黄桃表面缺陷和可溶性固形物光谱同时在线检测

刘燕德,吴明明,孙旭东,朱丹宁,李轶凡,张智诚

(华东交通大学机电工程学院,南昌 330013)

黄桃表面缺陷和可溶性固形物光谱同时在线检测

刘燕德,吴明明,孙旭东,朱丹宁,李轶凡,张智诚

(华东交通大学机电工程学院,南昌 330013)

表面缺陷和可溶性固形物是评价黄桃品质的重要指标,采用可见/近红外漫透射光谱技术,探讨黄桃表面缺陷与可溶性固形物同时在线检测的可行性。在运动速度为5个/s、积分时间100 ms、光照强度1 000 W的条件下采集黄桃表面缺陷果与正常果的近红外漫透射光谱。对比分析了同一个黄桃样品损伤前后的光谱特征,建立了黄桃的最小二乘支持向相机判别模型与偏最小二乘判别模型。同时建立了黄桃可溶性固形物偏最小二乘回归模型并采用连续投影算法对模型进行优化,研究了表面缺陷果对黄桃可溶性固形物检测模型精度的影响,最终实现了黄桃表面缺陷与可溶性固形物同时在线检测。采用未参与建模的样品来评价模型的在线分选的准确性,其中表面缺陷果的正确判断率为100%,可溶性固形物分选准确率达到93%。试验结果表明:黄桃表面缺陷与可溶性固形物同时在线检测是可行的,研究可为黄桃在线分选提供技术参考和理论依据。

光谱检测;农产品;可见近红外光谱;漫透射;在线检测;表面缺陷;可溶性固形物

刘燕德,吴明明,孙旭东,朱丹宁,李轶凡,张智诚.黄桃表面缺陷和可溶性固形物光谱同时在线检测[J].农业工程学报,2016,32(6):289-295.doi:10.11975/j.issn.1002-6819.2016.06.040 http://www.tcsae.org

Liu Yande,Wu Mingming,Sun Xudong,Zhu Dangning,Li Yifan,Zhang Zhicheng.Simultaneous detection of surface deficiency and soluble solids content for Amygdalus persica by online visible-near infrared transmittance spectroscopy[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2016,32(6):289-295.(in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.06.040 http://www.tcsae.org

0 引言

黄桃不仅味道鲜美,而且营养价值高,富含维生素C。但大黄桃在人工采摘、运输及分选过程当中会对果表面造成不同程度的机械损伤,在很大的程度上影响大黄桃的出口。传统的人工分选方法不仅分选周期长,难以判断未显示出来的表面缺陷,而且在分选的同时可能会对桃子造成二次损伤,同时人工不能够将桃的糖度进行准确分级,满足不了水果分级包装的商业化的需求。可见/近红外光谱技术能够快速、无损的检测水果的内部品质及表面缺陷[1-3],因此研究出一种能够快速、无损、批量检测大黄桃表面缺陷及可溶性固形物(soluble solids content,SSC)的方法,具有重大意义。

目前,有不少利用近红外光谱技术对桃子快速分选的研究报道。大多数都是对猕猴桃可溶性固形物、硬度、表面初期损伤等单一指标进行检测[4-10]。黄桃是有果核型水果,已有报道多采用漫反射方式,因在杂散光控制方面难度较大,检测精度较低。本试验中采用弹性垫圈和透光孔组合结构,依靠黄桃自重实现密封,能较有效抑制漫透射的杂散光。表面缺陷检测和可溶性固形物检测都是黄桃采后商品化处理的必要环节,目前还未见在同一条分选线上,在剔除表面缺陷黄桃样品的同时,实现按可溶性固形物含量分选。本文主要提出了能够综合考虑大黄桃表面缺陷以及可溶性固形物的动态在线检测方案,并对比了不用的判别方法对判别模型的影响。

1 材料与方法

1.1 试验材料

试验所采用的大黄桃由河北省某果园提供。试验前先挑出表面无损伤、无畸形的正常果作为试验样品,然后去除黄桃样品表面灰尘并将其编号,分别将黄桃样品缝合线光滑侧和凸起侧标号并置于25℃的环境中保存12 h,待试验样品温度与室温基本一致后,依次测量黄桃样品的横纵径、重量等物理指标如表1所示。试验所需的样品表面缺陷果,采用聚四氟乙烯球撞击标号的2个面来模拟实际生产运输过程中的碰撞挤压造成的表面损伤。撞击面为缝合线光滑面和凸起面。据有关报道,桃子表面对撞伤等损伤最为敏感,30 min后表面就有明显变化[11]。撞击后试验中所使用的表面缺陷果与撞击示意图如下图1所示,最右侧2个为正常果,其余10个均为表面损伤果,图中H=108 mm,β约为13°,小球的质量约为0.38 kg,样品置于斜坡最下方位置,忽略斜坡与小球之间的摩擦力,近似计算碰撞的能量约为0.4 J。

图1 试验样品及试验Fig.1 Experiment and Samples

试验中共100个样品,其中正常果60个,表面缺陷果40个。为考察黄桃表面缺陷对可溶性固形物模型的影响,将试验所用黄桃样品分为2组进行考察,按3∶1的比例划分建模集与预测集。组1为60个正常果样品与40个表面缺陷果样品,其中75个用于建立正常果与表面缺陷果的可溶性固形物混合模型,且75个样本中包含44个正常样品以及31个异常样品,剩余25个用于对模型进行预测。组2为60个正常果样品用于建立及预测正常果的可溶性固形物混合模型。其可溶性固形物真实值与横纵径统计如表1所示。

表1 建模集与预测集黄桃样品可溶性固形物真实值与横纵径统计结果Table 1 Statistical values of soluble solid content and diameter for Amygdalus persica in calibration and prediction set

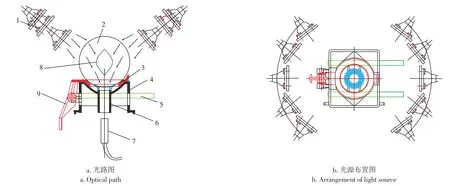

1.2 在线检测装置与光谱采集

试验所采用的光谱采集装备为漫透射式动态在线检测装置如图2所示,该装置由光源、果杯、传送链条、光谱仪这几部分组成。试验中所用的光谱仪为Ocean Optics公司的QE65000光谱仪,其采集光谱是短波近红外光谱,波长范围为350~1 150 nm,光源采用10个12 V、100 W的卤钨灯成一定角度分布在样品2侧如图所示,果杯内装有一圈特殊的软塑料遮光圈,由于果的重力作用,能够抑制杂散光现象,在动态采集光谱时,传送链带动果杯移动,经过下方探头采集光谱信息。

图2 近红外漫透射在线检测装置Fig.2 Device of NIR diffuse transmittance detection

在采集光谱前,先要将光源预热30 min。待光源基本稳定后,用白色聚四氟乙烯球作为参比,多次采集参比球的能量谱至标准差小于1%后开始试验。采用人工按序号依次上果,由于黄桃样品中存在较大的果核影响光的通过,故将黄桃样品果柄与运动方向一致、缝合面垂直于水平面放置,光线如图2所示经过样本被探头接收,大大降低了大果核对检测的影响。在光谱采集时,触发过程如下:大小2个齿轮都安装在主轴上如图3所示,驱动齿轮68齿,编码盘17齿,驱动齿轮4齿对应编码盘一齿,驱动齿轮每4齿对应4节链条安装一个果盘,即编码盘每转一齿位置,传送链行程为一个果盘位置。在编码盘齿顶2 mm安装霍尔传感器,实现编码盘每转一齿,触发霍尔传感器,使相应电路发出3.5 V高电平信号,触发光谱仪采集并保存一条光谱。

图3 在线检测设备的光谱数据采集原理图Fig.3 Schematic diagram of spectral data acquisition in on-line detection equipment

光谱仪设定的参数为:积分时间100 ms,运动速度5个/s,光谱仪能采集到的信息为整个果的信息,并在样品底部形成一个5~10 mm的光斑。

1.3 SSC含量与表面缺陷果判定

试验所用的黄桃样品采用折射式数字糖度计(PR—101a,日本)进行可溶性固形物含量测量,测量前,需将糖度计擦干后用纯净水标定糖度0%,在测量时,取光谱采集部位约5 mm深果肉挤汁滴于糖度计上测试窗口,重复测量3次,取2次或2次相同的糖度值作为测量值。由于实际生产中果被测量一次就被推入分选框中,故不取平均值。表面缺陷的试验样品模拟实际贮藏、包装过程的挤压、碰撞获得。表面出现变软现象及有明显深色颜色差异即判定为表面缺陷果。

1.4 数据处理

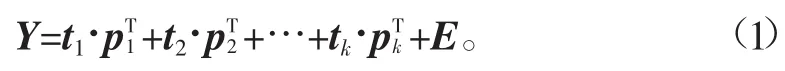

黄桃样品的试验所得的光谱由Spectrasuite软件采集,试验数据采用主成分分析(principal component analysis,PCA)进行聚类分析,主成分分析能够有效的用来压缩光谱数据和提取光谱特征信息[12-13]。其原理如公式1所示。

其中Y为样品的光谱矩阵;t为样品的得分矩阵,反映样品与样品之间的差距;p为载荷向量,反映光谱能量之间的差距;E为残差矩阵。采用最小二乘支持向量机(least squares support vector machine,LS-SVM)建立定性判别模型,其基本原理如公式2所示。

其中,K(x,xi)是核函数,xi输入向量,αi是拉格朗日算子也叫支持向量;b是偏差;N是样品数量,通过该公式计算模型预测值。本试验将表面损伤果定义为8,而将正常果定义为2,采用表面缺陷果与正常果的正确率评价最小二乘支持向量机与最小二乘判别模型的效果。采用相关系数与均方根误差来评价偏最小二乘模型(partial least squares,PLS)的效果。

2 结果与讨论

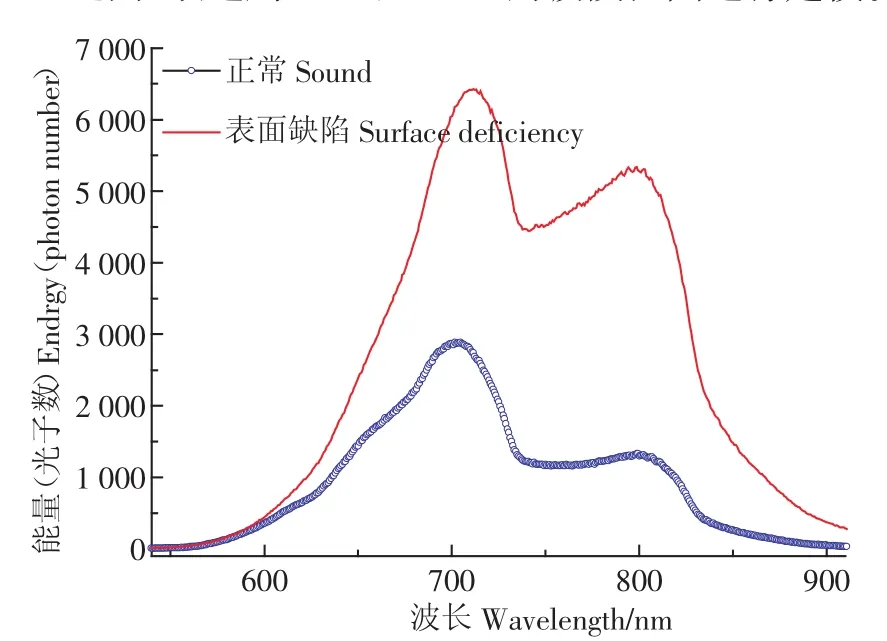

2.1 正常果与表面缺陷果的光谱对比

随机取同一个试验样品,采集其表面损伤前后的光谱信息如图4所示,据上图显示,2条光谱有明显的差异,首先表面损伤果能量谱明显高于正常果,其中表面损伤果光谱能量最高值达6500光子数,而正常果的光谱能量最高值仅仅只有3000光子数左右,产生这种光谱能量的差异的原因可能是黄桃碰伤后,果肉组织发生变化,影响光的透过能力,撞击导致果内组织变软,透光能量增强。试验装置采用光源四周照射、探头底部接收的方式,采集的光谱反映了整果的光谱信息,一侧或两侧存在碰伤均可在光谱中有所体现,所以在试际采摘运输中一侧碰伤也能有效的进行判别。本试验中,采集过黄桃样品的一侧碰伤的可见近红外光谱,并与两侧碰伤的样品的光谱进行了对比,对比发现一侧碰伤与两侧碰伤的黄桃样品光谱差异极小。另外2条光谱的波峰与波谷的位置基本一致,均在710与800nm附近存在波峰,在730nm附近存在波谷。其光谱有效信息都集中在550~900nm之间,故选用550~900nm的波段范围进行建模。

图4 正常与表面缺陷果光谱Fig.4 Spectra of sound and surface deficiency

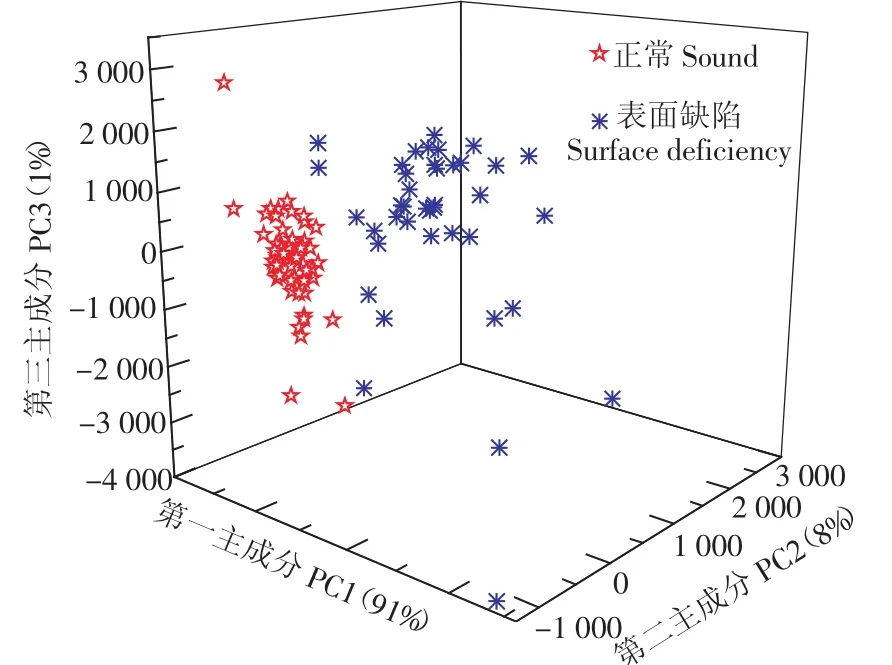

2.2 主成分分析

主成分分析采用全谱分析,将试验所采集的光谱信息压缩为若干个主成分的线性组合,前3个主成分因子的得分散点图如图5所示。由图5可以看出,正常果与表面损伤果存在聚类现象,图中正常样品60个,表面损伤样品40个,由主成分分析可得,第一个主成分累积的贡献率为91%,而第二个主成分仅仅只8%的贡献率,第三个主成分的贡献率为1%。通过主成分分析能够简单的将100个样品简单的分为2类。

图5 主成分得分散点图Fig.5 Scores plots of principal component

2.3 最小二乘支持向量机

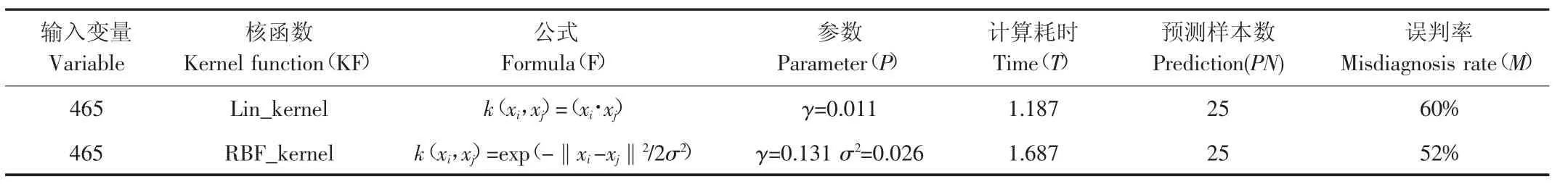

最小二乘支持向量机在进行模型判别分析的时候,其映射函数为非线性的,在高纬度的空间把近红外光谱变量与特征矩阵进行一一对应,将优化问题转化为等式约束条件问题[14-15]。分别讨论最小二乘支持向量机线性核函数(Lin_kernel)与径向基核函数(RBF_kernel)对判别模型的影响,在550~900 nm波段进行建模,共465个波长点。模型预测结果如表2所示。由表2可知,采用不同的核函数建立的判别模型有较大差异,其中采用线性核函数模型预测效果较好,在25个预测样品中,误判率较高为60%;另外采用核函数为径向基核函数时,模型预测25个样品计算所耗比采用线性核函数更多,而模型预测效果却更差其误判率为52%。由于选用2种核函数误判率均较高,因此在本试验中最小二乘支持向量机判别模型不适用于判别表面缺陷果。

表2 不同核函数对LS-SVM模型预测结果的影响Table 2 Effect of different core function on prediction in LS-SVM model

2.4 偏最小二乘判别分析

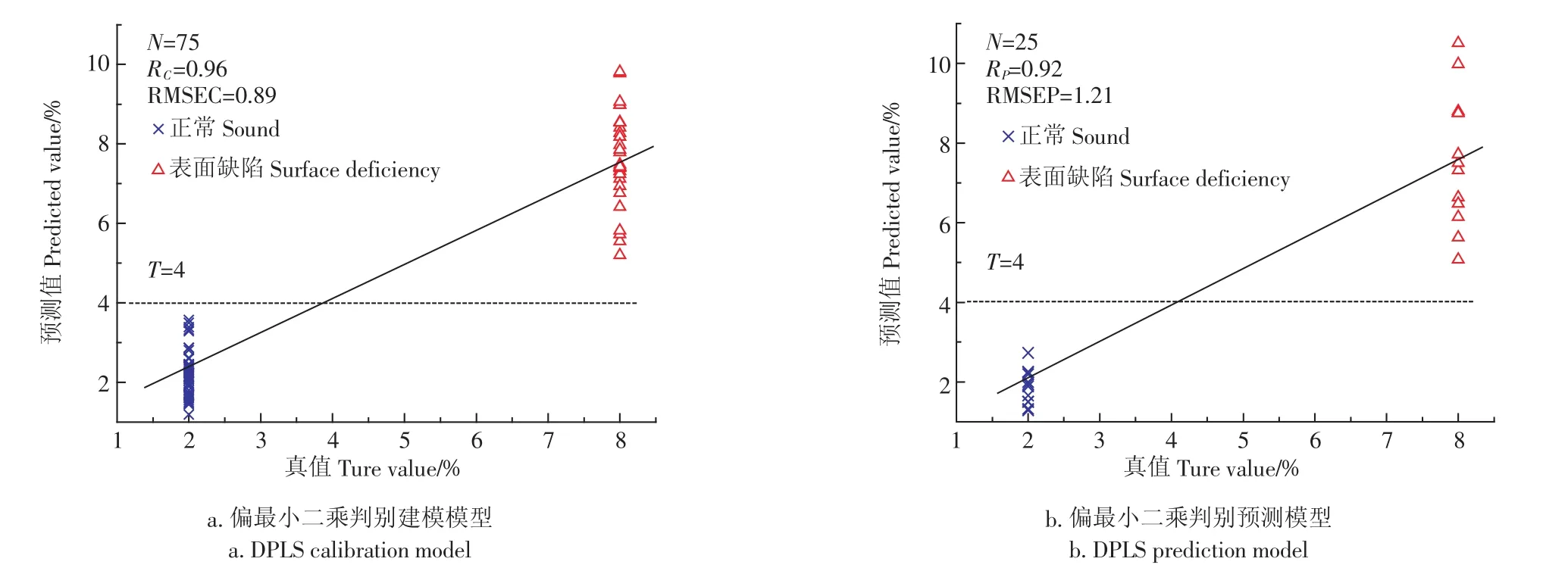

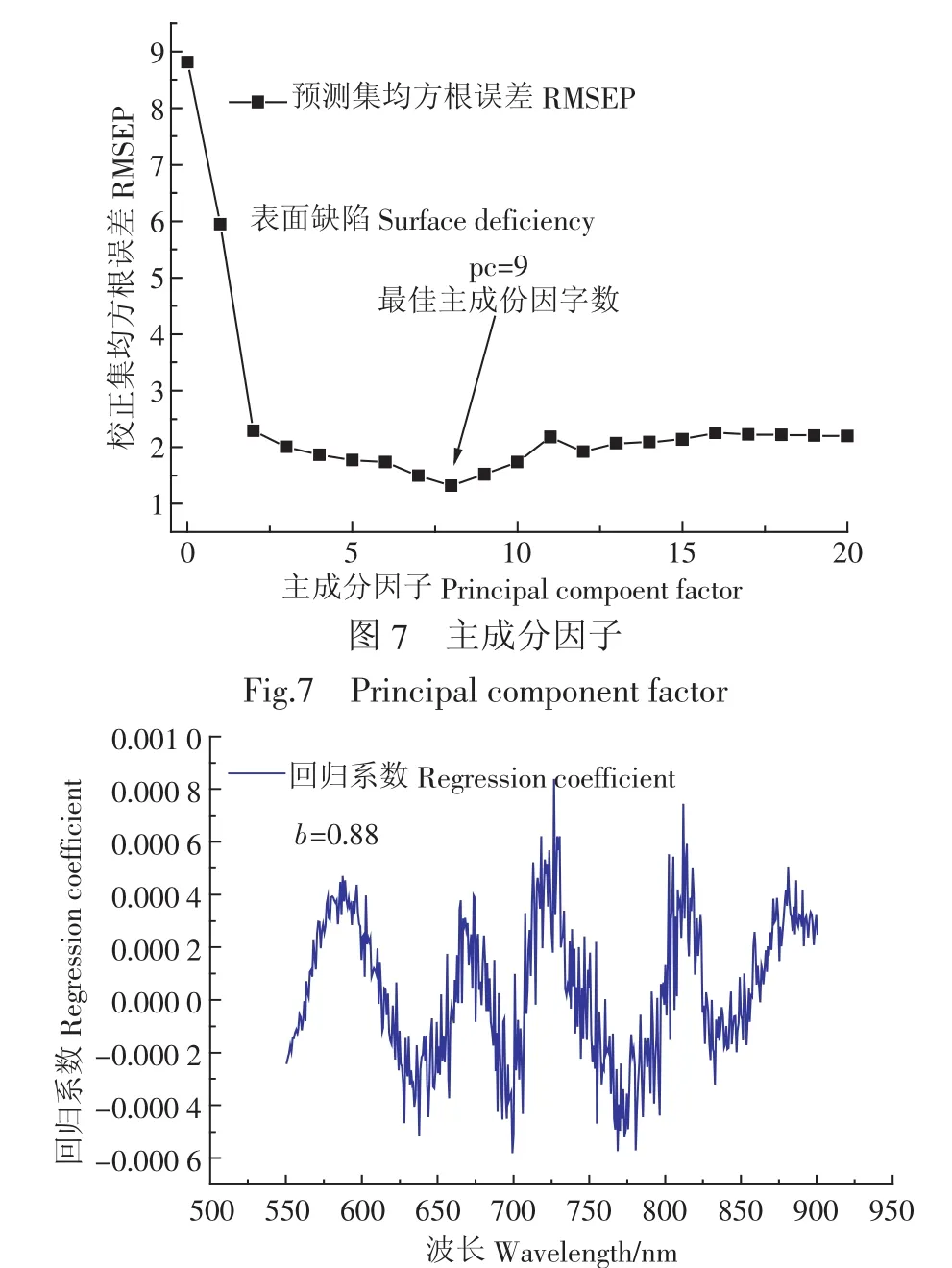

偏最小二乘判别分析方法是在偏最小二乘法的基础上建立的样本分类模型。该方法需要按照样本的类别特性,赋予样本分类变量值[16-20]。选用550~900 nm建立偏最小二乘判别模型,其建模结果如图6所示,采用75个样品建模,人为设定正常样品为2,表面缺陷样品为8,域值设置为4。模型相关系数RP为0.96,建模的标准偏差为0.89,由图6a可得模型的误判率为0%,能够很好的将正常果与表面缺陷果分开。图6b为PLSDA预测模型,相关系数为0.92,预测模型的标准偏差为1.21,误判率为0%。该模型选用的主成份数与预测集的均方根误差关系如图7所示。据图可知,随着主成数的增加,预测集的均方根误差逐渐降低,当主成分数为8时,预测集均方根误差最小。当主成分数选用过小时会造成“欠拟合”现象,损失较多的有效信息,直接导致模型效果变差,当主成分数选用过高时会产生“过拟合”现象,其中包含了较多的噪声干扰信息,模型效果不好。回归系数如图8所示,所用的光谱变量与回归系数的加权求和再加上截距b=0.88,即为PLSDA模型预测的类别值。再通过与阈值的比较,实现表面缺陷样品的预测。

图6 偏最小二乘判别模型Fig.6 DPLS model

图8 回归系数Fig.8 Regression coefficient

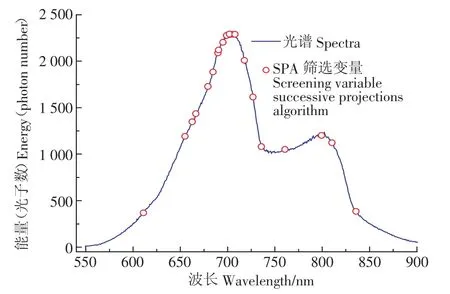

2.5 偏最小二乘可溶性物模型及优化

首先将75个样品混合建模,其中包含44个正常果,31个表面缺陷果,建模结果如下表3所示,采用全部样品建模预测集相关系数仅为0.72,预测集均方根误差为1.45%。而组别2用45个正常果进行建模,用连续投影算法(successive projections algorithm,SPA)进行光谱变量筛选,连续投影算法是随机选取光谱矩阵中的某几个变量,最后分别计算对其他变量的投影,根据均方根误差最小的原则来决定变量个数。经过连续投影算法筛选,共产生21个光谱变量。其结果如图9所示。采用筛选后的光谱建模,预测集相关系数为0.95,预测集均方根误差为0.71。对比可得,组别2的效果优于组别1,因此表面缺陷果影响黄桃的可溶性固形物的模型预测精度,故要建立黄桃的可溶性固形物模型需将表面缺陷样品剔除。最终建立的黄桃可溶性固形物偏最小二乘模型如图10所示。

图9 连续投影算法筛选变量Fig.9 Screening variable of SPA

图10 偏最小二乘回归建模和模型预测散点图Fig.10 Scatters PLS calibration and prediction models

表3 不同组别的模型的统计结果Table 3 Model statistical results of different classes

该模型的主成分因子数与交互验证均方根误差的关系如图11a所示。随着主成分数量的增加,交互验证均方根误差逐渐减小。当主成分数为9的时候,交互验证均方根误差达到最小值。主成分数继续增加,交互验证均方根误差基本不变,故主成分数选用9。图11b为通过连续投影算法筛选的21个变量的回归系数。截距b=9.24。其糖度的预测公式如公式2所示。

图11 偏最小二乘模型Fig.11 Model of partial least squares

其中,y为模型的预测糖度值;N为参与建模的光谱变量数;β为能量谱强度;λ为回归系数;b为模型的截距。

2.6 在线分选准确性评价

首先,将建立的表面缺陷果偏最小二乘判别模型与可溶性固形物偏最小二乘模型加载到自主开发的在线检测软件中,其中2种模型的基本参数有模型的回归系数和截距。然后将未参与建模的12个黄桃样品对模型进行预测,12个黄桃样品中包含7个正常果和5个表面缺陷果。由于在实际水果出口中是不允许有表面缺陷果的存在,故在糖度分级检测前必须先将表面缺陷果剔除,再进行糖度的分级检测。检测方法将将定性分析与定量分析相结合。首先,样品经过检测器,在线分选装置自动采集该样品的光谱信息,然后通过偏最小二乘判别模型预测出一个值与阈值进行比较,若大于阈值4,则判定为异常果,直接被推入表面缺陷果分级口;若小于阈值4,则判定为正常果,则继续通过可溶性固形物偏最小二乘模型预测其可溶性固形物含量。据研究表明,糖度存在2%的差距,能够有明显的口感差异,综合考虑模型的预测均方根误差,故将糖度分级区间定为10%以下、10%~12%、12%~14%、14%以上。在试验中,将12个预测集样品按照标号次序依次放置在分选线上,每个样品按标记位置进行上果,每个面放置4次,共放置96次并记录每次进入的分级口,其中表面缺陷果均被分至所设置的表面缺陷分级口,判别准确率为100%,而在分选可溶性固形物中,将果误分入相邻的分级口6次,在线分选准确率为93%。

3 结论

本文采用近红外光谱漫透射技术,实现了黄桃表面缺陷与可溶性固形物的同时检测,并建立了黄桃表面缺陷最小二乘支持向量机判别模型与偏最小二乘判别模型,其中最小二乘支持向量机判别模型的误判率为4.1%,但该模型将表面缺陷果误判为正常果,故不适用与实际生产分选中,而偏最小二乘判别模型的准确判别精度为100%,并且在采用未参与建模的预测集试验样品验证中,能够准确的将表面缺陷果推入分级入口。另外在建立了黄桃可溶性固形物最小二乘回归模型的同时考察了表面缺陷果对模型预测精度的影响,最终建立了黄桃正常果的可溶性固形物最小二乘回归模型,提出了黄桃表面缺陷与可溶性固形物同时检测的方案。模型的预测均方根误差为0.71%,采用未参与建模的样品进行实际在线分选,在线分选的准确率为93%。论文研究可为黄桃出口生产在线检测分选方案提供参考和理论依据。

[1]Wang Aichen,Xie Lijuan.Technology using near infrared spectroscopic and multivariate analysis to determine the soluble solids content of citrus fruit[J].Journal of Food Engineering, 2014,143:17-24.

[2] 迟茜,王转卫,杨婷婷,等.基于近红外高光谱成像的猕猴桃早期隐性损伤识别[J].农业机械学报,2015,3:235-241. Chi Qian,Wang Zhuanwei,Yang Tingting.Recognition of early hidden bruises on kiwifruits based near infrared hyperspectralimaging technology[J].Transactions of the Chinese Society for Agricultural Machinery,2015,3:235-241.(in Chinese with English abstract)

[3] 郭文川,王铭海,岳绒.基于近红外漫反射光谱的损伤猕猴桃早期识别[J].农业机械学报,2013,2:142-146. Guo Wenchuan,Wang Minghai,Yue Rong.Early recognition of bruised kiwifruit based on near infrared diffuse reflectance spectroscopy[J].Transactions of the Chinese Society for Agricultural Machinery,2013,2:142-146.(in Chinese with English abstract)

[4]郭文川,王铭海,谷静思,等.近红外光谱结合极限学习机识别贮藏期的损伤猕猴桃[J].光学精密工程,2013,10:2720-2727. Guo Wenchuan,Wang Minghai,Gu Jingsi,et al.Identification of bruised kiwifruits during storage by near infrared spectroscopy and extreme learning machine[J].Optics and Precision Engineering, 2013,10:2720-2727.(in Chinese with English abstract)

[5] 马广,傅霞萍,周莹,等.大白桃糖度的近红外漫反射光谱无损检测试验研究[J].光谱学与光谱分析,2007,5:907-910. Ma Guang,Fu Xiaping,Zhou Ying,et al.Nondestructive sugar content determination of peaches by using near infrared spectroscopy technique[J].Spectroscopy and Spectral Analysis, 2007,5:907-910.(in Chinese with English abstract)

[6]McGlone V A,Clark C J,Jordan R B.Comparing density and VNIR methods for predicting quality parameters of yellowfleshed kiwifruit(Actinidia chinensis)[J].Postharvest Biology and Technology.2007,1:1-9.

[7] 刘卉,郭文川,岳绒.猕猴桃硬度近红外漫反射光谱无损检测[J].农业机械学报,2011,3:145-149. Liu Hui,Guo Wenchuan,Yue Rong.Non-destructive detection of kiwifruit firm ness based on near-infrared diffused spectroscopy [J].Transactions of the Chinese Society forAgricultural Machinery.2011,3:145-149.(in Chinese with English abstract)

[8]Moghimi A,Aghkhani M H,Sazgarnia A,et al.Vis/NIR spectroscopy and chemometrics for the prediction of soluble solids content and acidity(pH)of kiwifruit[J].Biosystems Engineering,2010,3:295-302.

[9] 王铭海,郭文川,商亮,等.基于近红外漫反射光谱的多品种桃可溶性固形物的无损检测[J].西北农林科技大学学报:自然科学版,2014,2:142-148. WangMinghai,GuoWenchuan,ShangLiang,etal.Nondestructive detection of soluble solids content for multiple peach fruits using near-infrared diffuse reflectance spectra[J].Journal of Northwest A&F University:Natural Science Edition,2014,2:142-148.(in Chinese with English abstract)

[10]吕强,汤明杰,赵杰文,等.近红外光谱预测猕猴桃硬度模型的简化研究[J].光谱学与光谱析,2009,7:1768-1771. Lu Qiang,Tang Mingjie,Zhao Jiewen,Study of simplification of prediction model for kiwifruit firmness using near infrared spectroscopy[J].Spectroscopy and Spectral Analysis,2009,7: 1768-1771.(in Chinese with English abstract)

[11]Zhiguo Li,Colin Thomas.Quantitative evaluation of mechanical damages to fresh fruits[J].Trends in Food Science&Technology, 2014,35:138-150.

[12]Chang Yang,Chao Yin Tsai,Kuang-Wen Hsieh.Integration of SCIMCA and near-infrared spectroscopy for rapid and precise identification of herbal medicines[J].Journal of Food and drug analysis,2013,21:268-278.

[13]Nejadgholi I,Bolic M.A comparative study of PCA,SIMCA andCole model for classification of bioimpedance spectroscopy measurements[J].Computer in Biology and Medicine,2015,63: 42-51.

[14]刘雪梅,章海亮.基于DPLS和LS-SVM的梨品种近红外光谱识别[J].农业机械学报,2012,9:160-164. Liu Xuemei,Zhang Hailiang.Identification of varieties of pear using near infrared spectra based on DPLS and LSSVM model [J].Transactions of the Chinese Society for Agricultural Machinery,2012,9:160-164.(in Chinese with English abstract)

[15]刘燕德,周延睿,潘圆媛.基于最小二乘支持向量机的辣椒可溶性固形物和维生素C含量近红外光谱检测[J].光学精密工程,2014,2:281-288. Liu Yande,Zhou Yanrui,Pan Yuanyuan.Determination of soluble solid contents and vitamin C of fresh peppers based on NIR spectrometry and least square support vector machines[J]. Optics and Precision Engineering,2014,2:281-288.(in Chinese with English abstract)

[16]董学锋,戴连奎,黄承伟.结合PLS-DA与SVM的近红外光谱软测量方法[J].浙江大学学报:工学版,2012,5:824-829. Dong Xuefeng,Dai Liankui,Huang Chengwei.Near-infrared spectroscopy soft-sensing method by Combining partial least squares discriminant analysis and support vector machine[J].Journal of Zhejiang University:Engineering Science,2012,5: 824-829.(in Chinese with English abstract).

[17]郝勇,孙旭东,高荣杰.基于可见/近红外光谱与SIMCA和PLSDA的脐橙品种识别[J].农业工程学报,2010,26:373-378. Hao Yong,Sun Xudong,Gao Rongjie.Application of visible and near infrared spectroscopy to dentification of navel orange varietis using SIMCA and PLS-DA Methods[J].Transactions of the Chinese Society of Agriculture Engineering(Transactions of the CSAE),2010,26:373-377.(in Chinese with English abstract)

[18]Huirong Xu,Bing Qi,Tong Sun,et al.Variable selection in visible and near-infrared spectra:Application to on-line determination of sugar content in pears[J].Journal of Food Engineering,2012,109: 142-147.

[19]Ignat T,Schmilovitch Z,Fefoldi J.Non-destructive measurement of ascorbic acid content in bell peppers by VIS-NIR and SWIR spectrometry[J].Postharvest Biology and Technology,2012,74: 91-99.

[20]Fu Haiyan,Dong Chenhuang,Yang Tianming.Rapid recognition of Chinese herbal pieces of Areca catechu by different concocted processes using Fourier transform mid-infrared and near-infrared spectroscopy combined with partial least-squares discriminant analysis[J].Chinese Chemical Letters,2013,7:639-642.

Simultaneous detection of surface deficiency and soluble solids content for Amygdalus persica by online visible-near infrared transmittance spectroscopy

Liu Yande,Wu Mingming,Sun Xudong,Zhu Dangning,Li Yifan,Zhang Zhicheng

(School of Mechatronics Engineering,Eash China Jiaotong University,Nanchang 330013,China)

Surface deficiency and soluble solid content(SSC)are important indexes for evaluating the quality of Amygdalus persica.The feasibility was investigated for detecting surface deficiency and SSC of intact Amygdalus persica simultaneously by online visible-near infrared(visible-NIR)transmittance spectroscopy.Ten tungsten halogen lamps were installed in a sorting line.The power of each lamp was 100 watt.The light sources were illuminated from both sides of the production line,and the detector received light from the bottom of the fruit cup.The spectrum of each sample was recorded automatically by using the hardware trigger mode.The index plate and driving gear were mounted on the same shaft.The location of the index plate′s tooth was matched with the location of the fruit cup.Hall sensor was placed at a height of 2 mm above the tooth of the index plate.When the index plate turned one tooth,a Hall sensor sent a 3.5 V high frequency signal to trigger spectrometer to save one spectrum.The spectra were recorded with the integration time of 100 ms in the wavelength range of 550~900 nm when the samples were conveyed at the speed of five samples per second.The spectra of the same sample before and after damage were analyzed for investigation of the influence of the damage tissue within a peach affected the spectral content of the light transmitted through it.The spectral intensity of the damage was lower than the healthy ones for the damage issue affected the penetration of the light inside the fruit.Three quality discrimination methods of principle component analysis(PCA),least squares support vector machine(LS-SVM)and partial least squares discrimination analysis(PLSDA)were used to identify the damage samples.The input vector and parameters of kernel function of LS-SVM model were optimized by two step grid search method.The PLSDA model yielded the best results of accuracy rate of 100%compared to PCA or LS-SVM methods.Considering the robustness of the partial least squares(PLS) regression model,two groups of healthy samples and the combinations of healthy samples and damage ones.Then the PLS regression model was developed for predicting SSC values.The performance of the PLS regression model was improved with the stand error of prediction(SEP)of 0.71%when the damage samples were removed out.The effective spectral variables were chosen by successive projections algorithm(SPA)method for improving the robustness of the PLS regression model.It was also investigated that the influence of the damage sample to the predictive ability of the PLS regression model. Therefore a new strategy was proposed for detection of surface deficiency and SSC for intact Amygdalus persica simultaneously by online visible-NIR transmittance spectroscopy.The new samples,which were not used in the calibration, were used to access the abilities of recognizing the damage samples and predicting SSC of intact Amygdalus persica.The accuracy rate was 100%for identifying surface deficiency samples,and the SEP was 0.71%for predicting SSC.The accuracy of sorting grade was 93%according to the SSC values.The results showed that simultaneous detection of surface deficiency and SSC were feasible by visible-NIR transmittance spectroscopy.

spectrometry;agricultural product;visible-near infrared spectroscopy;diffuse transmittance;online detection; surface deficiency;soluble solids content

10.11975/j.issn.1002-6819.2016.06.040

S24

A

1002-6819(2016)-06-0289-07

2015-12-02

2016-01-27

“十二五”国家863计划课题(SS2012AA101306);江西省优势科技创新团队建设计划项目(20153BCB24002);南方山地果园智能化管理技术与装备协同创新中心(赣教高字[2014]60号);江西省研究生创新资金项目(YC2015-S238)

刘燕德(1967-),江西泰和人,博士,教授,博士生导师,主要从事光机电检测技术研究。南昌 华东交通大学机电工程学院,330013。Email:jxliuyd@163.com