基于基斯勒尔法中间相沥青的流变性质

金鸣林,程洁羚,王连星,金双玲,张 睿

(上海应用技术学院 材料科学与工程学院,上海 201418)

1 Introduction

Applications of mesophase pitch in the high strength carbon fibers,the ultra high power electrode,the carbon materials with a high thermal conductivity and the C/C composite material have been extensively investigated for several decades[1,2].With the growing demands for new functional carbon materials to meet rigorous applications,especially high thermal conducting graphite for heavy-load electronic devices becomes a hot and challenging research topic[3,4].Mesophase pitch is one of the precursors to prepare graphite with a high thermal conductivity,whose rheological property needs in-depth investigation[5].

In the past,the U-type viscosity-temperature curve of mesophase pitch was found in the temperature range between ambient temperature and 500 ℃[6].The steady state RDS-II shear rheometer was used to research the influence of isotropic component on rheological properties of the anisotropic mesophase pitch[7].The HTHP rheometer and double rotary RDS-II rheometer were also employed to study the rheological properties of mesophase pitch[8,9].

In this paper,Giseeler fluidity instrument was used to quantitatively describe the fluidity of mesophase pitch as an evaluation method for the rheological properties of mesophase pitch.The Giseeler fluidity index was once used to investigate fluidity and swelling properties of bituminous coal.

2 Experimental

2.1 Materials

The raw pitch was obtained from Dong Dao Co.,Ltd,which has an isotropic optical characteristic under the polarizing microscope.Its properties are listed in Table 1.The mesophase pitches were prepared from the raw pitch by heat treatments at 420 ℃for 3,6,12,18 h as described elsewhere[10].

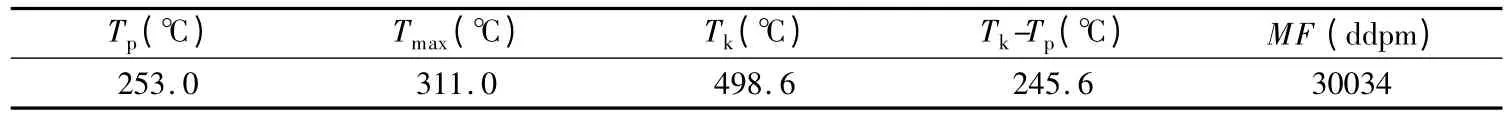

Table 1 Properties of the raw pitch.

2.2 The Giseeler fluidity measurement

The Giseeler fluidities of the raw pitch and mesophase pitches were measured by the Giseeler fluidity instrument with a reference to the United States ASTM-D182 standard.The characteristic parameters of the Giseeler fluidity can be extracted,which include:

(1)the initial softening temperature (Tp,℃),the temperature at which the agitator blade in the heating samples begins to rotate;

(2)the maximum temperature (Tmax,℃),the temperature at which the Giseeler fluidity reaches a maximum;

(3)the curing temperature (Tk,℃),the temperature at which the agitator blade in the heated sample is stopped;

(4)the maximum fluidity (MF,ddpm),the fluidity value of the sample when the agitator blade rotates at the fastest speed.

3 Results and discussion

3.1 Repeatability evaluation of the Giseeler fluidity

The Giseeler fluidities of the raw pitch were tested twice (1stand 2nd)under different heating rates of R=1,1.5,2.0 and 3 ℃/min.The fluidity is plotted as a function of temperature as shown in Fig.1.The relative derivations between the two runs are listed in Table 2.

From Fig.1,it can be found that with the increasing of temperature,the fluidities of the sample increase slowly before the softening temperature of the raw pitch,then grow exponentially near the softening temperature and finally reach a steady state with an almost constant value.Meanwhile,the Giseeler fluidity instrument showed a high repeatability under different heating rates.It can be concluded from Table 2 that the heating rates had some influence on the fluidity and the deviation at the heating rate of 1.0 or 1.5 ℃/min is small,which is suitable as a heating rate to test the fluidity.

Fig.1 Repeatability evaluation of the fluidity degree versus temperatures at different heating rates (R=1,1.5,2 and 3 ℃/min for the first (1st)and the second (2nd)run).

3.2 The varying pattern of rheological property of raw pitch

The raw pitch was chosen to investigate the changing of rheological property with temperature in an extended temperature range from room temperature to 550 ℃under a heating rate of 1.0 ℃/min.The relationship between temperature and the fluidity is shown in Fig.2,and the characteristic fluidity parameters of the sample are listed in Table.3.

From Fig.2 and Table 3,it can be found that the fluidity of the raw pitch grows slowly from 253 to 282 ℃before the softening temperature,increases exponentially from 282 to 311 ℃near the the softening temperature,and reaches a constant value between 311 and 498 ℃,and drops sharply beyond 498 ℃.

This changing pattern of fluidity with increasing temperature can be analyzed as follows.Within the temperature range from 253 to 282 ℃,the TS in the raw pitch begins to soften into liquid phase,which is rapidly adsorbed and wrapped on the surface of the solid particles[11],forming a solid-liquid two phase system,in which liquid is a dispersed phase[12].

Table 2 Relative derivations of Giseeler fluidity(ddpm)between two runs at different temperatures under different heating rates.

Fig.2 The relationship between fluidity and temperature at 1.0 ℃/min.

So the fluidity of the raw pitch grows slowly in this temperature range.With the continuous melting of the raw pitch,the liquid transforms from a dispersed phase into a continuous phase and the pitch becomes a Newtonian fluid[13].The fluidity of the pitch increases exponentially from 282 to 311 ℃due to the shear thinning property of non-Newtonian fluid and the growing liquid phase content.In the temperature range from 311 to 498 ℃,the pitch shows the Newtonian fluid properties,owing to the continuous increase of the melting part that act as solvent.Therefore,the fluidity changes little in this wide temperature range[14].The sharp decrease of fluidity can be ascribed to coking of the pitch near 498 ℃.

Table 3 Fluidity parameters of the raw material.

3.3 Fluidity-temperature relationship

In order to investigate the rheological properties of mesophase pitch,the raw pitch was heat-treated at 420 ℃for 3,6,12 and 18 h and the resulting mesophase pitch with different TI contents was measured by the Giseeler fluidity instrument.The TI contents of the four mesophase pitches are listed in Table 4.The fluidity of the mesophase pitches as a function of temperature is shown in Fig.3.

From Fig.3,it can be found that the TI content of the mesophase pitch increases gradually with the heat-treatment time.The higher the TI content,the higher the initial softening temperature (Tp)of the sample[15].The narrowing of the Newtonian fluidity with the heat-treatment time is caused by the increasing of TI content.As Newtonian fluidity region should be large enough to ensuring the ordering of mesophase pitch molecules in the preparation of high thermal conductivity graphite,the mesophase pitch should have an optimum TI content.

Fig.3 The relationship between fluidity and temperature for the mesophase pitches with different TI contents (TI contents of 67.3%,73.8%,82.4% and 88.7% for sample 1,sample 2,sample 3 and sample 4,respectively).

The Ln plot of the fluidity versus temperature before Newtonian fluid is established as shown in Fig.4.It is found from Fig.4 that the fluidity of mesophase pitch can be separated into three parts,two linear parts with different slopes at low temperatures and a level-off part at high temperatures,indicating different viscous properties at different temperatures.

Fig.4 Relationship between fluidity and temperature at a heating rate of 1.0 ℃/min Newtonian fluid region(heat treated at 420 ℃for 3,6,12 and 18 h for sample 1,sample 2,sample 3 and sample 4 respectively).

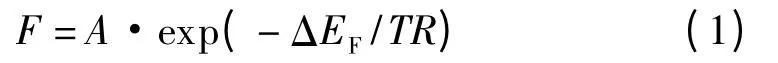

The slope of the linear parts increases with increasing temperature.The linear part can be formulated by the Arrhenius equation (1)

Where A is pre-exponential factor,F the fluidity,△EFthe viscous flow activation energy in kJ/ mol,R the universal gas constant and T temperature of mesophase pitch.The viscous flow activation energy can be extracted from the equation (1),which is tabulated in Table 4 together with TI content of mesophase pitches.It is found that the flow activation energies at low temperature range are between 203.6 and 294.0 kJ/mol.At high temperature range,only the sample 4 heated at 420 ℃for 18 h has a steady flow property and its viscous flow activation energy reaches as high as 692.8 kJ/mol.For the other samples,the temperature range in the linear part at high temperature range is too narrow to extract the viscous flow activation energy.

The different fluidity behaviors of the four samples heat-treated at 420 ℃for 3,6,12 and 18 h for sample 1,2,3 and 4 respectively could be caused by a slight dehydrogenation and or polycondensation reactions of the raw mesophase pitch,which increase molecular weight,and therefore decrease fluidity.The longer is the treatment time,the high the reaction extent and the low is the fluidity.Therefore,the decreasing order of fluidity of sample follows the order:sample 4 >sample 3 >sample 2 >sample 1.Another possibility is the evaporation of light components that has the same effect as the dehydrogenation and or polycondensation reactions because the light components in the mesophase pitch act as solvent for heavy fraction and increase fluidity of the whole pitch.

Table 4 TI contents and viscous flow activation energies of four mesophase pitch samples.

4 Conclusions

The rheological properties of the raw and mesophase pitch can be characterized by the Giseeler fluidity method with a good repeatability.With increasing of temperature,raw and mesophase pitch experiences a transition from a non-Newtonian fluid to a Newtonian fluid.In the non-Newtonian region,the fluidity can be formulated by the Arrhenius equation,from which the flow activation energy can be extracted.The fluidity can be separated into three parts according to their viscous flow activation energies.The flow activation energy at low temperature range are between 203.6 to 294.0 kJ/mol.If the mesophase pitch is used as a precursor for high thermal conducting graphite,the linear part indicating a Newtonian fluid region should be large to ensure a thorough ordered growth of mesophase pitch.Therefore,the mesophase pitch should have an optimum heat treatment time and temperature.

[1]S Kundu,A A Ogale.Rheostructural studies on a synthetic mesophase pitch during transient shear flow[J].Carbon,2006,44:2224-2235.

[2]D Grecov,A D Rey.Computational rheology of carbonaceous mesophases[J].Carbon,2004,42:1257-1261.

[3]I Mochida,Y Korai,C H Ku,et al.Chemistry of synthesis,structure,preparation and application of aromatic-derived mesophase pitch[J].Carbon,2000,38:305-328.

[4]M L Jin,J Chen,X L Zhou,et al.Study on the preparation of ordered mesophase coke[J].Journal of Chemical Engineering of Chinese Universities,2008,22:644-649.

[5]N Diez,P Alvarez,R Santamaria,et al.Optimisation of the melt-spinning of anthracene oil-based pitch for isotropic carbon fibre preparation[J].Fuel Processing Technology,2012,93:99-104.

[6]E Fitzer,D Kompalik,K Yudatet.Rheological characteristics of coal-tar pitches[J].Fuel,1987,66:1504-1511.

[7]C Blanco,O Fleurot,R Menendez,et al.Contribution of the isotropic phase to the rheology of partially anisotropic coal-tar pitches[J].Carbon,1999,37:1059-1064.

[8]P M Khandare,J W Zondlo,P B Stansberry,et al.Rheological investigation of pitch materials:Part I:Design and development of a high-temperature high-pressure (HTHP)rheometer[J].Carbon,2000,38:881-887.

[9]A D Cato,D D Edie.Flow behavior of mesophase pitch[J].Carbon,2003,41:1411-1417.

[10]WANG Lian-xing,JIN Ming-lin,ZHOU Xiao-long.Effects of high pressure hot shearing on thermal conductivity of mesophase based carbon[J].New Carbon Materials,2012,27(2):135-140.

[11]H W Arshad,L K Lutfullah,Preparation and characterization of pitch-based carbon Fibers[J].New Carbon Materials,2009,24(2):83-88.

[12]C Berrueco,P Alvarez,N Diez,et al.Characterisation and feasibility as carbon fibre precursors of isotropic pitches derived from anthracene oil[J].Fuel,2012,101:9-15.

[13]Y Hao,K X Yan.Discussion on rheologic behaviour of coal pitch[J],Carbon Techniques,2005,24:49-50.

[14]A D Cato,D D Edie.Flow behavior of mesophase pitch[J].Carbon,2003,41:1411-1417.

[15]R H Liu,M L Jin,Z H Bao,et al.Preparation of the ordered carbon block presursor by mesophase pitch[J].Coal Conversion,2010,33:63-66.

——材料科学与工程