Analysis of working behavior of Jinping-I Arch Dam during initial impoundment

*

Yalong River Hydropower Development Company,Ltd.,Chengdu 610051,China

Analysis of working behavior of Jinping-I Arch Dam during initial impoundment

Shi-yong Wu*,Wei Cao,Jiang Zheng

Yalong River Hydropower Development Company,Ltd.,Chengdu 610051,China

Available online 9 November 2016

To study the stress,deformation,and seepage pressure during the initial impoundment of the Jinping-I Arch Dam,monitoring analysis and numerical calculation were used in a dam behavior analysis that focused on the working behavior of the dam during the late period of the initial impoundment up to the end of November 2014.The numerical calculation was performed based on feedback analysis of the deformation and stress of the arch dam through inversion of the elastic moduli(E)of the dam body and foundation,using a three-dimensional finite element model for the linear elastic material of the arch dam.The main monitoring indices presented insignif i cant changes in the late period of the initial impoundment,and the results of feedback analysis were consistent with monitoring results.Analysis results also show that the deformations of the dam body and dam foundation were within the design range;the dam stress distributions were normal,with values lower than the design control criteria;and the seepage flows through the dam body and dam foundation were lower than the design drainage capacity of the deep-well pump house,demonstrating that the Jinping-I Arch Dam was in good working condition,and the initial impoundment had been successfully completed.The results of the working behavior analysis of the Jinping-I hydropower project during the initial impoundment can provide references for safe operation of similar projects.

Dam safety monitoring;Working behavior;Elastic modulus;Dam impoundment;Jinping-I hydropower project

1.Introduction

During the dam's initial impoundment,monitoring indices change with the water load and other factors,so impoundment is crucial to dam safety.Many engineering accidents occur in the initial impoundment period,so it is important to analyze the working behavior of a dam during this period to ensure the dam's safe operation.

China has several of the world's highest dams,for example the Shuangjiangkou hydropower project,with a maximum height of 314 m,which is the highest dam under construction in the world,and the Jinping-I hydropower project,with a maximum height of 305 m,which is the highest completed dam in the world.Basic information on some large hydropower projects in China is given in Table 1.As some large hydropower projects,such as the Shuibuya,Laxiwa,Xiaowan, and Xiluodu hydropower stations,have been put into operation,the safety evaluation of hydropower projects during the initial impoundment has been extensively carried out in China (Wu,2003;Hu et al.,2012;Jin et al.,2011).Monitoring and analysis of the dam foundation deformation,stress-strain,and seepage pressure during the initial impoundment,using an automatic observation system,have been carried out for the Laxiwa and Xiaowan hydropower projects(Li et al.,2009; Han et al.,2010;Wang et al.,2003,2010;Huang et al., 2006).The monitoring results show that the dam deformation is closely related to the reservoir water level,and the deformation in the upper part of the dam is more sensitive tothe water load than that in the lower part.Based on prototype monitoring results,a finite element model has been used to carry out feedback analysis of the working behaviors of the Shuibuya and Xiluodu hydropower projects,and to perform safety assessment of the dams in the late operation stage(Zhou et al.,2011;Zhang and Yin,2014;Zhang et al.,2016).According to analysis results,dam deformations appear downstream and towards the banks under the water load.The dam deformation during the initial impoundment is consistent with the variation of the reservoir water level.According to the comprehensive analysis results,the dams are in a safe condition during the initial impoundment.

Table 1Basic information on high dams in China.

With regards to the Jinping-I hydropower project,Zhou and Rao(2014)launched seepage control research,dam safety monitoring analysis,structural stress and deformation analysis,and safety assessment of the dam during the reservoir impoundment according to the construction progress and monitoring information.Chen and Ruan(2014)and Yang and Dong(2015)carried out preliminary analyses of the working behavior of the dam based on the monitoring results during the initial impoundment.The deformation,stress-strain,and seepage pressure of the dam meet general rules,with their values within the range of design control indices,and the performances of the structures are normal overall.Based on relevant research achievements,two methods,monitoring analysis and numerical calculation,were used in the working behavior analysis of the dam in this study.The working behavior of the dam during the initial impoundment,such as the stress,deformation,and seepage pressure,was evaluated through monitoring result analysis and feedback analysis,so as to provide a technical foundation for comprehensive study of dam performance,successful completion of the initial impoundment,and safe operation of hydropower projects.

2.Impoundment process and monitoring design of Jinping-I Arch Dam

2.1.Project overview

Located on the main stream of the Yalong River in Yanyuan County and Muli County,in the Liangshan Yi Autonomous Prefecture in Sichuan Province,the Jinping-I hydropower project is a controlling reservoir downstream of the Yalong River,with signif i cant compensative regulation effect on downstream cascade hydropower stations.

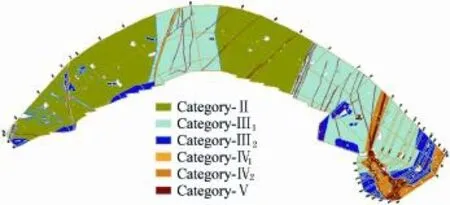

The project consists of a water-retaining structure,a f l ood discharge and energy dissipation structure,and power generation facilities,with a total installed capacity of 3600 MW. The water-retaining structure is a concrete double-curvature arch dam with a maximum height of 305 m,and is the highest completed arch dam in the world.The dam is composed of 26 sections from the left bank to right bank,poured with concrete without longitudinal joints,and the concrete material is divided into three areas known,respectively,as A,B,and C, with area A being a strong constraint area and area C a weak constraint area.The partition of dam sections and zoning design of the concrete material are shown in Fig.1.The normal water storage level of the reservoir is 1880 m,the dead water level is 1800 m,and the total storage capacity is 7.76 km3.The project construction started in 2005,and the fi rst two generation units were put into operation in August 2013.All the units had been put into operation by July 2014.

2.2.Initial impoundment process

The Jinping-I hydropower project is large in scale with complicated geological conditions.The initial impoundment was divided into four stages.In November 2012,the right bank diversion tunnel was closed for impoundment.In December,the diversion bottom outlet was opened,and the water level in front of the dam reached 1707 m,the impoundment goal of the first stage.In July 2013,the reservoir water level reached the design dead water level,1800 m, completing the second stage of the initial impoundment.In September 2013,the diversion bottom outlet was closed,and the water level reached 1840 m in October,the impoundment goal of the third stage.The fourth stage of the initial impoundment was started in July 2014.In August 2014,the reservoir reached the normal water storage level,1880 m, which meant the completion of the fourth stage of the initial impoundment.In order to comprehensively evaluate the working behavior of the dam during the initial impoundment, this study focused on the working behavior of the dam just after the completion of the fourth stage of the initial impoundment,from August 2014 to the end of November 2014,which is called the late period of the initial impoundment in this paper.During this period,the water level was kept between 1876 m and 1880 m,close to the normal water storage level.In contrast to the late period,the period that consists of the four stages of the initial impoundment is calledthe early stage of the initial impoundment.The initial impoundment process of the dam is shown in Fig.2.

Fig.1.Partition of dam sections and zoning design of concrete material.

2.3.Dam monitoring design

Key technical issues related to the impoundment safety of high dams include the dam structural stress and deformation, as well as seepage control.In order to guarantee the safe operation of the dam in the initial impoundment period, comprehensive monitoring measures of the Jinping-I hydropower project were designed,with a monitoring range covering the dam body,dam foundation,pedestal,dam outlets, plunge pool,and subsidiary dam.The main monitoring items included the deformation,stress-strain,seepage pressure, temperature,environmental parameters,and special factors (Wu and Cao,2014).By November 30,2014,a total of 3450 sets of monitoring instruments had been installed(Deng and Dong,2014).

3.Analysis of working behavior of dam

Fig.2.Initial impoundment process.

The study focused on the working behavior of the dam during the late period of the initial impoundment up to the end of November 2014.Monitoring data obtained during this period include the radial horizontal deformation with positive values downstream and negative values upstream,the tangential horizontal deformation with positive values towards the left bank and negative values towards the right bank,the chord length variation with positive values for elongation and negative values for shortening,the vertical deformation with positive values for settling and negative values for upraising,the joint opening with positive values for enlargement and negative values for shrinkage,and the stress with positive values for tensile stresses and negative values for compressive stresses.

3.1.Monitoring results

3.1.1.Monitoring results during early period of initial impoundment

The arrangement of plumb lines for deformation monitoring of the dam is shown in Fig.3,where PL means the plumb line,IP means the inverted plumb line,the subscripts L and R mean the left and right banks,respectively,and the other subscripts mean the numbers of the dam section and plumb line in each section,respectively.

The monitoring results of the maximum deformation and seepage of the Jinping-I Arch Dam before and after each stage in the early period of the initial impoundment are shown in Table 2.The statistical results show that they are positively correlated with the reservoir water level.

3.1.2.Monitoring results during late period of initial impoundment

During the late period of the initial impoundment,the relevant monitoring results can be described as follows:

(1)Dam foundation deformation

Fig.3.Monitoring arrangement of plumb lines.

Thecalculatedresultsofthemaximumradialdeformationand tangential deformation of the dam foundation obtained from the arch-cantilever method,with values of 27.2 mm and 22.5 mm, respectively,were taken as the reference control standards.

According to the monitoring results,the maximum radial deformation was 14.24 mm,and the maximum tangential deformation was 2.36 mm.The measured values were within the design range.

The dam foundation joints were in a compressive state. When the water level reached 1880 m at the end of the early period of the initial impoundment,the opening variation of the dam foundation joints was less than 0.1 mm,and the value was less than 0.2 mm during the late period of the initial impoundment,demonstrating that the dam foundation joints were in a safe condition.

(2)Dam body deformation

The dam body deformation includes the horizontal deformation,vertical deformation,chord length variation,and joint opening variation.The calculated results of the maximum radial deformation and tangential deformation of the dam body obtained from the arch-cantilever method,with values of 85.0 mm and 24.3 mm,respectively,were taken as the reference control standards.

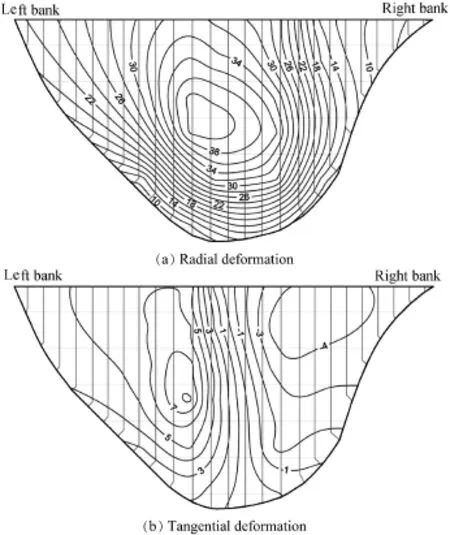

According to the monitoring results from November 2014, the horizontal deformation of the dam body appeared downstream and towards both banks of the river.The radial deformation of the dam body appeared downstream.The maximum value appeared in the middle section,and the deformation decreased gradually towards both banks.The largest radial deformation occurred in the#13 dam section at an elevation of 1730 m,leading to a displacement value of 40.75 mm (Fig.4(a)).The tangential deformation of the dam body pointed to the left on the left bank,and to the right on the right bank.The largest tangential deformation on the left bank occurred in the#11 dam section at an elevation of 1730 m, leading to a displacement value of 8.31 mm;the largest tangential deformation on the right bank occurred in the #16 dam section at an elevation of 1829 m,leading to a deformation value of-4.72 mm(Fig.4(b)).The radial displacement graph of the#13 dam section and the tangential displacement graph of the#11 dam section during the initial impoundment are shown in Fig.5.According to the monitoring results,the dam body deformation had a strong correlation with thereservoirwaterlevel,and theoveralldeformation was insignif i cant.All measured values were within the design range.

Table 2Comparison of monitoring results of maximum deformation and seepage before and after four stages in early period of initial impoundment.

Fig.4.Contour maps of horizontal deformation of dam body in November 2014(units:mm).

Fig.5.Horizontal deformation graphs for#11 and#13 dam sections at different elevations during initial impoundment.

The vertical deformation of the dam body presented the following characteristics:the largest deformation of 12.04 mm in November 2014 appeared at the arch crown,and the deformation decreased gradually towards both banks.

The chord length of the dam body was shortened for approximately 4—7 mm during the early period of the initial impoundment.However,the chord length was then extended approximately 1—2 mm during the late period.The horizontal joints of the dam were under compression,with a variation of less than 0.2 mm.

In general,the distribution patterns of the radial,tangential, and verticaldisplacements complied with the design expectations.

(3)Dam stress

According to the current arch dam design code,concrete strength control standards were determined by categorized factors.The concrete material of the Jinping-I Arch Dam was divided into three sections,and their concrete strength control standards are shown in Table 3.

According to stress calculations,the strain gauge groups should be arranged at the locations with large tensile and compressive stresses,the locations at 1/4 of the dam length from the two ends,the locations at 1/4 of the arch ring from the two ends,the representative arch crowns,and the two ends of the abutments.According to industry standards,the uniaxial,f i ve-direction,and nine-direction strain gauge sets as well as the non-stress meter were adopted in monitoring.The monitoring points of stress-strain of the dam body are shown in Fig.6.

During the late period of the initial impoundment,the upstream water level was basically unchanged,and the dam stress monitoring results obtained in November 2014 can be described as follows:

The dam heel and dam toe were in strong constraint areas, close to the dam foundation(area A).They were in a compressive state in general.The maximum vertical compressive stress of 4.57 MPa appeared at the dam heel in the#12 dam section.The maximum vertical tensile stress of 0.1 MPa appeared at the dam heel in the#2 dam section.The maximum tangential compressive stress of 5.13 MPa appeared at the dam toe in the#21 dam section.The maximum tangential tensile stress of 0.26 MPa appeared at the dam toe in the#4 dam section.The maximum radial compressive stress of 4.76 MPa appeared at the dam toe in the#9 dam section. The maximum radial tensile stress of 0.83 MPa appeared at the dam heel in the#2 dam section.The stress graphs for the arch abutment heel in the#12 dam section,the arch abutment toe in the#21 dam section,and arch abutment toe in the#9 dam section during the initial impoundment are shown in Fig.7.

The dam body(areas B and C)was generally in a compressivestate,withouttensile stressdetected.The maximum vertical compressive stress of 5.93 MPa appeared in the middle part of the#11 dam section at an elevation of 1720 m.The maximum tangential compressive stress of 6.94 MPa appeared downstream of the#13 dam section at anelevation of 1684 m and in the middle part of the#11 dam section at an elevation of 1720 m.The maximum radial compressive stress of 4.76 MPa appeared downstream of the #9 dam section at an elevation of 1648 m.

Table 3Compressive and tensile strength control standards of concrete material of dam body.

Fig.6.Monitoring arrangement of stress-strain of dam body.

Fig.7.Stress graphs recorded by f i ve-direction strain gauges at arch abutment heel or arch abutment toe in different dam sections during initial impoundment.

Basically,the arch dam was in a compressive state,the stress distribution of the dam could be considered normal,and all values were less than the design control criteria.

(4)Seepage pressure

According to the Design Specif i cation for Concrete Arch Dams(DL/T 5346—2006)and engineering practices,the uplift pressure reduction coeff i cients are set mainly based on the pros and cons of the geological conditions of the dam foundation,seepage proofcurtain,and drainage facilities. Considering the actual situation of the Jinping-I Arch Dam, the relevant design control criteria for seepage proof structures were set as follows:the uplift pressure reduction coeff i cient for the seepage proof curtain of the dam foundation was a1≤0.4,the uplift pressure reduction coeff i cient for the main drainage curtain of the dam foundation was a2≤0.2,and the design drainage capacity of the deep-well pump house was 450 m3/h.

The curtain and drainage effects,determined by the uplift pressure reduction coeff i cient,were studied.As the water level downstream of the Jinping-I hydropower project was lower than the bedrock elevation,the following formula for the uplift pressure reduction coeff i cient was adopted:

where H1is the upstream water level,H4is the bedrock elevation,and Hiis the actual water level at the measurement location i.

The arch dam foundation curtain showed a strong antiseepage performance.The maximum reduction coeff i cient was 0.29 behind the seepage proof curtain,and 0.08 behind the drainage curtain,less than the design value of the reduction coeff i cient.

The practically measured seepage flow through the dam body and dam foundation corridors was 64.34 L/s.The total seepage flow through the left bank dam foundation was 54.36 L/s,and the total seepage flow through the right bank dam foundation was 9.99 L/s.These values were lower than the design drainage capacity of the deep-well pump house.

According to the monitoring results,the working behavior of the dam body and dam foundation was basically normal at the water level of 1880 m,and seepage controlling works operated normally.The dam was in an elastic state during the late period of the initial impoundment.

3.2.Feedback analysis

Feedback analysis is an effective complementary analysis approachfortestresultanalysis.Toobtaintheaccurateresultsof deformation and stress and provide a more comprehensive evaluation of the working behavior of the arch dam,feedback calculation of the deformation and stress of the arch dam,based on inversion of the elastic moduli(E)of the dam body and dam foundation,was carried out by means of a statistical model and fi nite element model.In the feedback analysis,a representative period and a target point for re fl ecting deformation characteristics of the arch dam were selected,and the observed displacement at the target point was taken as the target value. The elastic moduli of the dam body and dam foundation were adjusted repeatedly so that the computed deformation at the target point approached its observed value.The mean square deviation between the observed displacement and computed displacement was used to check their agreement,and the elastic modulus leading to the minimum mean square deviation was taken as the best feedback parameter.

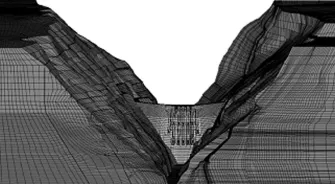

3.2.1.Numerical model

Basedontheengineeringdesignandgeologicaldata,a threedimensional finite element model for the linear elastic material of the Jinping-I Arch Dam was established.The model used the centerline of the arch dam as a reference,from which a range of 900monbothsideswasincluded.Themodelalsousedtheorigin ofthecrestasareference,fromwhicharangeof750mupstream and downstream was included,respectively.A range of 700 m below the foundation surfacewas covered as well.In the model, the slope of the rock mass above the crest was cut to the natural boundary elevation;for the mountains on both banks,a range of 2.5 times the dam height was extended upstream and downstream,and one dam height was extended upwards from the crest.Thefiniteelementmodelwasusedtosimulatethecomplex faults f2,f5,f8,f42-9,f13,f14,and f18(Fig.3),lamprophyre veins, and other weak structural planes,as well as the terrain and stratum partitions in the project area.The faults f8and f42-9are not shown in Fig.3.The fault f8was a subfault near the hanging wall ofthefaultf5,andthefaultf42-9was locatedontheleftdam abutment.Simulation was also carried out of the engineering measures,such as the pedestal,concrete plug,shear force transmissiontunnel,replacementofconcretegrillage,subsidiary dam,plunge pool,and grouting.The classif i cation of rock mass qualityinthedamfoundationisshowninFig.8.Themechanical parameters of rocks and structural planes are shown in Table 4. The three-dimensional finite element model is shown in Fig.9.

3.2.2.Inversion of elastic modulus

Fig.8.Classif i cation of rock mass quality in dam foundation.

Table 4Mechanical parameters of rocks and structural planes.

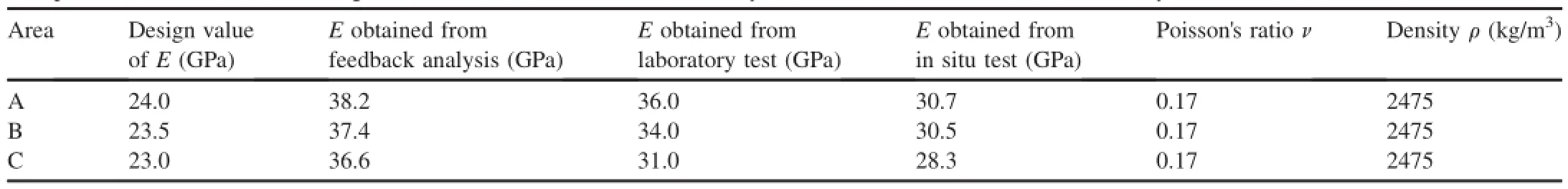

Fig.9.Three-dimensional finite element model.

Feedback analysis was first performed for the duration from the starting of the water level monitoring on December 1,2011 to the completion of the fourth stage of the initial impoundment on August 24,2014 for inversion of the elastic modulus. The load that was taken into account mainly consisted of the dead weight and water pressure.Comparisons of test results and design values of the elastic moduli of the dam body and dam foundation with those obtained from the feedback analysis are shown in Tables 5 and 6.In the arch dam design, the long-term elastic modulus of dam body concrete was used, which was only 0.6—0.7 times the instantaneous elastic modulus,leading to a signif i cant difference between the design values of the elastic modulus and those from the feedback analysis.Meanwhile,the age of concrete for laboratory tests and in situ tests of the elastic modulus was only 180 d,far less than the actual age of concrete under the water load.Thus,the elastic modulus increment after the age of 180 d was not included in the tests.Therefore,the elastic moduli of the dam body from the feedback analysis are greater than the design values and experimental values,and the values from the feedback analysis,ranging from 36.6 to 38.2 GPa,are deemed consistent with the actual situation.For the elastic moduli of the dam foundation,the design values were determined based on the most unfavorable situation,while,in the feedback analysis,the deformation parameters that most probably occurred in the actual situation,instead of the parameters that might occur in the most unfavorable situation,were used.Moreover,the elastic modulus of boreholes would increase after consolidation grouting of the dam foundation. Due to these factors,the elastic moduli of the dam foundation from the feedback analysis are also greater than the design values,and the values from the feedback analysis are generally considered reasonable.

Table 5Comparison of test results and design values of elastic modulus of dam body with those obtained from feedback analysis.

Table 6Comparison of design values of elastic modulus of dam foundation with those obtained from feedback analysis.

3.2.3.Feedback analysis of dam deformation and stress

The deformation and stress of the arch dam at the normal water storage level were analyzed based on inversion of the elastic moduli of the dam body and foundation.Analysis results are shown below:

(1)Feedback analysis of dam deformation

At the normal water storage level,radial deformation appeared towards the inner side of the arch dam,with the maximum value occurring in the middle sections,while tangential deformation appeared towards the two banks.The maximum radial deformation was 48.8 mm,which appeared in the#12 dam section at an elevation of 1870 m(Fig.10(a)). The maximum tangential deformation was 13.9 mm,which appeared towards the right bank at an elevation of 1875 m in the#18 dam section(Fig.10(b)).The overall deformation pattern was basically consistent with the monitoring results, and the calculated results were within the design range.

(2)Feedback analysis of structural stress

At the normal water storage level,key sections of the arch dam in the upper and lower reaches were in a compressive state.On the upstream face,the maximum hoop compressive stress was 5 MPa,the maximum arch compressive stress was 8 MPa,and the maximum tensile stress was 1.47 MPa.These values were lower than the design control standards.On the downstream face,the maximum hoop compressive stress was 9 MPa,and the maximum tensile stress was 1.2 MPa,which also met the design requirements.

In conclusion,feedback analysis results show that the deformation and stress distribution patterns of the arch dam were normal,and the arch dam operated normally at the normal water storage level.

Fig.10.Dam deformation at normal water storage level obtained from feedback analysis.

4.Conclusions and suggestions

(1)The monitoring results show that the observed deformation values of the dam body and foundation were lower than the design values;the total seepage flows through the dam body and foundation were lower than the design drainage capacity of the deep-well pump house;the dam stress distributions were normal,with values lower than the design control criteria;and the arch dam was basically in a compressive state during the initial impoundment.The results of the dam deformation and stress distribution from the feedback analysis were basically consistent with the monitoring results,and the values were within the design range.The working behavior of the Jinping-I Arch Dam was normal during the initial impoundment.

(2)The two approaches,monitoring analysis and numerical calculation,supplement and prove each other in the comprehensive analysis and evaluation of the working behavior of the dam in terms of stress,deformation,and seepage pressure.The results of analysis and evaluation provide a technical foundation for safe operation of the dam in the future,and can provide a reference for similar high dam projects.

(3)Thesafe operation of high dams during impoundment isa long-term dynamic process.Thus it is necessary to carry out long-term safety monitoring and analysis based on monitoring, tracing,and feedback,and pay close attention to the working behavior of the dam,so as to provide reliable technical support for the long-term safe operation of projects.

Chen,X.P.,Ruan,Y.S.,2014.Analysis on the vertical monitoring results of the initial impoundment for the arch dam of Jinping-I hydropower station. Sichuan Water Power33(s1),128—131.http://dx.doi.org/10.3969/ j.issn.1001-2184.2014.z1.037(in Chinese).

Deng,J.H.,Dong,Y.J.,2014.Report on Safety Monitoring Analysis of Jinping-I Hydropower Project during Fourth-stage Impoundment.Jinping Construction and Administration Bureau,Chengdu(in Chinese).

Han,S.D.,Zhao,B.,Liao,Z.Y.,Xia,J.H.,2010.Analysis and evaluation of monitoring data by plumb lines in early impoundment period of Xiaowan Arch Dam.Dam Saf.(3),44—47.http://dx.doi.org/10.3969/j.issn.1671-1092.2010.03.012(in Chinese).

Hu,B.,Wu,Z.R.,Liu,G.B.,Zhao,B.,Xu,B.,2012.Safety evaluation of replacement reinforcement quality in abutment contact zones of ultra-high arch dam in first impoundment period based on prototype monitoring. Water Sci.Eng.5(2),210—218.http://dx.doi.org/10.3882/j.issn.1674-2370.2012.02.009.

Huang,X.C.,Tang,L.,Zhao,W.,2006.Deformation monitoring design for Goupitan hydropower station.Yangtze River 37(3),48—50.http:// dx.doi.org/10.3969/j.issn.1001-4179.2006.03.018(in Chinese).

Jin,F.,Hu,W.,Pan,J.W.,Yang,J.,Wang,J.T.,Zhang,C.H.,2011.Comparative study procedure for the safety evaluation of high arch dams.Comput.Geotechnics 38(3),306—317.http://dx.doi.org/10.1016/j.compgeo.2010.10.008.

Li,P.J.,Wei,P.,Zhang,Q.,2009.Behavior of Laxiwa Arch Dam in the period of first impounding.Hydropower Stn.35(11),12—15.http://dx.doi.org/ 10.3969/j.issn.0559-9342.2009.11.005(in Chinese).

Wang,Z.H.,Hu,Q.Y.,Yu,X.H.,Duan,G.X.,2010.Analysis of operation condition of Goupitan Hydropower Station arch dam in initial impoundment period.Yangtze River 41(22),29—31.http://dx.doi.org/10.3969/ j.issn.1001-4179.2010.22.008(in Chinese).

Wang,Z.Y.,Yang,H.,Huang,H.D.,2003.Analysis on dam deformation during initial impoundment period of Dachaoshan hydropower station. Hydropower Automation Dam Monit.27(5),57—60.http://dx.doi.org/ 10.3969/j.issn.1671-3893.2003.05.018(in Chinese).

Wu,S.Y.,Cao,W.,2014.AnalysisonworkingbehaviorsofJinping-Ihydropower project during initial impoundment period.In:Proceedings of 2014 Academic Annual Conference of Chinese National Committee on Large Dams. The Yellow River Conservancy Press,Guiyang,pp.309—318(in Chinese).

Wu,Z.R.,2003.Safety Monitoring Theory and It's Application to Hydraulic Structures.Higher Education Press,Beijing(in Chinese).

Yang,H.,Dong,Y.J.,2015.Analysis on monitoring data of Jinping-I hydropower dam during first impoundment.Dam Saf.(3),34—40.http:// dx.doi.org/10.3969/j.issn.1671-1092.2015.03.008(in Chinese).

Zhang,C.,Yin,H.A.,2014.Feedback analysis of extra-high arch dam of Xiluodu in the initial impoundment phase.Hydropower Stn.Des.30(2), 7—12.http://dx.doi.org/10.3969/j.issn.1003-9805.2014.02.002(in Chinese).

Zhang,C.,Wang,R.K.,Tang,X.J.,2016.Safety evaluation of Xiluodu ultrahigh arch dam during the initial impoundment period.J.Hydraulic Eng. 47(1),85—93.http://dx.doi.org/10.13243/j.cnki.slxb.20150404(in Chinese).

Zhou,W.,Hua,J.J.,Chang,X.L.,Yang,Q.G.,Ma,G.,2011.Estimation of work status and deformation prediction of Shuibuya CFRD.Chin.J. Geotechnical Eng.33(s1),65—70(in Chinese).

Zhou,Z.,Rao,H.L.,2014.Special Report on Monitoring,Analysis and Assessment of Dam and Slope Safety of Jinping-I Hydropower Project in Initial Impoundment.Power China Chengdu Engineering Corporation Limited,Chengdu(in Chinese).

Received 7 April 2016;accepted 8 July 2016

This work was supported by the National Key Technology Support Program(Grant No.2013BAB05B05).

*Corresponding author.

E-mail address:wushiyong@ylhdc.com.cn(Shi-yong Wu).

Peer review under responsibility of Hohai University.

http://dx.doi.org/10.1016/j.wse.2016.11.001

1674-2370/©2016 Hohai University.Production and hosting by Elsevier B.V.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

©2016 Hohai University.Production and hosting by Elsevier B.V.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

Water Science and Engineering2016年3期

Water Science and Engineering2016年3期

- Water Science and Engineering的其它文章

- Numerical analysis of rapid drawdown:Applications in real cases

- Stability analysis of unsaturated soil slope during rainfall inf i ltration using coupled liquid-gas-solid three-phase model

- Seismic responses of high concrete face rockfill dams:A case study

- Numerical simulation of seismic damage and cracking of concrete slabs of high concrete face rockfill dams

- Design considerations and behavior of reinforced concrete core dams during construction and impounding

- Numerical stress-deformation analysis of cut-off wall in clay-core rockfill dam on thick overburden