图1 铁芯薄片结构图

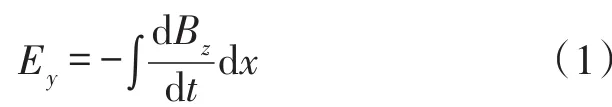

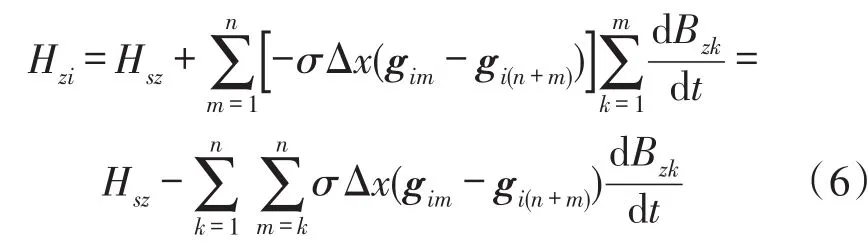

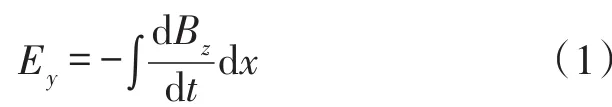

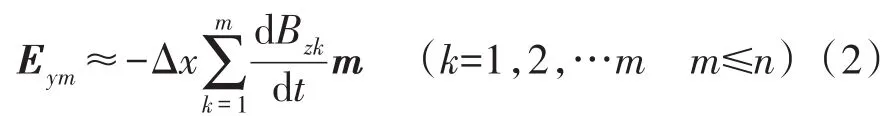

考虑磁感应强度在铁芯横截面积分布不均匀,电场强度的解析表达式为:

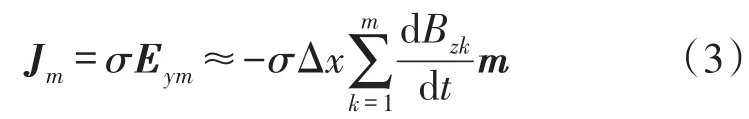

将积分近似为求和可得第m个单元的电场强度为:

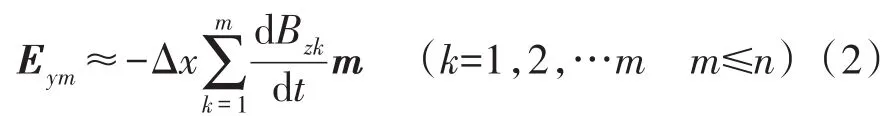

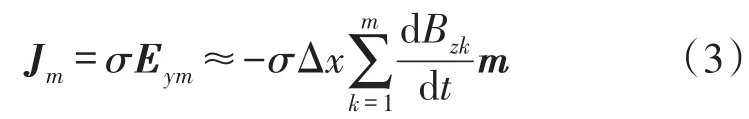

其中m为y轴方向的单位矢量,根据对称性,可得第n+m个单元的电场强度为,根据欧姆定律可得在第m个单元的电流密度为:

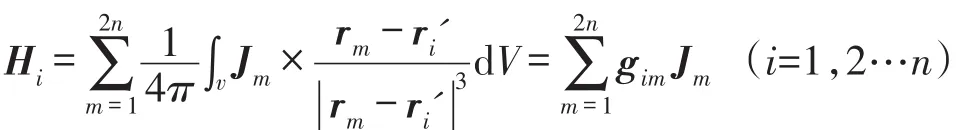

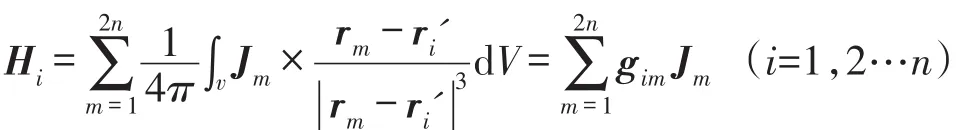

第n+m个单元的电流密度为Jn+m=-Jm。根据毕奥-萨伐尔定律可知,涡流在第i个单元产生的磁感应强度为:

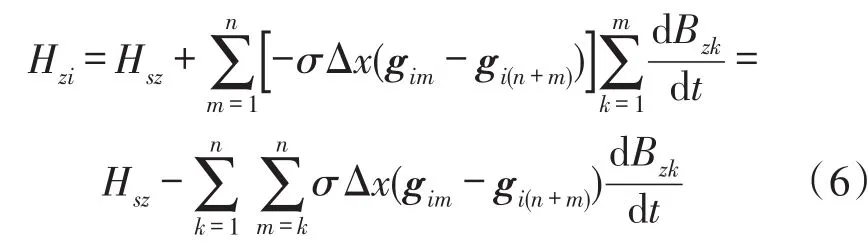

将Jn+m=-Jm代入上式可得:

将式(3)代入式(5),同时考虑激励磁场Hsz,可得铁芯内第i个单元的磁场。

2 铁芯磁滞回线模型

本文所选磁滞回线模型是公式(7)所示的Jiles动态模型[10-13],该模型为微分磁化方程,它描述磁滞回线与频率的关系。方程中δ为方向参数,当dH/dt> 0时取+1,当dH/dt<0时取-1;a为形状参数,k为磁滞损失参数,α为平均场参数,c为磁畴壁弯曲常数,Man为非磁滞磁化强度,μ0为真空磁导率,ρ为铁芯材料电阻率,d和w分别表示薄片的厚度和宽度。该模型由四部分组成,其中前两部分表示磁滞损耗,第三部分表示涡流损耗,第四部分表示额外损耗;在高频情况下,第四部分可以忽略。

3 结果与分析

对式(6)在SPICE软件中建模,联立铁芯材料的磁滞模型式(7)(即Bz(Hz)关系)SPICE模型,便可计算瞬态的铁芯截面的磁场和磁感应强度的分布。因铁芯材料模型选择文献[6]采用的Jiles模型,相关参数为d=0.5 mm,w=30 mm,ρ=45×10- 8Ωm,s=60 mm,B=1.5 T,a=130.22 A/m,k=56.855 A/m,α=1.69× 10-4,c=8.547×10e-3。并同Sebti Boukhtache等的实验和仿真结果进行对比验证。

图3是当电压源激励频率为500 Hz时,图3(b)为本文的HSPICE仿真磁滞回线波形图,与图3(a)为文献[6]模型和实验图相比,拟合较好。同时对电压源激励频率为0.5 Hz、50 Hz和200 Hz这3种情况,利用HSPICE对磁滞回线进行了仿真。不同频率下的仿真和实验数据如表1所示。从表1的数据可以看出,当矫顽力Hc随着频率增加而增大时,剩磁Br基本不变。

图3 500 Hz频率下磁滞回线

表1 仿真与实验数据比较

4 结论

本文采用不同于文献[6]的方法,运用欧姆定律和毕奥-萨伐尔定律,推导得到涡流对磁滞回线影响的数学模型。该方法的优势在于涡流产生的寄生磁场分布可以解析表示,得到的方程组对空间不需要进行微分,形式简单,易于求解。HSPICE仿真结果与文献[6]的实验和仿真结果对比表明,考虑磁场在截面的非均匀性和涡流影响的磁滞回线SPICE模型有较高的准确性。

参考文献:

[1]de la Cheisserie E T,et al. Magnetisme II—Materiaux et Applica⁃tions,EDP Sciences,Paris,2000.

[2]Brissonneau P.Magnetisme et. Materiaux Magnetiques Pour L’Electro-Technique,Hermes,Paris,1997.

[3]Bertotti G,Mayergoyz I D. The Science of Hysteresis:3-Volume⁃set,Academic Press,G.B.,2005.

[4]Zirka S E,Moroz Y I,Marketos P,et al. Measurement and Model⁃ing of B-H Loops and Losses of High Silicon Nonoriented Steels [J]. IEEE Transactionson Magnetics,2006,42(10):3177-3179.

[5]Zirka S E,Moroz Y I,Marketos P,et al. General-Isation of the Classical Method for Calculating Dynamic Hysteresis Loopsin Grain Oriented Electrical Steel[J]. IEEE Transactionson Magnet⁃ics,2008,44(9):2113-2126.

[6]Sebti Boukhtache,Malika Yakhlef,Mabrouk Chabane. Magnetic Field Computation in a Non-Oriented Sheet Cross-Section Consid⁃ering the Hysteresis Phenomenon[J]. Journal of Magnetism and Magnetic Materials,2010,322:505-509.

[7]Rouve L L,Ossart F,Waeckerle T,et al. Magnetic Fluxand Losses Computation in Electrical Laminations[J]. IEEE Transactionson Magnetics,1996,32(5):4219-4221.

[8]Rouve L L,Waeckerle T,Kedous- Lebouc A,et al. Analytical Computation of Average Induction in a Sheet Cross-Section Con⁃sidering Magnetic Diffusion and Hysteretic Features[J]. IEEE Transactionson Magnetics,1997,33(2):1271-1274.

[9]Rouve L L,Waeckerle T,Kedous-Lebouc A,et al. Determination of the Parameter k of the Generalized Dynamic Preisach Model [J]. IEEE Transactions on Magnetics,1996,32(3):1124-1127.

[10]Jiles D C. Modelling the Effects of Eddy Current Losses on Fre⁃quency Dependant Hysteresis in Electrically Conducting Media [J]. IEEE Transactionson Magnetics,1994,30(6):4326-4328.

[11]Jiles D C. Frequency Dependence of Hysteresis Curves in Conduct⁃ing Magnetic Materials[J]. Appl Phys,1994,76(10):5849-5855.

[12]Boukhtache S,Azoui B,Feliachi M. A Novel Model for Magnetic Hysteresis of Silicon-Iron Sheets[J]. The European Physical Jour⁃nal—Applied Physics,2006,34:201-204.

[13]Bertotti G. Hysteresis in Magnetism for Physicists,and Engineers,Academic Press,USA,1998.

崔智军(1978-),男,陕西渭南人,讲师,西北工业大学电子信息学院在读博士生,专业方向为微电子器件与微传感器,现在主要从事微型磁通门传感器研究,Cuizj_163@163.com;

刘诗斌(1960-),男,河南巩义市人,西北工业大学电子信息学院教授,博士生导师。长期从事无人机传感器系统研究工作,研究领域为磁场和压力测量,智能传感器系统,微电子和计算机应用,liushibin@nwpu.edu.cn。

Research of Spiral Coil on EMAT to Improve Transduction Efficiency*

FAN Jizhi1,2,WU Yunxin1,2*,SHI Wenze1,2,GONG Hai1,2,TAN Liangchen1,2

(1.State Key Laboratory of High Performance Complex Manufacturing,Central South University,Changsha 410083,China;2.School of Mechanical and Electrical Engineering,Central South University,Changsha 410083,China)

Abstract:A novel method for improving the transduction efficiency of Electromagnetic Acoustic Transducer (EMAT)is introduced. In this paper,a model of a doubled-layer spiral coil EMAT for generating shear wave was modeled in the finite element software COMSOL Multiphysics. And then the effects of the substrate thickness,cop⁃per conductor thickness and lift-off on the efficiency are investigated. Results show that the reducement in the sub⁃strate thickness and lift-off,the increasement in the copper conductor thickness can help to improve the efficiency. And the simulation results are verified by the experiments.

Key words:electromagnetic acoustic transducer;finite element method;spiral coil;transduction efficiency

doi:EEACC:723010.3969/j.issn.1004-1699.2016.01.006

收稿日期:2014-05-10修改日期:2015-06-15

中图分类号:TP212.1;TM936.2

文献标识码:A

文章编号:1004-1699(2016)01-0026-03

项目来源:高等学校博士学科点专项科研基金项目(20126102110031)