种层厚度对油麦兼用集排器供种装置充种性能的影响

雷小龙,廖宜涛,李兆东,张闻宇,曹秀英,李姗姗,廖庆喜

(华中农业大学工学院,武汉430070)

种层厚度对油麦兼用集排器供种装置充种性能的影响

雷小龙,廖宜涛,李兆东,张闻宇,曹秀英,李姗姗,廖庆喜※

(华中农业大学工学院,武汉430070)

为研究种层厚度对油麦兼用集排器供种装置充种性能的影响,该文运用EDEM(engineering discrete element method)软件和高速摄像技术,对不同种层调节板倾角和种层厚度的种群运动与供种性能进行了仿真与试验研究。EDEM仿真分析了种层厚度与转速对种群压力、种群与供种机构切向力和充种数量的影响;台架试验研究了种层厚度对充填角和供种性能的影响。结果表明:倾角为60°种层调节板的种群压力较大,充填角和充种性能均较优;种群压力和切向力随纵向距离增加而增加,随横向距离增加而降低;随转速增加,种群压力趋于稳定,切向力随之增加,单个型孔充种数量降低5%。转速为10~50 r/min时,初始充填角、充填角和供种速率均随纵向距离增加和横向距离降低而增加,但充种数量变异系数呈先降后升的趋势。种群压力、切向力、初始充填角、充填角与供种速率均呈极显著正相关,种群压力和切向力与初始充填角和充填角均呈极显著正相关,种层厚度和转速影响充填角分别源于种群压力和切向力。在纵向距离分别为15和20 mm,横向距离为46 mm条件下,油菜、小麦供种速率变异系数和破损率分别均低于1.0%和0.1%。田间试验表明该优化种层厚度条件下的集排器油菜种植密度满足农艺种植要求。该研究明确了种层厚度影响油麦兼用集排器供种装置充种性能的原因,为油麦兼用集排器供种装置种层厚度调节和结构改进提供了参考。

农业机械;作物;EDEM仿真;高速摄像;供种装置;充种性能;油菜;小麦

雷小龙,廖宜涛,李兆东,张闻宇,曹秀英,李姗姗,廖庆喜.种层厚度对油麦兼用集排器供种装置充种性能的影响[J].农业工程学报,2016,32(6):11-19.doi:10.11975/j.issn.1002-6819.2016.06.002 http://www.tcsae.org

Lei Xiaolong,Liao Yitao,Li Zhaodong,Zhang Wenyu,Cao Xiuying,Li Shanshan,Liao Qingxi.Effects of seed layer thickness on seed filling performance of seed feeding device for rapeseed and wheat[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2016,32(6):11-19.(in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.06.002 http://www.tcsae.org

0 引言

精量播种和通用性强已成为油菜、小麦等作物种植的发展方向[1],能显著提高作物产量和机具利用率。气送式集排器具有高速、高效和种子适应性强等优点,广泛应用于多种作物播种[2]。

气送式集排器供种装置采用机械定量供种方式,充种环节尤为关键[3],其充种性能显著影响供种质量。机械式排种器充种性能的影响因素主要包括充填力大小、型孔结构和充种室内种群形态等[4],其中充种室内种群形态受种层厚度和种子流动特性的影响。种子流动特性与内摩擦系数有关,特定种子的内摩擦系数为常数[5],种层厚度成为影响充种性能的重要来源。相关学者采用振动方式扰动种群,使种群呈“沸腾”状态,降低种子间摩擦力和提高充种性能[6-8]。罗锡文等[9]设计2个充种室以改善排种轮型孔的充种性能,邢赫等[10]采用分层充种室提高了水稻气力式精量穴播排种器性能。李兆东等[11]发现排种均匀性变异系数和各行排量一致性变异系数以种子充填高度影响最大。种层厚度较低时,充填率显著下降,从而降低充种性能;种层厚度较大时,种层“拖带现象”严重,不利于精量充种。因此,适宜的种层厚度可提高充种性能,进而提高播种质量。

油菜、小麦种子属散粒体物料,其物理和机械特性复杂,难以准确描述受到的种群压力及其运动规律。离散单元法DEM(discrete element method)作为仿真颗粒物料运动和机械特性可靠的数值技术[12-13],可准确描述颗粒间、颗粒与外壳和颗粒与液(气)体间的作用力和运动状态[14-18]。史嵩等[3]采用EDEM软件分析种群内摩擦力,发现种群扰动通过降低种子瞬态的法向应力以提高充种性能;李耀明等[19]采用离散元法分析振动对种群运动的影响,得出较优的初始种层厚度。高速摄像技术广泛应用于工业和农业[20],可为深入研究排种器充种机理提供依据。王在满等[21]采用高速摄像技术研究稻种的充种姿态和流动性能,确定充种过程主要发生在第2充种区。丛锦玲等[22]结合高速摄像解析充种区种子层的流动特性和充填角,阐明嵌入导种条的油麦兼用排种器充种机理。因此,综合高速摄像技术和EDEM(engineering discrete element method)仿真可揭示排种器充种机理和优化性能参数。

为实现油麦兼用供种,前期已设计一种油麦兼用型倾斜锥孔轮式供种装置[23],通过充种过程力学分析,明确影响其充种性能的因素包括型孔倾角、种群压力和转速等。文献[23]已优化锥柱状型孔倾角,而种群压力难以通过数学模型描述,主要受种层厚度的影响。本文结合离散元仿真软件EDEM和高速摄像技术,分析种层厚度和转速对油菜、小麦充种性能的影响及其机理,明确较优的种层厚度,为改进种层调节板倾角和优化油麦兼用供种装置结构提供理论依据。

1 颗粒模拟

1.1 供种装置结构

油麦兼用型气送式集排器如图1所示,包括供种装置、供料装置、送种管道、增压管、分配器、导种管、风机和变速装置等。供种装置向供料装置定量供种,风机产生的高速气流将种子流吹入送种管道进行混合、输送,在分配器中均匀分配成行,经输种管进入开沟器完成播种。本文以幅宽为2 m的油麦兼用型气送式集排器进行研究,其主要技术参数如表1所示,其中供种装置是调节供种量和影响播种质量的关键部件。

图1 油麦兼用型气送式集排器结构示意图Fig.1 Structure of air-assisted centralized metering device for rapeseed and wheat

表1 气送式集排器主要技术参数Table 1 Main parameters of air-assisted centralized metering device

供种装置结构如图2所示,其工作包括充种、携种和供种3个过程。供种装置工作时,种子由进种口进入由壳体、种层调节板和供种机构形成的充种室中,供种机构顺时针转动形成种子强制运动层和摩擦拖动层,种子在锥孔轮型孔间的斜齿扰动、重力和种群压力(搅种装置顺时针转动向充种区输送小麦种子增大种群侧向压力)共同作用下充入型孔。充种后经携种区和供种区完成定量供种过程。种层调节板通过调节纵向距离h(种层调节板底面与锥孔轮水平中心面的间距)与横向距离l(供种机构中心与种层调节板底角的横向距离)改变充种区种层厚度,从而改变充种性能。

图2 油麦兼用型供种装置结构示意图Fig.2 Structure of seed feed device for rapeseed and wheat

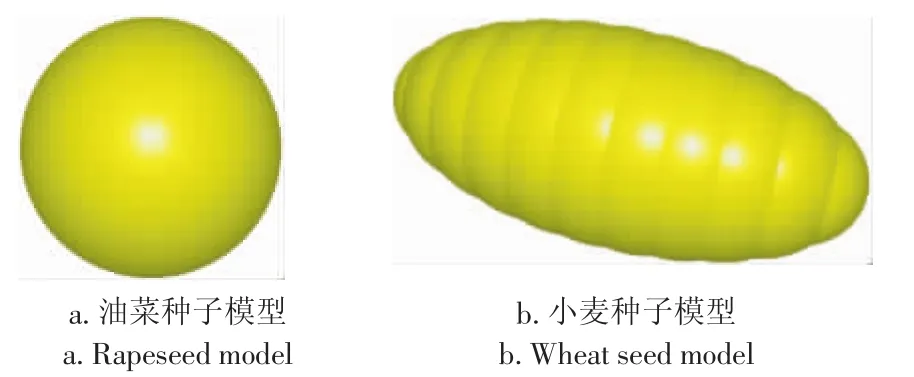

1.2 材料特性

EDEM仿真中将供种装置几何体模型简化为外壳、供种机构和搅种装置3个部分,根据供种装置加工所用材料,外壳设定为铝合金,供种机构和搅种装置为工程塑料ABS(acrylonitrile butadiene styrene copolymer)。油菜籽的球形度较高,小麦种子呈椭球状,根据油菜和小麦种子的三轴尺寸建立的仿真颗粒模型如图3所示。油菜和小麦种子表面均光滑,仿真中选取Hertz-Mindlin无滑动接触模型。种子、铝合金和工程塑料ABS的材料特性及其相互间的力学特性参数[24-26]见表2。

图3 油菜与小麦种子的仿真颗粒模型Fig.3 Simulation model of rapeseed and wheat seed

表2 种子与材料特性参数Table 2 Values of seed and material properties used in,EDEM

1.3 模型的验证

为检验仿真模型及参数的合理性,对比分析了供种装置EDEM仿真与台架试验结果。试验以气送式集排器供种装置为试验装置和锥柱孔倾角[23](0°、10°、20°和30°)为试验因素,锥孔轮数量和转速分别为2和20 r/min,小麦供种时搅种装置与供种机构的转速比为1.0(下同),每个处理重复6次。以20个型孔充种数量平均值为评价指标,比较EDEM仿真与台架试验条件下充种数量的相对误差。

仿真与台架试验结果比较分析(表3):在不同锥柱孔倾角条件下,型孔充种数量仿真值与试验值的相对误差在9%范围内,表明该模型与参数选择能较好地模拟供种装置充种过程和反映种子颗粒的运动与力学特性。

表3 仿真与台架试验结果对比Table 3 Results between simulation test and bench experiment

2 EDEM虚拟仿真

2.1 试验方法

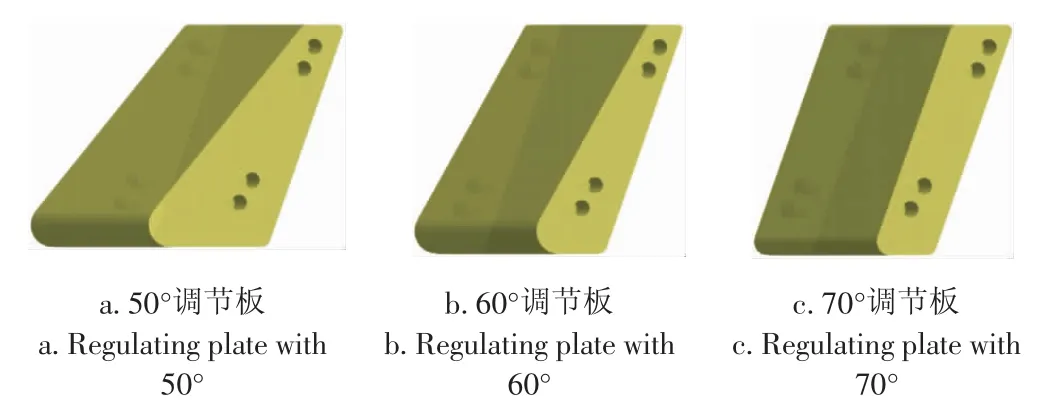

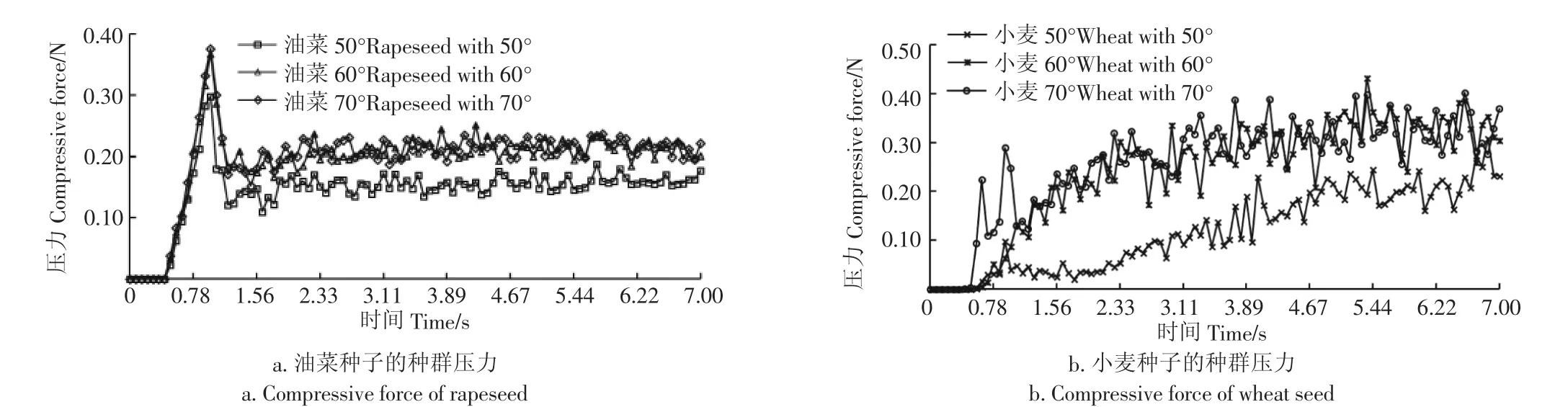

为研究种层调节板倾角对种群充种性能的影响,开展了种层调节板倾角对种群作用力影响的仿真研究。仿真模型设定3种种层调节板倾角,分别为50°、60°和70°,如图4所示。油菜和小麦种子数量为50 000和6 500,输出供种机构受到的种群压力。

为分析不同种层厚度对充种性能的影响,通过改变种层调节板安装位置调节种层厚度。研究纵向位置的影响时,供种油菜时设定纵向距离h为0~25 mm,设6个水平;供种小麦时纵向距离h为15、20和25 mm,增量均为5 mm,横向距离为46 mm。研究横向位置的影响时,横向距离l设50、46和42 mm 3个水平,供种油菜时纵向距离为10、15和20 mm 3种条件,供种小麦时纵向距离为20 mm,转速均为20 r/min。速度对充种性能仿真试验转速为10~50 r/min,设5个水平,增量为10 r/min,纵向距离h和横向距离l分别为15和46 mm。仿真中采用60°种层调节板,第1.0 s时供种机构开始转动,输出不同处理下1.2~7 s供种机构受到的种群压力、种群与供种机构切向力(以下简称切向力)和单个型孔充种数量,取其平均值。

图4 不同种层调节板的结构示意图Fig.4 Overall diagram of different regulating plate of seed layer

2.2 仿真结果与分析

2.2.1 种层调节板倾角对种群压力的影响

图5表明,倾角为50°种层调节板时种群对供种机构压力明显低于60°和70°种层调节板,而60°和70°种层调节板之间的种群压力差异较小。倾角为50°、60°和70°种层调节板条件下单个型孔油菜充种数量分别为11.98、13.42和 13.20,其变异系数分别为 11.47%、8.91%和10.03%;单个型孔小麦充种数量分别为0.60、1.49和1.31,其变异系数分别为92.28%、38.83%和63.67%。倾角为60°种层调节板作用下的种群压力较大,充种数量及其变异系数均较优,说明倾角为60°种层调节板具有较好调节种层厚度的作用。

图5 种层调节板倾角对种群压力的影响Fig.5 Effects of regulating plate’s inclined angle on compressive force

2.2.2 种层厚度对种群压力的影响

纵向距离为0~25 mm范围内,供种机构受到的种群压力和切向力随纵向距离增加而增加(图6);充种过程中随纵向距离增加,供种机构与种群间的作用力的变化剧烈程度增加,说明适当增加纵向种层厚度可以提高种群扰动及种群压力,从而提高充种性能。

图6 种层厚度对种群压力和切向力的影响Fig.6 Effects of seed layer thickness on compressive and tangential force

纵向距离为10~20 mm时,油菜供种的种群压力和切向力均随横向距离增加而降低,这是由于供种机构与种层调节板的距离减小,供种机构扰动的种群受到种层调节板的阻碍,增大了对种群的挤压力。供种小麦时切向力随纵向距离和横向距离增加呈抛物线变化趋势,明显高于油菜充种的切向力。因此,在保证种群对供种机构具有较大压力时,可适当增加种层调节板与供种机构之间的距离,以保证充种率及降低种子破损率;纵向距离为15~20 mm和横向距离适中时较优。

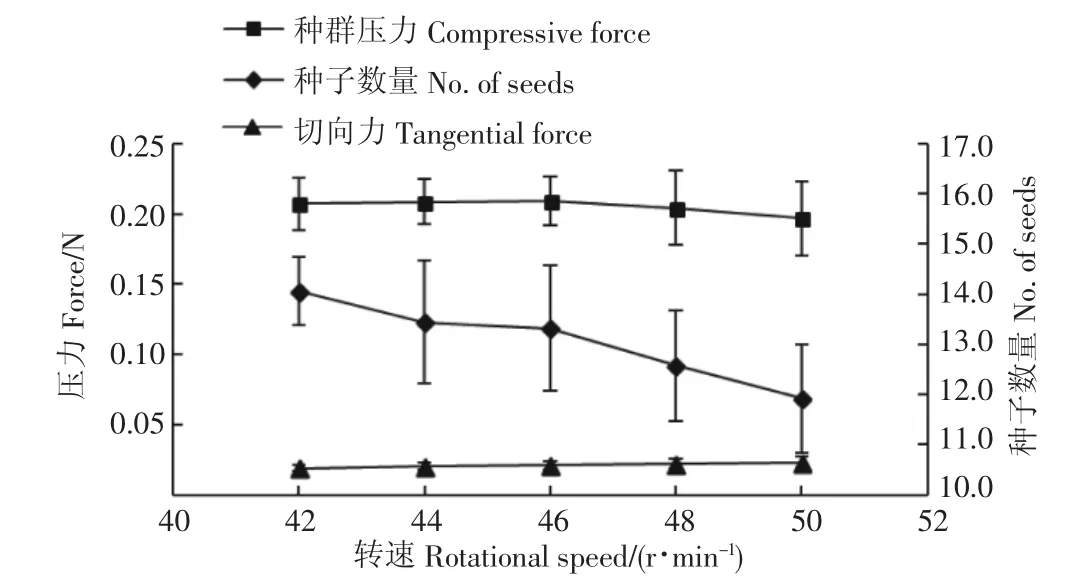

2.2.3 转速对压力的影响

从图7可知,不同转速下种群压力差异很小,切向力随转速增加而增加。转速增加10 r/min,单个型孔充种数量降低5%,其标准差随转速增加有所增加。结果表明,相同种层厚度条件下,不同转速的种群压力趋于稳定,转速主要影响其切向力;由于转速增加使单个型孔充种时间缩短,其充种数量明显减少。

图7 转速对压力与种子数量的影响Fig.7 Effects of rotational speed on force and No.of seeds

2.2.4 种群压力与充种性能的关系

从种群压力与充种性能的关系可知(图8),型孔充种颗粒数与种群压力呈正相关,表明增加种群压力能够提高型孔的充填率。型孔充种数量变异系数随种群压力增加呈抛物线变化趋势,油菜与小麦充种时型孔充种数量变异系数分别在0.20~0.25 N和0.28~0.40 N范围内较低。油菜和小麦充种时纵向距离分别为15和20 mm时种群压力位于该区间。

图8 种群压力与充种性能的关系Fig.8 Coefficients between compressive force of seeds and seed filling performance

3 台架试验

3.1 材料与方法

试验以华油杂62和郑麦9023为试验材料,华油杂62的千粒质量为4.67 g,含水率为7.15%;郑麦9023的千粒质量为44.87 g,含水率为8.44%。采用pco.dimax HD(德国PCO公司)、Cam Ware V3.09高速摄像系统和供种装置试验台进行供种装置充种性能试验,试验设备及装置如图9所示。试验中设定高速摄像时长为30 s,拍摄速度为500帧/s;摄像方向为供种装置正面水平,摄影区域忽略供种机构轴向方向。

图9 供种装置高速摄像试验Fig.9 High speed photography experiment of seed feed device

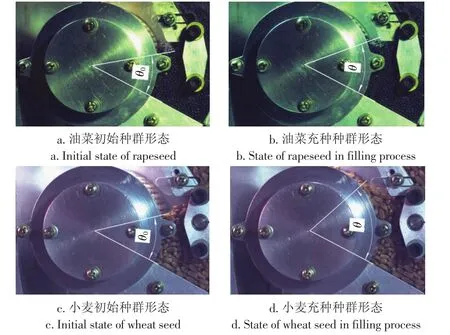

为获得较优的种层厚度以提高供种性能,并验证EDEM仿真的合理性,开展了不同转速条件下种层厚度对充种性能影响的试验。种层调节板倾角分别为50°、60°和70°,供种油菜和小麦时纵向距离h分别为15和20 mm。种层厚度通过种层调节板位置决定,设纵向距离h和横向距离l共2个因素,供种油菜时纵向距离h设15和20 mm 2个水平,横向距离l设42、46和50 mm 3个水平;供种小麦时纵向距离h为20mm。油菜供种时转速为10~40 r/min,小麦为20~50 r/min[23],增量为10 r/min。采用高速摄像系统拍摄种群的初始状态与供种时的充种状态,分析图片获得种子初始充填角θ0和充填角θ,如图10所示。

图10 油菜、小麦充种区的种群形态Fig.10 State of seeds in filling zone for rapeseed and wheat

以GB/T 9478-2005“谷物条播机试验方法”为依据,开展了种层厚度和转速对供种性能影响的试验。试验在供种装置试验台测定,试验中油菜、小麦供种时锥孔轮数量分别为1和4。用容器收集供种口排出的种子,称量净质量,采集时间为1 min,重复6次,计算供种速率、供种速率稳定性变异系数和种子破损率[23]。应用SAS 9.0软件进行方差分析。

3.2 结果与分析

3.2.1 种层调节板倾角对充种性能的影响

表4表明,50°种层调节板的初始充填角显著低于60°和70°。在转速为10~40 r/min条件下,50°种层调节板的充填角明显低于60°和70°,60°与70°种层调节板之间差异较小。油菜供种时,50°种层调节板的充填角均低于初始充填角,60°和70°种层调节板的充填角在40 r/min时高于初始充填角;小麦供种时,3种倾角种层调节板的充填角均高于初始充填角,其原因是供种小麦时搅种装置增强了种群挤压力。充填角随转速增加而增加,说明转速增加增强了种群扰动,从而增加了充填角。综合油麦兼用及EDEM仿真结果,60°种层调节板能保持较高充填角,保证种子充种性能。

表4 种层调节板倾角对充种性能的影响Table 4 Effects of regulating plate’s structure on seed filling performance

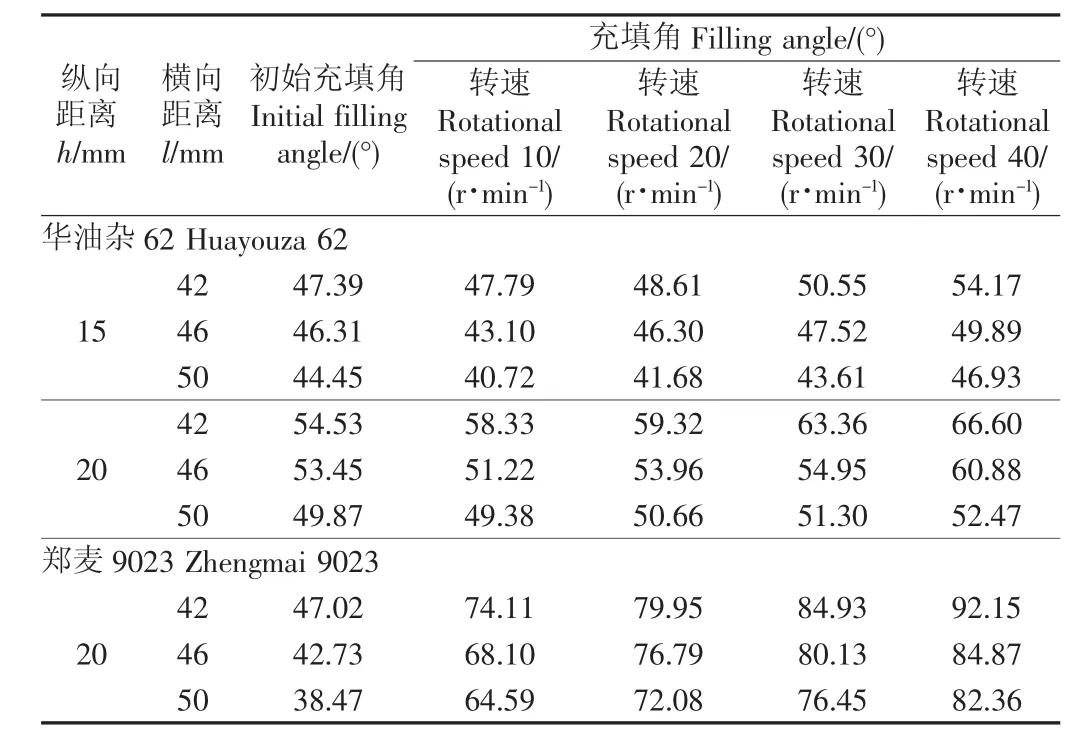

3.2.2 种层厚度对充种性能的影响

油菜充种的初始充填角随纵向距离增加而增加(表5),纵向距离越大,种群进入充种室的初始充填高度越高;横向距离减小使种层调节板与供种机构的间距缩小,受种子休止角的影响,初始充填角也随之增加。在转速为10~40 r/min条件下,纵向距离为20 mm充填角明显高于15 mm;充填角随转速增加和横向距离降低而增加。在纵向距离为15 mm,横向距离为50和46 mm时,充填角低于初始充填角的转速分别为低于30 r/min和20 r/min;横向距离为42 mm时,充填角均高于初始充填角;纵向距离为20 mm时充填角高于初始充填角的转速较15 mm明显降低。种层厚度对小麦种子充填角的影响与油菜种子趋势一致,但其充填角明显高于初始充填角,在40~50 r/min时充填角高达80°。充填角低于初始充填角时,供种装置主要通过型孔囊种;高于初始充填角时,充种依靠切向力引起的“种群拖带”辅助。由于油菜种子流动性较好,纵向距离15 mm利于保持较优的充填角;小麦种子流动性较差,搅种装置保持连续输种并增加种群挤压力。

表5 种层厚度对油菜、小麦充填角的影响Table 5 Effects of seed layer thickness on seed filling angle for rapeseed and wheat

3.2.3 种层厚度对供种性能的影响

表6和表7表明,在10~40 r/min时,油菜、小麦的供种速率均随纵向距离增加显著增加,随横向距离增加显著降低,小麦供种速率随横向距离增加速率较油菜大;供种速率随转速增加呈线性增加趋势,油菜的供种速率变异系数均低于1.0%。在纵向距离为15 mm和横向距离为46 mm时,供种速率变异系数低于0.4%。小麦供种速率以横向距离为46 mm较高,其变异系数在20~40 r/min范围内低于0.75%;种子破损率随横向距离降低而增加,但均低于0.1%。综合考虑种子供种量和供种稳定性,油菜、小麦供种时较优的纵向距离分别为15和20 mm,横向距离均为46 mm左右,该结果与EDEM仿真结果一致。

表6 种层厚度对油菜供种性能的影响Table 6 Effects of seed layer thickness on seed feed performance for rapeseed

表7 种层厚度对小麦供种性能的影响Table 7 Effects of seed layer thickness on seed feed performance for wheat

3.2.4 种群压力、充填角与供种性能的相关关系

表8表明,种群压力、切向力、初始充填角、充填角与供种速率均呈极显著正相关,种群压力和切向力与初始充填角和充填角均呈极显著正相关。种群压力和切向力与充填角均呈线性关系(式1),其决定系数分别为0.956 9和0.920 0。因此,增加纵向距离和降低横向距离可增加种群压力、切向力和充填角,从而增加了供种速率。种层厚度和转速影响充填角分别源于种群压力和切向力。

式中y为充填角,(°);Pc为种群压力,N;Pt为种群与供种机构间切向力,N。

表8 种群压力、充填角与供种性能的相关系数Table 8 Coefficients between compressive force,filling angle and seed feed performance

4 田间试验

为进一步验证EDEM仿真及台架试验结果,考察优化的种层厚度条件下的播种效果,分别于2015年9月9日和10月3日在华中农业大学校内现代农业科技园开展了油菜供种性能试验,如图11a所示,地表土壤含水率平均为14.74%。试验以2BFQ-6油菜精量联合直播机为平台,牵引动力为东方红-LX854,机组前进速度为2.52 km/h,播种8行,行距为200 mm。依据仿真与台架试验结果,供种装置的种层调节板设定纵向距离和横向距离分别为15和46 mm。油菜播后20 d,在田间选取6段,以1 m为测量单位,测定8行的总苗数及其稳定性变异系数,出苗效果如图11b所示。该集排器直播油菜田间种植密度为38~50株/m2,稳定性变异系数为10.64%。

图11 油菜田间试验与出苗效果Fig.11 Field experiment and emergence performance of rapeseed

5 结论

1)本文以种群压力、切向力和充种数量为指标,对EDEM仿真结果进行了分析:倾角为60°种层调节板作用下的种群压力较大,充种数量及其变异系数均较优;增加纵向距离和降低横向距离有助于增加种群压力和切向力;随转速增加,种群压力趋于稳定,切向力随之增加,单个型孔充种数量降低5%。

2)转速为10~40 r/min时,50°种层调节板的充填角明显低于60°和70°,60°种层调节板能保持较高充填角;初始充填角和充填角均随纵向距离和转速增加而增加,随横向距离增加而降低;纵向距离为15 mm时油菜种子依靠型孔结构充种,小麦主要依靠种群拖带充种。

3)油菜、小麦的供种速率均随纵向距离增加和横向距离减小而增加。种群压力、切向力、充填角与供种速率均呈极显著正相关,种群压力和切向力与充填角均呈极显著正相关。种层厚度和转速影响充填角分别来自种群压力和切向力。在油菜、小麦纵向距离分别为15和20 mm,横向距离为46 mm时,供种速率变异系数和破损率分别低于1.0%和0.1%。在优化种层厚度条件下,田间试验集排器直播油菜田间密度为38~50株/m2,稳定性变异系数为10.64%,满足农艺种植要求。

本研究中小麦供种较优的种层厚度是在特定搅种装置与锥孔轮的转速比恒定条件下获得,但搅种装置对种群压力和充种性能也有较大影响,需进一步深入研究。

[1]李宝筏.农业机械学[M].北京:中国农业大学出版社,2003.

[2]Downs H W,Taylor R K.Evaluation of pneumatic granular herbicide applicators for seeding small grains in Oklahoma[J]. Applied Engineering in Agriculture,1986,2(2):58-63.

[3]史嵩,张东兴,杨丽,等.基于EDEM软件的气压组合孔式排种器充种性能模拟与验证[J].农业工程学报,2015,31(3):62-69. Shi Song,Zhang Dongxing,Yang Li,et al.Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2015,31(3):62-69.(in Chinese with English abstract)

[4] 刘宏新,徐晓萌,郭丽峰,等.具有复合充填力的立式浅盆型排种器充种机理[J].农业工程学报,2014,30(21):9-16. Liu Hongxin,Xu Xiaomeng,Guo Lifeng,et al.Research on seed-filling mechanism of vertical shallow basin type seedmetering device with composite filling force[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2014,30(21):9-16.(in Chinese with English abstract)

[5] 陈进,李建华,李耀明.气吸振动盘式精密播种机吸种高度控制与加种装置[J].农业机械学报,2013,44(增刊1):67-71. Chen Jin,Li Jianhua,Li Yaoming.Analysis of suction height and seed-adding device for suction-vibration precision seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013,33(Supp.1):67-71.(in Chinese with English abstract)

[6] 陈进,李耀明.气吸振动式播种试验台内种子运动规律的研究[J].农业机械学报,2002,33(1):47-50. Chen Jin,Li Yaoming.Study on seeds movement law in sowing test stand with suction and vibration[J].Transactions of the Chinese Society for Agricultural Machinery,2002,33(1):47-50. (in Chinese with English abstract)

[7] 张石平,陈进,李耀明.振动气吸式穴盘精量播种装置种子群“沸腾”运动分析[J].农业工程学报,2008,24(7):20-24. Zhang Shiping,Chenjin,Li Yaoming.Analysisofseeds“Boiling”motion on vibrational air-suction tray seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2008,24(7):20-24.(in Chinese with English abstract)

[8]董春旺,毛树春,胡斌,等.盘吸式穴盘播种机抛振系统运动分析与优化[J].农业工程学报,2010,26(6):124-128. Dong Chunwang,Mao Shuchun,Hu Bin,et al.Motion analysis and optimization on ejection mechanism of air-suction tray seeder[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2010,26(6):124-128. (in Chinese with English abstract)

[9]罗锡文,蒋恩臣,王在满,等.开沟起垄式水稻精量穴直播机的研制[J].农业工程学报,2008,24(12):52-56. Luo Xiwen,Jiang Enchen,Wang Zaiman,et al.Precision rice hill-drop drilling machine[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2008,24 (12):52-56.(in Chinese with English abstract)

[10]邢赫,臧英,王在满,等.水稻气力式排种器分层充种室设计与试验[J].农业工程学报,2015,31(4):42-48. Xing He,Zang Ying,Wang Zaiman,et al.Design and experiment of stratified seed-filling room on rice pneumatic metering device[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2015,31 (4):42-48.(in Chinese with English abstract)

[11]李兆东,李姗姗,曹秀英,等.油菜精量气压式集排器排种性能试验[J].农业工程学报,2015,31(18):17-25. Li Zhaodong,Li Shanshan,Cao Xiuying,et al.Seeding performance experiment of pneumatic-typed precision centralized metering device[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2015,31 (18):17-25.(in Chinese with English abstract)

[12]Zhu H P,Zhou Z Y,Yang R Y,et al.Discrete particle simulation of particulate systems:A review of major applications and findings[J].Chemical Engineering Science,2008,63:5728-5770.

[13]Tijskens E,Ramon H,Baerdemaeker J D.Discrete element modelling for process simulation in agriculture[J].Journal of Sound and Vibration,2003,266:493-514.

[14]Skrinjar O,Larsson P L.On discrete element modeling of compaction of powders with size ratio[J].Computational Materials Science,2004,31:131-146.

[15]Rajia A O,Favier J F.Model for the deformation in agricultural and food particulate materials under bulk compressive loading using discrete element method.II:Compression of oilseeds[J]. Journal of Food Engineering,2004,64:373-380.

[16]Rezvani F,Azargoshasb H,Jamialahmadi O,et al.Experimental study and CFD simulation of phenol removal by immobilization of soybean seed coat in a packed-bed bioreactor[J].Biochemical Engineering Journal,2015,101:32-43.

[17]Wojtkowski M,Pecen J,Horabik J,et al.Rapeseed impact against a flat surface:Physical testing and DEM simulation with two contact models[J].Powder Technology,2010,198:61-68.

[18]Lenaerts B,Aertsen T,Tijskens E,et al.Simulation of grainstraw separation by Discrete Element Modeling with bendable straw particles[J].Computers and Electronics in Agriculture, 2014,101:24-33.

[19]李耀明,赵湛,陈进,等.气吸振动式排种器种盘内种群运动的离散元分析[J].农业机械学报,2009,40(3):56-59,76. Li Yaoming,Zhao Zhan,Chen Jin,et al.Discrete element method simulation of seeds motion in vibrated bed of precision vacuum seeder[J].Transactions of the Chinese Society for Agricultural Machinery,2009,40(3):56-59,76.(in Chinese with English abstract)

[20]Karayel D,Wiesehoff M,Ozmerzi A,et al.Laboratory measurement of seed drill seed spacing and velocity of fall of seeds using high-speed camera system[J].Computersand Electronics in Agriculture,2006,50:89-96.

[21]王在满,罗锡文,黄世醒,等.型孔式水稻排种轮充种过程的高速摄像分析[J].农业机械学报,2009,40(12):56-61. Wang Zaiman,Luo Xiwen,Huang Shixing,et al.Rice seeds feeding process in cell wheel based on high-speed photography technology[J].Transactions of the Chinese Society for Agricultural Machinery,2009,40(12):56-61.(in Chinese with English abstract)

[22]丛锦玲,廖庆喜,曹秀英,等.油菜小麦兼用排种盘的排种器充种性能[J].农业工程学报,2014,30(8):30-39. Cong Jinling,Liao Qingxi,Cao Xiuying,et al.Seed filling performance of dual-purpose seed plate in metering device for both rapeseed&wheat seed[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2014,30(8):30-39.(in Chinese with English abstract)

[23]雷小龙,廖宜涛,李兆东,等.油麦兼用型气送式集排器供种装置设计与试验[J].农业工程学报,2015,31(20):10-18. Lei Xiaolong,Liao Yitao,Li Zhaodong,et al.Design and experiment of seed feed device in air-assisted centralized metering device for rapeseed and wheat[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2015,31(20):10-18.(in Chinese with English abstract)

[24]丛锦玲.油菜小麦兼用型气力式精量排种系统及其机理研究[D].武汉:华中农业大学,2014.Cong Jinling.Study on Seeding System and Mechanism of Pneumatic Precision Metering Device for Wheat and Rapeseed [D].Wuhan:Huazhong Agricultural University,2014.(in Chinese with English abstract)

[25]曹秀英,廖宜涛,廖庆喜,等.油菜离心式精量集排器枝状阀式分流装置设计与试验[J].农业机械学报,2015,46(9):77-84. Cao Xiuying,Liao Yitao,Liao Qingxi,et al.Design and experiment on value-branch distributor of centrifugal precision metering device for rapeseed[J].Transactions of the Chinese Society for Agricultural Machinery,2015,46(9):77-84.(in Chinese with English abstract)

[26]Zhao Zhan,Li Yaoming,Liang Zhenwei,et al.DEM simulation and physical testing of rice seed impact against a grain loss sensor[J].Biosystem Engineering,2013,116:410-419.

Effects of seed layer thickness on seed filling performance of seed feeding device for rapeseed and wheat

Lei Xiaolong,Liao Yitao,Li Zhaodong,Zhang Wenyu,Cao Xiuying,Li Shanshan,Liao Qingxi※

(College of Engineering,Huazhong Agricultural University,Wuhan 430070,China)

Seed feeding device determines the seeding performance of the air-assisted centralized metering system.Seed filling performance is the key parameter to affect feeding quality of seed feeding device.As seeds′flow properties and compressive force significantly affect seed filling performance,the effects of seed layer thickness on filling performance for rapeseed and wheat were studied in this research.EDEM(engineering discrete element method)software was used for simulating the filling performance and high speed camera technology was used for executing the experiment.Adjustable regulating plate was adjusted for seed layer thickness under different treatments.In EDEM simulation,the experimental factors were inclined angle of adjustable regulating plate with 3 levels(ranging from 50°to 70°),longitudinal distance of regulating plate with 6 levels(ranging from 0 to 25 mm),lateral distance with 3 levels(ranging from 42 to 50 mm)and rotational speed with 5 levels(ranging from 10 to 50 r/min)in single-factor test.Seeds′compressive force,tangential force and number of seeds in model-hole were used as test indices in simulation.Bench test was performed on test rig by using Huayouza 62 and Zhengmai 9023 as materials,while field experiment was carried out in the modern agriculture science park of Huazhong Agricultural University in 2015.The 3 inclined angles of adjustable regulating plate,2 longitudinal distances and 3 lateral distances were evaluated for seed filling performance at 5 rotational speeds(10,20,30,40 and 50 r/ min).Angles of adjustable regulating plate were 50°,60°and 70°using complete randomized design(one-factor), longitudinal distances were 15 and 20 mm and lateral distances were 42,46 and 50 mm with two-factor full factorial test. Seeds′initial filling angle,filling angle which was measured by high speed camera using pco.dimax HD system,seed feeding rate,coefficient of variation of seed feeding rate and damage rate were dependent variables in bench experiments. The relationships between seed feeding rate,coefficient of variation of seed feeding rate and seeds′compressive force, tangential force,filling angle were analyzed.Results showed that:1)Seeds′compressive force,seed filling angle and feeding performance of regulating plate with the angle of 60°were better than other parameters.Seeds′compressive and tangential force increased with the increase of longitudinal distance and the decrease of lateral distance.Coefficient of variance of seeds′number decreased and then rose up.Seeds′compressive force was generally stable and tangential force increased with the increase of rotational speed.The number of seeds in each model-hole decreased by 5%with the rotational speed increasing of 10 r/min.2)When rotational speed was within the range of 10~50 r/min,seed initial filling angle,filling angle and seed feeding rate rose with the increasing of longitudinal distance and the decreasing of lateral distance.In addition,the coefficient of variation of seed feeding rate decreased and then rose up with the increasing of longitudinal distance and the decreasing of lateral distance.Seeds′compressive force,tangential force and seed filling angle were positively and significantly correlated with seed feeding rate.Effects of seed layer thickness and rotational speed on seed filling angle mainly resulted from compressive force and tangential force,respectively.Regarding the agronomic requirements,the ideal parameters were longitudinal distance of 15 and 20 mm for rapeseed and wheat,and lateral distance of 46 mm.Under the combination condition of optimum seed layer thickness,the coefficient of variation of seed feeding rate and the damage rate for the seed feeding device were less than 1.0%and 0.1%,respectively.3)Field experiments demonstrated that planting density was 38~50 plants per square meter and their coefficient of variation was 10.64%using the air-assisted centralized metering device under the condition of optimum seed layer thickness.Results showed that the use of this metering device made the emergence performance of rapeseed meet the agronomic requirements.This study investigated the mechanism of seed layer thickness which affected seed filling performance in seed feeding device for rapeseed and wheat.The investigation of seed layer thickness in this research can provide the basis for optimizing the structure of regulating plate and improving the feeding performance.

agricultural machinery;crops;EDEM simulation;high speed photography;seed feed device;seed filling performance;rapeseed;wheat

10.11975/j.issn.1002-6819.2016.06.002

S223.2+3

A

1002-6819(2016)-06-0011-09

2015-10-26

2016-01-22

国家自然科学基金资助项目(51575218、51275197、51405180);国家油菜产业体系专项资助项目(CARS-13);中央高校基本科研业务费资助项目(2662015PY133)

雷小龙,男,四川营山人,博士生,主要从事现代农业装备设计与测控研究。武汉 华中农业大学工学院,430070。Email:leixl1989@163.com※通信作者:廖庆喜,男,湖北江陵人,教授,博士生导师,主要从事油菜机械化生产技术与装备等方面的研究。武汉 华中农业大学工学院,430070。Email:liaoqx@mail.hzau.edu.cn