Infuence of solution treatment on microstructure,mechanical and corrosion properties of Mg-4Zn alloy

Hongmin Jia,Xiaohui Feng,Yuansheng Yang*

Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

Infuence of solution treatment on microstructure,mechanical and corrosion properties of Mg-4Zn alloy

Hongmin Jia,Xiaohui Feng,Yuansheng Yang*

Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

The solution treatment parameters,mechanical properties and corrosion behavior of binary Mg-4Zn alloy were investigated.The results showed that after the solution treatment at 335°C for 16 h,Mg-4Zn alloy had an ultimate tensile strength of 184.13 MPa and elongation of 9.43%. Furthermore,the corrosion resistance was evaluated by electrochemical measurements and immersion tests in 3.5%NaCl solution.The results revealed that the corrosion current density of the solution treatment Mg alloy was 11.2 μA/cm−2,it was lower than 15.8 μA/cm−2for the as-cast Mg alloy under the same conditions,which was greatly associated with the micro-cathode effect of the second phases.

Solution treatment;Magnesium alloy;Mechanical property;Corrosion behavior

1.Introduction

Magnesium alloys have attracted great attention as medical implant material and devices due to their low density,perfect biocompatibility and close mechanical properties to natural bone[1–3]and it is also naturally found in the human body, where it plays essential roles in metabolic pathway[4–7]. Various magnesium alloys have been researched as biodegradable materials,such as AZ31,AZ91,AE21,WE43,LAE442 and so on[8,9].Unfortunately,most of the reported biomedical magnesium alloys contain aluminum and/or rare earth elements.Many researches[10–13]have shown Al is harmful to neurons and osteoblasts and also associated with dementia and Alzheimer’s disease.The administration of RE could lead to hepatotoxicity[14].Song explored several Mg alloys,pointing out that Zn,Ca and Mn could be appropriate element for biomedical application[6].It was also found that zinc was one of the most abundant nutritionally essential elements in the human body and had basic safety for biomedical application[12]. Therefore,Zn-containing Mg alloys have been paid more attention and developed as promising biomaterials.

However,the application of Mg alloys has been limited due to their high corrosion rate at physiological conditions and their fast biodegradation before the new tissue has adequately been healed[15].The early researches[16–21]have indicated that the poor corrosion resistance of Mg alloys mainly results from two reasons:The frst is the intrinsic dissolution tendency of magnesium,which is only weakly inhibited by corrosion product flms;the second is the presence of second phases acting as local cathodes and thus causing local micro-galvanic to accelerate corrosion[15].The effect of second phases on the corrosion resistance of Mg alloys has been investigated widely [22–27],especially for theAZ91 Mg alloys.The second phases usually act as cathodes to accelerate corrosion,while they may act as barrier against corrosion if they are in the form of continuous network along grain boundaries.In general,heat treatment is the most effective method to adjust the second phases, corresponding to change in the properties of Mg alloys[23].In this paper,the most suitable parameter of solution treatment is discussed and the effects of solution treatment on mechanical and corrosion properties of Mg-4Zn alloy as a degradable biomaterial are investigated to clarify the role of second phases in the corrosion mechanism.

2.Experimental

Ingots with nominal alloy compositions of Mg-4wt%Zn alloy were prepared with pure magnesium(99.99 wt%)and pure zinc(99.99 wt%)in an electronic resistance furnace underthe protection of CO2and 0.8%SF6mixture gas.The alloying melt was held at 730°C for 30 minutes to homogenize,and cast as ingots at 690°C into a graphite mold.The chemical compositions of the alloy were measured by inductively coupled plasma atomic emission spectrum (ICP-AES) apparatus.

还好,我脑海中不断显现的尴尬局面并没有在第一天的傍晚出现,为第二天正式拍摄的探路工作在浅尝辄止之后就结束了。而为了让我在第二天不成为整个拍摄计划的最主要障碍,牧马人车主自告奋勇地开始帮我复习曾在各种“冰雪试驾”和“越野体验”活动中收获的知识点。一番理论教授结束之后,在一群改头换面的北汽BJ40、三菱帕杰罗的围观下,我成功依靠全新AMG G 63那充沛到有些过剩的动力摆脱了一个因为掉头而陷入雪窝的尴尬。

Specimens cut from the ingots were frst solution treated with different times,then quenched into water.The temperature of solid solution was determined by the Mg-Zn binary phase diagram[28]and DSC analysis.Microstructures of specimens for different heat treatment times were observed with an optical microscope(OM).Vickers hardness testing was taken using 100 g load and holding time of 10 s,not fewer than 5 points were taken in each specimen.Tensile tests were performed at room temperature and a constant cross-head speed of 1 mm s−1. Three specimens were used for same test conditions to ensure the reproducibility of data.

[1]Y.F.Zheng,X.N.Gu,F.Witte,Mater.Sci.Eng.R 77(2014)1–34.

Samples for electrochemical test were cut from the ingots and mounted by epoxy resins with an exposed area of 1 cm2. The surface was grinded by 600–2000#SiC papers.The polarization test was carried out at room temperature in a beaker containing 3.5%NaCl solution using a standard three electrode confguration:the saturated calomel as a reference,a platinum electrode as the counter and the sample as the working electrode.In the polarization tests,the working electrode was frst immersed in NaCl solution for 5 minutes and then the polarization curve was measured at a scanning rate of 0.5 mV/s.

This work has been concerned with the solution treatment parameters,mechanical and corrosion properties.The main results can be summarized as follows.

3.Results and discussion

3.1.The optimum solution treatment parameters

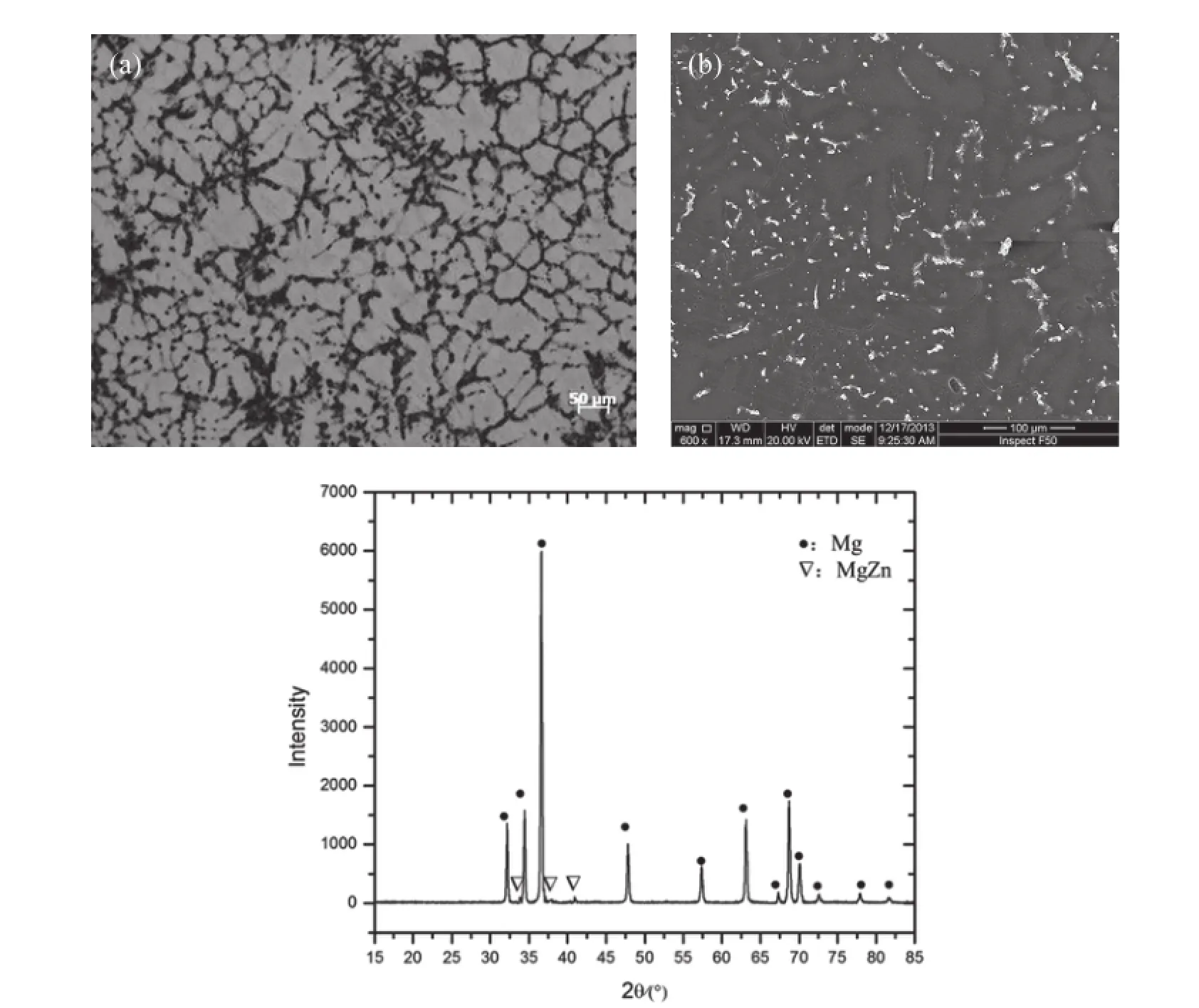

The optical microstructure and XRD results of the as-cast Mg-4Zn alloy are shown in Fig.1.It can be seen that there were two main phases in the as-cast samples,namely,the matrix α phase and the second phases MgZn,precipitating along the grain boundary.

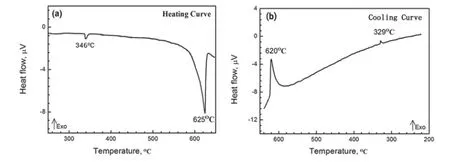

The DSC curves of the Mg-4Zn alloy are shown in Fig.2,the second phases dissolve at 346°C and exist steadily below 329°C.So the solid solution treatment temperature wasdetermined at 335°C in consideration of the furnace temperature fuctuation.

(一)在主推品种方面 武隆县在肉牛产业发展中,主推西门塔尔牛和安格斯牛,首先用西门塔尔牛冷冻精液配种川南山地黄牛经产母牛,再用安格斯牛冻精配种“西杂牛”,并将“红西本”三杂牛作为商品牛进行育肥出售。

Fig.1.Microstructure of the as-cast Mg-4Zn alloy and XRD result.

Fig.2.The DSC curve of Mg-4Zn alloy.

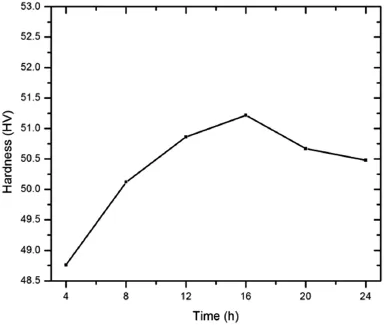

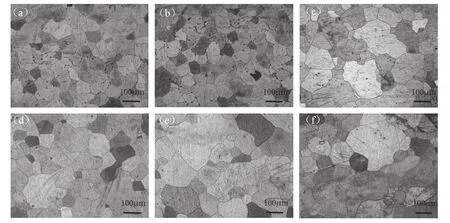

The curve of micro-hardness variation of the Mg-4Zn alloy for solution treatment at 335°C with time is shown in Fig.3. The hardness values are increased as solution time and reached a peak at 16 h,then the hardness started to decrease gradually. The change of the hardness can be explained through the microstructures during the solution treatment which are shown in Fig.4.It can be seen from Fig.4a and b that the microstructures contain a large number of second phases and the second phases become more dissolved into the Mg matrix with the increasing solution time(Fig.4c).By a solution time of 16 h,the second phases are dissolved completely(Fig.4d)and the alloy has a supersaturated single phase.There is a noticeable coarsening tendency of the grains in the following time(Fig.4e and f) compared with that of the original microstructure.As a result, the optimum solution parameter should be 335°C for 16 h for the Mg-4Zn alloy in the experiments.

Fig.3.Variation of the micro-hardness with solution time.

3.2.The effect of solution treatment on the mechanical properties

古往今来,传统文化一直是我们日常生活中的一部分,它贯穿了我们每个人的人生阶段,它是无形的,亦是有形的。但如何理解这份传统文化呢?

The tensile properties of the as-cast Mg-4Zn alloy in comparison with solution treatment Mg alloy are summarized in Table 1.The ultimate tensile strength(UTS)and elongation of the as-cast Mg alloy are 156.93 MPa and 7.38%,respectively. However,after the solution treatment,the UTS and elongation increased to 184.13 MPa and 9.43%,respectively.The enhancement of UTS is due to the solution strength effects of the alloying elements.Besides,Zn dissolving into Mg matrix will decrease the stacking fault energy of the matrix,which leads to the change of plastic deformation mechanism,i.e.,cross slip is diffcult to happen and twins will appear to adjust plastic deformation[29].Thus,the solution treatment will enhance the UTS and elongation at the same time.

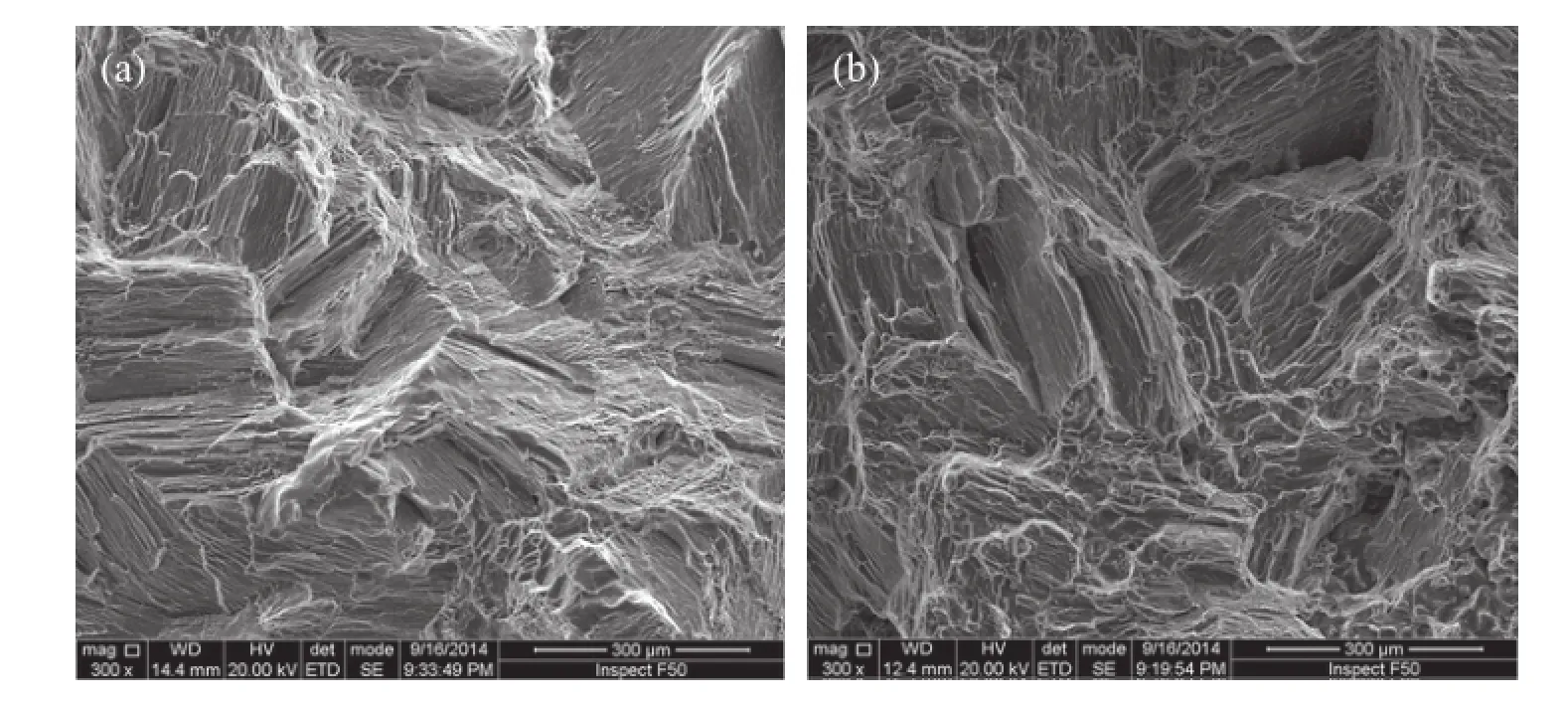

The SEM micrographs of the fracture surface of the Mg-4Zn alloy are illustrated in Fig.5.The fracture surface consists of cleavage planes for the as-cast Mg-4Zn alloy(Fig.5a),which is in accordance with its lower elongation of 7.38%,so the fracture mold of as-cast Mg-4Zn alloy is quasi-cleavage.For the alloy subjected to solution treatment at 335°C,the fracture surface contains dimples and tear ridges(Fig.5b),which is in accordance with its higher elongation of 9.43%.But the fracture mold is also quasi-cleavage.

目前我国人民银行、存款保险基金管理机构、银监部门都可以依法对问题银行采取早期纠正和风险处置措施,省级地方政府对农信社负有管理责任和风险处置责任。可建立存款保险管理机构、人民银行、银行业监管管理机构、省级地方政府等共同参与的问题银行市场退出磋商机制,加强监管协调和信息共享,强化协同推进,提高问题银行风险处置的效率。此外,还应进一步明确存款保险管理机构运用存款保险基金参与问题银行接管、重整、破产等风险处置的形式和职责范围,加强相关法律法规之间的有效衔接,完善问题银行市场化退出机制。

[18]A.Andrej,M.Liu,Z.A.Ishida,Mater.Sci.Eng.B 176(2011)1609–1636.

(1)The Mg-4Zn alloy was fabricated with high-purity raw materials and though DSC analysis,micro-hardness testing and microstructure observation,the optimum solution parameter is 335°C for 16 h.

Table 1Mechanical properties of Mg-4Zn alloy at room temperature.

Fig.4.Optical images of Mg-4Zn alloy during different solution time:(a)4 h,(b)8 h,(c)12 h,(d)16 h,(e)20 h,(f)24 h.

[3]G.L.Song,A.Andrej,D.H.St John,X.D.Wu,Corros.Sci.39(1997) 1981–2004.

老杜家不远。一到小区大门,老杜就活泛起来,忙不迭地下车。看着丁小强的车驶离,老杜呸地吐出一口痰:“畜生。”

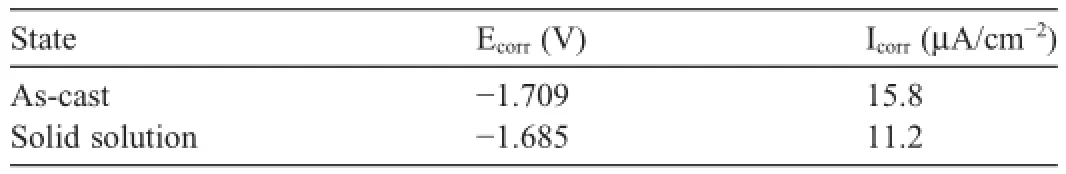

Table 2Electrochemical parameters of Mg-4Zn alloy.

Fig.5.Typical fracture and SEM images:(a)as-cast,(b)335°C solid solution.

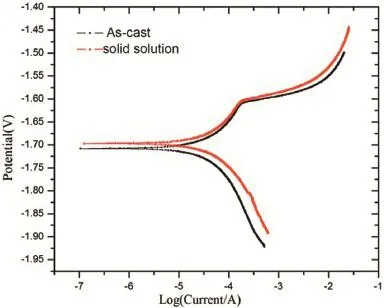

Fig.6.Polarization curves of the Mg alloy specimens in 3.5%NaCl solution.

As confrmed in the microstructure characterization of the as-cast and as-solution treatment specimens,the signifcant difference in microstructure between them is the second phases.In general,the second phases have nobler potential than the Mg matrix,so they may act as micro-cathode and the Mg matrix as the anode,resulting in galvanic corrosion.For the as-cast Mg-4Zn alloy in this experiment,the second phase particles MgZn can be regarded as the cathode sites and Mg matrix as the micro anode site.Thus,a lot of reactions happened on the surface of the samples,which resulted in an accelerated corrosion.Meanwhile,as to the solution treatment Mg-4Zn alloy,all the second phase particles were dissolved in the Mg matrix and less local reactions happen,so the sample surface experiences a uniform corrosion,resulting in a lower corrosion rate.

4.Conclusion

Immersion tests were also carried out according to ASTMG31-72[23]and the ratio of surface area to solution volume was 1 cm2:20 mL.Samples were removed for characterization after 4 h,12 h,24 h and 48 h of immersion in 3.5%NaCl solution,rinsed with distilled water and dried in air.The solution was refreshed at 12 h intervals to ensure the solution concentration unchanged.The corrosion products were cleaned with chromate acid(200 g/L CrO3 and 10 g/L AgNO3)for 1–2 minutes without removing any amount of metallic Mg,then washed with distilled water and alcohol,dried in air.The surface morphology after immersion was observed using scanning electron microscopy(SEM).

大豆根系作为大豆的重要器官之一,在大豆整个生长发育、生理功能和物质代谢中发挥着重要作用。由于根系生长环境的特殊性,使得作物根系的研究远远滞后于地上部分,虚拟植物克服了传统方式下试验周期长、环境因素难以控制的缺点,大豆根系的虚拟研究具有重要现实意义。

The polarization curves of the as-cast Mg alloy and solution treatment Mg alloy in 3.5%NaCl solution are shown in Fig.6. The corrosion parameters obtained from the polarization curves are listed in Table 2.It can be seen that the corrosion potential shifts toward nobler direction and the corrosion current density of solution treatment Mg alloy is 11.2 μA/cm−2,lower than thatof the as-cast Mg alloy(15.8 μA/cm−2),which is related with the second phases in the as-cast alloys.

(2)The UTS and elongation of the solution treatment Mg-4Zn alloy were about 184.13 MPa and 9.43%, respectively.The fracture mold of the Mg-4Zn alloy was quasi-cleavage and it was not changed by solution treatment.

(10)Patent Litigation,Personal Jurisdiction,and the Public Good译文:专利诉讼、属人管辖和公共产品。

(3)The corrosion resistance of solution treatment samples is superior to the as-cast ones.The corrosion morphologies and immersion testing as well as electrochemical measurements proved that the corrosion resistance is strongly associated with the second phases,which act as the micro-cathodes to accelerate the corrosion of Mg matrix.

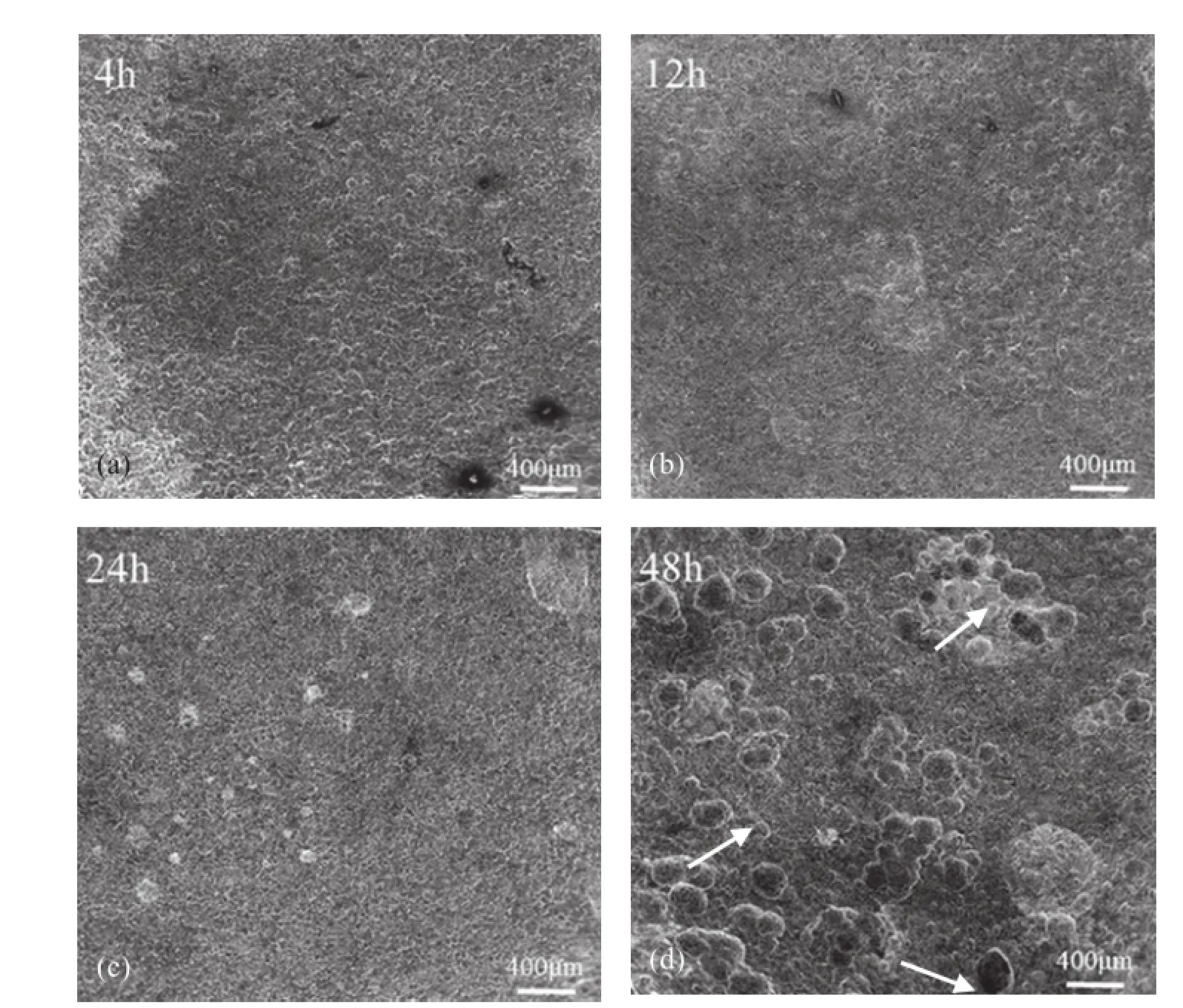

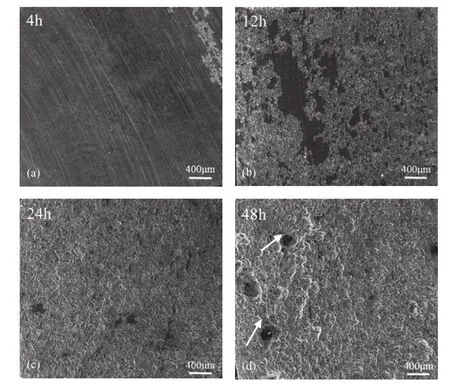

Fig.7.SEM micrographs of as-cast Mg-4Zn alloy.(a)4 h;(b)12 h;(c)24 h;(d)48 h.

Fig.8.SEM micrographs of solid solution Mg-4Zn alloy.(a)4 h;(b)12 h;(c)24 h;(d)48 h.

本文利用预应力钢丝绳对某座既有后张混凝土空心板梁桥进行了加固,详细介绍了该加固方法的实施步骤,并对加固前后的空心板进行了荷载试验。通过对正常使用状态下的荷载-挠度、裂缝宽度和钢筋应力进行比较,明确了预应力钢丝绳对既有PC桥梁的加固效果。

[2]G.L.Song,A.Andrej,D.H.St John,J.Nairn,Y.Li,Corros.Sci.39(1997) 855–875.

The corrosion morphologies of the as-cast and as-solution treatment specimens of the Mg-4Zn alloy are observed to further clarify the effect of the second phases by immersion test in 3.5%NaCl solution,which are shown in Figs.7 and 8, respectively.In the early stage of immersion,a large number of hydrogen bubbles were evidently arising from the surface of theas-cast specimens indicating a fast rate of corrosion,compared to the solution treatment ones.After 4 h,the as-cast specimens were covered with corrosion products shown as Fig.7a,while only a small area of solution treatment specimens was covered with corrosion products(Fig.8a).As the immersion time increased,corrosion products were observed on all samples. With the immersion time increased to 48 h,there were a large number of deep pits as indicated by arrows shown in Figs.7d and 8d,respectively.However,the quantity and depth of the corrosion pits in the as-cast samples present a much larger scale compared with that in the solution treatment ones and these corrosion pits suggested that localized corrosion attacks happened during the immersion process.It was noted that the corrosion products were found on the bottom of beaker containing the as-cast specimens after immersion for 12 h.

[4]K.Y.Chiu,M.H.Wong,F.S.Cheng,H.C.Man,Surf.Coat.Tech.202 (2007)590–598.

[5]M.Jamesh,S.Kumar,Corros.Sci.53(2011)645–654.

1.规范管理,严格建立企业合格供应商库,优化供货渠道。企业应实行供应商准入制度,从供应商的供应品种、经营规模大小、商业信用情况、发票开具情况等多维度来进行供应商的筛选,其中同一品种的供应商应保证有三家至五家以满足比质比价的需求。如果供应商在供应原材料过程中发生质量问题、价格虚高或开票不规范等情况,可以给予对方整改的机会,但如再次发生经协调无果的,应及时从企业供应商名录中删除,以保证供应商库的质量。供应商库每年应进行动态管理,及时掌握供应商的经营和信用等情况。特别是营改增之后企业需要对经营不正规、不能提供所需发票的供应商进行剥离,从源头上达到节税的目的,同时对提高原材料质量也有积极的促进作用。

[6]G.L.Song,Corros.Sci.49(2007)1696–1701.

[7]S.X.Zhang,X.N.Zhang,C.L.Zhao,Acta Biomater.6(2010)626–640.

[8]F.Witte,V.Kaese,H.Haferkamp,E.Switzer,Biomaterials 26(2005) 3557–3563.

[9]F.Witte,J.Fischer,J.Nellesen,H.-A.Crostack,Biomaterials 27(2006) 1013–1018.

[10]M.B.Yang,X.F.Liang,Z.Yi,F.S.Pan,Mater.Des.32(2011)1967–1973.

[11]X.B.Zhang,Z.Z.Wang,G.Y.Yuan,Y.J.Xue,Mater.Sci.Eng.B 177 (2012)1113–1119.

[12]X.N.Gu,N.Li,Y.F.Zheng,L.Q.Ruan,Mater.Sci.Eng.B 176(2011) 1778–1784.

[13]W.Zhang,M.Li,Q.Chen,M.Hu,Mater.Des.39(2012)379–383.

[14]S.X.Zhang,J.N.Li,Y.Song,C.L.Zhao,X.N.Zhang,C.Y.Xie,Mater. Sci.Eng.B 29(2009)1907–1912.

[15]Y.J.Chen,Z.G.Xu,C.Smith,J.Sankar,Acta Biomater.10(2014) 4561–4573.

[16]G.L.Song,S.Z.Song,Adv.Eng.Mater.9(2007)298–302.

新经济环境下对于中小制造企业不单是机会,也有不少挑战,以往的问题更加凸显出来。中小企业应当意识到这些情况,同时积极应对,适应市场的演化,保持长远健康成长。

[17]M.Jamesh,S.Kumar,N.T.Sankara,Corros.Sci.53(2011)645–654.

3.3.The effect of solution treatment on corrosion properties

朋友此文写好后,为察纳雅言、博取众长,将其发在一个不大的文友群里。凑巧看到,我便认真拜读。读后,有所感,不吐不快,便在其后留评:这个故事文字流畅生动,情节虽略缺新意,但曲折瑰丽,点赞之外,说几句不限于这篇文章的题外话——如果这美丽的传说,能借助文字而得以流传,若干年后,我们的后代,会以为这片桃园,竟有如此神奇的来历,但他们不会知道,这只是在公元21世纪之初,在蔚然成风的人工造景热潮中,悄然绽放的一朵小花,在桃园之前,这里曾是棉海粮仓。倘如此,他们岂不会把他们某一代祖宗的功劳,错记到神仙头上?要是他们从凑巧得到的历史知识中知道了真相,那时,他们对我们这些已经作古的编故事的祖宗,作何感想?

[19]Y.W.Song,E.H.Han,D.Y.Shan,Corros.Sci.65(2012)322–330.

[20]Y.W.Song,E.H.Han,D.Y.Shan,Corros.Sci.60(2012)238–245.

1)进行参数化设计,新型技术需要满足设计师对建筑信息的需求,BIM技术中应用到的软件可以将观察到的对象信息设计成整体的结构状态;

[21]S.H.Cai,T.Lei,N.F.Li,Mater.Sci.Eng.C 32(2012)2570–2577.

[22]M.C.Zhao,M.Liu,G.L.Song,A.Andrej,Corros.Sci.50(2008) 1939–1953.

[23]Y.W.Song,D.Y.Shan,R.S.Chen,Corros.Sci.52(2010)1830–1837.

在传统乡村社会,稳定的人际网络和稔熟的社会交往是道德得以发挥作用的重要伦理基础和价值基础。人与人之间的关系由简单的善恶原则相指引,这是一种对传统美德的维护和遵守,也是对较为稳定的习惯角色进行服从和认同。而在市场经济的现代社会,以金钱和权力为媒介的强大体系开始渗透到生活的方方面面,并且不断地越过生活的边界。生活领域由此不断收缩,个人意愿和社会需要相互冲突,技术和道德相互脱节,最终引起生活世界相对于体系世界的强烈反抗。

[24]W.C.Neil,M.Forsyth,P.C.Howlett,C.R.Hutchinson,B.R.Hinton, Corros.Sci.51(2009)387–394.

[25]S.Amira,D.Dube,R.Tremblay,E.Ghali,Mater.Charact.59(2008) 1508–1517.

[26]G.L.Song,A.Andrej,X.L.Wu,B.Zhang,Corros.Sci.40(1998) 1769–1791.

[27]S.Mathieu,C.Rapin,J.Steinmets,P.Steinmets,Corros.Sci.45(2003) 2741–2755.

[28]H.Okamoto,J.Phase Equilibria 15(1994)129–130.

[29]X.F.Yu,S.G.Tian,H.Q.Du,Rare Metal Mater.Eng.36(2007) 2148–2151.

Received 4 May 2015;accepted 26 August 2015 Available online 1 October 2015

*Corresponding author.Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China.Tel.:+86 24 23971728;fax:+86 24 23844528.

E-mail address:ysyang@imr.ac.cn(Y.Yang).

http://dx.doi.org/10.1016/j.jma.2015.08.006

2213-9567/©2015 Production and hosting by Elsevier B.V.on behalf of Chongqing University.

©2015 Production and hosting by Elsevier B.V.on behalf of Chongqing University.

Journal of Magnesium and Alloys2015年3期

Journal of Magnesium and Alloys2015年3期

- Journal of Magnesium and Alloys的其它文章

- GUIDE FOR AUTHORS

- Infuence of sulfate ion concentration and pH on the corrosion of Mg-Al-Zn-Mn(GA9)magnesium alloy

- Research of growth mechanism of ceramic coatings fabricated by micro-arc oxidation on magnesium alloys at high current mode

- Effect of experimental parameters on the micro hardness of plasma sprayed alumina coatings on AZ31B magnesium alloy

- Electrochemical deposition of Mg(OH)2/GO composite flms for corrosion protection of magnesium alloys

- Effect of temperature and strain rate on compressive response of extruded magnesium nano-composite