Prediction ofdispersed phase holdup in pulsed disc and doughnut solvent extraction columns under different mass transfer conditions

Yong Wang,Kathryn H.Smith,Kathryn Mumford,Teobaldo F.Grabin,Zheng Li,Geoffrey W.Stevens*

Particulate Fluids Processing Centre,Department ofChemicaland Biomolecular Engineering,The University of Melbourne,Parkville,VIC 3010,Australia

1.Introduction

Various types of solvent extraction contactors,including spray columns,packed columns and Karr columns,have been used for a range of applications in the hydrometallurgical,pharmaceutical and petrochemical industries for many years.The pulsed disc and doughnut solvent extraction column(PDDC)was originally described by Van Dijck[1].Today,this column has found application in the separation and purification ofcomponents that include the spent nuclear fuel and uranium industries[2].Compared to mixer-settlers,which are frequently used in the mining industry,the PDDC is attractive from both safety and economic stand points,in particular its simplicity ofdesign,less space consumption,higher throughput and no internal moving parts[3].

Introduction of a solvent into any extractor causes the droplets to undergo repeated coalescence and breakage,leading to an equilibrium drop size distribution.The resulting fractional volumetric holdup,xd,is defined as volume fraction of the active section of the column thatis occupied by the dispersed phase:

where vdrepresents the volume of the dispersed phase and vtrepresents the totalvolume of the two phases for the effective length of the column.

The dispersed phase holdup is an important parameter in the design of solvent extraction columns as it is related to the inter facialarea for mass transfer and the flood point of the column.Therefore prediction of the dispersed phase holdup is off undamentalimportance in the design of solvent extraction columns[4].

Additionally,extraction experiments have revealed that mass transfer direction has a significant effect on the droplet behaviour in liquid dispersions[5].In the case of solute transfer from the continuous phase to the dispersed phase,smaller drop sizes are observed due to higher breakage rates.The smaller drops have longer residence times and therefore the holdup increases.Conversely for mass transfer from the drop to the continuous phase,the coalescence rate is enhanced creating larger drops and lower holdup[4,6,7].Therefore,dispersed phase holdup is also affected by the direction of the mass transfer.

In the presentwork,we analyse the published holdup data for a PDDC both with and without mass transfer and suggest new empiricalcorrelations in terms ofphysicalproperties,operating conditions and column geometry.

2.Previous Work

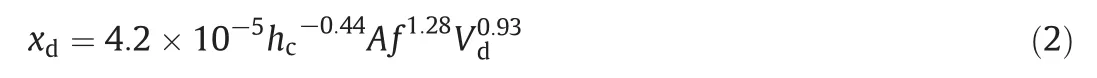

Jeong[8]presented a correlation for the prediction of dispersed phase holdup in a 4.2 cm diameter pulsed disc and doughnut column using the kerosene-water system.The doughnut and disc plates were made of 1 mm thick stainless steel.The organic phase(Kerosene)was the dispersed phase.This correlation does notinclude the physicalproperties of the phases but is dependenton the operating conditions and plate geometry as follows:

where hcis the compartment height(cm);A is the pulsing amplitude(cm);f is the pulsing frequency(min-1);and Vdis the dispersed phase velocity(cm·min-1).

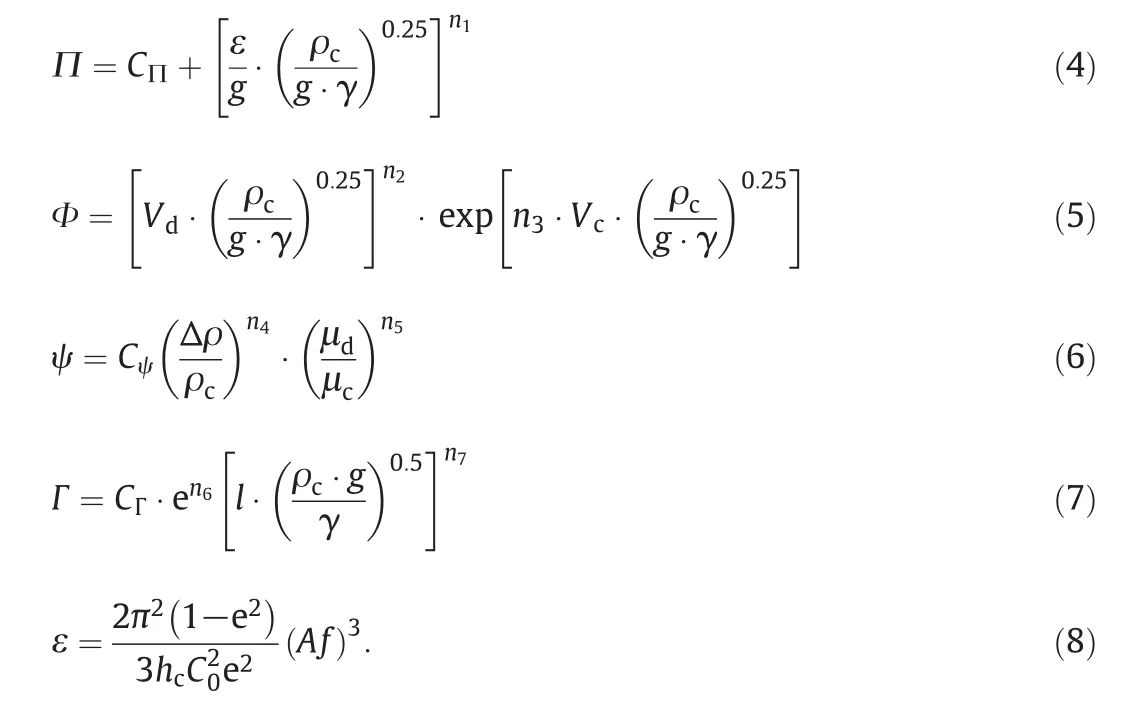

Kumar and Hartland[4]used a large bank ofpublished data including eight different types of solvent extraction columns(but did not include the PDDC)to develop a unified correlation for holdup as a function of various dimensionless groups as follows:

in which Π allows for the mechanicalpower input per unit mass,ε;Φ allows for the effect of the phase velocities,Vcand Vd;ψincorporates the physicalproperties andΓrepresents the geometrical characteristics of the column.The parameters are defined as:

The constants CΠ,CΨand CΓand the coefficients n1to n7were adjusted to each type of column.For no mass transfer,CΨ=1 and different values of CΨwere defined foreach column type depending on the directions of mass transfer.

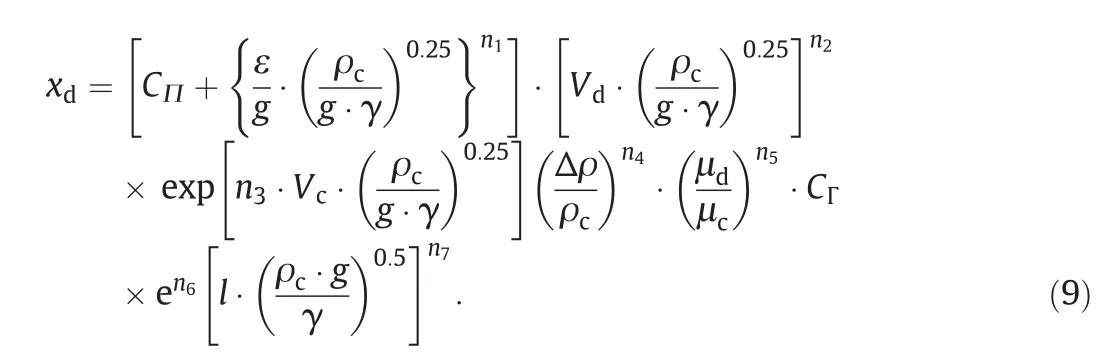

Combining Eqs.(3)to(8)resulted in a unified correlation[4]for eight different types of solvent extraction columns which did not include the PDDC.The resulting correlation is:

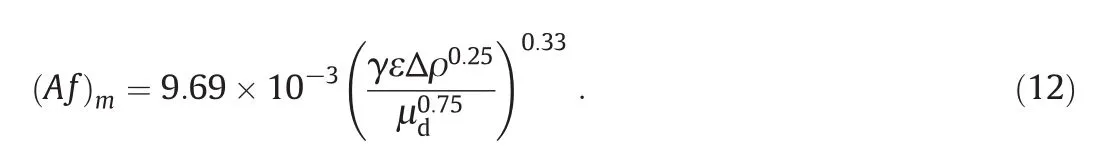

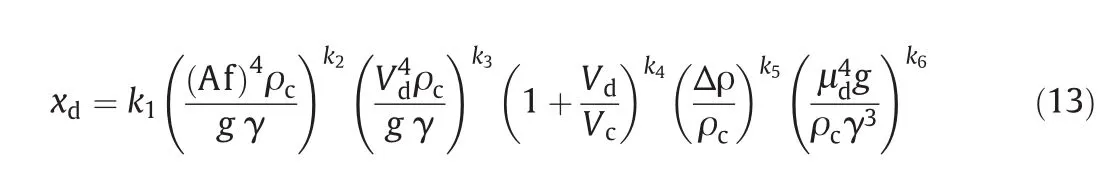

Delden[9]used Eq.(9)to predictholdup in a PDDC based on his data for the forward and back-extraction of caprolactam using toluene.The holdup data was obtained under different mass transfer conditions but this was not taken into account when developing a holdup correlation.Very large deviations(Average absolute value of the relative error,AARE=68.8%)between experimental and predicted values were found when using the original fit parameters provided with the unified correlation(Eq.(9))presented by Kumar and Hartland[4](the correlation fit parameters can be found in Table 1).Delden[9]re fitted the constants for Eq.(9),as shown in Table 1,and the AARE was reduced to 12.2%.This study did notconsider the effect of mass transfer direction on holdup.More recently,Rajnish[10]re fitted the holdup data from a PDDC using Eq.(9)for a system of nitric acid 0.5 mol·L-1(continuous aqueous phase)and 30%(by volume)TBP in normalparaffinic hydrocarbon(an industrial substitute of n-dodecane;dispersed organic phase).The re fitted constants by Rajnish(CΠ=3.11 and n1=0.68)were able to predict the experimental data to within±20%but again mass transfer direction still was not included in this correlation.

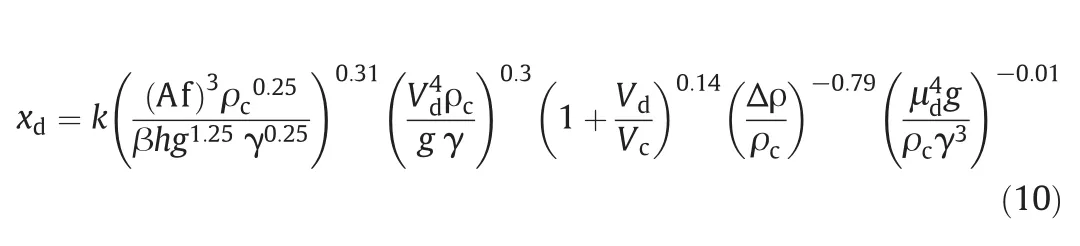

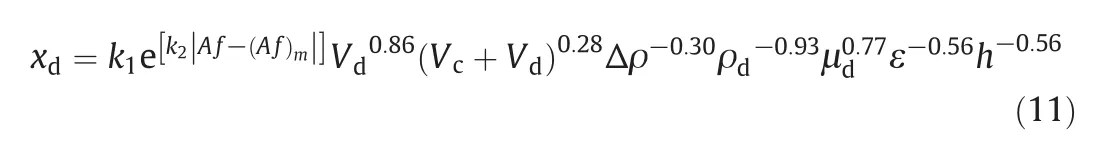

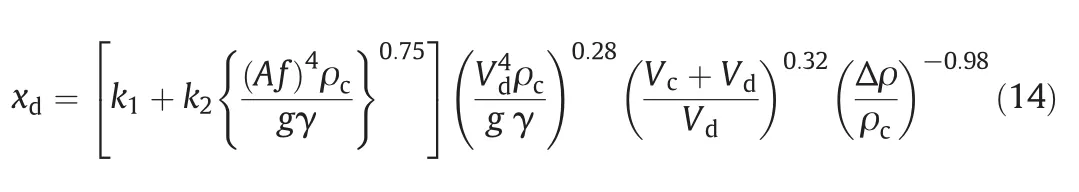

The mostextensive study on holdup using a PDDC has been done by Jahya[11]and included the operation of non-mass transfer conditions as well as dispersed to continuous phase and continuous to dispersed phase mass transfer.He made use of an existing correlation for holdup(Eq.(10))which is for a pulsed sieve-plate liquid–liquid extraction column(PSPC)[12]and re fitted his experimental data.where the parameter k is fitted under different extraction system without considering the mass transfer direction.At the same time,another existing correlation[12]for a pulsed perforated-plate extraction column was used to predict the holdup data from a PDDC by Jahya[11]:

in which

k1and k2were constant parameters(refer to Table 2 for values of constants k1and k2and corresponding AARE).It can be seen from Table 2 that the parameters in Eq.(11)were different depending on the pulsing conditions and the extraction systems being studied.

Table 2 Fitted parameters and AARE for predicting holdup using Eq.(11)and Jahya experimental data[11]

Table 1 Originaland re fitted constants for predicting holdup in a PDDC using Eq.(9)and Delden[7]experimental data

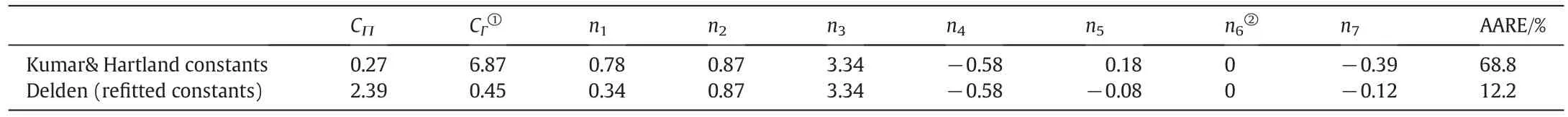

Finally Torab-Mostaedi[13]proposed a correlation for prediction of holdup for a PDDC,based onn-butylacetate-water,toluene-water,and kerosene-water system with stainless steel plates in the absence of mass transfer.For mixer settler regime and transition/emulsion regions,the correlation is as follows in Eq.(13)and the fitted parameters and AARE are shown in Table 3.

Table 3 Fitted parameters and AARE for predicting holdup using Eq.(13)and Torab-Mostaedi[13]experimental data

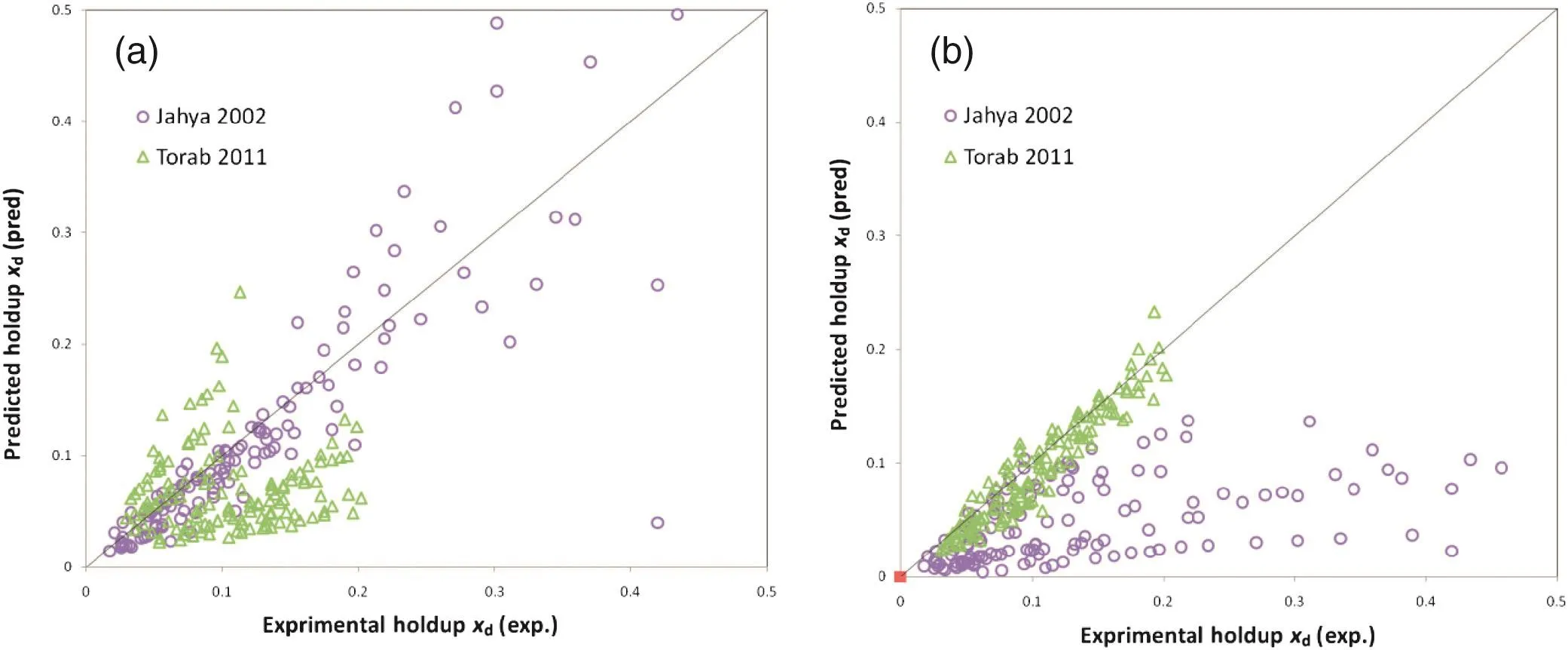

Using Eqs.(11)and(13),itcan be seen that the holdup ofPDDCs can be predicted well(AAREs in Table 2 and 3 are relatively small).However,these two equations can only be used for predicting holdup using these specific columns,extraction systems and pulsing conditions.The accuracy of the prediction decreases dramatically ifthese correlations are used for the holdup prediction in other PDDCs and atdifferento perating conditions.Forexample,Fig.1 shows the comparison between the experimentalPDDC holdup data from Jahya[11]and Torab[13]with thecorrelations developed by Jahya(Eq.(11))and Torab(Eq.(13)).These equations can only predict the holdup in their own study well and there are large deviations when these correlations are used to predict holdup for other studies.

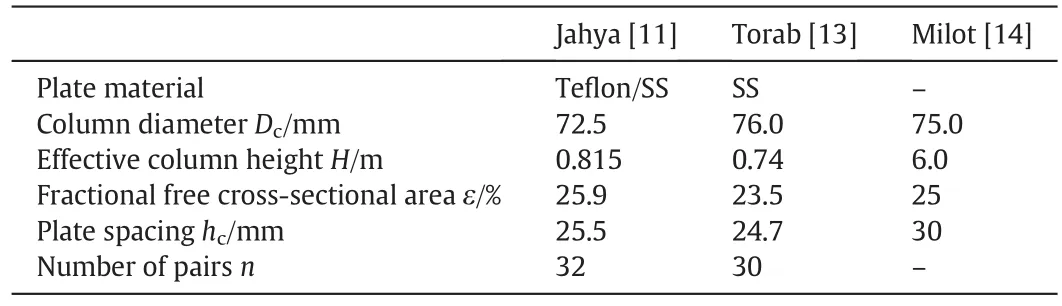

Table 5 Column specifications

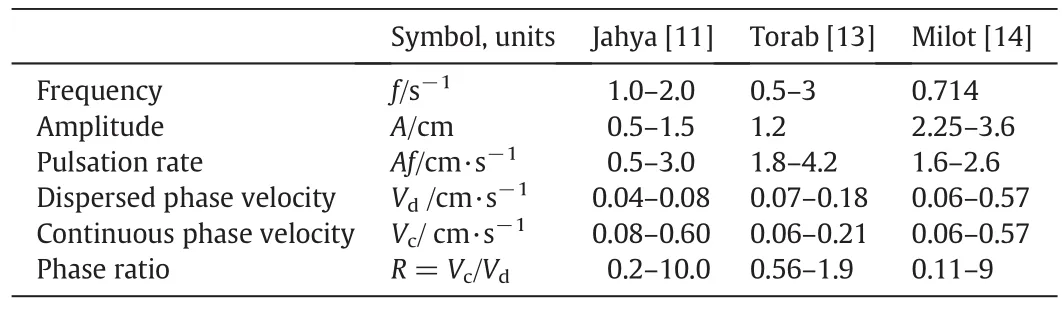

Table 6 Range of operating conditions

Fig.1.ExperimentalPDDC holdup data from Jahya[11]and Torab[13]compared with correlations developed by(a)Jahya(Eq.(11))and(b)Torab(Eq.(13)).

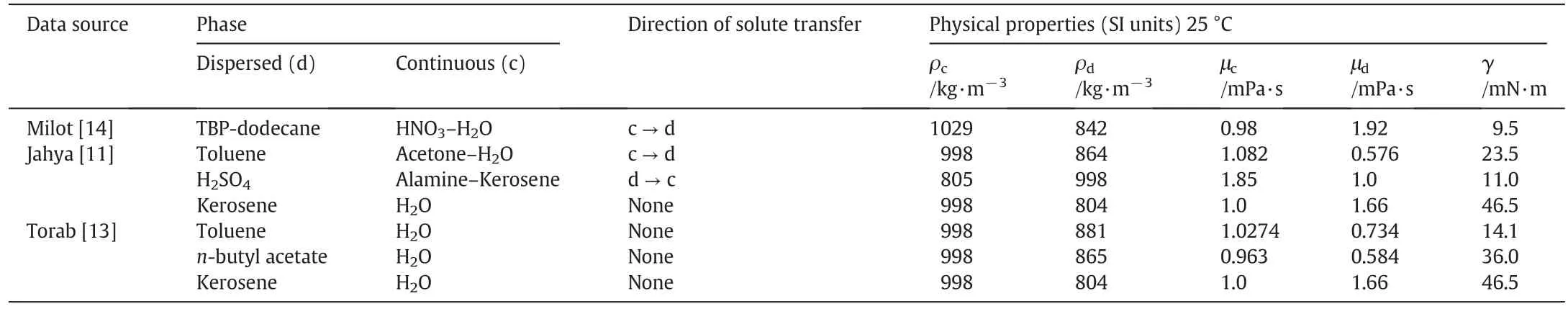

Table 4 Physical properties of the continuous and dispersed phases for the different systems studied

Table 7 Regressed constants k1 and k2 for Eq.(14)based on experimentalPDDC data

3.Data Bank for Development of New Uni fied Correlation

Table 4 describes the experimental dispersed phase holdup data sources for a PDDC,which wil be used in this study to develop a new unified correlation for predicting holdup in a PDDC.The table also lists the materials used in the experiments and the corresponding physical properties of the systems.The main geometrical features ofeach PDDC are presented in Table 5.Table 6 shows the operating conditions used in the different data sources.

4.Development of a Correlation for Predicting Holdup in a PDDC

Since the holdup is known to be affected by the direction of mass transfer of the solute from one phase to the other,Kumar and Hartland[5]proposed a correlation for predicting the holdup of Karr column as a function of mass transfer direction as follows:

where k1and k2are constants which change depending on the mass transfer direction.

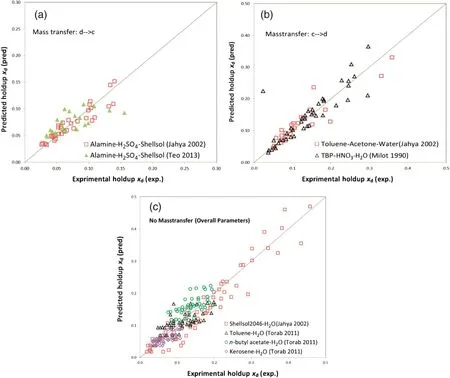

Fig.2.Comparison between experimentalholdup data and the re fitted Kumar and Hartland correlation[5](represented by Eq.(14)with constants from Table 7)for a PDDC with different mass transfer directions((a)d→c,(b):c→d;(c):no mass transfer,regressed using individualconstants).

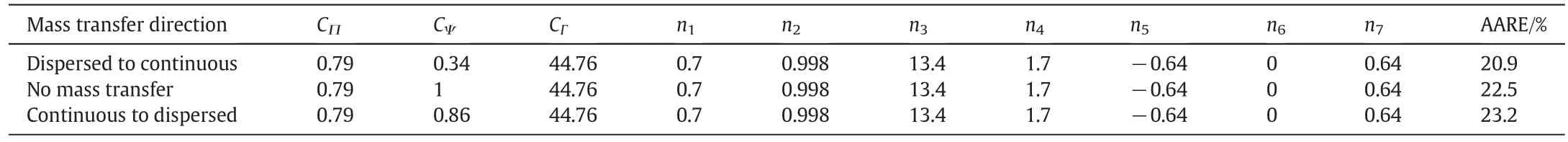

Table 8 Values of regressed constants CΠ,CΨ,CΓand n1–n7 in Eq.(3)and corresponding AARE for predicting holdup in a PDDC

Using this existing holdup correlation based on the Karr column(Eq.(14)),regression analyses were performed using holdup data from the PDDC and the values of k1and k2were obtained as shown in Table 7.It can be seen that the experimental holdup data obtained underd→c and no mass transferconditions can be regressed wellusing overallconstants k1and k2for the different data sources.However,the experimentalholdup data which was obtained under c→d mass transfer conditions from different sources cannot be predicted wellusing an overallconstant.This could be because Eq.(14)does notinclude the effect of column geometry and there are large differences in the plate spacing between Jahya's[11]and Milot's[14]columns which represent the data for c→d mass transfer.Therefore,experimental data could not be fitted using single parameters and two sets ofconstants are presented for c→d mass transfer conditions in Table 7.The AARE for holdup predicted using individualparameters is less than 20%,and the AARE for holdup predicted using overall parameters with no mass transfer is 20.7%(Fig.2).

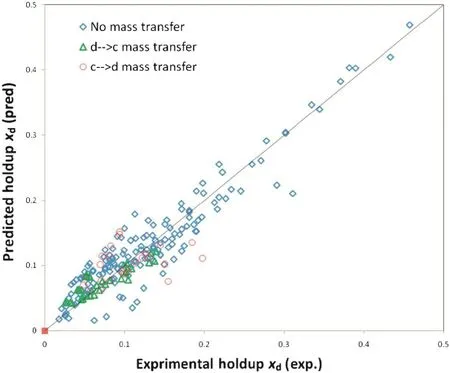

Kumarand Hartland[4]later proposed a unified correlation(Eq.(3))for the prediction of holdup in solvent extraction columns which considered the effects of the mechanical power input,the phase velocities,the physical properties,and the geometrical characteristics of the columns.However,the correlation did not include the PDDC.Using the published experimental holdup data for a PDDC,the parameters for Eq.(3)were regressed.Table 8 lists the regressed values of the parameters CΠ,CΨ,CΓand n1–n7in Eq.(3)for the PDDC column.The characteristic length of the PDDC is selected as the plate spacing.Table 8 shows that CΠ,CΓand n1–n7are the same for different mass transfer directions and CΨ(which is related to the physical properties)is changed depending on the mass transfer direction.For d→c and c→d cases of mass transfer,the values of the constant CΨare 0.34 and 0.79 respectively.For the no mass transfer case,CΨis 1 which is the same as for all the other kinds of columns[4].This correlation predicted the experimental data to within 22.5%for allno mass transfer experimental data(Fig.3).

Fig.3.Comparison of the experimental holdup data with the re fitted correlation presented by Kumar and Hartland[4](Eq.(3))in a PDDC with different mass transfer directions.Experi mentaldata was from Jahya[11],Torab[13]and Milot[14].

Although the Eq.(14)has a smaller prediction error,it cannot predict the holdup for mass transfer from the continuous phase to the dispersed phase using one setof parameters.The unified holdup model[4](Eq.(3))did not provide any constants or references to the pulsed disc and doughnutcolumn.The parameters regressed from this work can be used to complement the modeldeveloped by Kumar and Hartland[4]and be used with PDDC with different sized geometries.

5.Conclusions

Experimental dispersed phase holdup data for a PDDC has been collected from literature in order to develop a correlation for predicting holdup in a PDDC over a range of operating conditions,physical properties and mass transfer directions.The main conclusions from this study are summarized below.

Without considering the effects of column geometry,the dispersed phase holdup can be predicted by the correlation presented by Kumar and Hartland[5]via Eq.(14)with individually regressed constants(which are dependent on column geometry)as shown in Table 7;the highestprediction error is 20.7%.

By considering the differences in column geometry and mass transfer direction,the experimental dispersed phase holdup data were regressed using the unified correlation proposed by Kumar and Hartland[4]via Eq.(3)and the new re fitted constants for a PDDC shown in Table 8;the highest prediction error is 23.2%.

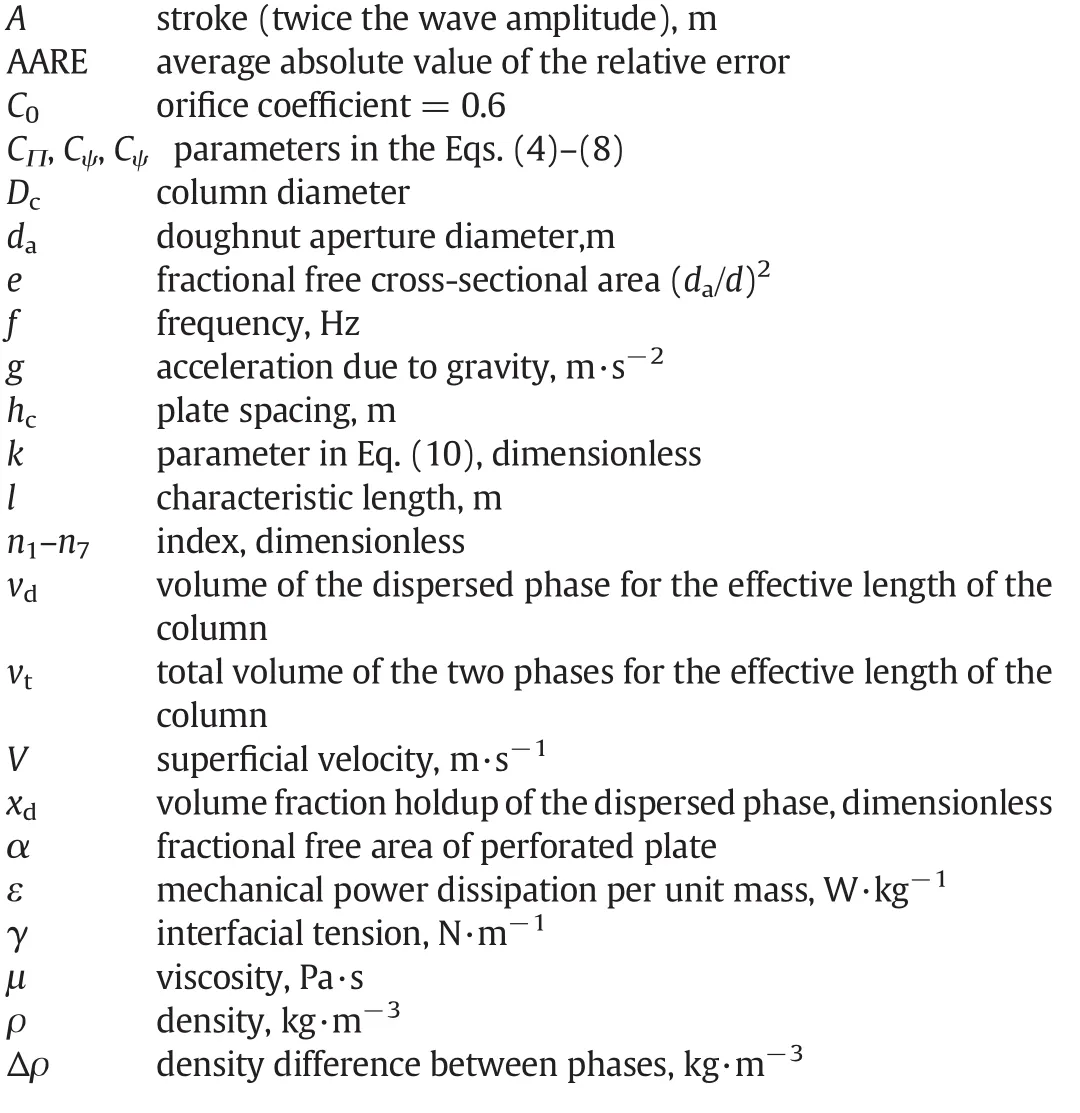

Nomenclature

Subscripts

[1]W.Van Dijck,Tower with internal perfor ated plate suitable for extracting liquids by treatment with other liquids and for similar concurrent processes.US Pat.2011186(1935).

[2]A.B.Jahya,H.R.C.Pratt,G.W.Stevens,Comparison of the performance of a pulsed disc and doughnut column with a pulsed sieve plate liquid extraction column,Solvent Extr.Ion Exch.23(2005)307–317.

[3]R.L.Movsowitz,R.Kleinbergr,E.M.Buchalter,Application ofBateman Pulse Columns for Uranium Solvent Extraction,Bateman Projects Ltd,Israel,1997.

[4]A.Kumar,S.Hartland,A unified correlation for the prediction of dispersed-phase holdup in liquid–liquid extraction columns,Ind.Eng.Chem.Res.34(1995)3925–3940.

[5]A.Kumar,S.Hartland,Prediction of dispersed-phase holdup and flooding velocities in Karr reciprocating-plate extraction columns,Ind.Eng.Chem.Res.27(1988)131–138.

[6]C.Gourdon,G.Casamatta,In fluence of mass transfer direction on the operation of a pulsed sieve-plate pilot column,Chem.Eng.Sci.46(11)(1991)2799–2808.

[7]Z.J.Shen,R.N.V.Rama,M.H.I.Baird,Mass transfer in a reciprocating plate extraction column-effects of mass transfer direction and plate material,Can.J.Chem.Eng.63(1985)29–36.

[8]G.Jeong,C.Kim,A study on the flow characteristics in a pulsed doughnut-disc type plate extraction column,Korean J.Chem.Eng.1(2)(1984)111–117.

[9]M.L.Delden,G.S.Vos,N.J.M.Kuipers,A.B.Haan,Extraction of caprolactam with toluene in a pulsed disc and doughnut column—part II:experimentalevaluation of the hydraulic characteristics,Solvent Extr.Ion Exch.25(2006)519–538.

[10]R.Kumar,D.Sivakumar,S.Kumar,U.K.Mudali,Modelling of hydrodynamics in a 25 mm pulsed disk and doughnut column,ISRN Chem.Eng.(2013)1–10.

[11]A.B.Jahya,Performance of the Pulsed Disc and Doughnut Solvent Extraction Column(Ph.D.Thesis)Univ.Melbourne,Australia,2002.

[12]A.Kumar,S.Hartland,Correlations for dispersed phase holdup in pulsed sieve-plate liquid–liquid extraction columns,Chem.Eng.Res.Des.61(1983)248–252.

[13]M.Torab-Mostaedi,H.Jalivand,M.Outokesh,Dispersed phase holdup in a pulsed disc and doughnut extraction column,Braz.J.Chem.Eng.28(2)(2011)313–323.

[14]J.F.Milot,J.Duhamet,C.Gourdon,G.Casamatta,Simulation of a pneumatically pulsed liquid–liquid extraction column,Chem.Eng.J.45(1990)111–122.

Chinese Journal of Chemical Engineering2016年2期

Chinese Journal of Chemical Engineering2016年2期

- Chinese Journal of Chemical Engineering的其它文章

- Relationship between breakthrough curve and adsorption isotherm of Ca(II)imprinted chitosan microspheres for metaladsorption☆

- Experimental study on the effects of big particles physical characteristics on the hydraulic transport inside a horizontal pipe

- Investigation of extraction fraction in con fined impinging jet reactors for tri-butyl-phosphate extracting butyric acid process☆

- Experimental evaluation and modeling of liquid jet penetration to estimate droplet size in a three-phase riser reactor

- Photorheologically reversible micelle composed ofpolymerizable cationic surfactant and 4-phenylazo benzoic acid☆

- Review on current advances,future challenges and consideration issues for post-combustion CO2 capture using amine-based absorbents☆