MEMS惯性传感器在汽车领域和消费领域的应用

Doug Sparks,Leonardo Sala

(罕王微电子(辽宁)有限公司,辽宁沈阳110016)

MEMS惯性传感器在汽车领域和消费领域的应用

Doug Sparks,Leonardo Sala

(罕王微电子(辽宁)有限公司,辽宁沈阳110016)

微机电系统(MEMS)惯性传感器在车辆领域的应用有导航辅助、检测冲击、检测由牵引力损失所造成的翻滚与偏移。惯性传感器包括线性加速度测量,转动行为测量,如偏移、翻滚、纵摇,也包括压力传感器测试高度。在消费领域,惯性传感器已经应用在游戏机、智能手机、无人机、照相机、虚拟现实头盔和其他器件;阐述了各类型应用于汽车领域和消费领域的MEMS惯性传感器的生产、测试和封装。

惯性MEMS;陀螺仪;加速度计

1 Automotive Applications

The first automotive application for accelerome-ters was frontal and then side impact detection.50 to 500g linear g impulses would be detected by the early(late 1980's to mid-1990's)1-axis accelerometersto trigger the firing of the air bags.Low g accelerometers were also employed in chassis control system along with the first 1-axis angular rate(yaw) sensors in the late 1990's(1).These inertial sensors worked along with steering wheel position and pressure sensors in the antilock braking system to prevent undesired vehicle yaw rates by applying a counter torque about the vehicles vertical axis.The anti-lock brake system and traction control system would use the sensor's input to prevent loss of control under icy driving conditions.Angular rate sensors were also employed in vehicles to detect roll over and deploy air bags or tighten seat belts.Navigational assist modules were also developed vehicles. Given the number of inertial sensors in a vehicle,Inertial Measurement Units (IMUs)were soon proposed and developed(2)in the late 1990's using single axis MEMS devices joined and packaged together on the printed circuit board (PCB)as shown in Figure 1.DIP (Dual In-Line)and SIP(Single In-Line)packages were used for these early inertial MEMS sensors.

Figure 1 The change in IMU size over the last 17 years from PCB assembly to a single MEMS chip in a small LGA package

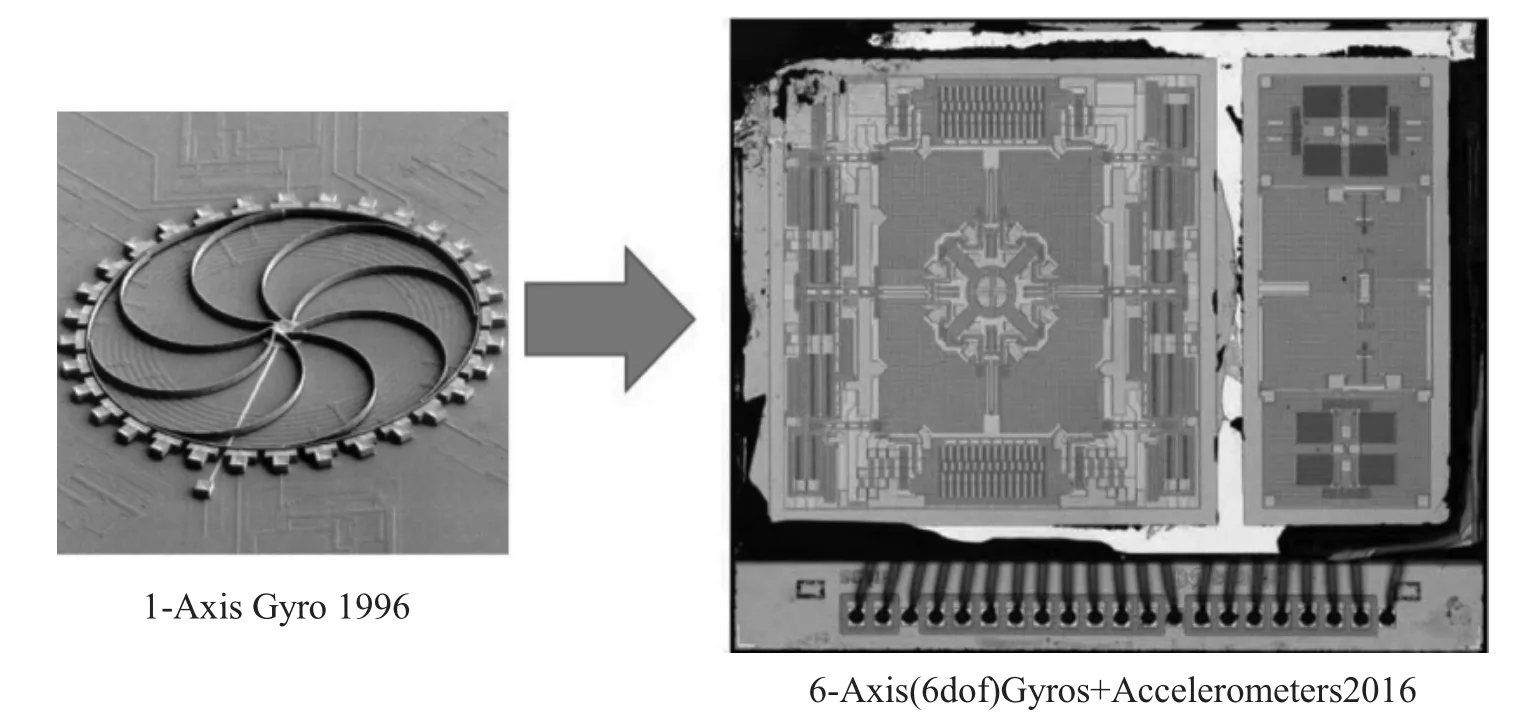

Figure 2 MEMS gyroscope chip shrinkage over 20 years from 1 axis to 6 axis.

Advances in MEMS design,processing and packaging have made it possible to go from 1-axis MEMS devices to 6-axis (6dof)devices in a single chip (3,4)or package as shown in Figures 1 and 2. This has dramatically reduced the size,weight and power requirements for IMUs.This improvement hasbenefited the automotive industry but created a new market for MEMS devices in many consumer applications.

These MEMS advances required new test equipment to be developed.Figure 3 shows a full 6-axis capable active test system that can provide linear and angular motion of packaged parts to calibrate and test these new MEMS IMUs.

In addition to test and calibration,automotive inertial sensors must pass rigorous qualification testing that involves mechanical shock,drop testing onto concrete,vibration,long term testing at high temperature as well as humidity,electrostatic discharge (ESD)and electromagnetic impulse and operate over a wide range of temperature.Some of these testing conditions are presented in Table 1.The various sensors in an IMU must remain within the specification limits while operating from-40℃to either 85℃or 125℃.The high end of the operation temperature limit depends on the location of the sensor in the vehicle.

Figure 3 6-axis MEMS IMU Test System.

Table 1 Typical IMU automotive qualification tests.

The MEMS devices are also required to operate within specification,without failure for 5 to 10 years,depending on the model of the vehicle.These operating conditions and long product life times often required protective coatings and multiple layers of packaging.For MEMS the packaging starts at the chip level,via wafer to wafer bonding.The moving elements used in an accelerometer or gyroscope,shown in Figure 2,are protected by the wafer level capping process.Next this MEMS chip scale package will be covered with the Land Grid Array(LGA)as shown in Figure 1.Further protection maybe provided by a module housing at the system level.Coating of silicone films are often sprayed over the MEMS chip after wirebonding or the component of the system module to provide additional protection against humidity and other contaminants.Multiple layers protect the MEMS elements from the extreme automotive environment at the package level.

2 Consumer Applications

MEMS inertial sensor found their first applications in automotive markets,but the largest annual sales volumes and price reductions began with the advent of consumer applications.This first began in video gaming and cell phones and has since spread to many consumer devices.Sensors used in gaming,smart phones and cameras do not encounter the extreme environmental challenges encountered in automobiles.Certainly,video games and virtual reality headsets are not used at-40℃ or 125℃,nor are they exposed to harsh chemicals.The product lifetime of a toy or cell phone is also much shorter than a luxury car or heavy duty truck.These differences allow for less expensive packaging methods and ofcourse result in a lower sales price for the sensors used in the consumer market.

Smart phones employ MEMS inertial sensors for the user interface and screen rotation.Activity monitoring and image stabilization of the camera as well as walking navigation use MEMS devices.Personal navigation in a smart phone allows the user to continue to navigate in cities where GPS signals are blocked by tall buildings,or when inside a large building that shields the GPS signal or when the steel structure interferes with the magnets used by e-compass chips. Another MEMS device,the absolute pressure sensor can serve as a altimeter and barometer.This MEMS pressure sensors,shown in Figure 4,can be used for measuring the floor in a building the user is currently on.

Figure 4 MEMS pressure sensor chip.

Drones use MEMS inertial sensors for flight control and camera control and stabilization.Wearables such as smart watches and fitness devices employ inertial MEMS sensors to count steps and indicate if the person is moving at all.MEMS inertial sensors are employed in virtual reality headsets for motion tracking.High end cameras also incorporate MEMS IMUs for image stabilization.

Consumer applications have driven the shrink on MEMS packaging even more than automotive applications.While automotive and industrial IMUs first used 1-axis devices on a PCB,the consumer market,with smaller,lower cost devices drove the development of combo packages in which different MEMS sensors like accelerometer,gyroscopes and magnetic sensors were stacked on top of each other or next to each other in a single cavity package.With clever MEMS design work this was driven to 6 inertial devices on the same MEMS chip as shown in Figure 2.

Consumer devices like smart phones and wearables lead to thinning the MEMS and CMOS wafers for a low profile LGA package.While the MEMS chip for an automotive sensor maybe 1 to 3 mm thick,the same type of inertial MEMS device in a consumer application may only be a few 100 microns thick (5).It should be noted that thicker MEMS sensor chips generally have better operating performance over a wide temperature range due to better thermos-mechanical decoupling between the silicon sensor elements and the packaging materials.For consumer packages the housing material is most often plastic,which has a higher thermal expansion coefficient than silicon.While this difference is not an issue in consumer applications where the devices is basically only used at room temperature,it can be a problem when the device must operate at-40℃ as well as +125℃.

Smartphone manufacturersalso drove the MEMS suppliers to adapt standard package sizes and pad layouts.This simplifies system level designs andenables high vol ume manufacturers to maintain at least 2 suppliers for each critical component in their systems.This reduces the risk of a supply shortage and enables the manufacturer to keep component prices lower.The drive for lower cost also pushed MEMS manufacturers to use larger wafers.Today high volume MEMS wafers are being fabricated with 200mm diameterwafers,allowing thousandsof MEMS chips to be produced on each silicon wafer. The smaller,lower cost MEMS devices developed for the consumer markets have led to manufacturing volumes of 100's of millions of inertial sensors per year.

[1] D.Sparks,S.Zarabadi,J,Johnson,M.Chia,G.Jiang,W. Higdon,O.LarsenandP.Castillo-Borelly.CMOSIntegrated Surface Micromachined Angular Rate Sensor for Automotive Applications[C].Transducers'97,3B1.04,p851-854,1997.

[2] D.Sparks,T.Noll,D.Agrotis,T.Betzner and K.Gschwend. Multi-Sensor Modules with Data Bus Communication Capability[J].Automotive Engineering,Vol.107,p37-38,1999.

[3] K.Volker.Microgyroscope for determining rotational movements about an X and/or Y and Z axis[Z].US Patent 8,479,575,2013.

[4] H.Hammer.Micromechanical sensor with multiple spring bars[Z].US Patent 9,103,850,2015.

[5] D.Sparks.MEMS Packaging:heading towards convergence[J].Chip-Scale Review,Vol.19,p58-60,May-June,2015.

图7 兆声DI水清洗原理图

4 结束语

减薄抛光后,晶圆表面不可避免残留有抛光液以及磨削产生的污染物,无法满足后续的划切、通孔电镀或TSV封装的来料工艺要求。清洗系统集成到减薄抛光一体机内部,通过合理的工艺配置,能够对污染物进行有效祛除,保证输出的晶圆满足下道工艺在洁净度方面的具体要求,为下一道加工降低技术难度和风险。

[1] 费玖海,杨师,周志奇.集成电路工艺中减薄与抛光设备的现状及发展[J].电子工业专用设备,2014,43 (2):6-10.

[2] 刘永进,杜建科,冯小强.单晶圆兆声清洗技术研究及兆声喷头方案优化[J].电子工业专用设备,2011,40 (1):15-17.

MEMS Inertial Sensors for Automotive and Consumer Applications

Doug Sparks and Leonardo Sala

(Hanking Electronics(Liaoning)Ltd.,Shenyang 110016,China)

MicroElectro Mechanical Systems (MEMS)inertial sensors are used in vehicles for navigational assist,safety for detecting impact,roll and yaw from loss of traction.The sensors include linear acceleration,rotational motion such as yaw,roll and pitch as well as pressure sensors for altitude measurement.For consumer applications,they have been employed in gaming,smart phones,drones,cameras,virtual reality headsets and other devices.This paper will examine how the various micromachined inertial sensors are fabricated,tested and packaged for both the automotive and consumer markets.

Inertial MEMS;Gyroscope;Accelerometer

TN948.43

B

1004-4507(2016)12-0039-05

2016-11-10

刘玉倩,(1984-),女,山东阳谷人,工程师,现就职于中国电子科技集团公司第四十五研究所,从事半导体设备研发工作。