal design of L9(34)

Sig.in the main effect analysis of variance table is a critical value of significant probability p.In the variance analysis,assuming that no significant differences between means of various factors and critical value of significant probability p is equal to 0.05.That value of Sig.is greater than 0.05 suggests that the original assumptions cannot be denied,which means the factor did not significantly affect the results.The larger the value of Sig.,the greater the probability of the original assumptions is true,namely the influence of the factor on experimental results is not obvious;on the contrary,the factor has a significant influence.The table 3 shows that Sig.of Ar=0.007<0.05,so the Ar flow rate ratio is highly significant influence on etching rate. Sig.of pressure=0.267>0.05 and Sig.of bias RF= 0.366>0.05,so the influence of pressure and bias RF on etching rate is not significant.

2.2Mechanism analysis of various process parameters influenced on etching rate

It was concluded from the results of the F-check in the Table 7 that the influence of three factors on the etching rate was in the order of Ar>pressure>bias RF,meanwhile trend graphs were plotted by SPSS.We can intuitively come to the conclusion that the chemical reaction was more effective than the physical sputtering from this order.

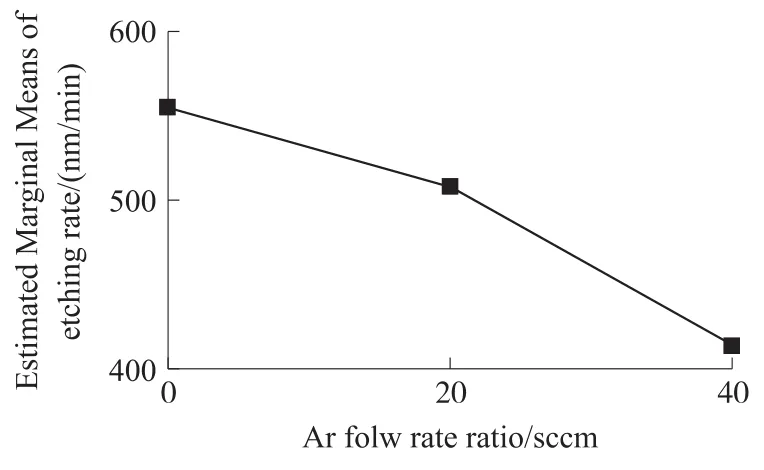

Fig.1 Effect of Ar flow rate ratio on etching rate

2.2.1Effect of Ar flow rate ratio

Fig.1 shows the etching rate when the Ar flow rate ratio is changed.For Pyrex glass there is a monotonic decrease greatly in etching rate with Ar percentage(the total gases flow rate is constant)increased.The difference between maximum and minimum etching rate is about 141 nm/min,which means that Ar percentage changing has a significant influence on etching rate and it is a major factor determining the etching rate of Pyrex glass.Ar has effects of steady,uniform and dilute plasma and enhance the effect of anisotropic etching as an inert gas[12].The Ar influences the etching rate by supporting chemical reaction is attributed to increase the ionic bombardment and chemical bond breakage efficiencies[13],but the experimental results which the etching rate of Pyrex glass decreases at the Ar flow rate ratio varying from 0 to 40 percentage due to the dilution of the reactants,meanwhile indicate thatchemical reaction etching plays a main role in etching of Pyrex glass for CHF3and for a given range of experimental conditions,physical etching effect of Ar as an additional gas is far less than chemical effect of CHF3. However,the addition of Ar to CHF3can strongly increase verticality of the sidewall of etching pattern by removing the nonvolatile compounds which absorbed on the surface of sidewall in some other reports[14].

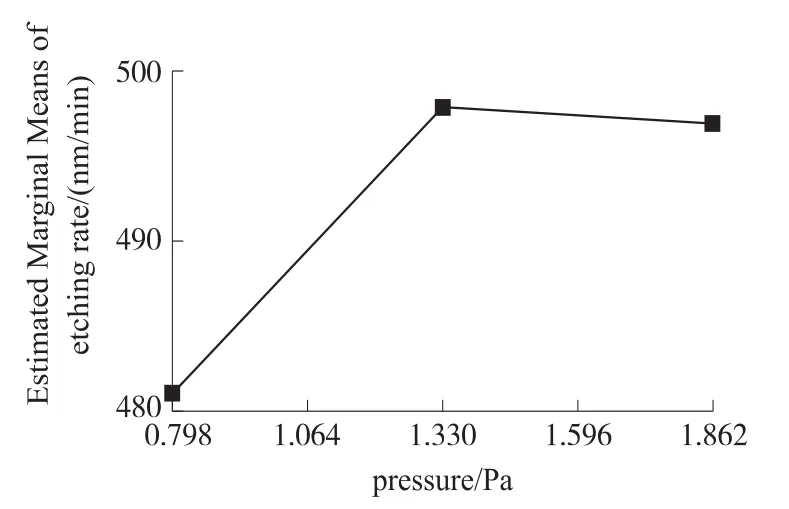

2.2.2Effect of reaction chamber pressure

Fig.2 shows the variation of the etching rate with reaction chamber pressure.The etching rate initially increases with pressure from 6 to 10 mTorr and then tends to decrease slightly though the pressure is increased from 10 mTorr to 14 mTorr further.The manner in which the etching rate depends on pressure is complex as many effects occur simultaneously.Firstly,when the pressure is increased initially,the residence of gas species by the equation:

Where t,P,V,and Q are the residence time,pressure,volume,and throughout,respectively.When the total gas flow rate is constant,the residence time is proportional to the reactor pressure.The reaction chamber pressure influences the chemistry in the plasma by affecting the residence time of the gases which result in more molecule of the etching mixture dissociated and evaluate the number of radicals simultaneously to raising the chemical reaction rate.It is well known that the compositions of Pyrex glass contain atoms such as Na,Al,Ca,and Mg and so on[15].As the etching rate is raised,these atoms produce more many nonvolatile compounds(AlF3,NaF etc.)during chemical reactions etching[16].Increasing the pressure means that nonvolatile products cannot be pumped away more quickly from the tube so that they redeposition the etching surface of the substrate as micro-masks to prevent the etching process going further.Not only resulting in grassing and surface roughness[17],but decreasing etching rate.

Fig.2 Effect of reaction chamber pressure on etching rate

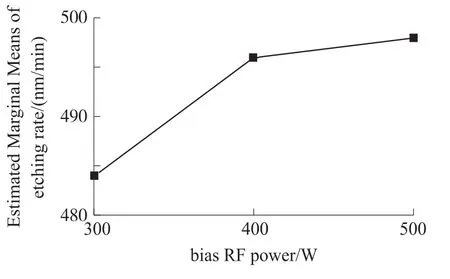

2.2.3Effect of bias RF

Fig.3 shows etching rate versus bias RF.As bias RF increased,the etch rate of the Pyrex glass increases but gradually slowly.The observation indicates the importance of ion energy in the etch mechanism.Bias RF can provide ion bombardment energy for physical etching independently[18].The increase of bias RF is contribution to increase energy and directionality of the ions to the substrate which results in a more anisotropic pattern characteristic of the sidewall by physical sputtering etching.Meanwhile the chemical reaction etching rate also is raised.Nevertheless,as the bias RF increases further,increase of the etching rate become slow.There are two main reasons for the situation. Firstly,the number of bombardment of ions is too large for the reactant to sufficiently react with materials on the sample surface and being carried away so that restraining the reaction rate increased quickly.On the other hand,the results of strong physical bombardment result in nonvolatile products recombination more quickly and deposit on the etching surface of the substrate[19].

Fig.3 Effect of bias RF on etching rate

3.3The quantitative analysis of effect of three

factors on etching rate of Pyrex glass

Orthogonal experiment results have shown that all three factors have an influence on etching rate and Ar has a significant influence.Based on the above,we suppose to find the numerical relationship between etching rate and levels of three factors,and the nonlinear regressions of the evaluating etching rate against individual factors were treated in SPSS software.

The approximate equation of the nonlinear relationship has a form of quadratic polynomial of the independent variable,so combining with the analysis in Section

3.1,we proposed the regression modelthatwas as follow:

Y(etching rate)=a+b×(Ar percentage)+c×(bias RF)+d×(pressure)+e×(Ar percentage)2+f×(Ar percentage)×(bias RF)+g×(bias RF)×pressure+h×(pressure)2

Where a is constant term,b,c,d,e,f,g and h are all coefficient of quadratic equation.The Ar percentage,bias RF and pressure for etching rate replace content,respectively.

The corresponding two-order polynomial equation was obtained through the simulation and regression analysis of numerical results listed in Table 2 by SPSS software:

Etching rate=532.680 0+2.055 6×Ar+0.012 7× (bias RF)-0.964 1×pressure-0.065 5×Ar2-0.006 7Ar× (bias RF)+0.021 7×(bias RF)×pressure-0.050 4× (pressure)2

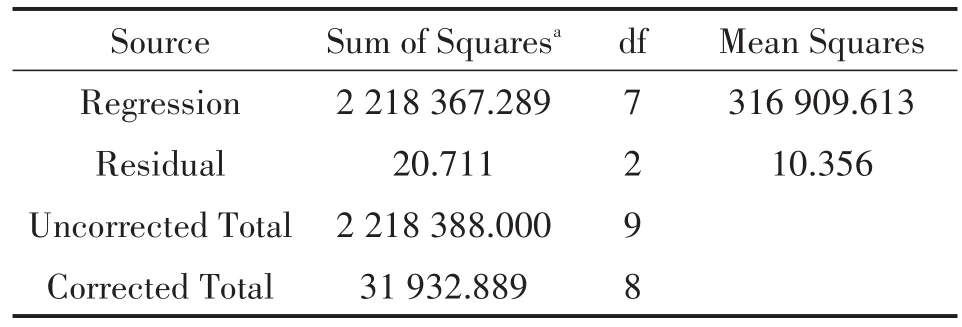

The analysis of variance(ANOVA)was used to determine statistical validity of the regression equation, of which analysis results were displayed in Table 4.

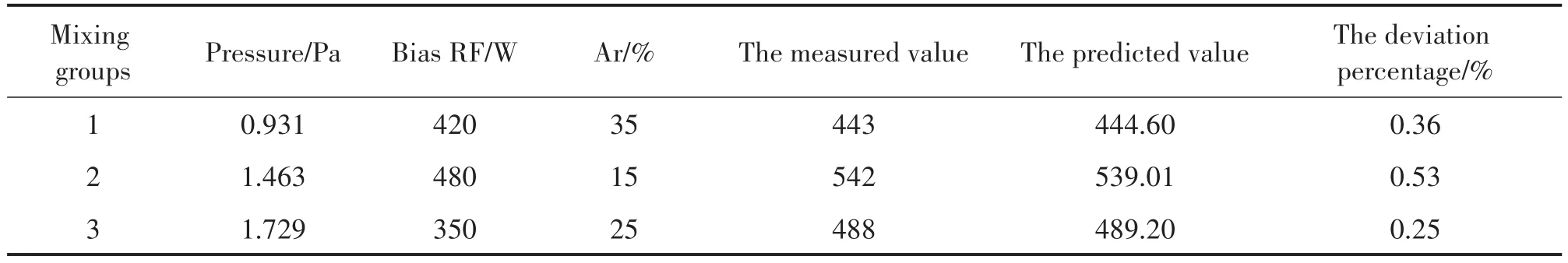

As we can see in Table 4,correlation R2=1.000,therefore mathematical fitting of the regression equation is very excellent.In addition,within the scope of the value of three factors,freely choose the parameters of three combinations for etching.the etching rate results were predicted using the regression equation that had been obtained above to verify the accuracy of the regression equation.The predicted data and measured data on the etching rate were summarized in Table 5.

Table 4 The analysis of variance(ANOVA)table

Table 5 Comparison table of the predicted data and measured data

It can be clearly seen from Table 5 the experimental and numerical results showed a good agreement,which demonstrates that the proposed regression equation are accepted completely.

3 Conclusions

In this paper,a scheme of orthogonal experiment which includes three factors and three levels for was designed and carried out based on the principle of inductively coupled plasma etching using a mixture of CHF3/Ar to study the influence and significance of reaction chamber pressure,bias RF,and Ar flow rate ratio on the etching rate of Pyrex glass.The Ar flow rate ratio is obtained are highly significant influence on the etching rate and decrease of Ar percentage is contribution to increase the etching rate obviously.Meanwhile experimental results showed that the factors influencing the etching rate in descending order was Ar>pressure>bias RF.The influence mechanism was discussed.Also,the relation between the etching rate and three factors,including was calculated and analyzed by the regression analysis method,of which mathematical expression is Etching rate=532.68 0+ 2.055 6×Ar+0.012 7×(bias RF)-0.964 1×pressure-0.065 5×Ar2-0.006 7Ar×(bias RF)+0.021 7×(bias RF)×pressure-0.050 4×(pressure)2,and the verification results confirmed that mathematical fitting was very excellent.

References

[1]Iliescu C,Jing J,Tay F E H,et al.Characterization of Masking Layers for Deep Wet Etching of Glass in an Improved HF/HCl Solution[J].Surface&Coatings Technology,2005,198(s 1-3):314-318.

[2]Li X,Abe T,Liu Y,et al.High Density Electrical Feedthrough Fabricated by Deep Reactive Ion Etching of Pyrex Glass[C]// IEEE International Conference on Micro Electro Mechanical Systems.2001:98-101.

[3]Jin J Y,Yoo S,Bae J S,et al.Deep Wet Etching of Borosilicate Glass and Fused Silica with Dehydrated AZ4330 and a Cr/Au Mask[J].Journal of Micromechanics&Microengineering,2014,24(1):163-175.

[4]He Kaixuan,Huang Bin,Duan Baoming,et al.Comparison Research on the Protection Methods for MEMS Suspended Structure Deep Reactive Ion Etching[J].Chinese Journal of Sensors and Actuators,2016,29(2):202-207.

[5]Kolari K,Saarela V,Franssila S.Deep Plasma Etching of Glass for Fluidic Devices with Different Mask Materials[J].Journal of Micromechanics&Microengineering,2008,18(6):584-588.

[6]Szczesny A,Sniecikowski P,Szmidt J,et al.Reactive Ion Etching of Novel Materials—GaN and SiC[J].Vacuum,2003,70(70):249-254.

[7]Lee T Y,Kim E H,Chung C W.Inductively Coupled Plasma Reactive Ion Etching of IrMn Magnetic Thin Films Using a CH4/O2/ Ar gas[J].Thin Solid Films,2012,521(43):229-234.

[8]Li Dandan,Li Ting,Li Sai,et al.Design of SOI High Temperature Pressure Sensor Based on MEMS Process[J].Chinese Journal of Sensors and Actuators,2015,28(9):1315-1320.

[9]Ronggui S,Righini G C.Characterization of Reactive Ion Etching of Glass and Its Applications in Integrated Optics[J].Journal of Vacuum Science&Technology a Vacuum Surfaces&Films,1995,76(4):609-617.

[10]Choe H H.Basic Study of a Glass Substrate in Dry Etching System [J].Vacuum,2006,81(3):344-346.

[11]Garay A A,Su M H,Chung C W.Dry Etching of Co 2 MnSi Magnetic Thin Films Using a CH 3 OH/Ar Based Inductively Coupled Plasma[J].Vacuum,2015,111:19-24.

[12]Garay A A,Su M H,Chung C W.Dry Etching of Co 2 MnSi Magnetic Thin Films Using a CH 3 OH/Ar Based Inductively Coupled Plasma[J].Vacuum,2015,111:19-24.

[13]Tang Y H,Lin Y H,Chen P L,et al.Comparison of Optimised Conditions for Inductively Coupled Plasma-Reactive Ion Etching of Quartz Substrates and Its Optical Applications[J].Micro&Nano Letters,2014,9(6):395-398.

[14]Park J H,Lee N E,Lee J,et al.Deep Dry Etching of Borosilicate Glass Using SF6 and SF6/Ar Inductively Coupled Plasmas[J].Microelectronic Engineering,2005,82(2):119-128.

[15]Baram A,Naftali M.Dry Etching of Deep Cavities in Pyrex for MEMS Applications Using Standard Lithography[J].Journal of Micromechanics&Microengineering,2006,16(11):2287-2291.

[16]Li X,Abe T,Esashi M.Deep Reactive Ion Etching of Pyrex Glass Using SF 6 Plasma[J].Sensors&Actuators A Physical,2001,87 (3):139-145.

[17]Kim J H,Kim E J,Choi H C,et al.Evaluation of Fluorinated Polyimide Etching Processes for Optical Waveguide Fabrication[J]. Thin Solid Films,1999,341(1/2):192-195.

[18]Woo J C,Chun Y S,Joo Y H,et al.The Dry Etching Property of TiO 2 Thin Films Using Metal-Insulator-Metal Capacitor in Inductively Coupled Plasma System[J].Vacuum,2012,86(12):2152-2157.

[19]Li X,Abe T,Esashi M.Deep Reactive Ion Etching of Pyrex Glass [C]//IEEE International Conference on Micro Electro Mechanical Systems.2000:271-276.

张迪雅(1991-),女,籍贯山西省,在读研究生,主要研究方向为MEMS高温压力传感器,18234157832@163.com;

梁庭(1979-),男,籍贯山西省,副教授、硕士生导师、博士,主要研究方向为光学气体传感器及高温压力传感器,liangtingnuc@163.com。

Experimental Study of the Influence of ICP Process Parameters on Etching of Pyrex Glass*

ZHANG Diya1,2,LIANG Ting1,2*,LIU Yutao1,2,WANG Taolong1,2,LI Wangwang1,2,YAO Zong1,2,XIONG Jijun1,2

(1.Key Laboratory of Instrumentation Science&Dynamic Measuremen(tNorth University of China),Ministry of Education,Taiyuan 030051,China;2.Science and Technology on Electronic Test&Measurement Laboratory,North University of China,Taiyuan 030051,China)

The influence of the inductively coupled plasma etching process parameters including reaction chamber pressure,bias RF power and Ar flow rate ratio.By the method of orthogonal experiment,ICP etching technology was used to etch Pyrex glass using a mixture of CHF3 and Ar as the reactant gas sources.The regression analysis method was adopted to build quadratic equation model describing the relationship between etching rate and three factors.Experimental results demonstrated the influence of Ar rate ratio(the total gases flow rate(CHF3+Ar)was constant)on etching rate was highly significant,and the factors affecting the etching rate in descending order was Ar flow rate ratio,reaction chamber pressure and bias RF power.The mathematical expression between etching rate and three factors was Etching rate=532.680 0+2.055 6×Ar+0.012 7×(bias RF)-0.964 1×pressure-0.065 5×Ar2-0.006 7Ar×(bias RF)+0.021 7×(bias RF)×pressure-0.050 4×(pressure)2,and the verification results confirmed that mathematical fitting was very excellent.

inductively coupled plasma etching;Pyrex glass;orthogonal experiment;etching rate;mathematical fitting EEACC:0570

10.3969/j.issn.1004-1699.2016.08.004

TN305

A

1004-1699(2016)08-1149-06

项目来源:National Science Foundation for Distinguished Young Scholars of China(51425505)

2015-11-24修改日期:2016-04-26