430 ℃下2.98 dpa中子辐照后CLAM钢的拉伸和冲击性能

信敬平,刘少军,李春京,徐 刚,黄群英,吴宜灿

(中国科学院核能安全技术研究所,中子输运理论与辐射安全重点实验室,安徽 合肥 230031)

430 ℃下2.98 dpa中子辐照后CLAM钢的拉伸和冲击性能

信敬平,刘少军,李春京,徐 刚,黄群英,吴宜灿

(中国科学院核能安全技术研究所,中子输运理论与辐射安全重点实验室,安徽 合肥 230031)

利用高通量工程试验堆HFETR开展了CLAM钢430 ℃下2.98 dpa的中子辐照实验,通过辐照前后拉伸和冲击性能测试与对比分析,研究了CLAM钢的中子辐照硬化和脆化效应。结果显示,CLAM钢辐照后室温测试的抗拉强度和屈服强度分别为710 MPa和615 MPa,较辐照前分别下降16 MPa和-0.5 MPa,总延伸率减小1%,断面收缩率下降4%,保持良好的强度、塑性和韧性。冲击测试表明,CLAM钢辐照前后韧脆转变温度基本相同,上平台能量无明显变化,约为217 J,未出现明显辐照脆化。CLAM钢的抗辐照性能略优于其他低活化铁素体/马氏体RAFM钢在类似辐照条件下的性能。

CLAM钢;中子辐照;拉伸;冲击

国际上正广泛开展研究的聚变堆候选结构材料包括低活化铁素体/马氏体(Reduced Activation Ferritic/Martensitic,RAFM)钢、钒合金和SiC复合材料,其中RAFM钢以其良好的机械性能、低活化和抗辐照肿胀特性,及较好的研究基础和相对成熟的工业技术基础,被普遍认为是未来聚变示范堆和第一座聚变电站的首选结构材料[1-4]。世界各国针对其各自研发的RAFM钢(如欧洲的EUROFER、日本的F82H、中国的CLAM等)进行了大量中子辐照性能测试和机理研究。中国低活化马氏体(China Low Activation Martensitic,CLAM)钢是中国具有自主知识产权的RAFM钢,已经过十余年的自主研发[5-8],其主要性能与国际同类材料相当,部分性能更优[9-15],已成为国际上三大RAFM钢之一。

目前CLAM钢被选为国际热核聚变实验堆中国实验包层模块(ITER-CN-TBM)结构材料,为获得ITER应用许可,需要评估CLAM钢在ITER剂量环境下的中子辐照性能。为推动CLAM钢在ITER 中的应用进程,利用高通量工程试验堆HFETR开展了CLAM钢ITER剂量(1~3 dpa)系列中子辐照实验。本文针对CLAM钢在430 ℃下2.98 dpa中子辐照实验,开展了辐照前后拉伸和冲击性能测试,获得了CLAM钢在此实验条件下的辐照硬化和脆化规律。

1 实验

1.1 实验材料

实验材料为CLAM钢HEAT 0603A,其测试成分见表1。HEAT0603A为300公斤铸锭,通过热锻和轧制形成12 mm板材。热处理工艺为淬火(980 ℃/30 min/空冷)和回火(760 ℃/90 min/空冷)[16,17]。

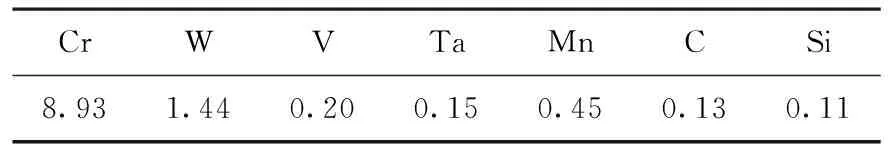

表1 CLAM钢化学成分(wt %)

1.2 中子辐照与性能测试

中子辐照实验在HFETR中开展,辐照温度为430 ℃,辐照剂量为2.98 dpa。

性能测试包括辐照前后的拉伸和冲击性能。拉伸试验样品长度为51 mm,标距段尺寸为Ф4 mm×20 mm,试验的应变速率为1×10-3s-1。冲击试验样品尺寸为55 mm×10 mm×10 mm,其V缺口为45°×2 mm,测试标准为ASTM E23。

2 结果与讨论

2.1 拉伸性能

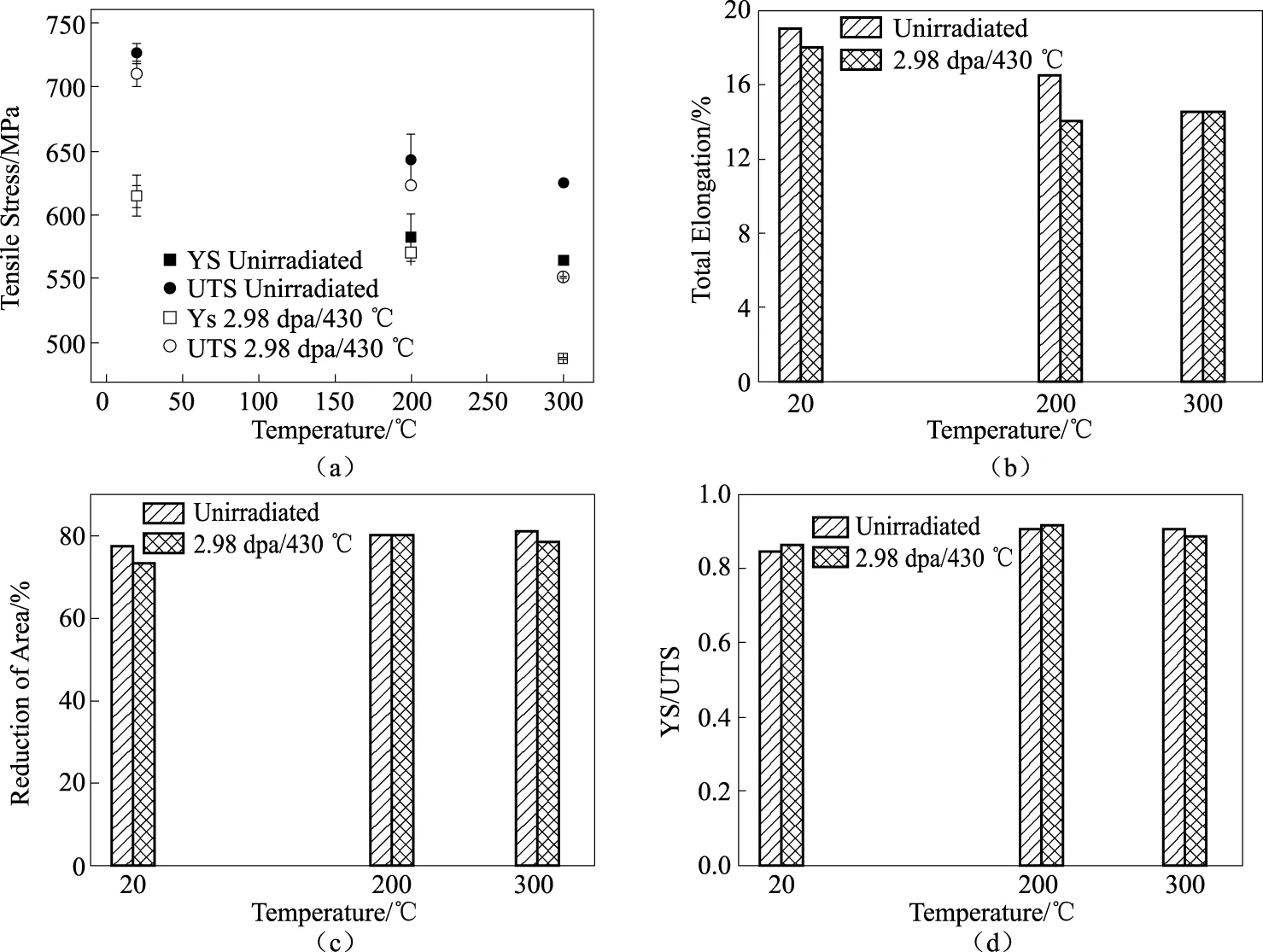

图1给出CLAM钢在430 ℃下2.98 dpa中子辐照前后的拉伸实验结果。辐照后的抗拉强度和屈服强度室温下测试时分别为710 MPa和615 MPa,较辐照前分别减小16 MPa和-0.5 MPa,200 ℃时分别减小20 MPa和12.5 MPa,300 ℃时分别减小74 MPa和77.5 MPa(图1(a))。

CLAM钢辐照前后的总延伸率随测试温度的变化如图1(b)所示,辐照后室温测试的总延伸率为18%,较辐照前下降1%;200 ℃ 测试时辐照后延伸率为14%,较辐照前下降2.5%;300 ℃测试时辐照前后的总延伸率相同,均为14.5%。因此,辐照后总延伸率在测试温度范围内无明显变化,整保持良好的延性。

在室温到300 ℃的测试温度范围内,辐照后的断面收缩率为73%~80%,较辐照前下降幅度小于4%(图1(c))。辐照前后的断面收缩率均保持较高值,表明CLAM钢具有良好的塑性。

屈强比(Y/T)在室温下从辐照前的0.846增加到辐照后的0.866,而在200 ℃和300 ℃时,则分别从辐照前的0.906和0.904变化到辐照后的0. 915和0.885(图1(d))。辐照前后均保持了较高的屈强比,表明CLAM钢辐照前后均有良好的强度储备,且出现高温辐照软化倾向。

图1 CLAM钢在430 ℃下2.98 dpa中子辐照前后的拉伸性能Fig. 1 Tensile properties of HEAT 0603A before and after neutron irradiation at 2.98 dpa/430 ℃

Eurofer97在60 ℃下2.5 dpa中子辐照后室温下测试结果显示[18],屈服强度增加了400 MPa,抗拉强度增加了190 MPa,总延伸率下降了7%。而Eurofer97在300 ℃下2.5 dpa中子辐照后辐照温度下测试时,屈服强度和抗拉强度分别上升约303 MPa和226 MPa,总延伸率降低5%[19]。F82H在450 ℃下0.8 dpa中子辐照后出现辐照软化现象,而OPTIV在相同条件下辐照后出现辐照硬化现象。CLAM钢在此条件下出现辐照软化的内在机理,有待后续进一步分析研究。

2.2 冲击性能

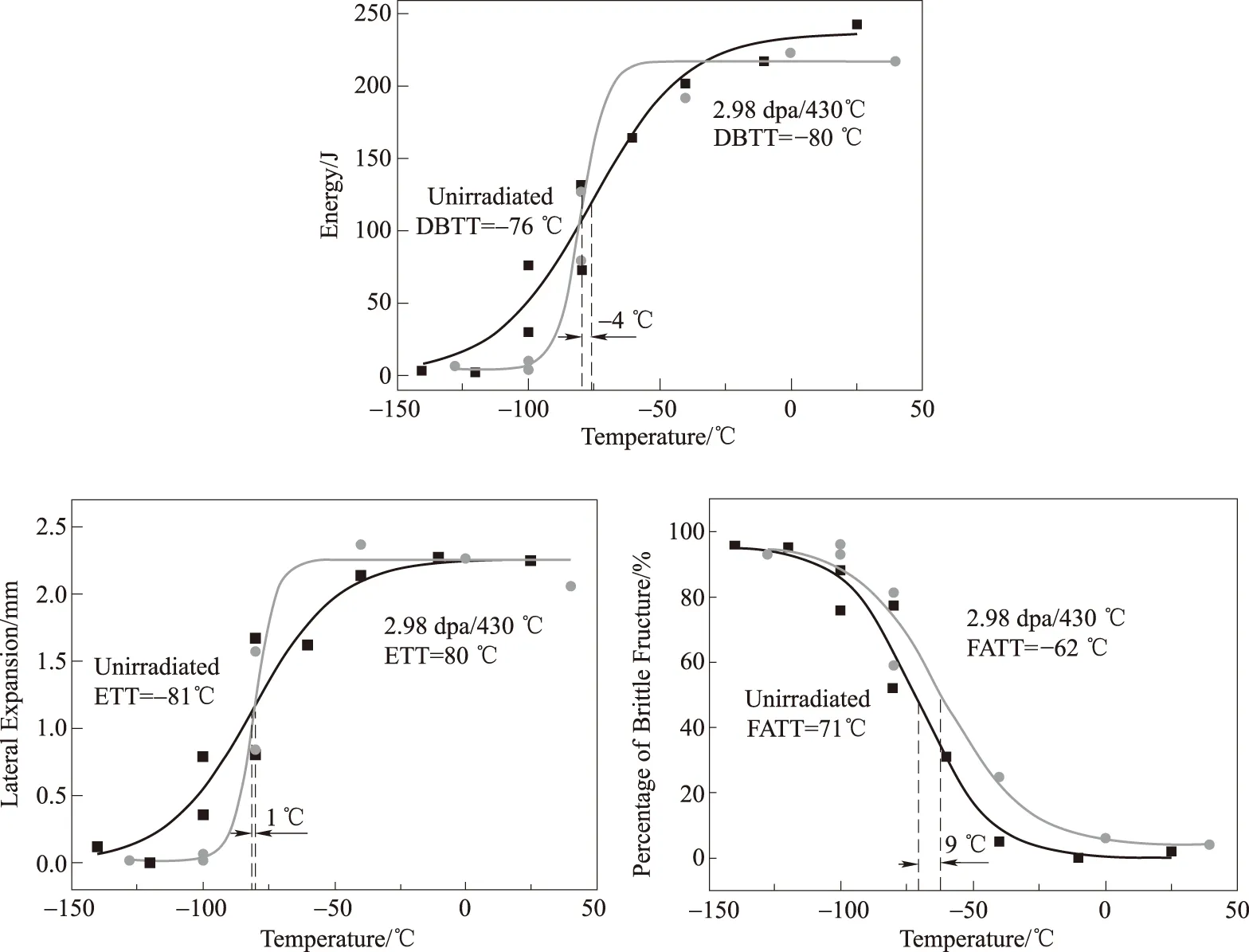

图2给出CLAM钢在430 ℃下2.98 dpa中子辐照前后的夏比冲击实验结果,通过玻尔兹曼函数拟合得到,韧脆转变温度(DBTT)取上下平台冲击吸收功中间值对应的温度。辐照后DBTT上升了-4 ℃,上平台能量为217 J,较辐照前降低约20 J。从侧膨胀量与测试温度的关系曲线,得到侧膨胀量为0.89 mm时的温度T0.89由辐照前的-81 ℃,变为辐照后的 -80 ℃,上升了1 ℃。从脆性断面率与测试温度的关系曲线,得到脆性断面率50%时的温度FATT由辐照前的-71 ℃,变为辐照后的 -62 ℃,上升了9 ℃。

F82H在500 ℃下5 dpa中子辐照后的DBTT上升了33 ℃[20],在300 ℃下2.4 dpa中子辐照时的DBTT上升了60 ℃[21]。Eurofer97在300 ℃下1.6 dpa中子辐照时的DBTT上升了约60 ℃,而OPTIFER在300 ℃下2.4 dpa中子辐照时的DBTT上升了约105 ℃[21]。与F82H和Eurofer97等RAFM钢相比,CLAM钢的ΔDBTT要小得多,表明CLAM钢在具有更优的抗中子辐照脆化能力。

图2 CLAM钢在430 ℃下2.98 dpa中子辐照前后的夏比冲击性能Fig.2 Impact curves of CLAM steel before and after neutron irradiation at 2.98 dpa/430 ℃

3 总结

CLAM钢在HFETR中完成了430 ℃下2.98 dpa的中子辐照实验,开展了拉伸和冲击性能测试,并对其辐照硬化和脆化效应进行了初步分析。

(1) CLAM钢辐照后的抗拉强度和屈服强度在室温测试时分别为710 MPa和615 MPa,较辐照前强度分别下降16 MPa和-0.5 MPa,总延伸率减小约1%,断面收缩率为73%,较辐照前下降4%。保持良好的强度、塑性、延性。

(2) CLAM钢的DBTT为-80 ℃,上平台能量与辐照前相近,而侧膨胀量和脆性断面率分析结果转变温度略有增加,表明CLAM钢在此辐照条件下未出现明显脆化。

(3) 在类似辐照条件下,CLAM钢的抗辐照脆化能力优于国外RAFM钢的结果。

致谢

感谢FDS团队其他成员的帮助,感谢中国核动力研究设计院孙寿华总工、莫华君主任,及张海生、孙凯、黄娟、崔永海、雷阳、李福荣等老师在辐照实验及后测试过程中给予的各种帮助与支持。

[1] T. Muroga, M. Gasparotto, S.J. Zinkle, Overview of Materials Research for Fusion Reactors [J], Fusion Eng. Des. 61-62 (2002) 13-25.

[2] Q. Huang, N. Baluc, Y. Dai, et al., Recent progress of R&D activities on reduced activation ferritic/martensitic steels [J], J. Nucl. Mater. 442 (2013) S2-S8.

[3] 黄群英,郁金南,万发荣等,聚变堆低活化马氏体钢的发展[J],核科学与工程,24 (2004) 56-64.

[4] Y.C. Wu, J.P. Qian, J.N. Yu, The Fusion-Driven Hybrid System and Its Material Selection [J]. Journal of Nuclear Materials, J. Nucl. Mater. 307-311 (2002) 1629-1636.

[5] Q.Y. Huang, Y.C. Wu, J.G. Li, et al., Status and strategy of fusion materials development in China [J]. J. Nucl. Mater. 386-388 (2009) 400-404.

[6] Y. Wu, Design status and development strategy of China liquid lithium-lead blankets and related material technology [J]. J. Nucl. Mater. 367-370 (2007) 1410-1415.

[7] Y. Wu, FDS Team, Fusion-based hydrogen production reactor and its material selection [J]. J. Nucl. Mater. 386-388 (2009) 122-126.

[8] Y. Wu, FDS Team, Conceptual design and testing strategy of a dual functional lithium-lead test blanket module in ITER and EAST [J]. Nucl. Fusion, 47 (2007) 1533-1539.

[9] J. Yu, Q. Huang, F. Wan, Research and development on the China low activation martensitic steel (CLAM) [J], J. Nucl. Mater. 367-370 (2007) 97-101.

[10] Q.Y. Huang, J.G. Li, Y.X. Chen, Study of Irradiation Effects in China Low Activation Martensitic Steel CLAM [J]. J. Nucl. Mater. 329 (2004) 268-272.

[11] L. Peng, Q. Huang, Y. Wu, Swelling of CLAM steel irradiated by electron/helium to 17.5 dpa with 10 appm He/dpa [J], Fusion Eng. Des. 86 (2011) 2624-2626.

[12] Y. Li, T. Nagasaka, T. Muroga, et al., Effect of thermal ageing on tensile and creep properties of JLF-1 and CLAM steels [J], J. Nucl. Mater. 386-388 (2009) 495-498.

[13] Qunying Huang, Sheng Gao, Zhiqiang Zhu, et al., Progress in compatibility experiments on Lithium-Lead with candidate structural materials for fusion in China [J]. Fusion Eng. Des. 84 (2009) 242-246.

[14] Q. Huang, C. Li, Q. Wu, et al., Progress in development of CLAM steel and fabrication of small TBM in China [J], J. Nucl. Mater. 417 (2011) 85-88.

[15] 黄群英,李春京,李艳芬等,中国液态锂铅包层材料研究进展[J],原子能科学技术,41 (2007) 96-105.

[16] Y. Li, Q. Huang, Y. Wu, et al., Mechanical properties and microstructures of China Low Activation Martensitic steel compared with JLF-1 [J], J. Nucl. Mater. 367-370 (2007) 117-121.

[17] Q. Huang, C. Li, Y. Li, et al., Progress in development of China Low Activation Martensitic steel for fusion application [J], J. Nucl. Mater. 367-370 (2007) 142-146.

[18] J. Rensman, H.E. Hofmans, E.W. Schuring, et al., Characteristics of unirradiated and 60 ℃, 2.7 dpa irradiated Eurofer97 [J], J. Nucl. Mater. 307-311 (2002) 250-255.

[19] E. Lucon, W. Vandermeulen, Overview and critical assessment of the tensile properties of unirradiated and irradiated Eurofer97 [R], SCK·CEN, Belgium, report, 2007.

[20] R.L. Klueh, K. Shiba, M.A. Sokolov, Embrittlement of irradiated F82H in the absence of irradiation hardening [J], J. Nucl. Mater. 386-388 (2009) 191-194.

[21] E.Lucon, R.Chaouadi, M. Decréton, Mechanical properties of the European reference RAFM steel (EUROFER97) before and after irradiation at 300 ℃ [J], J. Nucl. Mater. 329-333 (2004) 1078-1082.

Tensile and Impact Properties of CLAM Steel after Neutron Irradiation to 2.98 dpa at 430 ℃

XIN Jing-ping, LIU Shao-jun, LI Chun-jing, XU Gang, HUANG Qun-ying, WU Yi-can

(Key Laboratory ofNeutronics and Radiation Safety, Institute of Nuclear Energy Safety Technology, Chinese Academy of Sciences, Hefei, Anhui, 230031, China)

The neutron irradiation experiments for China Low Activation Martensitic (CLAM) steels were carried out in High Flux Engineering Test Reactor (HFETR),the effects of neutron irradiation on the hardening and embrittlement behavior of CLAM steels were investigated before and after neutron irradiation to 2.98 dpa at 430 ℃. The results showed that ultimate strength and yield stress of CLAM steel tested at room temperature are 710 MPa and 615 MPa, which decreased about 16 MPa and -0.5 MPa as compared with the unirradiated samples, respectively. And its Ductile to Brittle Transition Temperature (DBTT) shift was no obvious shift. While the upper shelf energy after irradiation was 217 J, which almost the same with that of unirradiated samples. The irradiation resistant of CLAM steel are slightly better than that of other Reduced Activation Ferritic/Martensitic (RAFM) steels under similar irradiation conditions.

CLAM steel; Neutron irradiation; Tensile; Impact

2016-07-20

国际热核聚变实验堆ITER计划国内配套专项项目(2013GB108005、2014GB112003)、中国科学院战略性先导科技专项(XDA03040000)、中国科学院知识创新工程重要方向项目(KJCX2-YW-N35)

信敬平(1981—),男,山东人,副研究员,主要从事先进核材料研究工作

黄群英:qunying.huang@fds.org.cn

TL341

A

0258-0918(2016)04-0487-05