热电材料发电的商业化进展与前景展望

何琴玉, 李维谦, Hao Qing, 李 炜, 王银珍, 曾葆青

(1.华南师范大学物理与电信工程学院,量子工程和量子材料实验室,广州 510006;2.亚利桑那大学航空和机械工程系, 亚利桑那 85721, 美国;3.成都电子科技大学物理电子学院,成都 610054)

热电材料发电的商业化进展与前景展望

何琴玉1*, 李维谦1, Hao Qing2*, 李炜1, 王银珍1, 曾葆青3

(1.华南师范大学物理与电信工程学院,量子工程和量子材料实验室,广州 510006;2.亚利桑那大学航空和机械工程系, 亚利桑那 85721, 美国;3.成都电子科技大学物理电子学院,成都 610054)

综述了热电材料作为绿色环保能源转换材料的商业化进展与应用前景. 阐述了商业化的热电材料热电性能指标要求,分析了提高热电性能的条件和理论上的局限性. 通过分析近20年提高热电性能的研究,总结了一些突破上述局限性的有效手段,提出了将来提高热电性能的一些有效方法. 预测了热电性能商业化的前景.

热电材料; 商业化; 绩效因子(ZT)调制

热电材料是一种基于温差电效应(Seebeck效应)的固态能量转换材料; 涉及材料的热、电、半导体性能;能将热能转换成电能,或将热能转移和制冷[1]. 热发电与蒸汽发电相比,其优点在于[2]:(1)无需运动部件,因而无噪音.(2)设备简单. 由一块连接外部负载的导线和置于冷热端的热电模块(包括陶瓷导热片)组成发电器件. (3)应用器件大小各异. 可用于热发电工厂、家用太阳灶集热发电和废热发电;规模和场所灵活多变. (4)性能稳定,设备轻盈. 美国的“遨游号”宇航飞船即采用热电模块将同位素衰变时放出的热量发电,以维持电子设备的正常运作60多年[3]. 在太空宇航上需要持久提供电源和重量轻盈的供电器件. 所以,热电材料的发电具有蒸汽发电无法比拟的优点[4]. (5)热电材料制冷和制热是同一套热电系统的反转[3]. 即在热电材料的一端制冷,那么在同样的电源提供下该热电模块的另一端必然制热. 即该热电模块相当于1个热量搬运装置——热泵,将热量从制冷端搬运至制热端. 这些现象类似于现有的以液体作为工质运行的空调.

热电材料制冷与目前以氟利昂作为工质的制冷方式相比,由于其制冷的运行工质是载流子,没有噪音. 氟利昂排放在大气中后破坏大气层中能吸收紫外线的臭氧,导致大气中紫外线增加. 而过量的紫外线辐射对人体有害. 热电材料制冷对环境没有破坏,绿色环保. 运行工质-电子的运行对热电模块没有机械磨损,寿命长.

热电效应发现了100多年,但热电材料在发电、制冷、热泵等方面的应用仍然没有商业化,其主要原因是热电材料的转换效率与制冷效率较低,无法和现有商业化的发电和制冷方式相竞争. 本文就热电材料商业化的热电性能指标要求、提高热电性能的条件和理论上的局限性、近20年突破上述局限性的一些有效手段,以及对热电性能商业化的前景进行阐述.

1 影响热电模块发电效率的内禀因素及其调制途径

1.1影响热电模块发电效率的内禀因素

决定热电材料能量转换效率与制冷效率的内禀因素主要是温差电优值系数(ZT):

ZT=S2σT/K,

(1)

式中,S为材料的Seebeck系数,σ为电导率,K为热导率,T为绝对温度. 为了获得高ZT,热电材料的σ与S越大越好,K越小越好. 如果ZT为2.0,热电发电才具有商业价值;ZT接近3.0,热电发电效率才能和现有的蒸汽发电的效率相当[5]. 比如若冷端温度为300 K,热端温度为700 K,则对于ZT为1.0、2.0、3.0、4.0及5.0的热电模块,其热电转换效率分别为12.84%、19.36%、23.53%、26.51%和28.78%. 但由于S、σ、K之间在物理上相互关联,其中1个量的优化往往使另1个或2个量向不利的方向变化[5],3个参数难独立调制. 使得热电材料的商业化进展缓慢.

Seebeck效应由Seebeck于1821年在金属中首次发现.由于金属中S较低,即Seebeck效应较小,从发现到随后的1个世纪内仅在温差热电偶方面有商业应用,尚无能量转换方面的概念.1957年Ioffe[6]研究半导体材料的Seebeck效应后,才有Seebeck效应在能量转换方面的探索. 对于能量转换材料,金属的S较低;绝缘体材料的σ较低;而对于半导体材料,S和σ居中,刚好合适. 因而其ZT最高,半导体更适合作为能量转换材料使用[6]. 以下针对半导体材料进行讨论.

1.2热电参数

1.2.1热导率K半导体材料的热导率主要来自电子热导率(Ke)和声子热导率(KL),即K=Ke+KL. 半导体块体材料的Ke基本满足Wiedemann-Franz定律:

Ke=L0σT,

(2)

与σ成正比,L0≈2.45×10-8V2/K2为Wiedemann-Franz常数. 式(1)可以变为

ZT=S2σT/(Ke+KL)=S2σT/(L0σT+KL)=S2T/(L0T+KL/σ).

(3)

从式(3)可知:对于普通半导体材料,不能通过过度减小Ke降低K,因为会直接导致σ下降,达不到大幅度提升ZT的效果. 关键在于通过降低KL来降低K. 于是Slack[7]提出一种理想的半导体热电材料的模型:在半导体材料中,其电导率与单晶中一样高,晶格热导率(KL)与玻璃中一样低, 即该材料是一种“电子晶体,声子玻璃”. 在声子玻璃中,声子截止,KL=0,此时

Kmin=Ke=0.25-0.5 W/(m·K)[8].

实际材料中,即使是晶格振动无序的非晶体,KL仍不可能为0(声子以爱因斯坦局域化振动模为特征,声子主要局限在1个原子范围内,KL≈0.1 W/(m·K). 总之,K一般大于0.25~0.5 W/(m·K). 半导体热电材料的声子波长和平均自由程在很宽的范围分布,在高温其能量主要由长波声子携带[9].

1.2.2电导率σ普通半导体的电导载流子是电子与空穴,由载流子浓度与迁移率μ决定:

σ=neeue+npeup,

(4)

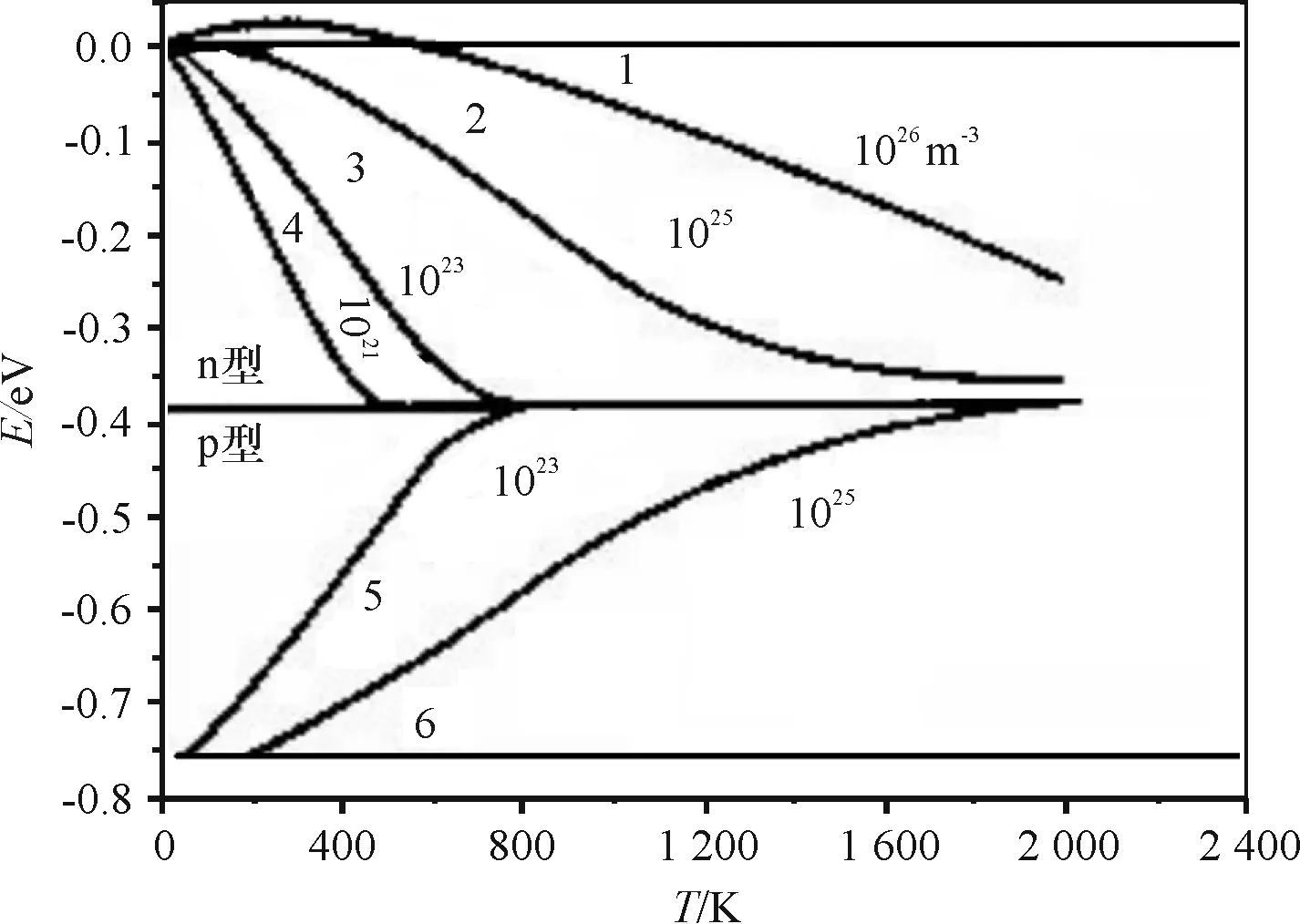

ne、np分别为半导体材料中电子与空穴浓度,e为单个电子和空穴电量,ue、up分别为热电材料中电子与空穴的迁移率. 如图1所示,由于热电材料所用半导体主要为重掺杂半导体,处于饱和区或者过渡区,因而载流子浓度主要由杂质浓度和温度决定[9]. 削弱μ的主要因素是各种杂质、缺陷、声子、电子的散射.

1.2.3Seebeck系数S影响Seebeck效应的因素有费米能级、载流子速度与能量、电子能带结构,低温时还与声子速度相关.

图1 不同浓度和不同温度下n型与p型半导体的费米能级[9]

Figure 1The Fermil levels of n-type and p-type semiconductor in case of different concentration and different temperature[9]

(1)费米能级的影响

Seebeck效应的产生主要是热端的载流子往冷端扩散的结果. 在开路情况下,就在半导体的冷端出现净的多子,热端出现净的少子电荷. 此宏观积累电荷在半导体内部产生电场;当扩散作用与电场的漂移作用相互抵消时,即达到稳定状态,在半导体的两端产生了由于温度梯度所引起的电动势——温差电动势. 自然,n型半导体的温差电动势的方向是从低温端指向高温端(Seebeck系数为负);相反,p型半导体的温差电动势的方向是高温端指向低温端(Seebeck系数为正). 因此利用温差电动势的方向即可判断半导体的导电类型. 物理上,Seebeck系数是平均电子能量与Fermi能级差.费米能级随温度的变化率越大,Seebeck系数在该温度段的值越大[10]. 由图1 可知,费米能级随温度的变化可以通过掺入杂质进行调制. 此时载流子浓度也发生了变化. 合适的杂质掺入可以获得较优化的Seebeck系数.

(2)载流子速度与能量

因为热端和冷端的载流子能量不同,因而半导体Fermi能级在两端存在着差异. 这种作用也会增强Seebeck效应.

(3)电导率σ

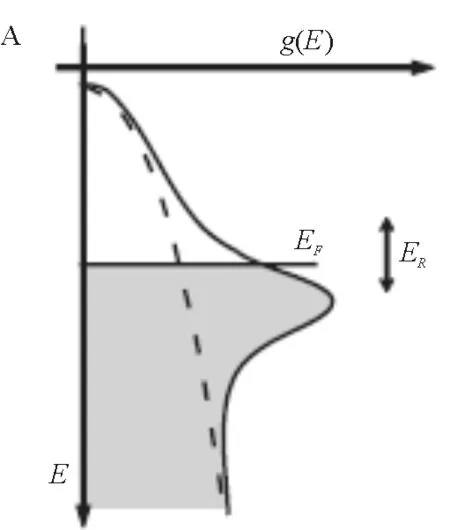

S与载流子浓度满足对数反比关系:

(5)

而如式(4)所示σ与载流子浓度成正比. 故σ越大,S越小. 其实是以上综合因素作用的结果.

(4)声子速度

因为热端的声子数多于冷端,则声子也将要从高温端向低温端扩散,并在扩散过程中与载流子碰撞时将能量传递给了载流子,故加速了载流子的运动(声子牵引),这种作用同样会增加载流子在冷端的积累、增强Seebeck效应.

近年来调制S的方法有[11-13]:

①利用μ对能量的依赖性:增强μ对能量依赖性,引入强烈依赖于载流子浓度的散射机制,且保证迁移率对能量导数为正——即载流子能量增加时,其μ与S均增加. 合适的电离杂质满足这一要求.

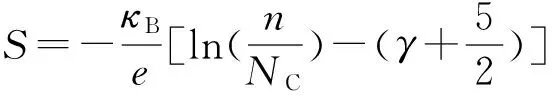

②利用载流子浓度对能量依赖性:如掺入适当的杂质,该杂质能与导带(n型)或者价带(p型)发生共振,引起导带(n型)或价带(p型)附近态密度明显变化(如图2的ER附近的态密度),从而提升S[14].

③低能载流子过滤:利用颗粒纳米化界面能产生势垒过滤低能载流子,使S增加但σ受影响小.

由于S和σ有关,一般情况下σ增加时S会减小,故前两种方法提升ZT幅度不大,而且适合的杂质不多,且杂质的掺入可能影响σ,因此前两种方法较难独立地调节S. 后一种方法是最近发展起来,能相对独立地调节S而不使σ、K往不利的方向变化.

图2 EF附近的态密度ER[14]

以上阐述说明,σ的增加会使K增加、使S减小;这3个因素之间相互牵制. 但是自从 Glass 提出“电子晶体、声子玻璃”的理念后,通过寻找一些特殊的材料、人工掺杂、人工结构等方法获得了一些准“电子晶体、声子玻璃”的材料. 如在方钴矿中存在天然的较大空洞结构,在其中插入较小的原子. 该原子与晶格的耦合较弱,能很好地散射声子,但对电子的输运影响较小;从而实现降低K及提高ZT. 或者通过一些特殊的人造微结构来散射声子,若该微结构对电子影响不大,但提高S、降低K,则能获得ZT的大幅度提高. 这些晶体相比天然的材料在理念上更趋于 “电子晶体、声子玻璃”的目标,故称之为准“电子晶体、声子玻璃”.

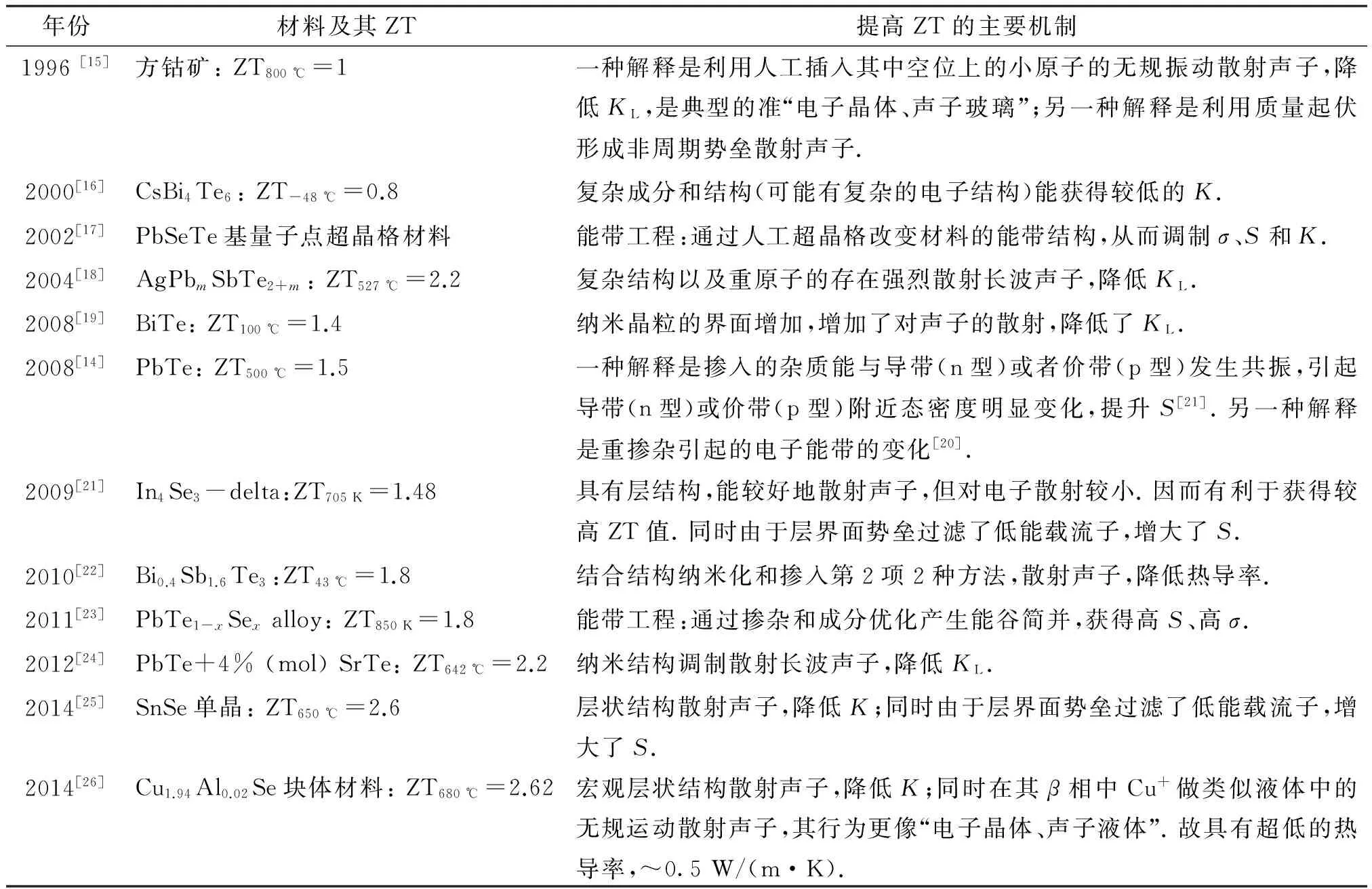

2 热电材料绩效因子提高的标志性成果

近年来通过S、σ、K的人工调制,热电材料的ZT获得了较大的提高. 表1列出了关于热电材料及其调制机制的标志性研究进展.

表1 热电材料的发展史上标志性研究成果及其调制机制

近年来为提高热电绩效因子ZT所采取的一些有效机制总结如下:

2.1在具有天然较大空洞的材料中填入小原子

采用小原子的无规振动散射声子[27-30],即让小原子与携热声子耦合,降低KL,但对σ影响不大[15,31-34];这类是典型的准“电子晶体、声子玻璃”. 也有另外的观点,有人认为主要是小原子与长波声子的谐振引起的KL的降低[35].

2.2能带工程

通过掺入杂质,该杂质能与导带(n型)或者价带(p型)发生共振,引起导带(n型)或价带(p型)附近态密度明显变化,提升S,降低KL[18,36-68];或通过轨道相互作用产生载流子囊,增加载流子浓度[39-40];或改变能带,改变电子的有效质量[41].

在钛(Ti)掺杂的p型FeV0.6Nb0.4Sb中发现8重的能带简并,热电性能大幅提高[42-44].

2.3热自旋流

自旋Seebeck效应[45-50]:通过裁剪材料的成分、人工结构等调制热电参数,提高热电性能的方法总受到一些限制. 因为载流子引起的Ke无法避免. 自旋电子不与晶格产生碰撞,不传导热,打破了Ke=LσT的约束,使得对热导率的调制不但可以独立调制晶格部分,也可以独立调制电导部分而不影响其他参数. 同时热自旋电子的热电性能只需要通过调节电压就可以调制,调制不涉及到材料本身,因而不受材料的限制,预期能有很高的ZT值.

2.4热电材料层状结构制造新技术

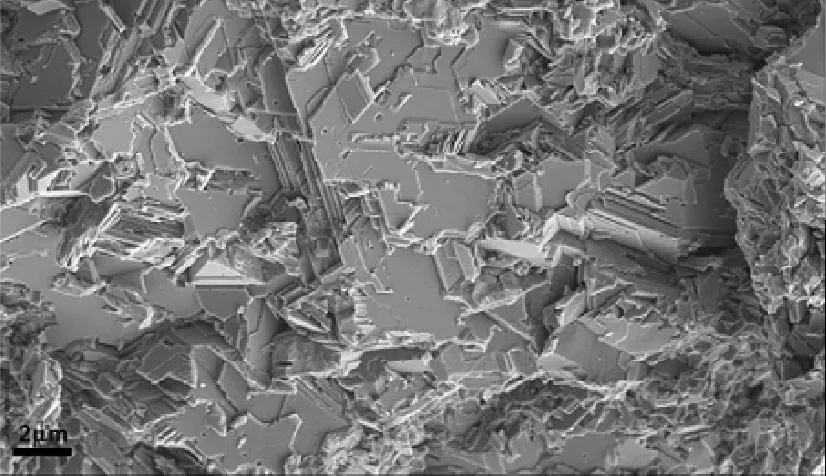

由于在层状结构材料中,大都能被独立调制1个或者多个热电参数,获得较大的ZT值. 如具有层状结构的NaxCoO2-δ的ZT800 K=1.2, Bi2Sr2Co2Oy的ZT973 K=1.1,Ca2Co2O5的ZT873 K≈1.2~2.7[51-54]. 又如,最近在一些材料中调制其微结构制备出微米级层状结构,在垂直层结构的方向由于声子受到散射降低了热导率,而低能载流子被过滤又提高了Seebeck系数,由于层和层之间的晶体结构匹配较好,电导率几乎不变,只有略微降低;从而ZT大幅度提高至2~3[26-27, 55-56]. 本课题组在Cu1.94Al0.02Se中制备层状结构实现ZT从1.7提高到2.62[26]. 制备的Cu1.94Al0.02Se层结构一致,层间晶体结构匹配好,层横向尺寸在微米级以上(图3). 获得了很低的热导率和很好的Seebeck系数,电导率没有显著的降低. ZT在2.62以上,是目前块体材料中最高的ZT. 但是Cu1.94Al0.02Se的制备条件很苛刻,对氧特别敏感而降低了热电性能. 所以,如何将该材料在高温使用时隔离氧,或者说隔离氧的装置是否廉价是该材料商业化应用的关键.在研究中还发现:Bi0.45Sb1.55Te3.02中无层结构时,ZT仅为1.15,形成层微结构后ZT达到1.4.

图3 室温时Cu1.94Al0.02Se的SEM照片[26]

2.5掺杂重原子、增加纳米结构块体材料中晶粒界面或形成异质结构势垒

重金属元素质量重,其共振频率低,与长波声子频率相当,能很好地散射半导体中晶格导热的主要载体——长波声子;降低KL[57].

第二相或者异质结形成的势垒会散射声子,降低热导率[57-66]. 异质结构的势垒为内建场,内建场的特点是对半导体中少子和多子有相反的作用力,能有效地降低K[59]. 纳米尺寸增强了界面散射低能载流子和长波声子的效果,提高S,降低KL[19,57,67-72].

2.6超导离子体中“电子晶体、声子液体”机制

在一些超导离子体中,超导离子做类似于液体的无规运动,散射声子,具有甚至比非晶还低的超低的K值,类似于液体的低导热能力. 其行为更像“电子晶体、声子液体”[73]. 本课题组在超导离子体Cu1.94Al0.02Se块体材料中获得了2.62的ZT值[26],虽然单晶的成本高,不适于商业化,但通过这些手段将热电材料的ZT提高到2以上,从某种意义上说是提高块体材料ZT的又一个里程碑[26],同时说明热电技术进入可商业化时代[27].

2.7调制微结构至各向异性的织构、层结构与其它各向异性的微结构

织构[74-75]、层结构[76-77]、各项异性大的材料的热电性能好[78-81]. 织构会引起应力的各向异性,电子有效质量的各向异性[82]. 层结构在层的法线方向和层平面内对声子的散射不同. 如果让温差落在垂直层结构方向,则能获得低KL. 这一点在多层人工膜Bi/Cu里也得到证实[83]. 天然复杂结构的材料具有天然低的KL.

2.8空洞散射声子

有大量文献报道在材料中引入孔洞,由于其散射低频声子,故能大幅降低K[28, 84-86].在材料InSb-In2Te3中,空洞、质量起伏、应力三者中空洞对声子散射最强[87]. 在石墨烯中存在有序的空洞能大大降低K,提高热电性能[88]. 有孔洞的锗膜其K值也大幅降低[89].在具有纳米孔洞的氧化锌(ZnO)中存在类似的结果[90].

还有一些其他的非主流机制增强热电材料ZT的方法. 这里不一一列举.

3 热电发电商业化有待解决的问题和可能的研究发展方向

3.1热电发电商业化有待解决的问题

热电材料的发电商业化的瓶颈主要有:一是热电材料的成本问题,ZT高的块体材料,如Cu2Se体系,Bi-Te体系等均采用多步制备,而且要求原材料是高纯单质,这些因素使这些块体材料具有较高的成本[26]. 二是p、n型的匹配. Bi-Te体系中p型的ZT高于n型的ZT;Cu2Se体系只有p型材料,暂时还没有好的n型材料. 对于热电发电模块,既需要p型的“脚”,也需要n型的“脚”.

3.2热电发电商业化可能的研究方向

3.2.1研究体系高ZT和低成本是今后热电材料选择和研发的总原则. Bi-Te体系、Cu2Se超导离子体系、SnSe体系、β-Fe2Si体系[23]等由于其原材料成本相对低,目前获得的体材料的ZT最高在1.5~2.62之间,因而这些体系将是今后几年商业化研究的热点. 这些材料都是天然层状微结构,如果通过控制制备工艺可以获得宏观层状结构的材料,则可望获得更高的ZT. 低成本大批量制备热电材料的工艺和制备设备是在制备方面的努力方向[91]. 其次高导热聚合物材料由于其柔性、质轻、可批量生产等优点可望成为下一个低成本热电材料的研究热点[32,92-94]. 自旋绝缘体也可能是下一个热电材料的研究热点[95-96].

3.2.2热电系数的调制方法大体的思路还是尽量朝着“电子晶体、声子玻璃”或者“电子晶体、声子液体”的理念努力,在保持高σ,S的前提下尽可能降低KL. 在文献[26]中提到了超导离子“液体”输运需要启动能量,使得KL有可能变负,将K拉得很低. 最近也有相变附近的热电效应研究[97],也是想通过相变储热来阻止热量从高温端向低温端输运,从而降低K. 这些新的研究方向有可能带来更高的热电性能.

4 结语

本文综述了热电材料作为绿色环保能源转换材料的商业化进展与应用前景. 阐述了商业化的热电材料的电导率、热导率、Seebeck系数等热电性能指标要求,分析了提高热电性能的条件和理论上的局限性. 通过分析近20年提高热电性能的研究,总结了突破上述局限性的有效手段,提出了提高热电性能的有效方法.

[1]Bozin E S. Malliakas C D, Souvatzis P, et al. Entropically stabilized local dipole formation in lead chalcogenides[J]. Science, 2010, 330(6011): 1660-1663.

[2]He J, Liu Y F. Funahashi R. Oxide thermoelectrics: The challenges, progress, and outlook[J]. Journal of Materials Research, 2011, 26(15): 1762-1772.

[3]Ji H. Caillat T. Thermoelectric materials for space and automotive power generation[J]. Material Research Science Bulletin, 2006, 31(3): 224-229.

[4]Morse J G. Energy for remote areas: Generators fueled with radionuclides are supplying power in small terrestrial and space systems[J]. Science, 1963, 139(3560): 1175-1180.

[5]Terry M T. Recent trends in thermoelectrics materials research, semiconductors and semimetals[M]. New York: Academic Press, 2001.

[6]Ioffe A F. Semiconductor thermoelements and thermoelectric cooling[M]. London: Infosearch Ltd.,1957.

[7]Slack G A. In Solid State Physics[M]. New York: Acedemic Press, 1979.

[8]Sood K C, Roy M K. Longitudinal phonons and high-temperature heat conduction in germanium[J], Journal of Physics: Condensed Matters, 1993, 5(3): 301-312.

[9]刘恩科,朱秉升,罗晋生, 等. 半导体物理学[M]. 西安:西安交通大学出版社,2008.

[10]Chen G. Nanoscale energy transport and conversion[M]. Oxford: Oxford University Press, 2005.

[11]Bharat J, Susanne S. Large seebeck coefficients and thermoelectric power factor of La-doped SrTiO3thin films[J]. Applied Physics Letters, 2010,97(4): 042106.

[12]Liu J, Sun Q F, Xie X C. Enhancement of the thermoelectric figure of merit in a quantum dot due to the Coulomb blockade effect[J]. Physical Review B:Condensed Matter,2010,81(24): 245323.

[13]Bell L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems[J]. Science, 2008, 321(5895): 1457-1461.

[14]Heremans J P, Jovovic V, Toberer E S, et al. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states[J]. Science,2008, 321(5888): 554-557.

[15]Sales B C, Mandrus D, Williams R K. Filled skutterudite antimonides: A new class of thermoelectric materials[J]. Science, 1996, 272(5266): 1325-1328.

[16]Duck Y C, Hogan T, Brazis P, et al. CsBi4Te6: A high-performance thermoelectric material for low-temperature applications[J]. Science, 2000, 287(2455): 1024-1027.

[17]Harman T C, Taylor P J, Walsh M P, et al. Quantum dot superlattice thermoelectric materials and devices[J]. Science, 2002, 297(5590): 2229-2232.

[18]Kuei F H, Sim L, Guo F, et al. Cubic AgPbmSbTe2+m: Bulk thermoelectric materials with high figure of merit[J]. Science, 2004, 303(5659):818-821.

[19]Poudel B, Hao Q, Ma Y, et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys[J]. Science, 2008, 320(5876): 634-638.

[20]Singh D J. Doping-dependent thermopower of PbTe from Boltzmann transport calculations[J]. Physical Review B: Condensed Matter, 2010,81(19): 195217.

[21]Jong S R, Kyu H L, Lee S M, et al. Peierls distortion as a route to high thermoelectric performance in ln4Se3-delta crystals[J]. Nature, 2009, 459(7249): 965-968.

[22]Gao P, Lu X, Berkun I, et al. Reduced lattice thermal conductivity in Bi-doped Mg2Si0.4Sn0.6[J]. Applied Physics Letters, 2014, 105(20): 202104.

[23]Pei Y Z, Shi X Y, LaLonde A, et al. Convergence of electronic bands for high performance bulk thermoelectric[J]. Nature, 2011, 473(7345): 66-69.

[24]Biswas K, He J Q, Blum I D, et al. High-performance bulk thermoelectrics with all-scale hierarchical architectures[J]. Nature, 2012, 489(7416):414-418.

[25]Zhao L D, Lo S H, Zhang Y S, et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals[J]. Nature, 2014, 508(7496): 373-377.

[26]Zhong B, Zhang Y, Li W Q, et al. High superionic conduction arising from aligned large lamellae and large figure of merit in bulk Cu1.94Al0.02Se[J]. Applied Physics Letters. 2014, 105(12):123902.

[27]Tyagi K, Gahtori B, Bathula S, et al. Band structure and transport studies of copper selenide: An efficient thermoelectric material[J]. Applied Physics Letters, 2014, 105(17):173905.

[28]Hopkins P E, Rakich P T, Olsson R H, et al. Origin of reduction in phonon thermal conductivity of microporous solids[J]. Applied Physics Letters, 2009, 95(16):161902.

[29]Pei Y Z, Yang J, Chen L D, et al. Improving thermoelectric performance of caged compounds through light-element filling[J]. Applied Physics Letters, 2009, 95(4): 042101.

[30]Yu J, Zhao W Y, Wei P, et al. Enhanced thermoelectric performance of (Ba,In) double-filled skutterudites via randomly arranged micropores[J]. Applied Physics Letters, 2014, 104(14):142104.

[31]Prokofiev A, Sidorenko A, Hradil K, et al. Thermopower enhancement by encapsulating cerium in clathrate cages[J].Nature Materials, 2013, 12(12): 1096-1101.

[32]Voneshen D J, Refson K, Borissenko E, et al. Suppression of thermal conductivity by rattling modes in thermoelectric sodium cobaltate[J]. Nature Materials,2013,12(11): 1028-1032.

[33]Guo L, Xu X, Salvador J R, et al. Coupled vibrational modes in multiple-filled skutterudites and the effects on lattice thermal conductivity reduction[J]. Applied Physics Letters, 2013, 102(11): 111905.

[34]Paul A, Klimeck G. Tuning lattice thermal conductance by porosity control in ultrascaled Si and Ge nanowires[J]Applied Physics Letters, 2011, 98(8): 083106.

[35]Koza M M, Johnson M R, Viennois R, et al. Breakdown of phonon glass paradigm in La- and Ce-filled Fe(4)Sb(12)skutteruditesv[J]. Nature Materials, 2008, 7(10):805-810.

[36]Ohta H, Kim S, Mune Y, et al. Giant thermoelectric Seebeck coefficient of two-dimensional electron gas in SrTiO3[J]. Nature Materials, 2007, 6(2): 129-134.

[37]He Q Y, Hu S J,Tang X, et al. The great improvement effect of pores on ZT in Co(1-x)Ni(x)Sb(3)system[J]. Applied Physics Letters, 2008, 93(4):042108.

[38]Wang Q Q, Qin X Y, Li D, et al. Enhancement of thermopower and thermoelectric performance through resonant distortion of electronic density of states of beta-Zn4Sb3doped with Sm[J]. Applied Physics Letters, 2013, 102(15):154101.

[39]Zhu H, Sun W H, Armiento R, et al. Band structure engineering through orbital interaction for enhanced thermoelectric power factor[J]. Applied Physics Letters, 2014, 104(8): 082107.

[40]Liu M, Qin X Y, Liu C S, et al. Enhanced thermoelectric power factor with impurity-induced resonant level[J]. Applied Physics Letters, 2011, 99(6): 062112.

[41]Takagiwa Y, Pei Y, Pomrehn G, et al. Dopants effect on the band structure of PbTe thermoelectric material[J]. Applied Physics Letters, 2012, 101(9): 092102.

[42]Pei Y Z, Shi X Y, LaLonde, et al. Convergence of electronic bands for high performance bulk thermoelectrics[J]. Nature, 2011,473(7345): 66-69.

[43]Liu W, Tan X J, Yin K, et al. Convergence of conduction bands as a means of enhancing thermoelectric performance of n-type Mg2Si1-xSnxsolid solutions[J]. Physical Review Letters, 2012,108(16):166601.

[44]Zaitsev V K, Fedorov M I, Gurieva E A, et al. Highly effective Mg2Si1-xSnxthermoelectrics[J]. Physical Review B, 2006,74(4):045207.

[45]Jaworski C M, Myers R C, Johnston-Halperin E, et al. Giant spin Seebeck effect in a non-magnetic material[J]. Nature, 2012, 487(7406): 210-213.

[46]Uchida K, Takahashi S, Harii K, et al. Observation of the spin Seebeck effect[J]. Nature, 2008, 455(7214):778-781.

[47]Kun R J, Byoung C M, Spiesser A, et al. Voltage tuning of thermal spin current in ferromagnetic tunnel contacts to semiconductors[J]. Nature Materials, 2014, 13(4):360-366.

[48]Kirihara A, Uchida K, Kajiwara Y, et al. Spin-current-driven thermoelectric coating[J]. Nature Materials, 2012, 11(8):686-689.

[49]Bauer G E W, Saitoh E, van Wees B J. Spin caloritronics[J]. Nature Materials, 2012, 11(5):391-399.

[50]Lu H F, Zhu L C, Zu X T, et al. Thermospin effects of a quasi-one-dimensional system in the presence of spin-orbit interaction[J]. Applied Physics Letters, 2010, 96(12):123111.

[51]Fujita K, Mochida T, Nakamura K. High-temperature thermoelectric properties of NaxCoO2-δsingle crystals[C]∥IEEE,20th International Conference on Thermoelectrics. Beijing, 2001: 168-171.

[52]Funahashi R, Shikano M. Bi2Sr2Co2Oywhiskers with high thermoelectric figure of merit[J]. Applied Physics Letters, 2002, 81(8):1459-1461.

[53]Ohkubo I, Mori T. Two-dimensional layered complex nitrides as a new class of thermoelectric materials[J]. Chemistry of Materials, 2014, 26(8): 2532-2536.

[54]Funahashi R, Matsubara I, Ikuta H, et al. An oxide single crystal with high thermoelectric performance in air[J]. Journal of Japanese Applied Physics, 2000, 39 (11B): L1127-L1129.

[55]Coleman J N, Lotya M, O′Neill A, et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials[J]. Science, 2011, 331(6017): 568-571.

[56]Shan R, Ouardi S, Fecher G H, et al. A p-type Heusler compound: Growth, structure, and properties of epitaxial thin NiYBi films on MgO (100)[J]. Applied Physics Letters, 2012, 101(21):212102.

[57]Skoug E J, Cain J D, Morelli D T. Structural effects on the lattice thermal conductivity of ternary antimony- and bismuth-containing chalcogenide semiconductors[J].Applied Physics Letters,2010, 96(18):181905.

[58]Li H, Tang X F, Zhang Q J, et al. High performance InxCeyCo4Sb12thermoelectric materials with in situ forming nanostructured InSb phase[J]. Applied Physics Letters, 2009, 94(10):102114.

[59]Bahk J H, Shakouri A. Enhancing the thermoelectric figure of merit through the reduction of bipolar thermal conductivity with heterostructure barriers[J]. Applied Physics Letters, 2014, 105(5): 052106.

[60]Zhang B P, Cai C F, Zhu H, et al. Phonon blocking by two dimensional electron gas in polar CdTe/PbTe heterojunctions[J]. Applied Physics Letters, 2014, 104(16):161601.

[61]Li Z Y, Li J F, Zhao W Y, et al. PbTe-based thermoelectric nanocomposites with reduced thermal conductivity by SiC nanodispersion[J]. Applied Physics Letters, 2014, 104(11):113905.

[62]Quintela C X, Rodriguez G B, Rivadulla F. Thermoelectric properties of heavy-element doped CrN[J]. Applied Physics Letters, 2014, 104(2): 022103.

[63]Basu T S, Yang R G, Thiagarajan S J, et al. Remarkable thermal conductivity reduction in metal-semiconductor nanocomposites[J]. Applied Physics Letters, 2013, 103(8): 083115.

[64]Min H L, Jong S R, Vaseem M, et al. Thermoelectric properties of SrTiO3nano-particles dispersed indium selenide bulk composites[J]. Applied Physics Letters, 2013, 102(22): 223901.

[65]Lin J P, Qiao G J, Ma L Z, et al. Heterogeneous in-situ nanostructure contributes to the thermoelectric performance of Zn4Sb3[J]. Applied Physics Letters, 2013, 102(16):163902.

[66]Bahk J H, Bian Z X, Zebarjadi M, et al. Thermoelectric power factor enhancement by ionized nanoparticle scattering[J]. Applied Physics Letters, 2011, 99(7): 072118.

[67]Zebarjadi M, Esfarjani K, Shakouri A, et al. Effect of nanoparticle scattering on thermoelectric power factor[J]. Applied Physics Letters, 2009, 94(20): 202105.

[68]Wang X W, Lee H, Lan Y C, et al. Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy[J]. Applied Physics Letters, 2008, 93(19):193121.

[69]Ghoshal U, Ghoshal S, McDowell C, et al. Enhanced thermoelectric cooling at cold junction interfaces[J]. Applied Physics Letters, 2002, 80(16): 3006-3008.

[70]Zhao H Z, Pokheral M, Zhu G H, et al. Dramatic thermal conductivity reduction by nanostructures for large increase in thermoelectric figure-of-merit of FeSb2[J]. Applied Physics Letters, 2011, 99(16): 163101.

[71]Li Z Y, Li J F. Fine-grained and nanostructured AgPbmSbTem+2alloys with high thermoelectric figure of merit at medium temperature[J]. Advanced Energy Materials, 2014, 4(2): 1300937.

[72]Chen S, Lukas K C, Liu W S, et al. Effect of Hfconcentration on thermoelectric properties of nanostructured N-Type Half-Heusler materials HfxZr1-xNiSn0.99Sb0.01[J]. Advanced Energy Materials, 2013, 3(9): 1210-1214.

[73]Liu H L, Shi X, Xu F F, et al. Copper ion liquid-like thermoelectric[J]. Nature Materials, 2012, 11(5):422-425.

[74]Lin Y H, Lan J L, Shen Z J, et al. High-temperature electrical transport behaviors in textured Ca3Co4O9-based polycrystalline ceramics[J]. Applied Physics Letters, 2009, 97(7): 072107.

[75]Bhame S D, Pravarthana D, Prellier W, et al. Enhanced thermoelectric performance in spark plasma textured bulk n-type Bi2Te2.7Se0.3and p-type Bi0.5Sb1.5Te3[J]. Applied Physics Letters, 2013, 102(21): 211901.

[76]Hopkins P E, Piekos E S. Lower limit to phonon thermal conductivity of disordered, layered solids[J]. Applied Physics Letters, 2009, 94(18): 181901.

[77]Ishiwata S, Shiomi Y, Lee J S, et al. Extremely high electron mobility in a phonon-glass semimetal[J]. Nature Materials, 2013, 12(6):512-517.

[78]Takahashi K, Sakai A, Kanno T, et al. Tailoring of inclined crystal orientation in layered cobaltite thin films for the development of off-diagonal thermoelectric effect[J]. Applied Physics Letters, 2009, 95(5): 051913.

[79]Rhyee J S, Cho E, Lee K H, et al. Thermoelectric properties and anisotropic electronic band structure on the In4Se3-xcompounds[J]. Applied Physics Letters, 2009, 95(21): 212106.

[80]Carrete J, Mingo N, Curtarolo S. Low thermal conductivity and triaxial phononic anisotropy of SnSe[J]. Applied Physics Letters, 2014, 105(10):101907.

[81]Wan C L, Wang Y F, Norimatsu W, et al. Nanoscale stacking faults induced low thermal conductivity in thermoelectric layered metal sulfides[J]. Applied Physics Letters, 2012, 100(10):101913.

[82]Liao A D, Yao M L, Katmis F, et al. Induced electronic anisotropy in bismuth thin films[J]. Applied Physics Letters, 2014, 105(6): 063114.

[83]Kanno T, Yotsuhashi S, Sakai A, et al. Enhancement of transverse thermoelectric power factor in tilted Bi/Cu multilayer[J]. Applied Physics Letters, 2009, 94(6): 061917.

[84]Lee J H, Grossman J C. Thermoelectric properties of nanoporous Ge[J]. Applied Physics Letters, 2009, 95(1): 013106.

[85]Singh R, Bian Z X, Shakouri A, et al. Direct measurement of thin-film thermoelectric figure of merit[J]. Applied Physics Letters,2009,94 (21): 212508.

[86]Kashiwagi M, Hirata S, Harada K, et al. Enhanced figure of merit of a porous thin film of bismuth antimony telluride[J]. Applied Physics Letters, 2011, 98(2): 023114.

[87]Pei Y Z, Morelli D T. Vacancy phonon scattering in thermoelectric In2Te3-InSb solid solutions[J]. Applied Physics Letters, 2009, 94(12): 122112.

[88]Thiyagarajan P, Oh M W, Yoon J C, et al. Thermoelectric properties of nanoporous three-dimensional graphene networks[J]. Applied Physics Letters, 2014, 105(3): 033905.

[89]Stoib B, Filser S, Petermann N, et al. Thermal conductivity of mesoporous films measured by Raman spectroscopy[J]. Applied Physics Letters, 2014, 104(16): 161907.

[90]Ohtaki M, Hayashi R. Enhanced thermoelectric performance of nanostructured zno: A possibility of selective phonon scattering and carrier energy filtering by nanovoid structure[C]∥25th International Conference on Thermoelectrics, ICT′06. Vienna, Austria, 2006: 276-279.

[91]Snyder G J, Toberer E S. Complex thermoelectric materials[J]. Nature Materials, 2008, 7(2): 105-114.

[92]Chabinyc M. Thermoelectric polymers behind organics’ thermopower[J]. Nature Materials, 2014, 13(2): 119-121.

[93]Bubnova O, Khan Z U, Wang H, et al. Semi-metallic polymers[J]. Nature Materials, 2014, 13(2): 190-194.

[94]Bubnova O, Khan Z U, Malti A, et al. Optimization of the thermoelectric figure of merit in the conducting polymer poly(3,4-ethylenedioxythiophene)[J]. Nature Materials, 2011, 10(6): 429-433.

[95]Uchida K, Xiao J, Adachi H, et al. Spin Seebeck insulator[J]. Nature Materials, 2010, 9(11): 894-897.

[96]Schreier M, Roschewsky N, Dobler E, et al. Current heating induced spin Seebeck effect[J]. Applied Physics Letters, 2013, 103(24): 242404.

[97]Mi W L, Qiu P F, Zhang T S, et al. Thermoelectric transport of Se-rich Ag2Se in normal phases and phase transitions[J]. Applied Physics Letters, 2014, 104(13): 133903.

【中文责编:谭春林英文责编:肖菁】

Development in Commercialization and Application Prospect of Thermoelectric Materials

He Qinyu1*, Li Weiqian1, Hao Qing2*, Li Wei1, Wang Yinzhen1, Zeng Baoqing3

(1.Guangdong Key Laboratory of Quantum Engineering and Quantum Material, School of Physics and Telecommunication Engineering,South China Normal University, Guangzhou 510006, China;2.Department of Aerospace and Mechanical Engineering, University of Arizona, Arizona 85721, USA;3.School of Physical Electronics, University of Science and Technology of China, Chengdu 610054, China)

The development in commercialization and the application prospect of thermoelectric materials as green energy material are reviewed in this paper. The parameters requirement of thermoelectric materials in application is discussed. And the upper limit of thermoelectric properties has been analyzed. Some effective routes to break the above-said limit have been advanced after analyzing the last two decades researches in thermoelectric materials. Finally, the application prospect of thermoelectric materials is forecasted.

thermoelectric material; commercialization; figure of meritz (ZT) adjustment

2015-03-06《华南师范大学学报(自然科学版)》网址:http://journal.scnu.edu.cn/n

国家自然科学基金项目(51172078,51372092);广州市科技计划项目(2013J4100045)

何琴玉,教授,Email: gracylady@163.com; Hao Qing, assistant research professor, Email: qinghao@email.arizona.edu.

TN304

A

1000-5463(2015)05-0009-09