用图像法分析茄子在冻干过程中的水分动态运移规律

李晓斌,郭玉明※,崔清亮,付丽红,张 静,邱述金(.山西农业大学工学院,太谷03080;.山西农业大学食品科学与工程学院,太谷03080)

用图像法分析茄子在冻干过程中的水分动态运移规律

李晓斌1,郭玉明1※,崔清亮1,付丽红2,张静1,邱述金1

(1.山西农业大学工学院,太谷030801;2.山西农业大学食品科学与工程学院,太谷030801)

摘要:为研究真空冻干果蔬内部水分扩散及运移过程和规律,以茄子为研究对象,运用图像处理技术建立水分运移微位移场并以微位移量对真空冻干过程中果蔬内部水分扩散及运移规律进行表达和定量分析。使用CCD(charge coupled device)相机每隔1 h采集茄子样本在真空冻干过程中横截面图像,直至6 h冷冻干燥完成终止。用自动阈值分割法、K均值聚类算法、伪彩色图像处理法可准确提取出原始图像中未冻干区域,再用Sobel边缘检测法提取得到水分边界。将6幅边界图像叠加并以物料几何中心为原点建立微位移场,用Harris角点检测法提取水分边缘与坐标轴相交的各个角点及其坐标值,计算得到每隔1 h各角点的位移量。通过对角点位移量与物料含水率相关性分析可知,模型显著性检验概率<0.000 1,决定系数达0.999 8,说明模型检验极显著且拟合精度高。回归参数的检验结果表明,四个角点的微位移量对物料含水率平方的响应极显著,说明物料干燥水分边界微位移场变化量与含水率的关系可用该回归模型预测,物料含水率可用表达水分边界的微位移场参数来表示。该研究为果蔬冻干水分在线检测提供了一种新的方法,同时也为探索冻干机理和低能耗冻干工艺提供了参考。

关键词:冷冻;干燥;图像处理;茄子;真空冷冻干燥;水分运移;水分检测

李晓斌,郭玉明,崔清亮,付丽红,张静,邱述金.用图像法分析茄子在冻干过程中的水分动态运移规律[J].农业工程学报,2016,32(01):304-311.doi:10.11975/j.issn.1002-6819.2016.01.042 http://www.tcsae.org

Li Xiaobin, Guo Yuming, Cui Qingliang, Fu Lihong, Zhang Jing, Qiu Shujin.Moisture diffusion and transfer dynamic analysis of eggplant during vacuum freeze-drying based on image processing technique[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2016, 32(01): 304-311.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.01.042 http://www.tcsae.org

0 引言

真空冷冻干燥技术可使物料内部水分由固态直接升华为气态而干燥,并使物料外形、味道、颜色等性质基本得以保留,因此是一种先进的农产品加工技术。但由于冻干能耗大、成本高,这项技术在农产品加工中还不能广泛地应用,需要针对不同加工对象探索冻干过程的水分在线检测方法,以求获得最佳冻干工艺和参数。果蔬冻干过程含水率的在线检测方法主要有称质量法、介电参数法等[1],本研究运用果蔬冻干过程水分收缩轮廓线动态变化图像特征来表达冻干过程的含水率,同时可了解果蔬冻干过程水分扩散及运移规律。

目前对果蔬和农产品物料在干燥过程中内部水分运移的研究方法主要有有限元分析法和核磁共振法等。

傅志一等[2]研制出空间轴对称湿扩散有限元计算软件,利用该软件得到稻谷在干燥和缓苏状态下湿度及其梯度场随时间变化的规律,并客观比较了稻谷圆球模型和椭球模型在不同烘干温度下的差异,但该软件仅能分析谷物湿扩散过程,适应性不理想。而核磁共振技术则具有明显优势。该技术不但能直观展现物料在储存[3]、制作[4-9]和干燥[10]过程中水分迁移过程,而且也使定量研究水分扩散成为可能,具有无损、非接触和无污染的特点。

Ghosha等[11]利用核磁共振成像技术(magneticresonance imaging,MRI)获得小麦籽粒干燥过程水分分布图像,并建立热-水分迁移三维干燥动力学模型。徐建国等[12]使用低场核磁共振成像技术对胡萝卜切片在热风干燥中内部水分传递过程进行研究,得到水分轮廓线收缩特征,为研究热风干燥水分传递过程提供支持。但经过观察分析发现,由于成像原理不同,MRI图像水分边界清晰度和锐利度明显低于CCD相机直接获取的水分边界图像;其次,MRI图像分辨率较低,难以精确描述水分边界细节特征,而用CCD相机可获取高分辨率图像,能真实、客观地反映水分边界变化并展现物料横截面上丰富的细节特征,且使用CCD相机可直接获取图像,较MRI技术高效快捷、简便经济。

本文以茄子为例,利用CCD相机直接获取果蔬冻干过程的横截面图像,应用微位移场理论并结合相关图像处理方法,在微位移场中提取并分析物料内部水分边界及其位移大小,定量描述边界的二维运动轨迹,并建立边界位移与样本含水率关系模型,从而为探索果蔬冻干机理和检测果蔬内部水分变化提供一种可行的方法。

1 材料、设备与方法

1.1材料与设备

以太谷本地产茄子为试验材料,所用仪器设备主要有:JDG-0.2型真空冻干试验机(兰州科近真空冻干技术有限公司),M0814-MP型镜头(Computar,f=8mm,F1.4),F201C型CCD(Allied vision technologies GmbH,1/2.3英寸CCD),RL500W型环形漫反射LED光源(维视数字图像技术有限公司,带偏光镜,9W),CP502型电子天平(Ohaus公司,感量0.01 g)和R2004三脚架(思锐集团,工作高度48.5~1 740 mm)。

1.2试验方法

1.2.1样本预处理

茄子样本经清洗、去皮后,用自制切片工具将样本切成10 mm×10 mm×10 mm立方体状,从中取30块形状规整的样本(TA),均匀置于料盘中,放入冰箱冷冻至物料共晶点[13]以下,以备冻干。试验同时研究高压脉冲电场预处理对样本冻干的影响,故再取30块样本(TB)经高压脉冲电场预处理[13]并冷冻至共晶点(注:如无特殊说明,文中样本均指TA样本)。

1.2.2样本真空冻干与图像采集

JDG-0.2真空冻干机需要设置的主要参数有:冷阱温度-50℃,真空度45~50 Pa,加热板温度50℃,每隔10 min将加热板温度升高10℃,至70℃终止。

为尽量减小图像采集时频繁开关冻干机对冻干过程及物料本身的影响,每隔1 h采集一次样本断面图像并称量样本质量,关键操作是:

1)采集图像前,先使冻干机停止工作并迅速且完全打开与冻干仓连通的通气阀。

2)事先调整好电子天平,保证称量现场整洁。

3)预试验发现,冻干正式开始1~3 h,由于样本表面仍有大量冰,若此时物料暴露在室温下操作,冰会迅速融化,再次冻干时,已融化的冰会在真空作用下产生大量气泡从样本表面溢出,影响试验准确性,故进行1~3 h图像采集及称量时,须使用装有冰块的泡沫箱,以保证物料表面的冰不发生迅速融化,保证试验准确性。而冻干3 h后相关操作在室温下快速进行即可。

4)使用刀片并在自制工具辅助下完成样本横截面切割,切割时迅速、彻底,并尽可能保证样本横截面平整、光滑。

5)CCD相机和光源牢固安装在三脚架上,其位置和角度在整个图像采集过程中保持不变,光圈大小和快门时间等参数同样保持不变。

6)准备样本时做好相应标记,充分保证图像数据采集统一。

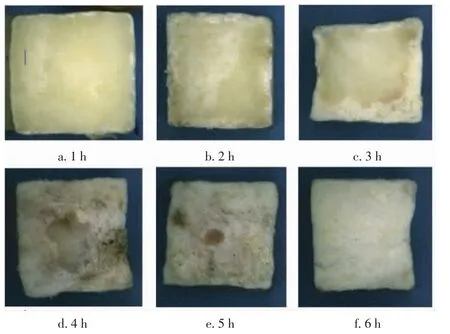

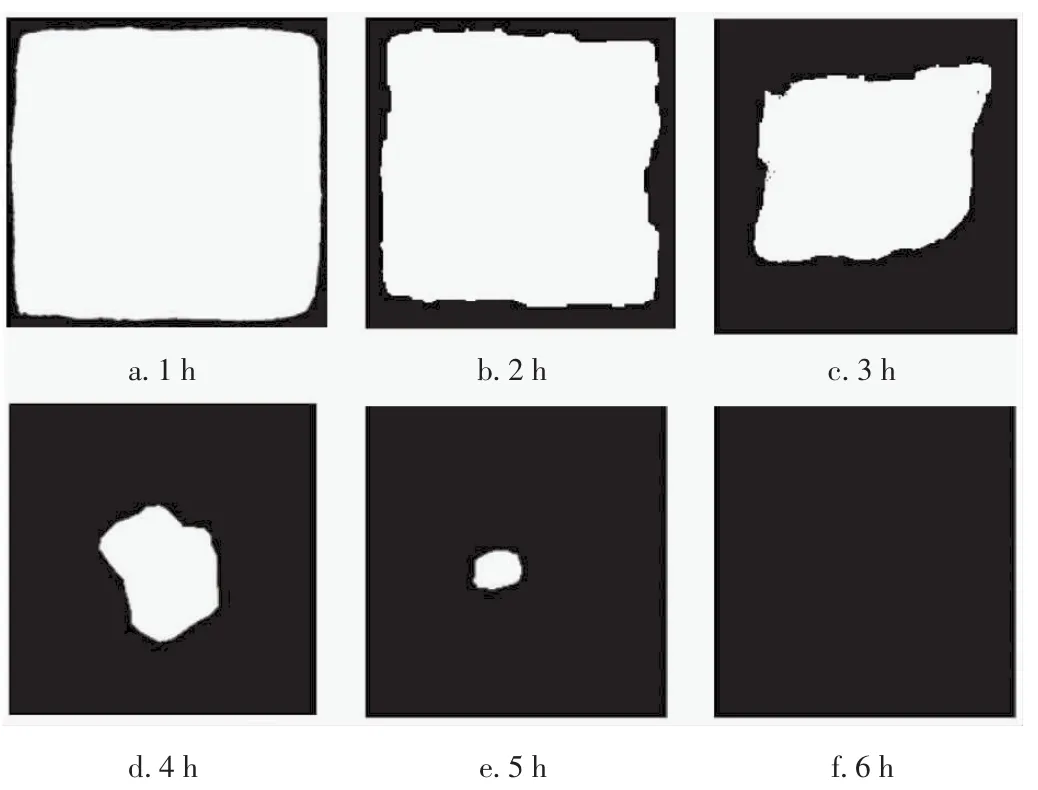

试验以1 h为间隔,连续采集样本在一个完整冻干周期内的横截面序列图像,可表达物料内部水分扩散过程和规律,如图1所示。

图1 不同取样时间茄子样本横截面水分边界序列图像Fig.1 Boundary serial images of cross section of eggplant sample by 1 h interval

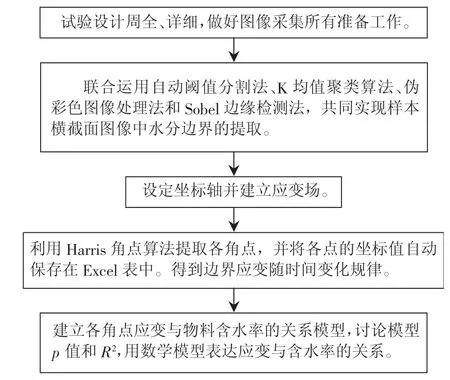

1.2.3技术路线

试验技术路线如图2所示。

图2 技术路线Fig.2 Route chart of study

2 图像处理

原始图像质量决定图像分割难易程度及步骤。由图1可以看出,随着冻干时间延长,已冻干部分与未冻干部分边界逐渐向内收缩,说明冰逐渐减少,物料逐渐被冻干。冻干前期横截面中已冻干与未冻干区域灰度值略有差异,对比度较小,边缘呈现不规则,某些区段甚至不锐利,给后续图像分割带来一定难度。而冻干中后期二者对比度增大,有利于图像分割和边缘提取。其次,当拍摄参数及视场一定时,其外形轮廓均与冻干初始状态有差异,这与物料含水率变化及冻干环境等因素有关。本试验采集图像时,考虑到样本厚度,每块样本只切割一次,每次切割拍照的样本是同一批。

图像分割就是去除冗余信息,只把目标完整、准确地提取出来。就本试验而言,图像分割的主要任务是清晰、准确地将物料横截面冻干边界序列图像上已冻干区域和未冻干区域分割并且提取二者的边界。图像预处理发现,要实现该目标,依靠某种单一图像分割方法效果不理想。在真空冻干茄子样本背景下,联合使用K均值聚类算法、伪彩色图像处理法和自动阈值分割法可以实现目标的准确分割。

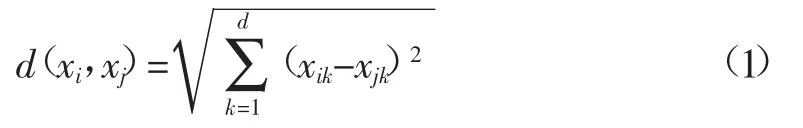

2.1K均值聚类算法

K均值(K-means method)聚类算法作为从复杂RGB图像中提取特定目标的理想方法[14-16],样本xi和xj的相似度通常用欧式距离d(xi,xj)来表示,其计算思路为:

假设给定的数据集X={xm|m=1,2,…,total},X中的样本用d个描述属性A1,A2,…,A6来表示,并且d个描述属性都是连续性属性。数据样本xi=(xi1,xi2,…,xid),xj=(xj1,xj2,…,xjd),其中xi1,xi2,…,xid和xj1,xj2,…,xjd分别是样本xi和xj对应d个描述属性A1,A2,…,A6的具体取值。样本xi和xj之间的相似度通常用它们之间的距离d(xi,xj)来表示,距离越小,样本xi和xj越相似,差异越小;反之则样本xi和xj越不相似,差异越大。故欧式距离为:

自动阈值分割法作为一种将灰度图像转换为二值图像的方法,既能使目标边缘平滑,又能减少图像中的干扰因素,因此是一种理想的图像分割方法[18]。

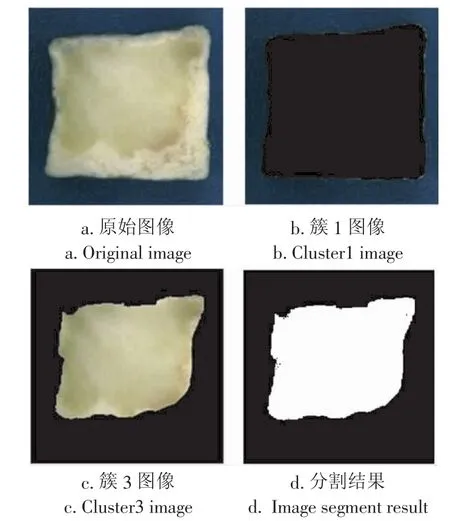

联合应用上述3种方法,对样本序列图像进行分割,以真空冻干3 h横截面图像为例,其图像分割过程如图3所示。

由图3可以看出,只有簇3图像(图3c所示)真实表达了样本未冻干区域提取结果,故选簇3图像做进一步处理。用自动阈值法对簇3图像进行处理,结果如图3d所示。用相同方法可得到其余图像的提取结果,如图4所示。其中,白色部分为未冻干区域。

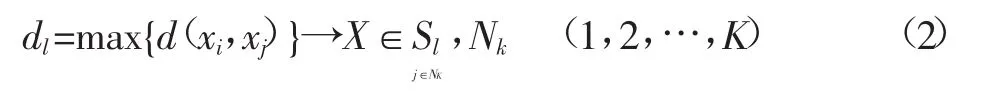

再假设簇的个数为k,则该聚类算法步骤为:

1)取任意k个属性值向量为初始簇中心,设这k个值为Y1(l),Y2(l),…,Yk(l),循环处理次数为n,其初始值为1;

2)所有属性值向量X由下式进行分类,使向量集{X}中的向量分别属于簇中心Y1(n),Y2(n),…,Yl(n),Yk(n)相应的子集S1(n),S2(n),…,Sl(n),Sk(n):

图3 茄子样本未冻干区域分割过程Fig.3 Images segment process of non-freeze-drying field of eggplant sample

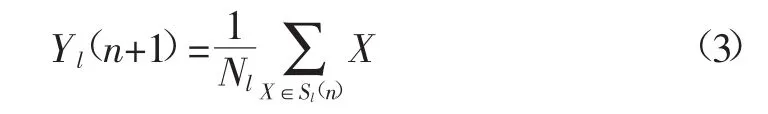

3)由式(2)计算各子集Sl(n)(l≌{1,2,3,…,K})的新簇中心Yl(n+1):

其中,Nl是集合Sl(n)中的元素个数,Yl(n+1)是属于Sl的X的平均值;

4)对所有簇,当式(4)成立时处理结束,否则回到步骤(2)继续处理:

2.2伪彩色图像处理法

伪彩色图像处理(pseudo coloring)实质是对原来灰度图像中不同灰度值区域赋予不同颜色,以形成明显区分。从图像的角度看,输入是灰度图像,输出则是彩色图像[17]。其基本原理可以表示为:

式中f(x,y)为待处理图像;R(x,y)、G(x,y)、B(x,y)为f(x,y)映射到RGB空间的3个颜色分量;fR、fG、fB为某种映射函数。

实际使用中,映射函数常用取绝对值的正弦函数。通过变换每个正弦波的相位和频率,就可以改变相应灰度值所对应的彩色。在上述3个映射函数的数值变化较为剧烈处,像素灰度值受彩色变化影响比较明显,这样不同灰度值范围的像素就得到了不同的伪彩色增强效果。

图4 不同取样时间茄子样本未冻干区域分割结果Fig.4 Images segment results of non-freeze-drying field of eggplant sample by 1 h interval

由图4可以看出,原始茄子样本未冻干部分(白色区域)面积减小速率(反映冻干速率)随冻干时间增加而逐渐增加,直至冻干6 h后,样本横截面图像中已无明显的冰存在,表明物料已被冻干。

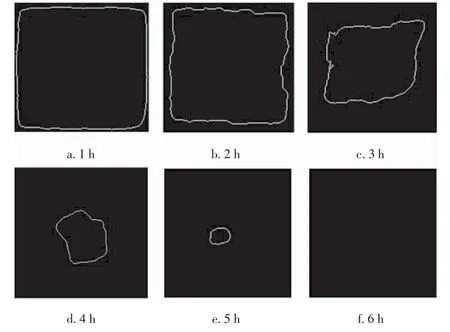

2.3边界提取及边缘细化

为定量分析真空冻干物料内部水分扩散及运移规律,并构建微位移场,除对未冻干区域进行分割外,还必须对区域边界进行提取。在图像处理技术中,边界提取方法十分丰富。本节采用Sobel算子[19]对样本图像(图4所示)进行边缘提取。同时为得到单像素宽度线条,提高试验结果精确性,再对提取出的边界进行骨骼化[20]处理,结果如图5所示。

图5 不同取样时间茄子样本未冻干区域边缘提取结果Fig.5 Boundary of non-freeze-drying field of eggplant sample by 1 h interval

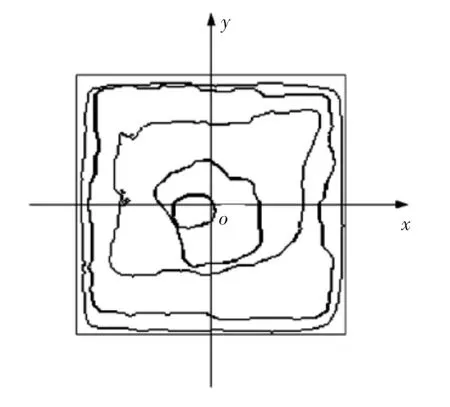

2.4微位移场建立

在物理学等学科中,微位移场表达位移状态随时空变化的情况,即位移的某种变化规律[21-22]。本节将微位移场用于研究真空冻干物料水分扩散及运移规律,期望将水分边界位置变化以位移量在微位移场中表达,并通过微位移场分析,探索水分边界位移与含水率相关关系。

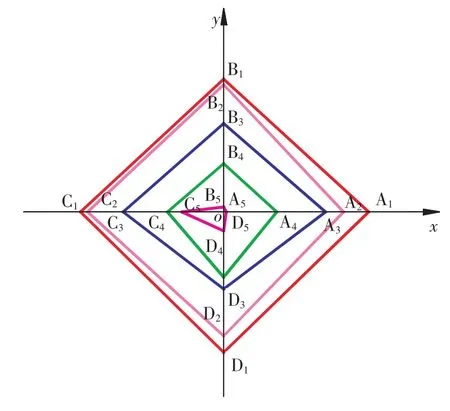

图6 茄子样本真空冻干水分边界微位移场Fig.6 Displacement field of water boundary of eggplant sample during freeze-drying process

采用“外廓对齐”原则,即不考虑物料内部水分界面变化情况,只将图5中a~f六幅图像按原始外形轮廓对齐,形成如图6所示样本真空冻干水分边界动态变化图。在图6上,设定X轴和Y轴,在一个二维平面场中分析边界的动态变化过程,具体方法为:

以样本初始尺寸(10 mm)为依据,选取样本横截面的几何中心为坐标原点,水平方向为X轴,竖直方向为Y轴,建立坐标系,并规定X轴向右为正,Y轴向上为正。

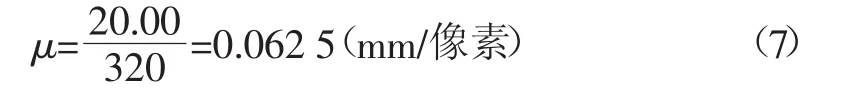

2.5图像标定

进行图像标定[23],计算图像中单位像素代表的实际长度,可为水分边界位移测定及位移与含水率相关性分析提供支持。

假设n1、n2分别为标定参照物实际尺寸(mm)和图像尺寸(像素),令:

μ为图像中单位像素表示的实际尺寸值。以20.00 mm标准圆盘作为参照物,拍摄参数与图像采集时一致,运用自动阈值分割法及regionprops函数[13],测得标准圆盘图像尺寸为320(像素),故:

即图像中单位像素代表的实际长度为0.062 5 mm。

3 水分边界位移测定及与含水率相关性分析

3.1水分边界位移测定

运用图像法对冻干边界纵向位移和横向位移进行测量,测量方法和步骤为:

1)令第1 h获得的水分边界与x轴正半轴、y轴正半轴、x轴负半轴和y轴负半轴的交点分别为A1、B1、C1和D1,以此类推,第5 h水分边界与坐标系的交点则分别为A5、B5、C5和D5,如图7所示。显然,在同一个半轴上相邻两点之间的距离就是水分边界在1 h内对应的横向位移或纵向位移[13]。

图7 茄子样本水分边界与坐标轴交点的连线Fig.7 Lines between intersection points of eggplant sample’s water boundary and coordinate axis

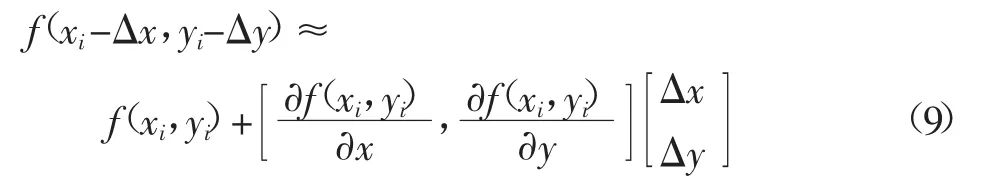

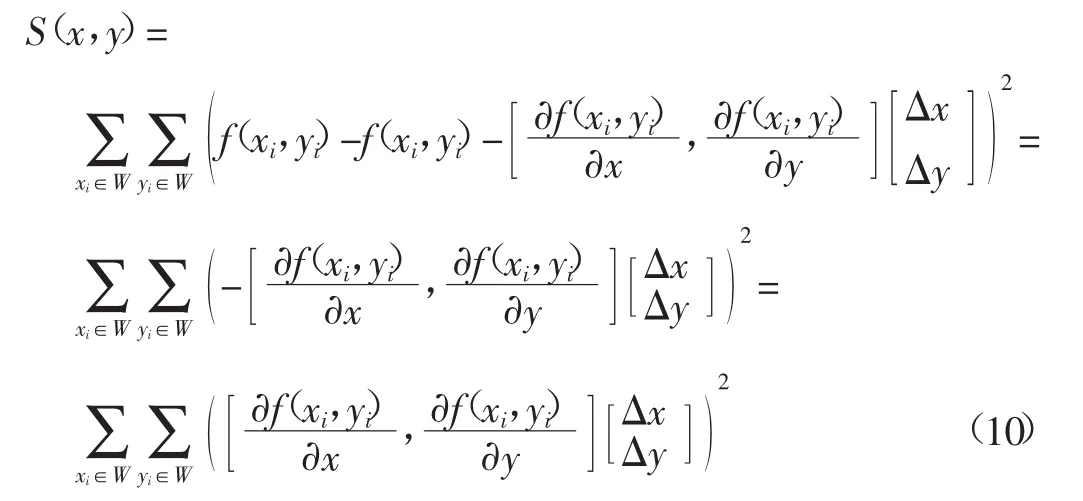

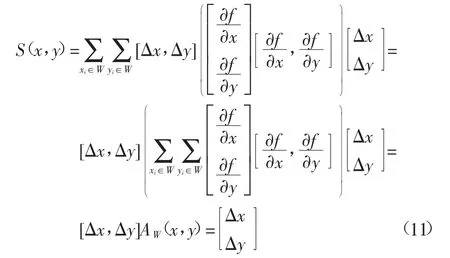

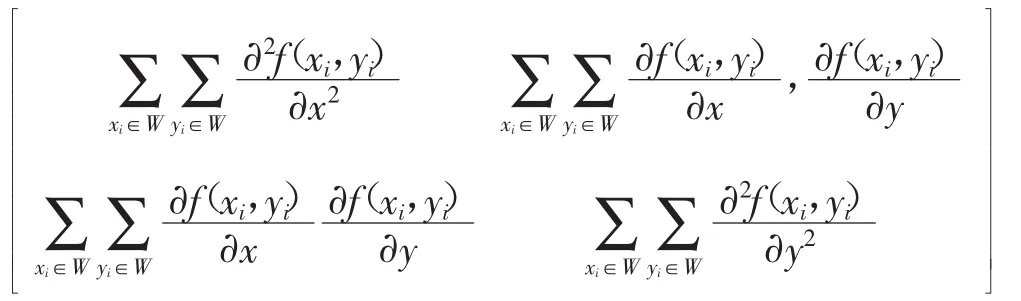

2)运用Harris角点检测器(harris corner detector)提取水分边界与坐标轴的交点,即拐点。这类点主要由边界上曲率较大或多条曲线的交点所构成,其算法为:

假设一幅二维灰度图像为f,取出一个图像块W∈f,并平移Δx,Δy。图像块W内图像灰度值与其平移后灰度值之差的平方和S为:

将平移图像用一阶泰勒展开式近似,表示为:

此时,SW(Δx,Δy)的最小值有解。将式(9)代入式(8),得:

因为u2=uTu,故:

其中,AW(x,y)就是Harris矩阵,它是S在点(0,0)处的二阶导数,A为:

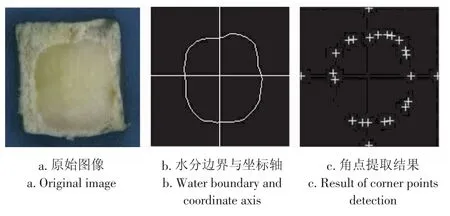

根据上述算法,通过计算每个像素的Harris响应值并对非极大值进行抑制,则局部极大值点就是图像中的角点,用“+”标出,如图8所示(以TB样本冻干3h图像为例)。

图8 茄子样本水分边界角点提取过程Fig.8 Corner points detection process of water boundary of eggplant sample

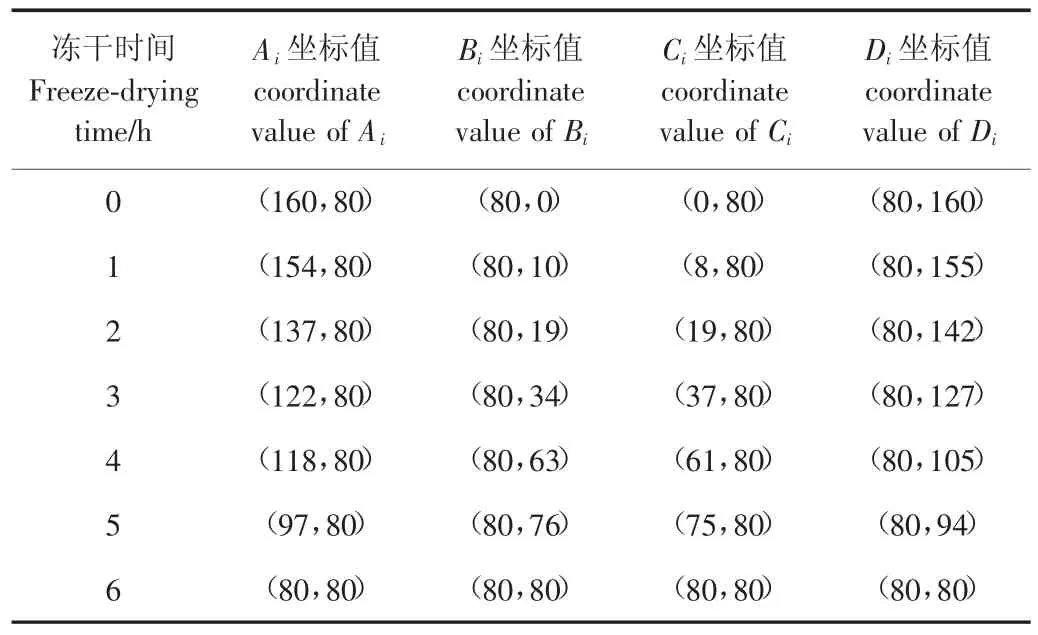

由图8c可以看出,提取到的角点并非只有水分边界与坐标轴的交点,在冻干边界上还有其他角点,可在Harris角点检测程序后附加for循环语句,遍历角点坐标矩阵,即可提取出水分边界与坐标轴的交点坐标值,如表1所示,其中下标i为冻干时间。

表1 角点坐标检测结果(以TB样本为例)Table 1 Results of corner points coordinate value (take TB samples for example)

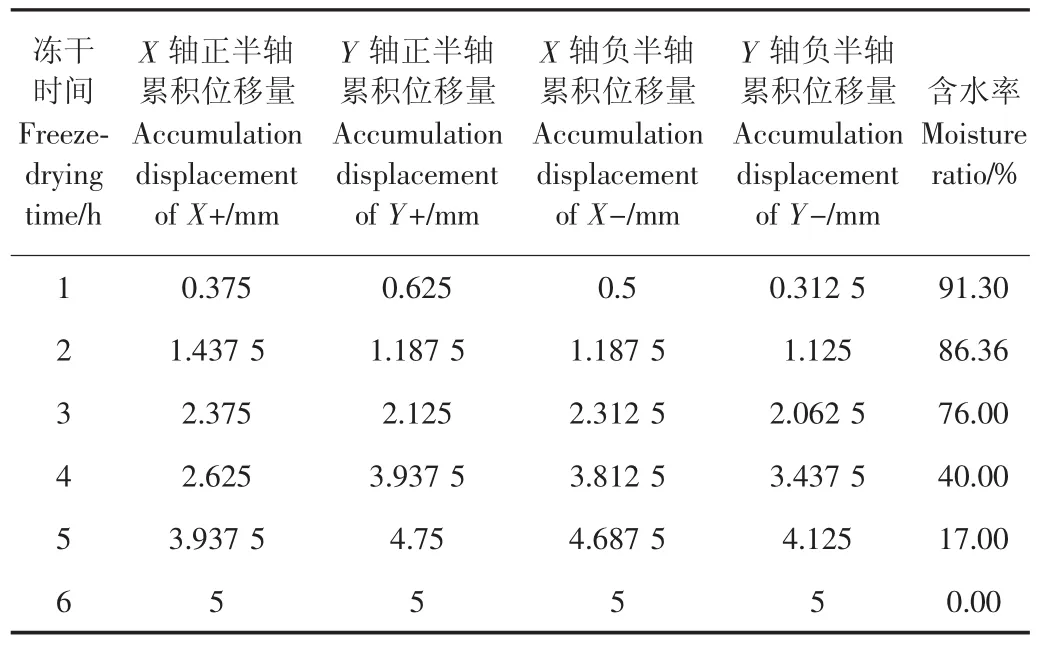

根据标定结果,由表1可计算出单位时间间隔(1h)水分边界扩散实际位移量和累积位移量大小,结果如表2所示,其中X+、Y+、X-、Y-分别表示X轴正方向、Y轴正方向、X轴负方向和Y轴负方向。

表2 水分边界扩散累积位移量(以TB样本为例)Table 2 Accumulation displacement results of water diffusion boundry(take TB samples for example)

3.2水分边界位移与含水率相关性分析

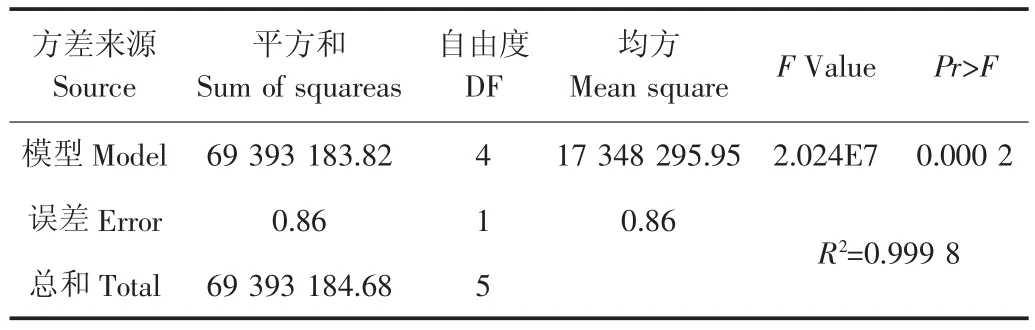

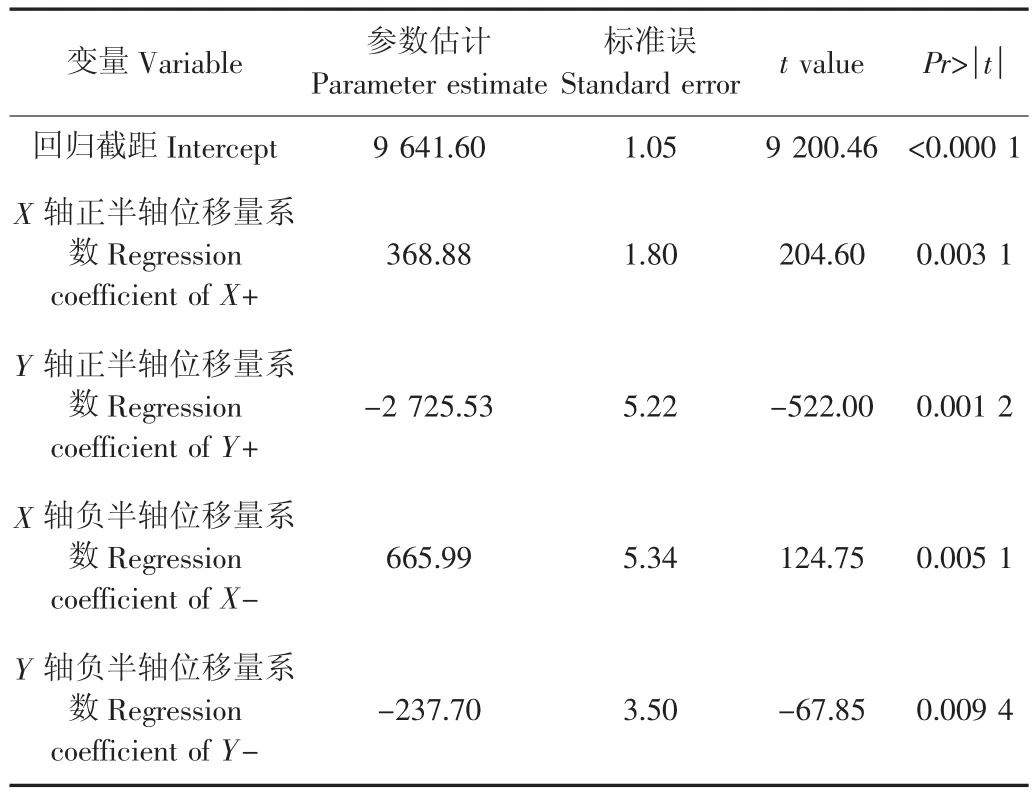

表2表达了水分扩散随时间变化的运移过程。以物料含水率为因变量,以四个角点的累积位移值为自变量,运用SAS统计分析软件对表2数据进行可线性化非线性回归。将因变量平方项转化为一次项,再用glm过程进行回归分析,结果如表3和表4所示。

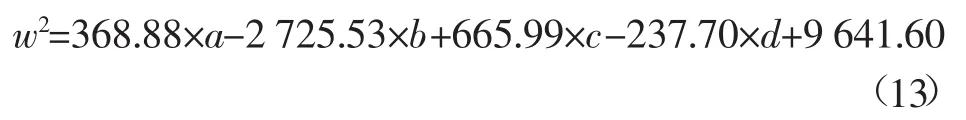

由表3和4可知,模型显著性检验概率<0.000 1,决定系数达0.999 8,说明模型检验极显著,而且是一个较理想的拟合。回归参数检验结果表明,角点位移量对物料含水率平方的效应极显著(显著性检验概率分别为0.0031、0.001 2、0.005 1和0.009 4),说明可用该回归模型解释物料冻干水分边界位移与含水率的关系,回归方程为:

式中w表示物料的含水率;a、b、c和d分别表示水分边界在X轴正方向、Y轴正方向、X轴负方向和Y轴负方向的位移量,mm。

上述模型表达了物料含水率与真空冻干水分边界位移量相关关系,说明位移场理论可以用于监测物料真空冻干含水率,即只要水分边界发生极小位移,可通过式(13)所示的模型反映出物料含水率。

表3 水分边界位移量与含水率相关性分析结果Table 3 Regression analysis result between strain and moisture rate

表4 回归参数估计及显著性检验Table 4 Estimate value and test of coefficient

4 结论

本文通过微位移场和相关图像处理方法,以微位移量的变化对真空冻干过程中物料内部水分扩散及运移规律进行了表达和定量分析。有如下结论:

1)采用自动阈值分割法、K均值聚类算法、伪彩色图像处理法和Sobel边缘检测法共同提取水分运移边界是可行的。

2)用Harris角点检测法找到水分边缘上的各个角点,并在微位移场中提取到与坐标轴相交的各角点坐标值,计算得到每隔1 h各角点位移量。

3)通过对角点位移量与物料含水率相关性分析可知,模型显著性检验概率<0.000 1,决定系数达0.999 8,说明模型检验极显著且拟合精度高。回归参数检验结果表明,四个角点的位移量对物料含水率平方的效应极显著,说明物料冻干水分边界位移与含水率的关系可用该回归模型解释。

[参考文献]

[1]李晓斌,郭玉明,付丽红.应用纹理分析方法在线监测苹果冻干含水率[J].农业工程学报,2012,28(21):229-235.Li Xiaobin, GuoYuming, Fu Lihong.On-line monitoring of moisture ratio for apple during freeze-drying based on image texture analysis[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2012,28 (21): 229-235.(in Chinese with English abstract)

[2]傅志一,华云龙.稻谷颗粒内部水分迁移过程的有限元分析[J].农业工程学报,1999,15(2):189-193.Fu Zhiyi, Hua Yunlong.The analysis of moisture diffusion in rough rice with finite element method[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),1999,15(2):189 -193.(in Chinese with English abstract)

[3]陈森,孟兆磊,陈闰堃,等.樱桃水分变化的低场核磁共振[J].实验室研究与探索,2013,32(8):52-54.Chen Sen, Meng Zhaolei, Chen Runkun, et al.The change of moisture in cherry by low-field NMR[J].Research and exploration in laboratory, 2013, 32(8): 52-54.

[4]李资玲,刘成梅,万婕,等.核磁共振研究膳食纤维面包制作过程的水分迁移行为[J].食品科学,2007,28(10):127-130.Li Ziling, Liu Chengmei, Wan Jie, et al.Study on molecular mobility in dietary fiber bread by NMR[J].Food science, 2007, 28 (10):127-130.

[5] Akemi K, Horigane A, Keitaro S, et al.Moisture distribution in rice grains used for sake brewing analyzed by magnetic resonance imaging[J].Journal of Cereal Science, 2014, 60: 193-201.

[6] Akemi K H, Keitaro S, Mitsuru Y.Moisture distribution of soaked rice grains observed by magnetic resonance imaging and physicochemical properties of cooked rice grains[J].Journal of Cereal Science, 2013, 57: 47-55.

[7] Gregory R Z, Bryce M, Bruce J B.Moisture migration in starch molding operations as observed by magnetic resonance imaging [J].Food Research International, 2003, 36: 331-340.

[8] Quynh D, Anastasia P, Farnaz M.Dynamics of moisture diffusivity in solid triacylglycerol matrices [J].Food Research International, 2015, 75: 131-139.

[9] María G, Amidou T,Ásbjörn J, et al.The effects of pre-salting methods on salt and water distribution of heavily salted cod, as analyzed by 1H and 23Na MRI, 23Na NMR, low-field NMR and physicochemical analysis[J].Food Chemistry, 2015, 188: 664-672.

[10]张绪坤,祝树森,黄俭花,等.用低场核磁分析胡萝卜切片干燥过程的内部水分变化[J].农业工程学报,2012,28(22):282-287.Zhang Xukun, Zhu Shusen, Huang Jianhua, et al.Analysis on internal moisture changes of carrot slices during drying process using low-field NMR[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2012, 28 (22): 282-287.(in Chinese with English abstract)

[11] Ghosha P K, Jayasa D S, Smithb E.A, et al.Mathematical modelling of wheat kernel drying with input from moisture movement studies using magnetic resonance imaging(MRI), Part I: Model development and comparison with MRI observations[J].Biosystems engineering,2008,100:389-400.

[12]徐建国,徐刚,张绪坤,等.利用核磁共振成像技术分析胡萝卜干燥过程中内部水分传递[J].农业工程学报,2013,29 (12):271-276.Xu Jianguo, Xu Gang, Zhang Xukun, et al.Moisture transport in carrot during hot air drying using magnetic resonance imaging[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2013, 29(12): 271-276.(in Chinese with English abstract)

[13]李晓斌.运用图像处理技术在线监测真空冻干果蔬含水率[D].太谷:山西农业大学,2013.Li Xiaobin.On-line Monitoring Study of Moisture Ratio for Fruits and Vegetables During Vacuum Freeze-drying Based on Image Processing[D].Taigu: Shanxi agricultural university, 2013.(in Chinese with English abstract)

[14]徐黎明,吕继东.基于同态滤波和K均值聚类算法的杨梅图像分割[J].农业工程学报,2015,31(14):202-208.Xu Liming, Lü Jidong.Bayberry image segmentation based on homomorphic filtering and K-means clustering algorithm [J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 202-208.(in Chinese with English abstract)

[15]彭红星,邹湘军,陈琰,等.基于演化算法的水果图像分割[J].农业工程学报,2014,30(18):294-301.Peng Hongxing, Zou Xiangjun, Chen Yan, et al.Fruit image segmentation based on evolutionary algorithm[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2014,30(18):294-301.(in Chinese with English abstract)

[16] Victor C O, Ezekiel F A, Jelilli O O.Reducing the time requirement of K-Means algorithm[J].PLoS One, 2012, 7(12): e49946.

[17] Bruno C, Didier M, Simon S.UV light reveals the diversity of Jurassic shell colour patterns: examples from the cordebugle lagerstaae(calvados, france)[J].PLoS One, 2015, 10(6): e0126745.

[18] Kohichi O, Shingo N.Automatic threshold-setting method for iris detection for brown eyes in an eye-gaze interface system with a visible light camera[J].Optics & Laser Technology, 2015, 66(3): 112-121.

[19]李灿灿,孙长辉,王静,等.基于改进的Sobel算子和色调信息的叶脉提取方法[J].农业工程学报,2011,27(7):196-199.Li Cancan, Sun Changhui, Wang jing, et al.Extraction of leaf vein based on improved Sobel algorithm and hue information[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2011, 27(7): 196-199.(in Chinese with English abstract)

[20]瞿中,蒋玉萍,文倩云.一种方向链码扫描与跟踪的图像细化后期处理算法[J].计算机科学,2015,42(2):292-295.Qu Zhong, Jiang Yuping, Wen Qianyun.Algorithm of image thinning post-processing based on direction chain code scanning and tracking[J].Computer Science, 2015, 42(2): 292-295.

[21]于妍妍.数字散斑干涉测量微变形技术研究[D].合肥:合肥工业大学,2009.YuYanyan.Micro-deformationMeasurementUsingDigitalSpeckle Pattern Interferometry[D].Hefei: Hefei industrial university, 2009.

[22]侯志武.微构件拉伸测试系统设计与实现[D].大连:大连理工大学,2008.Hou Zhiwu.Design and Implementation of the Micro—component Tensile Test System [D].Dalian: Dalian university of technology, 2008.

[23]张雷,贺虎,武传宇.蔬菜嫁接机器人嫁接苗特征参数的视觉测量方法[J].农业工程学报,2015,(9):32-38.Zhang Lei, He Hu, Wu Chuanyu.Vision method for measuring grafted seedling properties of vegetable grafted robot [J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2015,(9): 32-38.(in Chinese with English abstract)

[24]周志艳,闫梦璐,陈盛德,等.Harris角点自适应检测的水稻低空遥感图像配准与拼接算法[J].农业工程学报,2015,31 (14):186-193.Zhou Zhiyan, Yan Menglu, Chen Shengde, et al.Image registration and stitching algorithm of rice low-altitude remote sensing based on Harris corner self-adaptive detection [J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2015, 31(14): 186-193.(in Chinese with English abstract)

Moisture diffusion and transfer dynamic analysis of eggplant during vacuum freeze-drying based on image processing technique

Li Xiaobin1, Guo Yuming1※, Cui Qingliang1, Fu Lihong2, Zhang Jing1, Qiu Shujin1

(1.College of Engineering, Shanxi Agricultural University, Taigu 030801, China; 2.College of Food Science and Engineering, Shanxi Agricultural University, Taigu 030801, China)

Abstract:Vacuum freeze-drying, which is the transformation from ice to vapor without passing through the liquid phase, has a wide application in the food industry and is now increasingly being used in the agricultural products processing because the absence of heating in this process preserves nutrients and sensory characteristics within the fruits and vegetables.However, the sublimation process makes freeze-drying operation expensive to use.Therefore, it is important to research moisture diffusion and transfer process within fruits and vegetables.This paper provides a new experimental method based on image processing technique to estimate moisture ratio of eggplant samples by analyzing moisture diffusion and transfer process.Eggplant samples were bought from local supermarket, and the experiment was carried out at the mechanics laboratory of Shanxi agricultural university in 2015.After cleaning and peeling, eggplants were cut into 10 mm× 10 mm×10 mm cube samples by a sharp self-made knife, 30 regular samples(TA)and another 30 samples(TB)were chosen and frozen in a refrigerator at -40℃for 10~12 h.However, TB would be treated by high pulsed electric field before freezing while TA without any treatments.After that, TA and TB were dried by JDG-0.2 vacuum freeze-drying machine.Meanwhile, section images of TA and TB were captured by a CCD camera with LED light source by 1h interval until drying end for 6h, and the mass of samples were measured simultaneously for calculating moisture ratio.All images, saved in RGB color model, were segmented with K-means clustering method, pseudo-color image processing method and automatic threshold segmentation method.Three cluster images were obtained with K-Means and pseudo-color method, and only No.3 cluster was fit for further segmentation.Automatic threshold segmentation method was able to extract non-freeze-drying area (white pixel)correctly.After thresholding, sobel edge detection method was used to extract the boundary of non-freezedrying area.In order to obtain a boundary whose width was one pixel, a skeletal image processing method was used for treating the boundary.After that, displacement field was used to express the displacement change of moisture boundary during vacuum freeze-drying process.Geometric center of samples as the origin point of the coordinate system was established, and the dynamic change process of moisture boundary was shown clearly by means of six images overlapping.The Harris corner detection method was used to find the corner points on the boundary, and extract coordinate values of corner points which intersect the coordinate axis, displacement of the two adjacent points was calculated by 1h interval.SAS software was carried out to analyze correlation relationship between the displacement change of moisture boundary and moisture ratio.Regression analysis results showed that significant test probabilities of moisture ratio model was less than 0.000 1, and the coefficients of determination(R2)was 0.999 8, which indicated that the model test was very significant and had quite strong explain ability and high fitting accuracy on original variable.Test results of regressive coefficient showed that the displacement of the four corner points and moisture-ratio-squared of the material were very significant(P<0.000 1).In other words, moisture ratio can be expressed and predicted by the displacement field of the moisture boundary.In summary, the mentioned model not only provides a new monitoring method of moisture ratio, but also gives a foundation of monitoring moisture ratio for other drying processes.

Keywords:freezing; drying; image processing; eggplant; vacuum freeze-drying; moisture diffusion and transfer; moisture measurement

通信作者:※郭玉明,男,山西平定人,教授,博士生导师,主要从事农业生物力学与物料机械特性方面的研究。太谷山西农业大学工学院,030801。Email:guoyuming99@sina.com

作者简介:李晓斌,男,山西平定人,讲师,博士,主要从事图像处理和分析方面的研究。太谷山西农业大学工学院,030801。Email:lxb8008105858@163.com

基金项目:国家自然科学基金资助项目(30771242,31171450);山西农业大学科技创新基金项目(2014004)

收稿日期:2015-08-25

修订日期:2015-11-12

中图分类号:TS255

文献标志码:A

文章编号:1002-6819(2016)-01-0304-08

doi:10.11975/j.issn.1002-6819.2016.01.042