Effect of Different Pretreatments on Explosion Puffing Drying of Hami Melon at Modified Temperature and Pressure in Xinjiang

, , , ,

Institute of Agro-product Processing/Key Laboratory of Agro-product Processing, Xinjiang Academy of Agricultural and Reclamation Science, Shihezi 832000, China

1 Introduction

The Hami melon is a type of muskmelon, and its outer color is generally white through pink or yellow through green. The inside flesh is sweet and crisp. It contains rich vitamins, glucose, fructose and trace elements[1]. Hami melon is a fruit unique to China, and also a fruit product with obvious advantages in Xinjiang. The explosion puffing drying technology at modified temperature and pressure is an emerging environmentally friendly, energy-saving puffing drying technology exclusively for producing non-fried fruit and vegetable chips in recent years, with broad application prospects in fruit and vegetable processing[2-4]. Currently, there are some problems in the process of explosion puffing drying at modified temperature and pressure. First, during the processing, the material is prone to browning; second, the high moisture content will reduce product crispness, thereby losing commercial traits. In order to develop Xinjiang’s fruit and vegetable specialties puffed at modified temperature and pressure, our institute cooperates with relevant scientific research institutes to make a series of related studies, and has made stage progress in technological research on explosion puffing drying of a variety of fruits and vegetables at modified temperature and pressure. However, there are many factors affecting explosion puffing drying of fruits and variables at modified temperature and pressure, and especially the interaction between some important parameters, such as slicing manner of raw materials before puffing and pretreatment mode, has not yet been fully understood. This test is designed to investigate the influence of three pretreatment modes (blanching, citric acid soaking and NaCl soaking) on the quality of Hami melon products under explosion puffing drying at modified temperature and pressure, and improve processing technology of the related products.

2 Research at home and abroad

Domestic and foreign scholars have done a lot of researches on the pretreatment of fruit and vegetable drying processing. Cai Yadongetal.[5]study the pretreatment of fried and puffed Hami melon products, and find that before the frying of raw material, using calcium salt hardening treatment, NaCl soaking treatment and dextrin infiltrating and filling treatment can help to make the processed puffed products have good color and intact shape. Mujica-Pazetal.[6]study the vacuum infiltration pretreatment of Hami melon and other fruits, and use response surface methodology to optimize the infiltrating and soaking process of Hami melon. Moreover, Varnalis AIetal.[7-8]study the influence of blanching and sulfur bleaching pretreatment on the hot air drying and puffing effect of potato, and find that sulfur bleaching treatment has no significant influence on puffing of potato, and hot air drying after blanching will increase degree of puffing. Bi Jinfengetal.[9]study the influence of three different pretreatment methods (blanching, freezing and soaking) on the quality of Hami melon products under explosion puffing drying at modified temperature and pressure, and results show that moderate blanching pretreatment helps to reduce puffed product moisture content, and improve the degree of puffing and product color.

3 Materials and methods

3.1MaterialsHami melon (purchased from Shihezi fruit wholesale market); citric acid, NaCl (Beijing Chemical Reagent Company).

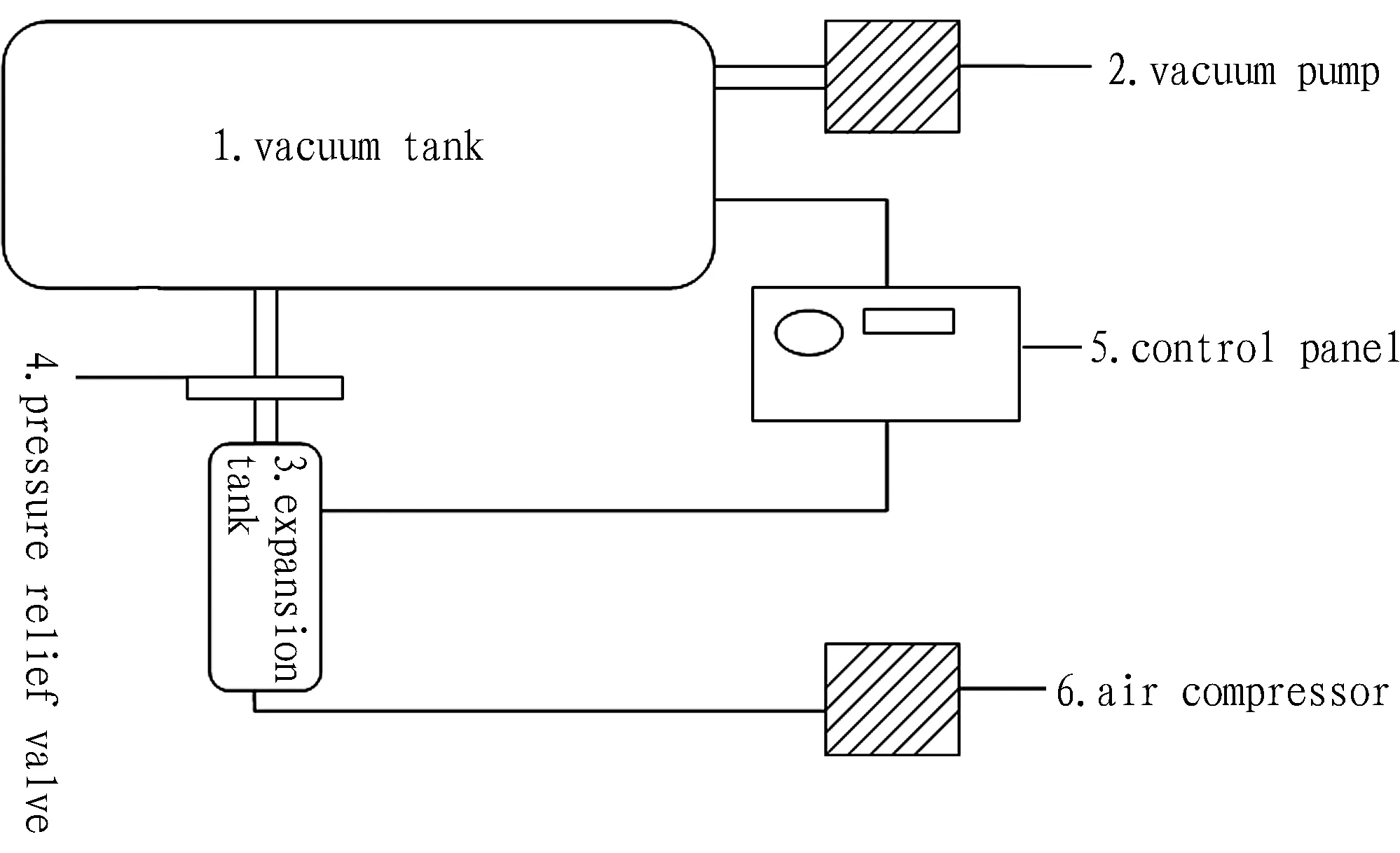

3.2InstrumentsandequipmentsPuffed fruit and variable dryer at modified temperature and pressure (QDPH10-1, Tianjin Qinde New Materials Technology Co., Ltd.); electric constant temperature blast box (DHG-9123A, Shanghai Jinghong Experimental Equipment Co., Ltd.); properties analyzer (Ta.XT 2i/50, UK Stable Micro Systems Company); color difference meter (CR-400, Japan Minolta Company); refrigerator (BCD-219D, Qingdao Haier Co., Ltd.). The experimental apparatus is shown in Fig. 1.

Fig.1Puffedfruitandvegetabledryeratmodifiedtemperatureandpressure

3.3Methods

3.3.1Process. Raw materials→cleaning→removing inedible part→segmentation→ pre-drying→softening→puffing drying→cooling→packaging→product. By the experimental study, the explosion puffing drying conditions at modified temperature and pressure were determined as follows: puffing temperature of 85℃; puffing pressure of 0.2 MPa; puffing time of 30 min; vacuum temperature of 70℃; evacuation time of 90 min.

3.3.2Indicator measuring method. (i) Moisture content determination: according to Rodrigues direct drying method[10]. (ii) Color measuring: with whiteboard color as standard for correction, using colorimeter to measure lightness index of Hami melon (L). The larger the L value of product, the better the color of product[11]. (iii) Determination of degree of puffing: specific volume method. Ultra-fine quartz sand filling method was used o measure the volume of puffed products. The measuring instrument was made by ourselves, and the volume was averaged. The degree of puffing was calculated according to Equation (1):

Degree of puffing=V-V0

(1)

whereVis the volume after puffing, mL;V0is the volume before puffing, mL. (iii) Crispness and hardness determination. Texture analyzer was used for determination, and the measurement conditions were as follows: measuring force in the process of lower pressure; test speed of 2.0 mm/s before test; test speed of 1.0 mm/s; test speed of 2.0 mm/s after test; test distance of 5.0 mm; data acquisition rate of 500 times/s; threshold of 5 g; probe P/100. Referring to the method of Hawladeretal.[12], crispness can be denoted by the number of peaks in the stress curve. The crispness in this test was denoted by the number of peaks generated during test. The larger the number of peaks, the better the product crispness. The hardness value was equal to the force peak in the curve, namely the greatest force needed to break samples, with the unit of "g". The greater the value, the harder the product.

3.3.3Experimental design. (i) Blanching treatment. The Hami melon was cut into 1 cm slices, and they were divided into five treatment groups. They were put into the boiling water to be blanched for 0, 60, 120, 180 and 240s, respectively, and then placed into 60℃ electric blast oven for 8 h of drying. In the same conditions, the explosion puffing drying was conducted at modified temperature and pressure, and the moisture content, degree of puffing, color, hardness and crispness of puffed products were measured. (ii) Citric acid soaking treatment. After the Hami melon was cut into 1 cm slices, they were divided into five treatment groups. They were soaked in 0, 1.5, 2.5, 3.5 and 4.5% citric acid solution for 4 h, respectively, and then put into 60℃ electrothermal blast oven for 8 h of drying. In the same conditions, the explosion puffing drying was conducted at modified temperature and pressure, and the moisture content, degree of puffing, color, hardness and crispness of puffed products were measured. (iii) NaCl treatment. After the Hami melon was cut into 1 cm slices, they were divided into five treatment groups. They were soaked in 0, 2, 4, 6 and 8% NaCl solution for 3 h, respectively, and then put into 60℃ electrothermal blast oven for 8 h of drying. In the same conditions, the explosion puffing drying was conducted at modified temperature and pressure, and the moisture content, degree of puffing, color, hardness and crispness of puffed products were measured.

3.3.4Data analysis. SPSS 18.0 was used for data difference analysis.

4 Results and analysis

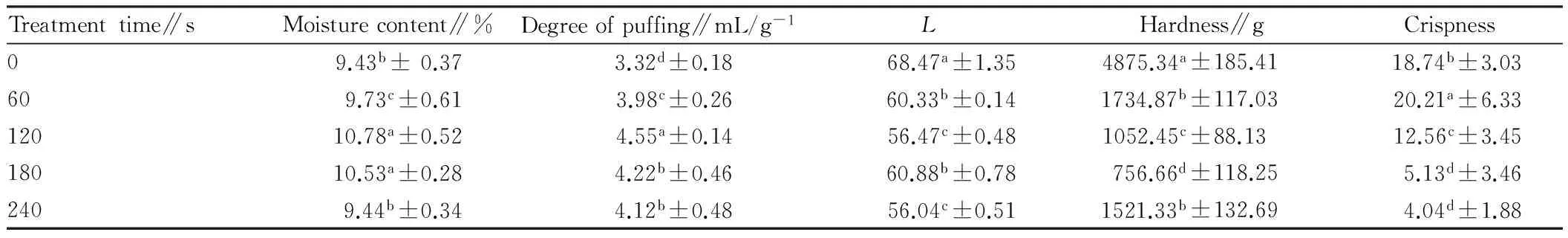

4.1EffectofblanchingtreatmentonthedriedpuffedproductqualityAs shown in Table 1, with increasing blanching time, the moisture content of puffed product first increased and then decreased, and at 60s, it was significantly different from other groups (P≤0.05). After 120s, the moisture content gradually decreased, and at 240s, the moisture content was lowest, indicating that proper blanching treatment could accelerate material dehydration, possibly because the high temperature blanching could increase the deformation ability of materials during puffing, and speed up water loss. With increasing blanching time, the degree of puffing first increased and then decreased, and the puffed product under 120 s blanching treatment had the degree of puffing significantly higher than under other treatments. With increasing blanching time, the product color decreased, at 60s and 180s, the differences between treatments were not significant (P≥0.05), and at 240s,Ldecreased, indicating that excessive blanching was detrimental to product color, because with the destruction of material cell surface, cell lysates flowed out, and the material’s ability to maintain color decreased. With increasing blanching time, the product hardness showed a downward trend, but rose suddenly from 240s, indicating that proper blanching could help to reduce puffed product hardness, but excessive blanching would increase product hardness. The puffed product crispness first increased and then decreased, and it was highest at 60s. Considering the above factors, the puffed product quality was good under 60s blanching treatment.

Table1Effectofblanchingonthedriedpuffedproductquality

Treatmenttime∥sMoisturecontent∥%Degreeofpuffing∥mL/g-1LHardness∥gCrispness09.43b±0.373.32d±0.1868.47a±1.354875.34a±185.4118.74b±3.03609.73c±0.613.98c±0.2660.33b±0.141734.87b±117.0320.21a±6.3312010.78a±0.524.55a±0.1456.47c±0.481052.45c±88.1312.56c±3.4518010.53a±0.284.22b±0.4660.88b±0.78756.66d±118.255.13d±3.462409.44b±0.344.12b±0.4856.04c±0.511521.33b±132.694.04d±1.88

Note: Different letters in the same column represent significant differences,P≤0.05, the same in Table 2 and Table 3.

4.2EffectofcitricacidtreatmentonthedriedpuffedproductqualityAs shown in Table 2, with the increasing concentration of citric acid, the moisture content of puffed product showed a rising trend. When the citric acid concentration was 2.5% to 3.5%, the moisture content difference between products was not significant (P≥0.05), and when the citric acid concentration was 4.5%, the moisture content declined sharply, possibly because the high concentration acid could soften the material and exacerbate dehydration when products were puffed. With the increasing concentration of citric acid, the degree of puffing first increased and then decreased, and when the concentration was 2.5%, the degree of puffing was best. With the increasing concentration of citric acid, the product color showed a decreasing trend, and there was no significant difference in L between the concentration of 1.5% and 2.5% (P≥0.05), but the difference between the level of 2.5% and 4.5% was significant (P≤0.05), indicating that too high citric acid concentration was not conducive to maintaining product color, possibly because too high concentration acid treatment destroyed the cell structure and led to content loss, resulting in decreased product color. With the increasing concentration of citric acid, the hardness of puffed product showed an overall downward trend, but it rose when the concentration was 4.5%, indicating that proper citric acid treatment could reduce the hardness of the product and increase the degree of puffing. When the citric acid concentration was 2.5%, the crispness of puffed product was best. Therefore, by the 2.5% citric acid pretreatment, good product quality could be obtained.

Table2Effectofcitricacidtreatmentonthedriedpuffedproductquality

Citricacidconcentration∥%Moisturecontent∥%Degreeofpuffing∥mL/g-1LHardness∥g Crispness09.43c±0.373.32c±0.1868.47a±1.354875.34a±185.4118.74b±3.031.59.73b±0.613.98b±0.2660.33b±0.141734.87b±117.0312.56c±3.452.510.78a±0.524.55a±0.1460.88b±0.781052.45c±88.1320.21a±6.333.510.93a±0.284.22b±0.4656.47c±0.48756.66d±118.255.13e±3.464.59.44c±0.344.12b±0.4856.04c±0.511521.33b±132.697.04d±1.88

4.3EffectofNaCltreatmentonthedriedpuffedproductqualityThe effect of NaCl treatment on puffed product quality can be shown in Table 3. With increasing NaCl concentration, the moisture content showed an overall downward trend, possibly because NaCl had high penetration capacity, and could accelerate dehydration of material, thereby reducing the moisture content during puffing. The degree of puffing was best when the NaCl concentration was 2%, and with the increasing NaCl concentration,Lcontinued to increase, indicating that high concentration NaCl treatment could improve puffed product color. The hardness of puffed product decreased with the increasing NaCl concentration, but suddenly increased when the concentration was 8%, indicating that high concentration NaCl treatment would increase the hardness of puffed product, detrimental to product quality. The crispness was best when the concentration was 2%. In summary, the effect was best under 2% NaCl treatment.

Table3EffectofNaCltreatmentonthedriedpuffedproductquality

NaClconcentration∥%Moisturecontent∥%Degreeofpuffing∥mL/g-1LHardness∥g Crispness09.78a±0.173.89c±0.1851.02d±1.354875.34a±185.4118.74b±3.0329.96a±0.314.98a±0.2663.33c±1.141734.87b±117.0320.21a±6.3349.58b±0.523.78c±0.3368.47b±0.891052.45d±88.1312.56c±3.4568.93c±0.284.22b±0.4669.88b±0.78756.66e±118.255.13e±3.4687.83d±0.124.02b±0.1971.04a±1.081521.33c±132.697.04d±1.88

5 Conclusions

Proper blanching pretreatment could help to reduce the moisture content of puffed product, but excessive blanching would cause a decline in product color, and 60s blanching had good effect; the citric acid pretreatment helped to increase the degree of puffingand crispness for the dried puffed products, but the moisture content was high, and 2.5% citric acid treatment was appropriate; NaCl solution soaking treatment could effectively promote material dehydration, and high concentration NaCl penetrating fluid played a significant role in maintaining material color, but it would increase product hardness and reduce product quality, and 2% NaCl treatment had the best effect.

[1] YABUMOTO K, JENNINGS WG. Constituents of cantaloupe, cucumismelon and their biogenesis[J]. Journal of Food Science,1977(42):32-37.

[2] ZMAMER CM. Gun-puffed vegetable snacks: A new way to eat your veggies[J]. Food Technology, 1995, 49(10):64-65.

[3] SULLIVAN JF, CRAIG JC. The development of explosion puffing[J]. Food Technology, 1984,38(2):52-55.

[4] SULLIVAN JF, EGOVILLE MJ, KONSTANCE RP,etal. Storage stability of continuous explosion puffed potatoes[J]. Food Science and Technology, 1983, 16(2):76.

[5] CAI YD, ZHAO CJ. On the technology of vacuum fried crisp melon[J]. Science and Technology of Food Industry, 1998(6):59-60. (in Chinese).

[6] MUJICA-PAZ H, VALDEZ-FRAGOSO A, LOPEZ-MALO A,etal. Impregnation properties of some fruits at vacuum pressure[J]. Journal of Food Engineering, 2003(56): 307-314.

[7] VARNLIS AI, BRENNAN JG, MACDOUGALL DB. A proposed mechanism of high-temperature puffing of puffing. Part. The influence of blanching and drying condition on the volume of puffed cubes[J].Journal of Food Engineering, 2001(48): 361-367.

[8] VARNLIS AI, BRENNAN JG, MACDOUGALL DB. A proposed mechanism of high-temperature puffing of puffing. PartⅡ.The influence of blanching and initial drying on the permeability of the partially dried layer to water vapour[J]. Journal of Food Engineering, 2001(48): 369-378.

[9] BI JF, FANG F, DING YY,etal. Effect of different pretreatments on the product quality of explosion puffing drying for hami-melon[J]. Food and Machinery, 2010(2): 15-18.

[10] RODRIGUES S, FERNANDES FAN. Dehydration of melons in a ternary system followed by air-drying[J]. Journal of Food Engineering, 2007(80): 678-687.

[11] NATH A, CHATTOPADHYAY PK. Optimization of oven toasting for improving crispness and other quality attributes of ready to eat potato-soy snack using response surface methodology[J]. Journal of Food Engineering, 2007(80): 1282-1292.

[12] HAWLADER MNA, PERERA CO, TIAN M. Properties of modified atmosphere heat pump dried foods[J]. Journal of Food Engineering, 2006(74): 392-401.

Asian Agricultural Research2016年9期

Asian Agricultural Research2016年9期

- Asian Agricultural Research的其它文章

- Empirical Study on the Relationship between Organizational Flexibility and Performance of Agricultural Enterprise

- Correlation between Employment Quality and Skill Training of Land-expropriated Farmers

- A Study on Spatial Distribution of Commercial Housing Prices in Xiangtan City

- Design and Experiment of Fluid Dynamic Ultrasonic Water Aerator

- The Relation between Age Structure of Population and Resident Consumption Based on Endogenous Growth Theory

- Design and Implementation of National Meteorological Service Platform