直斜错位桨搅拌槽内流场的探究

舒安庆,王敏,魏化中,刘康

武汉工程大学机电工程学院,湖北 武汉 430205

直斜错位桨搅拌槽内流场的探究

舒安庆,王敏,魏化中,刘康

武汉工程大学机电工程学院,湖北 武汉 430205

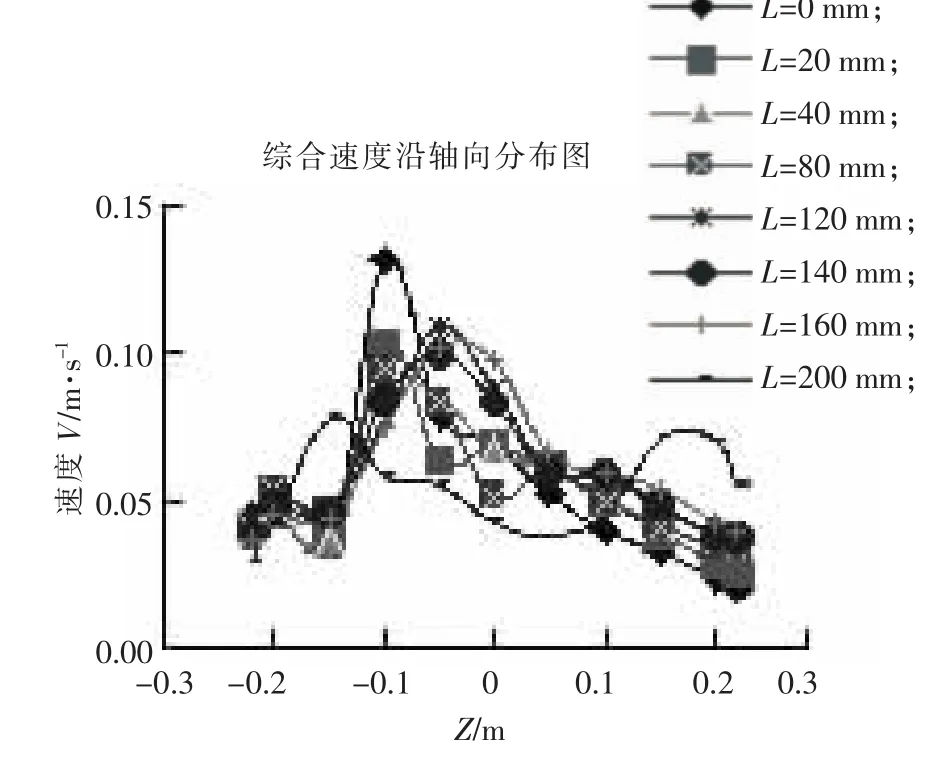

为了进一步增强直斜错位搅拌桨的搅拌效果.对桨叶直径D=160 mm,不同桨叶间距的搅拌桨进行三维数值模拟,通过分析它们的宏观流场特征,综合速度、轴向速度、径向速度、切向速度的变化规律及死区分布规律,探究直斜错位桨的最优桨叶间距.结果表明:当桨叶间距在3D/4-3D/4范围内,各速度分布的不均匀性较小,搅拌槽中基本无死区且流体的循环范围最广.当桨叶间距在D/2-D范围内,高速区范围最大,且无明显变化.当桨叶间距在3D/4-D范围内,流体的平均速率较大,当桨叶间距为3D/4时,轴向速度和径向速度较大,故搅拌效果较佳,混合效率较高.因此,桨叶间距在3D/4-7D/8范围内可取最佳值.

直斜错位搅拌桨;桨叶间距;FLUENT;流场;优化

0 引言

搅拌设备在化学工业、生物工程、制药工程、材料加工及食品加工等领域有着广泛的应用[1].现代化学工业越来越向复杂化和大型化发展,单一的桨型已不能满足对物料的混合要求[2].搅拌槽内的流场结构对介质混合效果的好坏至关重要,对搅拌槽内流动特性的深入了解是搅拌设备优化设计的基础[3].在直斜错位桨中,搅拌桨的直径、宽度、桨叶间距、直斜叶在搅拌槽中的分布位置,都会引起搅拌槽内流场的变化.王令闪采用数值模拟的方法对最大叶片式桨结构尺寸做了优化,得到了最佳结构尺寸组合[4].目前,对双层桨和错位桨的研究也有很大的进展,梁瑛娜等采用数值模拟的方法,研究了双层直斜叶及直斜组合搅拌桨搅拌槽三维流场特性[5],崔蕴芳验证了六直叶交错上下变位对隔离区的破坏作用以及对流场的改善情况[6].而对直斜错位桨结构参数优化的研究则较少.

通过FLUENT软件,采用多重参考系(MRF)的方法,探究了桨叶间距对直斜错位搅拌桨的流场的影响,对直斜错位桨的桨叶间距进行了优化,为直斜错位桨的设计及安装提供参考.

1 搅拌槽结构和控制方程

采用FLUENT软件对直斜错位搅拌桨流场进行数值模拟,搅拌介质为水,其操作密度为998.2 kg/m3,操作粘度为0.001 003 kg/m·s.文中使用直径D1=500 mm搅拌槽,液面高度H=460 mm,搅拌轴直径d=34 mm,挡板宽度a=25 mm,厚度b=4 mm,长度l=450 mm.搅拌槽结构示意图如图1所示,搅拌桨结构参数如表1所示.搅拌流场的控制方程组:

图1 搅拌桨结构示意图Fig.1The structure of agitators

表1 搅拌桨结构参数表Table1The size of agitators

1)连续方程

2)动量方程

2 模拟求解的方法

由于搅拌槽和搅拌桨的结构不规则,网格划分采用非结构化网格,为了提高近桨区的计算精度,将近桨区的网格进行加密处理[7],整个搅拌模型被划分为103 099个网格.模拟计算采用的是MRF多重参考系模型,桨叶所在区域采用旋转坐标系,其他区域采用静止坐标系[8].因此,将搅拌槽整体区域分为包括搅拌槽的静区和包括搅拌桨的动区,设置为FLUID.搅拌器和搅拌轴都设为动壁面WALL,搅拌槽壁和挡板设为静壁面WALL,搅拌槽顶部为自由液面,搅拌槽中动区和静区的重合面设为交接面,FLUENT在计算过程中,自己在交接面处进行插值传递.求解器选用压力基求解器,湍流模型选择标准的k-ε双方程湍流模型,数值模拟的搅拌转速设为5 rad/s,设定流动性质为稳态流动,使用稳态隐式分离求解,动量方程按照一阶迎风格式离散求解,压力速度耦合选用SIMPLE.改变桨叶间距,分别通过FLUENT软件模拟其流场.

3 结果分析

3.1 宏观流场分析

图2 搅拌槽中y=0截面速度矢量图Fig.2The velocity vector of Y=0 cross section in stirred tanks

3.2 速度分布

图3 速率变化曲线图Fig.3The change of the velocity

图4 综合速度沿轴向变化曲线图Fig.4The change of the velocity along the axial

3.3 死区分布

4 结语

致谢

感谢武汉工程大学机电工程学院过程装备模拟与仿真实验室所有成员对该研究的支持和帮助!

[1]梁瑛娜.直-斜叶组合桨搅拌槽内三维流场的数值模拟与实验研究[D].秦皇岛:燕山大学,2008.

LIANG Ying-na.Study on the numerical simulation and experiment of the Three-dimensional flow field in Straight-gradient impeller stirred tank[D].Qin huangdao:Yanshan University,2008.(in Chinese)

[2]于亚辉.双层交错桨搅拌槽层流流场的数值模拟与实验研究[D].秦皇岛:燕山大学,2010.

YU Ya-hui.Numerical simulation and experimental Research on the flow field ofDouble-staggered impller stirredtank[D].Qinhuangdao:Yan shan University,2008.(in Chinese)

[3]张少坤,尹侠.双层桨搅拌槽内流场的数值模拟[J].食品与机械,2011,27(1):71-73.

ZHANG Shao-kun,YIN Xia.Numerical simulation of fluid flow in stirred tank with double impellers[J].Food&Machinery,2011,27(1):71-73.(in Chinese)

[4]王令闪.数值模拟法优化最大叶片式桨结构尺寸的研究[D].烟台:烟台大学,2011.

WANGLing-shan.Studyontheoptimizationof maxblend impeller structure size by numerical simulation[D].Yantai:Yantai University,2011.(in Chinese)

[5]梁瑛娜,高殿荣.双层直斜叶及其组合叶桨搅拌槽三维流场数值模拟[J].机械工程学报,2008,44(11):290-297.

LIANG Ying-na,GAO Dian-rong.Numerical simulation of the three-dimensional flow field in stirred tank with double straight and inclined impeller and its combination[J].Chinese Journal of Mechanical Engineer ing,2008,44(11):290-297.(in Chinese)

[6]崔蕴芳.错位叶片搅拌槽内的混沌混合模拟和实验研究[D].济南:山东大学,2008.

CUI Yun-fang.Chaotic simulation and experimental research of the flow field stirred by dislocated blades[D].Jinan:Shandong University,2008.(in Chinese)

[7]魏化中,陶保林,舒安庆,等.磷酸陈化槽两相流搅拌的数值模拟[J].武汉工程大学学报,2012,34(12):54-57.

WEI Hua-zhong,TAO Bao-lin,SHU An-qing,et al.Numerical simulation of two phase flow in phosphate aging tank[J].J Wuhan Inst Tech,2012,34(12):54-57.(in Chinese)

[8]童长仁,李俊标,黄金堤,等.基于多参考系与滑动网格模型的搅拌器流场仿真[J].山西冶金,2011,34(2):4-6.

TONG Chang-ren,LI Jun-biao,et al.Based on multireference with sliding mesh of the stirrer flow field simulation[J].Shanxi Metallurgy,2011,34(2):4-6.(in Chinese)

Flow field in stirred tankof straight-gradient dislocated agitator

SHU An-qing,WANG Min,WEI Hua-zhong,LIU Kang

SchoolofMechanical&electrical Engineering,Wuhan Institute of Technology,Wuhan430205,China

To improve thestirringperformance,the fluid flow in stirred tank withdifferent agitators was numerically simulated by FLUENT as agitators diameter is 600 mm.The optimal span of the agitator was explored by analyzingthe characteristic of flow field,the distribution of velocity,axial velocity,radial velocity,tangential velocity and dead-zone volume.The researchindicates that the larger area of fluid circulation and the more uniformvelocity distribution appear in stirred tank,and dead-zone largely disappears whenthe span of blades is between 3D/4 and 7D/8;the large-scale regional speedy fluid is observed and itdoes not change obviously when the span is between D/2 and D;the fluid moves with the larger average velocity in stirredtank when the span is between 3D/4 and D;the better mixtureperformance and higher stirred efficiency can be obtained due to the largeraxial velocity and radial velocity when the span is 3D/4.Therefore,the optimal span of blades can be obtained in thescope of 3D/4 to 7D/8.

straight-gradientdislocated agitator;span;flow field

TH137

A

10.3969/j.issn.1674-2869.2015.01.010

本文编辑:陈小平

1674-2869(2015)01-0044-05

2014-09-12

舒安庆(1964-),男,浙江宁波人,教授,硕士.研究方向:压力容器压力管道、流体机械和搅拌设备的研究开发、新型高效过程装备及仿真技术.